#oor layouts

Explore tagged Tumblr posts

Note

No real theme oor aesthetic other than critters / bugs , and yeah I meant layouts, sorry 😭 -prev anon

Posted! Hope you like beetles!

1 note

·

View note

Text

🕳️ 𝐃𝐎𝐍'𝐓 𝐑𝐄𝐏𝐎𝐒𝐓 :: ikon & one ok rock layouts.

like/reblog if u save or use ♥︎ nctbz on pinterest.

— one ok rock toru's icon ©

#nctbzies ikon#nctbzies oor#ikon layouts#one ok rock layouts#oor layouts#ikon icons#one ok rock icons#oor icons#ikon aesthetic#one ok rock aesthetic#oor aesthetic#ikon moodboard#one ok rock moodboard#oor moodboard#ikon lockscreen#one ok rock lockscreen#oor lockscreen#ikon#one ok rock#oor#jrock layouts#jrock icons#kpop layouts#kpop icons

104 notes

·

View notes

Text

Taka's smile please ㅠㅠㅠㅠㅠㅠㅠㅠㅠㅠㅠ

(Source: ONE OK ROCK - Making of Renegades #3)

#edit by me#taka#takahiro moriuchi#takahiro#taka moriuchi#oor#one ok rock#black and white#art#boys#music#asian#japanese#renegades#bands#rock#rock band#header#twitter layout#layout#toru yamashita#ryota kohama#tomoya kanki

58 notes

·

View notes

Text

have you watched the stream last night? — taka was amazing as always, ryota’s bass solos is giving me life, toru’s speaking voice is too much for my heart, tomo’s drum solo was a tease and last but not the least, the collab between masato, mah, koie and taka 😩 jesus, that was EPIC!

#oneokrock#icons#oorheaders#takamoriuchi#toruyamashita#ryotakohama#tomoyakanki#oor#jrock#rock#layout#oorjapan#oneokrockjapan#ambitionstour#japandometour

4 notes

·

View notes

Text

Bought myself a treat with Christmas money. An Italian Lima BR Class 37, special edition "Oor Wullie". Apparently it was a limited run? So thats cool. Dug out some EZ track and my other British stuff and set up a little temporary loop undet the kitchen table to test it with. Wish I had more space to set up a more permanent layout, without our kitties getting in the way.

Tuxedo kitty is named Carrot

#Train#Track#locomotive#railroad#railway#modeling#models#model railway#british railways#BR#Class 28#Class 08#oor wullie#Lima#rails#vintage#train#Bachmann

11 notes

·

View notes

Text

Week evaluation 11-01-21 to 15-01-21

This week I have completed my 1 day project - pangram grid and I drew some new type designs using shapes. I also presented something interesting about my project on the call meeting we had, I went on the talk suggested by the tourtor, I have updated my tumblr writing why my research links to my theme and project and to also wrote about what I wanted to achieve during that part of the project. I also just completed the small task of presentation for contextual studies, annualised and deconstruct some typefaces

I do still have a few things that i want to do which I need to do some research on what companies i like in graphics design for manuals lesson on monday, I need to write up about the call that I took notes of, I need to look at some slack research to see if any I like I need to include my sketchbook or get some ideas from. I want to try get the magazine complete during the weekend so I can try and focus on my type and manuel project.

I think I should be on set for all my deadline might need to do some extra hours just to catch up abit.

I don't think I need to make any changes to my project plan.

I have identified the risks of undertaking work and that for me was not getting exercise or not taking another work. I have started working out with my dad for at least 20 minutes every day I make sure to take an one hour break during my lunch and dinner and to take some small 10 minute breaks in between. I've also had to join some council and the council reps which I have had to stop work to talk to.

I don't think I have any risks in my project plan

The challenges I faced is to digitise my sketchbook which I found really weird but I have overcome this by just carrying on traditionally and then take photos of the sketchbook and then write about that in my tumblr account. It is a bit difficult to keep up with my time management but to overcome this I have made sure to write notes during all the lesson and then by them notes ticked of what I have done and haven't done.

I don't really feel that there are any risks to development work. The issues with it is you could possibly have one idea planned and developed but not work and then you would have to start the whole process again if you did get another idea.

My work justifies my change in direction because the research have all linked to my good vs evil theme and within them small research bubbles i research a little bit further to get more ideas oor to try some different ways of how the type could look or what I should add ect. Some of my research have also allowed me to see the type in a poster layout how it should be used which allows me to see if it should be changed, is it easy to read, does it make sense and does it look nice for the audience.

I have learned how to keep up with my time management a bit more because I now have three project at the same time and need to keep a tight schedule of when I do something and what. This will help me in the future because as a graphic designer I will have to take multiple briefs so by taking them now and trying to juggle now I will have better knowledge of how to deal with constraints of time and deadlines.

How I deal with my challenges and problems is I would probably say head on, I will, ask peers for and suggestion, or if I don't understand something I make sure to ask etc.

To improve for this project I think if I was told a bit earlier the deadline would be pushed back I wouldn't of rushed so much with getting the type finished and now i'm at a weird stage of done but still not done.

I think what aspect of work I am protising is the experimenting part of my project and the development at the moment trying to better the type I have and maybe even find a better one.

I feel like my work shows my achievement of the learning outcomes because I have experimented with all or at least have some drawing of how I want it done the only learning outcome I haven't looked at as so far is the portfolio pages but that's because I need all my work done to even approach that. I could look at some portfolio layout though while I try to finnish my work for the portfolio.

What I will be doing for next week is to finnish up the magazine before friday, I want to mess with the weight of my type and deconstruct the mistakes it has, I will also include picture of my deconstructed type in my tumblr, i'll make sure to include class work also that we get given. I'm also going to make sure my project plan is updated. put some of the slack research I did into my book, write about the call I went into about type.

2 notes

·

View notes

Text

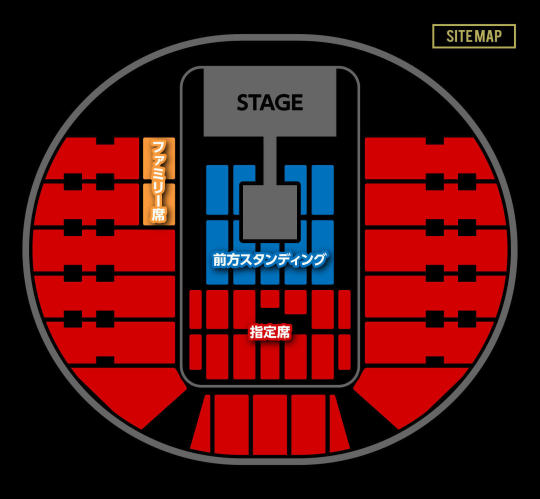

MY FIRST STORY & Saitama Super Arena capacity

I received this question on Twitter regarding the attendance at MFS TamaAri Tour Final. I think it would be interesting to share with my readers especially for those who might aspire to enter the showbiz.

Disclaimer: Answers were based on my personal observations as a longtime music fan. Also, I used ONE OK ROCK as a comparison because that's what my readers are familiar with. Peace everyone 😊

Question:

So I just read that MFS TamaAri was 18000 tickets? Normally I know the venue has a much larger capacity, so why is that? Are they taking it safely? And do you know what’s more important to secure bigger venues? Is it to sold out or the number of tickets you had there? Just trying to understand if this was necessary to get to Tokyo Dome. It just kinda makes me sad because they deserve so much!

I always just assumed that it’s 37000, didn’t know there was two modes, any idea on what’s the difference and why they went with arena mode instead of stadium.

------------------------------

MFS held an “arena" tour NOT “stadium" tour

First of all, from the start, MFS had declared their Kobe World Hall & Saitama Super Arena dates as “ARENA Tour". They never said “stadium". So, it only made sense that they booked Saitama Super Arena in its arena mode.

