#pharmaceutical wastewater treatment

Explore tagged Tumblr posts

Text

Best STP Plant Manufacturer/Supplier for Pharma Industry

In the pharmaceutical industry, managing wastewater is a complex and critical task. The nature of pharmaceutical production involves the use of various chemicals, solvents, and biologically active substances that pose unique challenges for wastewater treatment. Ensuring that this wastewater is treated effectively is essential not only for compliance with stringent regulations but also for…

#3D Aqua#activated carbon adsorption#AOPs#India STP supplier#MBBR technology#MBR technology#pharmaceutical wastewater management#pharmaceutical wastewater treatment#sewage treatment plant supplier#STP plant manufacturer#Water Treatment Technology

0 notes

Text

Prescription drugs accumulate in a box at the Back Cove Trail parking lot in Portland, Maine, during a take-back event. Photograph By Ben McCanna, Portland Portland Press Herald/Getty Images

How You Should Dispose of Unused or Expired Medications

Flushing or throwing away leftover drugs can contaminate waterways, threatening people and wildlife. Here are some safer solutions.

— By Priyanka Runwal | Published July 22, 2022 | Sunday August 6, 2023

If you have a stash of unwanted, unused, or expired medicines in a cabinet or drawer somewhere in your home and you don’t know the best way to get rid of them, you’re not alone.

A 2021 survey conducted on behalf of Covanta, a New Jersey-based waste management company, found that 53 percent of the 2,000 Americans polled had no idea what to do with their old medications. Pill hoarding is a common outcome, and many people eventually toss these drugs into household trash or flush them down the toilet or sink—none of which may be a good idea.

Unused or expired medicines lying around at home can get into the wrong hands, leading to accidental poisoning or drug overdose. One study found that between 2000 and 2015, U.S. Poison Control Centers received roughly 32 calls a day about children accidently ingesting opioids that had either been stored or disposed of incorrectly.

When drugs are flushed or sent to landfill, the pharmaceuticals can contaminate our groundwater, lakes, rivers, and streams, threatening human and aquatic life, although our urine and feces that contain remnants of consumed medication are bigger sources of pollution. Wastewater treatment plants aren’t designed to remove these pharmaceuticals, Tim Carroll, a spokesperson for the U.S. Environmental Protection Agency, says in an email. “EPA’s first message to everyone is do NOT put leftover, unused drugs down the drain.”

So how does one dispose of unneeded over-the-counter and prescription medications accumulating in our homes? There are a few options.

Drug Take-back Programs

In an effort to find a solution to drugs languishing in medicine cabinets or lurking in waterways, the U.S. Drug Enforcement Administration launched its first National Take-Back Day in September 2010. More than 4,000 sites across 50 states collected nearly 250,000 pounds of pharmaceuticals that people returned. Since then, DEA has hosted this single-day event biannually; in April this year, more than 5,000 sites collected about 721,000 pounds of pharmaceuticals.

People can also use mail-back envelopes or drop off their unwanted medications year-round at DEA-registered collection kiosks in police stations, pharmacies, community health centers, and hospitals. These returned drugs are then sent to medical waste incinerators.

Drug Enforcement Administration agents and Soldiers from the New Jersey National Guard's Counter Drug Task Force dumped prescription drugs to be incinerated at the Covanta Essex Resource Recovery Facility during Operation Take Back New Jersey in Newark, N.J., Oct. 31, 2017. Operation Take Back New Jersey is a DEA program that provides a safe and legal method for the citizens of New Jersey to dispose their unwanted, unused, and expired medicines. The New Jersey National Guard assisted with the collection and disposal of the medications. (U.S. Air National Guard photo by Master Sgt. Matt Hecht) Photograph By Master Sgt. Matt Hecht, AB Forces News Collection/Alamy Stock Photo

In 2021 Stericycle, the largest medical waste incinerator company in the U.S., burned 40 million pounds of unused and expired pharmaceuticals, says Jim Anderson, the company’s vice president for product management and innovation. Incineration produces an inert ash that’s sent to landfills. However, one downside of this disposal method is that transporting and burning such waste and its packaging can release greenhouse gas emissions that can be potentially greater than those generated if the drugs were dumped in landfill, according to one study estimate.

But take-back programs are preferred as they reduce the risk of drug misuse and the incineration “effectively eliminates the entrance of these pharmaceuticals into our nation’s waters,” Carroll says.

However, Steve Skerlos, a mechanical, civil, and environmental engineer at the University of Michigan argues that take-back programs could still result in medicines piling up in homes—a problem such programs were designed to address in the first place. “The question is, if I have extra, unused medication, am I going to leave my house in the next day, or week, even a month, to return that,” he says, especially in rural settings where take-back sites may not be as easily accessible. “A reasonable person may consider landfill to get it out of the house fast.”

In such cases, the DEA suggests mixing medicinal tablets and capsules with undesirable substances like coffee grounds or kitty litter and tossing the mixture into the trash inside a sealed bag or container. (Don’t crush the drugs though.)

And while the EPA advises against flushing pharmaceuticals down the drain, the U.S. Food and Drug Administration maintains a list of limited medications that have the potential to be misused or result in death if taken inappropriately and so can be flushed when safer disposal alternatives are lacking.

