#pile crusher machine

Explore tagged Tumblr posts

Text

Trains, Planes, and Autobots

Summary Fic Part 10

[Previous] [Next]

(decided to stop stringing you guys along. So have the confrontation with DeadEnd. As a treat.)

---

Megatron comes down and Dorothy disembarks. Atlantic City is just visible in the distance. Optimus pulls up not too far from their landing spot and Twitch, with much relief and stretching emerges from his trailer.

Dorothy looks speculatively up at the gates of a scrapyard and wonders why a robot would take up residence where machines are destroyed. Megatron simply replied that it's the sort of place Deadend would go as he "has a lot of thoughts about life and the universe and places like this prove him right".

Dorothy mutters that he's not painting a pretty picture.

Optimus tells the group they'll likely have to split up to canvas the scrapyard and find Deadend. He tells them to leave their comms open and remain in communication as they search.

They split into two groups; Dorothy and Megatron, and Twtich and Optimus, and head into opposite directions.

Dorothy asks Megatron for more information about DeadEnd. Megatron asks her to be more specific and she says she just wants to know if hes going to have any "nasty surprises" for them like shooting lasers from his eyes or something.

Megatron laughs at the idea, but quickly recovers and tells her that no. Deadend is just a regular cybertronian. Unless he has had some sort of special upgrades and he can't imagine Deadend bothering with that without being convinced.

However he does tell her not to let down her guard. Deadend might not have any special powers to speak of, but he could be clever. And while he had a nihilistic defeatist mindset, once properly motivated he could be fierce and clever.

Meanwhile Twitch is hovering around the junkyard and trying to spot cybertronians but is quickly becoming frustrated. She points out that the junkyard has a TON of cars that Deadend could be hiding out as. She asks Optimus if he has a energon detector. He answers negatively, and is about to talk out a strategy when he quickly hushes her. Twitch lowers her voice and asks what it is. Optimus tells her to listen.

After a moment, Twitch realizes she can hear a voice.

They peek around a trash pile and quickly realize that their caution might be misplaced.

Deadend is leaning on a junk pile that hes fashioned into a sorta chair watching a car crusher do its work. He's surrounded by odd junk sculptures and is currently trying to vocally write some cheesy edgy poetry. Said poetry is terrible. Oh and theres music playing.

((I can't decide what sorta music Deadend would listen to. Screamo or classical music. Note in the replies what sorta music you think Deadend would listen to while making junk scultures, writing bad poetry, and watching cars get crushed.))

Twitch asks if thats Deadend and once Optimus confirms she decides to fly over and try and "read him his rights" or whatever her idea of that is. Optimus tries to stop her, but its too late.

Deadend doesn't really react to Twitch's voice as his music is so loud. Twitch tries to raise her voice above the noise, but can't manage it. She eventually get frustrated and shoots an EMP at the device playing the music FINALLY getting Deadends attention.

However Deadend isn't really intimidated by Twitch. Literally snatching her out of the air and wondering what she is. At first he thinks shes an autobot drone until she transforms back into robot mode.

He winds up dropping her on the ground hard in surprise and vocally wonders if shes an autobot only to fail to see an autobot insignia on her.

Twitch is about ready to launch at him only for Deadend to pull a gun on her. He conversationally asks what shes doing there.

Twitch hesitantly tries to answer with something that wont get her shot only for Deadend to cut her off and say that it doesnt matter anyway. Obviously shes either an autobot spy there to arrest him, a decepticon thats come looking to collect on some kind of bounty or else trying to take over "his" junkyard, or else an unaffilated bot tryin to do one of the former. Regardless he should probably just shoot her and-

Thats when Optimus is on the scene and successfully manages to get the jump on Deadend kicking off a fight that attracts Megatron and Dorothys attention.

Deadend largely plays evasion as he moves to retrieve his firearm (which he dropped when Optimus attacked before) and focuses on firing at Optimus from a distance. Twitch manages to get his attention and draw his fire while Optimus transforms into truck mode and nearly rams into Deadend who just barely manages to transform himself and speeds off.

Megatron and Dorothy appear overhead tracking after Deadend from overhead. Dorothy radios Optimus telling him they have their sights on the Con. Optimus radios back that he and Twitch are in pursuit on the ground.

Dorothy watches Deadend racing along the road and consults her GPS. She tells Optimus that he seems to be heading for the interstate. Megatron tells OP to cut him off before he can reach the interstate.

Twitch wonders why. If he tries to hit the interstate the traffic would slow him down wouldn't it?

Megatron darkly says that he doubts Deadend intends to drive responsibly.

Hes proven correct when they fail to cut Deadend off from the interstate and he very deliberately enters the opposite exit and barrels down the interstate in the wrong direction. Cars swerving out of his way, endangering the drivers.

Optimus growls that he'll need to leave pursuing Deadend to the others as his truck mode giving chase will likely only endanger more lives. So he directs Twitch to follow after Megatron while he follows on foot trying to keep an eye out for any crashed cars.

Megs and the others follow his direction and chase after Deadend, who swerves expertly between oncoming cars. Occassionally coming dangerously close to some of the cars.

