#non sparking magnetic tools

Explore tagged Tumblr posts

Note

i really wabna hear your thoughts on yandere daddy Arthur Harrow with a reader who goes completely non verbal after the kidnapping and his attempts of regressing them..i often go non verbal when im depressed or scared how does he deal with that?

A.Harrow Headcanons

Thankyou so much for your ask!! 🤍

-He likes that you've become non-verbal

-It makes him feel reassured knowing that you can't verbally fight back or go against him, he has an upper hand.

-He enjoys knowing that the rest of the village has difficulty communicating with you aswell, you're all his.

-Though rather quickly it becomes clear to him that a form of communication must be established between you.

-Sure he knows you can understand every word he says, and he loves believing that you being non verbal is a result of your regression rather than a response to anxiety or burnout.

-He lays out a piece of yellowed paper on the desk Infront of you, before setting down a tin of worn crayons beside it.

"Can you write for me baby?"

-Paper, Crayons and an old kids magnetic writing board are how you usually communicate, when you're allowed to.

-When you're given a spark of courage and write something rather unsavoury then he'll let you know, his eyes slowly moving from your words to your eyes, glaring at you with not only disappointment but disgust, as he takes away your writing tools with ease.

-Theres no real need for you to be able to write to him anyway, I mean afterall, little kids aren't given choices because they can't make decisions.

-You'll eat what he decides to make you.

-You'll wear what he picks out and dresses you in.

-He uses other cues to understand your needs.

-Constantly tugging on his shirt when you need to use the bathroom? Too bad, it's dinner time now and he took you to the bathroom an hour ago, you should have gone then.

-Acting fussy and misbehaving, looks like it's time for your nap.

-And when you decide to act like a "big kid", he'll treat you like one, just to make you feel unable.

-"Honey, I thought you were grown up now, you have to cook your own food."

-"If you want something you have to ask them, I can't ask for you, you're a big kid now."

-"I'm not tying your shoes, you have to figure it out yourself."

47 notes

·

View notes

Text

Also! Why go through all that nonsense inventing antibiotics when you could invent electricity? For a lot less effort (or rather, fewer steps to remember)

WHAT YOU WILL NEED

Iron

Copper

A blacksmith with tools

A way to find north (compass if you have it, sun if you don't)

The wheel

Tar or rubber

Take a bar of iron and line it up north-south. Clamp it down. Smack it real hard with a hammer for a while. You'll know you're done when little bits of iron stick to it. Congrats! You have made a permanent magnet.

Have your blacksmith make copper wire. Any thickness will do to start, but as shit gets more complicated you'll need it thinner. Bend the wire into this shape:

The size does not matter, apart from where you're planning to install it.

Attach the hoop end to the wheel, and slot the stick-out-y bits into a bigger copper hoop that you have cut in half to make two semicircles, so that they are just barely touching and can scrape by, like so:

The wheel can be attached to a watermill or a windmill or a small child turning it, whatever works. The two semicircles are then attached to whatever circuit you want to make (we'll get to that in a sec).

Now put two permanent magnets (you did make a second one, right? go back and make a second one) on either side of the original hoop (in orange, not white). Make sure they're pointed the same way, so one has a north pole closest to the hoop, and one has a south pole closest. Congratulations! You have invented alternating current.

As the hoop is turned by the wheel, the electrons inside will want to flow to counteract the changing magnetic field inside it caused by it turning inside a uniform magnetic field. This flows to the stick-out-y bits, and then to the hoop. However, it doesn't flow at a constant rate, and in fact changes direction halfway through. That's why we cut holes in the second hoop - this keeps the current flowing in the same direction the whole time.

The faster you can get the wheel to spin, the stronger your current will be. The easiest way to do this is use gears to go from, say, a big water wheel to a small wheel spinning your copper hoop. (Yes, they will know what gears are in medieval Europe, ask your blacksmith.)

Now what do you do with your electricity? Well, you need some resistive element placed in circuit with your broken hoop, like so:

The resistor is going to be the hardest part here, as modern resistors are made of nichrome, a nickel-chromium alloy. Medieval Europeans did not know how to find, let alone smelt, nickel or chromium, and you can't be expected to just find some wherever you land. What you could expect to find would be graphite, then called "black lead" or "plumbago". It makes a decent resistor. Lacking that, wrap some of your copper wire around a non-flammable insulator, like a ceramic.

The resistor can then be used as a heating element! You can start fires, warm homes, make toast, whatever your creative heart can think of. Lightbulbs are a bit more complicated, because those typically require a vacuum, which I wouldn't expect a medieval village to be able to make.

However, you could use this to rotate things! Just make this whole set up again, on the other side of your circuit. Why mill your flour right next to the waterwheel, when you can run wires from the waterwheel to your mill and do it there? And that's what the tar/rubber is for - if you're going to be moving electricity any appreciable distance, you'll want to coat your copper wires with an insulator, to protect them, as well as anyone who happens to touch them.

One last thing - if instead of fully completing the circuit with a resistor, you just hold the two copper wires real close to each other but not actually touching, you can make a spark jump, showing your new medieval friends that there is lightning inside metals.

I can understand how "modern person thrown into the past gets by pretending to be a healer/doctor" is as surprisingly common of a trope as it is. I mean I'm fluent enough at bullshitting to be pretty sure I could pull it off to impersonate a doctor in any time pre-1800s. If I have no idea what something is or how to treat it, I could just get the opinion of the other whatever-passes-as-medical-professionals around, but if their suggestions sound like bullshit I'm not doing it. And I'll beat the shit out of anyone suggesting bloodletting or mercury. With my healing stick. I've tied little bells on it, that jingle comically with every smack.

The awesome curative powers of my healing stick come from two separate sources: Placebo, and me using it to beat anyone trying to give my patients mercury.

38K notes

·

View notes

Text

Want High ROI? Here’s Why Investing in a STEM Lab Pays Off Big!

Want High ROI? Here’s Why Investing in a STEM Lab Pays Off Big!

The Future Starts Here: A Story of Innovation

In a quiet school district, Principal Johnson faced a challenge—how to prepare students for a future that was evolving faster than ever. Standard classrooms weren’t enough; students needed hands-on experience with technology, engineering, and real-world problem-solving. Then came the idea of a STEM lab a state-of-the-art learning space designed to spark curiosity, innovation, and career readiness.

A year after launching the STEM lab, the results were astonishing: higher student engagement, a 25% increase in STEM course enrollments, new corporate sponsorships, and recognition as a top-performing district. What started as an investment in education turned into a high-ROI decision that reshaped the future not just for the students, but for the entire community.

This isn’t just one school’s story. Across the globe, investing in STEM labs is proving to be a game-changer. Here’s why:

1. Future-Proofing Students for High-Demand Careers

The job market is changing rapidly, and STEM careers are leading the way. The U.S. Bureau of Labor Statistics predicts an 8% growth in STEM jobs from 2019 to 2029, significantly higher than the 4% growth in non-STEM occupations. Careers in AI, cybersecurity, data science, and engineering are booming, with STEM professionals earning 26% more than non-STEM workers.

2. Increased College and Scholarship Opportunities

Students who have hands-on STEM experience in high school are more likely to get into top universities and secure STEM-related scholarships. Studies show that 85% of STEM graduates participated in hands-on lab experiences before college, leading to stronger applications and career pathways.

3. Higher School Rankings and Enrollment Growth

A well-equipped STEM lab boosts a school’s reputation, making it a magnet for students and parents seeking a future-ready curriculum. Schools that invest in STEM education often:

See a 20-30% increase in STEM course enrollment within the first year.