Pharmacies also sell drug destroyers such as DisposeRx that can work with pills, tablets, capsules, liquids, and powders. “It’s about the size of a packet of sugar,” says Thomas Menighan, former CEO of the American Pharmacists Association. “You open it, put it in a bottle of unused opioids, or any medicine, for example, you pour a little water in and shake it up, it turns into a white slurry,” which can then be tossed into the trash.

But it’s unclear if these products permanently bind or inactivate the medicinal compounds so that they don’t end up in the landfill liquid, which is released into wastewater treatment plants, and can eventually contaminate our waterways.

Recycling Pharmaceuticals

Perhaps surprisingly, not all unused medications need to be thrown away.

Every year five billion dollars’ worth of unexpired medicine ends up being discarded in the U.S. That could happen because a patient dies, their condition improves and they no longer need their prescribed medication, there’s a dose change, or they experience side effects and are put on new drugs. In such cases these unexpired medications—worth an estimated $700 million—can be recycled.

“We’re wasting a lot of medication which is already paid for,” says Anandi Law, a patient engagement specialist at the Western University of Health Sciences in California. “We could have somebody else who needs it have it.”

Millions of U.S. adults skip or delay getting their prescriptions filled due to high costs. Hence, at least 40 states have passed legislation to establish medication repository programs that allow pharmacies, drug manufactures, medical and long-term care facilities, and sometimes individuals to donate their unused drugs in original sealed containers or tamper-evident packaging.

A licensed pharmacist then inspects the donated medication to check the expiry date and look for signs of tampering, misbranding, or any indication that the drug could be compromised. Once approved, the drugs can be dispensed to uninsured or underinsured individuals via state-approved pharmacies, hospitals, charitable clinics, or community health centers.

Since its inception in 2007, Iowa’s drug donation program, SafeNetRx, has served more than 117,000 patients and redistributed nearly $54-million worth of medication and supplies. Georgia’s program formally launched in 2018, and it has already filled prescriptions worth over $50 million.

“Even though over 40 states have these drug donation laws, a lot of people don’t know that they exist,” says Kiah Williams, co-founder of SIRUM, a nonprofit organization that works with pharmacies and health facilities across the country to assist with drug donation.

Donating unused medications or using take-back programs are voluntary for households, but experts hope more people will use these options instead of disposing of their leftover drugs in the trash or down the drain, which tends to be more convenient.

“All of these efforts are still relatively new,” Carroll says. “We expect we have a long way to go until households change their habits.”

#Science#Prescription Drugs#Expired Medications#Disposing Off#Flushing | Throwing#Leftover Drugs#Contaminations of Waterways#Threat to Wildlife#Covanta | New Jersey#Pill Hoarding#Household Trash | Flush#U.S. Poison Control Centers#Wastewater Treatment Plants | Pharmaceuticals#Tim Carroll#U.S. Environmental Protection Agency#EPA#National Take-Back Day#Steve Skerlos: Mechanical Civil and Environmental Engineer#University of Michigan#U.S. Food and Drug Administration#DisposeRx#Thomas Menighan#American Pharmacists Association#Recycling Pharmaceuticals#Anandi Law#California | Western University of Health Sciences#Iowa | SafeNetRx#Kiah Williams | SIRUM#The National Geographic

0 notes

Text

Also preserved on our archive

By Adeola Adeosun

Amidst a resurgence of COVID-19 cases across the United States, pharmaceutical company Gilead Sciences, Inc. has announced a voluntary recall of its antiviral drug Veklury, commonly known as remdesivir, in cooperation with the U.S. Food & Drug Administration (FDA).

The recall comes after the discovery of glass particles in vials of the medication, raising concerns about patient safety at a time when the drug's importance in treating severe COVID-19 cases is once again being underscored.

The affected lot, identified as 47035CFA, was distributed nationwide in the United States beginning July 16, 2024. This FDA-monitored recall coincides with data from the U.S. Centers for Disease Control and Prevention (CDC) showing high levels of COVID-19 viral activity in wastewater across the country, despite a recent decrease in positive cases.

As of September 13, the CDC reports that while overall viral activity in wastewater has been demoted from "very high" to "high," 21 states still show "very high" levels, particularly in the West. Sixteen states exhibit "high" levels, eight are classed as "moderate," and only Michigan and Rhode Island show "low" levels. New York stands out with "minimal" levels, the lowest classification.

The recall of Veklury comes at a critical juncture in the pandemic's trajectory. While positive tests now account for 14.9 percent of all COVID tests (excluding at-home testing) in the U.S., down 1.6 percent from the previous week, the emergence of new subvariants has kept health officials on high alert.

According to Gilead's risk statement, the administration of Veklury which contains glass particles could lead to a range of complications, from local irritation to potentially life-threatening situations if particles enter the bloodstream and cause blockages in vital organs.

Veklury has been a key tool in treating COVID-19 since its FDA approval in October 2020. It is indicated for use in both hospitalized patients and those with mild-to-moderate COVID-19 who are at high risk for disease progression.

The recall affects the lyophilized form of Veklury in single-dose clear glass vials containing 100 mg of remdesivir in powder form. Gilead has reported no adverse events related to this recall to date but is taking proactive measures to mitigate risks.

