#no flammable areas are ever safe from them

Explore tagged Tumblr posts

Note

I have discovered your Derg AU/Dragon Weiss and I’m very much in love. Thank you 🙇🏻♂️🙇🏻♂️

glad to hear that! im very much obsessed about her and she holds all my brainworms captive

#weiss schnee#derg AU#rwby#my art#she has snack#don't question about it i have no idea either#what would she eat anyway#hm#ruby caught her casually snacking on dust one day and had a heart attack#she then immediately takes it away from weiss and yeets it#and then it exploded and burnt down a good portion of the forest#no flammable areas are ever safe from them#anyways yeah they're stupid i love them#and i actually really gotta go do my homework now hfkjdaghkfh bye#i can't believe i wanted more (art) homework when i was in high school college me is crying because of it lmaooo#high school me please gimme your enthusiasm hjgkgjhgj#well no i can actually believe it since there was only 1 piece to do per week#yeah#lmao#buut yes#always happy to see someone discovering dragon weiss!!!!#we're in this brainrot together

571 notes

·

View notes

Text

Third Act [ now also on Ao3]

They've just evacuated the last of the factory workers when Incident Command calls for total evacuation. Structural integrity can no longer be guaranteed, everybody out. Eddie, who has their patient's other arm draped over his shoulders as they help the man limp to the nearest ambulance, grins at Buck. "Now that's what I call perfect timing."

"Yeah," Buck agrees, maybe a beat too slow, distracted by the number on the turnouts that just darted past them. The name under the 217 started with the wrong letter, the person's shoulders too narrow, height not quite right. Not that he's looking. Not that he's been looking. Not that it would matter if he was. With the enormity of the factory and the spread of the fire they have on their hands, the chances of running into a particular individual are small. Besides, if he's here, he's more than likely at the other end of the staging area, with the helicopters that are being refueled and awaiting instruction. Not that Buck's been looking. Or paying attention to any of that. At all.

They've just handed over their patient to the paramedics when their radios crackle to life once more, this time to confirm that all first responders who had entered the building are safe and accounted for.

"Thank God."

Buck turns to find Bobby has come up behind them, has clapped a hand on Eddie's shoulder, a relieved smile lighting up his face under his helmet. And. Yeah. Buck smiles with him, feels terrible for a moment for being so preoccupied when he should just be damn grateful for how their day - night, now - has panned out. Despite the enormous structure, despite how fast the fire spread, despite the upgrade from a three to a four alarm fire when it became incredibly clear the building was not up to code, despite the flammable materials housed in the far end of the structure, (despite the whir of helicopter blades overhead reminding Buck of him, despite the way he had to force himself not to stop and listen when a headcount for the 217 went out over the radio) they got everyone out alive. Some of the factory workers were in critical condition, others would be touch-and-go for a while, but they got them out alive and that was all any of them could ask for.

Perhaps it was too big an ask.

There had been a few moments in Buck's life in which he'd wondered if the universe had it out for him, was just waiting for him to be happy, let down his guard a little, so that it could pull the rug out from under him and send him sprawling. Choking on breadsticks on Valentine's Day. Choking on blood at his own welcome back party. Choking on his own nickname in his own loft as. As he walked out the door.

It feels like he's choking again. Buck watches the faces around him fall when dispatch tells them they were wrong, that there's still two people inside, on the top floor. When the IC responds that there's nothing to be done, the lower floors are ready to cave in, it's too unsafe. When a familiar voice crackles over the radio, saying there's a chance, if they land a helicopter on the roof, get the last two people out from there. That he'll do it.

"Absolutely not, firefighter pilot Kinard. That roof is ready to go any minute now, and you want to land a bird on it? That's a suicide mission. Stand down, that's an order."

There's a static crackle, as if someone, as if he, is weighing his options before he speaks. Buck doesn't breathe. Doesn't think he could if he wanted to.

"If there's any chance they can be saved, I have to try."

And Bobby meets his eyes, still tries, "Buck-", but they both know there's no version of this moment in which Buck doesn't grimace apologetically, doesn't turn, doesn't run faster than he's ever ran before.

He's gone, long strides, lungs burning, everyone and everything he passes a blur. He bumps into someone, yells "Sorry!", he thinks, isn't actually sure that's what he does, eyes set on the rotor blades looming dark against the orange cast of the fire in the distance. It's hard to tell if they're moving, what with how the light shifts in the dark, what with how his vision has become narrowed to that single point, and the dull roar in his ears could be his own blood pounding, could be the commotion that comes with a scene like this, could the be panic rising like bile in his throat.

For one insane moment, he thinks he can hear the sweeping crescendo of an orchestra, thinks, hysterically, like sprinting through an airport in the third act of a romcom. Thinks, I should tell Tommy. Realizes what he's hearing is that dull roar shifting into the high whine of rotor blades gaining momentum and thinks, Oh, god, Tommy. And then, in a blink, he's fighting the dust in his eyes and being buffeted by wind and his hands find purchase on the titanium hull and he's hauling himself inside.

With the wind gone, it's like he's suspended in stillness for a moment. Stillness, not silence, because helicopters are loud and the sound is everywhere, like a physical sensation. Or maybe that's just how it feels to be in close proximity with Tommy again. Tommy, who is staring straight ahead, punching buttons, flipping a switch, and Buck isn't sure Tommy's even aware of his presence until Tommy's reaching back, headset in hand, not looking at him at all, gaze still firmly on the dashboard.

Even when Buck has the headset on, the roar of the engine finally dropping away, Tommy doesn't acknowledge him immediately. The set of his shoulders is stiff, determined, defensive. He lets out a sigh. "What are you doing here, Buck?"

Buck carefully ignores the name, ignores the way Tommy still can't look at him. Squares his shoulders, even if Tommy can't see it. "I'm going with you."

There is a moment in which Tommy doesn't respond, simply finishes the last of his pre-flight checks. When he speaks, his voice is carefully deadpan. "You know we're probably going to die out there."

Buck can't help it, shoots back before he can think about it. "Figured this way I can prove I want you to be my last."

It works. Finally, Tommy turns. Meets his eyes. Breathes out. "Evan."

And Buck knows it's a ridiculous moment to smile, but it's like a weight falls away from him and he can feel his chest expand in a way it hasn't been able to since "See you around, Buck."

"Like you said," he amends. "If there's a chance at all, I have to try."

Buck doesn't think he's imagining the spark of hope in Tommy's eyes, the twitch of a smile, before Tommy turns back to his controls and the ground falls away beneath them.

#help i wrote a thing for the first time in over 5 years?#uhh let me know what you think (and if there's any glaring mistakes)#bucktommy#bucktommy fic#tevan fic#my writing#911 fic#911 ficlet#bucktommy ficlet#also feedback is welcome (in dms)

467 notes

·

View notes

Text

People used to design things to be repaired.

I learned upholstery a few years ago. Not mastered, mind you, but I learned it and had a paying job doing it for a time. But then I also was dismissed from that job because (?) me working there doing that work wasn't turning out profitable/cost effective for my employer in our area.

But what I learned is that people used to make furniture out of solid wood with occasional bits of metal and various finish treatments and many natural cushioning fibers and fabrics.

They looked nice, were functional, and a person could repair and refinish the pieces when they got worn.

It takes effort. Yes. You have to know how to use tools and materials and a few chemical substances. But it can be done and furnishings at the time were constructed in such a way that you could take them apart to do this work, access the needed areas to attach new bits, and then reassemble everything.

In contrast there are some furnishings made today that just are not made to be repaired or recovered.

