#osh hazards

Explore tagged Tumblr posts

Text

Examples of border initiatives.

Singapore: Dengue control programme

Australia: Skin cancer prevention programme

"Climate change and safety and health at work." World Day for Safety and Health at Work 2024, April 28th.

#singapore#workers#safeday#australia#workplace health and safety#uv radiation#UV safety training#exposure risks#knowledge of hazards and risks#osh hazards#occupational hazards#identifying hazards#international labour organization#occupational health#28 april#worker's safety#worker's health#climate health nexus#changing climate#climate change#climate change mitigation

0 notes

Text

Who is protected by OSHA?

The most frequently asked question I recieve is "Am I even covered by OSHA?" It's not always clear who is and isn't covered by OSHA, and there can even be room for interpretation.

The official text on OSHA.gov states:

"The OSH Act covers most private sector employers and their workers, in addition to some public sector employers and workers in the 50 states and certain territories and jurisdictions under federal authority."

In order to fall under OSHA jurisdiction you must be an employee working in the US or a US territory. There are a number of exceptions however. Private sector employees not covered by OSHA are:

"self-employed workers (independent contractors), immediate family members of farm employers, and workers whose hazards are regulated by another federal agency"

Follow this link to see list of other US regulatory agencies

Federal OSHA also does not cover employees of government agencies, which includes: public schools/universities, public transit agencies, and first responders such and firefighters and law enforcement.

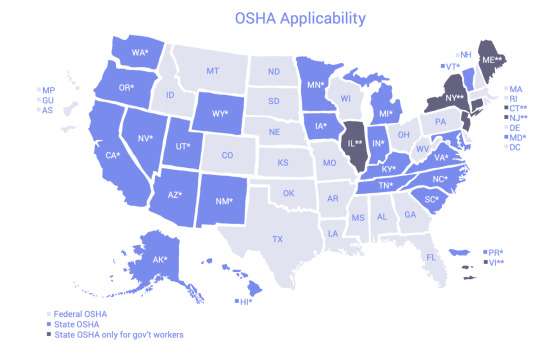

However public sector employees are required to be covered in states that have an OSHA approved state plan. The map below shows which states have their own OSHA plans.

(Source: sixfifty.com)

You can visit OSHA.gov/stateplans to learn more about your OSHA coverage

393 notes

·

View notes

Text

Chapter 13: Wheelbarrow

Number of regulations violated: 5

Unfortunately, the recent safe streak has ended almost the moment out protagonist stepped onto a boat. While the now expected description of whaling as a dangerous business brings concerns to mind, this pales in comparison to the fact that the boom of the ship begins swinging wildly, knocking a passenger overboard and putting employees at risk. While my closest personal experience is riding a small sailboat, and so I struggle to determine how exactly this risk could be effectively and entirely prevented, I have identified a number of regulations that appear inconsistent with conditions described.

That's all for now, and

Stay safe sailors!

OSH Act of 1970 Sec. 5. Duties

The workplace and employment should be free of hazards that are known to cause serious physical harm or death

Whaling is described as ‘perilous’. That is not a workplace free of hazards.

1910.22 Walking-working surfaces

All walking-working surfaces must be maintained free of hazards, and any hazard must be immediately corrected, or else employees should be prevented from using this surface.

The boom of the ship is swinging uncontrollably and dangerously, despite this being a surface used by many employees.

1917.95 Other protective measures

Anyone who has a reasonable chance of being knocked into the water while working should be given a PFD and instructed to wear it, and life rings should also be present, depending on the size of the boat. The PFD must also be approved by the US Coast Guard and maintained in good condition

The small boat is rocking dramatically, and later someone is easily knocked overboard by the boom of the ship. As the only description we get of anyone’s outfit is Queequeg being shirtless, it is reasonable to assume that no one has a PFD and there are no life rings to be used, despite someone being knocked overboard. I am considering this regulation to account for personal protective equipment as it is more specific than the regulation for general industry.

1917.112 Guarding of edges

If there is a risk of falling more than 4 feet, there must be a guardrail or safety net in good condition

Again, someone has fallen overboard and there is no railing or other measure in place to prevent this. While a similar regulation for fall protection also exists under general industry guidelines, the regulation in the maritime section is somewhat more relevant, and including both would be redundant

1917.151 Machine guarding

Rotating parts that are 7 feet or less above working surfaces must be guarded to prevent them from hitting an employee. This can include railings, covers or by preventing employees from walking in the path of the hazard

While I have no idea if and how this could be practically achieved, there is a large swinging and rotating piece of the boat that is moving around many employees out of control, and measures must be taken to prevent it from coming into contact with an employee.