Attract state and national recognition, opening doors for funding and grants.

Improve their college acceptance rates and student career outcomes.

Data Source: Education Commission of the States, 2021

4. Increased Corporate Sponsorships and Funding

Tech giants like Microsoft, Google, and Tesla are actively investing in school STEM programs, offering grants, mentorships, and advanced learning tools. Schools with strong STEM labs are more likely to secure funding partnerships, reducing costs and increasing long-term ROI.

5. Hands-On Learning = Higher Retention & Engagement

Students learn better when they engage with real-world projects. STEM labs encourage hands-on experiences, leading to:

6. A Competitive Edge for Schools & Districts

Schools that embrace STEM labs:

Rank higher in national education assessments. Attract talented educators looking for innovative teaching environments. Produce more college-ready graduates in STEM fields.

With STEM education being a top priority for governments and industries, schools that invest in labs today are preparing for long-term success.

Example: Schools with dedicated STEM labs score 15% higher on standardized tests.

7. Stronger Community and Economic Growth

A thriving STEM education system leads to:

More high-paying jobs in local industries.

Better-trained workforces for the digital economy.

Higher community investment from technology and engineering firms.

For every $1 spent on STEM education, communities see a $3-5 return through job creation and innovation.

Invest in the Future – Act Now!

A STEM lab isn’t an expense—it’s an investment with lifelong returns. From higher student success rates and corporate funding to stronger economic growth, the ROI is undeniable. Don’t wait! Give students the tools they need to succeed. Partner with top STEM programs, apply for funding, or enroll in a STEM lab initiative today!

Apply for STEM Lab Funding Schedule a Consultation Join a STEM Initiative Today

Contact us now to build your STEM learning center! Website: www.makermuse.com Email: [email protected] Empower students, embrace innovation, and future-proof your school with a high-impact STEM program!

0 notes

Text

Essential Gear for Himalayan Motorcycle Adventures: A Beginner’s Guide

Did you know that the Himalayas, home to the world’s highest peaks, also boast some of the most thrilling motorcycle routes? Riding through these majestic mountains is every biker’s dream, offering a perfect blend of adventure, breathtaking scenery, and cultural richness. But while the experience is unforgettable, it’s no walk in the park.

For beginners, preparing for a Himalayan motorcycle adventure starts with one crucial step: having the right gear. Whether it’s navigating rugged terrain or battling unpredictable weather, your equipment can make or break the trip. In this guide, we’ll walk you through the essential gear you need for a safe and enjoyable journey in the Himalayas.

The Foundation: Your Motorcycle Gear

Helmet: Your Ultimate Safety Companion

The most important piece of gear is your helmet. In the Himalayan region, a full-face helmet is essential to protect against wind, dust, rain, and unexpected falls.

Look for helmets with high impact resistance and good ventilation.

Popular options: LS2 Helmets, AGV K3, and MT Blade.

Riding Jacket and Pants: Armor for the Mountains

A good riding jacket and pants set will protect you from the elements and minor accidents.

Choose gear with CE-certified armor for elbows, shoulders, back, and knees.

Opt for materials like Gore-Tex for waterproofing and breathability.

Gloves: Keep Your Grip Secure

The Himalayan weather can be harsh on your hands. A quality pair of gloves ensures comfort and safety.

Types to consider: Waterproof, insulated gloves with good grip.

Boots: Protect Your Feet

Your boots should be sturdy, waterproof, and extend above your ankles for maximum protection.

Recommended brands: Alpinestars, Forma, and TCX.

Weather-Ready Essentials

Rain Gear: Stay Dry in Sudden Downpours

The Himalayas are infamous for unpredictable weather.

Invest in a lightweight, packable rain suit.

Ensure your gear includes rain covers for luggage.

Thermal Layers: Be Ready for the Cold

High altitudes can bring sudden temperature drops.

Pack thermal base layers to stay warm without adding bulk.

Consider heated gloves or jackets for extreme cold.

Sunglasses or Visor Inserts: Beat the Glare and Fog

Polarized sunglasses protect against the harsh Himalayan sun.

Anti-fog inserts for your helmet visor improve visibility in damp or cold conditions.

Navigation and Communication

GPS or Offline Maps: Never Lose Your Way

With limited connectivity in remote areas, having a reliable navigation system is vital.

Use GPS devices like Garmin Zumo or download offline maps from apps like Maps.me.

Communication Devices: Stay Connected

For group rides or emergencies, intercom systems and satellite phones are a great help.

Sena and Cardo systems are popular for helmet communication.

Luggage and Storage Solutions

Saddlebags and Tank Bags: Travel Light, Stay Organized

You’ll need durable, waterproof bags to carry your essentials.

Hard panniers or soft saddlebags: Choose based on your preference and bike type.

A magnetic tank bag is perfect for easy access to items like maps and snacks.

Bungee Cords and Straps: Secure Your Load

Unsecured luggage can be dangerous on bumpy Himalayan roads. Always double-check and secure your gear with bungee cords or straps.

Tools and Spare Parts

Tool Kit: Be Ready for Minor Repairs

Mountain roads can be unforgiving, so a basic tool kit is non-negotiable.

Include items like wrenches, tire levers, and a multi-tool.

Puncture Repair Kit and Air Pump

Flat tires are common, so carry a repair kit and portable air pump to handle emergencies.

Spare Parts

Brake and clutch cables, spark plugs, and fuses are handy in case of breakdowns.

Safety and Emergency Equipment

First Aid Kit: Prepare for the Unexpected

A compact first aid kit should include:

Bandages, antiseptic, pain relievers, and altitude sickness medication.

Reflective Gear: Be Visible at Night

Visibility can be a challenge in low-light or foggy conditions. Reflective vests or strips on your gear can prevent accidents.

Portable Charger or Power Bank

Keep your devices charged, especially if you rely on GPS or emergency communication.

Packing Essentials for Comfort and Convenience

Clothing: Be Layered and Prepared

Light, moisture-wicking clothes for daytime.

Warm layers for evenings.

Hydration Pack: Stay Hydrated on the Go

A hydration pack allows you to sip water without stopping, essential for long rides in the mountains.

Snacks and Energy Bars

Long stretches without food stalls make carrying non-perishable snacks a smart choice.

Mental and Physical Preparedness

Riding Skills

Practice riding on uneven terrain before tackling the Himalayas. Get comfortable with braking and turning on gravel roads.

Know Your Limits

Don’t push yourself too hard. Take breaks and listen to your body, especially at high altitudes.

Sustainability on the Road

Respect Nature

The Himalayas are a treasure, and it’s our responsibility to keep them pristine.

Avoid littering and carry your trash.

Stay on designated trails to protect local ecosystems.

Support Local Communities

Stay at locally-owned guesthouses.

Buy food and supplies from small, local businesses.

Conclusion: Gear Up for the Adventure of a Lifetime

Embarking on a motorcycle adventure in the Himalayas is an experience like no other. With the right gear, you’ll not only ensure your safety but also make your journey smoother and more enjoyable. From choosing the right helmet to packing essential tools and understanding the terrain, preparation is key.

So, whether it’s your first ride or your fiftieth, remember: the Himalayas are as challenging as they are rewarding. Gear up, plan smart, and get ready for the adventure of a lifetime.

1 note

·

View note

Text

Fun and Educational Montessori Activities for Children at Home

Are you looking for engaging and educational activities to do with your child? Incorporating Montessori-inspired activities into their playtime can be a rewarding experience. Children are naturally curious and imaginative, which makes Montessori activities an excellent way to encourage their love of learning. In this post, we’ll share 18 exciting Montessori activities your child will enjoy.