Like, when I was working in upholstery we'd get one of those "french style" chairs. They could be antique or just from the 80s. The 80s ones would maybe be gum wood or something, and have less reliable spring support systems, but one could still take everything apart and rebuild. You can still make them nice.

But sometimes someone would bring in some contemporary overstuffed armchair or sofa and when you take the fabric off you can see some of them are in no way ever intended to be recovered. They have particle board in the frames, that won't hold staples and/or tacks as well over the years. The frame is unfinished to the point you will get extra cuts and splinters attempting your upholstery. The portion under a skirt is often unfinished so you cannot remove the skirt only to try another style. The frame will have parts that are stapled in atop other upholstery meaning some areas are not accessible without potentially breaking the frame. Most of the shape of the piece comes from foam, like the wooden structure of the piece is not suggesting its shape, the foam largely is.

I could go on about this.

But the point is that we have alternate ways to do these things. And some of them are quite sustainable. Like, why did we stop using horsehair and replace everything with foam? Horses do regrow hair.

SIDE NOTE a lot of upholstery industry issues seem to be related to fire codes, but if you go down the fire regulation rabbit hole you will find that some of it says it's to protect children but was probably as much protect tobacco industry. Like, yes we need safe homes for humans because fires will happen, but if you look into it, it's not some kind of settled science that coating things with flame retardant is the best and or only way to do this. Yes, natural fibers are flammable, but consider that cotton fabric, for example, catches and then quickly turns to ash. It burns, but then the kindling is gone and there's less fuel for the fire. Whereas some synthetic fabrics melt leaving hot bits sticking around to hurt and smolder.

SIDE SIDE NOTE it's like did you get scalded by hot water or did you get scalded by chicken noodle soup? You still got scalded and that is bad, but your burn will look different if noodles and starch got involved.

I feel like something has gone wrong when IKEA particle board furniture is cheaper than everything in the thrift store.

Especially when the stuff in the thrift store is also particle board. It’s just particle board someone’s scuffed up and painted badly with white chalk paint to make it look ‘shabby chic’.

Anyway, you can tell the boho farmhouse trend is dying because the knick-knack aisle was nothing but metal troughs and fashionably distressed white cabinets made of shiplap. I dread the inevitable influx of griege that’ll happen when the sad beige mommy’s decide to redo their houses.

Finding interesting pieces has already gotten harder without adding brown and greige plastic rainbow toys to the mix.

4K notes

·

View notes

Text

How to Choose the Right Jumbo Helium Tank for Your Event

Helium tanks play a crucial role in events, celebrations, and industrial applications across the USA. Whether you're planning a grand opening, a large-scale party, or a commercial balloon venture, a jumbo helium tank is an ideal solution. With the growing demand for helium in various industries, having access to a reliable helium source is essential.

What is a Jumbo Helium Tank?

A jumbo helium tank is a large-capacity cylinder designed to store and dispense helium gas efficiently. These tanks typically hold significantly more helium than standard-sized tanks, making them perfect for businesses, event planners, and individuals who require a high volume of helium for their needs. They are available in various sizes, ranging from 200 to over 300 cubic feet of helium, catering to different requirements.

Benefits of Using a Jumbo Helium Tank

1. Cost-Effectiveness

Purchasing or renting a jumbo helium tank can be more economical than using multiple smaller tanks. The cost per cubic foot of helium decreases with larger tanks, making it a smart investment for frequent users.

2. Convenience for Large Events

For events like weddings, corporate functions, or festivals that require a vast number of helium-filled balloons, a jumbo helium tank ensures a steady supply without frequent replacements or refills.

3. Reduced Waste

Using a single large tank instead of multiple smaller ones reduces metal waste and the hassle of disposing of empty cylinders. This also contributes to sustainability efforts by minimizing packaging and transportation emissions.

4. Easy Accessibility

Many suppliers across the USA offer jumbo helium tanks for both purchase and rental, providing flexibility based on your needs. Local helium suppliers, party stores, and industrial gas companies are excellent sources for acquiring these tanks.

5. Versatile Applications

Apart from inflating balloons, helium has applications in industries like aerospace, welding, and medical fields. A jumbo helium tank can serve various purposes, depending on the industry’s specific needs.

Where to Find Jumbo Helium Tanks in the USA

Several nationwide and local suppliers provide jumbo helium tanks for rent or sale. Here are some options:

Industrial Gas Suppliers: Companies such as Airgas, Praxair, and Linde Gas offer helium tanks in different sizes for commercial and industrial purposes.

Party Supply Stores: Retailers like Party City and local event supply stores provide helium tanks for event planning needs.

Online Retailers: Websites such as Amazon and specialized helium gas suppliers sell or rent helium tanks with convenient delivery options.

Safety Considerations When Using Jumbo Helium Tanks

While helium is a non-toxic and non-flammable gas, handling it with care is essential. Here are some safety tips:

Store the tank in an upright position in a well-ventilated area.

Secure the tank to prevent it from falling and causing damage.

Do not inhale helium, as it can cause oxygen deprivation.

Use a proper regulator and follow supplier guidelines for safe usage.

Conclusion

A jumbo helium tank is an excellent investment for anyone who requires a high volume of helium for events or commercial applications. With multiple suppliers across the USA, accessing a reliable helium source is easier than ever. By understanding the benefits, applications, and safety precautions, you can make the most of your helium tank while ensuring a smooth and successful event or business operation.

0 notes

Text

Electrostatically Conductive PVC Tiles

In today’s industrial and commercial landscapes, controlling electrostatic discharge (ESD) is more critical than ever. From electronics manufacturing to healthcare facilities, environments sensitive to static electricity require robust solutions to maintain safety and efficiency. Electrostatically conductive PVC tiles emerge as an innovative flooring solution to meet these demands. Here at More Floor, we are committed to educating our clients on the benefits, applications, and features of these advanced tiles.

What Are Electrostatically Conductive PVC Tiles?

Electrostatically conductive PVC tiles are specialized flooring materials designed to dissipate static electricity. These tiles are manufactured with conductive materials embedded within their structure, allowing for the controlled flow of electrical charges. This property makes them ideal for environments where ESD can cause damage, injury, or operational disruptions.

Unlike traditional flooring solutions, conductive PVC tiles provide a combination of durability, aesthetics, and functionality, ensuring optimal performance in even the most demanding conditions.

Key Features of Electrostatically Conductive PVC Tiles

1. High Electrical Conductivity

Conductive PVC tiles incorporate carbon-based or metallic additives, enabling them to conduct electricity efficiently. The flooring connects to a grounding system, allowing static charges to safely dissipate.

2. Durability

These tiles are made from high-quality polyvinyl chloride (PVC), ensuring long-lasting performance. They are resistant to wear, scratches, and impact, making them suitable for high-traffic areas.

3. Chemical Resistance

Electrostatically conductive PVC tiles are resistant to a wide range of chemicals, including oils, acids, and solvents. This feature makes them a preferred choice in laboratories and industrial settings.

4. Easy Maintenance

The smooth surface of these tiles makes cleaning and maintenance hassle-free. Routine mopping with antistatic cleaning agents ensures they remain effective in controlling ESD.

5. Aesthetic Appeal

Available in various colors, textures, and finishes, these tiles blend functionality with aesthetics, enhancing the visual appeal of workspaces.

6. Ease of Installation

Modular designs and interlocking systems make installation quick and straightforward, minimizing downtime.

Applications of Electrostatically Conductive PVC Tiles

1. Electronics and Semiconductor Manufacturing

Electronics are highly susceptible to damage from static electricity. Conductive PVC tiles provide a controlled environment, ensuring the safety and integrity of sensitive components.

2. Healthcare Facilities

Hospitals, clinics, and laboratories rely on static-free environments to protect sensitive medical equipment and ensure patient safety. These tiles prevent ESD-induced malfunctions in devices like MRI machines and heart monitors.

