#Plant-Based Textile Yarn Market trend

Explore tagged Tumblr posts

Text

Carpet and Rugs Market is Likely To Unfold Lucrative Business Opportunities During The Forecast

Market Overview/Outlook (2022 to 2032)

The global market for Carpets and Rugs is expected to grow between 2023 and 2032 due to the housing and construction industry growth, comfort and insulation, innovations in materials and technology, and e-commerce and online sales.

The Global Carpet and Rugs Market was valued at USD 81.79 Billion in 2022 and is projected to reach USD 151.20 Billion by 2032, registering a CAGR of 6.58 % for the forecast period 2023-2032.

Get Report Sample @ https://isayresearch.com/sample/2300

Global Carpet and Rugs Market Drivers

Comfort and Insulation: Carpets and rugs give people a pleasant feeling when they walk or stand on them because they are soft and comfortable underfoot. Because of their added layer of comfort, carpets, and rugs are a preferred option for rooms like living rooms and bedrooms where people spend a lot of time. Effective thermal insulators, carpets, and rugs help to keep heat inside and create a cozier atmosphere. The insulating qualities of carpets contribute to the coziness and comfort of homes and commercial spaces in colder climates or during the winter. Rugs and carpets absorb sound and lower the decibel level of noise in an area.

Global Carpet and Rugs Market – Merger and Acquisitions

Jacaranda and TENCEL launch carbon zero carpet and rug collection (2022)

Lenzing’s groundbreaking carbon-zero TENCEL branded lyocell fibers are making waves across the textile industry, including the home and interior segment. Recently, Jacaranda, a UK-based luxury carpet and rug brand, launched the world’s first collection of handwoven carpets and rugs made from 100% true carbon-zero TENCEL Lyocell fibers to boost the sustainability standard of home furnishings and decorations.

List of Prominent Players:

Mohawk Industries, Inc.

Shaw Industries Group

Lowe's Companies, Inc.

Taekett S.A.

Home Depot, Inc.

Interface, Inc.

Dixie Group, Inc.

Orientals Weavers Carpet Company

Tai Ping Carpets International Limited

Victoria Plc

Others

Read Full Report Summary @ https://isayresearch.com/report/2300/carpet-and-rugs-market/

Segmentation of Global Carpet and Rugs Market:

By Product Type:

Knotted Pile

Needle Punched

Tufted

Woven

Others

By Application:

Residential

Commercial

By Material:

Animal-made Yarn

Plant-made Yarn

Synthetic Fibers

By Region:

North America (U.S., Canada, Mexico)

Europe (Germany, France, UK, Italy, Spain, Rest of Europe)

Asia Pacific (China, Japan, India, Southeast Asia, Rest of APAC)

Latin America (Brazil, Argentina, Rest of Latin America)

Middle East & Africa (GCC Countries, UAE, Rest of MEA)

Enquiry For Pricing @ https://isayresearch.com/buying-request/2300

Regional Analysis:

North America:

Canada: One major factor affecting the demand for carpets and rugs in Canada is the amount of housing and construction activity. The demand for flooring products, such as carpets and rugs, is frequently driven by the expansion of residential and commercial construction projects. The lifestyle choices, interior design trends, and preferences of Canadian consumers can influence the demand for carpets and rugs. The demand for homes that are cozy, comfortable, and aesthetically pleasing is driving the market's expansion.

Read More @ https://www.linkedin.com/pulse/carpet-rugs-market-projected-reach-usd-15120-billion-2032-pooja-dayal-rqwlf/

About Us:

iSay Research is the leading research company offering both tactical and strategic support to all our customers. Customer satisfaction is our goal and that is why, we have a team of skilled and experienced specialist with the ability to do data mining, information management, and revenue enhancement solutions to ensure that our clients make informed decisions when coming to investing in the market.

Contact Us:

iSay Solutions LLC

166 Geary St. 15th Floor Suite #212,

San Francisco, California 94108,

United States

Tel: +14156709191

Email: [email protected]

0 notes

Text

Dextrin Market's Promising Role in Sustainable Packaging Solutions

The Dextrin market is a crucial and dynamic sector within the larger global starch industry. Dextrin, a carbohydrate derived from various sources like corn, wheat, and potatoes, is a versatile ingredient with a wide range of applications in various industries, including food and beverages, pharmaceuticals, textiles, and adhesives. This market analysis delves into the key factors, trends, and growth opportunities within the Dextrin market, offering a comprehensive overview for investors, stakeholders, and industry professionals.

Market Overview

Dextrin market is a water-soluble carbohydrate that finds its utility in numerous applications, primarily due to its adhesive, gelling, and binding properties. Its production typically involves the hydrolysis of starch, transforming it into a versatile compound used in a multitude of industries. The Dextrin market is driven by its widespread applications, increasing demand for convenience foods, and the growth of the pharmaceutical and cosmetics industries.

Market Drivers

Several key factors are driving the growth of the Dextrin market:

Rising Demand in the Food and Beverage Industry: Dextrin serves as a thickening and binding agent in the food and beverage sector, contributing to the increasing demand for processed and convenience foods. Its use in bakery products, confectionery, and other food items has witnessed steady growth.

Pharmaceutical and Cosmetic Applications: Dextrin's solubility and non-toxic nature make it an attractive ingredient in pharmaceutical formulations and cosmetics. The growing pharmaceutical and personal care industries are significant contributors to the expansion of the Dextrin market.

Textile Industry: Dextrin is used in the textile industry as a sizing agent to enhance the strength and quality of yarn and fabrics. The growth of the textile industry, particularly in emerging economies, has created a steady demand for Dextrin.

Adhesive Industry: Dextrin-based adhesives are eco-friendly and widely used in paper and packaging industries. With the increasing emphasis on sustainable practices, Dextrin-based adhesives are gaining popularity.

Regional Growth: Asia-Pacific, with its booming food processing, pharmaceutical, and textile sectors, is a major growth region for the Dextrin market. North America and Europe also have significant market shares due to their well-established industrial bases.

Market Challenges

While the Dextrin market presents significant opportunities, it also faces certain challenges:

Raw Material Price Fluctuations: Dextrin is primarily produced from starch, and its price is subject to fluctuations in the starch market. This can impact the cost of Dextrin-based products.

Regulatory Constraints: The food and pharmaceutical industries have stringent regulations regarding the use of additives and ingredients. Dextrin suppliers must comply with these regulations to ensure product safety.

Competitive Landscape: The Dextrin market is highly competitive, with numerous players operating globally. To stand out, companies need to innovate and offer high-quality products.

Market Segmentation

The Dextrin market can be segmented based on various factors:

Source: Dextrin can be derived from sources such as corn, wheat, and potatoes. The choice of source affects the properties of the Dextrin, making it suitable for different applications.

Application: The market can be segmented based on its application in food and beverages, pharmaceuticals, textiles, adhesives, and others.

Functionality: Dextrin can vary in terms of its functionality, including its solubility, viscosity, and adhesive properties. Different grades of Dextrin are available to cater to specific industry needs.

Market Trends

Several notable trends are shaping the Dextrin market:

Clean Label Products: Consumers are increasingly seeking clean label products with natural ingredients. Dextrin, being a plant-based carbohydrate, aligns with this trend, making it a preferred choice for food manufacturers.

Sustainability: Sustainable and eco-friendly practices are gaining prominence in the adhesive and packaging industries. Dextrin-based adhesives are eco-friendly and biodegradable, contributing to sustainability efforts.

Research and Development: Ongoing research is leading to the development of modified Dextrin with enhanced functionalities, broadening its scope of application.