((Won't lie I struggle to come up with how this chase ends or how they catch up with Deadend. What I DO have is that they eventually catch up to Deadend and manage to capture him.))

Deadend doesnt really argue against his capture. He ran, they chased, they caught up, he was captured. It was inevitable.

This irritates Twitch who demands to know why, if he thought getting captured was 'inevitable', he drove through the freeway and endangered all those people.

Deadend can only give the incredibly unsatisfactory answer of, "I dunno. Instinct?"

His callous attitude irritates Dorothy and Megatron as well with Megatron arguing that its just this careless attitude that has given their people such a hard time on the planet.

Deadend, once again, just shrugs and treats the concept of humans hating cybertronians like some inevitability.

However, Deadend tells them to relax as hes not intending to run anymore. He's tired of hiding out anyway. Pessimistically he wonders is Megatron will leave him to rot in prison or put him into stasis like he did with Motormaster.

Megatron takes the opportunity to say that they'd actually come to talk to Deadend about the stunticons. Asking him when he last saw the members.

Deadend asks why Megatron wants to know something like that, but doesnt wait for an answer before deciding its not worth asking. He then says that he hasn't seen any of the others since the end of the world. He himself has largely been waiting for GHOST and the autobots to come find him. Moving from scrapyard to scrapyard, stealing energy from gas stations and power plants, listening to music, making his statues, and watching "the inevitable fate of all cybertronians" which he describes as "a useless pile of junk only good for crushing and smelting down".

Strangely enough this behavior actually kept him largely under the radar. Something that Megatron doesn't miss. Internally speculating if Deadend would have continued wandering quietly if they hadn't shown up.

Optimus then shows up carrying his trailer behind him. Clearly out of breath, and tells the group that, thankfully, none of the drivers on the interstate were harmed.

To this news Deadend just shrugs.

Optimus ignores him for his own sanity, and asks Megatron if he's learned anything new from Deadend to which Megatron responds negatively.

The sudden interest in the stunticons peaking his interest, Deadend asks why they're asking him about the others. Twtich tells him that they're looking for the others before Dorothy can shush her.

Deadend suddenly becomes VERY interested and asks if any of the other stunticons have escaped from jail.

Megatron sighs and tells him they believe Motormaster may be reforming the group.

This clearly seems to shock Deadend and he begins to mutter to himself. Asking himself if he should run. Then wondering if its possible to hide. Finally he says "its all pointless" and "he" will find him no matter what.

With that he willingly walks into Optimus' trailer and asks them to "get it over with".

After closing the doors Dorothy wonders if they should be concerned with how easy that was after that chase.

---

#bdko#kobd#earthspark#transformers#transformers earthspark#tfe#tf earthspark#deadend#megatron#optimus prime#twitch maltos#dorothy maltos#earthspark dorothy#earthspark dot#earthspark megatron#earthspark optimus prime#tf deadend#tf megatron#tf optimus#earthspark optimus#earthspark twitch#maccadam

28 notes

·

View notes

Note

do you have anymore ideas/aus for prowlbee?

Well let's see!

We got Cyberbeast AU, and Revival!ProwlBee AU... huh i thought there was more. Oh well.

So- besides AUs, there's normal timeline where everything went normally (except Bee and Prowl got together and Prowl did not die during the fight) and they're just living a fun life on Earth and i write whatever comes to mind that could have happened.

Speaking of the more angsty stuff, i recently had an idea about Bee having a bit of a fight with his team before leaving for patrol. He was so upset and didn't notice Starscream coming (yes, cuz he is a sadist in my eyes). And so they fought and Bee got knocked out, Star took him to the docks where a ship with trash loaded was about to leave and dropped him there. Long story short- Bee woke up in a seemingly endless trash yard. His team thought that he's just being stubborn and doen't come back because of the argument, but then it was 3 days since he was gone and they were concerned, he wasn't picking up any of their comms. Then they fought with Starscream who made a snarky comment related to Bee.

"Let's just say, he's not a problem anymore.~" Starscream said before having to retreat.. That was the moment they realized something bad happened to Bee. They spend days, weeks, months searching bit by bit of the country but nothing. Soon enough 3rd or 4th month of him missing rolled around and they had to spend Christmas without him. Prowl was the most worried of them all; sure he didn't show much emotion on the outside but on the inside he was panicking and grieving. The scout had a special place in his Spark, even if Bee didn't know it. He wished and prayed to the Allspark to give him some sort of guidance to find Bee, if he's still alive.... and he got it. One of the feats he got from the ninja training was the vision-dreams that somehow predicted the future and told him what to do. It was rare and he didn't always understand them but this one he got clear- he saw water and many ships- docks. And piles upon piles of trash on them. Upon going closer he saw a figure in amidst the pile, damaged and bit rusted- it was Bumblebee. Before the vision ended Bee's optics light up and with a broken vox he heard "help".

He knew what he had to do, he packed some things and fuel and snuck out the same night. He headed to the docks and sure enough there was a giant ship loaded with trash. he snuck on it and began his search, he didn't notice when the ship parted, he only knew when the sun started rising and all he saw around was water.