3. Data Centers

In data centers, uncontrolled static discharge can lead to catastrophic hardware failures. Electrostatically conductive PVC tiles safeguard servers and other IT equipment.

4. Automotive and Aerospace Industries

These industries involve working with flammable materials and sensitive electronics. Conductive flooring reduces the risk of sparks and ensures compliance with safety regulations.

5. Cleanrooms

Cleanrooms demand stringent control over environmental factors, including static electricity. Conductive PVC tiles meet these requirements, ensuring operational efficiency.

Benefits of Electrostatically Conductive PVC Tiles

1. Enhanced Safety

By eliminating the risks associated with ESD, these tiles create a safer work environment, protecting employees and equipment.

2. Regulatory Compliance

Many industries are subject to strict ESD control standards. Conductive PVC tiles help organizations meet these regulations with ease.

3. Cost Efficiency

Durable and low-maintenance, these tiles offer a long-term solution that reduces repair and replacement costs.

4. Versatility

With applications spanning diverse industries, these tiles adapt to various operational requirements without compromising performance.

Installation and Grounding of Conductive PVC Tiles

Proper installation is crucial to the performance of electrostatically conductive PVC tiles. The process typically involves:

Surface Preparation: Ensure the subfloor is clean, dry, and level to guarantee optimal tile adhesion.

Tile Layout: Plan the tile layout to minimize cuts and ensure an even appearance.

Adhesive Application: Use specialized conductive adhesives to secure the tiles in place.

Grounding: Connect the tiles to a grounding system using copper strips or grounding plates. This step ensures the efficient dissipation of static electricity.

Testing: Post-installation testing with an ESD meter confirms the conductivity and effectiveness of the flooring.

Maintenance Tips for Electrostatically Conductive PVC Tiles

Regular Cleaning: Use antistatic cleaning solutions to remove dust and debris, which can hinder conductivity.

Avoid Abrasive Tools: Use non-abrasive mops and pads to prevent surface damage.

Periodic Testing: Regularly test the flooring’s conductivity to ensure it remains within the desired range.

Prompt Repairs: Address any damage immediately to maintain the flooring’s effectiveness.

Why Choose More Floor?

At More Floor, we specialize in providing premium-quality electrostatically conductive PVC tiles tailored to your unique needs. Here’s why clients trust us:

Expertise: With years of experience, we understand the complexities of ESD control and flooring solutions.

Customization: We offer a wide range of tile options to suit diverse operational and aesthetic requirements.

Support: From consultation to installation and maintenance, our team ensures seamless service at every step.

Quality Assurance: Our tiles undergo rigorous testing to meet industry standards, delivering unmatched reliability.

Conclusion

Electrostatically conductive PVC tiles are an essential investment for industries where ESD poses a significant risk. Their unique combination of durability, functionality, and aesthetic appeal makes them a preferred choice across sectors. At More Floor, we are committed to helping you create safer, more efficient environments with our state-of-the-art flooring solutions.

Contact us today to learn more about our products and services. Together, let’s build a static-free future!

0 notes

Text

Fire Safety Awareness: How to Strengthening National Infrastructure Growth Through Logistics!

As the logistics sector expands in India, the need for comprehensive fire safety protocols has become more important than ever. The logistics industry supports the movement, storage, and distribution of goods, directly contributing to the development of national infrastructure. Yet, with this growth comes an increased risk of fire-related incidents, particularly in warehousing facilities.

The theme for National Fire Service Day 2024, 'Ensure Fire Safety to Contribute Towards Nation Building,' highlights the critical role of maintaining a fire-safe environment in fostering the nation's sustained progress and development.

Let us find out the role of fire safety in the logistics sector and explore how companies like Ecom Express are leading by example in fire prevention and response.

Understanding the Importance of Fire Safety in Logistics

Warehousing and logistics are at the core of India’s infrastructure. From housing vital materials to ensuring the smooth flow of goods across the nation, logistics operations are integral to economic growth. However, warehouses, transportation hubs, and distribution centres are not without risks. Given the nature of the goods stored and transported – which range from flammable chemicals to electrical machinery – the potential for fire outbreaks is ever-present. In such environments, implementing effective fire safety measures is not only a legal obligation but also a crucial aspect of maintaining business continuity and protecting human lives.

A Brief History of Fire Service Week

Fire Service Week has historical significance in India. It began in 1956, following a catastrophic incident on 14th April 1944, when a massive fire broke out aboard the SS Fort Stikine at the Bombay Dockyard. The fire, exacerbated by the ship’s cargo of explosives and flammable materials, led to two deadly blasts, claiming the lives of between 800 and 1300 people, including 71 firefighters. This tragedy led to the establishment of Fire Service Week, celebrated annually from the 14th to the 20th of April. The week serves as a reminder of the sacrifices made by firefighters and the importance of fire safety in all sectors of the economy. Notably, the week aligns with the birth anniversary of Sir Ksheshrao Chaubey, who founded India's first organized fire service.

Fire Hazards in Warehousing and Logistics

The logistics industry is particularly prone to fire hazards due to several key factors:

Combustible Materials Warehouses often store flammable goods such as chemicals, oils, and fuel. Improper storage or handling can easily lead to fire outbreaks.

Electrical Faults Many logistics facilities rely on complex electrical systems, including conveyor belts, lighting, and machinery. Faulty wiring or neglected maintenance can spark electrical fires.

Human Error Mistakes in handling goods, using equipment, or even carelessness in storing hazardous materials are significant contributors to fire-related accidents.

Arson The logistics industry can also be vulnerable to intentional fire outbreaks, a threat that must be proactively managed.

These risks underline the importance of taking a proactive approach to fire safety in the logistics sector.

Ecom Express’ Commitment to Fire Safety

At Ecom Express, the team understands that fire safety is not an area that can be compromised. As a leading logistics company in India, they are committed to maintaining the highest standards of safety across all their facilities. Here are some of the key measures Ecom Express logistics have implemented:

Regular Fire Risk Assessments

Ecom conducts thorough fire risk assessments across all their facilities to identify potential fire hazards. These assessments help them to maintain a comprehensive audit system, ensuring compliance with legal and safety standards. By identifying risks early, they can take corrective action before an incident occurs.

Advanced Fire Safety Equipment

They have invested in state-of-the-art fire safety infrastructure. Their facilities are equipped with smoke detectors, heat sensors, automatic suppression systems, fire alarms, and sprinklers. These systems are designed to detect fires at their earliest stages and alert personnel immediately, allowing for swift action.

Compliance with Fire Safety Protocols

Ecom Express follows strict fire safety protocols, including standard operating procedures (SOPs) for the safe transport and storage of various goods. This ensures that all safety measures are integrated into their operations from the ground up.

Employee Training and Awareness

To ensure a culture of fire safety, Ecom Express invests in regular training for all employees. They conduct both internal and external training sessions, which cover essential topics such as fire prevention, emergency evacuation procedures, and the proper use of fire safety equipment. Employees are also trained on how to respond in case of a fire, ensuring they can act swiftly and safely.

Collaboration with Local Fire Departments

Fire safety doesn’t stop at their internal measures. Ecom Express works closely with local fire departments to ensure that fire safety practices are continuously updated. They collaborate with these agencies for regular fire drills, demonstrations, and mock fire-fighting exercises. This helps Ecom to maintain a high level of readiness and ensures that they are prepared to handle any emergency effectively.

Continuous Improvement

Fire safety is a continually evolving process, and at Ecom Express, they are committed to constant improvement. They review their fire safety practices regularly to incorporate new technologies and methodologies. They also stay updated on the latest safety regulations and industry best practices.