E-commerce and Retail Growth: The rise of e-commerce and online retail has boosted the demand for packaging materials, further driving the Dextrin market.

Competitive Landscape

The Dextrin market features several prominent players, including Cargill, Roquette Frères, AGRANA Beteiligungs-AG, Archer Daniels Midland Company, and Grain Processing Corporation. These companies are continuously innovating and expanding their product portfolios to cater to the evolving needs of various industries.

Future Outlook

The Dextrin market is poised for continued growth, driven by the diverse applications of Dextrin in various industries. As consumer preferences shift towards clean label products and sustainable materials, Dextrin's natural and eco-friendly properties will be key factors in its future success. Additionally, ongoing research and development efforts are likely to expand the scope of Dextrin applications, making it an even more versatile and essential ingredient across industries.

In conclusion, the Dextrin market is a dynamic and evolving sector with substantial growth potential. Its wide-ranging applications, coupled with emerging trends in clean labeling and sustainability, position Dextrin as a valuable ingredient in the global market. This analysis provides insights for investors and industry professionals looking to navigate the opportunities and challenges within the Dextrin market.

#Dextrin Market Share#Dextrin Market Growth#Dextrin Market Demand#Dextrin Market Trend#Dextrin Market Analysis

0 notes

Text

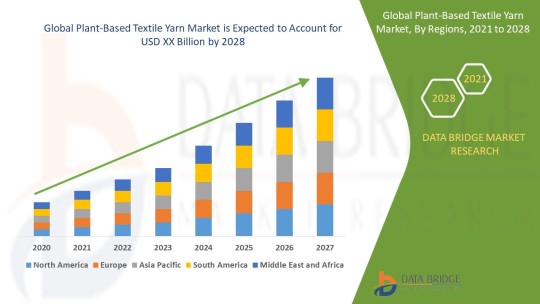

In the forecast period from 2021 to 2028, the plant-based textile yarn market is projected to expand at a rate of 4.40%. The rising demand for textile yarn for home textiles, apparel and other industrial purposes, which in the forecast period of 2021-2028 will act as a driver for the plant-based textile yarn market.

#plant-based textile yarn market#plant-based textile yarn market scope#plant-based textile yarn market share#plant-based textile yarn market size#plant-based textile yarn market trend#plant-based textile yarn market demand

0 notes

Text

Bamboo Apparel Market Analysis, Insight, Report 2022-2028

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimates the global bamboo apparel market size at USD 1.96 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects global bamboo apparel market size to grow at a steady CAGR of 7.7% reaching a value of USD 3.24 billion by 2029. Major factors for the expansion of global bamboo apparel market include a growing awareness among the consumers about environment-friendly products, including bamboo apparels, and their benefits and a favorable trend towards sustainable products made from renewable sources. However, disruptions in global supply chains caused by the impact of COVID-19 pandemic are anticipated to limit the growth of global bamboo apparel market during the period in analysis.

Global Bamboo Apparel Market – Overview

Bamboo is a wood or grass majorly found and grown in tropical and temperate regions, majorly in East Asian countries. Bamboo has hollow stems. Natural cellulosic polymer extracted from bamboo is a semi-synthetic textile, called bamboo fabric. Bamboo fabric is used for various applications, such as clothing fabrics. Bamboo fabric or bamboo rayon has various favorable characteristics, as it is soft, comfortable, lightweight, breathable, and moisture absorbent. Moreover, the cost of bamboo fabric is significantly low. Apparel producers use bamboo fiber for various types of products, including t-shirts, undergarments, bathrobes, towels, socks, and other apparels, such as bed sheets and mattresses.

Request for Sample Report @ https://www.blueweaveconsulting.com/report/bamboo-apparel-market/report-sample

Opportunity: Growing sustainable fashion trend to spur demand for bamboo fabric

The global fashion market for natural or plant fiber products is expanding primarily, because of rising environmental concerns and the consequent rise in the demand for plant-based materials. Natural fibers extracted from the extracts of cotton, bamboo, hemp, and other plants. When compared to products made from synthetic fibers, the use of these plant fibers can reduce carbon footprint considerably. Fibers from bamboo cost significantly low when compared with that of cotton. Bamboo fibers have various advantages, including high breathable quality, moisture-wicking and heat retention abilities, and stretchability. Pure bamboo fabric made in the mechanical process is up to 100% recyclable. All these favorable factors are expected to fuel the expansion of global bamboo apparel market. Another factor driving market growth is the expanding use of bamboo fiber in the global textile and fashion industries. Bamboo rayon, bamboo yarn, retting, and bamboo linen are being used to manufacture apparels and other clothing, and household textiles.

Impact of COVID-19 on Global Bamboo Apparel Market

Covid-19 had a detrimental effect on global bamboo apparel market, due to lockdowns in several countries as well as the closure of several manufacturing firms. Among those majorly affected were the textile and apparel industries. Industrial usage decreased, with the exception of industries that offer crucial services, as a direct effect of the closure of production unit. The global closure of manufacturing facilities during the early stages of the pandemic hurt the bamboo apparel market. Small and medium-sized enterprises (SMEs) recorded a sharp decline in their operations and the growth in revenues and profit due to the pandemic. The restricted movement of people and goods because of the lockdown measures put in place during the early stages of the pandemic's spread also had a negative impact on the global bamboo apparel market. However, during the post COVID-19 pandemic period, the global market for bamboo apparel is expected to grow at a significant growth rate as bamboo apparels provide significant benefits to the consumers.

Segmental Information

Global Bamboo Apparel Market - By Consumer Orientation

Global bamboo apparel market by consumer orientation is segmented into men, women, and kids. The men segment leads the global bamboo apparel market by orientation, due to the large online presence of males across the countries. However, the women segment is expected to grow at the highest CAGR during the forecast period, due to females’ increasing presence in the workforce and online.

Regional Coverage

Geographically, global bamboo apparel market covers five major regions: North America, Europe, Asia Pacific (APAC), Latin America, and Middle East and Africa. APAC dominates the global bamboo apparel market in 2022 and is expected to maintain its leadership position in the market during the forecast period. Bamboo holds a significant place in the Chinese culture and China is home to many large producers and exporters of bamboo fabric and apparels. Other major countries in bamboo apparel market, such as India, is also part of APAC. Meanwhile, the regional market in North America is expected to grow at the fastest rate, due to an increasing demand for bamboo apparels from the US.

Competitive Landscape

Major players operating in global bamboo apparel market include China Bambro Textile Co, Ltd., Bamboo Textile Co., Advantage Fibres, Wild Fibres, China Thrive Industrial Co., Towel Industrial Co. Ltd., Xiamen Ebei import & Export Co. Ltd., Boody Bamboo Clothing, Cozy Earth, Cariloha, Inc., BLUE BUNGALOW, Free Fly Apparel, Ettitude Holdings, Inc., and Thought Clothing. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Research Blog

Phone No: +1 866 658 6826

Email: [email protected]

0 notes

Text

Let's Make a Difference! The Newest Line Of Eco-Friendly Clothing Is Now Available || OhCanadaShop

Our goal at OhCanadaShop has always been to make it possible for everyone on the earth to express their creativity in an environmentally friendly manner. In order to give you and your customers additional sustainable options that benefit both people and the environment, we are today introducing six new designs of eco-friendly t-shirts, hoodies, and sweatshirts made of organic cotton and recycled polyester.

Utilize consumer demand for sustainable products.

According to a recent IBM survey, nearly 8 out of 10 consumers stated sustainability is important to them, and 6 out of 10 consumers said they are willing to change their shopping patterns if they can lessen their environmental effects. These trends will have an effect on your company's preparation for serving an expanding target market of environmentally conscious consumers.