After supposedly few days maybe a week of sailing they arrived at some other dock, Prowl kept down and snuck onto one of the trucks transporting the trash to some other place. The ride was long, few hours at best but finally they stopped and the trucks unloaded. Once they left he had a clear way to search; it was like a whole another planet, so much trash everywhere you looked. He didn't like this.

He must've walked for a long while but he found a seemingly abandoned factory, it was literally crumbling. He made a mistake while climbing and fell down into the scrap crusher, some rabble activated it... He was sure he was gonna get crushed to death, some more scrap fell as he tried to get out and knocked him out. What he didn't know is the machine got stopped and backtracked just when it was about to flatten him.

The next thing he knew is he woke up in some camp, his dents were covered in makeshift metal patches to stop the bleeding. "Prowl?" He heard a familiar vox, static laced thru it but still recognizable. It didn't take long to find a rusted greyish frame with dents, missing parts and similar plasters all over looking at him; paint nearly all gone, one optic shattered, one horn missing... It was Bee.

Before they could say anything Prowl jumped up and ran to him and hugged him.

It took a bit but they finally got to talk, turns out Bee was stranded here all alone for nearly 5 months without anything and he couldn't get out. Prowl made the right choice to leave. They were so happy to see each other. Bee fixed up Prowl some more to the best of his capabilities, he was missing a wheel after all.

The next day Bee packed few of the things he had in the camp that could be useful and they started the journey towards where Prowl thought was the docks, his gps didn't really work cuz of the crusher.

They walked for a week and still nothing, Bee was slower and slower the more time passed. At one point he couldn't go on, he sat down in sorrow. His optimistic spirit long gone since he got here and now... now he was gonna die here. In the trash. Prowl didn't want him to die, he didn't come all the way here just to witness the one he cared about so much wither away. They had a small argument, Bee's doubts finally taking control of him and speaking the worst about himself. In a fit of desperation Prowl said it. He said he loved him. And that he couldn't stand the idea of Bee dying right here before him.

There was a silence, Bee's optics flickered for the longest time, Prowl was scared- "I need energon.." a quiet plea was heard. Energon! Of course! Cybertronians needed energon to survive. But where? There was nothing containing energon in this area, nothing except- a gruesome idea struck Prowl, but he didn't care to acknowledge this part. Anything to make sure Bee lives. He found a clean pot and cut the side of his palm and let his own energon flow down into it. The pot was full and he wrapped his servo in some foil to not bleed out. He took it and made Bee drink it.

It did the trick. Bee, at the brisk of death, slowly became more lively. They rested for a bit before going again. Few more hours of walking and there is was, they could see the end of the trashy land and the docks on the horison.

They arrived and nearly missed the container ship going back to their region. They hid in the loading cargo between the shipping containers and they were off for few days of journey.

There is some more angsty conversation planned in the meantime but i don't wanna make it too long. They arrived at the ending location, they were in Canada.

It took another week to slowly make their way home. This time tho Prowl could drive. Bee was far too damaged to be even able to transform painlessly, he didn't even have wheels anymore. Lucky Prowl found a trailer for Bee to sit on and for him to tow it.

The trailer broke down in some forest hill road and they had to stop. Bee fixed it up and Prowl decided to have a quick look-around, he climbed one of the trees- there is was. Detroit, in all its glory, only few miles ahead.

They arrived back at their home at afternoon, it was eerily empty, the others must have been on a mission. Prowl helped Bee to medbay and gave him more energon. He drank one cube himself and got to work, first he cleaned and patched up his slashed servos properly before going to carefully clean up Bee to treat his injuries before Ratchet got here.

He was wiping the grime of his helm, he paused- one servo holding Bee's helm while the other held the rag pressed on the other side of his helm. They stared into each other's optics and Prowl leaned in and pressed his forehead to Bee's. In the moment of comfort they failed to notice the sound of shutter opening, voices and pedesteps. Before they knew it Ratchet was standing in the doorway shocked. His sudded outbust of panic alarmed the others and they came running too. And they saw them.

6 months missing for Bee. 2 for Prowl. They were back home.

Ratchet took no time to start fixing Bee. It was a long road to get him back to previous state but it didn't bother Bee much. He was just so happy to see them again.

Aaaaand i think i'm gonna stop here cuz this is already hella long and i don't like making these posts fanfic-sized. I could make a fanfic out of it tho, it seems decent and i already have most of the stuff planned out in my head. Anyway thanks for the ask, that's all i got!

17 notes

·

View notes

Text

Exploring the future of organic fertilizer makers: the key to sustainable agriculture

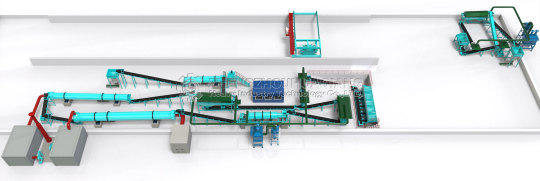

Organic fertilizers are becoming increasingly important in modern agriculture. As an environmentally friendly and sustainable solution, organic fertilizers not only improve soil fertility, but also reduce the use of chemical fertilizers, which is important for environmental protection. Today, we will take an in-depth look at the innovative technology of the Organic Fertilizer Maker to see how it contributes to sustainable agriculture and, in particular, the contribution of the LANE Group in this field.