30 notes

·

View notes

Text

What Is HSE (Health, Safety and Environment)

HSE (Health, Safety and Environment) is said to be an umbrella term for the laws, rules, guidance and processes designed to help protect employees, the public and the environment from harm.

It involves creating organized efforts and procedures for identifying workplace hazards and reducing accidents and exposure to harmful situations and substances. It also includes training of personnel in accident prevention, accident response, emergency preparedness, and use of protective clothing and equipment. #OHS #Health and safety #OSH

4 notes

·

View notes

Text

An international standard for OSH management systems that offers workable solutions for employee safety is ISO 45001. For all industries and worldwide supply chains, it can assist in establishing a foundation of worker safety standards and inspections that apply to contractors and subcontractors in every nation who provide goods to these supply chains.

The Reasons Why Small Businesses Consider ISO 45001 Certification The globally accepted Occupational Health Safety Management Systems (OHSMS) standard, ISO 45001, offers a methodical framework for controlling workplace safety hazards. Although being frequently linked to huge corporations, ISO 45001 certification has substantial advantages for small businesses.

#iso 45001#iso 45001 certification#iso 45001 training#iso 45001 awareness training#iso 45001 awareness training online

0 notes

Text

Understanding the Factories Act in India: A Comprehensive Guide

The Factories Act is one of India’s most pivotal labour laws, introduced to ensure the health, safety, welfare, and working conditions of workers employed in factories. Initially enacted in 1948, it has undergone various amendments to adapt to the evolving industrial landscape and labour requirements. Let’s delve into the key aspects of the Factories Act and its significance in modern India.

What is the Factories Act, 1948?

The Factories Act, 1948, is a central legislation that regulates working conditions in factories across India. It defines a “factory” as a premises where ten or more workers are employed with the aid of power, or twenty or more workers are employed without the aid of power, and work is carried out in connection with manufacturing processes.

Objectives of the Act

The primary goals of the Factories Act are:

To ensure adequate safety measures for workers.

To promote the health and welfare of workers.

To regulate working hours and conditions to prevent exploitation.

To safeguard workers against hazardous processes and unsafe working environments.

Key Provisions of the Factories Act, 1948

1. Health Provisions

The Act emphasizes maintaining a healthy workplace by mandating:

Cleanliness and hygiene.

Disposal of waste and effluents.

Proper ventilation and temperature control.

Availability of drinking water, lighting, and sanitation.

2. Safety Measures

To prevent workplace accidents, the Act includes:

Installation of safe machinery and protective gear.

Periodic maintenance and testing of equipment.

Fencing of dangerous parts of machinery.

Training for workers on handling hazardous substances.

3. Welfare Measures

The Act ensures worker welfare by mandating:

Adequate facilities for washing and storing clothing.

Canteens in factories employing more than 250 workers.

First aid facilities and welfare officers.

4. Working Hours and Leave

The Act regulates:

A maximum of 48 working hours per week.

Prohibition of overtime exceeding certain limits.

Mandatory weekly holidays and annual leave with wages.

5. Employment of Young Persons

The Act prohibits the employment of children below 14 years.

Adolescents (14-18 years) can work only after obtaining a certificate of fitness and under specific conditions.

6. Special Provisions for Women

Prohibition of night shifts for women (though this has been revised in some states under specific conditions).

Separate washrooms and crèches for factories employing more than 30 women workers.

The Role of State Governments

While the Factories Act is a central law, state governments have the authority to implement its provisions. They can also introduce rules and amendments to address specific local requirements. For instance, several states have revised the working hours or relaxed provisions for certain industries.

Recent Developments and Challenges

1. Impact of Labor Codes

The Factories Act, 1948, is set to be subsumed under the Occupational Safety, Health, and Working Conditions Code (OSH Code) introduced in 2020. This aims to simplify compliance and make labor laws more flexible for businesses while safeguarding workers' rights.

2. Balancing Automation and Employment

With the rise of automation and Industry 4.0, the Act needs to evolve to address challenges such as workforce displacement and the need for upskilling.

3. Health and Safety Concerns

The COVID-19 pandemic highlighted gaps in health and safety standards in many industries, emphasizing the need for stricter implementation of the Act’s provisions.

Significance of the Factories Act

The Factories Act remains a cornerstone of labour welfare in India. By ensuring a safe and conducive working environment, it not only protects workers but also enhances productivity and efficiency in industries. For employers, compliance with the Act fosters trust and minimizes legal risks.

Indian Factories Act 1948, has been instrumental in shaping industrial labour practices in India. As industries grow and evolve, it’s crucial for this legislation to keep pace with modern challenges, ensuring that worker welfare and industrial growth go hand in hand. Both employers and employees must understand their rights and responsibilities under the Act to create a fair and safe industrial ecosystem.