You are choosing to influence the world with your business by diversifying into eco-friendly apparel, but you are also empowering your customers to use their purchasing power to lessen their carbon footprint. You are encouraging more regional farmers, communities, and consumers to embrace the advantages of organic farming and more sustainable materials as you increase and grow your sales of eco-friendly products.

Expand your business with enduring products that have value

In addition to assisting you in having a beneficial impact on the environment, our selection of the best brands and materials allows for a more lasting print that will significantly improve your one-of-a-kind designs.

Check out the 7 fresh looks you can add to your shop, which includes options for both kids and adults:

Canadian Kids T-shirts For Sale

Comfy Canadian Hoddies For Adult

Comfy Canadian Hoodies for Sale

Pride Hoodies for Sale in Canada

Canadian Hoodies for Sale Online

Best T-Shirts Online in Canada

Best Canada Adult T-Shirt for Sale

natural cotton

Natural organic cotton that has not been genetically modified is grown without the use of chemical pesticides or fertilizers (non-GMO). Conventional cotton growing employs chemicals that have the potential to contaminate the fields and water sources used by humans, plants, and animals, including farmers. However, if more people and businesses switch to organic cotton, we can lower cotton's potential contribution to global warming by up to 46%. We can also encourage more farmers to utilize natural farming practices like crop rotation, which supports the soil's flora and biodiversity.

The cotton used in the new collection was grown organically without the use of GMO seeds or hazardous chemicals, according to the Global Organic Textile Standard organization, which oversees certification for the production of organic fibers based on both ecological and social criteria.

plasticized polyester

Recycled polyester, which is created with yarn from post-consumer PET bottles, is also used in the new product line. These are the same plastic water bottle containers that would often wind up in a landfill or the ocean. 9.5 million tonnes of single-use plastic are dumped into the ocean every year, polluting the waters and the creatures and plants that live there. By opting to market goods made from recycled polyester, you may reduce the amount of plastic that is thrown away and encourage the creation of individualized hoodies, t-shirts, and sweatshirts.

Global commerce has an impact everywhere.

As usual with OhCanadaShop, your items are produced regionally and as needed among our network of international manufacturing centers, assisting you in lowering carbon emissions, waste, and delivery times while boosting regional economies and communities. In the future, we plan to increase both the number of areas where eco-friendly items are manufactured and the number of products we offer.

Prepare to unleash the power of the new, more environmentally friendly products in your shop and assist your consumers in making worthwhile decisions.

To reach us out in offline mode do not forget to visit

Oh Canada Shop

Suite 263, 12-16715 Yonge St , Newmarket, Ontario, CANADA

Postal Code: L3X1X4

Email: [email protected]

Visit Our Website- https://www.ohcanadashop.com/

1 note

·

View note

Text

What Exactly Are Textile Goods?

Textiles are made from a variety of materials and used for a variety of purposes. They can be functional or decorative and are created by combining two or more types of yarn. Humans have been producing textiles for a long time and have developed new techniques and methods.

Natural fibers such as cotton and wool can be used to make home textiles, as can man-made fibers such as nylon, polyester, recron, and acrylic. Home textiles are a vast and diverse subject that is constantly changing. The industry is facing increased competition and demand and must implement practical changes in order to survive. The development of fragrance finishing is one of the most recent trends in home textiles. The process involves incorporating various fragrances into the fabric, resulting in a scent-infused material. Fragrance finishing necessitates the addition of at least 10% fragrance by weight and exhausting at 40 degrees Celsius for 20 to 30 minutes.

Home textiles are a subset of the fashion industry. It is one of the most extensively tested segments. To meet consumer demand for beautiful home furnishings, fashion designers are increasingly experimenting with home textile designs.

Apparel is clothing that people wear. There are two kinds of clothing: countable and uncountable. The former is used in a more formal sense, whereas the latter is used in a more relaxed feeling. Apparel has numerous applications and can refer to a wide range of items.

Companies in the apparel industry design and sell clothing, shoes, and other items. The products include both essential and luxury items. Shoes, jackets, pants, shirts, and skirts are some examples. Accessories such as earrings, necklaces, sashes, and pins are also included.

Pressers are skilled workers who apply pressure and heat to fabrics in order to create textile goods. This can be done by hand or with a press machine. Controls are used in pressing machines to maintain precise temperatures and pressures. Some Pressers will also brush the materials to remove spots or raise the naps. They may also use lubricants and cleaning solutions to keep their equipment in good working order. They may use measuring devices to ensure that finished products meet specifications.

Textile goods, such as yarns and fabrics , are produced using a variety of processes in the technical textiles industry. These processes can be as simple as weaving and knitting or as complex as stitch bonding and thermal bonding. These items are frequently used to make finished goods, such as clothing and medical supplies. Technical textiles are critical to today's global economy, accounting for up to 50% of total textile production.

Technical textiles are helpful for a variety of applications, including clothing and footwear, as well as automobile upholstery and insulation. They also aid in the separation of industrial products, the cleaning of gases and effluents, and the transportation of materials in factories and machines. They also serve as a base for coated products. To meet the needs of the industry, a wide range of technical textiles are available, ranging from lightweight nonwoven filters to heavyweight conveyor belting.

Because technical textiles can be subdivided into different applications, they are the most promising sector for industrialized nations. Medical textiles, geotextiles, sports textiles, and safety textiles are examples of these applications. The manufacturing process for these textiles is frequently complex, necessitating one-of-a-kind collaborations and extensive testing. As emerging economies grow, more companies are entering the technical textiles market.

Plant-based textiles are becoming increasingly popular due to their environmental friendliness. They are biodegradable and can be reused, unlike most manufactured fibers, which degrade over time and have adverse effects on the soil, water, and environment. This is especially important given the growing concern about global warming. Several plants' seeds are being used to create new types of fabrics.

Sisal is one such plant-based textile. Its natural fiber can be used to make rope, twine, bags, and other accessories, among other things. It has also made its way into the world of high fashion. Cesta Collective, a Rwandan design firm, creates whimsical sisal basket bags. The prickly pear cactus is another plant-based textile that has been used in luxury goods. The company collaborates with local farmers to cultivate this plant, which is native to Mexico and is harvested from prickly pear cacti.

Fibers, which are extremely long individual strands of material, are used to make textile goods. These fibers are then woven together to create a fabric. Threads differ in their properties and requirements. Industrial fibers, for example, have different needs than apparel/domestic fibers. For example, industrial fibers must have a tensile strength of 7-8 graddenier and an elongation at a break of 8 to 15%. They must also be durable and have a zero-strength temperature of 250 degrees Celsius. Other factors to consider include the fiber's thickness, width, length, and weight.

Synthetic fiber manufacturing is a complicated process. The process starts with preparing the yarn's components through a chemical process known as polymerization. This method employs repeated polymer chains known as macromolecules. Once prepared, these materials can be extruded and woven into fibers.

0 notes

Text

6 most famous dress materials in the textile market

First, 'fabric' is a material made by weaving fibers. Generally, a fabric is named after the fiber used to make it, some fabrics also use a blend of different fibers. The fabric is then given a name based on the fibers used, the pattern and texture, and the Dress manufacturing process implemented. Some fabrics also consider the origin of the fibers.

Whether you're making new clothes or trying to find the right way to clean dirty clothes, understanding the fabric can be important. This is especially true if you have a nice piece of fabric and want to care for it properly so it will last longer. Different types of fabric have different properties that can strongly influence how you treat your clothes. For example, the fiber content of one fabric will affect the cleanliness of the garment completely different from the fiber content of another fabric.

