#paper plate machine in Delhi

Explore tagged Tumblr posts

Text

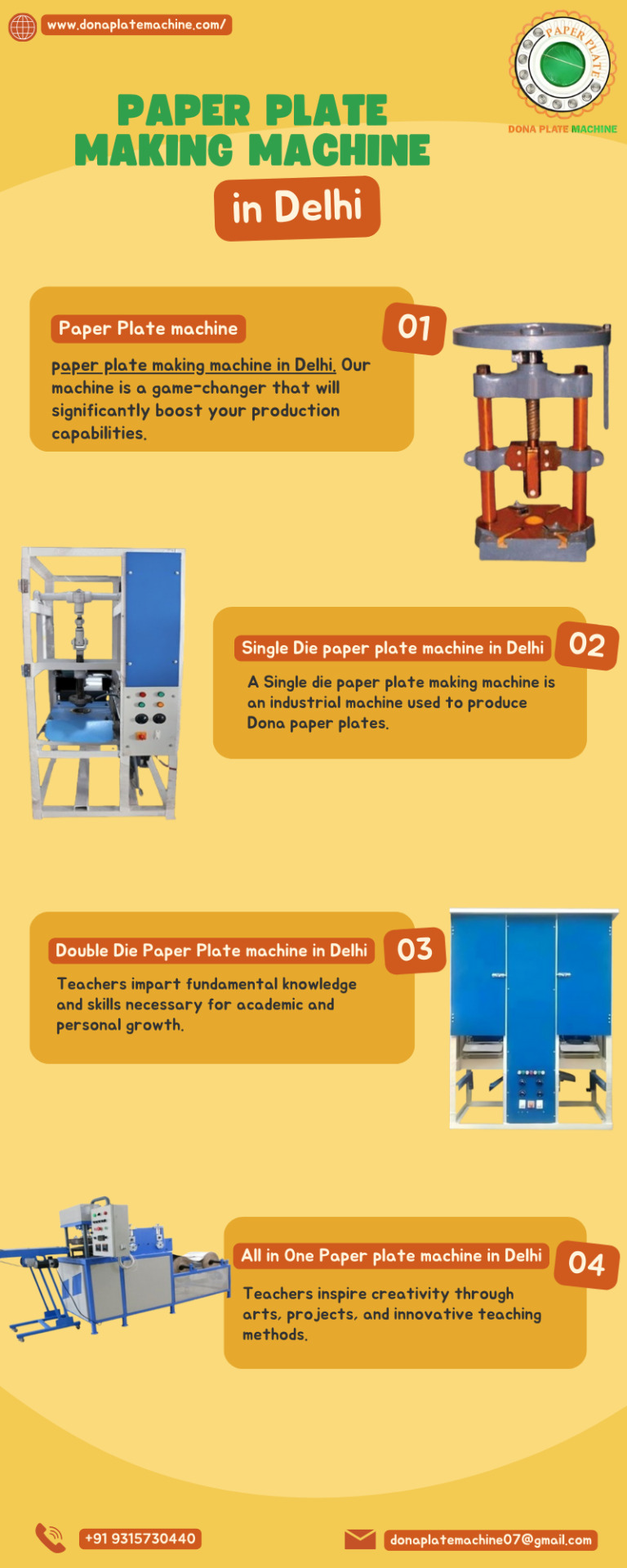

Buy Paper plate making machine in Delhi

Paper Plate Making Machine in Delhi

Introduction

Are you looking for a profitable business opportunity in Delhi? Paper plate manufacturing might just be the perfect choice! With the increasing demand for eco-friendly alternatives, paper plates have become a staple at events, food stalls, and households across the city. Investing in a paper plate making machine can help you start a lucrative business with minimal resources.

The Growing Demand for Paper Plates in Delhi

Delhi, being a bustling hub of events and street food culture, has seen a surge in the use of disposable plates. With the government promoting sustainable practices, businesses and consumers alike are shifting to biodegradable options like paper plates.

Why Paper Plate Making Machines Are a Smart Investment

Paper plate machines offer efficiency, cost-effectiveness, and scalability. Whether you’re starting small or planning to expand, these machines cater to diverse production needs, ensuring a steady income stream.

Types of Paper Plate Making Machines

Fully Automatic Paper Plate Making Machines

Fully automatic machines handle everything from cutting to molding, requiring minimal supervision. They are ideal for large-scale production.

Semi-Automatic Paper Plate Making Machines

These machines need some manual intervention but are more affordable, making them perfect for small businesses.

Manual Paper Plate Making Machines

Manual machines are cost-effective and suitable for entry-level entrepreneurs. They are simple to use but have lower production capacity.

Features to Look for in a Paper Plate Machine

Production Capacity

Choose a machine that aligns with your production goals. Machines with higher capacity are better for bulk manufacturing.

Durability and Material Quality

Invest in machines made from high-quality materials to ensure longevity and reduce maintenance costs.

Ease of Operation

Opt for user-friendly machines, especially if you’re new to the business. Simpler controls can save time and reduce errors.

Benefits of Using Paper Plate Making Machines

Cost-Effectiveness

These machines reduce labor costs and enhance production efficiency, ensuring better profit margins.

Environmental Benefits

Paper plates are biodegradable and eco-friendly, making them a sustainable choice.

Supporting Local Businesses

By producing paper plates locally, you contribute to Delhi’s economy and create job opportunities.

Leading Suppliers of Paper Plate Machines in Delhi

Reputed Manufacturers and Dealers

Delhi boasts a range of suppliers offering high-quality machines. Look for manufacturers with good reviews and after-sales service.

How to Choose the Right Supplier

Compare prices, features, and warranties before making a purchase. Always opt for suppliers who provide installation and training.