Conclusion

The logistics industry plays a pivotal role in the growth and development of national infrastructure in India. With this responsibility comes the need to prioritise safety, particularly fire safety. At Ecom Express, they understand the risks involved and have implemented comprehensive fire safety measures to protect their employees, assets, and operations. Their collaboration with local fire services further strengthens their fire prevention and response efforts. Through these initiatives, Ecom Express demonstrates a strong commitment to safety, ensuring that it contributes to the sustainable and secure growth of India's logistics infrastructure.

To know more about their fire safety provisions, contact their Corporate EHS Lead at [email protected]

0 notes

Text

How to Burn Coffee Grounds Like Incense

To burn coffee grounds like incense, first, put some used coffee grounds on a heat-resistant surface, light the coffee grounds, and blow out the flame to produce smoke. Have you ever thought about using coffee as an air freshener?

Instead of throwing used coffee grounds in the trash, why not try burning them like incense? This is a cheap and easy way to add a sweet aroma to your home, and you can even use the grounds as a substitute for traditional incense.

Plus, coffee grounds are said to have some health benefits, such as reducing unpleasant smells and repelling bugs. With just a few simple steps, you can turn your used coffee grounds into a cozy aroma therapy session at home. Keep reading to learn how to burn coffee grounds like incense in an eco-friendly manner.

Preparing The Coffee Grounds

Equipment Needed

Burning The Coffee Grounds

Benefits Of Burning Coffee Grounds As Incense

Precautions To Take

Frequently Asked Questions For How To Burn Coffee Grounds Like Incense

How Do You Burn Coffee Like Incense?

To burn coffee like incense, place coffee beans on a heat-resistant surface, light them with a lighter or match, and blow out the flame. The beans will continue to smolder and emit a pleasant aroma. Use caution as the surface and container may become hot.

How Do You Get Coffee Grounds To Burn?

To get coffee grounds to burn, you need to dry them out completely. Spread out used grounds on a baking sheet and let them dry in a well-ventilated area. Once dried, pack them tightly into a fire starter or add them to kindling to ignite.

Why Do People Burn Coffee Grounds?

People burn coffee grounds to reduce waste and as a natural odor eliminator. The smoke produced by burning coffee grounds contains compounds that help remove unpleasant smells. Additionally, some people believe that burning coffee grounds can enhance focus and energy levels due to the caffeine content.

Does Burning Coffee Grounds Keep Flies Away?

Burning coffee grounds may help deter flies due to their strong smell, but it is not a foolproof method. Flies are attracted to many scents, so a combination of tactics such as keeping a clean environment and using fly traps may be more effective.

What Are Coffee Grounds?

Coffee grounds are the residue left after coffee brewing, usually discarded as waste.

How Do You Burn Coffee Grounds?

Spread the coffee grounds on a heat-resistant surface and light them with a lighter or matchstick.

What Does Burning Coffee Grounds Smell Like?

Burning coffee grounds smell like roasted coffee with hints of chocolate and nutty aromas.

Is Burning Coffee Grounds Safe?

Burning coffee grounds is safe if done in a well-ventilated room, away from flammable objects.

What Are The Benefits Of Burning Coffee Grounds?

Burning coffee grounds can provide an aroma of roasted coffee that can help mask unpleasant smells.

Can You Burn Any Type Of Coffee Grounds?

Yes, you can burn any type of coffee grounds, but darker roasted coffee grounds tend to have a stronger aroma.

Conclusion

Overall, burning coffee grounds like incense could be a unique and practical way to enhance your living space with an alluring scent. It's easy to make, cost-effective, and has an array of benefits. This eco-friendly solution also reduces waste and adds to the overall sustainability of coffee consumption.

0 notes

Text

Omg wood bad

Is the gist of what certain politicians in my country just recently went with.

Summarised context: the politicians wanted to put into law that burning wood as primary source for internal house heating in condensed residential areas (towns, cities) should be illegal

Which is bullshit for a country that's ranked in top 10 most forested countries, as well as culturaly connected to those forests, BUT I DIGRESS, let's see what their arguments are.

"We won't have so many bad carbon emmisions"; "we'll be eco friendly"; "we'll be able to breathe easier and healthier"; mostly enviromental buzzword phrases you hear on the advertisement.

I'd be fooled to believe it, if it didn't reek of corporate lobbying and policymaking centralising around capital city.

Wood burning for house heating is more ecofriendly than vast majority of alternatives, that they advocated for. Yes the smoke can permeate the air, but dissipates quickly once it clears. Unlike smoke from burning fossil fuels, you know, like from 500+ cars all running around the city at the same time, because public transit ain't cheap anymore. And let's not forget factories creating so many pollutants, i'm suprised people aren't fully mutated into another species yet by now.

Let's list some thoughts of mine:

1. The capital city is regularly affected by temperature inversion, where the clouds above it will form heavy fog inside the valley it is in. Fog affected by smog. And a lot of road traffic happens during those hours. A point heavily neglected in the politicians ranting over wood burning.

2. Ever since Russian gas supply started being placed on the "avoid buying list". There has been extreme push towards coal and oil use for house heating and energy supply. Giving me a feeling there is corporate lobbying medling going on.

3. Properly stored and used wood, will give off a suprisingly low amount of carbon emmisions, due to the fact that as wood dries up, most of the harmful components produced by burning will already be safely gone before it even comes in contact with fire.

4. People burned wood for millenias in this countries area and never reported anything of the sort that the politicians were ranting about, until the industrialization of the country in recent present centuries.

5. And i could go on after more research

My parents own a small plot of land in the forest, out of which we take around 3-5 trees each year due to various naturaly caused damage to them that usually leads to the death of the tree (my dad literally took agricultural classes on maintaining a forest, so he knows which tree needs to collapse and when, to keep the forest healthy). The forest is thriving, because the owners of land in that forest KNOW what they're doing. Banning wood burning will lead to misinformation and ecoproblems.

The wood we store for a minimum of 1 year in a well airated, dry outdoor environment. By the time it gets used in the furnace, it is already perfectly dry and energy efficient. Banning wood burning will lead to misinformation and ecoproblems.

We have a 30+ year old mechanical, with some electrical components, because we used to also burn oil before realising it was a waste of money, furnace. We burn wood only when it is really cold outside. We recycle a ton of paper, and flammable stuff as fire starters, to the point our house can barely produce waste outside of stuff like plastic, glass, metal. And again banning wood burning will lead to misinformation and ecoproblems.

The ash remains can then be perfectly used as fertilizer. When the field is empty of veggie plants we will throw ash all over and let the rain and snow wash it into the soil, giving it many nutrients for plant growth. And when there are veggie plants on the field, we dump ash on the compost heap. We rarely use animal excrement to fertilize our veggie growing field and garden, and still yield healthy harvests each year. Banning wood burning will lead to misinformation and ecoproblems.

Seriously out of all things those idiot politicians will go after, the one thing i won't tolerate is wood.

#wood#political#political bullshit#lobbying#corporate greed#corporate agenda#forest#nature#environmental awareness#ecofriendly#depose slovenian politicians#the old farts#not funny#wood burning#misinformation economy

0 notes

Text

The Science Behind Fire Extinguishers: How They Work and Why They're Effective

When it comes to fire safety, having a fire extinguisher on hand can be a real lifesaver. But have you ever stopped to wonder how they work? In this article, we'll explore the science behind fire extinguishers, how they work, and why they're effective.First of all, let's take a look at the different types of fire extinguishers.

There are five main types of fire extinguishers: Water, Foam, Dry Powder, CO2 and Wet Chemical. Each type is designed to tackle specific types of fires.