Silk Dress Material:-

Known as the world’s most luxurious natural fabric, silk is a soft, elegant fabric choice with a smooth touch and shimmering look. Silk comes from the silkworm’s cocoon, which is found in China, South Asia, and Europe.

Cotton Dress Material:-

Known as the most popular material in the world, cotton is a light, soft natural fabric. The fluffy fiber is extracted from the seeds of the cotton plant in a process called ginning. The fiber is then spun into cloth, where it can be woven or knit.

Linen Dress Material:-

Linen is one of the oldest materials known to humankind. Made from natural fibers, this strong, lightweight fabric comes from the flax plant, which is stronger than cotton. The flax strands are spun into yarn, which is then blended with other fibers.

Chiffon Dress Material:-

Chiffon is a sheer, lightweight, plain-woven fabric made from twisted yarn that gives it a slightly rough feel. The yarn is usually made of silk, nylon, polyester, or rayon. Chiffon can be easily dyed and is usually seen in scarves, blouses, and dresses, including wedding gowns and prom dresses, due to its light, flowing material.

Georgette Dress Material :-

Georgette is a type of crêpe fabric that is typically made from pure silk but can also be made from synthetic fibers like rayon, viscose, and polyester. French dressmaker “Georgette de la Plante” introduced the eponymous silk fabric in the early twentieth century

Satin Dress Material :-

Unlike most of the fabrics on this list, satin is not made from fibre it is actually one of the three major textile weaves and is made when every strand is well-knitted. Satin was originally made from silk and is now made from polyester, wool, and cotton. This luxurious fabric is glossy, elegant, and slippery on one side and matte on the other.

SM Creation is India's exclusive website for Retailers, Wholesalers, Distributors and Suppliers as well as vendors looking to buy wholesale women's dresses in bulk. We are known to be the best wholesale supplier of women's clothing in India.

SM Creation offers the most satisfying market trends at reasonable prices. We have a great collection with great deals! Browse our sumptuous collection of beautiful Kurtis Garments, Sarees, and Designers at unbelievable prices and of the highest quality.

We try to shape the market according to the desire and fashions of consumers.

We are the best wholesale manufacturer of women's dresses in India, with delivery all over the country. Our site offers a large selection of Pakistani clothing collections made from high-quality fabric. We understand the frustration of women who can't find the right dress for them. Women can buy any clothing material of their choice from our online fabric store in Surat.

#Wholesale Kurtis Online#Buy Wholesale Dress Material#Surat Dress Material Wholesale Market#Wholesale Readymade Dress Material#Ready Made Dresses Wholesale Online#Cotton Kurtis Wholesale#Party Wear Kurtis Wholesale#Kurti In Wholesale#designer kurtis manufacturer & supplier#Readymade Dress Ladies#Designer Kurtis Manufacturer & Supplier#Wholesale Kurtis Catalogue#Georgette Kurtis Catalogue#Wholesale Dress Material Online#sarees catalogues#buy wholesale dress material#buy cotton kurtis catalog online at best price#surat dress material wholesale market#fashion#smcreation

1 note

·

View note

Text

Over a quarter of MSMEs lost over 3% market share due to Covid: Crisil

More than a quarter of India's micro, small and medium enterprises (MSMEs) lost over three per cent market share due to the Covid-19 pandemic, said Crisil Ltd on Monday. According to Crisil Research's SME Report 2022, half of them suffered a contraction in their earnings before interest, tax, depreciation and amortisation (Ebitda) margins because of a sharp rise in commodity prices last fiscal, compared with the pre-pandemic (fiscal 2020) level. The Crisil report covered 69 sectors and 147 clusters that logged aggregate revenue of Rs 47 lakh crore, representing 20-25 per cent of the gross domestic product (implying two-thirds coverage of the MSME universe). "SMEs in several sectors saw market share loss of over three per cent and Ebitda margin erosion compared with fiscal 2020 last fiscal. For instance, the pandemic-induced supply chain disruptions impacted small pesticides manufacturers more," Pushan Sharma, Director, Crisil Research, said. According to Sharma, the large pesticide makers leveraged their global presence to procure raw materials, so eating up a huge chunk of the SME pie. Edible oil SMEs lost market share because an increase in hygiene quotient because of the pandemic meant less buyers for oil sold loose. Pesticides and edible oil SMEs suffered margin contraction of 100 bps and 200 bps, respectively, due to partial pass-through - at less than 60 per cent - of increase in raw material costs, Sharma said. A handful of sectors, such as steel pig iron, gained share where only SMEs could capitalise on revival in infrastructure demand, as large plants captively consume their output, Crisil said. As a majority of tobacco selling points remained closed due to health concerns, tobacco processing SMEs, which largely sell loose tobacco and bidi, gained market share. Surging input costs weighed heavy on sectors that operate in low-margin products and have limited pass-through. Crisil sees sectors such as transport operators, edible oil, gems and jewellery to be the most vulnerable to Ebitda losses owing to wafer thin margin of less than three per cent and limited input cost pass-through of under 60 per cent. Despite a rise in freight rates, Ebitda margin of small fleet transport operators was impacted by 50 bps in fiscal 2022, over fiscal 2020, due to limited cost pass-through of rising fuel cost that forms about half of the total cost. Elizabeth Master, Associate Director, Crisil Research, said: "Amid the pandemic and ongoing geopolitical crisis, sectors such as textiles and pharmaceuticals have offered a ray of hope for exports. Cotton yarn exports have benefited from the US ban on Xinjiang, China-made items, apart from the China+1 policy." The readymade garment industry, with 70 per cent MSME share, gained from supply constraints in China, and from emerging global opportunities. Pharma exports soared on pandemic-related demand, even as the domestic industry was struggling with lower volume demand. Going forward, Tirupur-based MSME garment manufacturers could benefit from export orders diverted from an economically floundering Sri Lanka, Master said. In the milieu, MSMEs should see revenue increase 9-11 per cent this fiscal to 1.25 times the fiscal 2020 level, though Ebitda margin is likely to remain range-bound at 5-5.5 per cent. While the industry Ebitda margin is expected to touch the pre-pandemic level this fiscal, MSMEs in more than half the sectors will buck the trend. The performance is also underwhelming in the context of overall corporate India, which is expected to log a 10-14 per cent increase in revenue and Ebitda margin of 19-20 per cent. Read the full article

1 note

·

View note

Text

Antimicrobial Textiles Market Growth, Trends, Size, Share, Players, Product Scope, Regional Demand, COVID-19 Impacts and Forecast 2028

This antimicrobial textiles market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on the antimicrobial textiles market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The antimicrobial textiles market is expected to be growing at a growth rate of 9.1% in the forecast period of 2021 to 2028. The antimicrobial textiles market report analyses the growth, which is currently being growing due to the rising prevalence of chronic diseases.

Get Sample Copy of Report@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-antimicrobial-textiles-market

The utilization of antimicrobial textiles is a new practice from the traditional use of antimicrobial products mostly in the healthcare environments. The manufacturing of antimicrobial textiles includes the treatment with the additives during the intermediate or finishing stage of manufacture of the fabric. The method utilized is dependent on a multitude of factors, which involves the final usage of the fabric, manufacturer’s capability, and budget considerations.

Important factors that are expected to boost the growth of the antimicrobial textiles market in the forecast period are the increasing of the incidences of chronic diseases like the chickenpox, diphtheria, tuberculosis, and others, the growing of the prevalence of cross-infection and the growing adoption of the improved healthcare services have augmented the demand for antimicrobial textiles in the healthcare industry. On the other hand, the variations in the prices of raw materials for antimicrobial textiles and the increase in the cost of production are few of the factors estimated to further cushion the growth of the antimicrobial textiles market in the timeline period.