Cost Analysis of Paper Plate Machines in Delhi

Price Range of Different Machine Types

Fully Automatic: ₹1,50,000–₹3,00,000

Semi-Automatic: ₹50,000–₹1,50,000

Manual: ₹20,000–₹50,000

Factors Affecting Pricing

The type of machine, production capacity, and additional features significantly impact the cost.

Setting Up a Paper Plate Business in Delhi

Initial Investment and Budgeting

Your investment will include the cost of the machine, raw materials, and packaging. Plan a detailed budget to avoid overspending.

Licensing and Legal Requirements

Ensure you have the necessary licenses, such as GST registration, to operate legally.

Marketing Strategies for Success

Advertise through social media, local markets, and events to attract clients. Word-of-mouth referrals can also work wonders!

Maintenance Tips for Paper Plate Machines

Regular Cleaning and Upkeep

Clean your machine regularly to prevent blockages and ensure smooth operation.

Troubleshooting Common Issues

Learn to fix minor problems like paper jamming to avoid downtime.

Success Stories of Entrepreneurs in Delhi

Inspiring Examples of Local Businesses

Many small business owners in Delhi have scaled their operations using paper plate machines. Their success highlights the potential of this industry.

Lessons from Their Journeys

Focus on quality, customer satisfaction, and consistent marketing to build a successful business.

Conclusion

Investing in a paper plate making machine in Delhi is a fantastic way to tap into a growing market. With the right strategy, quality equipment, and dedication, you can establish a thriving business while contributing to environmental sustainability.

#paper plate machine in Delhi#paper plate making machine#paper plate machine#dona paper plate machine

0 notes

Text

youtube

Paper Plate Machine | Automatic Paper Plate Making Machine

#paper plate machine price#paper plate machine price in delhi#paper plate machine in delhi#paper plate machine near me#paper plate machine manufacturer in delhi#paper plate machine manufacturers#paper plate machine video#paper plate machine hsn code#paper plate machine price in hyderabad#paper plate machine automatic#paper plate machine manual#paper plate machine second hand#paper plate machine automatic price#paper plate machine manufacturers near me#paper plate machine die#paper plate machine single die#paper plate machine olx#paper.plate.machine#all in one paper plate making machine price#all in one paper plate machine price#paper plate 1kg price#paper plate machine price in india#1 paper plate cost#small paper plate machine price#paper plate machine price india#paper plate making machine under 20000#2nd hand paper plate machine#2 die paper plate machine#paper plate machine rate#paper plate machine details

0 notes

Text

Precision Engineering Redefined Kesya International Machine Manufacturing

Kesya International Machine Manufacturing is a globally recognized leader in the design, development, and production of advanced machinery for various industries. Established with a vision to revolutionize industrial processes through innovation and precision engineering, Kesya International has consistently set benchmarks in the field of machine manufacturing.

Kesya International Machine Manufacturing has evolved from humble beginnings to become a powerhouse in the sector. The company's journey is marked by a relentless commitment to quality, technological advancement, and customer satisfaction. Over the years, Kesya has expanded its operations globally, establishing a strong presence in key markets across continents.

Products and Solutions: Kesya International specializes in a diverse range of machines tailored to meet the specific needs of industries such as automotive, aerospace, electronics, pharmaceuticals, and more. Their product portfolio includes:

Precision Machining Systems: Cutting-edge CNC machines and automated systems that ensure unparalleled accuracy and efficiency in manufacturing processes.

Robotic Solutions: Advanced robotic systems designed to optimize production lines, enhance productivity, and improve operational safety.

Specialized Equipment: Custom-built machinery for specialized applications, catering to unique requirements and enhancing operational capabilities.

Integrated Systems: Comprehensive solutions that integrate various technologies to streamline operations and maximize output.

Innovation and Technology: At the heart of Kesya International's success lies a relentless pursuit of innovation. The company invests heavily in research and development to stay at the forefront of technological advancements. By leveraging the latest technologies such as AI, IoT, and machine learning, Kesya continuously enhances the performance, reliability, and sustainability of its machines.

Global Reach and Impact: With a strong global footprint, Kesya International Machine Manufacturing serves a diverse clientele ranging from small enterprises to multinational corporations. Their machines are renowned for their robustness, precision, and ability to meet the most demanding production challenges. Kesya's commitment to excellence has earned them a reputation as a trusted partner in industrial automation worldwide.

Corporate Values: Kesya International upholds core values of integrity, innovation, and customer-centricity in all aspects of its operations. The company fosters a culture of collaboration and continuous improvement, empowering employees to deliver exceptional solutions that drive client success.

Future Outlook: Looking ahead, Kesya International Machine Manufacturing remains dedicated to pioneering advancements in machine technology. By anticipating industry trends and evolving customer needs, Kesya is poised to shape the future of manufacturing with cutting-edge solutions that redefine efficiency, reliability, and sustainability.

Conclusion: Kesya International Machine Manufacturing stands as a testament to the power of innovation and dedication. With a rich history of excellence and a forward-thinking approach, Kesya continues to set new standards in the global machine manufacturing industry, driving progress and transformation across diverse sectors.

#paper plate making machine#paperplatebusiness#paperproducts#slipper making machine in delhi#slippers

0 notes

Text

youtube

Dona Machine Paper Plate Business #shorts #reels

Full video link: https://youtu.be/Utfu_Xk7-Ek

Dhanlaxmi Electricals & Engg Co.