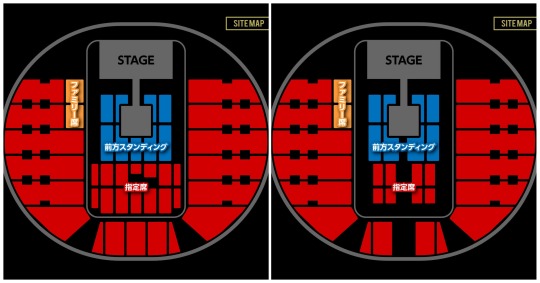

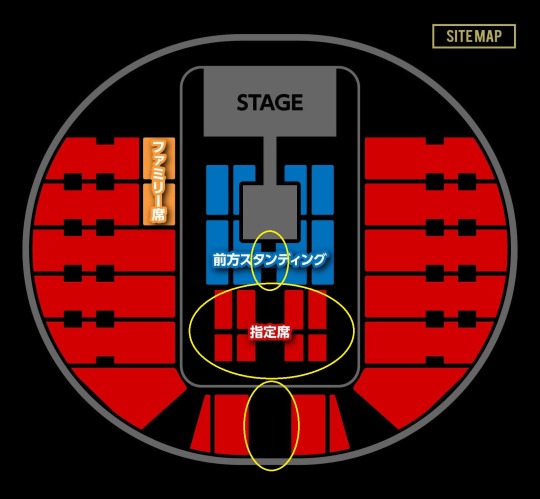

Based on MFS' proposed seating plan, they were honest from the start that they were NOT aiming for >30000 capacity. Just look at how small the space they allocated for standing spectators. The rest were all seated. They were pretty realistic about their crowd attracting capability & current limitations. They knew they were not OOR who could easily dedicate the entire floor area for standing spectators.

-----------------------------------------------------

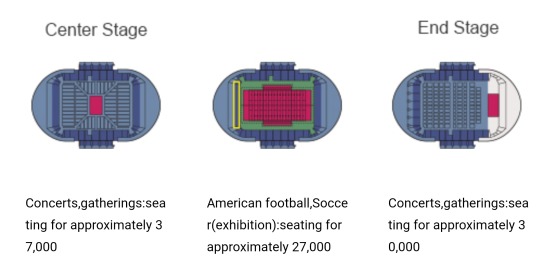

Saitama Super Arena was designed to be mechanically multi-sized to suit multiple purposes

Look at the “Stadium vs Arena” diagrams from the venue's official website.

Saitama Super Arena does have TWO modes i.e "stadium" and "arena". It is a multi-purpose venue which means it can be used for concerts, sports events, exhibitions, death memorials (if you want) etc. Thus, to serve the different functions, it was designed in such a manner.

What is meant with max capacity of 37000 pax is the entire fixed seats taken up PLUS the maximum additional seating that the floor area can take, which is more suited for sports events where a smaller space for the athletes/performers is needed e.g. boxing, wrestling etc. For sports such as soccer or baseball, the floor area obviously will not be used for seatings.

Stadium vs Arena configuration

Stadium = the full length space with seats all around facing the centre.

Arena = the space is partially blocked off reducing the seats & floor area.

Stadium Mode

Let's look at a typical concert stage end side configuration.

1. A chunk of the space is already taken up by the stage. Meaning the seated area behind the stage is already unusable for the spectators. Then, some artists have a runway or even multiple runways extending into the floor area. To my eyes, at least 1/4 or even 1/3 of the space is already reduced. Then, when you put designated seats on the arena floor, the number of people will be reduced even more because chairs take up more floor space per person than a free-standing area.

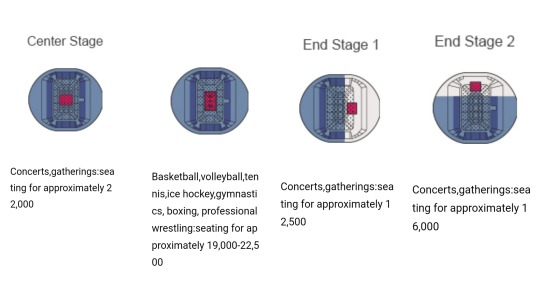

Arena Mode

How about centre stage configuration to maximize the viewing?

Here is an example of a centre stage from KOBUKURO LIVE TOUR 2015 at Saitama Super Arena. Even with this configuration and a more packed crowd than MY FIRST STORY, this only packed in 21000 spectators.

http://music.emtg.jp/liveReport/20150806213e27519

For safety reason, you can’t pack in more people than the officially declared maximum capacity

I'm not sure how the Law is in Japan or what legal obligations that the management of Saitama Super Arena needs to comply. However, generally, it concerns evacuating people safely and quickly in the case of fire or any disaster.

--------------------------------------------------

However, it looked like MFS didn't quite reach the number they were originally aiming for.

Got to be honest, there was a big block of unused seats at the end of the arena. The staff covered it with a huge piece of cloth. There was also some rather generous spaces around the floor seating area. They are not yet at OOR level who can easily attract >30000 crowd. But overall, it was good enough and not disastrous like the Shanghai show (unwise choice of venue that one... sorry my boys).

Photo by Taka Tallman

The difference of the Final outcome compared to the Original plan based on the official photo.

Why was it announced as "Sold Out"?

1. Logistics reason.

They needed to finalize the layout of the seatings and the number of chairs they actually needed. If they kept the ticket sales open to the performance day, it would be difficult for the staff to arrange the overall seated / standing areas. Notice how they often announced on-the-day tickets (toujitsuken) for their free standing Livehouse shows but not for Halls and Arenas. It's easy to squeeze in free standing audience as long as it is safe enough.

2. They very likely had already reached the sales target to cover the cost of the concert.

If you already sold out the quantity you needed to make profits, then it's not a lie to declare it that way. "Yeah, we sold out!". MFS is blessed to be an indie band because the money they earn mainly goes to them. Well, looking at the luxuries MFS members pampered themselves with (a huge rehearsal studio, holidays abroad, head-to-toe designer fashion etc), these guys made A LOT.

Despite playing to smaller crowds and playing less shows per year, MFS members are able to live comfortably at a more leisurely pace. Compare that to the major-label-and-talent-agency-tied OOR who certainly sell more in quantity but is being worked to death by their management with every Tour to make $$$!

3. In showbiz, image is everything.

Notice how once an actor won an Oscar, his publicity promo will always attach the term “Oscar winner (insert name)" with almost every appearance? Because it gives “value" to his name! Even if you only got nominated, being known as “Oscar-nominated actor" elevates your status.

It's the same with music artists. Saying “the band held a Sold-Out show at (insert a place)" gives “value" to your resume. The general public rarely ask the numbers or even question it.

Not only MFS, even OOR plays the same publicity game. For example, their Nagisaen show has always been hailed as attracting >100000 people. What is being downplayed is it was >100000 people over TWO days. Meaning >50000 pax per day and many of them actually went to BOTH days. But still, saying >100000 sounds better and it's not like they're lying. It's technically correct. So MFS saying, “Thank you. We sold out!" is technically true if they had passed their profit threshold. Anything extra is a bonus 😊.

Why still went for such a huge venue even though their fanbase still has not reached that level?

Just a basic management strategy no matter what field you’re in. Once you set a big target, you need to measure your achievement from time to time. They want to do Tokyo Dome. So, they need to see how far they can reach and what to plan to achieve it. With the Nippon Budokan, they knew that they could do 12000 pax. With Makuhari Messe and Yokohama Arena, they knew that 18000 figure was in their hands. With Saitama Super Arena, they very likely wanted to see if they could reach more than 20000. Now that MFS knew 20000 is a figure they need to still work on, they can plan from now what to do next. My prediction, there is a HUGE chance that the Tokyo Dome show would be fully or mostly seated.

What’s more important to secure bigger venues? Is it to be sold out or the number of tickets?

Strictly from the economic point of view, the number of tickets you can sell is more important. You'd want to earn enough to recoup your investment first & foremost. The venues don't care if your event is sold out or not. They just want their money. Being “sold out" is more for the artist's image.

Every artist has their own sales threshold of what they can call “sold out". MFS put limited standing tickets from the start which means they have a lower “sold out" threshold compared to a bigger band like OOR who allocates a lot more standing tickets.

The bigger your name, the higher the stake. I still remember when the late King of Pop Michael Jackson was deemed a failure for selling “only" around 45000 tickets for a stadium concert in the UK back in the late 90s.

So, was MFS playing it safe with Saitama Super Arena?

Nope.

On the contrary, they were daring themselves to take the risk in order to know where they are at. But hey, ANY indie artist in the world would KILL to have 18000 people per night. It’s awesome that MFS could reach that number as an independent band.