#FactoriesAct#IndianLabourLaws#WorkerRights#IndustrialSafety#FactoriesAct1948#LabourWelfare#WorkplaceSafety#EmployeeRights#IndustrialLaws#OSHCode#LabourLawReforms#FactoryCompliance#WorkplaceWellness#LabourStandards#SafeWorkplace

1 note

·

View note

Text

Building Succeeding Safely with a Manhattan OSHA Attorney

Understanding these regulations is crucial, but having a trusted Manhattan OSHA attorney by your side can make all the difference. In this blog post, we'll explore the pivotal role of OSHA compliance in construction, the invaluable support a Manhattan OSHA attorney provides, and how construction companies can benefit from their expertise.

The Importance of OSHA Compliance in Construction

OSHA compliance is a fundamental pillar in the construction industry. Construction sites are inherently hazardous environments, with workers exposed to risks such as falls, heavy machinery, and harmful substances. OSHA regulations exist to mitigate these dangers and ensure that safety is always a top priority. Non-compliance can lead to severe consequences, including costly fines, legal battles, and most importantly, the endangerment of workers' lives.

By adhering to OSHA standards, construction companies not only protect their employees but also foster a culture of safety that enhances overall productivity and project success.

Additionally, companies with a strong safety record often attract better talent and enjoy a positive reputation in the industry, giving them a competitive edge. It's also important to note that OSHA compliance is not a one-time effort but an ongoing commitment that requires regular updates and training to adapt to new standards and technologies.

The Role of a Manhattan OSHA Attorney

A Manhattan OSHA attorney is a legal expert specializing in OSHA regulations and construction law. These professionals play a crucial role in helping construction companies understand and adhere to OSHA standards. They provide invaluable insights into the legal landscape, helping businesses avoid costly mistakes and potential legal liabilities.

Whether it's conducting site inspections, reviewing safety protocols, or representing companies in legal proceedings, a Manhattan OSHA attorney is an indispensable asset for any construction firm.

Having a skilled attorney by your side not only minimizes legal risks but also helps protect your company's reputation and financial stability.

In addition to compliance, a Manhattan OSHA attorney is essential in navigating legal challenges that may arise. This includes representing companies during OSHA inspections, responding to citations, and negotiating settlements.

Having a skilled attorney by your side not only minimizes legal risks but also helps protect your company's reputation and financial stability.

The Process of Working with a Manhattan OSHA Attorney

Collaborating with a Manhattan OSHA attorney is a strategic move for construction companies committed to OSHA compliance. The process typically begins with an initial consultation, during which the attorney assesses the company's current safety practices and identifies areas for improvement. This initial assessment sets the foundation for developing a comprehensive compliance strategy tailored to the company's specific needs.

Once a compliance strategy is in place, the attorney works closely with the company to implement necessary changes. This may involve updating safety protocols, conducting employee training sessions, and establishing regular site inspections. The attorney also provides ongoing support, ensuring that the company's safety practices remain aligned with evolving OSHA regulations.

In the event of an OSHA inspection or citation, a Manhattan OSHA attorney plays a critical role in representing the company and resolving any legal issues. Their expertise in construction law and OSHA regulations ensures that the company is well-prepared to address any challenges that may arise and protect its interests.

Conclusion

In today's fast-paced construction industry, OSHA compliance is more important than ever. By understanding and adhering to OSHA regulations, construction companies can create safer work environments, minimize legal risks, and enhance their overall success.

A Manhattan OSHA attorney is an invaluable partner in this endeavor, providing the expertise and support needed to achieve compliance and protect your business.

0 notes

Text

The Complete Guide to Pursuing a Safety Diploma Course

In today's fast-paced industries, safety is a top priority. Whether in construction, manufacturing, or even office environments, ensuring the well-being of workers is crucial. For those aspiring to take on the responsibility of safeguarding workplaces, a Safety Diploma Course can be an excellent step toward becoming a certified safety professional.

What is a Safety Diploma Course?

A Safety Diploma Course is a specialized program designed to equip individuals with the knowledge and skills necessary to implement and manage safety protocols in various industries. These programs cover topics such as:

Risk assessment and hazard identification

Workplace health and safety regulations

Accident prevention strategies

Emergency preparedness and response

Safety management systems (SMS)

Industrial safety techniques

Why Pursue a Safety Diploma?

Career Advancement: Obtaining a diploma in safety management opens up opportunities to become a safety officer, safety auditor, or safety manager in diverse industries.

Industry Demand: Many industries are prioritizing safety and require certified professionals to lead safety initiatives, making it a growing field.

Legal Requirements: Some industries and countries require organizations to have certified safety personnel on-site, especially for high-risk operations.

Who Can Benefit from a Safety Diploma?

This course is ideal for:

Engineers (civil, mechanical, electrical) looking to transition into safety roles.

