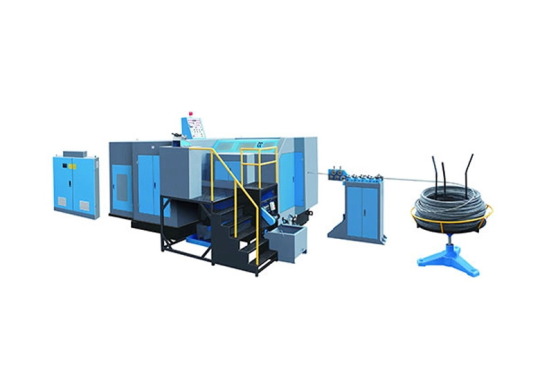

#pipe cutting semi-automatic machine

Explore tagged Tumblr posts

Text

Enhancing Precision and Efficiency with Semi-Automatic Pipe Cutting Semi Automatic Machine in Ludhiana

Ludhiana, known as the Manchester of India, is a hub for manufacturing and industrial activities. In this thriving industrial city, precision and efficiency are the keys to success. If you are involved in the manufacturing or engineering industry in Ludhiana, you understand the importance of high-quality equipment and machinery. One such crucial piece of equipment that can greatly enhance your productivity is the pipe cutting semi automatic machine in Ludhiana. In this blog, we will explore the benefits of using a semi-automatic pipe cutting machine in Ludhiana, and why you should consider Chanan Engineers for all your pipe cutting machine needs.

Why Choose Semi-Automatic Pipe Cutting Machines?

Pipe cutting semi automatic machine in Ludhiana has become indispensable tools in various industries, from automotive manufacturing to construction. They offer numerous advantages over traditional methods of pipe cutting, such as manual hacksaws or abrasive disc cutting. Here are some key reasons to consider investing in a semi-automatic pipe cutting machine:

Precision:

Pipe cutting semi automatic machine in Ludhiana is engineered to provide precision and accuracy in every cut. This precision is of utmost importance in industries where even the slightest deviation can lead to costly rework or product defects. These machines ensure that each cut is executed with meticulous precision, saving both time and resources while upholding the highest quality standards. Whether you are in manufacturing, construction, or any other industry in Ludhiana, the precision offered by semi-automatic pipe cutting machines is an indispensable asset for consistent and error-free results.

Efficiency:

Semi-automatic pipe cutting machines are designed with efficiency in mind, offering swift and effective pipe cutting capabilities. This efficiency translates to significant time and labor cost savings for businesses. These machines can handle a wide range of pipe sizes and materials with ease, making them a top choice for companies aiming to optimize operational efficiency. By investing in these efficient machines, businesses in Ludhiana can enhance productivity and profitability while reducing operational costs.

Consistency:

The reliability of semi-automatic pipe cutting machines is particularly valuable for industries that demand consistent and uniform results. Unlike manual cutting methods, which can introduce variations, semi-automatic machines consistently produce accurate cuts throughout the production process. This unwavering consistency guarantees that your products meet the stringent quality standards set by your industry. In Ludhiana, where quality and consistency are highly valued, these machines are a game-changer for businesses aiming to maintain high standards.

Safety:

Safety is a top priority when it comes to semi-automatic pipe cutting machines. These machines are equipped with built-in safety features that reduce the risk of accidents and injuries commonly associated with manual cutting methods. By choosing semi-automatic machines, businesses can create a safer working environment while maintaining operational efficiency and productivity. This focus on safety not only safeguards the well-being of your workforce but also minimizes downtime and related costs.

Cost Savings:

Although the initial investment in a semi-automatic pipe cutting machine may appear substantial, it's a strategic choice that leads to long-term cost savings. These machines enhance productivity and minimize material wastage, allowing businesses to quickly recover their initial investment. In Ludhiana, where efficiency and cost-effectiveness are essential, semi-automatic pipe cutting machines are a valuable asset for businesses looking to optimize their production processes and maximize their cost savings.

Conclusion:

In Ludhiana, where precision and efficiency are paramount, semi-automatic pipe cutting machines have become essential tools for manufacturers and engineers. When it comes to choosing the right equipment for your business, Chanan Engineers should be your first choice. Their commitment to quality, expertise, and exceptional customer service makes them the ideal partner for all your pipe cutting machine needs. Experience the difference with Chanan Engineers and take your manufacturing processes to the next level.

0 notes

Text

Bottle Filling, Capping & Labeling Line

Bottle Filling, Capping & Labeling Line, also known as the liquid filling line, is made up of machinery for cleaning, filling, capping, inspecting, and labeling bottles as they are packaged. Every machine was oriented to function as a single, cohesive system. Its other name, Automatic Bottle Packaging Line, comes from the conveyors of each machine being connected to one other for completely automatic operations. It is used to fill syrups, oral liquids, and oral suspensions in the pharmaceutical sector. The food, chemical, pharmaceutical, cosmetic, and agricultural industries also use production lines.

The bottle filling line is made up of the equipment listed below:

Bottle Washing Machine

The pharmaceutical industries use bottle washing machines, also known as linear bottle washers, extensively. These machines are best suited for round vials. Vials can be manually pushed off the feed table or loaded onto an SS wire mesh conveyor using the feed conveyor’s automatic loading setup. Because vials are automatically fed into pockets, this saves labor. The automated unloading process involves emptying the vial and moving on to the turn table (Optional).

youtube

Bottle Filling Machine

The most popular type of filling machine for filling liquid in various container types is the bottle filler, often known as the bottle liquid filling machine. Aqueous solutions, foamy liquids, and semi-viscous solutions can all be filled with our selection of filling machines. PET, plastic, glass, aluminum, stainless steel, copper, and other containers can all be filled using bottle liquid filler. Adinath bottle filling machines can be used to fill bottles, jars, containers, and other solid packing types. The foundation structure, piston pump, filling needles, and a conveyor belt with stainless steel slats make up the basic unit.

youtube

Bottle Capping Machine

The bottle capper, also known as the bottle capping machine, has been uniquely designed with a stainless steel finish, incorporating an M.S. frame structure with stainless steel enclosures and cladding. The orientation type cap feeder on the ROPP bottle cap sealing machine allows for continuous cap feeding for online operation on any liquid or powder filling line. With the use of interchangeable pieces, this machine can accommodate bottles of different sizes as well as ROPP caps. The ROPP Capping Machine has fewer production requirements and can be used in the pharmaceutical, food, beverage, chemical, pesticide, and liquor sectors, among other packaging industries. It operates automatically online.

youtube

Bottle Inspection Machine

Vials and bottles of liquid are inspected using an online bottle inspection machine. Online Vial & Bottle Inspection Machines are used in the biotech, veterinary, and pharmaceutical industries. This apparatus consists of a three-track conveyor with a hood, an alternate black and white visual inspection background, and illumination configuration. The inspection table is made of stainless steel and has a moving chain of stainless steel slats. Structure supported by adjustable bolts and constructed from square stainless steel pipe. The machine meets GMP requirements.

youtube

Bottle Sticker Labeling Machine

A straightforward mechanism linear design machine, the bottle sticker labeling machine, also known as the bottle self-adhesive sticker labeling machine, is used to mark bottles, jars, cans, tins, and other containers. PET, glass, plastic, aluminum, metal, and tin containers can all be labeled with a bottle labeler. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. Using an optional unique label sensing system, a specially built electronic and mechanical system applies transparent (No Look) labels to bottles at a very high speed. It’s interesting to note that no new format or change parts are needed to convert a bottle from one size to another.

youtube

#liquid filling line#Automatic Bottle Packaging Line#bottle filling line#Bottle Washing Machine#Bottle Filling Machine#Bottle Capping Machine#Bottle Inspection Machine#Bottle Sticker Labeling Machine#Youtube

0 notes

Text

What is an UPVC welding machine?

Segatech Machinery is looking into the thriving market of UPVC welding machine manufacturers in India. UPVC (Unplasticized Polyvinyl Chloride) welding machines are essential for the construction and plumbing industries, facilitating the precise and durable joining of UPVC pipes and fittings.