This recall also comes as the U.S. grapples with a new class of COVID-19 subvariants nicknamed FLiRT. As of August 31, the dominant subvariant, KP.3.1.1, accounted for more than 50 percent of all U.S. COVID-19 cases over the previous two weeks, with FLiRT variants collectively responsible for over 80 percent of cases.

While these new variants appear more infectious, they generally do not cause such severe symptoms. However, the CDC continues to monitor for common symptoms including fever, cough, shortness of breath, fatigue, and loss of taste or smell.

Healthcare facilities possessing the recalled Veklury are urged to cease use immediately and return the product. Gilead has established a dedicated information line at 1-866-633-4474 for those seeking details about the recall.

Patients with concerns about their COVID-19 treatment are advised to consult their healthcare providers, and any adverse reactions can be reported to the FDA's MedWatch Adverse Event Reporting program.

#mask up#covid#pandemic#covid 19#wear a mask#public health#coronavirus#sars cov 2#still coviding#wear a respirator

7 notes

·

View notes

Text

Netsol Water: Leader in Sewage Treatment Plant Manufacturers in Delhi

Water pollution is turning into a global crisis, as industries and urban centers produce massive amounts of wastewater each day. In populous areas like Delhi, the challenge of an effective sewage treatment has never come at such a crucial juncture. Netsol Water is one of the best Sewage Treatment Plant Manufacturers in Delhi, providing best solutions for waste waste management.

Untreated water is one of the major threats to public health, ecosystems, and the environment. It ruins the freshness of fresh-water sources, poses a threat to aquatic life and may unleash a waterborne diseases upsurge. And so comes companies like Netsol Water, breathing hope and practical solutions.

Netsol Water: A Brief Overview

With a mission to come out strongly with this vision in solving the needs of India pertaining to water treatment, Netsol Water has picked up the pace in this multiple-choice game-like environment of Delhi. The firm offers systems for designing, manufacturing, and installing the most sewage treatment plants (STPs) specifically designed according to the diversified needs of various industries.

What's special about Netsol Water?

Customized Solutions: Netsol Water knows that no two places are alike when it comes to sewage treatment. They thus ensure that solutions put in place specifically target the problem at hand and also meet the local regulatory compliances, based on their work with clients.

Latest Technology: By being on the forefront of water treatment technology, Netsol Water ensures efficiency, cost-effectiveness, and environmental friendliness of plants.

Comprehensive Services: Netsol Water offers complete services right from consultancy to installation and then next-line maintenance, thus making it a one-stop shop for all types of sewage treatment requirements.

Commitment towards Sustainability: Netsol Water doesn't treat water; it does water management sustainably with industries.

Science behind Netsol Water's Sewage Treatment Plants

Need of the Multistage Process Netsol Water STPs efficiently employ a multi-stage process so that polluted wastewater becomes usable clean water. A basic description of how such plants function would include the following:

Preliminary Treatment: It removes big debris and waste by screening and grit removal.

Primary Treatment: Sedimentation tanks allow suspended solids to settle, thereby reducing the overall pollutant load.

Secondary Treatment: Organic matter is broken down through biological processes that work through activated sludge or other microorganisms.

Tertiary Treatment: Final filtration and disinfection take away any remaining impurities and pathogens.

Sludge Management: Byproducts from the treatment process are managed safely and are frequently reused for beneficial purposes.

This multi-stage approach ensures that the water leaving Netsol Water's STPs meets or exceeds regulation standards; such water can be safely discharged or reused.

Netsol Water Changing Industries

Netsol Water caters to the diversified sectors, so its versatility can be seen in the diversified sectors that it caters to. Some of these sectors are as follows:

Textile and Dye Industries: Wastewater produced by this section of industries is heavily polluted. So they easily require the specialist treatment solutions of Netsol Water.

Pharmaceutical Companies: Sewage produced from drug manufacturing should be handled with care. To this, Netsol Water provides precision.

Food and Beverage Producers: From dairy plants to breweries, Netsol Water helps these businesses handle their organic-rich wastewater effectively.

Chemical Sector: Netsol Water's advanced technologies overcome the intricate chemical Sewages.

Automotive Industry: Netsol Water provides the automotive manufacturing and servicing industries with overall wastewater treatment solutions.

Environmental Impact of Netsol Water Delhi

Being one of the top Sewage Treatment Plant Manufacturer in Delhi, Netsol Water has been significantly contributing towards Delhi's environment. With effective wastewater treatment solutions, Netsol Water is assisting in all the ways:

Clean up pollution in the Yamuna River, which is Delhi's primary source of water

Reduce contamination and consequently boost the quality of groundwater

Improve public health by reducing probable waterborne diseases

Support the sustainable goals for the development of Delhi

Innovations and Future Outlook

Netsol Water does not boast of resting on its oars. The company keeps abreast of emerging challenges in water treatment with continuous innovations. A few areas of focus are:

Energy Efficiency: Developing treatment processes that consume less energy, thereby reducing the carbon footprint of STPs.

Water Reuse Technologies: Enhanced techniques to make treated water suitable for various industrial and agriculture applications.

Smart Monitoring Systems: Implementing IoT-based solutions for real-time monitoring and optimization of treatment plants.

Modular Designs: Creating scalable modular designs of STPs which can easily expand or change as and when the need arises.

Why Netsol Water?