What is an organic fertilizer maker? An organic fertilizer maker is a machine designed to convert various organic wastes into organic fertilizers. These wastes include livestock and poultry manure, straw, garden waste, etc. Through a series of treatment processes, these wastes are converted into nutrient-rich organic fertilizers for crops.

Working Principle of Organic Fertilizer Making Machine The working principle of organic fertilizer manufacturing machine mainly includes the following steps:

Raw material collection: various organic wastes are collected. Crushing treatment: Crush the large pieces of waste into small particles through the crusher for subsequent processing. Fermentation treatment: the crushed waste is piled up and fermented to decompose it into organic fertilizer through the action of microorganisms. Drying and granulation: The fermented organic fertilizer is dried and then made into granules by a granulator for easy storage and use. LANE Group's organic fertilizer production line

LANE Group is a leader in the field of organic fertilizer manufacturing machines, and its production lines have significant advantages in terms of technology and efficiency. Below are some of the key features of LANE Group's lines:

High-performance equipment: LANE Group's organic fertilizer manufacturing machines are equipped with the latest technology to ensure high production capacity and stable operational performance. Fully automated operation: The production line is equipped with a fully automated control system, which automates the entire production process from raw material handling to the final product, greatly reducing labor costs. Environmentally friendly design: LANE Group focuses on environmental protection, and each piece of equipment has been strictly designed for environmental protection to ensure that the impact on the environment is minimized during the production process. Customized service: According to the specific needs of customers, LANE Group can provide customized production line design and solutions to meet the needs of different scales and types of organic fertilizer production.

Advantages of Organic Fertilizer Manufacturing Machine Environmental protection: Using organic waste to manufacture fertilizer reduces the accumulation of waste and pollution to the environment. Improve soil fertility: organic fertilizers are rich in organic matter and trace elements, which can improve soil structure and enhance the soil's ability to retain water and fertilizer. Reduce costs: Compared with chemical fertilizers, organic fertilizers are widely available and inexpensive. Improve crop yield and quality: long-term use of organic fertilizers can improve crop yield and quality, and enhance its resistance to pests and diseases. Development prospect of organic fertilizer manufacturing machine With the global emphasis on sustainable agriculture, the market demand for organic fertilizer manufacturing machines is increasing. More and more farmers and agribusinesses are beginning to realize the advantages of organic fertilizers and are gradually adopting organic fertilizer manufacturing machines for their production.LANE Group has become a key player in the market by virtue of its advanced technology and quality services. In addition, government policy support and subsidy measures also provide a strong guarantee for the development of organic fertilizer manufacturing machines.

Organic fertilizer manufacturing machine, as an innovative agricultural technology, is gradually changing the production method of traditional agriculture.LANE Group has made remarkable achievements in this field with its high performance, full automation, environmentally friendly design, and customized services. It not only provides farmers with an environmentally friendly and efficient fertilizer solution, but also makes an important contribution to the development of sustainable agriculture. In the future, with the continuous progress and promotion of technology, the organic fertilizer manufacturing machine will surely play an even more important role in the agricultural field.

Contact Us!

2 notes

·

View notes

Text

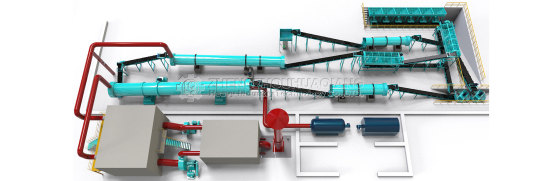

Many people are curious about how cow manure is made into commercial organic fertilizer, and are not familiar with the workflow of organic fertilizer production lines. Today, Huaqiang Heavy Industry will introduce you to the system how cow manure becomes organic fertilizer particles. First, the early fermentation part of organic fertilizer production line: 1. Cattle manure water is high, it is recommended to use aerobic fermentation treatment, you can use organic fertilizer starter fermentation, so it is better for crops. 2. The organic fertilizer equipment used in the fermentation process has a ground pile turning machine or a trough turning machine. Ground strip pile, with the ground pile turning machine; The fermentation tank is used to put the material, and the trough type flipping machine is used. 3. 7-12 days fermentation is completed, according to the temperature of different places how many times to turn the pile is different. Generally 48 hours after cattle manure accumulation, the temperature rises to 50 ~ 60 ° C, the third day can reach more than 65 ° C, in this high temperature by tipping once, under normal circumstances, the fermentation process will appear twice above 65 ° C high temperature, tipping twice can complete fermentation, normal week can be completed fermentation. The material is dark brown and the temperature begins to drop to normal temperature, indicating that the fermentation is complete.

4.Completely fermented and decomposed, out of the pool (ground type directly with forklift collection). Second, the late granulation part of the organic fertilizer production line: 1. Screening. The fermented organic fertilizer raw materials are coarse and fine screened with a grading screen, and the powder fertilizer can be directly sold. 2. Return material system. The selected bulk material is transported to the crusher through the automatic return system and then returned to the grading screen. The above is the work flow of the cow manure organic fertilizer production line. In the actual construction process, customers can increase or decrease the links and equipment of the organic fertilizer production line according to their own needs. If you are interested in organic fertilizer production equipment, please contact Huaqiang Heavy Industry.