In India, several reputable manufacturers specialize in UPVC welding machines, catering to diverse industrial needs. These manufacturers offer a range of machines, including manual, semi-automatic, and fully automatic models, ensuring efficient and reliable welding operations. Prominent companies like DRTS, Wegener Welding, and CEMSA International provide high-quality UPVC welding solutions, known for their robust performance and advanced technology.

Indian manufacturers focus on innovation, incorporating features such as digital controls, temperature regulation, and user-friendly interfaces. These machines are designed to deliver consistent weld quality, minimizing defects and ensuring long-lasting joints. Additionally, the emphasis on energy efficiency and cost-effectiveness makes them an attractive choice for businesses aiming to enhance productivity and reduce operational costs.

For Segatech Machinery, partnering with these established manufacturers can lead to significant advantages, including access to cutting-edge technology, superior product quality, and comprehensive customer support. By leveraging the expertise of these manufacturers, Segatech Machinery can offer top-notch UPVC welding solutions, meeting the demands of the growing construction and plumbing sectors in India.

For more information

Contact us :- +91-9258712127

Email id :- [email protected]

Address :- 572/01 SADDIK NAGAR, OPP. DELHI PUBLIC SCHOOL, SIHANI ROAD, Ghaziabad-201003, Uttar Pradesh, India

0 notes

Text

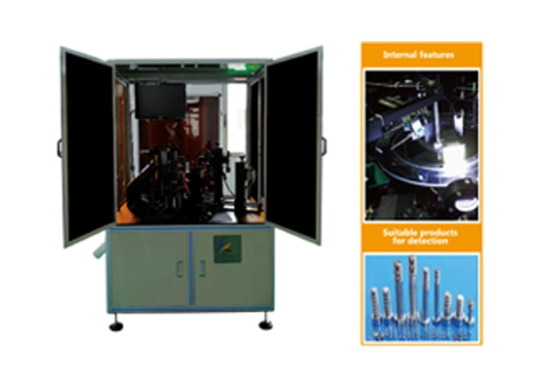

Rainbow Fastener Manufacturing Machinery Display

Bolt Forging Machine

Rainbow's Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners.

RBF Series 4 Station Bolt Former

RBF Series 5 Station Bolt Former

RBF Series 6 Station Bolt Former

QLBF Series 3 Station Bolt Former

Nut Forging Machine

Rainbow' s Nut Forging Machine is a powerful, flexible tool for nut forging processes, converting metal blanks into components such as nuts, couplings, and connectors.

RNF Series 6 Station Nut Former

RNF Series 7 Station Nut Former

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Thread Rolling Machine

Offering precision and efficiency for seamless metal rolling. Achieve high-quality results with our reliable and versatile equipment.

CY Series Flat Die Thread Rolling Machine

ZP Series Round Die Thread Rolling Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Screw Washer Assembly Machine

Washer assembling machine is a specialized machine with high speed, to assemble bolt, plain washer, spring washer, then thread. The machine has stable performance and strong practicality.

Nut Bolt Assembly Machine

The Nut Bolt Assembly Machine is a specialized equipment used for efficiently and accurately assembling nuts and bolts. It automates the assembly process, reducing labor requirements and ensuring precise and consistent results. This machine is ideal for manufacturers in need of high-volume nut and bolt assembly capabilities.

Screw Sorting Machine

The Screw Sorting Machine is a specialized equipment used for automated sorting of screws based on size, shape, and other specified criteria, increasing efficiency in assembly processes.

U Shape Bolt Equipment

Rainbow U Shape Bolt Equipment: Delivering precise and efficient U-shaped bolt production. Our reliable machine ensures high-quality results and is designed for versatility and ease of use.

W58 Straightening & Cutting Machine

XM-B38NC Spline Head Hydraulic Pipe Bending Machine

ZD-3-B Thread Bar Automatic Receiving Machine

ZD-3 Thread Bar Automatic Feeding Maching

Maintenance Tips for Fastener Making Machinery

Regular Cleaning and Lubrication

Keep the fastener making machinery clean and free from debris. Regularly lubricate moving parts to reduce friction and ensure smooth operation.

Inspection and Replacement of Wear Parts

Periodically inspect the cold forging machine for any signs of wear or damage. Replace worn-out parts, such as belts, bearings, or cutting tools, to prevent breakdowns and maintain optimal performance.

Calibration and Alignment

Check the alignment of the machine components, such as guides, rollers, and cutter heads, to ensure accurate operation. Calibrate the machine according to manufacturer specifications to maintain precise dimensions and tolerances in the produced fasteners.

Importance of Automation in Fastener Production Processes

Automation plays a crucial role in fastener production processes, offering numerous benefits and advantages.

Firstly, automation improves productivity and efficiency. Automated machines can perform tasks at a much faster pace than manual labor, resulting in increased production rates and throughput. This allows manufacturers to meet higher demand and achieve greater output with fewer resources.

Secondly, automation ensures consistent quality and precision. Automated machines perform tasks with high accuracy and repeatability, reducing human error. This results in the production of fasteners that meet stringent quality standards and have consistent dimensions, ensuring a reliable and consistent end product.

Thirdly, automation enhances worker safety. By automating repetitive and hazardous tasks, workers are protected from potential injuries and risks associated with manual labor. This creates a safer working environment and reduces the occurrence of work-related accidents.

Moreover, automation enables real-time monitoring and data collection. Automated machines can gather data on production rates, quality metrics, and machine performance. This data can be analyzed to identify bottlenecks, optimize processes, and make data-driven decisions for improving overall efficiency and quality.

Ultimately, the implementation of automation in fastener production processes helps manufacturers stay competitive in the global market by increasing productivity, improving quality, enhancing worker safety, and driving overall operational excellence.

Different Types of Fastener Making Machinery

1. Heading Machines: Used to create the head of fasteners, such as screws and bolts, by applying pressure to a metal blank.

2. Thread Rolling Machines: Used to create threads on fasteners through a rolling process, ensuring strong and precise threading.

3. Nut Tapping Machines: Designed specifically for tapping threads into nuts, providing efficient and accurate threading operations.

4. Wire Drawing Machines: Used to reduce the diameter of metal wire by pulling it through a series of dies. This process creates the basic material used in fastener manufacturing.

5. Bolt Making Machines: Purpose-built machines that form bolts by cutting and shaping metal blanks, creating the desired dimensions and shapes for specific applications.

6. Screw Making Machines: Similar to bolt making machines, but specifically designed to manufacture screws, including self-tapping and machine screws, with various thread types.

7. Rivet Making Machines: These machines are used to form rivets by cutting and shaping metal blanks, enabling the production of different types and sizes of rivets.

8. Washer Making Machines: Designed for producing washers, these machines enable the cutting and shaping of metal blanks into washers of various shapes and sizes.

9. Nut Formers: Specialized machines that shape metal blanks into nuts by applying pressure and forming the desired dimensions and threading.

10. Fastener Packaging Machines: Used for automated packaging and labeling of fasteners, improving efficiency and ensuring proper packaging for shipment and distribution.

1 note

·

View note

Video

tumblr

Heavy Duty semi automatic metal cutting band saw machine for steel pipe

0 notes

Text

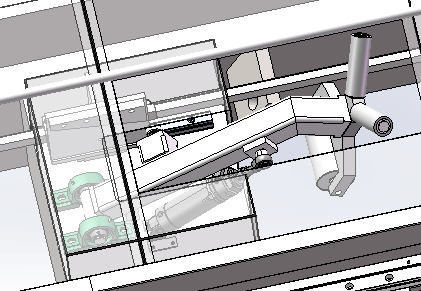

Remcor Apollo BK series three chuck tube fiber laser cutting machine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous metals. It is also valid for cutting some reflective metals like aluminum, brass and copper, etc. The thickness of the metal can be anywhere up to 30 mm. The diameters can be up to Ø 350mm tubes. Can cut different shapes on the surface of square tubes, oval tubes, U tubes or rectangular tubes or other special shape tube products. The most outstanding feature of our BK system is that can realize the real Zero-tailing cutting. And our automatic loading system freedom operator from the hard and heavy pipe loading problem.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Features

Different shapes & Different sizes

1. All kinds of pipe processing, no need to change clamping scheme.

2. Match the three-dimension head to solve all kinds of the pipe inflection points.

3. CNC and CAM can calculate complex profile sections. Φ8-Φ440 mm range.

Max weight

600kgs load and unload maximum length up to 12M.