Professionals working in high-risk environments like construction, mining, oil and gas, etc.

Those aspiring to become safety officers, managers, or consultants.

What to Expect in a Safety Diploma Program?

Typically, a diploma program lasts 6 months to a year, depending on the institution and learning format (online or in-person). Expect to cover both theoretical concepts and practical applications. Key modules may include:

Introduction to Occupational Safety and Health (OSH)

Overview of global safety standards (OSHA, ISO)

Introduction to health and safety legislation

Industrial Safety

Fire safety

Electrical safety

Construction site safety

Environmental Safety

Waste management

Air and water pollution control

Risk Management and Emergency Planning

Risk assessment methodologies

Disaster management and preparedness

Safety Auditing and Compliance

Internal and external audits

Maintaining safety standards

Eligibility and Prerequisites

While some diploma programs may accept individuals with high school diplomas, others require a background in engineering or related fields. Working professionals often take these courses to enhance their qualifications.

Job Roles After Completing a Safety Diploma

After obtaining your diploma, here are some of the career opportunities you can explore:

Safety Officer

Safety Manager

HSE (Health, Safety, and Environment) Coordinator

Safety Consultant

Risk Assessment Specialist

Conclusion

A Safety Diploma Course not only enhances your career prospects but also contributes to a safer and more compliant working environment. Whether you're an experienced engineer or new to the safety field, this diploma can open doors to fulfilling roles in safety management.

Safety course in chennai

Safety course in madurai

Nebosh course in chennai

Nebosh course in madurai

0 notes

Text

Workplace Safety and Health in India: Navigating the New Labor Code.

Workplace safety and health have always been critical components of labor law, but the urgency surrounding these issues has only heightened in recent years. With India’s expanding industrial sectors and the advent of the COVID-19 pandemic, the spotlight has firmly turned to how businesses ensure safe working environments for their employees. Introducing the Occupational Safety, Health, and Working Conditions Code (OSH Code), 2020, is India’s most recent attempt to overhaul and modernize its approach to workplace safety. However, the new code has ignited debates on whether it balances worker protection and employer flexibility. The Importance of Workplace Safety and Health Workplace safety and health are not just legal obligations but are critical for sustaining a productive workforce. Unsafe working conditions can lead to accidents, illness, and even loss of life, as seen in numerous industrial tragedies in India’s past, such as the Bhopal Gas Tragedy and more recent accidents in manufacturing units. These incidents have underscored the need for stringent safety regulations to protect workers from hazardous conditions. In addition to preventing accidents, workplace safety measures are essential for promoting overall worker health and well-being. This includes ensuring workers have access to clean facilities, adequate breaks, proper ventilation, and protection from hazardous materials or practices. Healthy workers are more productive, reducing absenteeism and increasing overall business efficiency. The OSH Code: An Overview The Occupational Safety, Health, and Working Conditions Code, 2020, consolidates 13 existing labor laws related to workplace safety and health into a single, comprehensive legal framework. The code covers a wide range of industries, including manufacturing, mining, construction, and the gig economy, and aims to simplify compliance for businesses while enhancing safety standards. Some of the key features of the OSH Code include:

Uniform Standards: The code introduces uniform safety standards across various sectors, ensuring that all industries follow consistent guidelines regarding working hours, safety protocols, and employee facilities like drinking water, restrooms, and first aid.

Coverage Expansion: The OSH Code extends its applicability to smaller establishments, including those with 10 or more workers, and it covers both formal and informal sector workers, including gig and platform workers.

Health and Welfare Provisions: The code mandates the provision of health check-ups, clean drinking water, ventilation, lighting, and other necessary facilities to safeguard worker health. For certain industries, it require safety committees to monitor compliance with these health provisions.

Increased Penalties for Non-Compliance: The code significantly increases penalties for violations of safety regulations, aiming to deter businesses from neglecting worker safety. Repeat offenses can result in higher fines and even imprisonment of employers.

Worker Participation: Workers are given the right to raise concerns about safety and health issues without fear of retaliation. This provision is aimed at empowering employees to speak out when they notice unsafe practices at work. The Case for the OSH Code Proponents of the OSH Code argue that it is a much-needed reform to India's outdated and fragmented labor laws. By consolidating multiple acts into one comprehensive code, the government aims to reduce the complexity and confusion that businesses often face when navigating the legal landscape of workplace safety. Additionally, the introduction of uniform safety standards is seen as a step toward improving working conditions for millions of workers, particularly in industries like construction and manufacturing, which are often prone to accidents. The inclusion of informal and gig workers in the safety net is also seen as a progressive move, recognizing that these workers, who often operate in high-risk environments, deserve protection under the law. Concerns and Criticisms Despite its merits, the OSH Code has not been without criticism. Labor unions and worker advocacy groups have raised several concerns about its potential effectiveness and whether it will truly lead to safer workplaces.