0 notes

Text

How to use sheep manure organic fertilizer granulator

The use of sheep manure organic fertilizer granulator involves the following steps:

1. Adding accessories: Add 30-70% of high-carbon materials, such as sawdust and wood bran, to the sheep manure to adjust moisture and porosity and increase permeability.

2. Starter use: According to the total weight of the material, use 0.05%-0.2% starter. When the temperature is above 5℃, the starter and rice bran can be mixed evenly first, and then mixed with the fermentation material to accumulate fermentation.

3. Moisture adjustment: Control the moisture at 50%-60%, grasp the material into a group without water droplets, and release it to ensure the fermentation effect.

4. Pile height: pile material is not less than 3 square, pile height of 0.8m-1.5m, when the ambient temperature is below 15 ° C, cover with film or straw curtain, when the internal temperature rises to 25 ° C, uncover the cover.

5. Tipping: Tipping starts when the pile temperature rises to 60 ° C, once a day, if the pile temperature exceeds 65 ° C, it needs to be tipped several times.

6. Signs of maturation: the heap temperature is reduced, the material is loose, there is no original smell of the material, a little ammonia smell, and white mycelium is produced in the heap, indicating that the organic fertilizer is mature.

7. Crushing and granulation: After drying the fermented material slightly, use the half-wet material crusher to smash, and then granulate through the organic fertilizer granulator.

8. Drying and cooling: the material after granulation is sent to the dryer for drying, so as to facilitate transportation and storage. The dried particles are sent to the cooling machine for cooling to increase the strength of the particles.

9. Screening and packaging: the cooled particles are sent to the screening machine for screening, the unqualified particles are sent to the granulator for re-granulation, and the qualified particles are packaged into bags by automatic packaging machine or manual packaging.

Through the above steps, the use of sheep manure organic fertilizer granulator can be completed and qualified organic fertilizer products can be produced.

0 notes

Text

In modern agriculture, the disposal of agricultural waste has always been an important issue. Through organic fertilizer fermentation equipment, these wastes can be converted into valuable fertilizer resources. So, how exactly do these devices work?

First of all, agricultural waste such as crop straw, livestock manure, etc., after preliminary collection and classification, is sent into the Organic Fertilizer Production Line. This production line usually includes crushing, mixing, fermentation and other steps. Fertilizer shredders such as Cage Crusher and Compost Crusher play a key role in breaking waste to the right size for subsequent processing.

Next, the crushed material enters the mixing stage. Horizontal Ribbon Mixer or Double Shafts Paddles Mixer mixes the waste with the right amount of microbial inoculant to prepare the fermentation process. The mixture is then fed into the Compost fermentation area, where the Windrow Compost Turning Machine regularly turns the pile to ensure adequate oxygen, promote microbial activity and speed up the fermentation process.

After fermentation is complete, the material enters the Fertilizer Granulating Production Line. Here, depending on your needs, you can choose between a Fertilizer Granules Compaction Machine, a Flat-Die Pellet Machine, Rotary Drum Granulato, or a Disc Granulator. Through different working principles, these granulators make the fermented material into granular organic fertilizer, which is easy to store and apply. If it is necessary to produce nitrogen, phosphorus and potassium composite fertilizers, appropriate amounts of nitrogen, phosphorus and potassium can be added before granulation to form NPK Fertilizer Production Line.

Finally, the organic fertilizer after granulation needs to go through the steps of screening, drying and cooling. Fertilizer screeners ensure uniform particle size, while Rotary Dryer machines and Rotary Cooler machines remove excess water and reduce temperature, respectively, so that the final product meets quality standards.

In the whole process, Uniform Feeder ensures the stable flow of materials between all links, improving production efficiency. Through these advanced organic fertilizer fermentation equipment and production lines, agricultural waste can be efficiently converted, not only to solve the problem of environmental pollution, but also to provide high-quality organic fertilizers for agricultural production, to achieve resource recycling and sustainable development.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#NPK Fertilizer Production Line#Uniform Feeder

0 notes

Text

Compost crusher in fertilizer production line application skills

Compost crusher plays a key role in the fertilizer production line, and its application skills directly affect the quality and production efficiency of organic fertilizer. Here are some tips for using compost shredders in your fertilizer production line:

1. Choose the right crusher model: Different crusher models have different processing capacity and crushing effect, and should be selected according to needs.

2. Control the size of the crushed particles: according to the characteristics of organic raw materials and the needs of the final product, control the size of the crushed particles of the crusher.

3. Timely cleaning and maintenance: During the composting production process, there may be some difficult raw materials or debris entering the crusher, and timely cleaning to prevent blockage or damage.

4. Adjust the feed speed and quantity: according to the processing capacity of the crusher and the nature of the raw materials, reasonably adjust the feed speed and quantity. Avoid overloading or clogging the mill due to too fast or too much feed.

5. Ensure the stable operation of the mill: the mill should be stable during operation to avoid frequent start and stop or excessive load fluctuations, which helps to improve production efficiency and extend the life of the equipment.