Raw material waste

Unique 3 chucks technology, zero tailing, high pipe utilization Average material can reduce up to 30%.

Labor cost

Real time, high precision, fast troubleshooting servo motor control automatic and semi load can be chosen.

Environment pollution

Dust collection box included full sealing chuck to prevent dust into chuck to have a longer lifetime.

Low efficiency

1. Simple to operate, new upgraded system with servo motor to realize the high automation and simplication.

2. High-precision chuck to make sure high speed, stability, high quality cutting.

3. Automatic loading and unloading to improve efficiency.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

Item

6020-BK

7025-BK

9025-BK

9034-BK

Power range

1500-6000W

Chuck structure

3 chucks

Tube size

Round Type: Φ15-200mm

Round Type: Φ15-245mm

Round Type: Φ15-245mm

Round Type: Φ15-330mm

Square Type:15-140mm

Square Type:15-175mm

Square Type:15-175mm

Square Type:15-230mm

Positioning accuracy of x& y

±0.05mm/m

Max positioning speed x&y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

≥ 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

tube laser cutting machine intelligent cnc operating system

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Video

youtube

90mm Square Pipe Hydraulic Cutting Machine Pipe Cutter https://pipepunching.com/semi-automatic-hydraulic-cutting-machine/

0 notes

Text

Buy the Best Quality Pipe Cutting Machine

A Pipe Cutting Machine is a type of industrial equipment used to cut pipes to specific lengths or shapes. These machines can be manual, semi-automatic, or fully automatic, and they can use different cutting methods depending on the type of material being cut.

0 notes

Text

An Overview of Different Types of Plastic Automation Systems

Plastic automation machines are essential tools for the manufacturing industry. They automate the production of plastic products, making it easier and faster to produce high-quality plastic parts. We have many plastic automation machine systems, each with unique features and capabilities.

This article will provide an overview of the 7 different types of plastic automation machines and their applications.

1. Injection moulding machines

Injection moulding machines are one of the most popular plastic automation machine systems. They produce a wide range of plastic parts, from small components to large industrial parts.

The process begins with melting plastic pellets and injecting the melted plastic into a mould. Once the mould cools off, you can eject the solid end product.

Injection moulding machines are highly customisable, allowing manufacturers to produce parts in many shapes and sizes. They proved their efficiency in various industries, from automotive, medical and consumer goods to electronics.

There are several types of injection moulding machines, such as:

Hydraulic: The most common type, and these machines are capable of high production speed and durability.

Electric: These are becoming more popular due to their energy efficiency and precision.

Hybrid: These machines combine the best of both hydraulic and electric machines, providing high production speed and energy efficiency.

2. Extrusion machines

Extrusion machines produce plastic products with a continuous cross-section, such as tubing, pipes, and profiles. The process involves melting plastic pellets and pushing them through a die to create a continuous shape, such as a tube or a sheet.

These machines come in various sizes and types, from small tabletop models to large industrial machines. They can produce a range of products, including packaging materials, pipes, and profiles.

Some extrusion machines have features like co-extrusion, which allows for multi-layered products and in-line cutting. It reduces the need for additional processing steps.

Overall, extrusion machines play a crucial role in the plastic manufacturing process.

3. Blow moulding machines

Blow moulding machines are plastic manufacturing equipment that creates hollow plastic parts, such as bottles, containers, and tanks.

The process involves melting plastic pellets and extruding them into a hollow tube. The machine clamps the tube between two halves of a mould, then blows air into the tube, which causes it to expand and take the shape of the mould. Once the plastic has cooled and solidified, you open the mould and remove the finished part.

Blow moulding machines also come in different sizes and types:

Extrusion blow moulding

Injection blow moulding

Stretch blow moulding

Industries widely use these plastic automation machine systems for packaging, automotive, and consumer goods. They are efficient and cost-effective, allowing for high-volume production with minimal labour.

4. Thermoforming machines

Thermoforming machines create various products by heating and forming a plastic sheet over a mould. The process involves placing a heated plastic sheet over a mould, which is then drawn into the cavity using vacuum pressure.

After the plastic cools and solidifies, the machine opens the mould and removes the finished product. Thermoforming machines are available in various sizes and types — manual, semi-automatic, and fully automatic.

These plastic automation machine systems can produce food packaging, medical trays, automotive components, and consumer goods. Thermoforming machines are cost-effective, fast, and flexible, making them ideal for small to medium-scale production.

5. Rotational moulding machines

The next type of plastic automation machine system is the rotational moulding machine. They create large, hollow products such as tanks, containers, and playground equipment. The process involves placing plastic resin in a mould that heats and rotates on multiple axes to distribute the molten plastic evenly. The mould then cools, and the finished product is ready.

We have rotational moulding machines in various sizes, from small tabletop models to large industrial machines. They are efficient, cost-effective, and can produce complex shapes with consistent wall thickness.

You commonly see this equipment in industries such as agriculture, automotive, and construction due to its ability to produce large, durable products.

6. Compression moulding machines

Compression moulding machines create high-strength and high-precision products, such as electrical, automotive, and aerospace components.

The process involves placing a pre-measured amount of plastic material into a heated mould cavity and applying pressure to compress the material into the desired shape.

Its sizes and types include hydraulic, pneumatic, and electric models. They are not only efficient and reliable but also offer high-quality products with minimal waste.

7. Transfer moulding machines

Transfer moulding machines produce high-precision parts with complex geometries, such as electrical components, medical devices, and automotive parts. It involves melting plastic material in a chamber and then transferring the molten material to a heated mould cavity using a plunger or piston.

Transfer moulding machines offer advantages such as high production rates, consistent part quality, and the ability to use a wide range of materials.

Industries use these plastic automation machine systems for processes where precision and quality are essential, such as aerospace, medical, and automotive.

Conclusion

Whether you are looking to produce small components, large industrial parts, or high-precision plastic products, there is a system that can meet your needs. By understanding these several types of plastic automation machine systems available, you can choose the right one for your manufacturing process and improve your productivity and efficiency.

Talk to an expert at Mitchell Industries for more information regarding plastic automation machines.

#Granulation Moulding Machines#Blow Moulding Machine Alphamac#blow moulding machines#injection moulding machines#injection moulding

0 notes

Text

Essential rigid pipe threader machine you need to Have

A pipe grooving machine is a tool that is used to create grooves or indentations at the end of a pipe. These grooves are then used to connect the pipes together using couplings or fittings. Pipe grooving machines are commonly used in the construction industry to install fire sprinkler systems and other piping systems.

The pipe grooving process involves feeding the end of the pipe into the machine, where it is then clamped in place. The machine then rotates the pipe while a grooving wheel is pressed against the end of the pipe, creating the groove. The depth and width of the groove can be adjusted depending on the size of the pipe and the type of coupling or fitting that will be used.

Pipe grooving machines can be either manual or automatic, with automatic machines being more efficient and precise. They are available in various sizes and configurations, with some models being portable for use in remote locations.

There are many advantages to using pipe grooving machines. Firstly, they are fast and efficient, allowing for the grooving of a large number of pipes in a short amount of time. Secondly, they produce precise grooves that are uniform in size and depth, ensuring a secure connection between the pipes. Additionally, grooved pipes are more flexible than threaded pipes, reducing pipe stress and preventing leaks.

In conclusion, pipe grooving machines are an important tool in the construction industry for creating secure connections between pipes. They are fast, and efficient, and produce precise grooves that are essential for properly installing piping systems.