What Is a Montessori Activity?

Montessori activities allow children to explore, learn, and grow through hands-on experiences. They are designed to encourage independence and foster a deeper understanding of concepts through exploration.

Key characteristics of Montessori activities include:

Self-guided exploration: Children navigate activities independently, driven by their interests.

Mistakes are opportunities: Errors are part of the learning process, teaching children how to self-correct.

Skill-focused: Each activity emphasizes developing a specific skill or understanding.

Encourages focus: These activities offer uninterrupted learning, allowing children to immerse themselves fully.

Montessori activities don’t require elaborate setups. Everyday household items can be turned into valuable learning tools.

18 Montessori-Inspired Activities for Children in San Antonio, TX

Adding Montessori-inspired activities to your child’s routine can be both fun and beneficial. Let’s explore ideas across different developmental areas.

Motor Skills

Balancing fun: Introduce your child to a balance board. It’s a fantastic way to strengthen gross motor skills while having fun.

Yoga for kids: Share kid-friendly yoga poses and practice them together in a safe, open space.

Baby doll bath time: Provide a tub, soap, and a soft brush to let your child “wash” their dolls, building motor skills through play.

Language

Descriptive “I Spy”: Play this classic game with a twist—focus on using descriptive language to expand your child’s vocabulary.

Rhyming hunt: Place an object like a spoon on the table and encourage your child to find items that rhyme, like a balloon.

Imaginative storytelling: Create a “story box” filled with props like hats or small toys, and let your child weave creative tales.

Sensorial Skills

Mystery bag exploration: Fill a small bag with objects and challenge your child to guess what’s inside using touch alone.

Scent match: Add different essential oils to cotton balls in jars, and let your child identify each unique scent.

Sound jars: Create sound jars with varying amounts of beans or rice and let your child explore their differences.

Math Skills

Button sorting: Provide buttons of different sizes and colors for sorting and counting to build early math skills.

Trail mix fun: Follow a simple recipe for trail mix. This activity incorporates measuring and sequencing.

Number tracing with stones: Use a tray filled with small pebbles and encourage your child to trace numbers drawn on cards.

Science

Sink or float: Gather household items and let your child predict whether they’ll sink or float in water, testing their hypotheses.

Magnetic exploration: Use magnets to determine which items in your home are magnetic, sparking curiosity about properties of materials.

Living vs. non-living: Teach the difference between living and non-living things with images, then let your child classify them.

Life Skills

Flower arranging: Provide fresh flowers, a vase, and water for your child to practice arranging a bouquet independently.

Window washing: Give your child a safe, kid-friendly cleaning solution and a cloth to help clean windows while improving fine motor skills.

Sweeping and mopping: Introduce basic cleaning tasks to help your child develop coordination and independence.

Discover the Joy of Montessori Education in San Antonio, TX, at Alphabetz Montessori

At Alphabetz Montessori in San Antonio, TX, we believe in the power of hands-on learning to nurture creativity, independence, and a lifelong love of discovery. Our programs are thoughtfully designed to provide children with the tools they need to succeed, both academically and personally.

Interested in learning more about how Montessori education can benefit your child? Visit us today! We’d love to meet your family and share the enriching experience that Alphabetz Montessori offers.

To know more about our childcare program please contact us at https://www.alphabetzmontessori.com/contact-us.html or visit-

Website: https://alphabetzmontessori.com/

Facebook: https://www.facebook.com/alphabetzmontessori/

Instagram: https://www.instagram.com/alphabetz_montessori/

Call us: (210) 350-9000, (210) 993-5577

#alphabetz montessori culebra#alphabetz montessori in san antonio#montessori school in Alamo Ranch SanAntonio"#Montessori in Alamo ranch#alphabetz montessori#san antonio montessori#Montessori School San Antonio

0 notes

Text

An Introduction to Aluminium Bronze Round Bar: Composition and Properties

Aluminium bronze is a versatile and highly sought-after alloy known for its exceptional properties and broad range of applications. One of the most common forms in which this alloy is utilised is the aluminium bronze round bar.

Rajkrupa Metal Industries is one of the Premium Quality Aluminium Bronze Round Bar Manufacturers In India. We are now the industry leader in Aluminium Bronze Round Bar. We have deliberately positioned ourselves as a leading manufacturer and supplier of aluminum bronze round bars on the international market thanks to our exceptional corporate and technical personnel skills.

Composition of Aluminium Bronze

Aluminium bronze is primarily composed of copper and aluminium, with aluminium content typically ranging from 5% to 12%. The addition of aluminium significantly enhances the alloy's strength and corrosion resistance. Other elements such as iron, nickel, manganese, and silicon are often added in smaller quantities to improve specific properties and performance characteristics.

Key Properties of Aluminium Bronze Round Bar

Corrosion Resistance

Aluminium bronze is renowned for its outstanding corrosion resistance, particularly in marine environments. The presence of aluminium forms a protective oxide layer on the surface, which shields the underlying material from corrosive elements.

High Strength and Hardness

The addition of aluminium significantly increases the strength and hardness of the alloy. This makes aluminium bronze round bars suitable for heavy-duty applications where durability and wear resistance are crucial.

Excellent Wear and Abrasion Resistance

Aluminium bronze offers superior wear and abrasion resistance, which is essential for components subjected to friction and mechanical stress. This property is particularly beneficial in applications involving sliding or rotating parts.

Good Thermal and Electrical Conductivity

While not as conductive as pure copper, aluminium bronze still retains good thermal and electrical conductivity. This makes it suitable for applications where heat dissipation and electrical conductivity are important considerations.

Non-Sparking and Non-Magnetic

Aluminium bronze is non-sparking and non-magnetic, making it ideal for use in hazardous environments where sparks could ignite flammable materials. Its non-magnetic properties are also beneficial in applications requiring non-magnetic materials.

Applications of Aluminium Bronze Round Bar

Due to its unique combination of properties, aluminium bronze round bars are used in a wide array of industries and applications:

Marine Industry

Aluminium bronze is extensively used in marine environments due to its exceptional resistance to seawater corrosion. Common applications include propellers, marine hardware, and underwater fastenings.

Aerospace Industry

The aerospace industry benefits from aluminium bronze’s high strength-to-weight ratio and excellent fatigue resistance. It is used in components such as landing gear parts, bushings, and bearings.

Oil and Gas Industry

In the oil and gas sector, aluminium bronze round bars are used for valve components, pump parts, and other equipment exposed to harsh and corrosive conditions.

Automotive Industry

Aluminium bronze is used in the automotive industry for various components that require high strength and wear resistance, such as transmission parts, gears, and valve guides.

Manufacturing and Tooling

The manufacturing sector utilises aluminium bronze for tooling and dies due to its hardness and durability. It is also used in heavy machinery and equipment components that are subjected to constant wear.

Aluminium bronze round bars are a vital material in many industries, thanks to their unique composition and outstanding properties.Our company, which manufactures with ISO 9001:2015 certification. As a leading Aluminium Bronze Round Bar Manufacturer, we meet all International Quality Standard (IQS) requirements.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are also the leading Round bars manufacturer in India.

#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar Manufacturer in India#Aluminium Bronze Round Bar Suppliers#Round bars manufacturer in India

0 notes

Text

DIY Methods to Test Electric Fences

Electric fences are vital for protecting your property, but they need regular testing to ensure they’re in top-notch condition. From checking voltage to locating faults, here’s how to test your electric fence effectively.