In addition, the growing popularity amongst the researchers and manufacturers due to their ability to provide safety and quality life to the users will further provide the potential opportunities for the growth of the antimicrobial textiles market in the coming years. However, the environmental and the health worries related with the release of the antimicrobial content in the surrounding might further challenge the growth of the antimicrobial textiles market in the near future.

Inquire About Report@ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-antimicrobial-textiles-market

Antimicrobial Textiles Market Scope and Market Size

The antimicrobial textiles market is segmented on the basis of active agents, fabric, finishing techniques and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

Based on the active agents, the antimicrobial textiles market is segmented into synthetic organic compounds, metal and metallic salts, bio-based agents, others. Synthetic organic compounds is further sub segmented into quaternary ammonium compounds (QACS), triclosan, polyhexamethylene biguanides (PHMB), zinc pyrithione, others. Metal and metallic salts is further sub segmented into silver, copper, zinc, others. Bio-based agents is further sub segmented into chitosan and others.

Based on the fabric, the antimicrobial textiles market is segmented into cotton, polyester, polyamide and others.

Based on the finishing techniques, the antimicrobial textiles market is segmented into pad-dry cure, exhaust, spraying, foam finishing method and others.

Based on the application, the antimicrobial textiles market is segmented into medical textiles, commercial textile, apparels, home textiles, industrial textile, others. Medical textiles is further sub segmented into attire, sheets and blankets, surgical supplies and wipes others. Commercial textiles is further sub segmented into protective wear and others. Apparels is further sub segmented into sportswear, intimates, outdoor clothing. Home textiles is further sub segmented into carpets, bedding, curtains and drapes and others. Industrial textile is further sub segmented into HVAC system, filters and others.

Antimicrobial Textiles Market Country Level Analysis

The antimicrobial textiles market is analysed and market size, volume information is provided by country, active agents, fabric, finishing techniques and application as referenced above.

Browse Complete Report@ https://www.databridgemarketresearch.com/reports/global-antimicrobial-textiles-market

The countries covered in the antimicrobial textiles market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the antimicrobial textiles market because of the growing utilization of implantable goods because of the limitations in the present drug therapies, treatment, and management of orthopedic, cardiovascular, ophthalmic, neurological, and several other chronic disorders. Moreover, the continuing advancements in the biotechnology which in turn will lead to the commercialization of the new and improved products will further boost the growth of the antimicrobial textiles market in the region during the forecast period. Asia-Pacific is projected to observe significant amount of growth in the antimicrobial textiles market because of the augmented governmental intervention in refining the healthcare facilities. Moreover, the growing wound care market is likely to rouse demand for the products and the occurrence of the major yarn and fiber manufacturers in Taiwan is further anticipated to propel the growth of the antimicrobial textiles market in the region in the coming years.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Antimicrobial Textiles Market Share Analysis

The antimicrobial textiles market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to antimicrobial textiles market.

The major players covered in the antimicrobial textiles market report are Microban International, Sciessent LLC, UNITIKA LTD., BASF SE, Dow, Lonza, BioCote Limited, Trevira GmbH, Herculite, Milliken & Company., Vestagen Protective Technologies, Inc., Resil Chemicals Pvt. Ltd., Smith & Nephew plc, Archroma, LifeThreads, Sinterama S.p.A., HeiQ Materials AG, smartfiber AG, PurThread Technologies Inc., Birlacril, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Global Antimicrobial Textile Market, By Active Agents (Synthetic Organic Compounds, Metal and Metallic Salts, Bio-based Agents, Others), Fabric (Cotton, Polyester, Polyamide and Others), Finishing Techniques (Pad-Dry Cure, Exhaust, Spraying, Others), Application (Medical Textiles, Commercial Textile, Apparels, Home Textiles Industrial Textile, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Browse Related Reports From Chemical Industry:

Air separation Plant Market

1,6-Hexanediol Market

Acrylic Ester Market

Alpha-Methylstyrene Market

Antistatic Agents Market

Aerospace Interior Adhesive Market

0 notes

Text

Textile Yarn Market 2021 | Covid19 Impact Analysis | Size, Share, Sales and Forecast to 2026: Parkdale Mills, Vardhman Textiles, Huvis, Grasim Industries, Raymond, etc.

Global Textile Yarn Market 2021 report is comprised of an in-depth analysis of the global industry which aims to deliver comprehensive market intelligence study associated with major market components. The report includes an overview of these markets on different fronts such as market size, market share, market penetration of the product and services, market downstream fields, key vendors operating within the territory, market price analysis and more. This might help readers across the worldwide business industry to comprehend a lot about the regional as well as key domestic markets for Textile Yarn. Reports include an overview and examination of the major companies operating within the industry which are considered to be revenue drivers for the market.

Click Here To Get Free Sample Report or PDF Copy Now!

Top Key players of Textile Yarn Market Covered In The Report: Parkdale Mills Vardhman Textiles Huvis Grasim Industries Raymond Weiqiao Textile Kairuide Holding Low & Bonar Hengli Key Market Segmentation of Textile Yarn:

By Type, Textile Yarn market has been segmented into:

Animal Plant Chemical By Application, Textile Yarn market has been segmented into:

Apparel Home Textile Industrial Others

The Textile Yarn report includes the study of these ventures on parameters such as market share, company profile, revenue figures, sales data, market presence, product or service portfolio, past performance, expected performance, and more. This may assist those who are willing to enhance their know-how of the competitive scenario of the Textile Yarn Market.

Buy Latest Copy of Report! @ https://www.qurateresearch.com/report/buy/CnM/global-textile-yarn-market/QBI-IMR-CnM-1007491/

Key Highlights from Textile Yarn Market Study:

Income and Sales Estimation – Historical Revenue and deals volume is displayed and supports information is triangulated with best down and base up ways to deal with figure finish market measure and to estimate conjecture numbers for key areas shrouded in the Textile Yarn report alongside arranged and very much perceived Types and end-utilize industry. Moreover, macroeconomic factors and administrative procedures are discovered explanation in Textile Yarn industry advancement and perceptive examination.

Assembling Analysis – The Textile Yarn report is presently broken down concerning different types and applications. The Textile Yarn market gives a section featuring the assembling procedure examination approved by means of essential data gathered through Industry specialists and Key authorities of profiled organizations.

Competition Analysis – Textile Yarn Leading players have been considered relying upon their organization profile, item portfolio, limit, item/benefit value, deals, and cost/benefit.

Demand and Supply and Effectiveness –

Textile Yarn report moreover gives support, Production, Consumption and (Export and Import).

Textile Yarn Market Region Mainly Focusing: — Europe Textile Yarn Market (Austria, France, Finland, Switzerland, Italy, Germany, Netherlands, Poland, Russia, Spain, Sweden, Turkey, UK), — Asia-Pacific and Australia Textile Yarn Market (China, South Korea, Thailand, India, Vietnam, Malaysia, Indonesia, and Japan), — The Middle East and Africa Textile Yarn Market (Saudi Arabia, South Africa, Egypt, Morocco, and Nigeria), — Latin America/South America Textile Yarn Market (Brazil and Argentina), — North America Textile Yarn Market (Canada, Mexico, and The USA)

The Textile Yarn Market report concludes with sharing vital report findings with readers. Here on the basis of study of historical data, examination of the current scenarios overserved in various markets including regional and domestic and trends recorded, it delivers forecast of the market. This includes segmental forecast, regional market forecast, market size forecast, consumption forecast.