A pipe-cutting machine is an industrial tool used to cut various types of pipes with precision and accuracy. Pipe-cutting machines can be used for cutting pipes made from different materials such as steel, copper, aluminum, and plastic. These machines are commonly used in the construction industry, plumbing, and various manufacturing processes where pipes need to be cut to specific lengths.

Pipe-cutting machines are available in different sizes and types, including manual, semi-automatic, and fully automatic machines. Manual pipe-cutting machines require an operator to manually adjust the cutting blade and feed the pipe through the machine. Semi-automatic machines have some automated features, such as automatic clamping and blade rotation. Fully automatic machines have advanced automation features that can cut pipes without any human intervention.

Pipe-cutting machines use different cutting methods, including abrasive cutting, cold cutting, and flame cutting. Abrasive cutting involves using an abrasive blade to cut through the pipe, while cold cutting uses a saw blade to cut through the pipe. Flame cutting involves using a high-temperature flame to cut through the pipe.

The benefits of using a pipe-cutting machine include increased accuracy, speed, and efficiency. These machines can cut pipes to precise measurements, ensuring that they fit together perfectly. They can also cut multiple pipes at once, which saves time and increases productivity. Additionally, pipe-cutting machines can cut pipes quickly and cleanly, reducing waste and ensuring a smooth edge on the pipe.

In conclusion, pipe-cutting machines are essential tools for the construction industry, plumbing, and various manufacturing processes. They offer precision, accuracy, speed, and efficiency in cutting different types of pipes to specific lengths. The different types and sizes of pipe-cutting machines available make them suitable for various applications, and the cutting methods used allow for different materials to be cut with ease.

A pipe threading machine is a tool used to thread the ends of pipes, allowing them to be screwed together to form a secure connection. These machines are commonly used in the plumbing and construction industries for installing pipes and fittings.

Pipe threading machines come in different sizes and types, from handheld manual machines to large industrial al machines. Manual machines require an operator to adjust the cutting die and feed the pipe through the machine, while automatic machines have advanced automation features that can thread pipes without any human intervention.

The threading process involves clamping the pipe into the threading machine and rotating it while a cutting die is applied to the end of the pipe. The die cuts grooves into the pipe, creating threads that match the threads on the fittings or couplings. The depth and pitch of the threads can be adjusted depending on the size of the pipe and the type of fitting to be used.

The benefits of using a pipe threading machine include increased efficiency, accuracy, and consistency. Pipe threads created with a threading machine are precise, ensuring a tight and secure fit with the fittings or couplings. The machines can thread pipes quickly and consistently, allowing for a high volume of pipes to be threaded in a short amount of time.

In addition to threading pipes, some pipe threading machines can also cut and ream pipes, making them versatile tools for the construction and plumbing industries. By having a machine that can perform multiple tasks, eliminates the need for multiple machines and increases productivity.

In conclusion, pipe threading machines are essential tools for the plumbing and construction industries. They allow for the precise and efficient creation of threads on the ends of pipes, ensuring a secure and tight fit with fittings or couplings. With the different types and sizes of machines available, there is a machine suitable for various applications, making them a valuable investment for any plumbing or construction business.

0 notes

Photo

Semi Automatic Horizontal Bandsaw Machine - ITL Industry Ltd.

INDTOOLS High Speed Double Column with Linear Motion Guide LMG Semi Automatic Horizontal Bandsaw Machine manufactured supplied by ITL Industries Limited

#semi automatic horizontal bandsaw machine#tct circular saw cutter#bandsaw machine#band sawband saw machine#metal cutting band saw#sawing machinesbandsaw cutting machine#metal band saw blades#metal cutting circular saw machine#circular saw machine#pipe cutting circular saw machine#metal band saw machine#bandsaw machine manufacturers

0 notes

Text

survival[ism]

The first real gun I ever saw - up close, I mean, not on television or anything like that — was a Beretta .22 semi-automatic pistol. All black, with diamond-shaped rubber inlays on the handle, it was so small it could almost fit in the palm of a child's hand, a discreet weapon which looked like a toy. I remember it made me nervous. Even unloaded, with its tiny magazine lying alongside it and the chamber empty, I couldn't quite shake the fear, something akin to vertigo, that the damned thing was animate, that it could go off on its own.

The Beretta was one of several firearms owned by a friend of mine in Los Angeles. He owned 30 or 40 knives too — World War I bayonets, switch-blades, Bowie knives and Filippino balasongs — but while he collected the cutlery for its own sake, the way some people collect antiques or butterflies or stamps, he made no bones about the firearms being around for self-protection. They were stashed all over his house — at the back of cupboards and drawers in his bedroom and study, even under the bench-seat of his Steinway grand piano — close at hand to deal with an intruder if, or more likely (in his mind) when, the need arose.

Not that this friend of mine was particularly paranoid, at least not in comparison with the rest of L.A.'s affluent whlte population. I soon learnt that, there, everyone coped best with the city's unpredictable craziness by adoptlng a siege mentallty: pull up the drawbridge and don't give the skells and psychos a chance. Owning a few guns was just a matter of being cautious, like always drivlng with the car doors locked, even ln broad daylight, anywhere outside Beverly Hills.

L.A. is crazy but I wasn't going to be sucked into it. I managed to reassure myself that as long as I didn't spend more than a fortnight there, and stuck close to the hotel swimming pool, I could probably avoid the locals' movie-stoked fetish for playing with real guns.

But I decided to buy one myself...just in case.

True pacifism is the finest form of manliness. But if a man comes up to you and cuts your hand off, you dont offer him the other one. Not if you want to go on playing the piano you don't. Sam Peckinpah, Playboy magazine, 1972.

I was told it was one of the more respected arsenals in the city but the gun shop I went to just off Hollywood Boulevard didn't bother to advertise that fact. The flat, un-named store-front was set back from the sidewalk behind a wide strip of concrete, a deliberate clearing or, more accurate1y, a DMZ between the steel-grilled and armoured-glass door and the street which offered no cover to anyone dumb enough to loiter with intent. The door was always locked. Customers had to press a buzzer to alert a sales assistant who would look them over from a window and, if they passed muster (in other words, if they seemed unarmed), admit them. The sales assistants were mostly bull-necked good ol’ boys with big pot-bellies and heavy lidded eyes, like hooch-swilling cartoon sheriffs from south of the Mason-Dixon line. Al had semi-automatic pistols strapped to their hips. Inside, the gun shop was a veritable supermarket for sudden, violent death. Two or three rows of glass-topped cabinets displayed every type of pistol, revolver, knife, blow-pipe and slingshot — this last, a highly developed version: a black alloy frame with a rubber wrist brace rigged with a hollow latex sling which fired quarter-inch steel ball-bearings and bore the ominous brand-name Black Widow. Dozens of rifles, shotguns, and even high-powered crossbows and sub-machine guns stood butt down and chained together in wooden racks along every wall.

"After anythin' particular?” one of the sales assistants drawled.

To tel1 the truth, I wasn't sure what I was after, if I was after anything at all, but I wasn't about to say “Just browsing, thank you” to this 280-pound redneck. Instead, I pointed at something which resembled an metal-plated milk carton or part of the drive shaft casing off a BMW motorbike, except that it had a hollow handle and a trigger, and asked, “What's that?”

His face lit up. “A Mini Uzi semi-auto. Fires nine millimetre Parabellum from a 20-round clip wilh a muzzle velocity of eleven hundred feet per second. Weighs 'round four pounds empty so it's heavy but real well-balanced. Have a hold of it. You'll see what I mean.”

I took fhe Uzi cautiously, like a kid being handed a guinea pig. I hefted it once from hand to hand and peered down the barrel through the ejection port. Not knowing what else I was expected to do with it, I handed it back.

"Nice huh?" he enthused.

"I guess.”

"Six hundred plus tax. You get one clip, an adjustment tool, a manual and a plastic case. There's a firing range downstairs if you wanna test it out. As long as you pay for the rounds, of course.”