Before diving into testing methods, let’s understand why it’s crucial. An electric fence acts as a barrier, deterring intruders or animals from entering your property. However, factors like grounding issues, short circuits, or wiring problems can compromise its effectiveness. Regular testing ensures it’s working optimally, providing reliable security.

Tools You’ll Need

You’ll need specific tools to test your electric fence accurately:

Electric fence tester is designed to precisely measure fence output power.

Non-contact voltage tester is widely used for voltage testing, ideal for quick checks.

Screwdriver sparks when touched to live fence wires.

Compass detects magnetic field irregularities caused by electric current.

Indicator light or bulb glows when connected to live wires indicating power.

Multimeter, while not ideal, it can measure voltage and current if no other option is available.

Electric fence fault finder helps measure power & locate faults like short circuits quickly.

Testing Methods

Testing the Energizer: Start by checking if the energizer is outputting power. Take a screwdriver & touch it both output terminals of the energizer and there should be spark if the energizer is outputting power. Same as you can you can test fence wires by touching the screwdriver.

Testing fence with Grass: This simple DIY methods involve using grass to check for electric current. Hold a piece of grass against the fence; if you feel a light pulse, it’s charged.

Using Electric Testers: Non-contact voltage testers or electric testers indicates power in fences with glowing bulbs. Simply touch them to the fence, and they’ll glow, if there’s power in fence.

Using a Compass: A compass can detect magnetic field irregularities near the fence, indicating the presence of electric current. Just take it near the charged fence wires & the needles should move.

Indicator Lights or Bulbs: Connect an indicator light or bulb to the fence; if it lights up, there’s power.

Electric Fence Tester: The most accurate method involves using a dedicated electric fence tester. Connect the tester’s probes to the fence and ground, and it will display voltage readings.

Multimeter Testing: While not ideal, a multimeter can measure voltage and current. Set it to DC mode, connect the probes, and measure the values.

Electric Fence Fault Finder: If you suspect a fault, use a fault finder to locate it quickly. Follow the device’s instructions to identify and fix the issue.

Conclusion

Regular testing is essential for ensuring your electric fence functions correctly. By using the right tools and methods, you can quickly identify any issues and address them promptly. Protect your property effectively by testing your electric fence regularly.

Reference: https://fencefacts.com/test-electric-fence/

0 notes

Text

Why Does Brass Make the Best Hammer Material?

Brass hammers are well-known for their exceptional malleability, heat tolerance, conductivity, non-magnetic, non-sparking, and non-marring properties. Brass is a cheap, easily shaped, and less likely to bend metal. For additional information about the advantages of purchasing brass hammers from reliable providers in brasshammersuppliersindubaiuae, continue reading the following section of the article.

KNOW MORE>> https://azaharalitools.wixsite.com/tools-suppliers-in-u/post/why-are-brass-the-best-material-for-hammers

#carbideburrsupplierindubaiuae#chaintongssuppliersinuaedubai#combinationwrenchsupplierindubaiuae#copperhammersuppliersindubaiuae#dubai

0 notes

Text

Fusion Biopsy Market Challenges, Drivers, Outlook, Growth Opportunities - Analysis to 2032

Fusion Biopsy Market: Illuminating Precision in Cancer Diagnosis

The Fusion Biopsy market stands at the forefront of oncology diagnostics, representing a revolutionary approach to detecting and characterizing prostate cancer with unparalleled precision. This innovative technology combines magnetic resonance imaging (MRI) with real-time ultrasound, offering clinicians an advanced tool to target suspicious areas within the prostate gland with pinpoint accuracy. The Fusion Biopsy market has seen substantial growth due to its potential to reduce unnecessary prostate biopsies, enhance early cancer detection, and ultimately improve patient outcomes.

Precision and Accuracy: Fusion biopsy, also known as MRI-ultrasound fusion biopsy, marries the anatomical detail of MRI with the real-time guidance of ultrasound, enabling healthcare professionals to visualize and biopsy suspicious lesions within the prostate with unparalleled accuracy. This minimally invasive approach reduces the risk of missing clinically significant cancers and helps in distinguishing aggressive from non-aggressive tumors, guiding treatment decisions and potentially sparing patients from unnecessary procedures.

Expanding Applications: While the primary application of Fusion Biopsy has been in prostate cancer diagnosis, it has also begun to find applications in other areas of oncology. The technology's ability to fuse different imaging modalities has sparked interest in utilizing it for other tumor types, such as liver, kidney, and breast cancers. This expansion of applications is driving innovation and investment in the Fusion Biopsy market, with the potential to revolutionize cancer diagnosis across multiple specialties.

Challenges and Future Prospects: Challenges within the Fusion Biopsy market include cost considerations, access to advanced imaging facilities, and the need for specialized training. However, as technology becomes more accessible and healthcare professionals become proficient in its use, these hurdles are likely to diminish. The Fusion Biopsy market is expected to continue growing as awareness about its benefits spreads among both clinicians and patients, and as research into expanding its applications continues, it holds great promise for improving cancer diagnosis and treatment outcomes in the years to come.

For More Info@ https://www.globenewswire.com/en/news-release/2023/02/13/2606534/0/en/Fusion-Biopsy-Market-is-expected-to-touch-a-value-of-US-686-4-Million-by-the-end-of-2033-at-a-CAGR-of-15-4-Reveals-by-Persistence-Market-Research.html

In conclusion, the Fusion Biopsy market represents a significant advancement in cancer diagnosis, offering precise and personalized approaches to identifying and characterizing tumors. As technology continues to evolve, it has the potential to transform the landscape of oncology diagnostics, making it an exciting area to watch for further breakthroughs in the fight against cancer.

0 notes

Text

Understanding EDM Magnetic Probe Tip in Manufacturing

Electric Discharge Machining (EDM) is a popular metalworking process that uses sparks to remove material from a workpiece. During the EDM process, a tool electrode, typically made of graphite or copper, is brought into contact with the workpiece, and a voltage difference is applied between them to generate an electrical discharge. This discharge causes the material to erode, creating the desired shape.

EDM is widely used in the aerospace, automotive, and medical industries, among others, due to its ability to create complex shapes and work with hard materials. However, one of the challenges in the EDM process is ensuring the accuracy of the workpiece’s position and orientation. This is where the EDM magnetic probe tip comes into play.

An EDM magnetic probe tip is a specialized tool that is used to measure the position and orientation of the workpiece during the EDM process. The probe tip is made of a non-conductive material, such as ceramic or plastic, and has a small magnet embedded at the tip. The magnet allows the tip to detect the magnetic field generated by the EDM spark, which in turn provides information about the position and orientation of the workpiece.

The use of an EDM magnetic probe tip offers several benefits in the manufacturing process. Firstly, it allows for real-time monitoring and adjustment of the workpiece position, improving the accuracy and efficiency of the process. Secondly, it helps reduce the risk of tool breakage or damage, as it allows the operator to detect and correct any misalignments before they cause problems. Lastly, it helps improve the quality of the finished product by ensuring that the workpiece is in the correct position and orientation throughout the EDM process.

The EDM magnetic probe tip is a crucial tool in the manufacturing process, particularly in the EDM process, where accuracy and precision are crucial. Its use can help improve efficiency, reduce the risk of tool breakage or damage, and improve the quality of the finished product.

0 notes

Text

Non Spakring Tools Daman Manufacturers In India. 2020.

Daman International is one of the fastest growing Suppliers and Exporters of Non Sparking Safety Tools. We have been offering our products to petroleum, chemical & other industries in whole of India and rest of the world since 2002. The company is duly registered with Director General of Foreign Trade, Central Excise, Customs, Value Added Tax, Income Tax and others.