For the sewage treatment requirements of any business firm at Delhi, Netsol Water offers:

Specialized Consultation: Professional experts to calculate exact requirements.

Tailor-made Design: Space-suitable, budget-suitable, and requirement-suitable STPs.

Installation Process: No Disruption in Its Services.

Comprehensive Training: Your manpower operates and maintains the STP

Ongoing Support: Maintenance and Troubleshooting services are provided to ensure the continuity of the plant.

Conclusion: A Greener Future with Netsol Water

In the middle of the ongoing rapid growth phase of the city, Delhi cannot afford to have anything short of industry-level wastewater management. Netsol Water stands at the forefront of this critical industry: With innovative, reliable, and sustainable solutions for sewage treatment. Netsol Water is top on Sewage Treatment Plant Manufacturer in Delhi, offering solutions for waste waster.

Therefore, by opting for Netsol Water, a Delhi based company would be abiding by the rules of the land while creating an environment for the generations to come that will be cleaner and healthier. And with such companies like Netsol Water, we do have hope for the future because the right technology combined with the right commitment can significantly assist in conquering the obstacles presented in front of us by water pollution and creating a more sustainable world.

Whether a small businessman or industrial giant, if you are based in Delhi and battling against wastewater issues, there is hope for you, perhaps in the form of Netsol Water, transforming those battles into opportunities for environmental stewardship.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#sewage#stp#stps#delhi

3 notes

·

View notes

Photo

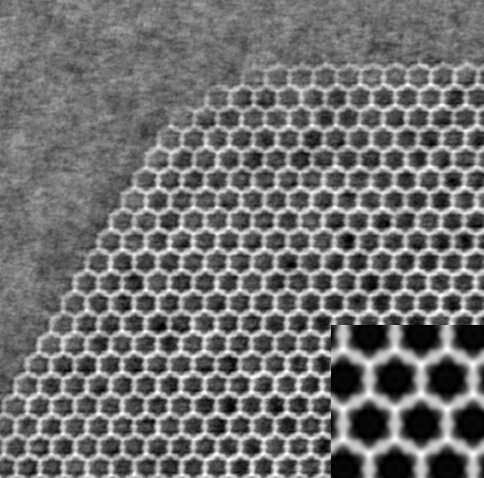

Porous crystals made from plant extracts purify water from pharmaceutical pollutants

Researchers from Stockholm University have developed porous crystals made from pomegranate extract to capture and degrade pharmaceutical molecules found in local municipal wastewater. The research is published in the scientific journal Nature Water.

Pharmaceutical compounds affect the human body to improve our health, but they can also have unintentional adverse effects for the well-being of wildlife. Hence wastewater treatment plants are facing the challenge of removing emerging organic contaminants (EOCs) such as active pharmaceutical ingredients, and therefore new materials and technologies are required.

One strategy for removing pollutants from water is by using porous materials that behave like sponges. Metal-organic frameworks, so called MOFs, are a type of nanoporous material that are made of metal ions and organic molecules. Most MOFs are made using synthetic organic molecules. But now researchers from the Department of Materials and Environmental Chemistry, Stockholm University, have managed to develop new porous MOFs using a naturally occurring molecule found in plants—ellagic acid.

Read more.

#Materials Science#Science#Pollutants#Porosity#Clean water#Metal organic framework#Biomaterials#Stockholm University

44 notes

·

View notes

Text

What do you know about Membrane ?

Membranes are everywhere, quietly working behind the scenes in many industries. But what exactly do they do? In simple terms, membranes are like selective filters. They let some things pass through while blocking others, making them perfect for tasks like filtration, separation, and purification.

Take water treatment, for example. Membrane solutions are used to remove contaminants from drinking water, ensuring it’s clean and safe. Reverse osmosis is a well-known membrane process that many households and industries rely on. But that’s just one use.

In the food and beverage industry, membranes help filter products like milk or fruit juice, giving you that clear, high-quality drink. They’re also critical in pharmaceuticals, where precise filtering ensures the purity of medicines.

Even industries dealing with wastewater rely on membranes to treat water before releasing it back into the environment. These systems are crucial for filtering out harmful pollutants, ensuring the water is safe and clean. By doing so, they play a huge role in protecting both people and the planet, helping to preserve natural resources and reduce environmental harm.

So, whether it’s making water drinkable, refining medicines, or producing clean food, membrane solutions are at the heart of these essential processes.

#membrane #solutions #permionics

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

doing this in a separate post bc the reblog was getting like. no votes

so sorry to everyone who voted space science ur still valid to me <333

below the cut i've put brief explanations of what each option is based on google and Wikipedia lol don't worry about providing canon-based responses (if you think pitts just wants to fuck around with chemicals all day, that is so valid <3)

electrical - basically what it says on the tin: playing with electrical equipment. this takes many forms: telecommunications, radio-frequency, hardware, and many more

chemical - deals with chemical plants; converting raw material into usable products

biomedical - making and managing medical equipment, like cat scans, MRI machines, but also development of pharmaceutical drugs

environmental - creating solutions to improve the health of living creatures and the environment, such as wastewater treatment and air pollution management

#dead poets society#me#dps#dps fandom#dead poets#gerard pitts#dead poets fandom#dps headcanons#dead poets headcanons

4 notes

·

View notes

Text

What is Hospital Sewage and Why Its Treatment is Necessary?