Address: House No.: 2514, Gali No.- 12, Bihari Colony, Shahdara, Delhi- 110032

Mobile / WhatsApp: 7042435808, 7428015508

Watch Full video: https://youtu.be/Utfu_Xk7-Ek

#donamachine, #paperplatemachine, #smallbusinessideas, #businessideas2025, #businesskaisekareinshortshannel, #bkkshorts

0 notes

Text

Prime Trade International: Empowering Home-Based Entrepreneurs with Paper Dona Making Machines

Prime Trade International Company ( Rohini, Delhi )

In the ever-evolving landscape of entrepreneurship, finding a business model that is both sustainable and profitable can be a challenging endeavor. However, Prime Trade International has carved out a niche by providing aspiring entrepreneurs with the tools and resources they need to establish successful home-based businesses. One of the flagship offerings of Prime Trade International is the provision of the best Paper Dona Making Machines and raw materials, enabling individuals to generate a substantial income from the comfort of their homes. In this article, we will delve into the various aspects of this business opportunity, exploring how it works, the benefits it offers, and why it stands out as a viable and lucrative option for many.

The Prime Trade International Business Model

Prime Trade International's business model is built on a foundation of simplicity and efficiency. The company provides individuals with state-of-the-art Paper Dona Making Machines along with high-quality raw materials. The process is straightforward: you use the machine to manufacture Paper Donas, package them, and supply the finished products back to Prime Trade International. This model eliminates the complexities and risks associated with traditional business setups, allowing you to focus on production without worrying about sales, marketing, or distribution.

Why Choose Paper Dona Making?

The demand for eco-friendly and disposable products has been on the rise, driven by increasing environmental awareness and regulatory measures aimed at reducing plastic waste. Paper Donas, which are used for serving food items at various events, functions, and eateries, offer a sustainable alternative to plastic or styrofoam plates. This growing demand presents a lucrative market opportunity for those involved in the production of Paper Donas.

Benefits of Partnering with Prime Trade International

1. Access to the Best Equipment

Prime Trade International prides itself on providing the best Paper Dona Making Machines in the market. These machines are designed to be user-friendly, efficient, and durable, ensuring that you can produce high-quality Paper Donas with ease. The advanced technology incorporated in these machines allows for smooth and hassle-free operation, minimizing downtime and maximizing productivity.

2. High-Quality Raw Materials

In addition to the machines, Prime Trade International supplies top-grade raw materials needed for Paper Dona production. The quality of raw materials plays a crucial role in determining the final product's durability and appearance. By providing premium raw materials, the company ensures that the Paper Donas you produce meet industry standards and customer expectations.

3. Simplified Production Process

The production process is designed to be straightforward and easy to manage. With comprehensive training and support from Prime Trade International, you can quickly learn how to operate the machine and produce Paper Donas efficiently. The company also offers ongoing technical support to address any operational challenges you might encounter.

4. Guaranteed Market and Income

One of the most significant advantages of this business model is the guaranteed market for your products. Prime Trade International takes care of the marketing, sales, and distribution aspects, providing you with a ready market for your Paper Donas. This assurance eliminates the uncertainty and financial risk associated with finding customers and selling products. As a result, you can earn a steady income of 70,000 to 80,000 rupees per month, with the potential for higher earnings as you scale up production.

5. Flexible Work Environment

Running a home-based business offers unparalleled flexibility. You can manage your work hours according to your convenience, allowing you to balance work with personal commitments. This flexibility is particularly beneficial for individuals who may have other responsibilities, such as homemakers or retirees looking to supplement their income.

The Process: From Setup to Production

1. Initial Setup

Getting started with Prime Trade International is a seamless process. Upon expressing your interest, a representative will guide you through the initial steps, including machine installation and setup. The company ensures that the equipment is properly installed and operational before you begin production.

2. Training and Support

Prime Trade International provides comprehensive training to ensure you are well-versed in operating the Paper Dona Making Machine. This training covers all aspects of the production process, from machine operation to packaging the final product. Additionally, the company offers continuous support to address any technical issues or operational queries you may have.

3. Production and Packaging

Once the setup and training are complete, you can begin production. The machine is designed to be efficient and easy to use, allowing you to produce Paper Donas in large quantities with minimal effort. After production, the Donas are packaged according to the guidelines provided by Prime Trade International to ensure they are ready for distribution.

4. Supplying the Finished Products

After packaging, the final step is to supply the Paper Donas back to Prime Trade International. The company handles all aspects of distribution, ensuring that the products reach the end customers promptly. This streamlined process allows you to focus solely on production, without the stress of marketing and sales.

Success Stories: Real-Life Examples

Prime Trade International has empowered numerous individuals to achieve financial independence through its innovative business model. Here are a few success stories that highlight the impact of this opportunity:

1. Sunita Sharma, Homemaker

Sunita Sharma, a homemaker from Jaipur, was looking for a way to contribute to her family's income without compromising her household responsibilities. After partnering with Prime Trade International, she successfully set up a Paper Dona manufacturing unit at home. With consistent production and the company's support, Sunita now earns around 75,000 rupees per month. This additional income has significantly improved her family's financial stability.

2. Rajesh Gupta, Retiree

Rajesh Gupta, a retired government employee, was searching for a productive way to utilize his time post-retirement. He decided to join Prime Trade International and start a home-based business. Rajesh's dedication and the company's efficient support system have enabled him to generate a steady income, giving him a sense of purpose and financial security in his retirement years.

3. Anita Singh, Small Business Owner

Anita Singh, a small business owner, wanted to diversify her income streams. She found the Paper Dona Making opportunity offered by Prime Trade International to be an ideal addition to her existing ventures. With her business acumen and the company's resources, Anita has expanded her operations and now earns a significant monthly income, further enhancing her entrepreneurial success.

Why Prime Trade International Stands Out

Several factors set Prime Trade International apart from other business opportunities:

1. Proven Track Record

Prime Trade International has a proven track record of helping individuals establish successful home-based businesses. The company's commitment to quality and customer satisfaction has earned it a reputable position in the market.

2. Comprehensive Support

The comprehensive support provided by Prime Trade International ensures that you are never alone in your entrepreneurial journey. From training to technical assistance, the company is dedicated to helping you succeed.