------------------------------------------------------

My 2 cents

Why did MFS struggle a bit to fill up Saitama Super Arena?

To me it still boils down to one thing. Their archrival ONE OK ROCK.

This had been the first time ever that MFS was doing a major Tour head to head against OOR. They even had a few clashing dates!

* (Remember that Summer Sonic Tokyo (MFS) vs Osaka (OOR) incident? A small crowd in Tokyo vs a packed crowd in Osaka?)

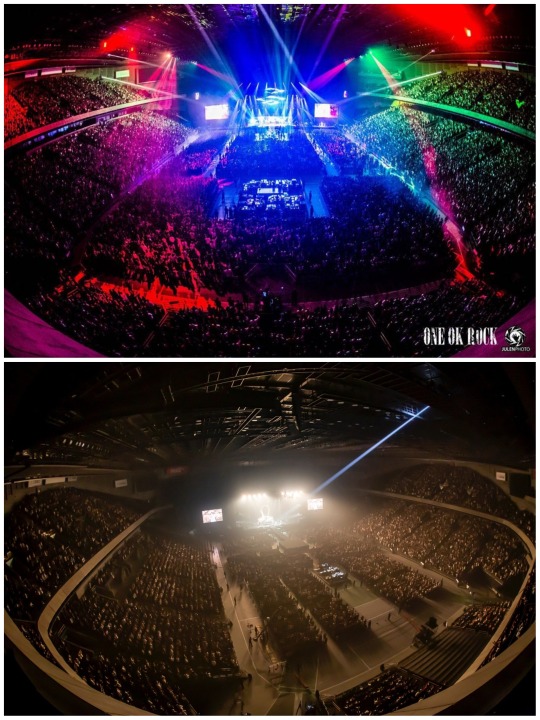

OOR by Julen Photo

For the most part, getting the majority of their fans from OOR fandom has been a huge blessing for MFS. But we must take note that many of them still keep OOR as their main band and thus, are more likely to spend their money on the OOR Tour instead. Not to mention that OOR ticket & merch prices are higher.

MFS hardcore fans are still way smaller and probably will never top OOR, which is fine to me (seriously, I don’t want MFS to compromise their music like OOR did 😑 ). However, I do believe that the day will come when MFS can attract 30000 crowd in one show but it will take more time for that to happen.

But comparing it to OOR, it wasn’t too bad even though it is still a long way to go :-)

Someday MFS will be able to pack in fully standing crowds on the floor 😃 !

What MFS needs to do?

1. Keep on with their current strategy of reaching out and expanding to fans outside of the OOR crowd. Keep on collaborating, guys!

2. I personally hope that the little darling Hiroki can continue being careful with anything that comes out of his mouth so as not to make another faux pas e.g that misunderstood MC at Summer Sonic (OOR fans accused him of jealousy towards Taka again because of it... oops 🙈), that "kiddy tantrum" at Storyteller Tour Osaka (your warped sense of humour may not necessarily work outside of your band & crew, Hiro 😑). Watching him in the later part of 2019, I do feel Hiro had learned a bit from it all though.

3. Continue strengthening the bond with the existing fans. It’s important to cherish their loyalty. I had talked before about the benefit of keeping your core fans. Thankfully, MFS is doing it right in this area. Bringing awareness to ALS, dedicating their songs to special selected fans and helping in realizing their dreams. After all, support is a two-way street.

4. Connecting with the younger crowd like they did during the ALONE era with the “university tour” might be a good idea too 🤔. I still remember photos of the members walking through the crowd among the stalls at students’ fairs 😃. That was an exciting time 😊

-----------------------------------------------

So, what do you all think 😃?

17 notes

·

View notes

Text

Online quizzes

Sooo. I spent wayy too much time researching different quizzes, and tbh, they were all pretty bunk. Silver lining, I found out that I am not a sociopath, I am indeed heterosexual and my knowledge of horror movies, Futurama, and Greek mythology is superb af 💥.

However none of these quizzes really seemed to have any umph or memorable qualities to them whatsoever. Nor were they in any way challenging or anything either. Finally I stumbled across one random quiz via BuzzFeed which actually seemed somewhat interesting. Not gonna lie, it was still super dumb and I wouldn’t recommend this 5 minute waste of time to anyone. But, in essence, the quiz made subtle changes to common logos such as Google, Pepsi, Microsoft and other household titles whom’s marks have seen countless times by the average American. The quiz is aptly titled, “Can you get 18/24 on this ultimate logo quiz.” Spoiler alert, yes. You definitely can. It’s really not that hard. Also, it’s 24 questions on a buzzfeed article. There’s nothing “Ultimate” about it. Like, why not just call it a logo quiz.. Wtf makes it so “ultimate?”

Anyways. The purpose of this quiz is basically just to waste time and see if you can random subtleties within corporate logos. Like how many white lines intersect the IBM logo, or if the color pattern of the letters in Google goes blue, yellow, red, blue, green, yellow or rather, blue, red, yellow, blue, green, red. I honestly don’t know the intended target market here is. But just a quick glance at the comments below and because it’s a Buzzfeed article, it’s probably directed mostly towards an American millennial crowd. Although it does seem like something old people might do with their time on the internet too.

The prime reason this snagged my attention is my interest in logos and on graphic design. I sorta wanted to test myself to see if I could indeed catch the little nuances and designer decisions that make the logo work in an effective and memorable way. It was interesting and I was actually legit surprised on how challenging some of them were and by the fact that I actually did get two wrong. My bad on not remembering what side the stripes go in Colonel Sanders’ apron or that IBM has a stupid amount of lines striking thru it’s letters.

There are a few things I would change about the nature and layout of the quiz. First of all the name is stupid. They didn’t gain any additional clicks by calling it “ultimate” or inviting users with a challenge like “can you get 18 out of 24.” 18 out of 24 doesn’t have a catchy ring to it. Also, 18/24 is 75%. When the hell has 75% been bragging rights about anything? Nonetheless 75% sounds better than 18/24. Secondly, the ads are obnoxious. Like all over the place and really destroys the essence of the intended layout. And on the note of layout, it just seems like it would be more effective of a quiz if each question took you to a follow up page all of which, being time-sensitive. Otherwise, what’s to keep the user from opening a new tab and just typing Pepsi logo real quick oor closing the browser to inspect the Instagram and Twitter icons on their dashboard. Seems like there’s gotta be some way to make it a little more cheat-proof. I was however impressed by the curator/designer’s choice on logos and the changes made to make the quiz a legit challenge. And it was interesting to look at two seemingly identical images, but one of em just seeming “off” for some reason. All bout them little details I suppose. 😎

1 note

·

View note

Text

Video Editing Software & Apps: The 14 Best for Any Budget or Skill Level

We all know the future is video.

Whether you have fancy lights and a camera that costs more than a car, or you have your iPhone taped to a broom, you know you have to come up with the best you possibly can to keep your audience engaged.

I’m not going to pretend that all media is created equally.

If you’re filming on an R3D, your interview or commercial will look better than if you just have a GoPro, but it’s not all in the capturing of the footage.

Arguably most of the creative storytelling comes from the post-production stage.

I mean, we’ve seen short films recorded on a handheld camcorder that probably cost $100 make it into Sundance. What I’m saying is, it’s about content and storytelling more than it is pixel count for most people.

Like with all content, with video, you really want to put your best foot forward. Showing the world a cohesive, stylized vision can help sell your brand the way you want to. Conversely, showing the world a haphazard video can lower viewer’s confidence and opinion of your brand.

But how do you make that story? How do you take the raw footage you have and turn into something that people will talk about and share? Especially as a marketer who may be new to video?

There are a lot of editing programs and tools out there for a variety of budgets and skill levels. If you know your way around an editing suite, great. If not, don’t worry. The internet is full of tutorials and easy-to-use programs.

Learn how to start differentiating your brand from the competition by telling a remarkable story that resonates with your audience.

Free (& Nearly Free) Video Editing Software & Apps for Beginners

If you've never edited a video before, don't panic. There are plenty of free and paid video editing options on the market that are easy to use.

1. VSDC

This free program provides a lot of bang for no buck. So, if you’re a beginner, it’s a pretty good place to start.