6. Cooperate with other equipment: In the fertilizer production line, the crusher is usually a part of the early raw material treatment, to coordinate with the subsequent fermentation device, pile turning machine and other organic fertilizer equipment to ensure the smooth and efficiency of the entire production process.

7. Regular inspection and maintenance records: Establish regular inspection and maintenance records of the crusher, including lubrication, replacement of wearing parts, etc. This helps to find and repair problems in a timely manner, ensuring long-term stable operation of the equipment.

0 notes

Text

The Introduction

Pig breeding is an important part of China's agriculture, but the problem of handling a large amount of pig manure has become increasingly prominent. If not handled properly, pig manure not only causes environmental pollution, but may also pose a health threat to farm staff. Fortunately, through scientific treatment methods, pig manure can be converted into valuable organic fertilizer, which not only solves the pollution problem, but also realizes the recycling of resources. This article will describe in detail how pig manure is converted into organic fertilizer and the machinery and equipment required.

Feasibility of converting pig manure into organic fertilizer

Pig manure is a waste rich in organic matter, which can be converted into high-quality organic fertilizers after proper treatment. Pig manure contains a large amount of nitrogen, phosphorus, potassium and other nutrients, which are essential for plant growth. In addition, pig manure also contains a rich microbial community, which can decompose organic matter and produce heat and carbon dioxide during fermentation, achieving the effect of disinfection and sterilization. Therefore, it is completely feasible to convert pig manure into organic fertilizer.

Method of converting pig manure into organic fertilizer

Composting Method:

The pig manure was mixed evenly with organic materials such as straw and rice husk in a certain proportion.

Stacked in a ventilated, dry place for aerobic fermentation.

Turn the pile regularly to facilitate oxygen entry and heat release, speeding up the fermentation process.

After a period of time (usually a few months), pig manure will be converted into decomposed organic fertilizer.

Digester method:

Pig manure was mixed with water and put into a digester for anaerobic fermentation. In this process, microorganisms decompose organic matter to produce biogas and biogas residue.

Biogas can be used for electricity generation or domestic gas, while biogas residue can be used as organic fertilizer.

Biological fermentation method:

Use professional microbial agents to accelerate the fermentation process of pig manure.

After the bacteria agent and pig manure were mixed evenly, sealed fermentation was carried out. This method can shorten the fermentation time and improve the quality of organic fertilizer.

Required machinery and equipment

In order to efficiently convert pig manure into organic fertilizer, a series of professional machinery and equipment need to be used. Here are some of the main equipment introductions:

Fermentation and stacking machine:

It is used to turn the pile regularly to ensure sufficient oxygen inside the pig manure pile and promote the fermentation process.

There are trough type and crawler type (Windrow Compost Turning Machine) and other types, can be selected according to the site and demand.

Organic Fertilizer Crusher:

The large debris and stones in the fermented organic fertilizer are crushed to improve the quality of the fertilizer.

Rotary Screening Machine:

The crushed organic fertilizer was screened to remove impurities and ensure the purity of the fertilizer.

Double Shafts Paddles Mixer:

The organic fertilizer after screening and crushing is stirred and mixed to ensure stable product quality.

At the same time, it can be used to add other fertilizers and trace elements, and produce special fertilizer or compound fertilizer.

Disc Granulator:

The evenly mixed materials were pelleted to make granular organic fertilizer.

Rotary Dryer Machine:

The finished particles are dried to remove excess water and increase the strength of the particles for easy storage and transportation.

Rotary Cooler Machine:

The dried particles were cooled to prevent clumping.

Rotary Screening Machine:

The cooled particles were graded and screened to select qualified finished products.

Enveloping machine:

The qualified particles were coated to increase their brightness and roundness.

Packing machine:

The encapsulated organic fertilizer particles are bagged for easy storage and sale.

Conveying machine:

It is used for conveying materials between different processes to improve production efficiency.

Conclusion

The conversion of pig manure from pig farms into organic fertilizer not only solves the problem of environmental pollution, but also realizes the recycling of resources. By using scientific treatment methods and professional machinery and equipment, high quality organic fertilizer can be produced efficiently. This will not only help improve soil quality and plant growth, but also bring additional economic benefits to the farm. Therefore, pig farms should actively promote the production and application of pig manure organic fertilizer.

1 note

·

View note

Text

Predictive Maintenance as a Service for Cement Industry: An Overview

The cement manufacturing industry is one of the oldest and most critical manufacturing industries for the global civilization. It has witnessed unparalleled growth at the heart of most economic developments and international growth this decade. Fortune Insights report says, the global cement market will grow from $326.80 billion in 2021 to $458.64 billion in 2028, a steep 5.1% globally. It is then no wonder that cement plants face pressure for process and asset maintenance.

Predictive Maintenance checklist for cement industry:

Extractors: Used to Quarry the raw materials, i.e. limestone & clay

Crushers used to crush high rock piles into coarse powders called raw meal

Blenders & Mixers mix the crushed raw meal in the right proportions

Grinders to further grind the raw material to free different minerals in the ore

A rotary kiln where the raw meal is heated up to 1450 degrees & then cooled

Assembly belts & conveyors to carry the cement for packing & dispatching to customers

These processes & machines need to occur in tandem, without intervals, to create high-quality cement. Unplanned downtime in even one of these machines can unleash havoc on the ongoing process, not just endangering efficiency & quality but also health & safety of personnel on-site.