Hospital sewage refers to the wastewater generated from various activities within a healthcare facility, including patient care, laboratory procedures, laundry, and sanitation. This sewage contains a complex mixture of biological and chemical contaminants, making it significantly different from domestic sewage. The presence of pathogens, pharmaceuticals, chemicals, and radioactive materials necessitates specialized treatment to ensure environmental and public health safety.

The Composition of Hospital Sewage

Hospital sewage is laden with microorganisms, including pathogenic bacteria, viruses, and fungi. Additionally, it contains a variety of chemicals such as antibiotics, disinfectants, and heavy metals. The concentration of these hazardous substances poses a significant risk if discharged untreated into the environment. This makes the treatment of hospital sewage crucial for preventing the spread of infections, protecting aquatic life, and safeguarding public health.

The Necessity of Treating Hospital Sewage

Public Health Protection: Untreated hospital sewage can release harmful pathogens into the water supply, potentially causing waterborne diseases. The use of bioculture for sewage treatment plants, specifically designed to target and neutralize these pathogens, is essential in mitigating this risk.

Environmental Safety: Chemical contaminants in hospital sewage can disrupt ecosystems and harm aquatic life. Implementing biological additives for STPs helps in breaking down these chemicals, making the water safe for discharge.

Regulatory Compliance: Hospitals are required to comply with stringent environmental regulations. Utilizing microbial culture for STPs ensures that the effluent meets these regulatory standards, avoiding hefty fines and legal issues.

Treatment Solutions for Hospital Sewage

One effective method for treating hospital sewage is aerobic wastewater treatment, which involves the use of oxygen-loving bacteria to decompose organic matter. The manufacturer of bacterial culture plays a critical role in providing high-quality bioculture for STP systems. These biological cultures are essential for maintaining the efficiency and effectiveness of sewage treatment processes.

PureBact Solutions

PureBact offers a range of products designed to enhance the treatment of hospital sewage. Our biological culture for sewage treatment plants, such as PureBact 10, is engineered to optimize the breakdown of complex contaminants. By using our advanced bacteria culture for STP, hospitals can achieve superior treatment results, ensuring compliance with environmental standards and promoting public health.

For more information, visit PureBact.

#HospitalSewage#SewageTreatment#BiocultureForSTP#MicrobialCulture#WastewaterTreatment#PublicHealth#EnvironmentalSafety#BiologicalAdditives#AerobicTreatment#PureBact#SustainableSolutions

2 notes

·

View notes

Text

What are the Major Applications of Stainless Steel Pipes in Various Industries?

Stainless steel, an alloy known for its extraordinary qualities and adaptability, has garnered significant popularity in a wide range of industries. Stainless steel pipes are of significant importance in various applications due to their exceptional durability, resistance to corrosion, and capacity to endure severe temperatures. Tired of corrosion? Choose stainless steel! Rely on the expertise of Tube Trading Co. as the most trusted Stainless steel pipes dealer in Vadodara, Gujarat for high-quality solutions.

This blog post aims to explore the primary applications of stainless steel pipes across many industries, highlighting the substantial influence and enhancement that this material brings to numerous sectors.

· Chemical and Petrochemical Industry:

The utilisation of stainless steel pipes is essential within the chemical and petrochemical sector. These containers are employed for the purpose of conveying substances that possess corrosive properties, such as chemicals, acids, and other things that are deemed dangerous. The inherent corrosion resistance exhibited by stainless steel guarantees the secure and effective conveyance of crucial substances necessary for production procedures while upholding safety standards.

· Oil and Gas Industry:

The utilisation of stainless steel pipes is of utmost importance in the oil and gas industry, as they play a critical role in the processes of drilling, extraction, and transportation. The aforementioned pipes possess desirable characteristics that make them well-suited for the transportation of crude oil, natural gas, and refined goods. These attributes include their ability to withstand corrosion, endure high pressure, and tolerate harsh temperature extremes.

· Water Treatment and Desalination:

Stainless steel pipes are widely utilised in water treatment facilities and desalination procedures. The corrosion-resistant characteristics of these materials contribute to an extended operational lifespan, rendering them a highly suitable option for the conveyance of potable water and the effective treatment of wastewater.

· Food and Beverage Industry:

The food and beverage industry commonly utilises stainless steel pipes as a fundamental component, mostly due to their hygienic properties, resistance to corrosion, and simplicity of cleaning. They are employed for the purpose of transporting various constituents, processed edibles, and even potable water, thereby guaranteeing both the safety and purity of the aforementioned substances.

· Automotive Industry:

The automotive industry utilises stainless steel pipes in exhaust systems due to their capacity to endure elevated temperatures and their resistance to corrosion resulting from exhaust gases. This use enhances the durability and effectiveness of automobiles.

· Construction and Architecture:

The construction and architecture industry extensively uses stainless steel pipes for many structural applications, including the construction of building frameworks, installation of handrails, and reinforcement of support columns. The combination of their robustness, visual attractiveness, and ability to withstand all weather conditions renders them a highly suitable option. Forge a path of longevity and reliability with stainless steel. Trust Tube Trading Co. – an excellent Stainless steel pipes distributor in Vadodara, Gujarat, for top-notch products.