Included in the program are somewhat advanced options like blend overlays, and the options to mask and key. You can also control the speed of the clips as well as add filters transitions.

If your brand is looking to get cinematic and try out some green screen footage, this might be a good program to start with and with its free filters, it would also be a good option for social media videos.

Some reviews say it’s not exactly user-friendly, and it does have its quirks, but if you’re looking to try out editing and don’t want to put any money behind it, there’s really no downside.

Price: Free!

2. iMovie

iMovie is a quick and easy way to edit videos for beginners.

There are a ton of templates which makes this the ideal software for quick turnaround projects and the transitions and animated titles give your production a little extra flare with almost no effort. It’s also good for just quick clip cutting and cobbling together something simple.

Marketers would find this useful for quick culture videos on social media or those that only need basic cuts and fades. If you’re new to video editing and intrigued by the idea of templates, I would steer clear of these when it comes to crucial sales videos or those on your website.

As iMovie is a popular tool among general consumers, using them could be seen as unprofessional or low-budget.

Aside from that word of caution, the only really annoying thing to note is you can’t transfer project files which has hurt me with a client before.

Price: Free (But only available on Macs)

3. Shotcut

Now, this free program is easy to use once you get a hang of the UI.

It has good video and audio filters, making it a good choice for posting to social, but it has a limited amount of preset export formats.

Knowing the destination of your final export is important for quality. If you’re focusing heavily on YouTube or Facebook Marketing, you may not want to use this tool until you’re more familiar with the settings best used for each platform.

There also doesn’t seem to be a huge support community for questions, which can be tough for newcomers.

Price: Free

4. Magisto

Magisto is basically automatic editing.

You can select your own music or use one of their suggested tracks, and it’ll put something together for you assuming you don’t need to trim anything out in the app.

This automation is cool and efficient if you need a video quickly, but it does limit creativity as there’s not way to control the order of the images you put in there.

There’s also a time limit for the length of your video with each budget. Still, it’s a fun way to put something quick together if you’re looking to post mostly to social. It’s especially great to use on mobile.

Price: Best value is their $9.99/month Professional Plan

5. Adobe Premiere Clip

Edit on-the-go with this free app!

It has a clean interface, comes with background music, and has a good collection of filters.

You don’t need a paid Creative Cloud account for this, but if you have one, you can export what you started on your phone and finish it in Premiere, oOr, finish it on your phone and upload straight to social media.

This is ideal for the marketer who’s always on the move, but posts to social media frequently. Adobe is always the peak of professionalism so it will make your Instagram and Facebook videos really stand out.

Make sure you film in traditional, horizontal orientation though, because you can’t rotate your clip in this. There’s also no real templates or transitions, but it’s simple and fairly easy to use.

Price: Free

Advanced Video Editing Apps & Tools

Now, if you've dabbled in video editing before -- or you like to think of yourself as more of a video pro -- you probably want to dive right into video editing software that caters to the more seasoned marketer.

We are all for that, but not without a word of caution first.

Advanced tools may seem appealing to a beginner because you will get more "advanced" results. However, you should only take that step up in sophistication if you already have the skills in-house, or if you have a team member who is dedicated to learning the art of video editing.

In short, if you don't have advanced resources, don't pull in an advanced tool.

With that caveat in mind, here are a few of our favorite advanced video editing software options:

6. Adobe Premiere Pro

I won’t lie, I’m an Adobe girl myself.

I basically started out editing on this program and have rarely been disappointed in it.

This is an advanced editing software, and while it is possible to learn, if you’re looking for a quick turnaround, you might want to start somewhere else.

That being said, if your team needs to edit an interview for a customer testimonial or has the need for a lot of graphics, it’s very easy for this to be your only software and be more than enough.

The essential graphics panel gives you presets that you can fit to your needs, whether it be names and titles for your lower thirds, or an opening graphic for your video.

These features do a lot of the work for you and make you look professional and polished. If you create your videos with it, you can publish confidently on any platform, whether it be social, web, film, or even TV.

You can get all sorts of paid and free third-party plugins to help you along in your creative adventure too!

If you keep reading, you’ll find a few of my favorites, but these plugins can range anywhere from color correction presets to light flares. They add that extra glitz to your videos that will make people remember them.

As a subscription SaaS, Premiere also rolls out updates to make sure you’re getting the most out of your software at all times. Sometimes they are glitchy early on, but they are quickly resolved, and the community is always helping out with solutions.

Plus, with literally millions of subscribers, you can bet that their online support community is solid. Only once or twice have I been unable to fix a problem thanks to their very specific forums.

Overall, this software is amazing, but is not really geared towards those starting out, especially with it’s monthly subscription pricing model.

Price: If you have the skills or have time to invest to learn the software and $40 a month, or $20 if you’re a student (or $20 for just Premiere, and not the entire suite), it is definitely worth it.

7. Final Cut Pro

I learned on this one when I first started at film school. When I used it, it was basically iMovie’s older brother. It has that same layout feel, and ease of use to it, but with a lot more function.

It now supports 360 and HDR footage, includes Mac Touch Bar support, and has over 100 video and audio effects. It’s also good for color correction, but bear in mind, this all comes with a bit of learning curve. There are a limited amount of codecs and file types included which will limit what kinds of footage you can work with.

This is a program that can give you a more cinematic look and feel to your projects. If you want your brand to look professional and artistic, but don’t have a huge budget, this tool will definitely help.

This program is for a marketer on a budget that wants to get the most out of their videos, and isn’t afraid to get into the weeds with their editing.

Similar to Premiere, you can add third-party plugins as well.

However, honestly, I’d say if you’re serious about putting together professional marketing videos, are a Mac user, and don’t need the razzle-dazzle elements of Premiere, this is the best choice.

Price: For a flat rate of $300, you are also entitled to any updates they do for free.

8. PowerDirector

Now, for the price, PowerDirector is definitely the PC pick for me. It is extremely user-friendly, but you get advanced features like 360 footage editing, motion tracking, and keyframing and it supports 4K as well.

If you’re looking to create complex videos and have an editor willing to learn, this is the software for you.

It can be a little overwhelming for beginners, but there are tutorials out there. Users have also reported weak color matching, but if you keep your white balance in mind while shooting, you should be fine.

Price: There’s a 30-day trial version you can do before you go for either the $100 or $130 version.

9. Lightworks

This Mac and PC-friendly software is free and quite robust. It supports a wide range of video formats, allows you to make proxies, which let you edit huge video files at a lower resolution and replace before exporting, and has easy timeline editing.

This program is for marketers with their eye on their budget, looking to post mostly to social media sites mainly because the exports it offers align with what is optimal for those sites.

Although you can use it on Mac, users of the machines have reported it isn’t very Mac-friendly and that there’s a steep learning curve.

Price: Free (but the free version only allows you to export to 720p web resolution. You have to pay extra to get more.)

10. Sony Vegas Pro

Sony Vegas Pro is on the pricier side for sure, but you get the pro-editor features like motion tracking, HDR support, 360 footage support, video stabilization, speed control, masking, and good presets for color correction.

This is for a marketer who knows what they’re doing and wants a professional finished product, but also has the budget. If you’re going to spend the money, I suggest you already know how to use the best features of this program (or have someone on staff who does).

If you’re looking for a flat rate program that nearly stands up to Premiere, this is your guy.

Price: Another flat rate program, it’s yours in differing packages from $400-800. Only available for PC.

11. Blender

I love me some 3D animation and this software lets you do it!

You can get some truly amazing stuff out of this program, and there are tons of websites like Turbosquid to lend a hand in free and paid objects for you.

Whether it’s realistic 3D renders of under-construction real estate, or animated characters for an explainer video, there’s not much you can’t do with 3D animation.

Blender can help you add a little variety to your videos, and possibly add a lot of value if you get someone who becomes a pro. There’s also a ton of tutorials and online support, which you’ll need to get going since it’s a little quirky.

If you’re looking to get started with 3D editing, this is a good place to start.

Price: Free

12. Adobe After Effects

There’s so much you can do with this program. I’m obsessed with it, honestly.

Marketers will get the most out of this program if they’re looking to do advanced/custom motion graphics, a lot of motion tracking (for example, personalized videos for Vidyard), or animated explainer videos.