How can Predictive Maintenance as a Service help?

With the stakes so high and a constantly changing environment, real-time machine diagnostics are necessary to empower plant managers with the correct data. IIoT can enable this by enabling a 360-degree view of interconnected assets across the plant. Predictive maintenance as a service allows plant managers in cement managers to move away from reactive measures like reactive maintenance and preventive maintenance to a predictive one, where critical machines don’t have to be pulled down unless there is a specific anomaly. At a grass root level, predictive maintenance as a service by IU for cement plants can be implemented by putting sensors at strategic positions on the machines. Vibration analysis of mechanical equipment components like Air Compressors, Belt drives or Conveyors, Fans and blowers, Kiln rollers, Motor bearings & Vertical and horizontal mills can help predict anomalies. The Predictive Maintenance as a service solution by Infinite Uptime involves collecting data, analysis & computing of the triaxial vibrations, temperature and noise of the mechanical equipment on edge at real-time via a patented edge computing system. The data then is monitored & analyzed in real-time, and a machine health score is assigned. A machine with a lower health score is flagged to the plant supervisor or plant engineer with a diagnostic assessment of the probable cause for the anomaly and a recommendation on improving the same. Not just that, if not considered severe yet, but still significant; the fault is continuously monitored, with relevant parameters like temperature, vibration etc., to assure that it does not aggravate the status quo. This information can be made available in real-time to the appropriate people at their fingertips. An access-based dashboard ensures that you get access to the most relevant machine data for the plant from single machine access for a plant operator to multiple machines across the plant access for a plant head and a multi-plant machine score for a manufacturing head. Let’s look at a case study around how we helped a top Indian cement manufacturer reduce 250 hours of downtime.

To Know more about Predictive Maintenance Services in Cement Industry : https://www.infinite-uptime.com/predictive-maintenance-as-a-service-for-cement-industry-an-overview/

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

#fertilizer granulator machine#granulator machine for fertilizer#fertilizer#drum granulator#roller granulator

0 notes

Text

Cow manure Organic fertilizer production line is how to deal with cow manure?

1. Collection: First of all, you need to collect fresh cow manure, which can be obtained from cattle sheds, pastures, etc.

2. Storage: The collected cow manure will be stored, you can choose to build a special cow manure storage pool or use a closed storage facility.

3. Pretreatment: After storage for a period of time, cow manure will become drier. Before entering the organic fertilizer production line, it needs to be pre-treated, such as mixing, mixing, etc., to make it reach the appropriate humidity for subsequent processing.

4. Fermentation: The pre-treated cow manure is sent to the fermentation equipment. In the fermentation process, by controlling temperature, humidity, ventilation and other conditions, the organic matter in cow manure is decomposed and organic fertilizer is produced.

5. Pile turning: During the fermentation process, it is necessary to regularly use the fermentation compost turning machine to turn cattle manure to ensure uniform and adequate fermentation. The turnover machine can turn the manure pile so that it is in full contact with the air and promotes the fermentation process.

6. Detection: In the fermentation process, it is necessary to regularly test the pH value, water content and other indicators of cow manure organic fertilizer to ensure that it meets the specified standards.

7. Crushing: After fermentation is completed, organic fertilizer crusher can be used to crush cow manure organic fertilizer to improve its uniformity and quality.

8. Packaging: The crushed cow manure organic fertilizer is packaged and made into bagged products of different specifications. During the packaging process, attention should be paid to keeping the environment clean and preventing pollution.

9. Storage and sales: Packaged cow manure organic fertilizer needs to be stored in a ventilated and dry place to prevent moisture and mildew. After that, the products can be sold to agriculture, landscape and other industries for soil improvement, plant growth and so on.

0 notes

Text

Organic fertilizer equipment of chicken manure organic fertilizer production line

The construction cycle of organic fertilizer equipment project is short, the market risk is small (organic fertilizer generally has a shelf life of at least 5 years), the recovery period is short (oversupply in busy farming), and the market potential is large (China's land and resources are rich, especially in Henan, Northeast and other agricultural provinces, and the consumption is quite large). Under normal circumstances, the investment can be recovered in one year and the profit can be generated in the current year. Organic fertilizer production lines generally include: raw material selection (chicken manure, etc.) → drying and sterilization → mixing of ingredients → granulation → cooling and screening → metering and sealing → storage of finished products. The more complex organic manure production process is: Organic fertilizer raw materials (livestock and poultry manure, domestic waste, dead leaves, biogas residue, waste bacteria, etc.) after turning the pile machine fermentation by half-wet material crusher, then add nitrogen, phosphorus, adding potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.), so that the mineral elements meet the requirements of the standard, stirred with a blender, into the granulator, dried out, screened with a screening machine, Packaging of qualified products, unqualified products returned to granulator granulation. The equipment configuration and construction scale of chicken manure organic fertilizer production line is generally 30,000-100,000 tons/year. Local resources, market capacity and market coverage should be considered comprehensively. First, the scale of investment and product design should be based on the characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, plant site conditions, production automation and other conditions, if you have special requirements, you can call us directly, we will provide equipment according to your requirements.