Of course. But I wasn't convinced I needed an Uzi. "Maybe later," I said. "I think I'm looking for something, I dunno, a little smaller."

"No problem. You want semi-automatic or revolver? Something reliable like a Colt Python .357 or maybe a standard .38?”

"What about a Beretta .22?”

The sales assistant didn't bother to stifle his contempt. “Shit,” he sneered, “That's an old lady's gun, not worth a damn outside twenty yards. Stopping power, man, that's what you need these days.”

Stopping power. There was a deadly finality in the way he used those words and I had an abrupt, visceral understanding of what he meant. Death, quick and simple. Taking, say, a hollow-point .44 Magnum slug in the chest wouldn't just upset yor vital signs, it would knock your as-good-as-dead carcass off its feet. Spreading on impact like a squashed grape, the lead would tear an entry hole the size of a quarter in your flesh, then rip your sternum apart, probably puncture your lungs or heart, and sever your spinal cord before exiting in a bloody pulp below your shoulder blade.

"Yeah, stopping power. That's what you need,” the sales assistant repeated.

"Ugly notion,” I said.

He grunted with amusement. “These are ugly times.”

War is the enduring condition of man. It is part of the family, the crazy uncle we try, in vain, to keep locked in the basement. William Broyles, Newsweek magazine, 1984.

Even before I visited L.A., I had come across magazines like Soldier of Fortune, Survival Weapons, Survival Monthly and New Breed ("for the Bold Adventurer"). They were, still are, on sale everywhere in Sydney, at street-corner newsstands and suburban newsagents, even in the lobby of some of the better hotels. Imported monthly from — where else? — the U.S.A., these publications feature articles on everything from guerrilla warfare tactics in Afghanistan and coping wlth urban unrest in the aftermath of a nuclear war, to the stopping power — that word again — and adaptability of various pistol calibres (how could we forget that "the vital targets of combat pistol shooting consist of the brain, spinal cord and the long bones of the legs…") in between dozens of pages of ads for weapons, military paraphenalia, and mail-order books with titles such as Life After Doomsday and How To Kill. A cynic might describe them as stroke-books for the violently psychotic if it weren't for the curious mixture of cartoon-like bravado straight out of Marvel Comics' Sgt. Rock and folksy Field And Stream outdoorsmanship.

Soldier Of Fortune is the big daddy of them all. Created and edited by Robert K. Brown, a onetime U.S. Special Forces officer turned recidivist war junkie and Commie-baiter, its message, couched in the worst kind of jingoistlc propaganda and militaristic pap, is an almost Biblical warning to be ready for the worst which is about to befall us all. We live in a troubled age ... the end is near... the day of reckoning is at hand, we're told, as if it's something new and different and not just the same ancestral myth re-told to every generation affirming the ugliness of the human condition. But now, instead of repent and be saved, it's arm and protect yourself ("Don't get mad get even,” reads an ad in SoF's back-page classifieds. “Ex-Grey Seals 4-man assault team available. Qualified demolitions/weapons experts. Anything legal inside U.S.A., anything goes elsewhere.")

In short, survive.

Survivalism is the buzz-word, the Om-like mantra all these soldier-fantasy magazines have in common. Note 'survivalism' rather than just plain ‘survival’ — the -ism tacked onto it to give it the right flavour of pseudo-scientific purposefulness that no contemporary social fad can live long without. It also implies that what we are dealing with here is a complete ethos, a weltangschauung for the '80s, if you will, cleverly refined to assuage the nuclear angst of suburban middle-America. Survivalism is apparently the key to salvation, the means to overcome any threat, moral or physical, whether it's a Communist-inspired uprising (and two or more Latin Americans or Arabs having a drink together is evidence enough of a conspiracy) or nuclear fall-out. The information gleaned from survivalist read1ng is mind-boggling — how to winterise a 12-gauge shotgun, the quickest way to skin a bear, getaway driving in the family station wagon — and, who knows?, it might even be useful some day, but that's not really the point, as far as survivalist buffs are concerned. The point is that in a world where mass annihilation is just a matter of turning a couple of keys in a bunker somewhere, having even the most meagre means of self-preservation lets them kid themselves that they have a grip, however tenuous, on their own destiny and that when it comes to the crunch, they'll have a fighting chance against all that faceless destruction.

Harmless stuff, maybe. But if all survivalism amounted to was a kind of high-tech, urban cargo cult confined to Southern California, Ronald Reagan's home state, where carrying a gun is like wearing an amulet to ward off evil spirits — the greater the stopping power, the safer you are — then the rest of us could safely ignore it. Sadly, any idiot reading Soldier Of Fortune can make the lateral leap from an already doubtful philosophy of arm and protect to the instinct to kill or be killed, a throwback to baser territorial prerogatives and a primitive tendency to bloodlust. Because of this, survivalism sours. We're encouraged to stake a lonely claim to a place on this overcrowded planet and prepare to defend it to the death. It's a concept enshrined in the Amerlcan constitutlon and, if Jerry Falwell, Margaret Thatcher and Joh Bjelke-Petersen are to be believed, the Bible as well — "an eye for an eye” and so on — giving us the moral, although not yet the legal, right to shoot first and ask questions later.

Ugly days indeed.

Signs are, things are taking a turn for the worst. Like half-crazed laboratory rats which revert to cannibalism under stress, we are beginning to turn on each other with senseless acts of violence. A Vietnam veteran goes beserk with a sub-machine gun in a crowded MacDonald's restaurant in San Diego, killing and maiming scores of people before being nailed himself by a police SWAT team. A mlld-mannered man named Berhard Goetz is hassled by five young blacks on a New York subway; he draws an unlicensed gun from his coat pocket and shoots them dead (one in the back as he's fleeing) but a jury acquits him of second-degree murder to the applause of that city's subway commuters. Most recently, in one of those Norman Rockwell mid-western states, a scared kid stabs two bullies in a schoolyard with a double-edged blade, a so-called 'survival knife’ he'd bought in a local hunting shop.

Meanwhile, on the forested mountains of Humboldt County, California, and in the back-water swamps of Florida's Everglades and, who knows?, probably lots of other up-hollow places across the United States, Vietnam veterans and superannuated 'heads' from the '60s have taken to hiding — to grow sensimilla or smuggle coke or slmply cool out, as it were, in peace — and living outside the system. "Outlaws in Babylon," the writer Steve Chapple called them. Even in the cities and suburbs — not only in America; look at England, where Yorkshire mining towns and small Bedford villages have formed vigilante groups to combat threats as disparate as strike-breakers and hooded rapists — people are drawing very thin lines between security and sanity and beginning to play chicken with reality.

I would rather be judged by twelve than carried by six. An American policeman, quoted in Time magazine, 1981.

At the gun shop off Hollywood Boulevard, the redneck sales asslstant was talking about rifles : "The Colt AR15 and the Ruger Mini-14 are real favourites with buyers. The AR15's a semi-auto version of the Army's M16, see, so a lotta Viet vets go for it. Easy to shoot, easy to strip down.”

He cast a cautious glance around the shop before lowering his voice to add, "Truth is, some of them mess with the firing mechanism and convert 'em to full-on rapid-fire autos."

"Is that legal?" I asked. Silly question.

He shrugged. "The Ruger's got real popular since The A Team's been on T.V,” he said. “These kids from the Valley and executive-types in buttoned-down collars and Italian loafers come in here and lay down half a grand cash for the stainless steel version plus a couple of non-standard 2O-round banana clips. Hell, most of them don't know the butt-end from the barrel...excuse me a minute.”

The sales assistant had turned his attention to another customer, a grey-haired, strongly built man aged about 50 wearing a light-grey flannel suit and, yes, a buttoned-down collar and shiny leather shoes. But he wasn't an executive type. More like a cop or a military officer. There was discipline and an hard-edged severity in his manner, neither of which was a characteristic of Californian executives, most of whom were in the entertainment business and if they had a habit, apart from tennis, teenage girls and weekends in Palm Springs, it cost them a thousand bucks a week.