3. Sustainable and Eco-Friendly Products

By producing Paper Donas, you contribute to the growing demand for eco-friendly products. This not only makes your business environmentally responsible but also aligns with global trends towards sustainability.

4. Scalable Business Model

The business model offered by Prime Trade International is scalable. As you gain experience and confidence, you can increase production capacity and explore additional product lines offered by the company, further boosting your income potential.

Conclusion

Prime Trade International offers a unique and lucrative opportunity for individuals looking to establish a home-based business. By providing the best Paper Dona Making Machines and high-quality raw materials, the company simplifies the production process and ensures a steady market for your products. With the potential to earn between 70,000 to 80,000 rupees per month, this business model offers financial independence and flexibility. Whether you are a homemaker, retiree, or small business owner, partnering with Prime Trade International can help you achieve your entrepreneurial goals and transform your home into a thriving business hub. Join Prime Trade International today and embark on a journey towards financial success and empowerment.

0 notes

Text

Double Die Paper Plate And Dona Plate Machine in Delhi

Are you looking to take your paper plate-making business to the next level? Then contact ASVR ENGINEERING for a Double Die Paper Plate Machine. This innovative machine has been designed to streamline the paper plate-making process, allowing you to produce more plates in less time and with greater efficiency. In this article, we will explore the features and benefits of the Double Die Paper Plate Machine, as well as compare it to other paper plate-making machines such as the single die paper plate machine and the all-in-one paper plate machine.

What is a Double Die Paper Plate Machine?

A Double Die Paper Plate Machine is a cutting-edge piece of equipment that is revolutionizing the paper plate-making industry. Unlike traditional paper plate-making machines that only have a single die, the Double Die Paper Plate Machine is equipped with two dies, allowing for the simultaneous production of two paper plates at once. This results in a significant increase in productivity and efficiency, making it the ideal choice for businesses looking to scale up their operations.

Features of the Double Die Paper Plate Machine

Dual Die Design: The most notable feature of the Double Die Paper Plate Machine is its dual die design, which allows for the production of two paper plates at the same time.

High Output: With the ability to produce double the number of paper plates in the same amount of time, the Double Die Paper Plate Machine boasts a high output capacity.

Easy to Operate: Despite its advanced technology, the Double Die Paper Plate Machine is surprisingly easy to operate, making it suitable for operators of all skill levels.

Durable Construction: Built to last, the Double Die Paper Plate Machine is made from high-quality materials that ensure longevity and durability.

Comparison with Single Die Paper Plate Machine

When comparing the double-die paper Plate Machine to a single-die paper plate machine, the advantages are clear. While a single-die machine can only produce one paper plate at a time, the double-die machine can produce two, effectively doubling the output. This means that with the Double Die Paper Plate Machine, you can meet demand quicker and more efficiently, leading to increased profits and customer satisfaction.

Comparison with All in One Paper Plate Machine

The all-in-one paper plate machine is another popular option for paper plate-making businesses. However, when compared to the Double Die Paper Plate Machine, it needs to improve in terms of output capacity. The Double Die Paper Plate Machine's ability to produce two paper plates simultaneously gives it a clear edge in terms of productivity and efficiency, making it the preferred choice for businesses looking to maximise their output.

Conclusion

the Double Die Paper Plate Machine is a game-changer for the paper plate-making industry. With its dual die design, high output capacity, and ease of operation, it offers unmatched productivity and efficiency. If you want to take your paper plate-making business to the next level, investing in a Double Die Paper Plate Machine is the way to go. Upgrade your equipment today and start reaping the benefits of increased profitability and customer satisfaction.

0 notes

Text

0 notes

Text

What cool things can you make with sublimation?

Motivate Box is the leader in Sublimation products Wholesale from Kolkata, Noida, & Delhi.

In the process of sublimation, a substance moves straight from its solid state to its gas state, skipping beyond its liquid counterpart. Many fascinating applications of this method can be found in many different industries, such as manufacturing, printing, and science. We'll talk about a few of the fascinating things that can be created utilizing sublimation in this article.

Personalized clothing and T-shirt sublimation: Customized designs can be printed via sublimation on clothing such as caps, T-shirts, and other accessories. Using specialized sublimation inks and transfer paper, the pattern is printed, and then using a heat press, it is transferred to the cloth. The end result is a vivid, long-lasting print that is of great quality.

Phone cases and other accessories: Custom phone cases and other accessories can be made using sublimation. The procedure resembles that used for T-shirts and other clothing and entails printing the design on transfer paper before using a sublimation heat press machine to apply it to the phone cover or accessory. This offers countless personalization possibilities and can result in fantastic personalized gifts.

Ceramic mugs and plates: Custom designs can be imprinted on ceramic mugs and plates using sublimation. The design is first printed using sublimation inks on specialized sublimation paper, and then it is heated in a press to transfer it to the ceramic. The end result is a print that is strong, excellent, and safe for the dishwasher and microwave.

Metal prints: Stunning metal prints can also be made with sublimation. The design is first printed with sublimation inks on specialised sublimation paper, and then it is heated up in a press to transfer it to the metal. The end product is a vivid, high-quality print that is water- and scratch-resistant.

Custom mousepads can be made using sublimation as well. The procedure, which is similar to how T-shirts and other clothing are made, entails printing the pattern on transfer paper first, then using a heat press to apply it to the mousepad. This offers countless personalization possibilities and can result in fantastic personalized gifts.

Signage and displays: Custom signage and displays can also be made using sublimation. The procedure entails printing the design with sublimation inks on specialised sublimation paper, and then using a heat press to transfer the pattern to the sign or display. The end result is a print that is vivid, sturdy, and long-lasting.