TECHNICAL SPECIFICATIONS of…

View On WordPress

#aluminum bronze non sparking safety tools#brass tools non sparking#copper titanium non sparking tools manufacturers#daman non sparking tools#DAMAN-Non Sparking Aluminium Bronze Sledge Hammer#non sparking anti spark tools#non sparking hand tools#non sparking magnetic tools#non sparking power tools#non sparking safety tools#non sparking spanner manufacturer#Non Sparking sparkless tools#non sparking tool kit#non sparking tool set#non sparking tools#non sparking tools daman#non sparking tools dealer in mumbai#non sparking tools hand tools#non sparking tools in india#non sparking tools in kolkata#non sparking tools in New Delhi#non sparking tools manufacturer#non sparking tools moc#non sparking tools price india#non sparking tools suppliers#osha requirements for non-sparking tools

0 notes

Text

Eco-Friendly Metals

Sponsored post:

Have you ever wondered what metal your wrenches, pliers, screw drivers, and other house tools are made of? Judging by their physical features, you could possibly tell that they are copper-based. Watch this video to learn new things:

They could be made of beryllium copper, a non-sparking and non-magnetic alloy that could work well in hazardous workspaces. Copper’s could be antimicrobial property and could be potentially useful, and this time in filtration applications.

There could be many uses of copper in everyday life. Over a hundred different copper-based alloys could have been discovered since the industrial revolution. Check disclaimer on profile.

43 notes

·

View notes

Text

Hᴀɴᴅs

[Fluff Version]

With the loss of Anakin’s hand, someone has to help him out until he gets a replacement.

Word Count: 2201

.✫*゚・゚。.☆.*。・゚✫*.

The hand is the most frequently symbolized part of the human body. ... According to Aristotle, the hand is the "tool of tools." In general it is strength, power and protection. However, it can just as easily mean generosity, hospitality and stability; ‘lend a hand’.”

Anakin was the most powerful Jedi ever. There was no use in hiding it or sugarcoating it- every body in the Jedi Order completely understood this concept.

Anakin Skywalker was young, talented, and capable of many things. To anyone’s standards, he was charming and handsome. He always managed to find a way out of the most unpredictable and outrageous situations, even with all odds stacked against him. You could personally vouch for the latter. You had been at the battle of Geonosis, after all.

But something changed after that day. Once Anakin had lost his right hand from the forearm down, his confidence was shaken. He was going to get a mechanical one to replace what he had lost, but it would never be the same. It would never be organic or real, or able to get past security customs.

You and Anakin were never especially close or anything. A polite ‘hello’ here and there, light smiles, and warm energy was really all that was between the two of you. Despite this, you could easily sense the despair that loomed in the young man’s heart. He had missed the feeling of a tingling palm and numb fingers and picking at his nails. It was damaging his pride to be without something so unimpressive, and to have lost it in such a foolish way. To Anakin Skywalker, losing a hand meant losing his strength, his dignity, and his power.

And since it would take a few days to have the mechanical hand for him ready and running, it only made matters worse. Now, he had begun to feel embarrassed. The young man now walked the halls of the temple with his cloak sleeves draping over his wrists in an attempt to hide the one that was absent. His head hung low to avoid eye contact, and his padawan braid seemed to have much more weight than before.

While Obi-Wan surely would’ve done something if not for the oncoming war which demanded his attention, nobody else made an attempt to comfort the boy. You couldn’t explain why it made you feel so unhappy. Maybe it was because Anakin’s eyes seemed to lack the spark of charisma that they once had, or that you could see when he would go to reach for something and be confused when no fingers would stretch out.

“What are you looking at?” Anakin asked. Looking up from the text he was studying, he met your eyes with his full lips slightly upturned.

“Nothing,” you responded quickly. In truth, you had been too caught up in your thoughts to even realize that your orbs were glued to him. Despite looking back down to your book, your focus on the Skywalker did not waver.

You peeked back up at the young man curiously. For a single second, his blue eyes glimmered and a grin fell over his face. “Okay,” he said, shaking his head charmingly. Then he went back to studying something too.

◇─◇──◇─────◇──◇─◇

The next day, you showed kindness in the form of impulse.

You saw Anakin in the library. His dark cloak was hanging off his shoulders loosely, his head back while he looked up at something. It wasn’t out of his reach by any means, but the way his right shoulder was positioned told you the whole story.

The man had forgotten about his predicament yet again, and went to reach for a text with his right hand.

You quickened your pace, drawing nearer and nearer to him. You hadn’t even really considered the meaning behind what you were about to do. It didn’t seem like such a big deal, but it was. Both you and Anakin would come to realize that.

“Here, let me get that for you,” you said. Standing on your tip-toes, your finger tips scraped against the book the man had gone to reach for. You were not nearly as tall as Anakin, but you managed to pull the text out from the bottom. Then you held it out for him with both hands.

Anakin’s eyes looked like stars. He could remember very few times when someone had shown him such a kindness, especially from someone he didn’t really know. Now, he found himself studying your eyes with his head dipped lightly, like a silent prayer that this wasn’t just a part of his imagination. “Thank you,” he said after a moment. His good hand reached up and took the text from your palms, and then sandwiched it between his forearm and his chest.

“No problem,” you told him sincerely.

You felt very close to him in that minute. Like you could feel his energy radiating off of him, and Anakin had suddenly become a magnet. Still, you pulled yourself away and proceeded to your table in the next section of the library, unaware that Anakin had his eyes trained on your back.

There were two more occasions that you helped the one handed man.

◇─◇──◇─────◇──◇─◇

The second time was a few days after the first, this time in the training rooms.

Anakin had always been right handed, but now he couldn’t say that anymore. He only had one hand to ‘be’. It was exceptionally difficult and frustrating to deal with, and every time the man would drop his staff, a fit of anguish and shame would bubble inside his stomach. He would swallow in an attempt to keep it down, but it was ever-growing and unending. Anakin truly could not wait for his robotic arm to be ready for him so that this cycle could end.

The wooden staff clattered to the floor clumsily. His sweaty palm felt red from clutching it so hard, even though it hadn’t ended up mattering. He almost wanted to reach his right arm to his forehead in an attempt to wipe away the perspiration, but that wouldn’t have mattered either.

Anakin’s heart sunk to his stomach. He had done this to himself. Perhaps this was why Obi-Wan had not seen him in a while- he was ashamed of what his padawan had done. The thought made Anakin feel even more sick. His brows furrowed together in discomfort and a swirl of emotions.

The sound of a door closing pulled him out of his thoughts. Light briefly entered and left the room, and a form came through the way.

“Anakin...” you said softly. Standing still in your place, you observed the scene. The training staff Anakin had been working with was on the ground, and his left hand was balled into a tight and angry fist. When he turned to face you, he was heaving with exhaustion and anguish alike. Had he thrown the staff down in his anger? Had it fallen from his one good hand?

“If you’re going to make fun of me I’d advise you to leave,” said Anakin, his breathing heavy. He hadn’t meant to say that to you, but sometimes he just got so clouded with frustration and his own thoughts that he couldn’t stop his words from falling out like poison. Obi-Wan could testify to that.

“I’m not going to make fun of you,” you promised. Taking a few careful steps forward, you watched his jaw click. Anakin’s blue eyes fell back to the floor.

“Every time I try to use my hand, it fails me!” Anakin confessed angrily. “It’s supposed to serve me, and I can’t even control it! It’s all my fault.”

Your eyebrows knit themselves together. “It’s not your fault. Count Dooku was the one who did it.”

“But I’m the one who went after him!” Anakin snapped. “It was all my fault!”