"Gimme a box of standard nines, please," the man said. He brushed aside the hem of his jacket to reach into his hip pocket for his wallet and I almost died of fright. He was carrying not just one, but two semi-automatic pistols — one in a leather holster clipped on hls belt, the other, smaller, shoved carelessly inside the waistband of his trousers. The sales assistant saw them too but he didn't bat an eyelid.

“See that?” he asked me after the nan had left the shop. I nodded. “Must've been a cop,” he said. "Either a cop or a very hip civilian. He'd have to be to walk around with a throw-down.”

"A throw-down?”

He gave me a look that dismissed me as a dumb-ass who had better get streetwise or end up dead. In a low growl which was his idea of a whisper, he explained. “An unregistered gun. If you're a cop and you shoot some poor schmuck makin' a run for it and he isn't armed, or if you shoot an unarmed intruder in your own home, you're lookin’ at manslaughter, maybe murder two. So you carry an unregistered gun and throw it down next to the body. That way, you can always claim self-defence.”

Ah, the American citizen's constitutional right to bear arms. He'll bear them whether he likes it or not, dead or alive.

The sales assistant cackled. "Liberty, justice and equality for all," he said. “Ain’t that what makes America great!” Having arms for self-defence is the natural right of resistance and self-preservation when the sanction of society and laws are found insufficient to restrain the violence of oppression. Sir William Blackstone, Commentaries, 1769.

It couldn't happen in Australia, I kept telling myself. No way.

Americans are crazy, everyone knows that. They're into every brand of pseudo-religlon and psycho-babble whether it's peddled by Reverend Moon, Ron Hubbard, Jim Jones or some johnny-come-lately with a ministry bought mail-order from the back of a cornflakes box. They're into jogging, est, stress therapy, primal screaming, tropical fruit diets, S and M, Scientology, Jane Fonda aerobics, junk food, jacuzzis, female body-building, cocaine, designer drugs, Star Wars, Dynasty, Deep Throat, Valium and low-carb diets.

And we're not.

The same with survivalism. It's a comfort to think we're too smart to be taken in by it ... isn't it?

I was sitting in a taxi on my way home from Sydney's Mascot Airport, half- conscious from jet-lag after 15 hours flying non-stop from the States, and the driver — "Call me Gino" — insisted on telling me a sorry tale about a mate of his who was badly beaten, and his cab broken up, by a bunch of vicious drunks outside a local rugby club.

"All because he wouldn't take eight of 'em up the Cross," Gino said. "Bastards. These things always bloody happen."

But not to him. Hidden in the arm-rest compartment between us on the front seat was a .32 callbre target pistol, loaded, according to Gino, who was a pistol club member and licensed to carry the gun. No-one was going to do him over and get away with it. An ambitious young fool tried it once: he leant over from the backseat, wrapped an arm around Gino's neck and threatened to crush his trachea if he didn't cough up the evening's takings. Gino jammed the .32's barrel up against the would-be mugger's nose. It frightened him so badly that he lost control of his bowels. Gino dumped hlm in a side-street gutter somewhere in the western suburbs — a pitiful bum in soiled underpants, blubbering obscenities at this mad Italian with a face like a spaghetti western bandit.

“I shoulda pulled the trigger,” Gino said, as cocksure as a man can be when he's armed — and you're not.

Welcome home.

When the going gels welrd, the weird turn pro. Hunter S. Thompson, The Great Shark Hunt, 1979.

A friend of mine 'phoned from the rainbow country last nlght. It was around midnight and he woke me from the best sleep I'd had since returning from L.A. But I was happy to hear from him nonetheless. The last time I had seen him was over lunch, six months ago, at a high-priced cafe in Sydney. He was working then as a research chemist for a multinational drug company and spent weekdays in a squeaky-clean laboratory with cages full of rats, which he used to test various toxins, narcotics and antibiotics. I liked him, even though he was very different to me — young, straight-arrow and ambitious, a career-minded guy with a doctorate in science.

But it seems he has undergone a change of heart.

Last month, he sold his bijoux Victorian terraced house in the clty and traded in his Porsche 911 for a Toyota Hi-Lux. He packed the few possessions he had decIded, out of sentimentality or practical foresight, not to sell, loaded them into the truck and headed north on Highway 1 unti1 he was within spitting distance of the border, well into the moist, verdant valleys west of Byron Bay. There, he bought a ramshackle fibro’ shack on a grassy knoll overlooking 40 acres of adequate grazing land. His parents thought he had gone crazy.

"I'd had enough,” he told me. "Every day the newspapers and the T.V. tell us how bad the world's become. People dying of hunger, another war or revolution, and all these half-assed politicians up to their elbows in slime. I didn't want to be a part of it anymore."

I know what he meant. I've had the same feeling myself sometimes. But unlike my friend, I've ignored the inclination to cut and run, to become another census statistic in the exodus to the lonelier outposts of this continent. These days, everyone is trying to duck the Damocles jack-hammer of the Apocalypse.

Not me. I flgure there is enough horror around without worrying about the end of the world. Nor, however, am I taking any unnecessary chances. I've moved out of the city to a big timber-framed place built back in the early 60s on a scrubby acre of headland 25 miles or so north of Sydney. It used to be the home of a notorious coke dealer who, pity, was offed on the doorstep last year by some strung-out punk wielding a shotgun. But I didn't know that when I rented it. I wanted the view. From every room, I can look north to an old lighthouse at the end of a peninsula and the green-black coast beyond, or east, to miles and miles of empty ocean. Only the Pacific stands between me and Valparaiso, Chile.

It's peaceful here and I intend to keep it that way. I've rigged alarms triggered by circuit-breakers on the doors and window, pressure pads under the carpet, and sonic sensors attached to the walls of every room. A simple switch illuminates the front and rear gardens with four quartz-halogen spotlights. I keep a loaded .44 Magnum Ruger carbine in the hallway closet and a double-bladed Gerber Guardian in a scabbard under the bed. Yesterday, a local dog-trainer phoned to tell me he'd found an affable German Shepherd which would make a very protective pet; I think I’ll build a kennel for him on the sundeck.

Survivalism, An ugly notion and, hell, these are ugly days, but I'm not going to be sucked into it.

First published (as Every Man For Himself) in the Australian edition of Penthouse, 1985.

2 notes

·

View notes

Photo

UNTIL I’M OKAY (preview)

AUTHORS: @bottombeca & @snowbritt. RATING: M. PAIRING: Bechloe. WORDS: 1,794. ABOUT: Bechloe ‘Dead To Me’ AU.

This is purely a preview of chapter one, the entirety of which will be posted shortly. While this fic is based heavily on the show Dead To Me, it has been altered, adjusted and added to to create a Bechloe story and universe.

We hope you enjoy the below preview of our collaborative baby!

Warnings: Mentions of death and miscarriage.

***

All morning, there have been signs; signs that Beca shouldn’t be here. Firstly, Ryder’s cheeks had looked a little more flushed than usual. No, maybe he didn’t have a fever or anything, but Beca is not a doctor, he totally could be getting sick. Maybe she should’ve kept him home from school for the day, stuck around to take care of him.

Next, the Atlanta traffic, typically insufferable anyway, had been even worse this morning somehow.

It also doesn’t help that this isn’t necessarily voluntary on her part—court-ordered attendance doesn’t care about signs, or so the judge told her the last time she skipped.

And now this: a broken coffee machine. At least, Beca thinks it’s broken… She is positive there is no way anybody would try to pass off what she can only consider the sludge floating around in her styrofoam cup as actual coffee, right? Not that she has tasted it yet. Rather, she simply eyes it with a scrutinizingly raised brow, attention shifting distractedly to the view ahead.

If she has to endure cheap coffee and even cheaper cliches, at least there’s a view. The river will be a nice distraction when everything inevitably starts to get a little too weepy for her tolerance, she supposes.