- Water extinguishers: These are designed to tackle Class A fires (fires involving solid materials like wood, paper, and cloth).

- Foam extinguishers: These are also designed to tackle Class A fires but they're more effective on Class B fires (fires involving flammable liquids like gasoline, oil, and solvents).

- Dry Powder extinguishers: These are designed to tackle Class A, B and C fires (fires involving flammable gases).

- CO2 extinguishers: These are designed to tackle electrical fires (Class E), and Class B fires.

- Wet Chemical extinguishers: These are designed for Class F fires (fires involving cooking oils and fats).

Now, let's take a closer look at how fire extinguishers work. Fire extinguishers work by removing one or more elements of the fire triangle: heat, oxygen, and fuel. The fire triangle is made up of these three components, and when they are present together, they can cause a fire to start and continue to burn.

Different types of fire extinguishers work in different ways to remove one or more of these elements:

- Water extinguishers remove the heat element by cooling the fire down and preventing it from spreading.

- Foam extinguishers remove the fuel element by smothering the fire and preventing oxygen from feeding it.

- Dry Powder extinguishers remove the oxygen element by creating a barrier between the fire and the oxygen in the air.

- CO2 extinguishers also remove the oxygen element, but rather than creating a barrier, they simply displace the oxygen by releasing carbon dioxide.

- Wet Chemical extinguishers work by creating a barrier between the fuel and oxygen, as well as removing the heat element.

So why are fire extinguishers so effective? Well, for one, they allow you to tackle a fire before it has a chance to spread and become unmanageable. They are also specifically designed to target specific types of fires, making them much more effective than using, say, water on a chemical fire.

In addition, having a fire extinguisher on hand can give you peace of mind. You may never need to use it, but in the event of a fire, having a fire extinguisher can help you stay calm and take action to protect yourself and those around you.

If you're in the Miami area, you can find a wide range of fire extinguishers at local suppliers. It's important to have one in your home, office, or place of business, and to make sure everyone knows where it is and how to use it in case of an emergency.

In conclusion, fire extinguishers are an essential tool for fire safety, and understanding how they work can give you a greater appreciation for just how effective they can be. Whether you're at home or at work, having a fire extinguisher on hand can help you stay safe and protect those around you.

0 notes

Text

Illuminating Safety: Explosion Proof Linear Lights

Introduction

In hazardous environments where flammable gases, vapours, and dust are ever-present, safety is paramount. These environments, such as chemical plants, oil refineries, mining operations, and offshore platforms, require specialized lighting solutions to minimize the risk of explosions and fires. Explosion proof linear lights are a crucial component in ensuring worker safety and operational efficiency in such hazardous locations. In this article, we can explain the significance of explosion proof linear lights, their features, and their applications.

Understanding Explosion Proof Linear Lights

Explosion proof linear lights, also known as hazardous location linear luminaires, are designed to function safely in environments where there is a high risk of explosion due to the presence of combustible substances. These lights are built to prevent the ignition of flammable gases, vapours, and dust by containing any potential sparks or hot surfaces within the fixture. Their construction and materials ensure that even if the luminaire were to fail, it would not threaten the surrounding environment.

Key Features of Explosion Proof Linear Lights

Robust Construction: Explosion proof linear lights are built to withstand the harshest conditions. They are typically made of heavy-duty materials like corrosion-resistant stainless steel or aluminium, which can resist chemical exposure, high humidity, and extreme temperatures.

Sealed Enclosures: These luminaires have sealed enclosures that prevent gases and dust from entering the fixture. This isolates any potential ignition sources within the luminaire, minimizing the risk of explosions.

Temperature Control: Explosion proof linear lights are designed with heat dissipation mechanisms that ensure the fixtures remain calm, even during prolonged use. This is crucial in preventing overheating and sparks.

Impact Resistance: In industrial settings, accidental impacts are not uncommon. Explosion proof linear lights are often designed to withstand physical abuse, ensuring they remain operational and safe even in challenging conditions.

Specialized Lenses and Optics: These lights come with optics designed to provide uniform and glare-free illumination, helping to enhance visibility in potentially dangerous environments.

Applications of Explosion Proof Linear Lights

Oil and Gas Industry: Explosion proof linear lights are a common sight in offshore drilling platforms, refineries, and petrochemical plants. They provide safe illumination for workers while minimizing the risk of igniting flammable substances.

Chemical and Pharmaceutical Manufacturing: Hazardous chemicals and volatile materials are commonplace in these industries. Explosion proof lighting ensures that workers can perform tasks safely and accurately.

Mining Operations: The mining sector often involves the presence of combustible dust and gases. Explosion proof linear lights help to maintain visibility while reducing the risk of outbreaks in underground and surface mining areas.

Food and Beverage Processing: Facilities that deal with combustible dust, like flour and sugar, need explosion proof lighting to prevent fires and ensure product safety.

Wastewater Treatment Plants: These plants can have a hazardous mix of gases and chemicals. Explosion proof lights ensure that workers can maintain the facility without compromising safety.

Conclusion

Explosion proof linear lights are vital in environments where safety is paramount. They not only provide adequate illumination for tasks but also significantly reduce the risk of explosions and fires caused by electrical sparks. Their robust construction, sealed enclosures, and temperature control mechanisms make them indispensable in various industries where hazardous conditions prevail. By investing in these specialized lighting solutions, companies can prefer the well-being of their workforce and the integrity of their operations in potentially explosive environments.

To know more about Explosion proof Linear Lighting, please visit our website: explosionproof.ae

0 notes

Text

Pioneering Safety Solutions for Lithium Ion Battery Venting

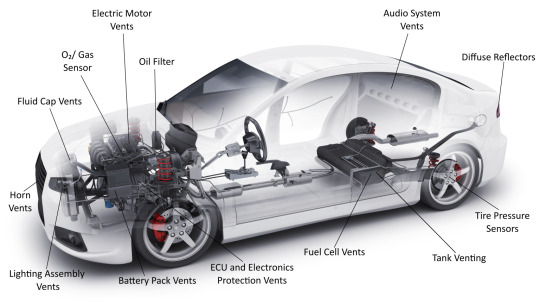

In the ever-evolving landscape of automotive technology, safety, and innovation remain paramount. As vehicles transition towards electric power, the role of lithium ion batteries has become pivotal. However, with great power comes great responsibility, and ensuring the safe venting of these batteries is crucial. This is where PorVent® automotive vents step in as game-changing solutions, safeguarding the integrity of lithium ion batteries and contributing to a safer, more efficient automotive future.

I) Understanding Lithium Ion Battery Venting

Lithium ion batteries are the backbone of modern electric vehicles (EVs) and plug-in hybrids (PHEVs). Their high energy density and rapid charging capabilities make them ideal for powering electric propulsion systems. However, under certain conditions, these batteries can undergo thermal runaway — a chain reaction leading to overheating, gas buildup, and potentially, fire. Venting is the process of releasing built-up pressure and gas to prevent catastrophic failures.

The Need for Venting: During charging, discharging, or abnormal operating conditions, lithium ion batteries can generate heat. If this heat is not properly managed, it can trigger a thermal runaway event. Venting provides a controlled release of gases, mitigating pressure buildup and minimizing the risk of fire or explosion.

Lithium Ion Battery Venting Importance: Ensuring effective lithium ion battery venting is crucial for both the safety of occupants and the longevity of the vehicle. Proper venting mechanisms prevent the accumulation of toxic and flammable gases, thereby minimizing the potential for a hazardous situation.