Lack of Robust Enforcement Mechanisms: One of the biggest criticisms is the lack of strong enforcement provisions. While the code increases penalties for non-compliance, critics argue that without regular and stringent inspections, many businesses may continue to ignore safety regulations. The code gives inspectors the ability to conduct surprise inspections, but it also promotes a "self-certification" model for employers, which could lead to underreporting of violations.

Dilution of Worker Protections: Some labor advocates believe that the OSH Code weakens existing protections for workers. For instance, the requirement for employers to provide free annual health check-ups is limited to certain industries, leaving large numbers of workers, particularly in smaller establishments, without guaranteed health screenings.

Limited Coverage for Small Businesses: Although the code extends coverage to establishments with 10 or more workers, many small businesses, which often employ informal or temporary labor, fall below this threshold. As a result, a significant portion of the workforce may not benefit from the protections offered by the code.

Informal Sector and Gig Workers: While the code covers informal and gig workers on paper, ensuring that these workers receive the protections they are entitled to in practice remains a significant challenge. Gig workers, in particular, often work without clear contracts or stable working hours, making it difficult to monitor and enforce safety standards. The Impact of COVID-19 The COVID-19 pandemic has further highlighted the need for stronger workplace safety and health regulations. The sudden surge in infections among workers in various sectors, particularly in factories and construction sites, revealed gaps in safety protocols and hygiene standards. The pandemic has pushed the government to rethink occupational safety in the context of public health, especially for essential and frontline workers. Under the OSH Code, employers are required to provide adequate health facilities, including medical insurance, which has become even more relevant in the post-pandemic world. However, the pandemic has also shown the difficulties of enforcing safety measures in densely populated workspaces and informal employment settings. The Road Ahead: Ensuring Effective Implementation While the OSH Code presents a modernized framework for workplace safety and health, its success will largely depend on effective implementation and enforcement. To achieve its objectives, the following steps will be crucial:

Strengthening Inspections and Enforcement: The government must ensure that regular and independent inspections are conducted to monitor compliance with safety standards. Reducing reliance on self-certification and increasing the frequency of inspections could deter businesses from neglecting safety measures.

Awareness and Training Programs: Employers and workers alike need to be made aware of their rights and responsibilities under the OSH Code. The government should invest in training programs that educate both employers and employees about safety protocols, risk prevention, and emergency preparedness.

Inclusion of Small and Informal Businesses: Expanding the reach of the OSH Code to cover more small and informal businesses is critical. Additional incentives and support mechanisms could encourage small business owners to comply with safety standards, even if they operate with fewer than 10 workers.

Support for Gig and Platform Workers: Ensuring that gig and platform workers have access to health and safety protections is essential in the evolving world of work. The government should work with platforms to enforce safety guidelines and provide gig workers with health benefits and accident insurance.

#employment lawyer in india#employment lawyers#labour lawyers#labor lawyers#employment lawyer#employment lawyers in india#labor lawyer#labour lawyers in india#best employment lawyer#labor lawyers in india

0 notes

Text

Exemples of provisions addressing excessive heat.

Qatar: Ministerial Decision N°17

Belgium: Code du bien-etre au travail

Spain: Royal Decree Law 4/202358

#advocacy#workers#worker's health#worker's safety#climate health nexus#osh hazards#international labour organization#safeday#qatar#belgium#spain

0 notes

Text

The General Duty Clause

Section 5 of the OSH act of 1970, (aka "The General Duty Clause") establishes that:

"Each employer shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees"

This means that an employer's top responsibility is to maintain a workplace that poses no risk to the health and safety of their employees.

If an employee feels that their duties pose a hazard to their health and safety they have the right to refuse to perform those duties until the hazard has been addressed. The employee(s) are also legally protect from retaliation from their employer in such cases.

169 notes

·

View notes

Text

Chapter 19: The Prophet

Number of regulations violated: 1

There are no novel safety concerns introduced in this chapter, except for the vague threats and warnings offered to Ishmael and Queequeg. While mentions are again made of various unfortunate events faced by Ahab, there is not enough description of the circumstances surrounding any of this to point to a clear and avoidable cause, besides the overall task of whaling. All in all, this chapter just further presents the general danger of the profession.

That's all for now, and

Stay safe sailors!

OSH Act of 1970 Sec. 5. Duties

The workplace and employment should be free of hazards that are known to cause serious physical harm or death

As has been mentioned numerous times, the number of injuries experienced at sea is indicative of an unreasonable threat to employee safety

19 notes

·

View notes

Text

Occupational safety and health act 1970

On this page you will read detailed information about Occupational Safety and Health Act.