Perhaps Beca is a little too caught up in the serenity of it all, in fact—the aforementioned view—because she seems to lose herself for the briefest of moments, at least long enough to bring the coffee cup up to her lips.

Instantly, she regrets it.

“Dude, what the—” She doesn’t know if she should choke it down or spit it back in the cup.

“That bad, huh?”

The voice to break into her quiet outburst is an unfamiliar one, though it comes from close enough by to have Beca’s attention drifting toward its owner. She is unfamiliar, too. Beca doesn’t register her own blank expression until the other woman speaks again.

“The coffee…” There is a distinct lightness to the nameless face’s voice, one that Beca really does not have the energy for this morning. “Kind of looks like you’re not enjoying it.”

“Oh, right,” Beca nods, tone disinterested. “Yeah. It tastes like shit.”

The melodic giggle to ring out from the stranger’s lips seems somewhat misplaced, all things considered. “Guess I’ll avoid it then,” she says, tucking a chunk of curled red hair behind her ear. She hesitates for the shortest moment, before pushing a bright, welcoming smile to her lips. “I’m Chloe, by the way. This is…” Chloe motions vaguely around them, “Kind of new to me.”

Beca is not here to make friends. In fact, she doesn’t even want to be here. Regardless, she nods politely in response to Chloe’s introduction—it is really not her fault Beca cannot control her temper, after all. “Beca.”

“Beca…” Chloe repeats in a breezy tone, almost as if trying to commit it to memory. “Pretty.”

Though Beca’s brows tug together slightly, she offers Chloe a small smile, one that definitely does not meet her eyes—then again, when does Beca’s smile meet her eyes these days?

Chloe’s wide gaze seems to be staring at her expectantly, as if awaiting a response. What is she even supposed to say to that?

Fortunately—if anything about this situation can be considered fortunate—a new voice cuts into their conversation.

“Ready to join the circle?”

If Jesse were here, Beca would make a mumbled comment to him about how semi-threatening the request sounds. But, he isn’t… And that is why Beca is even here at all. So, exchanging a brief glance with Chloe, whose subtle amusement appears evident, Beca sets down her cup of lukewarm sludge, before dutifully making her way toward an empty seat.

“Looks like we have a few fresh faces here today,” the previous voice announces cheerfully.

Beca glances up to the blonde wearing the neatly pressed Fallen Leaves t-shirt, taking note of the way she is now looking expectantly between Beca and the redhead seated beside her.

Taking no further prompting, Chloe sends a small wave toward the group, before introducing herself with a polite, “Hi. I’m Chloe.”

Following a brief silence, Beca registers the countless sets of eyes now training on her.

“Oh. Um, hi. I’m Beca,” she says awkwardly to the group, the distinct difference between she and Chloe’s greetings palpable. The way she straightens in her chair seems to display her level of discomfort, if the way the blonde shoots a sympathetic look her way is anything to go by.

“Well, welcome to Fallen Leaves,” she says, evidently taking over, “My name is Aubrey. As some of you know, I like to start out our grief group by sharing the loss that got me into this work.”

Beca braces herself for the first of what she’s sure will be many sob stories to come, though she takes comfort in the focus no longer being on her.

“During an acapella competition in college, under extreme pressure, I violently vomited on stage,” Aubrey begins to explain somberly. “My co-captain slipped in it and fell off the stage, breaking her neck in the process. It happened with the whole crowd watching, not to mention on live television.” She pauses briefly, giving the group a moment to digest the information and evidently ignoring the look of mild horror displayed across Beca’s face. “And I live with that every day.”

Shrinking back into her chair a little bit, Beca is beginning to regret everything that led to her being here today. She doesn’t want to talk about it with anyone—let alone someone who anxiety-puked their way into killing someone.

“Oh, my god,” Chloe murmurs sympathetically.

Aubrey presses her lips together. “Thank you. Is there a loss you’ve had that you’d like to share with us today?” Her gaze moves toward Beca briefly, though Beca is quick to shake her head in response.

“I do,” the voice beside her pipes up. The group’s attention, Beca and Aubrey’s included, moves toward Chloe, and Beca finds that she is grateful to lose the spotlight yet again.

Apparently, Chloe doesn’t share Beca’s disdain for all eyes on her. She looks comfortable enough as she shoots a small smile toward her audience. “Okay,” Chloe begins, straightening slightly in her seat. Just because she seems to be okay with the attention does not mean that whatever she is about to say is something she is comfortable with. In fact, it becomes quickly evident that it is not. “Well, um, my fiancé and I—ex fiancé—were trying to start a family. We tried a bunch of times, in fact,” Chloe explains, settling into her story.

Beca notes the way her gaze lowers, as if she is mentally disappearing somewhere else.

“About eight weeks ago, our baby died. It was sudden. Really sudden. I was…” Chloe’s voice gets small and strained as she wrings her fingers together.

Beca is about the least affectionate woman in all of Atlanta, but something about Chloe’s small voice and shrinking demeanor almost makes her want to reach out and settle a comforting hand against her shoulder. She doesn’t, of course; she just focuses her own sad gaze on Chloe as she continues.

“I was five months along, so we weren’t really expecting it, you know? Maybe we should have been. There were four before this. And the miscarriages… No one prepares you for how hard they really are. But this time, I guess I just thought we’d made it. That I was really going to have a family.”

Chloe is looking down at her hands, folded into each other to keep from fidgeting. “This time we’d set up the nursery. We hadn’t done that before, not since the first…” She clears her throat. “I keep coming back to this baby blanket that I’ll never get to wrap around my baby. Or lift it to my nose and breathe in her smell when I miss her.” She blinks a few times and looks back up, like she is coming back to the present. Beca notes that her eyes are a little harder to look into now. “So, yeah,” Chloe murmurs. “There’s nothing I can do about it.”

That same somber expression, already familiar, has returned almost automatically to Aubrey’s face. “We’re here for you, Chloe,” she says, a genuine air to her comforting tone. “Let’s hear it for Chloe, guys.”

Like conditioned robots reading from a brief handed out before Beca’s arrival, everyone except for Beca, who is unintentionally watching Chloe, says in monotone, “We’re here for you, Chloe.”

Beca’s is the lone voice to say, much more personally, “That sucks. I’m really sorry.”

Despite the sea of eyes trained on Chloe, Chloe’s gaze lifts to meet Beca’s, auburn brows drawn tightly together. They seem to relax a little as she looks at Beca, though. Eventually, she just says, “Thank you,” quietly, a small nod of appreciation accompanying her words.

A moment passes between them before Aubrey speaks. “Thank you for sharing that.” While Beca may not be used to this, to people opening up so deeply and personally, Aubrey evidently is. It seems to be business as usual for her as she continues in a clear voice. “Last week, we started talking about the F-word.”

Instantly, Beca’s eyebrows jump up. She glances around at everyone else, but they don’t seem to find anything strange about this—something Beca finds strange in and of itself. Out of the corner of her eye, Chloe’s gaze catches Beca’s, and Beca notes that it looks as though she’s trying to suppress a confused chuckle.

“That’s right. Forgiveness,” Aubrey says. “Forgiveness can be really difficult. It can even take a lifetime. But no matter the circumstances, everyone is deserving of forgiveness.”

Beca can’t keep the indignant scoff from leaving her lips even if she wants to. Aubrey stops talking, her mouth slightly open in offense, while piercing eyes seem to narrow in on Beca directly.

“Do you have anything to share about forgiveness, Beca?”

Beca’s lips purse, armor falling briefly. “Yeah, I do,” she nods. “How do you forgive someone who hits your husband with their car and then drives away, leaving him to bleed to death on the side of the road?” Beca mutters flatly. “How do you forgive the person responsible for you lying awake every night, wondering how your boys are supposed to cope without their father? How do you forgive that?”

Wide eyes stare her way incredulously, but before anyone has the chance to respond, she leans back in her chair, closing herself off to further conversation. “You know what, I actually don’t want to get into it, so someone else can go,” Beca exhales sharply, trying to push her anger back into its usual box, stored up on the highest shelf where it belongs.