Any query?Inquire Here For Discount Or Report Customization

Contact Us:

Web:www.qurateresearch.com E-mail:[email protected] Ph: US - +13393375221

*Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Asia.

A discovery in Meghalaya by Researchers – 100-Million-Year-Old Sauropod Dinosaur Bones

Blue Origin to fly 1st batch of individuals on the New Shepard in July

Elon Musk mentions that his Starlink Satellite Internet Service receives over 500,000 pre-bookings

Hughes and OneWeb receive U.S. Air Force agreement for Arctic broadband

KSAT quickly enlarges KSATlite small satellite network

Textile Yarn, Textile Yarn Market, COVID19 Impact on Textile Yarn Market, Textile Yarn Forecast, Textile Yarn Market Growth, Textile Yarn Market Sales, Textile Yarn Market Size, Textile Yarn Market Regional Analysis

0 notes

Text

At 31.25% CAGR, Smart Textile Industry Sales, Supply, Consumption 2021 Market Analysis and Forecasts to 2027

Smart Textile Market is valued at USD 93.3 Billion in 2018 and expected to reach USD 475.62 Billion by 2025 with the CAGR of 31.25% over the forecast period.

Clothing is one of the three basic human wants. From primitive age, textile is used for clothing which was extended to domestic and domestic purpose with advanced civilization. A textile is an object made by merging threads or yarns into a fabric. In the beginning, these yarns were made of natural animal or plant-based fibers. With advent in technology enhanced synthetic fibers were manufactured in laboratories that were durable and more multipurpose. Now digital communications technology has extended the point where the same very thin fibers that run through your smartphone and communicate data can be merged into cloth textiles. That’s what a smart textile actually is a cloth that has modern computer-based technology merged into it. The whole clue is that smart textiles are adaptive. For instance, when your laptop overheats, that change is listed as data that creates an automated reaction the computer fan turns on. That’s same it works with smart textiles. The technology merged into the fabrics will be able to notice environmental changes and respond accordingly depending on the programming or type of technology being used.

Global automotive camera market report is segmented on the basis of function, end user and region. On the basis of function is segmented into energy harvesting, sensing, thermoelectricity, luminescent, and others. On the basis end user industry market is segmented into healthcare, military and defense, entertainment, automotive, sport and fitness and others.

The regions covered in this Smart textile Market report are North America, Europe, Asia-Pacific and Rest of the World. On the basis of country level, market of Smart textile is sub divided into U.S., Mexico, Canada, U.K., France, Germany, Italy, China, Japan, India, South East Asia, GCC, Africa, etc.

Key Players for Global Smart textile Market Reports–

Global Smart textile market report covers prominent players Intelligent Clothing Ltd., International Fashion Machines, Inc., Interactive Wear AG, Vista Medical Ltd., Nike Inc., ONeill, Eleksen, Fibretronic Limited, ThermoSoft International, and Peratech Ltd. and Others.

Get Sample Copy of This Premium Report @ https://brandessenceresearch.com/requestSample/PostId/5

Increasing Demand and Adoption of Smart Textiles in Different Sectors

The increasing adoption of smart textiles across numerous applications, including sports & fitness are expected to be the key driving force for the industry. Sports & fitness sector is predicted to continue being the largest market segment for the next six years. Smart clothes are likely to take lead in the fitness segment and the market might see a surge in high finish athletic clothes that have biosensor installed. Growing technological advancements in smart textile are resulting into introduction of several textile products such as smart shirts including of bio-sensing circuitry that can be spun into the fibres. These shirts can simply read the vital signs of the wearer like coronary heart charge, exertion levels, changes in respiratory rate, etc. much easily in contrast to the wrist watches, as the surface of shirt is larger. The emergence of nanotechnology and its rising demand in smart textile industry delivers opportunities to the manufacturers of smart textiles.

North America is expected to Dominated the Smart textile Market

North America is the largest market for the smart textiles in terms of revenue generation followed by Europe. The U.S. is the major contributor to the regional market on account of substantial presence of well-established and leading end use industries such as aerospace & defense, and marine. Asia Pacific is expected to grow at the highest CAGR during the forecast period due to the surging demand from automotive, sports, building & construction industry. The major revenue grossers economies were India, China and Japan.

Key Benefits for Global Smart textile Market Reports –

Global market report covers in depth historical and forecast analysis.

Global market research report provides detail information about Market Introduction, Market Summary, Global market Revenue (Revenue USD), Market Drivers, Market Restraints, Market opportunities, Competitive Analysis, Regional and Country Level.

Global market report helps to identify opportunities in market place.

Global market report covers extensive analysis of emerging trends and competitive landscape.

Smart Textile Market Segmentation –

By Function

Energy harvesting, Sensing, Thermoelectricity, Luminescent, Others

By End-User Industry

Healthcare, Military and defense, Entertainment, Automotive, Sport and fitness

By Region: North America (US., Canada), Europe (UK., France, Germany, Italy), Asia Pacific (China, Japan, India, Southeast Asia), Latin America (Brazil, Mexico), Middle East and Africa (GCC, Africa, Rest of Middle East and Africa)

0 notes

Text

The Best Eco-Friendly and Sustainable T-Shirt Brand in Pakistan

Fashion has been generating headlines throughout the world in recent years, and the fashion industry has been dragged into the limelight for its environmental impact. And not for any good reason. A business that constantly releases new collections based on fashion icons, trends or celebrity looks, and makes them available to consumers at inexpensive prices, is known as a fashion store. These movements come and go rapidly, putting merchants under continual pressure to keep up with the latest product releases. In addition, it puts pressure on customers to replace worn-out clothing with new ones.

Manufacturers are also forced to create more clothes faster. Farmers are also under more pressure than ever to produce more cotton and do it quickly. As a result, we're all under pressure to do something about this rising issue.

Globally, sustainable fashion is on the rise. In addition to being an acceptable option, buying excellent items from sustainable sources is a fashion trend. An inexpensive T-shirt manufactured using exploitative labor can be purchased by just about anybody, but it takes taste to choose something that looks beautiful and is environmentally friendly. There are many types of T-shirts for mens available in the market. Such as V-neck T-shirt, ringer T-shirt, cap-sleeve T-shirt, pocket T-shirt, neck T-shirt. T-shirts with graphics are popular among all genders.

Shirts with soft and dark hues that have been digitally printed are popular these days. In contrast, logoed shirts are more comfy than other types of clothes.

Cotton is a natural material that may be dyed and woven. Cotton is a plant. Cotton is cultivated in numerous nations, including India, the United States, Egypt, and the Middle East. Cotton is a type of plant fiber that comes from seeds. Textiles made from cotton fibers can be made in a variety of ways (spinning, spinning, coloring, and washing) into yarns, colorful threads, and mixed fabrics (with polyester, lycra and other textile fiber).

Organic Cotton T-shirts are often composed of a light, soft that is easy to clean. It's not just men that benefit from wearing a t-shirt with jeans; it's ladies as well! T-shirts are their favorite casual clothing. It is easy to choose a t-shirt from the wardrobe without giving it a second look. Cool, sporting, and flexible casual top-wear is the t-shirt. As far as t-shirts go, there is nothing more comfy and fashionable.

If you want to know where your clothing originates from, and why it matters, then you need to know the right information about suppliers. On the inside of every garment, you'll discover the signature of the person who produced it.

In terms of color, design, and fit, t-shirts provide a wide range of options, which is why young people prefer to have a collection of them in their closet. All of these t-shirts are likely to become a part of your wardrobe once you see how we express fashion here.