The method of 3D sublimation involves transferring a picture to a specifically coated 3D object. This may apply to sipper bottles, keychains, and phone cases. The procedure entails printing the design onto specialized sublimation paper, which is then used to heat press the design onto the object. The end result is a vivid, long-lasting print that is of great quality.

Wood prints: Custom designs on wood can also be made using sublimation. The procedure entails printing the design with sublimation inks on specialised sublimation paper, which is then heated to transfer the design to the wood. The end product is a vivid, high-quality print that is water- and scratch-resistant.

Sports gear: Custom patterns can also be imprinted using sublimation on items like baseballs, basketballs, and soccer balls. The procedure entails printing the design using sublimation inks on specialised sublimation paper, and then using a heat press to apply the pattern to the sporting goods. The end result is a print that is vivid, sturdy, and long-lasting.

Custom designs can be made via sublimation and utilized on car accessories like license plate frames.

0 notes

Text

Semi-Automatic Paper Plate Machines Manufacturer.

Semi-automatic paper plate machine gets to sell a unique product which is high in demand nowadays where the companies you’re selling to increase their market reputation with their green business practices. You might decide to make your paper plates made from biodegradable material, recyclable coffee cups, and more sustainable practices. It is just one idea to help set you apart in this competitive industry. It is a great opportunity to start an individual Eco-friendly career. This article now gives you the required information about the business plans, licensing, layout plans, setup process and marketing strategies required to start and run a successful paper plate making business.

#disposable plate making machine#paper plate making machine in delhi#paper plate making machine price in delhi#paper plate machine manufacturer in delhi#paper plates machine

1 note

·

View note

Text

RK Printers’ new plant at IMT Faridabad

RK Printers was founded in 1972 by three brothers, KS Malik, Rakesh Malik, and Ramesh Malik. They were among the few printers in Delhi with offset presses for publishing and packaging. The company began and thrived in the industrial sector of Delhi’s Anand Parbat, conveniently positioned and accessible in those days.

[caption id="attachment_68751" align="alignleft" width="300"]

RK Printers at IMT Faridabd.[/caption]

When the second generation of the family joined the company, it quickly recognized the need for more visible space to expand. The search began, and the IMT Faridabad industrial region near Delhi was chosen because of its superior connectivity and infrastructure. However, with the constraints imposed by the Covid-19 lockdowns, it took over two years to establish the new plant at IMT Faridabad. It’s a planned 35,000-square-foot facility with specialized production floors.

“Sustainability is the company’s main focus,” say the nextgen Maliks. Since the brothers consider environmental issues proactively, the intention was to create an environmentally friendly infrastructure when developing the new facility.

30 kW solar power and rainwater harvesting

RK Printers built a 30 kW solar power plant and a rainwater harvesting plant at the new factory to alleviate its carbon footprint. Vikrant Malik, one of the nextgen partners, says, “We believe that the factory and process should be environmentally friendly. Using harvested rainwater and solar panels is an excellent way to reduce the carbon footprint and do our bit to help the environment. Team RK Printers is committed to an extensive recycling program, including everything from paper and inks to the plates we use on our presses. We’re proud of our efforts and continually strive to do whatever we can to protect the environment!”

Speaking about safety, he adds, “The company has installed fire safety measures in the plant. There are 5 to 6 fire extinguisher flasks on every floor, and for every recruit added to the plant, we have given fire hazard and safety training.”

[caption id="attachment_68750" align="alignleft" width="300"]

Boxtech velocity crash lock bottom carton machine.[/caption]

The company currently converts over 1.5 million cartons daily. At the new facility at IMT Faridabad, a pre-owned 6-color Heidelberg offset press with coater, Bobst die cutters, and three new crash lock pasting machines from Boxtech are operational. These substantially boost the company’s earlier production capacity.

The company manufactures 6-color monocartons with UV coating, embossing, and raised UV aqueous coating, along with other special decorative effects. In addition, the firm has widened its reach to new verticals and segments such as pharmaceuticals, cosmetics, foods, and beverages. The USP is to provide its customers with a one-stop solution.

“While many companies specialize in folding carton product boxes, we are a different type of box manufacturer. Our specialty is adding the finishes and textures to printed packaging that attract attention – and that makes the difference in selling the product,” said Malik. RK Printers produces blister cards with HSL and pet coating for cosmetics clients, rigid boxes for the luxury segment, labels, leaflets, danglers, and paper pouches for pharma and personal care mehendi (henna) clients, gift boxes for festivals, corrugated boxes for start-ups, and shipper boxes for exporters. It works with several companies and brands in the pharma, food, beverages, alcohol, agrochemicals, start-ups, and incense segments.

RK Printers plan to enter the European market

The company has invested in the infrastructure, machinery, and accessories to attain the certifications required for exports. The firm also has a contemporary quality control lab with the most up-to-date test equipment capable of performing all necessary tests to confirm the client’s specifications. Malik comments on the company’s plans, “We want to export our products to the European market. We are looking forward to participating in several exhibitions and entering new markets as we now have a robust infrastructure required for exports.”

Passion, creativity, and professionalism drive RK Printer’s growth. To be able to offer these values internationally, the firm produces and promotes novel packaging solutions for its client’s brands. “We leave no stone unturned to provide quality to our customers in India, and we hope that we can deliver the same to the international market as well,” concludes Malik.

0 notes

Text

Paper Plate making machine in Delhi

#paper plate machine#paper plate making machine#automatic paper plate making machine#dona plate making machine#paper plate making machine in delhi#dona paper plate machine#paper plate machine in delhi#dona plate machine

0 notes

Text

IDC Groups/ Flexo Printing Machine

6 Color Flexo Printing Machine with Sheet Cutting Machine

6 Flex shading printing machines with plate cutting machines are the resulting impact of the inclusion of over twenty years. Its constructed and helpful example serves in full measure the interest of the current versatile printing establishment.