As a professional in your field, it is imperative that you have a comprehensive understanding of the Occupational Safety and Health Act and how it impacts your operations. This foundational law outlines the responsibilities you have as an employer to provide a workplace free from recognized hazards to keep your employees safe and healthy. In this article, we will provide an in-depth look at the key components of OSHA that you need to be aware of. You will learn the origins of the act, the scope of OSHA standards, enforcement policies, penalties for violations, and best practices for compliance. Having a working knowledge of OSHA requirements is vital for any business leader to avoid citations and ensure you are protecting your greatest assets – your people. Equipped with this guidance, you will be able to confidently evaluate your current safety programs and make adjustments to align with your duties under the act.

An Overview of the Occupational Safety and Health Act

The Occupational Safety and Health Act (OSH Act) was passed in 1970 to ensure safe and healthful working conditions for workers. It requires employers to provide a workplace free from serious hazards and follow all occupational safety and health standards.

Coverage

The OSH Act covers most private sector employers and their employees, as well as some public sector employers and employees in states that have OSHA-approved occupational safety and health plans. It does not cover self-employed individuals, farms with 10 or fewer employees, or government employees.

Responsibilities

Employers must comply with all applicable OSHA standards and provide a workplace free from serious hazards. They need to keep records of work-related injuries and illnesses, and report any incident that results in a fatality or the hospitalization of three or more employees.

Employees must comply with all occupational safety and health standards that apply to their own actions and conduct. They should report any workplace hazards to their employer.

OSHA enforces the OSH Act and investigates whistleblower complaints, workplace complaints, referrals, and severe injuries and illnesses. OSHA also provides compliance assistance and consultation services to help employers identify and fix hazards.

Key Provisions

The OSH Act contains provisions for standards, inspections, citations, and penalties. OSHA sets mandatory occupational safety and health standards for various hazards such as chemicals, noise, and asbestos exposure. OSHA conducts workplace inspections, and can issue citations and propose penalties if violations are found. Employers have the opportunity to contest any penalties.

The OSH Act is intended to “assure safe and healthful working conditions for working men and women; by authorizing enforcement of the standards developed under the Act; by assisting and encouraging the States in their efforts to assure safe and healthful working conditions; by providing for research, information, education, and training in the field of occupational safety and health.” By following the provisions of the OSH Act, the rates of workplace injuries, illnesses, and fatalities have declined over the years.

For complete information please visit :

https://lawforeverything.com/occupational-safety-and-health-act-1970/

0 notes

Text

Occupational health and safety (OHS) is the practice of preventing, regulating, and training to minimize workplace hazards, injuries, and illnesses that could affect workers' health and well-being (Occupational Safety and Health Administration, n.d). It is such an important part of a company's rule and regulatory measures because not only does it ensure public safety, it ensures employees that their place of work is a secure environment, free from hazards. Healthy workers in a safe and healthy environment creates decreased workers compensation costs, rescues medical costs, increases productivity, increases company morale and rescues turnover rates. The Occupational Safety and Health Act of 1970 (OSH Act) is administered by the Occupational Safety and Health Administration OSHA and is responsible for enforcing and administering the OHS. OSHA ensures safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education and assistance (Occupational Safety and Health Administration , n.d).

The National Institute for Occupational Safety and Health (NIOSH) is the United States federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. It delivers on the nation's promise of safety and health at a workplace using research and prevention through Centers for Disease Control and Prevention (CDC) (2024).

About Osha. Occupational Safety and Health Administration. (n.d.-a). https://www.osha.gov/aboutosha#:~:text=With%20the%20Occupational%20Safety%20and,%2C%20outreach%2C%20education%20and%20assistance.

Wikimedia Foundation. (2024b, February 19). National Institute for Occupational Safety and Health. Wikipedia. https://en.wikipedia.org/wiki/National_Institute_for_Occupational_Safety_and_Health#:~:text=August%202023),Division%20of%20Industrial%20Hygiene

0 notes

Text

Bolstering Workplace Safety: Grasp ISO 45001 Certification in USA

/ Uncategorized / By Factocert Mysore

Grasp ISO 45001 Certification in USA

ISO 45001 Certification in USA, ensuring administrative center protection is a problem for corporations at some point in industries. ISO 45001 Certification in USA offers a robust framework for installing area, imposing, and retaining effective occupational health and safety management structures (OHSMS).

Developed through the use of the way of using the International Organization for Standardization (ISO), ISO 45001 Certification in USA hobbies to decrease occupational risks, save you artwork-related injuries and ailments and sell a way of life of protection. This article explores the significance of ISO 45001 certification in USA, its benefits, and the complete machine involved in acquiring certification.