Like Premiere, it updates with new features every so often, the support community is amazing, and the tutorials are seemingly limitless. It also integrates with C4D, another 3D editing software, which comes with it for free.

There are also tons of amazing paid and free third party plugins. I mostly use it for motion graphics, but have been known to use the occasional green screen or even turn someone’s eyes into demon eyes for Halloween.

You can do almost anything you set your mind to in here. That being said, it’s not geared towards newbies, and it’s still that monthly Adobe rate instead of the flat fee.

Price: If you have the skills or have time to invest to learn the software and $40 a month, or $20 if you’re a student (or $20 for just After Effects, and not the entire suite), it is definitely worth it.

13. DaVinci Resolve

DaVinci Resolve offers full editing, but most of my editor friends that use this program don’t necessarily do their cutting in here. They do rely on it for color correction pretty heavily, however. It’s compatible with Final Cut, Avid, and Premiere so you can move the color correction or whatever you do between projects easily.

With a helpful community, you can find great info on color correction, motion tracking, and even noise reduction.

These functions can help bring your video to that Hollywood style color that you see in movies (with enough practice) for no cost.

It is a steep learning curve, and you really need two screens, especially if you want to color correct, but if you’re a detail oriented person, you’ll like this program.

Price: Free!

14. Avid Media Composer

This is the most sophisticated video editing software you’ll get for free.

It has a lot of high-end tools like speed control, color correction, and footage stabilization that can take your footage from looking merely amateur to pro pretty quickly.

If you’re looking for really technical controls to add some polish to your videos, but you don’t want to pay for it, try Avid.

It does have a steep learning curve, and the free version doesn't support 4K, or a lot of image formats.

Price: Free (or upgrade for more features starting at $19.99/month)

Editing Extras

Editing programs are all well and good, but sometimes you need or want a little extra sparkle.. These are like the sprinkles on a delicious donut - not necessary for the final product, but definitely make it look better.

Shutterstock

A great toolkit to have to start out with can be found here on Shutterstock.

They have a ton of animations, transitions, LUTs, and overlay elements for free. I personally love adding a little dust or some light leaks sometimes, and it can be hard to get those organically.

These are awesome for that extra touch for someone with no budget to make your videos pop.

It also comes with instructions on how to use it. It’s compatible with Premiere and Final Cut Pro.

Price: Free

Red Giant

I couldn’t resist putting this in here.

If you have a serious budget and a serious will to learn, you can have a lot of fun with Red Giant’s plugins.

I got to play around with their trapcode suite and things you can do with it are incredible. You can create volumetric light, smoke, snow, rain, or almost any other VFX you can imagine.

These plugins range in complexity. There are almost Hollywood level VFX you can achieve, but there’s also motion graphics packages if you want to make your intro cards and lower thirds really stand out.

It’s compatible with a fair amount of programs too, but probably best used on Adobe. There’s also a lot of support and tutorials for it, so you won’t be alone in your investment.

Price: Ranges for each suite, but you can expect anywhere from $100-$400 for each suite

Video Copilot

Basically anything from Video Copliot is awesome.

I love their tutorials, and their plugins look amazing. They have an elements package that gives you a huge range of sound effects, motion graphics, and 3D elements like fluids and particles.

If you want to channel your inner JJ Abrams, they have a package of optical flares you can buy, starting from around $125,or, if you’re a Michael Bay fan, maybe go for their Action Essentials package, starting at around $100.

This is an add-on for a marketer on a budget who just needs a little extra flare to their videos.

It’s also compatible with After Effects, Final Cut Studio, Premiere, and other QuickTime based software.

Price: Depends on the package, but usually in the $50-150 range

What It All Comes Down To

Whether you’re just starting out, or into the weeds with editing, these are some helpful tools to get the most out of your footage.

This isn’t the dawn of film. Audiences can spot a bad edit, even if they don’t know technically why it’s bad.

Having these valuable tools can make or break your video marketing strategy because what you create, and how well you’re able to create it will tell the world exactly what value you have to offer.

If this seems way too overwhelming, we can help with that. Whether it’s our video training services, or our in-house production team, we can assist your video needs.

from Web Developers World https://www.impactbnd.com/blog/video-editing-software

0 notes

Text

10 quality Kickboxing shoes

10 best kickboxing shoes 1. crocs conventional clog there’s not a top notch deal to mention approximately the crocs conventional which you haven’t already heard, maximum probably. this version is, fingers down, the king of all cozy and breathable sandals/clogs; now not most effective in phrases of recognition however, moreover, capability. the crocs conventional is proper for steamy environments much like the kitchen; and the dark colours (black, preferably) may also additionally moreover meet artwork uniform etiquette. aside from being completely cozy, the traditional clog counts with sufficient perforations to ventilate your ft well.

water and warmth-pleasant it’s hard to nd a silhouette greater bendy than the conventional clog, as it endures quite lots a few thing you placed it up to. the air flow channels, additionally, work as a drainage device in environments exposed to liquids, and people very same channels allow air to ow continually in the build that preserve ft clean everywhere, on every occasion. moreover, the non-marking outsoles are precisely what you want to be seeking out as a kitchen employee or chef. kitchen suitability however the fact that now not, to begin with, designed to be inside the kitchen, the crocs conventional clog has the vital talents for it. the non-slipping outsole continues you far from slipping risks within the artwork surroundings, at the same time as the pleasant substances without issues address oil and sauce stains. they'll be, moreover, smooth to clean and quick dry. as even though that wasn’t sufficient, the heady scent-resistant internal build prevents the accumulation of bacteria. value and rate some clients would possibly argue that the rate of the crocs particular is a few aspect they’re no longer inclined to pay for with the form of easy technique. but, in fact, crocs depend with an amount of underlooked functions in case you need to marvel you; now not to point out, they’re some of the maximum-durable quantities to be had. we don't forget this shoes is really really worth the funding, in phrases of fantastic, consolation, and sturdiness.

2. dansko expert mule the dansko professional mule is one of the smartest-searching clogs for kitchen positioned on. the woven clog format of the shoe will upload a elegant contact in your ensemble. they're an tremendous trade from the plain and ordinary pairs one, commonly, nds for kitchen placed on. the large heel strike of these footwear will, also, provide you with nicely balance all day long. overall performance/use you can put on those footwear for prolonged hours at a time without dealing with any problems with the intention to hinder your movements within the kitchen. moreover, the footwear obtained’t weigh you down or make you enjoy tired on your feet.

comfort/cushioning the ones mules have a roomy and bolstered toe box for greater safety. the padded instep collar offers to the comfort trouble and the polyurethane outsole with rocker bottom permits more surprise absorption. fee and charge the professional clog is priced at the higher element. considering its stylish appearance, coupled with all-day assist and unbeatable consolation, we are able to apprehend why. in reality, the ones shoes can be worn for severa different sports and outings.

3. crocs professional clog

well-known for consolation, those crocs are organized for the kitchen. with a closed heel to help meet artwork surroundings desires and an adjustable assist strap, the ones crocs are prepared for folks that want comfort and capability. the 'roomy healthful' format caters to humans with huge quantity feet; in addition to, people with super ft. the croslite™ technology allows the shoe conform on your foot; making every t a non-public one. 'roomy suit' layout for those who've huge and/or excessive-amount ft, the ones crocs are a incredible preference. the 'roomy fit' layout permits you spacious glory to reach that 2d of costly comfort. croslite™ conform technology made from foam resin, croslite™ generation conforms to every body's foot on a personal and specific level; thereby, developing a custom t. this lets in to promote a comfy revel in, as you figure your way through the kitchen's extended hours. fee and fee value-ecient, the ones crocs are well priced for the undertaking-at-hand. having a 1.5-inch shaft peak, zero.25-inch platform top, and croslite™ conforming era, the ones footwear no longer nice stay as plenty as their 'roomy in form' format but, additionally, have the capability to customize the t, as it had been. as such, the ones exceptional kitchen shoes are properly well worth every penny. four. merrell jungle moc seasoned grip those shoes are to be had in every guys’s and ladies’s versions. this expert moc competencies the merrell air cushion underfoot, leather-primarily based completely uppers, and non-marking outsoles. the breathable, mesh lining is a blessing; especially if you have to spend prolonged hours in your footwear in a warmth environment. these slip-on footwear oer consolation, sturdiness, and slip-resistance in a unmarried fashionable bundle deal. overall performance/use the merrell jungle moc seasoned grip is right to be used on the tough and slippery oors of kitchens. they deliver fantastic useful resource to the toes within the tough moist and greasy environments of kitchens. consolation/cushioning the shoes encompass air cushioning within the heel that adds stability and absorbs marvel. a couple of merrell jungle moc seasoned grip, additionally, gives suitable arch assist; making the shoe relaxed for lengthy put on. in some times, a similarly insert can be needed; relying on individual dreams. rate and value those footwear are fee range-nice; and as such, the charge is justied thinking about the footwear’ multipurpose makes use of and numerous abilities. in the end, you'll be dishing out less coins, absolutely, for a pinnacle-great product.