Flexographic Printing Machines

The Best Flexo Printing Machine has fantastic enlistment limits to favorable print speed to get a colorful quality imprinting on various substrates with the higher economy. These machines are provided with "anilox" rolls appropriately engraved to work with long life and uniform association trade bringing printed and splendid prints. The drying structure is expected to arrange with speedy printing, giving the passing of hot air blowing cameras and the last hot air drying framework to get extraordinary drying on the print mat.

High velocity Flexo Printing Machine

We have in all cases promptly open print rolls with gears for all sizes of flexographic printing machines. Solid engraving precision and reflection structure for zero vibration quick printing chamber stacking to restrict the programmed get-away stop for the power warming indoor regulator for power saving helical pinion wheels for anilox rollers and milder chambers for water pictures framework Digital counter with to drop and rewind stations to run two positions at the same time Print loves — 1 5 or 2 4 or 3. We are viably creating, sending, and giving a wide scope of flexographic printing machines from the most recent long New Delhi, India. We are the victor of numerous occasions National Award and twice International honor for quality gathering. For quality printing machines, we manage a wide scope of materials, like paper, non-woven, HDPE, PP, SACK Woven, LD, BOPP, etc

Machine Specifications

The machines are made out of the subsequent units: Drying Camera Drying Bridge of Desperate Printing Stations — Rewind Station. The printing chambers, sound framework rolls, and anilox rollers are hard chrome plated covered to guarantee long life and powerful machine work. Dynamic accomplice changed showers for vibrations that work liberated from the machine. Mohindra does, sends and gives a wide scope of flexographic machines available in various sizes, for example, 18 ", 20", 22 ", 24", 26 ", 28", 28 ", 30" in four and six tones.

Why IDC Groups

Dependable and practical

Despite the fact that the flexo printing machine cost is rising, it is never the last thought for anybody. Let's face it, the expense is presumably the greatest element concerning purchasing a press. With vehicles, you might be paying extra for a brand. In any case, with flexographic printing machines, you pay for quality. Make an effort not to attempt to save a few features by purchasing or getting a lower quality machine. Machines of obscure makers or flexed printing hardware utilized may have utility issues or invalidated guarantees. Purchase new and work with affiliates to find subsidizing or other buy courses of action that needn't bother with utility or quality. We attempt to characterize the elite necessity for various producers to follow, with a constant interest in research and new improvement in the thing. In an overall environment of the ferocious contest, our commitment to make and consolidate advancement and our gathering of particularly experienced assist specialists with giving our clients the edge in the constraint of waste, decreasing costs, and finishing undertakings on schedule.

Outfitted with the most recent innovation

Any sensible individual would concur that we as a printing machine maker are glad for our accomplishments, including different thing licenses. Our latest name print advancement permits the quickest concealing changes in any push accessible today, with less close to home time, less waste, quicker creation, better return, and work quality. This isn't a pawn, yet it is the person who is played on various events on capability speculation reserves and deferred upgrades by our clients. We will be glad to respond to any inquiries you might have and converse with you regarding how our flexographic name printing machines can assist you with changing your business.

0 notes

Text

Kesya International Machine Manufacturing is a leading enterprise specializing in the production of high-quality machinery for the bakery and food processing industries. Based in Delhi, with operational reach extending to Patna and Bihar, we are committed to delivering innovative solutions that cater to the diverse needs of our clients.

Our flagship brand, Ovenbakeries, is renowned for its state-of-the-art oven making machines, bread making machines, and oven bakery machines. We pride ourselves on the efficiency, durability, and advanced technology integrated into our equipment, ensuring that our clients receive the best tools to enhance their production capabilities.

In addition to our bakery machinery, we offer specialized products like the 'single die paper plate machine' and the 'manual paper machine,' which reflect our versatility and commitment to addressing various manufacturing needs.

At Kesya International Machine Manufacturing, customer satisfaction is our top priority. We continuously strive to innovate and improve our product offerings, ensuring that our clients have access to the latest advancements in manufacturing technology. Our dedicated team of experts is always ready to provide support and guidance, ensuring seamless operations and maximizing productivity for our clients.

Choose Kesya International Machine Manufacturing for reliable, high-performance machinery that drives success in the competitive world of manufacturing.

0 notes

Text

Empower Your Future with Prime Trade International's Best Carry Bag Making Machines

Carry Bag Making Machine ( Rohini, Delhi )

In today's fast-paced world, the demand for eco-friendly and sustainable products is growing rapidly. Among these products, carry bags have become essential in our daily lives. They are used in shopping, packaging, and various other applications. Prime Trade International, a leading provider of business solutions, offers an incredible opportunity for individuals to set up their own home-based business by providing the best carry bag making machines and raw materials. This initiative not only empowers individuals to become entrepreneurs but also contributes to environmental sustainability.

About Prime Trade International

Prime Trade International is committed to helping individuals achieve financial independence by providing the necessary tools and resources to start their own businesses. Our company specializes in offering high-quality machines and raw materials for manufacturing various products, including tissue papers, tablets, paper plates, and carry bags. Our mission is to enable individuals to establish profitable home-based businesses with minimal investment and effort.

The Carry Bag Making Opportunity

Prime Trade International provides a comprehensive solution for setting up a carry bag manufacturing business from the comfort of your home. Our offering includes state-of-the-art carry bag making machines and high-quality raw materials. With our easy-to-use machines and reliable supply of raw materials, you can start producing carry bags and earn a substantial income every month.

Why Choose Carry Bag Manufacturing?

The carry bag manufacturing business is an excellent choice for several reasons:

High Demand: The use of carry bags is widespread, making them a high-demand product. With increasing awareness about environmental sustainability, the demand for eco-friendly carry bags is on the rise.