II) Enter PorVent® Automotive Vents: The Solution to Battery Venting Challenges

Introducing PorVent®: PorVent® automotive vents are innovative solutions designed to facilitate the safe venting of gases from lithium ion batteries. These vents are engineered using advanced materials like PTFE (polytetrafluoroethylene), which boasts exceptional resistance to heat, chemicals, and corrosion.

How PorVent® Works: In the event of a thermal runaway, PorVent® vents play a pivotal role. These vents allow gases to escape while preventing external elements from entering the battery enclosure. By maintaining a balance between pressure release and maintaining a sealed environment, PorVent® vents help to curtail the potential damage caused by thermal runaway incidents.

III) The Versatility of PorVent® Vents in the Automotive Industry

Lithium Ion Battery Venting: Lithium ion battery packs in electric vehicles are a prime area of application for PorVent®t vents. These vents are strategically integrated into the battery enclosures, providing a safety mechanism that reduces the risk of explosions and fires in case of thermal runaway.

Enhancing Battery Longevity: By enabling the controlled release of gases and pressure, PorVent® vents contribute to extending the lifespan of lithium ion batteries. A well-vented battery experiences reduced stress during heat build-up, resulting in improved overall performance and durability.

Electrical Component Cooling: Beyond lithium ion batteries, PorVent® vents find applications in cooling other crucial electrical components of electric and hybrid vehicles. These vents help dissipate heat generated during operation, ensuring optimal performance and mitigating potential overheating risks.

IV) Innovation Beyond the Automotive Sector

Diverse Applications: While automotive safety remains a primary focus, PorVent® vents have versatile applications beyond the automotive sector. Industries such as electronics, aerospace, and consumer goods benefit from these vents’ ability to manage pressure, temperature, and gas release.

Packaging Solutions: PorVent® vents are employed in the packaging of products that require controlled ventilation. This ranges from chemicals and agrochemicals to cosmetics, food supplements, and even veterinary formulations. The vents maintain product integrity by preventing pressure buildup and potential leakage.

V) Collaborative Advancements for a Safer Future

Collaboration for Safety: The automotive industry thrives on collaborative innovation. Manufacturers, researchers, and experts are continually working together to enhance safety standards. PorVent® vents represent a pivotal link in this chain by providing a critical safety measure for lithium ion battery-powered vehicles.

Continuous Research and Development: As technology evolves, so do the challenges. Continued research and development in the field of lithium ion battery venting contribute to the evolution of even more efficient and effective solutions, ensuring safer mobility for everyone.

Conclusion

In a world where electric vehicles are poised to reshape the automotive landscape, safety is non-negotiable. The introduction of PorVent® automotive vents marks a significant leap forward in lithium ion battery safety technology. By effectively managing pressure, temperature, and gas release, these vents safeguard against thermal runaway incidents that can compromise the integrity of vehicles and endanger lives. As we journey towards a cleaner and more sustainable future, solutions like PorVent® vents pave the way for a safer and more efficient automotive industry.

0 notes

Text

5 Common Electrical Hazards In The Workplace That Require Test And Tag

As an employer, you are responsible for the safety of your employees while they are at work. This includes ensuring that electrical equipment and appliances in the workplace are safe to use. Electrical Test and Tag Adelaide is a process that helps to identify and correct any potential electrical hazards in the workplace.

Testing and tagging must be carried out by a qualified electrician and should be conducted on all portable electrical equipment and appliances that are used in the workplace.

In this blog post, we will uncover the top five common electrical hazards that require immediate attention and proper testing. Don't wait for disaster to strike; read on to ensure a safe and secure working environment for everyone. It's time to test and tag those potential threats away!

Common Hazards Found in the Workplace that Require Test and Tag

The most common hazards found in the workplace that require an electrical test and tag Adelaide are electrical outlets and cords. These are typically found in areas where there is a lot of foot traffic or where there is a potential for water to come into contact with them. Other common hazards include extension cords, power strips, and surge protectors.

Damaged Cords & Plugs

If you have ever tripped over a cord or seen one that was frayed or damaged, you know how important it is to keep them in good condition. Here are some tips on how to do that:

Inspect cords and plugs regularly for damage. If you see any, replace them immediately.

Do not use extension cords as a permanent solution. If you need extra length, have an electrician install additional outlets.

Do not overload outlets. Use a power strip if necessary and never exceed the recommended number of appliances for each outlet.

Keep cords away from heat sources, sharp edges, and chemicals.

By following these simple tips, you can help prevent accidents and injuries in the workplace.

Overloaded Sockets & Outlets

Overloaded sockets and outlets are one of the most common electrical hazards in the workplace. When too many devices are plugged into a single socket or outlet, it can cause a fire. Electrical testing and tagging Adelaide are important ways to prevent this hazard.

Exposed Wires & Terminals

If you work with electrical equipment, you know that exposed wires and terminals are a hazard. They can cause shocks, burns, and even fires if they're not properly insulated. That's why it's important to have your electrical equipment tested and tagged by a qualified electrician. Test and tag or fire extinguisher service in Adelaide can help you identify problems before they cause serious damage or injury.

Unsafe Working Environment

Working with electricity can be dangerous if proper safety precautions are not followed. There are several common electrical hazards that can occur in the workplace, which is why it's important to have a regular testing and tagging regime in place. Some of the most common electrical hazards include:

Electrical shocks: This can happen when you come into contact with an electrical current. Symptoms of an electrical shock include muscle spasms, burns, and even cardiac arrest.

Fires: Electrical fires can start when there are faulty wires or other electrical components. These fires can spread quickly, so it's important to have working fire extinguishers in the workplace.

Explosions: If there is a build-up of static electricity, it can cause an explosion. This is more likely to happen in workplaces where there is a lot of dust or where flammable liquids are being used.

Falls: If you work on elevated platforms or near power lines, you could be at risk of falling and sustaining serious injuries.

Conclusion

Electrical hazards are a serious issue that can potentially cause injury or even death in the workplace. As such, it is vitally important for employers to ensure that they are aware of any electrical hazards and take steps to mitigate them.

With this article, we have highlighted five of the most common electrical hazards found in workplaces and why they require electrical tests and tags Adelaide-wide.

We hope that this information has been useful for you and helps you create a safe working environment for yourself and your employees.

0 notes

Text

Low Expansion Foam: A Simple Guide to Understanding its Benefits and Uses

Have you ever wondered how firefighters are able to control and extinguish dangerous fires? Or how construction workers fill gaps and seal cracks in buildings to enhance their energy efficiency? The answer lies in a remarkable material known as low expansion foam. In this easy-to-understand guide, we will explore what low expansion foam is, its unique properties, and the diverse range of applications that make it an invaluable tool in various industries.

What is Low Expansion Foam?

Low expansion foam, as the name suggests, is a type of foam with minimal expansion when applied. It is composed of water, foam concentrate, and air, which, when combined, create a foam solution. When dispensed, this foam rapidly expands into a highly effective fire suppression or insulation agent, depending on the intended use.

How Does Low Expansion Foam Work?

When low expansion foam is generated and applied, the foam solution is released through a specialized nozzle. Upon contact with air, the solution expands and transforms into a voluminous foam with small, stable bubbles. The secret behind its effectiveness lies in the foam's ability to rapidly cover large surface areas, effectively smothering fires or sealing gaps in buildings.

What Makes Low Expansion Foam Special?

Fire Suppression: One of the key advantages of low expansion foam is its exceptional fire suppression capabilities. The foam acts as a blanket over the fire source, cutting off the oxygen supply and extinguishing the flames.

Insulation and Sealing: Low expansion foam is also widely used for insulation and sealing purposes in construction. It can fill gaps and cavities, providing excellent thermal and acoustic insulation, as well as air sealing properties.