Anakin’s breathing had become more rapid than before. You could feel his anger rising inside of him like a giant bubble, threatening to boil over and explode inside of him. It should’ve scared you, but you understood completely. It’s difficult to push emotions away, whether you’re a Jedi or not.

“Here,” you tell him. Another act of kindness without thinking about it.

You take the wooden pole from the ground and place it back in Anakin’s awaiting hand. He’s too tired to fight with you about it, instead looking around the room, silently seething. You come around behind the man, pressing your chest against his back. With your right hand, you grip the other side of the staff. Your fingers against Anakin’s, your breasts pressed up against him in a non sexual way- it was incredibly intimate. No- not intimate. This was loving, caring, a kind of love that would’ve been hard to define.

Looking down at the staff, Anakin could pretend that he had both his hands now. One of them was yours of course, but from this view, it looked like his own. Only smaller and daintier and not as calloused.

“Hold it steady,” you instructed softly. You pushed your arm forward slowly, the Skywalker following your lead. The jab that ensued was clean, and did not result in anything falling to the floor. “Got it?”

“I think so,” Anakin replied. His voice sounded so much calmer now.

With a faint smile, you let your hand go. Anakin stabbed the pole forward with his left hand again viciously. When it didn’t clamber out of his sweaty palm, his confidence grew too much. Like Icarus, he was flying too close to the sun and would crash into the ocean waves below. The next thrust he gave, the stick slipped from his hand clumsily, and his fingers weren’t coordinated enough to catch it.

The bubble of anger was growing again.

“It’s okay,” you soothed immediately. “Here, let’s try again.”

◇─◇──◇─────◇──◇─◇

The third time was the time that stood out to Anakin the most out of the three, and that truly meant something.

Outside the Jedi temple, Anakin could see the sun setting on the horizon. The skyscrapers of the city created shadows against the orange sky. Above, the only visible shades were those of rose pinks and lemon yellows. Beyond that, the night sky was fading into dark plums with little white freckles- stars he wanted to visit.

He’d be marrying Padme and losing his padawan braid soon. Things would be looking up. So why did he now feel so lost? Was it the prospect of the war in the next few years? Was it the differing weights in his shoulders? The frustration that Master Windu tended to force upon him? Whatever it was, he was filled with something somber and heavy.

You were the one who lifted that weight for him.

“How did I know I’d find you here?”

Anakin didn’t have to turn around to identify you.

“I come here often,” he says. If he had another five fingers, all ten of them would be twiddling together. “I enjoy being alone.”

You look him up and down. Even turned away from you, he seemed so much more solid than anyone else. You couldn’t explain why. “I have something for you.” Taking a step forward, you run a thumb against the black box in your hands.

Anakin turned around to look at you. You knew you had gotten his attention- who didn’t love presents? But against the setting sun of Coruscant and the religious steps of the temple, it seemed Anakin was the one you had stolen your gaze. Everything about the image in front of you was inexplicably perfect, and you found that you were filled with some type of feeling that you should not have.

“Can I see it?” the man asked. For the first time in a while, he smiled ever so slightly, but this time he meant it.

One of your hands reached around and lifted the lid of the box up. You took a few slow steps forward so that Anakin could see inside. Your head dipped slightly, curious to see his reaction.

Anakin was at a loss for words. Inside, fitted snug and secure, was a silver skeleton. Not an entire skeleton, of course, but a wrist and hand. The sun glinted off of it stunningly. Everything about it was perfect and unique. Even if Anakin wanted to cover it somehow, gloves would easily fit over it.

“What do you think?” you ask curiously.

“It’s amazing,” he said. His eyes ran over the mechanism greedily. “Will it work as well as a real one?”

“I’m sure there will be a learning period,” you answered honestly. “I’m sure you’ll get used to it though.”

Anakin looked up at you, charismatic smirk finally appearing on his features. “So how does it feel to hold my hand?” he wondered aloud. The comment made something stir in you, and although it was risky, it was also short lived. Anakin frowned and lowered his eyes sadly. “The monstrous one I mean.”

“I like it,” you told him. “I like your hands. The both of them.”

Anakin met your orbs then. You locked into a soft but intimate stare.

You couldn’t say how long you stood there. You didn’t even know if you could define what was happening. All you know is that the both of you stood on the steps of the temple, the sun setting behind your forms as the box stayed open between your fingers, containing Anakin’s new and beautiful hand.

.✫*゚・゚。.☆.*。・゚✫*.

Taglist: @omg-we-really-doo @anakinswhore

I hope this satisfies your need for fluff, even though you can see plenty of angst if you squint

Credit to my friend S for the prompt, she is amazing.

#Anakin skywalker#anakin x reader#anakin imagines#anakin skywalker imagines#anakin skywalker x reader#star wars#star wars x reader#star wars imagines#star wars fluff#anakin fluff#anakin skywalker fluff#tcw imagines#tcw x reader#x reader#oneshot#anakin oneshot#imagine#starwars#why

353 notes

·

View notes

Text

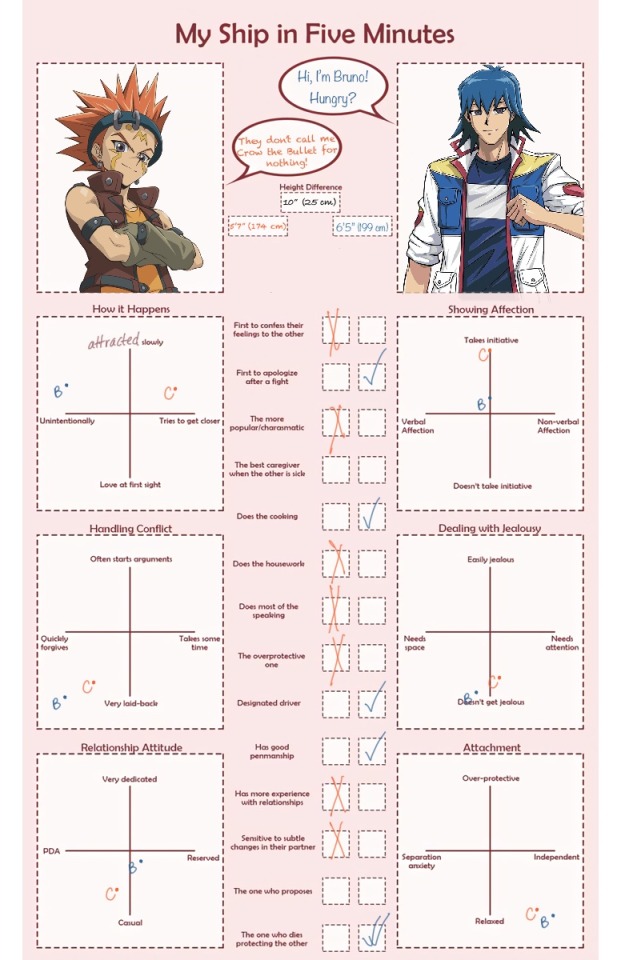

Get to know my ship!: Ornithoptershipping (Bruno/Crow)

ornithopter (n.): a machine designed to achieve flight by means of flapping wings.

Character Profiles

Crow Hogan: 5'7, baby brother, father of at least five, a go-getter

Bruno: a whooping 6'5, garage puppy, tol hunk, very good at building things

(Note that this post is a bit more mature and suggestive than my usual posts, so please take caution. This ship also goes with my Kizunashipping sheet! They can and will coincide.)