Sustainable T-shirts like Cotton cloth are very important in summer because during the summer months of June and July in Pakistan, the average temperature ranges from 37° to 48°. According to calculations, the average heat index is 43.2°C (109.8°F). Attention: Heat exhaustion and heat cramps are extremely likely to occur. In the case of extended exercise, heatstroke is likely to occur.

It’s very important for men and women both to wear cotton clothes because cotton absorbs sweating from the body, allowing it to evaporate quickly. Our bodies sweat more in the summer, and cotton clothing absorbs moisture to keep our bodies cooler. By improving air circulation and allowing perspiration to evaporate, cotton aids to remove body moisture generated by sweating. Cotton also protects us from creatures such as fungus. For those with sensitive skin, cotton might help reduce the severity of an allergic response.

Hot and cold water can be used to wash organic cotton T-shirts, including those that have already been washed many times. Use a regular washing machine and a mild detergent to clean your clothes. Bleach and fabric softener are two examples of harsh chemicals that should be avoided. Every year, top clothing brands in Pakistan offer a wide range of cotton t-shirts since they know what people need based on climate.

0 notes

Text

Get deep insights of Plant-Based Textile Yarn Market

In the forecast period from 2021 to 2028, the plant-based textile yarn market is projected to expand at a rate of 4.40%. The rising demand for textile yarn for home textiles, apparel and other industrial purposes, which in the forecast period of 2021-2028 will act as a driver for the plant-based textile yarn market.

Global Plant-Based Textile Yarn Market Scope and Market Size

Plant-based textile yarn market is segmented on the basis of type, and application. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of type, the plant-based textile yarn market is segmented into natural yarn, artificial yarn, and others. Natural yarn has been further segmented as plant yarn, and animal yarn. Animal yarn has been further sub segmented into silk yarn, and wool yarn. Plant yarn has been further sub segmented into cotton yarn, flax yarn, hemp yarn, jute yarn, and ramie yarn. Artificial yarn has been further segmented into polyester, nylon, acrylic, and viscose. Artificial yarn products will account for the largest share in the market due to the rising usages of the products in blended varieties.

Based on application, the plant-based textile yarn market is segmented into apparel, home textile, industrial, and other applications. Other applications have been further segmented into medical and sports applications.

Get the sample copy of the report here:

Market Analysis and Insights: Global Plant-Based Textile Yarn Market

A textile yarn is a strand of fibres or filaments that are natural or synthetic. In the textile industry, textile yarns are primarily used for the manufacture of clothing, home textiles, medical, and sports goods.

Increasing number of innovations in the production process of the product along with growth of the various end-use industries across the globe, rapid urbanization as well as industrialization, changing consumer preferences towards affordable and comfortable clothing such as silk, viscose, hemp, and others are some of the major as well as insightful factors which will likely to augment the growth of the plant-based textile yarn market in the projected timeframe of 2021-2028. On the other hand, growing demand for organic based yarns along with development of new varieties and blends which will further contribute by generating immense opportunities that will led to the growth of the plant-based textile yarn market in the above mentioned projected timeframe.

Stringent rules and regulations along with volatility in the prices of raw material which will likely to act as market restraints factor for the growth of the plant-based textile yarn in the above mentioned projected timeframe. High inventory holding cost, trans-pacific partnership, maintaining quality through scattered channels along with direct government assistance to raw material producers which will become the biggest and foremost challenge for the growth of the market.

Plant-Based Textile Yarn Market Country Level Analysis

Plant-based textile yarn market is analysed and market size, volume information is provided by country, type and application as referenced above.

The countries covered in the plant-based textile yarn market report are U.S., Canada, Mexico in North America, Germany, Poland, Ireland, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Chile, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Egypt, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

Plant-Based Textile Yarn Market Share Analysis

Plant-based textile yarn market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to plant-based textile yarn market.

Leading Brands in Plant-Based Textile Yarn Market

The major players covered in the plant-based textile yarn report are Parkdale Mills, Inc.; VARDHMAN GROUP; Huvis; Grasim Industries Limited.; Raymond Limited; Weiqiao Textile Company Limited.; TORAY INDUSTRIES, INC.; Bonar Yarns & Fabrics Ltd; Thai Rayon Public Company Limited; Aksa; Asahi Kasei Corporation.; Barnhardt Natural Fibers.; Celanese Corporation; Far Eastern New Century Corporation; FORMOSA TAFFETA CO., LTD.; Indorama Ventures Public Company Limited.; FiberVisions, L.P.; KURARAY CO., LTD.; PT Polychem Indonesia Tbk; Reliance Industries Limited.; among other domestic and global players. Market share data is available for Global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: Plant-based textile yarn market

Get TOC Details

rowse Related Reports@

Global Methylene Chloride Market – Industry Trends and Forecast to 2029

Asia-Pacific Oil Refining Catalyst Market is expected to grow at 9.1% in the Forecast Period of 2020 to 2027

The Global Auto Catalyst Market is projected to Grow at A CAGR of 4.20% During the Forecast Period

Global Oil Refining Catalyst Market is expected to grow at 5.1% in the Forecast Period of 2021 to 2028

The Global Polyolefin Catalyst Market is projected to Grow at a CAGR of 5.00% During the Forecast Period

The Global Syngas Catalyst Market is projected to Grow at a CAGR of 8.00% During the Forecast Period

Global Refinery Catalyst Market – Industry Trends and Forecast to 2028.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Plant-Based Textile Yarn Market#Plant-Based Textile Yarn Market scope#Plant-Based Textile Yarn Market size#Plant-Based Textile Yarn Market share#Plant-Based Textile Yarn Market trend#Plant-Based Textile Yarn Market demand#Plant-Based Textile Yarn Market future

0 notes

Text

Warp Knitting Machines Market- Industry Analysis and forecast 2027:

Warp Knitting Machines Market was valued US$ XX Bn in 2019 and the total revenue is expected to grow at a CAGR of 7.7% from 2019 to 2027, reaching US$ XX Bn.