Low Water Content: The foam's low water content ensures that it does not cause water damage, making it ideal for sensitive equipment and electronics.

Versatility: This foam can be used on various types of fires, including flammable liquids, gases, and even electrical fires.

Rapid Application: Low expansion foam is easy to apply, allowing for quick and efficient deployment in emergency situations.

Applications of Low Expansion Foam

Firefighting: Fire departments utilize low expansion foam to combat fires effectively, especially in scenarios involving flammable liquids and gases.

Building Construction: Contractors use low expansion foam for filling gaps around windows, doors, and wall penetrations to enhance energy efficiency and maintain airtight spaces.

Refrigeration and Cooling Systems: The foam is employed to seal and insulate components of refrigeration and cooling systems, ensuring optimal performance and energy savings.

Marine Industry: Low expansion foam is valuable on boats and ships to control fires and prevent them from spreading rapidly on board.

Aircraft Hangars: Due to its ability to suppress fuel-based fires, low expansion foam is commonly used in aircraft hangars.

Data Centers: Data centers often rely on low expansion foam for its non-conductive and non-corrosive properties to protect valuable equipment from fire damage.

Oil and Gas Facilities: The foam is utilized in oil and gas facilities to safeguard against flammable liquid fires.

FAQs About Low Expansion Foam

Is low expansion foam safe to use on electrical fires?

Yes, low expansion foam is safe to use on electrical fires because it does not conduct electricity. It effectively suppresses the fire without posing any risk to the user.

Can low expansion foam be used at home?

No, low expansion foam is typically not recommended for home use. It is best handled by professionals due to its specialized application and equipment requirements.

Does low expansion foam leave a residue after firefighting?

Yes, low expansion foam can leave a small amount of residue, but it is non-toxic and easy to clean.

How long does low expansion foam take to expand?

The expansion time may vary, but it generally takes only a few seconds for the foam to fully expand upon application.

Can low expansion foam be used more than once?

Once the foam is deployed, it cannot be reused, and a fresh batch must be generated for each application.

Is low expansion foam harmful to the environment?

Low expansion foam is formulated to be environmentally friendly and is designed to break down naturally over time.

What is the shelf life of low expansion foam concentrate?

The shelf life of low expansion foam concentrate is typically around 3 to 5 years if stored correctly in a cool and dry place.

Can low expansion foam be used in extremely cold temperatures?

Yes, low expansion foam is effective in cold temperatures and remains stable under freezing conditions.

Does low expansion foam require specialized equipment for application?

Yes, low expansion foam requires specific equipment, such as foam generators and nozzles, for proper application.

Can low expansion foam be used in conjunction with other firefighting agents?

Yes, low expansion foam can be used alongside other firefighting agents to enhance fire suppression capabilities.

Is low expansion foam suitable for Class A fires (wood, paper, etc.)?

Low expansion foam is not ideal for Class A fires, as it may not effectively penetrate deep-seated fires in solid materials.

Can I use low expansion foam in my car's engine compartment to suppress fires?

It is not recommended to use low expansion foam in a car's engine compartment, as it may interfere with the engine's functionality and cause damage.

Does low expansion foam have any odor?

Low expansion foam is formulated to be low in odor, which helps avoid respiratory irritation during application.

Can low expansion foam be used in underwater applications?

Yes, certain types of low expansion foam are designed for underwater use, such as sealing leaks in submerged structures.

Can low expansion foam be used in cooking-related fires?

No, low expansion foam should not be used on cooking-related fires as it may spread the fire and create additional hazards.

Is low expansion foam effective on large-scale fires?

Yes, low expansion foam can be effective in controlling large-scale fires, especially when applied promptly and correctly.

Can low expansion foam be colored for better visibility during application?

Yes, some low expansion foam products are available in different colors to enhance visibility during application.

Does low expansion foam require special cleanup procedures after use?

The cleanup process for low expansion foam is relatively straightforward and involves rinsing the affected area with water.

Is low expansion foam toxic to aquatic life?

Low expansion foam is formulated to be environmentally friendly and poses minimal risk to aquatic life.

Can low expansion foam be used in portable fire extinguishers?

No, low expansion foam is not typically used in portable fire extinguishers due to its specialized application and equipment requirements.

Can low expansion foam be used in high-temperature environments?

There are specific types of low expansion foam designed for high-temperature applications, but they may have limitations depending on the temperature range.

Is low expansion foam effective on fires involving metals?

Low expansion foam is not suitable for suppressing fires involving certain metals, as specialized agents are required for such scenarios.

Is low expansion foam non-corrosive to metal surfaces?

Yes, low expansion foam is generally non-corrosive to metal surfaces, making it safe to use in various industrial settings.

Can low expansion foam be used to suppress wildfires?

Low expansion foam is not commonly used for suppressing wildfires due to the scale of such fires and the need for specialized firefighting strategies.

Is low expansion foam suitable for use on chemical fires?

Low expansion foam can be effective on certain chemical fires, but it is essential to choose the appropriate foam concentrate based on the specific chemicals involved.

Conclusion

Low expansion foam is an impressive material with diverse applications, from firefighting to insulation and sealing. Its unique properties and ease of application make it an essential tool in various industries, ensuring safety and efficiency.

0 notes

Text

It’s cheaper to Run generators with coking gas than petrol, says Obin

Philip Obin is the Managing Director of Potech Limited, an ICT and marketing firm which also promotes Club 080, an empowerment programme that aims to empower Nigerian youths. Obin spoke with TOBI AWODIPE about hybrid carburetor, a modern technology that allows the running of generators with cooking gas, and its advantages

What is the hybrid carburetor about and how does it work?

The hybrid carburetor is just like any carburetor in a generator with the difference being that this type of carburetor allows you to run your generator with either cooking gas or petrol, whichever is available to you. It is easy to install and converts your existing petrol generator to also run on domestic gas (LPG or CNG).

Cooking gas has recently become scarce in the country with prices witnessing a staggering 40 per cent increase. How do you intend to cope seeing that it is the power behind this whole concept?

No matter how high the price climbs, 12.5kg cannot be sold for more than N4,000. The recent increment in gas price is not unconnected to the recent increment in petrol price. Whenever petrol price increases, all other crude oil products follow suit. So, it is normal as petrol usually controls the pricing of its other by products in Nigeria.

But beyond price, gas is cleaner, safer, always available and ‘greener’. We are talking about global warming and how to reduce carbon emissions and this is a sure way of achieving that. Using gas, the carbon emission is almost zero and there is no physical smoke when it is in use. Gas is far safer than using petrol. Even with the increase in price, it is still more economical than using petrol. Can you use N3,000 or N4,000 petrol for 10 days, at five hours daily? We all know this is not possible.

Most Nigerians are thinking of how to cut costs, especially in the area of buying fuel seeing that the economy is in recession. How affordable is using gas in the long run?

The average Nigerian doesn’t make long term plans; we always like the cheap, quick alternative to solving issues. Admittedly, the price of the carburetor is on the high side, judging with today’s economy. The carburetor goes for N25, 000 and N35, 000 respectively, depending on the KVA, and you would also need a gas cylinder, regulator hose and clips if you don’t have them, but these are all one off costs. This hybrid carburetor is an alternative for people that cannot afford to spend millions on inverters and solar systems. My aim is to make life easier for Nigerians that may not have the resources for the afore-mentioned but still want electricity at an affordable cost.

The best part is that the carburetor has a six-year life span if you use gas alone with the generator. The hybrid carburetor allows the use of both gas and petrol so if one runs out of gas and is unable to get immediately, one can still make use of petrol with it, though I would advise you try as much as possible to avoid petrol so that the carburetor and the generator last longer. However, this device is not compatible with I Better Pass My Neighbor (smallest Tiger generators) and generators with capacities above 10KVA.