Effectiveness of ISO 45001 Certification in USA:

Enhanced Workplace Safety Culture:

ISO 45001 Certification in USA performs a critical function in fostering a lifestyle of safety and fitness in American offices. Certified businesses prioritize identifying, evaluating, and controlling occupational dangers, selling extra stable painting practices and behaviours among employees.

Deduction of workplace incidents:

Implementing ISO 45001 necessities allows groups in the USA to lessen the frequency and severity of place-of-job incidents, injuries, and ailments. Certified agencies put into effect proactive measures to put off or mitigate dangers, growing extra robust working environments for personnel.

Compliance with Legal Requirements:

ISO 45001 Certification in USA guarantees compliance with occupational health and safety jail guidelines, pointers, and necessities within the USA. Certified agencies adhere to crook necessities, which include the Occupational Safety and Health (OSH) Act, guidelines on place of work safety, and relevant U.S. Of America-unique prison recommendations.

Improved Employee Well-being and Productivity:

ISO 45001 Certification in USA contributes to the overall well-being and productiveness of personnel inside the USA. Certified groups prioritize worker fitness and protection, which are most critical to decreasing absenteeism, advanced morale, and higher ranges of productivity and mission delight.

Enhancing Corporate Reputation:

ISO 45001 Certification in USA complements the company’s popularity and credibility of corporations within the USA. Certification demonstrates willpower to protect the health and safety of employees, contractors, and stakeholders, fostering obtain as actual with and self guarantee amongst customers, partners, and the network.

ISO 45001 Certification Process:

Leadership and commitment:

Top manipulative willpower is crucial for fulfilling and implementing ISO 45001 necessities. Leadership gives route, allocates resources, and communicates the significance of occupational fitness and safety to all degrees of the monetary agency organization.

Hazard Identification and Risk Assessment:

Conduct an in-depth chance identification and hazard assessment to emerge aware of the place of business risks, determine dangers, and prioritize management measures. Involve personnel in the chance assessment way to leverage their information and experience.

Development of OHSMS Documentation:

Develop and report an occupational fitness and safety control device (OHSMS) aligned with ISO 45001 necessities. This consists of suggestions, techniques, threat tests, emergency reaction plans, and facts about education and competency.

Implementation of control measures:

Implement and manage measures to dispose of or mitigate identified risks in the workplace. This also can contain engineering controls, administrative controls, personal defensive devices (PPE), and sturdy artwork practices to lessen the risk of accidents and illnesses.

Employee Training and Awareness:

Provide entire education and popularity packages to employees at any respect level to ensure understanding of occupational fitness and protection tips, strategies, and practices—training personnel on danger reputation, emergency response, and using shielding tools.

Internal Audits and Management Reviews:

Conduct normal internal audits of the OHSMS to assess compliance with ISO 45001 requirements, become aware of regions for improvement, and confirm the effectiveness of manipulation measures. Review OHSMS’ usual overall performance, dreams, and goals at a few unspecified times in future manipulation evaluation meetings.

Selection of a Certification Body:

Choose an authorized certification body with facts about ISO 45001 Certification in USA requirements and occupational health and safety manipulation. Select a certification body identified via international accreditation for the outdoor certification audit.

External Certification Audit:

Engage the chosen certification body to perform the OHSMS out-of-door certification audit. The audit approach consists of record assessment, internet site online inspections, interviews with employees, and assessment of compliance with ISO 45001 Certification in USA necessities.

Certification Decision and Surveillance Audits:

Upon fulfillment of the final touch of the certification audit, the certification frame troubles the ISO 45001 certificate, which is legitimate for a specific period (normally 3 years). Surveillance audits are executed periodically to ensure ongoing compliance and effectiveness of the OHSMS.

Benefits of ISO 45001 Certification for U.S. Organizations:

Improved workplace safety and health:

ISO 45001 Certification in USA allows companies inside the USA to beautify workplace protection and fitness practices, lowering the chance of incidents, injuries, and ailments among employees.

Legal Compliance and Risk Management:

ISO 45001 Certification in USA guarantees compliance with occupational health and safety criminal pointers, recommendations, and requirements, lowering the danger of criminal liabilities and consequences for non-compliance.

Enhancing Employee Well-being and Productivity:

Implementing ISO 45001 requirements contributes to personnel’s overall well-being and productiveness, primarily to reduced absenteeism, improved morale, and higher task pleasure and engagement.

Corporate Reputation and Stakeholder Confidence:

ISO 45001 certification enhances the corporation’s reputation and stakeholder self-belief in organizations within the USA, demonstrating the willpower to protect the fitness and safety of personnel and stakeholders.

Competitive Advantage and Market Differentiation:

ISO 45001 Certification in USA serves as a competitive differentiator, putting certified corporations aside from their competitors and demonstrating self-control to excellence in workplace protection and fitness.