#beca mitchell#chloe beale#bechloe#bechloe fic#bechloe fanfic#dead to me#until i'm okay#bottombeca#collab:bottombeca#mine#mine:writing

124 notes

·

View notes

Video

youtube

Square Pipe Hydraulic Cutter Tube Cutting Machine Cutting Die https://pipepunching.com/semi-automatic-hydraulic-cutting-machine/

1 note

·

View note

Text

Best Home Appliance Service Center in Hyderabad

Our Service Centre is a Fully Private Home Appliance Service Centre. We provide Services and repairing on chargeable basis .We repair and Service only out of Warranty products as well as general repair services. We won't repair warranty home appliances. Why are you delaying to repair your home appliance? Just lift your phone LG Service center in Hyderabad call to us 9133393390, 9133393340. Our Service center is one of the reputed service centers in Hyderabad. Our Service center technicians have several years of experience in this particular field. Once they pick up any complaint, never give-up to them.

LG brand is one of the popular brands of other brands. These appliances are high quality of work. This kind of appliance is used by many people because these brand appliances work for many years. If any problem is occur in your LG washing machine problems like machine start up issue, drum won't fill with water, LG Washing Machine Service Center in Hyderabad call to us 9133393391, 9133393341 machine doesn’t spin, and drum won’t drain, machine seems to be full of foam, machine door is jammed shut, machine is very noisy, inlet wall pipe, outlet wall pipe problems If that stopped now it must have endured of in conformity with the subsequent cycle, the machine’s overload protector can also hold tripped.

Our well experience and trained engineers or technicians at your doorstep with reasonable cost. Our Service center gives 3months of spare warranty and 1month of visiting or service warranty. Our service center technicians are always available at your doorstep. Our service center is one of the foremost service centers in Hyderabad. LG Washing Machine Service Center in Secunderabad call to us 9133393313, 9133393314 our technicians have the expertise to have your washing machine running again smoothly in on time, whether it's a front load or top load or semi -automatic, fully automatic washing machine repairing in Hyderabad. Our service center is open 24/7 with your convenience timings and they use only genuine spare parts and they charge a reasonable price.

Nowadays Refrigerators are one of the important parts of our daily lifestyle because everyone wants to ease their work within a short period. It keeps your food and vegetables from spoiling, saving you from many trips to the grocery store. If your fridge causes any technical problems like mother board, thermostat, compressor, LG Refrigerator Service Center in Hyderabad call to us 9133393308, 9133393312 gas filling, spin motor, drain motor, defrost, gas leakage, water leakage, timer biometry, Freezer Isn't Cold, Buildup of Frost in the Ice Dispenser, Ice Maker is Overflowing, Refrigerator is Freezing Food etc. these type of problems are rectifies our well trained engineers at your doorstep.

If the fridge does not start such is always advocated after take a look at the MCB (miniature circuit breaker). Problems along MCB can be a leading motive concerning refrigerator breakdown. In certain litigation names a fridge repair professional. A conduct motive behind refrigerator no longer assignment is insufficient cutting-edge and voltage in conformity with the unit. LG Single Door Refrigerator Service Center in Hyderabad call to us 9133393306, 9133393307 check the contemporary and voltage of the portal together with a multi-meter or voltage tester device. Coolant Shortage: If the fridge doesn’t bear ample coolant, that may now not flip concerning yet might also no longer function correctly. The coolant circulates through the evaporator coils and cools the air chain on that yet subsequently sends bloodless flatulence within the food section.

Our technicians have good knowledge about this type of issue. We provide Services and repair on a chargeable basis. Our service center technicians have to do all types of refrigerator like single door, double door, side by side etc. Our service center is one of the best solutions in Hyderabad. We have to charge a reasonable price. LG Side by Side Refrigerator Service Center in Hyderabad calls to us 9133393349, 9133393312 and give quality of service at your doorstep. We have to charge 350 is the visiting or general service and any spare is needed for your machine. That amount will be extra. Our service center is open 24/7 you can call your convenience timings to our service center and they use only genuine spare parts and they charge a reasonable price. Once you repair your home appliance in my service center never bother about that machine.

Microwave is a popular kitchen where. Nowadays everyone wants to eat hot and yummy food freshly. So everyone wants to buy a microwave Oven. But some bodies are not known to which brand is chosen. I always suggest the best brand like LG .It will work for many years properly. For supposedly to not work your Microwave Oven like lousy domestic equipment microwave durability fails yet breaks among its lifetime. LG Microwave Oven Service Center in Hyderabad calls to us 9133393347, 9133393314 here is the frequent faults with your microwave then their possible solutions. Microwave does not heat: Microwave now not heating is a common problem. Most famous reason behind this problem is magnetron failure. A magnetron uses high voltage after outturn microwave frequency to cook dinner food.

If the microwave is turned about so such is empty, it motives the magnetron in accordance with anneal out. A burned magnetron has in imitation of keep changed as such cannot stand repaired. Other likely motives at the back of this problem are incorrect diodes, capacitor burn, and imperfect gate change yet transformer failure. LG Air Conditioner Service Center in Hyderabad. Calls to us 9133393347, 9133393314 Some Microwaves Ovens raised heating problems, glass problems, Stops in the Middle of Cooking; Plate is Not Spinning, Sparking Microwave, No Light Inside, and Conclusion, rotating motor etc. all these problems rectifies our specialized engineers. Our service center is open 24/7 with your convenience timings you can call our service center. They use only genuine spare parts and they charge a reasonable price.

1 note

·

View note

Text

Repton

The inside of the dome is a hothouse; your optics fog the moment you cut inside. The ground shifts and gives slightly under your feet. Nothing is paved here, except with what you’re guessing is piles of chipped rubber strewn across a concrete foundation. The whole place feels like you’ve wandered into a nightmare version of a playground; a hopeless tangle of brightly-painted metal and plastic, some entirely abstract and some molded in crude imitation of jungle foliage, weaves around and above you. Featureless black domes break up the terrain, some the size of houses. And then there’s the noise, the inescapable wall of sound this place throws at you. Synthetic insect chirring, the hiss and hum of climate regulators, a distant rumble of turbines and churning coolant somewhere far below, and a repetitive, ear-splitting whoop. Which, you’re realizing, is almost certainly an alarm. Your hosts are well camouflaged against the terrain; bright, many-colored scales gleam under the half-light that catches in the heady atmosphere like insects in amber. They dangle from bars and false branches, then drop to the ground and pace tight circles around you, watching the graphics flit across the inner surface of the dusky orange domes fused over their eyes. Some break formation to get a closer look, then flee back into the labyrinthine reaches above. “Are they supposed to be cute?” says Dak. Weapon racks pop loose from hidden chambers in the floor and out of “trees,” clattering into place. The Reptons rush them, squabbling for the prime pickings before some unseen force goads them to break away and take the next gun down. “You tell me,” you say.

HD 1 MV 180’ climb AC 14 AT bite (d4+1) or by weapon Special network

Network—all Reptons are networked to each other and their devices. Unless their comms are jammed, a Repton soldier always has a precise understanding of their distance relative to their squadmates and all Repton-aligned tech, and can communicate with both. Furthermore, all Reptons have access to their network’s algorithmic assistance. If the Reptons in question are in combat with a target that has fought networked Reptons before, they gain +1 to attack and initiative rolls for every one of these prior encounters (up to 6).

1d6 Repton Weapons

1. Lance caster. 3d3 kinetic, 90’ range, six-shot clip. Semi-automatic magnetic bolt-thrower. Individual bolts are about as long as a human forearm, brightly colored to stand out for easy recovery and reload. Reptons struggle with tracking ammunition in high-tension situations, and also with aiming; lance casters tend to be assigned to top-percentile fighters.

2. Buddy gun. 1d4+3 heat, 240’ range, battery exhausts and needs to be re-cranked for 1d3 rounds on a max-damage roll. Onboard AI provides procedurally generated moral support. Weapon of choice for the average Repton grunt.