0 notes

Text

University Bridge Residences

New Post has been published on http://www.mii.miami/university-bridge-residences/

University Bridge Residences

University Bridge Residences

740 SW 109th Ave, University CitySweetwater

University Bridge Residences is a premier condominium purpose-built for student tenants and will be located across the street from the main campus of Florida International University (FIU).

UNIT TYPES: Studios, 1 Bed/1 Bath, 1 Bed/+Den/Bath, 2 Bed/2 Bath, 3 Bed/3 Bath, 4 Bed/4 Bath, 3 Bed/3 Bath & 4 Bed/4 Bed Townhouses

var map_fusion_map_5a2c3a688d365; var markers = []; var counter = 0; function fusion_run_map_fusion_map_5a2c3a688d365() jQuery('#fusion_map_5a2c3a688d365').fusion_maps( addresses: ["address":"740 SW 109th Ave, University City, Sweetwater, FL 33174","infobox_content":"740 SW 109th Ave, University City, Sweetwater, FL 33174","coordinates":false,"cache":false], animations: true, infobox_background_color: '', infobox_styling: 'custom', infobox_text_color: '', map_style: 'default', map_type: 'roadmap', marker_icon: '', overlay_color: '', overlay_color_hsl: "hue":0,"sat":0,"lum":100, pan_control: true, show_address: true, scale_control: true, scrollwheel: false, zoom: 13, zoom_control: true, ); google.maps.event.addDomListener(window, 'load', fusion_run_map_fusion_map_5a2c3a688d365);

With a direct connection to campus via the new 8th Street pedestrian bridge, University Bridge Residences will serve the school’s rapidly growing student population’s housing demand. Florida International University is the fourth-largest university in the United States by enrollment, with more than 55,000 students, but only eight percent of the student body lives in college owned, operated or affiliate housing. University Bridge Residences comprises of 20 floors, 492 units, and a dedicated connection to the pedestrian bridge from the building providing a secure, direct route to the campus. Scheduled for completion in time for the 2020-2021 academic year, the residences will be fully finished inclusive of specialized student furnishings. Each unit will have its own washer and dryer as well as a dedicated bathroom for each bedroom.

Floorplans range in size from 317 square feet to 1,634 square feet, the residences include studios, one, two, three and four bedroom units, as well as three and four bedroom townhouses. Prices range from the $190,000’s to the high $600,000’s. ”

CONDOMINIUM OVERVIEW

Directly connected to Florida International University (FIU) via a new pedestrian bridge to 2nd level bridge lobby

30 minutes from Miami’s famed beaches, 15 minutes from Miami International Airport and 5 minutes from shopping and dining destination, Doral

Visually striking premium student condominium designed by famed architects, Arquitectonica, re ecting Miami’s ocean setting with a podium-to-sky wave pattern across the exterior elevation

Premium student focused amenities throughout the building

Ground level designer lobby

Unencumbered views to the south overlooking the University

Upper level interior residences enjoy spectacular views overlooking The Deck pool area and The Rooftop terrace

Fully nished and furnished residences

Private bathroom for every bedroom

Washer and dryer included with each unit

SMART OWNERSHIP

Finished, furnished rent-ready condos

Optional unit management by Landmark Properties

Annual leaseback option available

Proven international development team

Content insurance included

Parking options available

BUILDING AMENITIES

2nd level bridge connection lobby

24-hour security

On-hours concierge in main lobby

WiFi throughout

Electric car charging stations

Bike parking spaces available

Study rooms on residential oors 2-20

7,750 sf ground level designer lobby with package center/mail room

THE DECK AND 6TH FLOOR INDOOR AMENITIES

Stunning amenity deck with landscaped recreational area and expansive terrace

Outdoor video screen for movies or sports

Resort-style pool with beach entry and pool volleyball/lap area

BBQ and dining areas

Cabanas

Sun deck with daybeds

4,050 sf state-of-the-art tness room with roll-up door to outdoor terrace

Yoga lawn

5,500 sf indoor lounge/games room

Business center with 4 fully equipped meeting rooms

STUDY AREAS

Shared study area on each oor from Level 2 and up

THE ROOFTOP WITH INDOOR SUNSET LOUNGE

Fabulous 1,700 sf sunset lounge area and 8,000 sf of outdoor terrace will include BBQs, dining tables, yoga green space and performance stage

.fusion-button.button-468 .fusion-button-text, .fusion-button.button-468 i color:#ffffff;.fusion-button.button-468 border-width:1px;border-color:#ffffff;.fusion-button.button-468 .fusion-button-icon-dividerborder-color:#ffffff;.fusion-button.button-468:hover .fusion-button-text, .fusion-button.button-468:hover i,.fusion-button.button-468:focus .fusion-button-text, .fusion-button.button-468:focus i,.fusion-button.button-468:active .fusion-button-text, .fusion-button.button-468:activecolor:#ffffff;.fusion-button.button-468:hover, .fusion-button.button-468:focus, .fusion-button.button-468:activeborder-width:1px;border-color:#ffffff;.fusion-button.button-468:hover .fusion-button-icon-divider, .fusion-button.button-468:hover .fusion-button-icon-divider, .fusion-button.button-468:active .fusion-button-icon-dividerborder-color:#ffffff;.fusion-button.button-468width:100%;DOWNLOAD DETAILED INFO IN PDF

FOR FURTHER INFORMATION ON PRICING, AVAILABILITY OF THE UNITS, LAYOUTS AND FLOOR PLANS, PLEASE CONTACT US

Your Name (required)

Your Email (required)

Your phone number (required)

Subject

Your Message

.modal-288 .modal-header, .modal-288 .modal-footerborder-color:#ebebeb;

×

Schedule tour request

Close

NEW DEVELOPMENTS IN SOUTH FLORIDA – BEST DEALS

Alexander 2017-11-06T01:34:34-05:00

Ritz-Carlton Residences, 15701 Collins Avenue, Sunny Isles Beach, FL 33160

Ritz-Carlton Residences, Sunny Isles Beach 15701 Collins Avenue Sunny Isles Beach The Ritz-Carlton Residences, Sunny Isles Beach is a sumptuous urban oasis composed of 212 condominium homes--including five penthouses with [...]

Christopher Lazaro 2017-11-19T15:57:05-05:00

3900 Alton

3900 Alton 3900 Alton Rd Miami Beach Rising gracefully amid the turquoise waters of Biscayne Bay, 3900 Alton brings the modern design of internationally acclaimed master architect Ricardo Bofill [...]

Christopher Lazaro 2017-11-05T23:58:59-05:00

Glass Miami Beach

Glass Miami Beach 120 Ocean Drive Miami Beach Glass luxury condo coming to South of Fifth neighborhood in Miami Beach. South Pointe Miami Beach is home to some of the [...]

Christopher Lazaro 2017-09-25T14:19:21-04:00

18 Brickell Condo

18 Brickell Condo 18 SW 8th Street Miami The City of Miami Board gave its approval to the mixed-use tower proposed to replace Brickell’s Burger King-anchored strip mall. The 78-story, [...]

Christopher Lazaro 2017-09-21T01:47:55-04:00

The Bristol Palm Beach

The Bristol Palm Beach 1100 South Flagler Drive West Palm Beach Discover luxury living on the West Palm Beach waterfront. The sleek towers of the Bristol Palm Beach will [...]

Christopher Lazaro 2017-09-17T11:03:54-04:00

Three Hundred Collins

Three Hundred Collins 300 Collins ave Miami Beach The ultra-lux, 19-unit boutique property situated in the heart of South Beach is a breath of fresh air for residents who [...]