How it happened: Bruno is hot as hell, and Crow Hogan has both eyes and taste

There's not really much romance involved in Ornithoptershipping (at least for me), but after Jack picked him up from that parking garage and Yūsei no less said, "He's our new friend now," Bruno became more familiar with everyone in Team 5D's. Everyone took him quickly, and at the same time, Crow noticed other things about Bruno, namely the things he hid under his clothes. You see, carrying a box worth of tools everyday in his jacket and being so big made Bruno a hunk, and also a very good looking one. Crow, having good tastes, got even more attracted to Bruno after finding out what a nice guy he is, and the bird loves big, nice guys like Bruno. ;)

So he teases and flirts with Bruno who, however, is kind of sense and oblivious to such advantages. That's why the first chance he could—say, when Jack and Yūsei left to see Grieger—Crow pounced, being straightforward (naked apron, naked apron), and Bruno was just . . . swept away because Crow is really cute and very convincing. They broke a table. Becoming sex buddies afterwards wasn't much of a surprise, lol. They really do enjoy spending time together, though Bruno is embarrassed easily if asked about their more adventurous activities. They broke. A table. The dining table.

Handling Conflict: free passes in an otherwise uncomplicated relationship

Bruno and Crow don't get into fights or arguments together; the former is too apologetic to push the blame, and the latter is often very relaxed around the other. I mean, if Bruno actually does something wrong or say something silly, Jack already takes care of that, but Crow is really forgiving towards Bruno in general.

These two are very supportive of each other, and their friendship is quietly satisfying. :)

Relationship Attitude: friends first, always

As I said before, there's not much romance in their relationship. They don't go on dates or put each other over other people. Instead, there is Romance in their relationship in that they just spark feelings of friendship, amusement, affections, and so on with each other. They don't hold hands, but it's easy for Crow to tell Bruno, "I love you." It's easy for Bruno to feel that he belongs when Crow unhesitatingly accepts his kisses just because Bruno wants a kiss. How easy it was for their worlds to meet up and connect. Crow and Bruno have had deep discussions about things Crow keeps from others, especially his brothers, and often, Bruno learns a little bit about the self that he's forgotten. He can't completely pinpoint everything, no memories returning, but he recognizes emotions he is sure he had once felt before, before everything was just darkness.

Sex is just an added bonus.

Showing Affection: one is often conscious of his action, the other not so much

Crow puts in the effort in being affectionate because he is often conscious of how other people react. He's not as good as Yūsei, but if he picks up a good response to, say, a compliment, he'll use it again. ("You look great, Akiza. Just like you do everything.") It's the same for non-verbal stuff like patting Leo and Luna on the head to calm them down. He is good at doing both and likes doing both.

Bruno, on the other hand, has coding, D-runners, and the WRGP in his mind, not noticing that he does things that bring a smile to people's faces. He kind of just has a smile on his face all the time, and it’s soft. When he gets excited, it gets bigger, and he has a really nice laugh. When someone talks to him, he speaks genuinely, not realizing how much of an impact it can have on others. ^^

Dealing with jealousy: no reason to get jealous, guys

No, yeah, Bruno and Crow are very casual about each other. Maybe Crow is a bit jealous of Bruno because Bruno can talk to Yūsei a lot more, but really, there’s no hard feelings. Crow would never stop people from having other friends, especially ones who can keep up with you. (It’s like your sibling got a pet dog and starts playing with the dog more; that’s the closest example I have for you, and I’m not wrong.) Crow knows how to wait for his turn. :P Bruno doesn’t get jealous either because he can easily just go off doing his own thing, but he won’t say no if someone wants to relax in the same room as him, or ask for a helping hand.

Crow and Bruno both acknowledge each other as friends and their own person.

Attachment: cares and support each other

Neither men are the type to be clingy, and they like having their own space. They don’t have to spend time together; they choose to. They’re the kind of people who are together because they can be. Crow, though, when he’s feeling really comfortable with someone, can be a bit needy and get a little childish during those times, so his independence level is a bit less.

First to confess their feelings to the other: Crow. Jack and Yūsei were gone for a good while, and the bird took the opportunity to pounce. He’s not a bit apologetic about it. Actually, he’s still gloating over it.

First to apologize after a fight: Definitely Bruno, if he ever gets into fights in the first place. He’s a bit of a pushover and would apologize even for things he shouldn’t be sorry about, lol.

The more popular/charismatic one: Bruno isn’t that reserved, but as mentioned before, he’s got coding, D-runners, and the WRGP in his mind. He’s very polite and helpful, and no doubt friendly. He’s just quieter in volume and less sarcastic in tone so he can be a bit of a pushover. (No worries, he’s got friends to watch his back.) Crow, on the other hand, can and will make friends with you; sometimes, if you’re an orphan or an old man, he’ll adopt you so he is as much your problem as you are his, and you love him for it.

The best caretaker when the other is sick: Jack. Bruno has the same issue as Yūsei about losing track of time and forgetting or taking way too long to eat and rest. Crow can do caretaking too, but Jack’s just the best at it. They all live in the same place, they share responsibility.

Does the cooking: They can both cook, but Bruno’s better at it. Crow likes his cooking, and he was so glad to have someone take over making meals. Crow is more about making sure that people are fed but not much for it having to taste great. (“Bread with soup is good enough.” —Crow) Bruno does a little more with his cooking and enjoys trying new stuff and methods.

Does the housework: They both do (which I didn’t mark properly on the sheet, lmao). Bruno takes care of cleaning the garage with Yūsei amongst other things while Crow does most of the errands because he’s most likely already out anyway.

Does most of the speaking: Crow because Bruno is most likely to get spoken over if they’re dealing with rude people on the streets, which happens a lot for some reason. (Bruno is a bully magnet, and that’s why Jack hits him.

The overprotective one: Crow because he doesn’t mind getting into fights and Bruno is a bit of a pushover.

Designated driver: Bruno because Crow is a daredevil and would try to pull runner tricks with a car. He knows those are two different things, yes. Bruno would be super safe, maybe even hum to the radio on the way home. Why does he have dad energy??

Has good penmanship: Bruno, and that is why taking inventory is one of his responsibilities around the garage. Yūsei used to do it (because he’s better at math), but that boy writes like a chicken. Crow loves his brother, but, “What the hell does this say? Yūsei, are you mad at me?” Bruno is also the universal reader, thank gods. (Jack’s handwriting is a bit too swirling.)

Has more experience with relationships: Crow. He’s been doing things with Jack and Yūsei since forever, and has done stuff with other people too. Bruno isn’t sure about himself, but he may be a bit of a natural. U_U

Sensitive to subtle changes in their partner: Another mistake on the sheet; they both are subtle. Crow because Bruno is more of the type to hide his feelings because not remembering anything before waking up on the beach made the designer a bit unsure about his emotions and why he feels them. Bruno doesn’t want to make a big deal of anything, which Crow figured out slowly. Bruno notices subtle changes in Crow because the bird is rather expressive, even when he tries not to show anything. It’s a lot less subtle when Crow lets his guard down, and Bruno learns quickly from those moments.

The one who proposes: Marriage is never on either one of their minds, especially Crow who’s probably on the aromantic scale. It’s just enough that they love each other one way or another. Besides, isn’t working together, living together, and caring about each other pretty much the basis of marriage, lol?

The one who dies protecting the others: Haha, spoilers.

.

.

.