Low Investment: Starting a carry bag manufacturing business requires a relatively low initial investment compared to other businesses. Prime Trade International provides affordable machines and raw materials, making it accessible to everyone.

Flexibility: This business can be operated from home, allowing you to balance your work and personal life effectively. You can choose your working hours and scale up the business at your own pace.

Profitability: With the right approach and dedication, you can earn between 70,000 to 90,000 rupees per month. The profit margins in carry bag manufacturing are substantial, ensuring a good return on investment.

Features of Our Carry Bag Making Machines

Prime Trade International offers the best carry bag making machines in the market. Our machines are designed to be user-friendly, efficient, and durable. Here are some key features:

1. Advanced Technology

Our carry bag making machines are equipped with the latest technology, ensuring high precision and efficiency in production. The advanced features of our machines include:

Automated Operation: The machines are fully automated, reducing the need for manual intervention and increasing productivity.

High-Speed Production: With high-speed capabilities, our machines can produce a large number of carry bags in a short amount of time.

Versatility: The machines can manufacture various types of carry bags, including different sizes, shapes, and materials.

2. User-Friendly Interface

We understand that not everyone has technical expertise, so our machines are designed with a user-friendly interface. The intuitive controls and simple operation make it easy for anyone to use the machines without prior experience.

3. Durability and Reliability

Our carry bag making machines are built to last. Made from high-quality materials, they are durable and require minimal maintenance. The reliability of our machines ensures uninterrupted production, allowing you to meet the demands of your customers consistently.

4. Energy Efficiency

Prime Trade International's carry bag making machines are energy-efficient, reducing your operational costs and contributing to environmental sustainability. The machines are designed to consume less power while maintaining high production efficiency.

Comprehensive Support and Training

At Prime Trade International, we believe in supporting our customers every step of the way. When you choose our carry bag making machines, you also receive comprehensive support and training to ensure your success.

1. Installation and Setup

Our team of experts will assist you with the installation and setup of the carry bag making machines. We ensure that the machines are set up correctly and are ready for operation.

2. Training

We provide thorough training on how to operate the machines, maintain them, and troubleshoot any issues that may arise. Our training program is designed to equip you with the knowledge and skills needed to run your business smoothly.

3. Ongoing Support

Our customer support team is always available to assist you with any queries or concerns. Whether you need technical support or business advice, we are here to help you succeed.

The Process of Carry Bag Manufacturing

Manufacturing carry bags with Prime Trade International's machines is a straightforward process. Here is a step-by-step guide:

1. Raw Material Preparation

Prime Trade International provides high-quality raw materials, including biodegradable and eco-friendly options. These materials are essential for producing carry bags that meet market standards and environmental regulations.

2. Machine Setup

Once the raw materials are ready, set up the carry bag making machine according to the provided instructions. Our machines are designed for easy setup and operation.

3. Production

Start the machine and begin the production process. The automated features of our machines ensure smooth and efficient production, with minimal manual intervention required.

4. Quality Control

Regularly check the produced carry bags for quality and consistency. Ensure that the bags meet the required standards and specifications.

5. Packaging and Delivery

Pack the finished carry bags according to your business requirements and deliver them to Prime Trade International. We handle the logistics and distribution, allowing you to focus on production.

Financial Benefits and Earnings

By partnering with Prime Trade International, you can achieve significant financial benefits. Our carry bag making machines and raw materials provide you with a profitable business opportunity. With the potential to earn between 70,000 to 90,000 rupees per month, you can achieve financial independence and improve your quality of life.

Factors Influencing Earnings

Several factors can influence your earnings in the carry bag manufacturing business:

Production Volume: Higher production volumes lead to increased earnings. Our high-speed machines enable you to maximize production.

Quality: Consistently producing high-quality carry bags will attract more customers and increase your profits.

Efficiency: Efficient use of raw materials and energy will reduce costs and enhance profitability.

Conclusion

Prime Trade International is dedicated to empowering individuals to become successful entrepreneurs. Our best carry bag making machines, coupled with high-quality raw materials and comprehensive support, provide an excellent opportunity to start a profitable home-based business. By producing eco-friendly carry bags, you not only contribute to environmental sustainability but also achieve financial independence.

Join Prime Trade International today and take the first step towards a brighter and more prosperous future. With our reliable machines, expert support, and profitable business model, you can turn your entrepreneurial dreams into reality.

0 notes

Text

Japan & Japanese through my eyes........

I wish to give you a brief background of my association with Japan & Japanese. It began in 1975 when I worked for Engineers India Ltd. in New Delhi. I was part of a project management team to look after a petrochemical project called “Acrylic Fiber” at IPCL, Baroda. The process technology came from Asahi Chemical and Front-End Engineering was carried out by Kobe Steel. They had deputed a full time Japanese at EIL office.

Next association was in 1980-81 when I took a field engineer job withToyo Engineering at Basra, Iraq. For about 15 months, my immediate bosses were Japanese, though there were many Indians on site.

My close and strong association was from 1984 to 87 when I was a project manager and managed a collaboration with Chiyoda Corporation of Japan to execute an EPC project at NFL, Guna.

I along with my family moved to Yokohama, as Chiyoda Corp. offered me a direct employment. My office and my daughter’s school were also in Yokohama.

I again had a chance to work with Japanese when Chiyoda set up a joint venture with L&T called L&T –Chiyoda at Baroda in the 90’s.

Lastly, I was asked to manage Chiyoda’s liaison office at Bangalore for two years in 2012-14.

I will segregate my observations in two parts- one from the people and another from the country. Most people know of the punctuality of Japanese and discipline at workplace Hence, I will not dwell on these.