Christopher Lazaro 2017-09-14T11:13:07-04:00

The Fairchild Coconut Grove Miami

The Fairchild Coconut Grove Miami 3581 E. Glencoe Street Coconut Grove The Fairchild Coconut Grove is designed thoughtfully to become your ultimate sanctuary. Every residence offers open and airy floor [...]

Christopher Lazaro 2017-09-07T03:48:03-04:00

One River Point Miami

One River Point Miami 24 SW 4th St Miami One River Point brings Viñoly’s concept of architecture as a dramatic performance to life. Two soaring symmetrical towers join in [...]

Christopher Lazaro 2017-08-29T22:14:26-04:00

Boulevard 57 Miami

Boulevard 57 Miami 5700 Biscayne Boulevard Miami SMART LUXURY When design, dimension, planning, efficiency and aesthetics all work together seamlessly, you get something that is more than just luxurious - [...]

Christopher Lazaro 2017-08-26T12:32:48-04:00

Aston Martin Residences Miami

Aston Martin Residences Miami 300 Biscayne Boulevard Way Downtown Miami Unrivalled prestige, unequalled craftsmanship, uncompromising standards. For over a century, the Aston Martin name has been synonymous with excellence [...]

Christopher Lazaro 2017-08-21T15:39:15-04:00

Satori, 16201 NW 87th Court Miami Lakes, FL 33018

Satori - Miami Lakes 16201 NW 87th Court Miami Lakes Satori is a master-planned community reflecting the very essence of The Serenity Collection’s inspiration. Our architects and designers studied [...]

Christopher Lazaro 2017-08-21T15:22:25-04:00

Metropica, 1800 NW 136th Avenue Sunrise, Florida 33323

Metropica, Sunrise 1800 NW 136th Avenue Sunrise Welcome to Metropica, a 4 million square foot master planned community. Located in West Broward County, it brings the best of city [...]

Alexander 2017-08-15T21:31:11-04:00

Residences at Park Square, 2950 NE 207th Street, Aventura, FL 33180

Residences at Park Square, Aventura 2950 NE 207th Street Aventura Aventura ParkSquare will be the new center of life in Aventura, Florida. A mixed-use urban project comprised of luxury residential [...]

Alexander 2017-08-15T21:06:32-04:00

Porsche Design Tower, 18555 Collins Ave, Sunny Isles Beach, FL 33160

Porsche Design Tower 18555 Collins Ave Sunny Isles Beach Porsche Design Group exceeds all expectations with their newest project – Porsche Tower Sunny Isles Beach – the ultimate in building [...]

Alexander 2017-04-17T11:38:34-04:00

Peloro, 6620 Indian Creek Drive, Miami Beach, FL 33141

Peloro, Miami Beach 6620 Indian Creek Drive Miami Beach Life on the water has always been about exploration and discovery. On the bayside shores of Miami Beach, Peloro is about [...]

Alexander 2017-04-17T13:05:11-04:00

Hyde Beach House, 4000 South Ocean Drive, Hollywood, FL 33019

Hyde Beach House 4000 South Ocean Drive Hollywood Hyde House Hollywood is a new project located on Hollywood Beach, in the heart of South Florida. The building is perfectly situated [...]

Alexander 2017-04-17T12:49:08-04:00

Jade Signature, 16901 Collins Ave, Sunny Isles Beach, FL 33160

Jade Signature 16901 Collins Ave Sunny Isles Beach Jade Signature’s extraordinary resort-like experience is further enhanced by having three floors entirely dedicated to amenities and 53 stories of elegantly sculptural, [...]

Alexander 2017-04-17T19:54:25-04:00

Gran Paraiso, 600 NE 31st St, Miami, FL 33137

Gran Paraiso 600 NE 31st St Miami Gran Paraiso - a new project of the developer The Related Group, located in Miami at 600 Northeast 31st Street. The building has [...]

Alexander 2017-04-17T20:20:52-04:00

ECHO Brickell, 1451 Brickell Avenue, Brickell, FL 33131

ECHO Brickell 1451 Brickell Avenue Brickell ECHO Brickell is an exclusive high-rise boutique-style hotel in the heart of Miami that will be constructed on the east side of Brickell Avenue. [...]

Alexander 2017-08-13T01:15:50-04:00

Brickell Heights, 850 South Miami Avenue, Brickell, FL 33130

Brickell Heights 850 South Miami Avenue Brickell Scheduled to be completed in 2017, Brickell Heights is one of the newest and most anticipated real estate developments in Brickell area. A [...]

Alexander 2017-04-19T14:26:50-04:00

Biscayne Beach Miami, 711 Northeast 29th Street, Miami, FL 33137

Biscayne Beach Miami 711 Northeast 29th St Miami Biscayne Beach is luxury condominium, being developed in cooperation of Eastview Development and GTIS Partners in Miami’s East Edgewater neighborhood. World-known [...]

Alexander 2017-04-19T15:41:09-04:00

Auberge Residences & Spa, 1440 South Biscayne Boulevard, Miami, FL 33132

Auberge Residences & Spa 1440 Biscayne Boulevard Miami Auberge Residences & Spa - a new residential 60-storey skyscraper, which will be located at 1440 South Biscayne Boulevard, Miami. The project [...]

Alexander 2017-04-19T15:44:15-04:00

Auberge Beach Residences & Spa, 2200 North Ocean Boulevard, Fort Lauderdale, FL 33305

Auberge Beach Residences 2200 North Ocean Boulevard Fort Lauderdale Each Auberge property is unique and authentic to its location. Carefully curated activities highlight the most desirable aspects of the surrounding [...]

Alexander 2017-04-19T15:48:27-04:00

Armani House, 18975 Collins Ave, Sunny Isles Beach, FL 33160

Armani House, Sunny Isles 18975 Collins Ave Sunny Isles Beach Armani House by Cesar Pelli is a new oceanfront master-peace, located in a luxury high-rise condominium community, Sunny Isles Beach.Armani [...]

Alexander 2017-04-19T15:53:26-04:00

Aria on the Bay, 1770 N Bayshore Dr, Miami, FL 33132

Aria on the Bay 1770 N Bayshore Dr Miami Aria on the Bay is a new luxury residential high-rise development by Architectonica, an internationally renowned architectural firm. Aria on the [...]

Alexander 2017-04-19T15:56:57-04:00

AquaBlu, 920 Intracoastal Drive, Fort Lauderdale, FL 33304

AquaBlu Fort Lauderdale 920 Intracoastal Drive Fort Lauderdale AquaBlu - a new residential building located in Fort Lauderdale at 920 Intracoastal Drive near the historical monument Bonnet House Museum and [...]

Alexander 2017-04-19T15:00:45-04:00

AVVA Residences

AVVA RESIDENCES, AVENTURA Country Club Drive & 34th Street Aventura A sumptuous residential complex Avva Residences is one of the best luxury buildings located in the center of Aventura, just in [...]