Warp Knitting Machines Market To know about the Research Methodology :- Request Free Sample Report This is a comprehensive international report targeted on present and future prospects of the Warp Knitting Machines Market. This report presents a consolidation of primary and secondary analysis that provides market size, share, dynamics and forecast for numerous segments and sub-segments considering the macro and small environment factors. The report also covers an in-depth analysis of COVID 19 pandemic impact on the sales revenue of Warp Knitting Machines Market by year-wise and region and on the key players revenue affected and expected short term and long-term impact on the market.Warp Knitting Machines Market Overview: Warp Knitting represents the quickest technique for creating texture from yarn. Knitting is mainly of two kinds: weft knitting and warp sewing. In weft knitting, yarn (for example the string utilized in knitting) loops are connected over the width of the fabric. In wrap knitting, yarn loops are connected a vertical way. Weft sewing is done by utilizing a single yarn, while wrap knitting utilizes different yarns for the knitting cycle. Wrap knitting is a modern cycle. Warp Knitting differs from weft sewing wherein each needle circles its own string. The needles produce equal lines of circles all the while that are interlocked in a crisscross pattern. Fabric is delivered in sheet or level form utilizing at least one sets of wrap yarn. The yarns are fed from wrap bars to a line of needles reaching out over the width of the machine.Warp Knitting Machines market – Dynamics Rising demand for manufactured weaved items across the globe is driving the demand for warp knitting machines. Expanding demand for weaved sportswear over the globe is likewise powering the demand for warp knitting machines. Rising demand for sports footwear across the globe is enlarging the interest in sports materials, which is the crude material used to produce sports footwear. This is moving the interest in warp knitting machines utilized in the creation of sports materials. For instance, Dong-Jin Textile, a South Korea-based producer of sports materials, supplies sports shoe textures to driving sports brands over the world, for example, Nike, Adidas, Reebok, New Balance, and Asics. The organization utilizes Karl Mayer's warp knitting machines for creation of sports materials. Presently, Dong-Jin Textile has bought in excess of 250 warp knitting machines, solely from Karl Mayer. A significant open door for warp knitting machine makers lies in the choice of Dong-Jin Textile to set up its first assembling plant in Indonesia in the second half of 2019. Industry sources said Surat is emerging city as a warp knitting sector with installed capacity of over 1,000 warp knitting machines. The annual turnover of warp knitting sector in 2019 was nailed at Rs1,000 crore. As per Synthetic and Rayon Textiles Export Promotion Council (SRTEPC), the scheme for knitting and knitwear sector would mostly benefit MSME which comes under decentralized sector and it would give a major boost to employment generation in the knitting sector of the country. 27% knitted fabrics contribute of the total fabrication in the country and 15% of them are exported.Warp Knitting Machines market: Regional Analysis North America is expected to the leading market for Warp Knitting machine market during the forecast period. Asia-Pacific is expected to dominate the Warp Knitting Machines Market all through the forecasting period, China is expected to be leading country in the warp knitting machines market. Presence of the significant wrap knitting manufacturers in Japan, South Korea and India are major market to put resources into Asia-Pacific and development in number of joint ventures with worldwide brands driving the market growth. The objective of the report is to present a comprehensive analysis of the Warp Knitting Machines Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers and new entrants. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding Warp Knitting Machines Market dynamics, structure by analyzing the market segments and project of the Warp Knitting Machines Market size. Clear representation of competitive analysis of key players By Type, Price, Financial position, Product portfolio, Growth strategies, and Regional Presence in the Warp Knitting Machines Market make the report investor’s guide. for more info:https://www.maximizemarketresearch.com/market-report/warp-knitting-machines-market/76955/ Scope of Warp Knitting Machines Market: Inquire before buying Warp Knitting Machines Market, By Type • Tricot Knit• Raschel Knit• Crochet Knit• Milanese KnitWarp Knitting Machines Market, By End-User • Inner Wears• Apparel• Household• Automotive• Industrial• ShoesWarp Knitting Machines Market, By Region • North America• Europe• Asia-Pacific• MEA & Africa• Latin AmericaWarp Knitting Machines Market Key Players • Karl Mayer• Jakob Müller AG• Santoni SpA• Taiwan Giu Chun Ind. Co., Ltd• Duksu Machinery Industry Co.• Changzhou Runyuan Warp Knitting Machinery Co., Ltd• Wuyang Textile Machinery (China) Co. Ltd.• Changzhou DIBA Textile Machinery Factory• Changzhou Longlongsheng Warp Knitting Machinery Co., Ltd.• COMEZ• Jingwei textile machinery• Ruanyuan• Xingang textile machinery• Diba Textile machinery• Longlongsheng• Voltas• A&L Simonyan German Engineering• Shima Seiki Mfg Ltd.• Pai Lung Machinery Mill Co. Inc.• Terrot GmbH For More Information Visit @:This Report Is Submitted By : Maximize Market Research CompanyCustomization of the report:Maximize Market Research provides free personalized of reports as per your demand. Thisreport can be personalized to meet your requirements. Get in touch with us and our sales teamwill guarantee provide you to get a report that suits your necessities. About Maximize Market Research:Maximize Market Research provides B2B and B2C research on 20,000 high growth emergingopportunities & technologies as well as threats to the companies across the Healthcare,Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages,Aerospace and Defense and other manufacturing sectors.

0 notes

Text

A Review of Some Significant Research Breakthroughs in Banana Fibre by Gokarneshan N* in in Open Access Journal of Biogeneric Science and Research

Abstract

The article reviews some significant research trends in the banana fibre. Bannana is a natural fibre and belongs to the category of bast fibres. One area of research explore the areas of applications, particularly in handicraft products such as mat, rope and twines, but only 10% of its pseudo stem is being used for making products and the remaining is used as waste or fertilizer. Owing to its many special properties it can be beneficial to farmers and also serve as a good raw material for the textile and packaging industry. In another area of research, flame retardant functionality has been imparted in cellulosic fabric using mixed formulation of banana psueudo stem sap and boric acid. Flame retardant characteristics of both the control and treated fabrics have been analyzed in terms of limiting oxygen index, vertical flammability, and temperature generation profile during burning. Another area of research reports the influence of treatment with caustic soda at various concentrations, on the physical, morphological, structural and thermal properties. An interesting study has focused on the production of bannana fibre yarns for textile reinforced composites. Thus the viability of spinning a yarn from banana fibres and weaving for the composite is explored. Attempt has been made to produce reinforced composite by weaving enzyme treated banna fibres.

Keywords: Bannana fibres; enzymatic treatment; value addition, composites; Alkali treatment; enzymatic treatment; reinforcement, sustainability.

Introduction

The banana plant not only yields fruit, but also fibre which finds use in textile and related applications. It grows under tropical conditions. All varieties of banana fibres have fibres in abundance. The banana fibre is basically a bast fibre, and is obtained after the fruit is harvested. After the plant yields the fruit, its trunk the pseudo stem largely goes as agricultural waste. These pseudostems can be effectlvely utilized in production of the banana fibres, as annually about 1.5 million tons of dry banana fibres can be produced from the outer sheath of pseudostem. Biomass (pseudostem) waste, a rich source of natural fibres the pseudostem can be profitably utilized for numerous applications and preparation of various products. Cotton being a cellulosic material is flammable and hence can create problems for health and life of mankind. Considerable attempts have been made over the years for enhancement of flame-retardant property of cotton textile materials through utilization of different synthetic chemicals and a number of them are commercially available. Of these, the common ecofriendly admixture formulation of boric acid and borax is considered the simplest [1]. But, higher quantity of chemicals used in this formulation degrades the treated fabric quality. The present days are witnessing increased use of natural lingo cellulosic fibres in composite production [2]. Natural lignocellulose fibres, such as sisal, hemp, coir, kenaf and jute, have low density, good thermal properties, better specific strength, ecofriendly nature and can be used as replacement for glass fibres during composite manufacturing [3,4]. Banana fibres, due to its high specific strength can be used as replacement of glass fibres as reinforcement in the manufacture of composites. Banana fibre is extracted from the pseudo stem waste of the plant after harvesting the fruits. Like any other ligno cellulosic fibre, the major constituents of these fibres are cellulose, lignin, and hemicelluloses [5]. The rising interest in natural fibers in the composites field is undeniable, mainly due to sustainability, but also because of their good mechanical properties and low cost. The differences observed among different natural fibers are due to their chemical composition, origin, climate conditions, etc. On average, vegetable fibers are made of 60%–70% of cellulose, 10%–20% of hemicellulose, 5%–15% of lignin and up to 2% of pectin and waxes [6]. Banana fiber is obtained from the superimposed leaves forming the pseudostem of the plant, which currently has no use, apart from a low percentage dedicated to cattle feed. It belongs to Musa genre, as a monocot. Banana is the most important crop in Canary Islands, which are the most important producers of bananas in Europe. It is important to highlight that fibers are obtained from the pseudostems of the plant once the fruit has been harvested, and that each plant only bears fruit once; this is one of the main benefits of banana fibers in comparison with other natural fibers, as this one is obtained from an agricultural residue.

Potential of Banana Fibre for Product Development