· Aerospace Industry:

Stainless steel pipes find application in the aerospace sector for the production of components that necessitate exceptional strength, resistance to corrosion, and a lightweight nature. The inclusion of these pipes significantly enhances the dependability and security of both aeroplanes and spacecraft.

· Pharmaceutical Industry:

The pharmaceutical industry heavily relies on the utilisation of stainless steel pipes for the transportation of medicinal substances and pharmaceutical-grade liquids. The sanitary features of the transportation system guarantee the preservation of the integrity and quality of the substances being conveyed.

· Marine Industry:

The marine sector relies heavily on the utilisation of stainless steel pipes for various purposes, such as shipbuilding, offshore oil drilling platforms, and undersea pipelines. Stainless steel possesses inherent anti-corrosive characteristics that contribute to its exceptional endurance and reliability when exposed to hostile marine environments.

· Energy Sector:

The utilisation of stainless steel pipes is of utmost importance in the energy sector, as they play a critical role in the construction of power plants, transmission lines, and renewable energy installations. These devices facilitate the transportation of steam, gases, and liquids in a dependable and effective manner.

Final Thoughts:

Stainless steel pipes have significantly transformed multiple industries due to their exceptional attributes of durability, reliability, and cost-efficiency. The various uses mentioned above highlight the importance of this alloy and its crucial contribution to the progress of contemporary industrial procedures. Stainless steel pipes are very valued assets in several sectors such as transportation, infrastructure, and safety-critical applications. Their significance is anticipated to increase as industries undergo additional advancements. Choose the best for your projects. Choose Tube Trading Co. as your reliable Stainless steel pipes supplier in Vadodara, Gujarat, for top-grade stainless steel products that drive excellence. Get in touch with the experts at Tube Trading Co. today and shape a stronger future.

#Stainless steel pipes dealer in Vadodara#Stainless steel pipes dealer in Gujarat#Stainless steel pipes distributor in Vadodara#Stainless steel pipes distributor in Gujarat#Stainless steel pipes supplier in Vadodara#Stainless steel pipes supplier in Gujarat#tubetrading#Vadodara#Gujarat

6 notes

·

View notes

Text

Types of Pipes and Their Applications: A Comprehensive Guide

Understanding common types of pipes and their applications is crucial for informed project decisions in various industries and applications.

Here is a detailed overview of the most popular pipe types:

Steel Pipes: Steel pipes are solid and adaptable, making them ideal for various uses including water delivery, gas pipelines, oil transportation, and structural purposes. They are incredibly strong and resilient under great strain.

PVC Pipes: Polyvinyl chloride (PVC) pipes are inexpensive, lightweight, and corrosion-resistant. They are frequently used in drainage, irrigation, and plumbing systems because they are simple to install and need little upkeep.

Copper Pipes: Copper pipes are renowned for having exceptional heat and corrosion resistance. HVAC (heating, ventilation, and air conditioning) applications, plumbing systems, and refrigeration systems all frequently use them.

HDPE Pipes: High-density polyethene (HDPE) pipes are ideal for sewage systems as well as subterranean water and gas distribution because of their strong chemical resistance and a high degree of durability.

PEX Pipes: Cross-linked polyethene (PEX) pipes are flexible and resistant to corrosion. They are frequently employed in home plumbing systems, notably in the distribution of hot and cold water.

Cast Iron Pipes: Cast iron pipes are renowned for their robustness and noise-isolating qualities. They are frequently employed for stormwater drainage systems and sewer pipes.

Galvanised Iron Pipes: To prevent corrosion, galvanised iron pipes have a zinc coating. They are frequently employed for outdoor applications and water supply lines.

Concrete pipes: Concrete pipes are sturdy and long-lasting, making them ideal for sewage applications, culverts, and underground drainage systems.

Stainless steel pipes: These pipes are utilised extensively in food processing, pharmaceuticals, and chemical processing sectors because they offer exceptional corrosion resistance.

Fibreglass Pipes: Fibreglass pipes have a high strength-to-weight ratio, are lightweight, and are resistant to corrosion. They are frequently employed in sectors including wastewater treatment, chemicals, and oil and gas. Considerations include the material's qualities, application requirements, durability, maintenance, and cost when choosing pipes for your projects. Getting advice from pipe suppliers or specialists can be extremely helpful in determining which pipe type is best for your requirements. RSS Engineering is the company that leads you with the most sustainable variety of pipes to choo

2 notes

·

View notes

Text

The significance of hazardous area lighting

Ensuring the safety of workers is paramount in every industry. Certain industries, including gas and oil, pose particular challenges and high risks of explosions. Improperly classified lighting fixtures can ignite a buildup of flammable gases and materials from a stray spark, resulting in an explosion. Therefore, it is crucial to have appropriately designed lighting fixtures in hazardous locations.

Hazardous area lighting is designed to be explosion-proof, containing any sparks or fire that may arise within the device. It plays a vital role in promoting the well-being of a business and, most importantly, its employees.

Facilities:

Numerous facilities and industries fall under one of the three risk levels of hazardous locations that necessitate adequately designed lighting fixtures.