Conclusion:

ISO 45001 certification is instrumental in advancing job safety and fitness practices, fostering safe lifestyles, and protecting the proper being of personnel within the USA. By imposing ISO 45001 Certification in USA necessities and obtaining certification, American businesses can mitigate occupational risks, lessen place-of-job incidents, and beautify the organization’s reputation and stakeholder self-guarantee.

The certification approach requires managing dedication, employee involvement, and ongoing power of the mind to occupational health and protection. However, the benefits always outweigh the demanding conditions. With ISO 45001 Certification in USA, corporations in the USA can create extra strong, more wholesome, and more powerful offices, contributing to sustainable growth and development inside the U.S.

For more information visit : ISO 45001 Certification in USA

Related Links :

ISO 14001 Certification in USA

ISO 9001 Certification in USA

ISO 27001 Certification in USA

ISO 22000 Certification in USAISO 13485 Certification in USA

0 notes

Text

Obtaining a Competitive Edge: ISO 45001 Certification for Saudi Businesses

/ Uncategorized / By Factocert Mysore

ISO 45001 Certification in Saudi Arabia

ISO 45001 Certification in Saudi Arabia Occupational Health & Safety Management Systems are the topic of the broadly accepted ISO 45001. ISO 45001 Certification in Saudi Arabia gives corporations a framework for identifying and handling health and safety risks. It decreases workplace injuries and enhances general appropriateness for stakeholders and personnel.

The worldwide ISO Certification in Saudi Arabia standard for Occupational Health and Safety Management Systems (OHSMS) is ISO 45001, which replaces OHSAS 18001.

By offering a framework to enhance employee safety, lower administrative center risks, and create higher, more secure operating conditions globally, ISO 45001 for occupational fitness and protection control structures will help businesses lessen this burden.

You may ensure that your fitness and protection controls are in keeping with the organizational method by obtaining ISO 45001 CERTIFICATION IN SAUDI ARABIA.

The primary adjustments to the norm center on:

Context of the organisation

Understanding the needs and expectations of the employee and different interested events

Leadership, a way of life and commitment

Rules pertaining to the employer’s fashionable strategic dreams and route

Participation and the session

Risk and opportunities

Performance evaluation

Evaluation of compliance

Management overview

What is the number one goal of ISO 45001 certification in Saudi Arabia?

A workable method for improving the safety and health of both employees and others is the global general ISO 45001 Certification in Saudi Arabia for Occupational Health and Safety Management Systems. No matter the scale, type, or nature of the agency, it is capable of implementing this ISO 45001 trendy.

How should ISO 45001 be applied at work?

A SIX-step motion plan for protection control in line with ISO 45001.

Become familiar with ISO 45001 Certification in Saudi Arabia and OSH Management Systems.

Check Your Current System.

Engage the stakeholders.

Prioritize your efforts and set your dreams.

Develop or Upgrade Your OSH Management System.

Select the appropriate safety control system.

What is needed for ISO 45001 certification in Saudi Arabia?

The fundamental steps to becoming ISO 45001 Certification in Saudi Arabia licensed are as follows:

Create and put into practice a control device compliant with ISO 45001Certification in Saudi Arabia.

Plan an audit with a recognized Third Anniversary.

To ensure compliance, an auditor will determine your implementation and strategies.

Benefits of ISO 45001 certification in Saudi Arabia

An Effective Health & Safety Management gadget can offer benefits to your clients & give you competitive advantages by:

Reduced working charges

Saving cash comes from a reduction in lost time from injuries and contamination. It also comes from cheaper legal and reimbursement charges, and fewer days off because of downtime.

Improved stakeholder relationships

People will respond if you prioritize protecting the safety and assets of your employees, clients, and providers.

Legal compliance

Know how criminal and regulatory policies affect your business and customers.

Improved threat control

In order to reduce hazard as low as possible and protect both personnel and clients, discover probable injuries and put controls and safeguards in the area.

Proven business authorizations

Independent validation of a large-scale trend says it all.

Customer pleasure and safety

Fulfill customer wishes while protecting their property and belongings.

Why Factocert for ISO 45001 Certification in Saudi Arabia

We provide the best ISO consultants Who are knowledgeable and provide the best solution. And to know how to get ISO certification. Kindly reach us at [email protected]. work according to ISO standards and help organizations implement ISO certification in India with proper documentation.

For more information, visit ISO 45001 Certification in Saudi Arabia.

Related links:

· ISO certification in Saudi Arabia

· ISO 9001 certification in Saudi Arabia

· ISO 14001 certification in Saudi Arabia

· ISO 45001 certification in Saudi Arabia

· ISO 27001 certification in Saudi Arabia

· ISO 22000 certification in Saudi Arabia

Related Articles

ISO Consultant in Saudi Arabia

0 notes