0 notes

Text

1. Using the mechanistic and organic structure models, compare and contrast the management styles of Acme and Omega. How do the differences between the companies’ management styles explain the way they coordinated the production of the memory unit prototypes for the photocopying customer? Which company did better? 2. If Omega was so much more effective than Acme, why didn’t it win the final contract? How can you account for the photocopier manufacturer’s decision? 3. What changes would you recommend to Acme and Omega if they are to survive in the future in this increasingly competitive industry? Do you think Acme and Omega should merge to better compete in the future? What problems might be encountered in such a merger? Attachment Preview: The Paradoxical Twins: Acme and Omega Electronics Part I In 1955, Technological Products of Erie, Pennsylvania, was bought out by a Cleveland manufacturer. The Cleveland ?rm had no interest in the electronics division of Technological Products and subsequently sold to different investors two plants that manufactured printed circuit boards. One of the plants, located in nearby Waterford, Pennsylvania, was renamed Acme Electronics, and the other plant, within the city limits of Erie, was renamed Omega Electronics, Inc. Acme retained its original management and upgraded its general manager to president. Omega hired a new president, who had been a director of a large electronics research laboratory, and upgraded several of the existing personnel within the plant. Acme and Omega often competed for the same contracts. As subcontractors, both ?rms bene?ted from the electronics boom of the early 1960s and both looked forward to future growth and expansion. Acme had annual sales of $10 million and employed 550 people. Omega had annual sales of $8 million and employed 480 people. Acme was consistently more effective than Omega and regularly achieved greater net pro?ts, much to the chagrin of Omega’s management. Inside Acme The president of Acme, John Tyler, credited his ?rm’s greater effectiveness to his managers’ abilities to run a “tight ship.” He explained that he had retained the basic structure developed by Technological Products because it was most ef?cient for high-volume manufacture of printed circuits and their subsequent assembly. Tyler was con?dent that had the demand not been so great, its competitor would not have survived. “In fact,” he said, “we have been able to beat Omega regularly for the most pro?table contracts, thereby increasing our pro?ts.” Acme’s basic organization structure is shown in Exhibit 1. People were generally satis?ed with their work at Acme; however, some of the managers voiced the desire to have a little more latitude in their jobs. One manager characterized the president as a “one-man band.” He said, “While I respect John’s ability, there are times when I wish I had a little more information about what is going on.” Inside Omega Omega’s president, Jim Rawls, did not believe in organization charts. He felt that his organization had departments similar to Acme’s, but he thought the plant was small enough that things such as organization charts just put arti?cial barriers between specialists who should be working together. Written memos were not allowed, since, as Jim expressed it, “the plant is small enough that if people want to communicate, they can just drop by and talk things over.” Other members of Omega complained that too much time was wasted “?lling in” people who could not contribute to the problem solving. As the head of the mechanical engineering department expressed it, “Jim spends too much of his time and mine making sure everyone understands what we’re doing and listening to suggestions.” A newer member of the industrial engineering department said, “When I ?rst got here, I wasn’t sure what I was supposed to do. One day I worked with some mechanical engineers and the next day I helped the shipping department design some packing cartons. The ?rst months on the job were hectic, but at least I got a real feel for what makes Omega tick.” Most decisions of any signi?cance were made by the management team at Omega. Part II In 1966, the integrated circuits began to cut deeply into the demand for printed circuit boards. The integrated circuits (ICs), or “chips,” were the ?rst step into microminiaturization in the electronics industry. Because the manufacturing process for ICs was a closely guarded secret, both Acme and Omega realized the potential threat to their futures and both began to seek new customers aggressively. In July 1966, one of the major photocopy manufacturers was looking for a subcontractor to assemble the memory unit for its new experimental copier. The projected contract for the job was estimated to be $5–$7million in annual sales. Both Acme and Omega were geographically close to this manufacturer and both had submitted highly competitive bids for the production of 100 prototypes. Acme’s bid was slightly lower than Omega’s; however, both ?rms were asked to produce 100 units. The photocopy manufacturer told both ?rms that speed was critical because their president had boasted to other manufacturers that they would have a ?nished copier available by Christmas. This boast, much to the designer’s dismay, required pressure on all subcontractors to begin prototype production before ?nal design of the copier was complete. This meant that Acme and Omega would have at most two weeks to produce the prototypes or delay the ?nal copier production. Part III – Inside Acme As soon as John Tyler was given the blueprints (Monday, July 11, 1966), he sent a memo to the purchasing department requesting them to move forward on the purchase of all necessary materials. At the same time, he sent the blueprints to the drafting department and asked that they prepare manufacturing prints. The industrial engineering department was told to begin methods design work for use by the production department foremen. Tyler also sent a memo to all department heads and executives indicating the critical time constraints of this job and how he expected everyone to perform as ef?ciently as they had in the past. On Wednesday, July 13, purchasing discovered that a particular component used in the memory unit could not be purchased or shipped for two weeks because the manufacturer had shut down for summer vacations. The head of purchasing was not overly concerned by this obstacle, because he knew that Omega would face the same problem. He advised Tyler of this predicament, who in turn decided that Acme would build the memory unit except for the one component and then add that component in two weeks. Industrial engineering was told to build this constraint into their assembly methods. On Friday, July 15, industrial engineering noti?ed Tyler that the missing component would substantially increase the assembly time if it was not available from the start of assembly. Mr. Tyler, anxious to get started, said that he would live with that problem and gave the signal to go forward on the assembly plans. Mechanical engineering received manufacturing prints on Tuesday, July 12, and evaluated their capabilities for making the chassis required for the memory unit. Because their procedure for prototypes was to get estimates from outside vendors on all sheet metal work before they authorized in-house personnel to do the job, the head of mechanical engineering sent a memo to the head of drafting requesting that vendor prints be drawn up on the chassis and that these prints then be forwarded to purchasing, which would obtain vendor bids. On Friday, July 15, Mr. Tyler called the head of mechanical engineering and asked for a progress report on the chassis. He was advised that mechanical engineering was waiting for vendor estimates before they moved forward. Mr. Tyler was shocked by the lack of progress and demanded that mechanical engineering begin building those “damn chassis.” On Monday, July 18, Mr. Tyler received word from the shipping department that most of the components had arrived. The ?rst chassis were sent to the head of production, who began immediately to set up an assembly area. On Tuesday, July 19, two methods engineers from industrial engineering went out to the production ?oor to set up the methods to be used in assembly. In his haste to get things going, the production foreman ignored the normal procedure of contacting the methods engineers and set up what he thought would be an ef?cient assembly process. The methods engineers were very upset to see assembly begin before they had a chance to do a proper layout. They told the foreman they had spent the entire weekend analyzing the motions needed and that his process was very inef?cient and not well balanced. The methods engineers ordered that work be stopped until they could rearrange the assembly process. The production foreman refused to stop work. He said, “I have to have these units produced by Friday and already I’m behind schedule.” The methods engineers reported back to the head of industrial engineering, who immediately complained to the plant manager. The plant manager sided with the production foreman and said, “John Tyler wants these units by Friday. Don’t bother me with methods details now. Once we get the prototypes out and go into full production, then your boys can do their thing.” As the head of industrial engineering got off the phone with the plant manager, he turned to his subordinates and said, “If my boss doesn’t think our output is needed, to hell with him! You fellows must have other jobs to worry about, forget this one.” As the two methods engineers left the head industrial engineer’s of?ce, one of them said to the other, “Just wait until they try to install those missing components. Without our methods, they’ll have to tear down the units almost completely.” On Thursday, July 21, the ?nal units were being assembled, although the process was delayed several times as production waited for chassis from mechanical engineering to be completed. On Friday, July 22, the last units were ?nished while John Tyler paced around the plant. Late that afternoon, Tyler received a phone call from the head designer of the photocopier manufacturer, who told Tyler that he had received a call on Wednesday from Jim Rawls of Omega. He explained that Rawls’s boys had found an error in the design of the connector cable and had taken corrective action on their prototypes. He told Tyler that he checked out the design error and that Omega was right. Tyler, a bit overwhelmed by this information, told the designer that he had all of the memory units ready for shipment and that as soon as they received the missing component, on Monday or Tuesday, they would be able to deliver the ?nal units. The designer explained that the design error would be recti?ed in a new blueprint he was sending over by messenger and that he would hold Acme to the delivery date on Tuesday. When the blueprint arrived, Tyler called the production foreman in to assess the damages. The alterations in the design would call for total disassembly and the unsoldering of several connections. Tyler told the foreman to put extra people on the alterations ?rst thing on Monday morning and to try to ?nish the job by Tuesday. Late Tuesday afternoon the alterations were ?nished and the missing components were delivered. Wednesday morning, the production foreman discovered that the units would have to be torn apart again to install the missing components. When John Tyler was told this, he “hit the roof.” He called industrial engineering and asked if they could help out. The head of industrial engineering told Tyler that his people would study the situation and get back to him ?rst thing in the morning. Tyler decided to wait for their study because he was concerned that tearing apart the units again could weaken several of the soldered contacts and increase their potential rejection. Thursday, after several heated debates between the production foreman and the methods engineers, John Tyler settled the argument by ordering that all units be taken apart again and the missing component installed. He told shipping to prepare cartons for delivery on Friday afternoon. On Friday, July 29, 50 prototypes were shipped from Acme without ?nal inspection. John Tyler was concerned about his ?rm’s reputation, so he waived the ?nal inspection after he personally tested one unit and found it operational. On Tuesday, August 2, Acme shipped the last 50 units. Inside Omega Jim Rawls calle