Some of the most common facilities that fall under hazardous locations and require properly designed lighting fixtures include:

Class 1 Flammable Vapor Environment:

Petroleum and Gasoline Refineries

Dry Cleaning Plants

Spray Paint Booths

Paint Shops and Facilities

Aircraft Hangars

Chemical and Utility Gas Plants

Detergent Manufacturing Plants

Alcohol Production Facilities

Textile Dyeing and Printing Plants

Wastewater Treatment Plants

Class 2 Ignitable Dust Environment:

Plastic Production Plants

Pharmaceutical Factories

Firework Factories

Coal Mines

Flour and Feed Mills

Grain Elevators

Class 3 Combustible Fibers Environment:

Textile Mills and Cotton Gins

Cotton Seed Mills

Flax Seed Processing Plants

Leather Goods Workshops

Shoe Manufacturing Plants

Alcohol Distilleries

Choosing Factors:

A safer lighting fixture is one that lasts longer. When selecting or designing lighting fixtures for hazardous locations, durability must be a top consideration. This includes examining the following characteristics of hazardous area lighting:

Operating temperature

IP Rating

Vibration and impact resistance

Surge resistance

Long-lasting LED technology.

An adequately designed and manufactured hazardous location light should be able to withstand constant vibrations and unintended impacts or shocks. Failure to test lighting fixtures for such extreme conditions could result in premature failure of the entire fixture. Therefore, hazardous area lighting must pass a 35-hour vibration test at 2,000 cycles per minute.

In certain hazardous locations, lightning strikes and current surges can pose a costly threat to a facility's lighting systems. To mitigate this risk, hazardous area lighting must be designed with built-in surge suppression, eliminating the need for additional protective devices.

A longer-lasting light is a safer one, especially in hazardous locations that require sturdier lighting fixtures capable of withstanding hazardous materials. As discussed in our previous blog, hazardous location LED lighting enables you to save on maintenance costs while providing a longer-lasting light without compromising the safety of workers. Hazardous location LED lights have fewer components that, when exposed to flammable gases or vapors, could cause or ignite a fire.

Types:

A variety of hazardous area lighting fixtures are available to provide widespread illumination while minimizing risk. Please find below a list of our explosion-proof lighting fixtures and their corresponding applications.

LED high bay lights are ideal lighting fixtures for buildings or areas with high ceilings. They are perfect for hazardous locations as they enhance visibility.

Area lights are primarily used for outdoor lighting and are typically explosion-proof. Area lights can be effectively used in hazardous outdoor areas such as gasoline and oil loading docks, gas stations, oil refineries, and distilleries.

Flood lights are also used for outdoor lighting and provide illumination for large areas while offering superior protection from the elements. Flood lights can be effectively applied in parking lots, warehouses, and loading dock driveways.

Inadequate lighting in hazardous locations can lead to three consequences:

Safety and security risks

Penalties for noncompliance

Diminished durability

Conclusion:

Properly classifying a hazardous environment and understanding its potential dangers is essential for safely lighting such areas. Before selecting any lighting fixtures, it is important to know the facility and identify flammable vapors, ignitable dust, or combustible fibers. This enables us to design lighting that offers a safe and productive working environment.

2 notes

·

View notes

Text

Engineers have developed a new kind of membrane that separates chemicals within wastewater so effectively that they can be reused, presenting a new opportunity for industries to improve sustainability, while extracting valuable by-products and chemicals from wastewater. Created for use in wastewater treatment, the thin-film composite nanoporous membrane known as a TFC NPM, exhibits an 'unprecedented' capability to separate salts and other chemical components from water, and could lead to more sustainable treatment and management of water in a range of industries. A research paper published today in Nature Water details the membrane's performance and explains how its unique properties, aspects of which are inspired by mussels, could pave the way for more sustainable management of water within industries such as pharmaceuticals, oil and gas, textiles and food processing. The paper is authored by academics from the UK's University of Bath alongside colleagues based in China, South Korea, Singapore, Australia and Belgium.

Read more.

#Materials Science#Science#Membranes#Clean water#Water#Thin films#Biomimicry#Mussels#Polymers#Coatings#University of Bath

17 notes

·

View notes

Link

3 notes

·

View notes

Text

MEE Plant Manufacturing Redefined: Excellence in Engineering Solutions

In today’s rapidly evolving industrial landscape, sustainability and efficiency are no longer just aspirations; they are essential components of any successful operation. Multiple Effect Evaporation (MEE) plants have emerged as a groundbreaking solution for industries seeking to manage wastewater effectively while conserving energy. India, a hub for industrial growth and innovation, has witnessed significant advancements in the MEE plant manufacturing sector. This article explores how MEE plant manufacturers in India are redefining engineering excellence and contributing to sustainable industrial practices.

What Are MEE Plants?

MEE plants are advanced systems designed to treat and recycle wastewater generated by industries. The process involves the evaporation of water using multiple stages, or effects, where the steam generated in one stage is reused in the subsequent stages. This technique maximizes energy efficiency and minimizes operational costs. MEE plants are widely used in industries like pharmaceuticals, textiles, chemicals, food processing, and power generation.

The Role of MEE Plant Manufacturers in India

India has become a global leader in engineering and technology, and the country’s MEE plant manufacturers have played a pivotal role in advancing wastewater treatment solutions. These manufacturers provide end-to-end solutions, from designing and manufacturing to installing and maintaining MEE plants. Their expertise ensures that industries can meet stringent environmental regulations while optimizing resource utilization.