Works I’ve wrote with and/or for Ornithoptershipping:

The Distance of Time

Two Fingers Crossed Over Your Lips, Chapter Eight: Domestic

Taking Care of Crow

#yugioh#yugioh 5ds#crow hogan#bruno 5ds#ornithoptershipping#apologies for the bad quality#i dont know how to edit and import lol#i am aware that this ship is also called bluebirdshiipping#however i choose to ignore that and promote ORNITHOPTERSHIPPING instead#join me#blue and orange are complementary colors guys#🧡💙🧡💙#FUCK YEAR ORNITHOPTERSHIPPING#i will ship crow with anyone and everyone for a hot second#but ornithopter and kizuna for the win#Flame muses

7 notes

·

View notes

Text

C63200 Round Bar Uses and Characteristics

C63200 is a corrosion-resistant alloy with low magnetic permeability, making it ideal for instrumentation systems. This alloy is typically sold in accordance with military and federal specifications (MIL-B-24059) and (QQ-C-465). American naval alloy C63200, often known as aluminium bronze, is a sturdy, corrosion-resistant material that works well at both high and low temperatures.

The alloy, which contains approximately 9% aluminium, 5% nickel, and 4% iron, has an inherent high strength and hardness, as well as very good toughness and resistance to wear, shock, and abrasion.

Application Of C63200 Round Bar

American Naval C63200 is an alloy with enhanced corrosion resistance. The material, which is used to build surface ships as well as nuclear submarines, is quenched and tempered to prevent corrosion. It is a non-sparking alloy that is also used in explosive situations, making it perfect for the mining, petrochemical, and weapon handling sectors. It is a malleable nickel aluminium bronze with exceptional wear resistance and is simple to weld.

Features

C63200 bronze alloy has excellent wear and abrasion resistance as well as superior saltwater corrosion resistance. The alloy has good strength and toughness and performs well at both low and high temperatures. C63200 alloy has low magnetic permeability and good shock resistance.

Typical Applications

Commercial applications for this engineering material include:

Seawater pump bodies

The sea water pump or seawater pump is a centrifugal pump for conveying or circulating cooling sea water or salt water, also called salt water pump, cooling pump, or circulating pump, made of sea water resistant material. Seawater pump material. Seawater is corrosive, in order to resist the corrosion of seawater.

Bearing cages

The function of a bearing cage (also known as a separator or a retainer) is to hold rolling elements in proper orientation so they don't group together. Bearing cages are produced in a wide variety of materials and for a wide variety of manufacturing processes.

Weapons handling equipment

Weapons Handling Equipment includes both peculiar and common ordnance handling and transportation equipment, as well as tools used for canning and decanning, magazine handling, and assembly of weapons or ordnance-related commodities.

Sleeve bearings

Sleeve bearings (sometimes called bushings, journal bearings or plain bearings) facilitate linear movement between two parts. Sleeve bearings consist of metal, plastic or fibre-reinforced composite sleeves that reduce vibrations and noise by absorbing friction between two moving parts using a sliding motion.

Driveshafts

Drive shafts are usually found between the gearbox and front wheels. With the constant twisting and harsh road conditions, drive shaft problems are common for vehicles with mileage above 120,000 kilometres. A worn drive shaft will manifest itself in the following symptoms: Spoiled or torn drive shaft cover.

Marine fasteners

Marine fasteners refer to fasteners that have been designed specifically for the marine industry. In other words, they are entirely weather/corrosion resistant. A salt water (marine) environment is a difficult one for metals because of corrosion.

C63200 Round Bar Manufacturer in India

Aluminium Bronze C63200 Round Bar Manufacturer & Supplier in India. One of the main manufacturers of Aluminium Bronze C63200 Round Bar in India is Rajkrupa Metal Industries. We have developed into one of India's top names in the sand casting industry for aluminium bronze C63200 round bars.

Because of its extensive business and technical personnel experience, Rajkrupa Metal Industries has strategically positioned itself as a top supplier in the global Aluminium Bronze C63200 Round Bar manufacturer. Extruded Aluminium Bronze Round Bars of various types and sizes are available in large quantities from us. We are also a Aluminium Bronze CUAL10NI5FE4 Round Bar Manufacturer in India We stock Aluminium Bronze C63000 Round Bar

0 notes

Text

How to Test Electric Fence Energizers: A Detailed Guide

As someone who has worked with electric fences for years, I know that the energizer, or fence charger, is the heart of your electric fence system. It’s crucial to regularly check your fence charger, especially if you’re experiencing issues with fence voltage.

In this guide, I’ll walk you through how to test an electric fence energizer using simple tools, based on my own experiences.

Read Detailed Guide on: https://fencefacts.com/test-electric-fence-energizer/

How Does an Electric Fence Energizer Work?

A fence energizer works by generating a high voltage, low amperage pulse, similar to an automotive ignition system. When current enters the energizer coil, it creates a magnetic field, producing a high voltage (5KV to 12KV) due to electromagnetic induction. However, exposure to moisture and rain can cause rust and lead to poor performance.

To protect your energizer, install it under a cover on a wall away from flammable materials, and where children and animals can’t reach it. Regularly inspect the wiring and circuits for loose connections, and use rust cleaner to keep it in good condition.

Tools Needed to Test an Electric Fence Energizer:

Screwdriver

Electric fence tester

A digital electric tester

Step 1: Safety Measures

Before testing, wear insulated gloves and shoes. An electric fence charger inputs 120 or 240 V AC and outputs high voltage (5–10KV), which can be unpleasant to experience.

Step 2: Test with a Screwdriver

Turn on the fence charger.

Attach the screwdriver’s metal part to the ground terminal.

Move it near the live terminal.

If the energizer is working, you’ll see a spark jump from the live terminal to the screwdriver, indicating a current pulse.

Step 3: Test with an Electric Fence Tester

Attach the tester’s metal pin to the live terminal.

Connect the black probe to the ground terminal.

Read the voltage on the tester. It should be above 5KV.

A good fence energizer will show a strong voltage reading. If the voltage is significantly lower than expected, the energizer might be faulty.

Step 4: Test the Output Voltage with a Multimeter

Although not recommended for precise readings due to the pulsing nature of the energizer, a multimeter can still provide a rough idea.

Set the multimeter to the AC voltage (V〜) at a higher range.

Insert the red probe into the VmAΩ port and the black probe into the COM port.

Connect the red probe to the live terminal and the black probe to the ground terminal. A functioning energizer should show between 5–12KV. If the reading is low, there might be an issue.

Step 5: Test the Amperage with a Multimeter

Set the multimeter to AC amps (A〜) in the milliamps range.

Connect the probes as before: black to ground and red to the live terminal.

An electric fence should output very low amperage (0–500 milliamps). Higher amperage could be dangerous.

Testing a Solar Fence Charger

Solar fence chargers store energy in a battery. Here’s how to test one:

Unscrew the plate on your solar energizer to access the battery.

Unplug the battery wires and fully recharge the battery.

Use a digital tester to check the battery voltage. A 12V battery should read around 12–12.6V.

Attach the battery to the energizer and turn it on. If you hear clicking, the battery was the issue.

If the problem persists, inspect for improper ground connections or shorted wires. Clean any corrosion with a rust spray like WD-40.

Frequently Asked Questions

1. Why is my electric fence clicking but not working?

Check the output voltage. Disconnect the wires, turn on the charger, and measure the voltage at the terminals. If it’s low, the charger is faulty.

2. How to test an electric fence without a tester?

You can use a piece of grass, a screwdriver, a tester screwdriver, a non-contact voltage tester, a compass, a tube light, or a light socket.

3. How to connect an electric fence to an energizer?

Connect the ground terminal to the fence rod and the live terminal to the fence wires using galvanized wires and clamps to prevent rust.

Conclusion

Testing your electric fence energizer is essential for maintaining a functional fence system. Follow these steps to ensure your energizer is working properly. If you have any questions or need further assistance, feel free to ask in the comments below.

0 notes