0 notes

Text

Organic fertilizer production line process and purchase points

Now many people have a certain understanding of the organic fertilizer production line, because the main problem facing the breeding site for environmental reasons is how to deal with livestock and poultry manure, this time organic fertilizer equipment comes in handy. Many people know that the use of organic fertilizer production line to treat livestock and poultry manure into organic fertilizer, and we as organic fertilizer production line manufacturers are also so teach others to make organic fertilizer, and now the country is also strongly supporting the use of organic fertilizer, so many people want to buy a set of organic fertilizer production line to make organic fertilizer to earn profits. Organic fertilizer production line mainly includes equipment process: fermentation pile turning machine - material crusher - mixer - organic fertilizer granulator - rotary dryer - rotary cooling machine - drum screening machine - envelope machine - packaging machine Although it is said that the purchase of organic fertilizer production line mainly depends on the price, but the appearance is also very important. The shape design should be able to meet the aesthetic point of view of consumers, and it can be comfortable to use, and now many manufacturers can customize the color, most of which can be customized according to user requirements. Also, we should pay attention to whether the details of the equipment are fine, whether the welding marks are obvious, whether the screws are in place, and whether the appearance of the whole machine is smooth.

0 notes

Text

In modern agricultural production, the conversion of chicken manure into organic fertilizer is an important work that is both environmentally friendly and economical. This not only reduces environmental pollution, but also provides valuable nutrients for farmland. This paper will introduce in detail the seven key steps of chicken manure treatment into organic fertilizer, as well as the key words involved in the equipment.

Step 1: Raw material collection and pretreatment

First, we need to collect fresh chicken manure and conduct preliminary screening and decontamination. This step ensures the smooth progress of the subsequent treatment process and also lays the foundation for improving the quality of the fertilizer.

Step 2: Compost and turn the pile

Next, pile the pre-treated chicken manure into strips and use the Windrow Compost Turning Machine to turn the piles. This process increases oxygen and speeds up the breakdown of organic matter while reducing undesirable odors.

Step 3: Crushing treatment

The chicken manure that has been turned over needs to be crushed to facilitate subsequent mixing and granulation. The Compost Crusher is used here.It can crush the material to the appropriate particle size.

Step 4: Mix and stir

The crushed material will be mixed with other organic or inorganic additives to ensure the nutrient balance of the fertilizer. A Horizontal Ribbon Mixer or a Double Shafts Paddles Mixer are commonly used in this process to ensure that the material is mixed evenly.

Step 5: Granulation molding

The evenly mixed material will enter the granulation stage. The Flat-Die Pellet Machine or Rotary Drum Granulator in the Organic Fertilizer Production Line can granulate the material for subsequent drying and packaging.

Step 6: Drying and cooling

Freshly granulated fertilizer usually contains high moisture and needs to be dried by Rotary Dryer Machine and then cooled to room temperature in Rotary Cooler Machine to ensure the stability of fertilizer and easy storage.

Step 7: Screening and packaging

Finally, the dried and cooled fertilizer particles are screened by Rotary Screening Machine, unqualified particles are removed, and packaged according to specifications, and finally formed into commercial organic fertilizers sold on the market.

Through these seven steps, chicken manure is transformed into an efficient organic fertilizer that provides important nutrient support for agricultural production. This process not only reflects the advanced concept of agricultural waste resources, but also shows the important role of modern agricultural equipment in agricultural production.

0 notes

Text

The application of organic fertilizer crusher for the production of organic fertilizer of mushroom residue in work

The treatment of mushroom residue by organic fertilizer crusher in organic fertilizer equipment is to first crush mushroom residue and mushroom stick, and then ferment mushroom residue and livestock manure with organic fertilizer fermentation equipment. The organic fertilizer produced by the mushroom residue organic fertilizer production line has complete nutritional elements, which can improve the soil and improve the soil compaction caused by the use of chemical fertilizer. Improve the physical and chemical properties of soil, and enhance the ability of soil to retain water, fertilizer and fertilizer. The use of mushroom residue organic fertilizer crusher equipment is suitable for a wide range of raw materials, organic fertilizer, biological organic fertilizer, compound fertilizer and other raw materials production.

1, organic fertilizer mushroom slag mill production of raw materials from a wide range of sources, such as livestock and poultry feces feces and urine, weed branches and leaves straw, pile retting fertilizer, green fertilizer, sea fertilizer, cake fertilizer, grass, soil fertilizer, three wastes, micro.

2, grinding particle size to meet the requirements of granulation. It can also be adjusted in a certain range according to the user's needs.

3, for organic fertilizer, compost production to shorten the process, reduce equipment investment, save operating costs, is the ideal machinery for fertilizer production and processing units

4, at the same time is also widely used in chemical, building materials, mining and other industries, the machine in the crushing process uses synchronous speed of high strength resistance to hard alloy chain plate, the inlet and outlet design is reasonable, the crushing material is uniform, not easy to stick to the wall, easy to clean.

0 notes