Key Features of Leading MEE Plant Manufacturers in India

Customized Solutions: Indian manufacturers understand the diverse requirements of industries and offer tailor-made MEE plant designs to meet specific needs.

Cutting-Edge Technology: Leveraging advanced engineering techniques, these manufacturers incorporate innovative features like automation, real-time monitoring, and energy recovery systems.

Sustainability Focus: Many manufacturers prioritize sustainable practices, ensuring their solutions minimize environmental impact.

Cost-Effectiveness: Indian manufacturers provide world-class MEE plants at competitive prices, making them a preferred choice for domestic and international clients.

Advantages of MEE Plants

Industries adopting MEE plants benefit from a range of advantages, including:

Energy Efficiency: The reuse of steam across multiple stages significantly reduces energy consumption.

Water Recovery: MEE plants enable the recycling of water, reducing dependency on freshwater resources.

Compliance with Regulations: These plants help industries adhere to stringent environmental and wastewater discharge norms.

Cost Savings: Lower operational and maintenance costs enhance profitability over time.

Innovations in MEE Plant Manufacturing

MEE plant manufacturers in India are consistently innovating to enhance performance and efficiency. Some recent advancements include:

Zero Liquid Discharge (ZLD) Integration: MEE plants are now integrated with ZLD systems to ensure that no liquid waste is discharged into the environment.

Energy Recovery Systems: Manufacturers are implementing advanced energy recovery technologies to further optimize energy usage.

Compact Designs: Space-saving designs are being developed to cater to industries with limited installation areas.

Smart Automation: Automation systems with IoT integration allow for real-time monitoring, predictive maintenance, and remote operation of MEE plants.

Prominent MEE Plant Manufacturers in India

Several Indian companies have earned a reputation for delivering high-quality MEE plants. These manufacturers are known for their commitment to excellence, reliability, and innovation. Their ability to cater to industries across various sectors has established India as a global hub for MEE plant manufacturing.

The Future of MEE Plant Manufacturing in India

The demand for efficient wastewater treatment solutions is expected to grow exponentially in the coming years, driven by increasing industrialization and environmental awareness. Indian MEE plant manufacturers are well-positioned to meet this demand by continuing to innovate and expand their capabilities.

Government initiatives promoting “Make in India” and sustainable industrial practices further bolster the growth of this sector. With a focus on research and development, Indian manufacturers are set to lead the global market in MEE plant technology.

Conclusion

MEE plant manufacturers in India are redefining engineering solutions by combining innovation, sustainability, and cost-efficiency. MEE plant manufacturers in India Their expertise not only addresses the critical need for wastewater management but also contributes to a greener and more sustainable industrial future. As industries increasingly recognize the value of MEE plants, Indian manufacturers will continue to play a vital role in shaping the global wastewater treatment landscape. By choosing Indian-made MEE plants, industries can achieve operational excellence while fulfilling their environmental responsibilities.

@ MEE Plant Manufacturer in India @

0 notes

Text

Supplier of Membrane in Karnataka

Saputo Process Engineering Pvt. Ltd. is a Specialist Manufacturer and Supplier of Membrane in Karnataka. Our Membrane Manufacturer is in Ahmedabad, Gujarat, India. Our membranes are designed and manufactured with precision to provide excellent filtration performance. Whether it’s for reverse osmosis, ultrafiltration, or microfiltration, we provide membranes that ensure efficient filtration with minimal maintenance. We utilize cutting-edge technology in the design and production of our membranes. This enables us to provide our clients with membranes that offer improved durability, reduced fouling, and higher efficiency over time. We provide excellent customer service from the initial consultation to post-installation support. Our team of experts is always available to guide you through the selection process, installation, and maintenance of your membrane system to ensure optimal performance. Applications of Membranes in Karnataka: Water Treatment Food and Beverage Pharmaceuticals Chemical and Petrochemical Wastewater Treatment Why Membranes are Crucial for Industrial Filtration? Efficiency: Membranes provide more efficient filtration with a lower footprint compared to traditional methods, reducing operational costs. Precision: Membranes offer fine separation, allowing for better quality of filtered products. Cost-Effectiveness: While membranes require an initial investment, they often result in lower long-term operational costs due to their high efficiency and minimal maintenance requirements. FAQs. Q1: Do you offer maintenance and after-sales support? A1: Yes, we offer comprehensive maintenance and after-sales support to ensure that your membrane systems continue to perform at their best. Q2: Are your membranes eco-friendly? A2: Yes, our membranes are designed with an eco-conscious approach, focusing on reducing waste, conserving energy, and ensuring long-term sustainability. Q3: How can I place an order for membranes in Karnataka? A3: You can contact us through our website, phone, or email to place an order. Our team will guide you through the process and help you choose the right membrane for your application. Saputo Process Engineering Pvt. Ltd. is a Supplier of Membrane in Karnataka and including Bangalore, Mysore, Hubballi-Dharwad, Kalaburagi, Mangalore, Belagavi, Davanagere, Bellary, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassan, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru, and Arsikere. For more details, reach out to us at Saputo Process Engineering Pvt. Ltd. and experience top-tier membrane solutions for your business. View Product: Click here Read the full article

0 notes