Most Japanese are concerned and sensitive of the discomfort or needs of fellow person. You can see that a Japanese not only picks up used plates and tray with trash in a McDonald’s but also wipes the table. You observe that a mother carries two types of napkins – one wet and another dry- when she takes her kid(s) out to play in the public garden. She cleans the child’s dirty hands with wet and then with clean napkin so that it does not dirty the rails or seats of the garden. Even in 90’s I saw Japanese wearing mask when they suffered from cough and cold. It was a common sight to see the dog owner carrying a paper bag and some broom to pick up poop.

Japanese people do not commit petty crimes or cheat which makes life so stress free and safe. My wife used to leave the apartment door open to go shopping nearby for 30 to 45 minutes. She learnt of this practice from neighbours. Initially we used to keep the money in our palm and the shop keeper would take the appropriate amount. All the shops-small or big – always charged us the VAT, whether we wanted a receipt of not. First time in my life I was offered a printed receipt of fare charged by a metered taxi without asking.

Japanese introduced us to see the beauty in the nature. The first time in our life we went to the mountains to see the autumn colours. There were conducted tours for local people to come to the mountains and soak in the beauty of the shades of colours from green to golden. We were also witness to the fire which is light up to dry leaves/grass on the mountain sides. The fire is light and controlled to spread in artistic way and you watch it from across the valley. Another experience was of hot (sulfur) springs in the mountains near Tokyo (Hakone). Our company guesthouse had a huge pond kind of hot water spot where natural spring was brought in. We soaked in this pond in the Japanese way-no clothes and separate areas for women and men. In five-star resorts, one could soak in the hot spring and sip from a glass of beer.

Japanese were also very health conscious. Our office had an indoor all weather Olympic size swimming pool and full-fledged gym with an instructor. Some of my colleagues were using this during lunch time before eating lunch. I used the facility on weekends. I went to a gym first time in my life and swam when there was almost zero-degree centigrade ambient temperature outside.

Japanese also retained some of “Indian” habits which may have reached them through Buddhism. Outdoor footwear cannot be used indoor whether in the residence or Japanese restaurants. We must leave outdoor footwear at the door and use in house slippers to go in. Most Japanese prefer to sit cross legged and ladies in Vajrasan. They do not shake hands or hug when the meet but bow and greet. Most prefer to sleep on the ground on a mattress rather than a western bed.

Japanese also have found ways to de-stress after an incredibly stressful office or factory workday. Karaoke bars are popular and now world famous. The normal bars without karaoke are also popular. They had huge halls with “ball” machines when they play a special game with stakes to lose or win, like what we played as a child. They also enjoy comics and there are comics to entertain all age groups.

Japan as a country is different from India. India is heterogeneous whereas Japan was homogeneous. This one feature made a lot of difference. They had only ten public holidays every year. Japanese was the main language for locals and it was developed to ensure that students get the latest information also. Japanese language also brings a very peculiar character to the people. The language has three alphabets-Hiragana, Katakana and Kanji. Kanji has no letters but only Chinese characters/pictures. There are over few thousand kanjis and a child takes more than 8 yrs to know them all though only a few hundred Kanji is extensively used. To write Kanji one must be precise and take care of the different strokes. This focus on details and accuracy is reflected in everything they do in my opinion.

The police in Japan were extremely helpful and friendly. On two occasions I got their help. Once I was lost in the central Tokyo area and I went to the police station. The policeman there came with me to show me the address. On another occasion, my family and me went to meet my friend but my Casio watch, which had his telephone no. ran out of battery and I was lost. I again went to police station near the rail station. He permitted to call my office to find out the contact no. of my friend (office colleague) but the office security refused. Then he opened the area map with names of the residents, and we located two Tanaka-san. I dialed the first one and fortunately he was my friend. In India, such help was unthinkable, going to the Police station for common man for help is a far cry!

I came across some interesting leave/holidays rule. Most Japanese joined a company for a lifetime and the company was expected to take care of the individual. After about 20 yrs. of service (mid-way I guess) the employee get paid leave (about 6 weeks) and a huge payment (app. one year salary). He is expected to enjoy with his family and many of colleagues went to Europe, USA or Latin America for two to three weeks with family.

I was happily surprised that most school students including my daughter walked to the school. My daughter walked about 20 minutes each way, there were volunteers on the route to guide the school kids. No school bus or parents driving to drop or pick-up kids.

For common people, the basic unwritten rule was- provide goods and services which are high quality and reliable. All public phones (as the world was not exposed to internet or mobile phones at the time) were in working order with coins or prepaid cards for both domestic and international calls. Such phones were plenty and located at all convenient locations like rail stations, supermarkets and including lift lobbies in office buildings. ATM rooms of banks had ATM machines for withdrawal and transfer facility. There were two other machines-passbook printing and change dispensing. ATM rooms were open 24x7. Japan was most known for vending machines- variety and exceptionally reliable. Vending machines would dispense soft drinks, beer, hot and cold coffee, tea, small snacks packets etc. These machines would not be out of stock and returned change.

Japan acts in unison for trade/commerce without side world. Immediately after WWII, their economy was shattered but soon they got on their feet. The five trade houses –Sumitomo, Mitsui, Marubeni, C Itoh and Mitsubishi- were the marketing agents for both import and export. The manufacturers were concentrating on design, engineering, and quality products. This brought down costs. The trade houses would bring enquiries and orders. They will also take care of payments. Each manufacturer will join a trade house so that there is no competition among the trade houses.

As a country, I saw Japan converting research output in other countries to application/products for common use. The classic example was digital watch from Texas Instrument to Casio. Another could be Video players. Even some collaborations were made successful and eventually did better than the collaborators. The classic example is of Toyota Car Co which had started with GM collaboration 1950s.

In all the efforts of private sector in commerce the Govt played a particularly important and positive role. The banks were ready to help exporters/vendors with five-month credit as L/C or other kind of payments after shipment may take 3 months.

I hope you like what I have scribbled above as much as I loved it writing.

0 notes

Text

0 notes