How safe is it considering gas is very flammable?

It is very safe. If for instance, the hose breaks and the gas is leaking and there is fire nearby, fire would burn from the hose but there would be no explosion. What causes fire explosion is when a cylinder is leaking in an enclosed place like a kitchen, the gas fills up the room easily and when there is ignition, it explodes. But because the cylinder and the generator are outside, it would be harder for it to explode because there is enough ventilation to disperse the leaking gas. I have been running my generator with gas since August last year and sold over 10, 000 units and nobody has ever come to report any explosion or fire incident to me.

How long does it last?

A 12.5kg cylinder on a 2.5KVA generator would guarantee you 40-50 hours of electricity, depending on the load on the generator. Now, if you want to calculate it by price, that is about N60 per hour, or 10 days if you run it for five hours daily, four days if you run it 10 hours a day. At the end of the day, it is far cheaper than petrol and it does not experience scarcity like petrol.

When you buy the carburetor, anyone can fix it for you. To borrow a tech word, it is simply ‘plug and play’. Simply remove your old carburetor and replace it with this one in the same space and connect it to the cylinder. You do not need to call a generator electrician to do it for you but if you would feel more comfortable having it fixed professionally, that is not a problem either.

1 note

·

View note

Text

Why a Portable Generator is a Smart Investment for Your Home

Introduction

Advantages of a Portable Generator

Types of Portable Generators

How to Use a Portable Generator Safely

Introduction

Have you ever experienced a power outage during a bad storm? How did you cope without electricity for hours or even days? A portable generator can provide a reliable source of power during emergencies or when you need to work in a place without electrical outlets. In this article, I will explain why a portable generator is a smart investment for your home.

Advantages of a Portable Generator

A portable generator is a compact and self-contained unit that can produce electricity by burning fuel, such as gasoline, propane, or diesel. It has many advantages over a standby generator or a traditional fuel-powered generator:

Portability: A portable generator is designed to be moved from one location to another easily. It usually has wheels and a handle for transportation. You can use it in different places, such as your backyard, camping sites, job sites, or RVs.

Cost-effectiveness: A portable generator is generally less expensive than a standby generator or a traditional fuel-powered generator, both in terms of the upfront cost and the maintenance cost. You can save money by choosing a model that suits your needs and budget.

Fuel efficiency: A portable generator is usually more fuel-efficient than a standby generator or a traditional fuel-powered generator, as it only produces the amount of electricity you need at the time.

Environmental friendliness: A portable generator produces less emissions and noise pollution than a standby generator or a traditional fuel-powered generator. You can choose a model that runs on cleaner fuel, such as propane or solar energy, to reduce your carbon footprint.

With these advantages, a portable generator can be a wise investment for your home, especially if you live in an area prone to power outages or if you need a power source in remote locations.

Types of Portable Generators

There are two main types of portable generators: conventional and inverter.

Conventional Generator

A conventional generator produces electricity using an alternator and a combustion engine. It operates at a constant speed, regardless of the load. It is suitable for powering appliances and tools with high starting wattage, such as refrigerators, air conditioners, and welders. However, it is usually bulky and noisy, and it may experience voltage fluctuations and surges.

Inverter Generator

An inverter generator produces electricity using a more advanced technology that varies the speed of the engine according to the load. It produces a clean and stable power output, with less than 3% total harmonic distortion (THD). It is suitable for powering sensitive electronics, such as laptops, smartphones, and TVs, as well as appliances and tools with low starting wattage. It is usually quieter and lighter than a conventional generator, and it may have additional features, such as parallel connection and fuel gauge.

When choosing a portable generator, you should consider the type, the size, the fuel type, the runtime, and the noise level, based on your specific needs and preferences.

How to Use a Portable Generator Safely

Although a portable generator can provide many benefits, it can also pose many risks if used improperly. You should follow these safety tips to avoid accidents or injuries:

Read the manufacturer's instructions and warnings carefully before operating the generator.

Place the generator on a level and stable surface, away from flammable materials and exhaust fumes.

Use only the recommended fuel and oil, and store them in a safe and ventilated place.

Connect the generator to your appliances or tools using the appropriate cords and outlets, and avoid overloading the generator.

Turn off the generator and unplug all cords before refueling or servicing the generator.

Keep children and pets away from the generator, and never operate it indoors or in a confined space.

Install a carbon monoxide detector in your home, and be aware of the symptoms of carbon monoxide poisoning, such as headache, dizziness, nausea, and fatigue.

By using a portable generator safely, you can enjoy the convenience and peace of mind that it provides without compromising your health or safety.

This article is brought to you by "None", a leading brand in the portable generator industry.

0 notes

Note

Hey, im not sure if you are the best person to go to for this but i thought you'ld atleast find it interesting.

Ive been having this issue with my mudkip. Recently she has been starting fires while unattended. It started out when i was babysitting my friends charmeleon who had a knack for accidently starting fires, and my swampert would put them out. My mudkip copies pretty much anything my swampert does and started putting them out herself.

At first i thought it was good and gave her treats to encourage her to put out fires. While the charmeleon was with us it was fine, but when they went back to their trainer, i was still finding fires which she would then put out. At this point i realised my matches were disapearing, so i stopped giving her treats and stowed my matches more carefully. I didnt really want to encourage her to not put out fires and this prevented any more instances for a while.

But a month later i found a draw open, baby lock broken, matches missing, and myterious scorch marks around my house. Soon after i found her staring at a fire, match box next to her. Once she realised i was there she put it out, sat on the burn mark and gave me puppy dog eyes. Ive hid the matches but this is has escalated and no matter where ive hid them she finds matches, even when i dont have any.

I've tried looking into it but i cant find any cases of this outside of fire types, and even there its extremely unusual behaviour. It seems to be the fire that interests her as she is doing this even without the treats. Ive talked with a doctor at the local pokemon hospital and will be seeing a behavioural specialist next month (apparently theyre busy and a water pokemon starting but proficently putting out fires isnt to high priority), but also wanted to get your opinion on this.

Hahaha little pyromaniac! I like em, what a busy little dude.

So like, If you came to me with this, you’re going to get my personal opinion, which would be to encourage safe fire practice. Hear me out.

Mudkip are pokemon that have been known to have heritage of species that can learn fire moves. If they have a garchomp, a marowak, maybe rhydon, or even exploud in their family, there’s a chance they have a small potion of fire wielding capabilities, even if it’s just the affinity with it. Because of their body however, they have no ignition to utilise this. They can however store great volumes of fluid within their mouth, and expel it over long and short range. You should take your buddy to go watch some fire breathers, and maybe even book a class with some if you get a chance, that you can do either in support of, or with your buddy. These folks are incredible performers that use flammable liquids in safe and controlled ways to wield fire. This is a teachable thing your mudkip might find interesting. Classes however start with safety training, often both the fire breather and their Pokemon being able to explain the dangers. Hearing that fire can be great but also dangerous from other Pokemon may help your partner realise there’s a time and a place (also helps with the language barriers). Being as safe as possible, but still doing what you enjoy, is a totally doable. This is where regular training with this must be accommodated for. A battle safe area with no trees or items, or flammable buildings are present. Local parks have em, gyms, even pokecentres usually have a practice pitch close by for people to use. Schedule in practice, put a little chart up on the fridge at their height, so they know the days and times they get to let loose and practice their skills. Investing in professionals time to tutor them is wise, but this is an unusual case of a water type just loving fire, and I for one couldn’t bring myself to fully squash that love, just make it safer, more focused. Encourage it in other areas. By the end, once they get the hang of it, they’re allowed the matches during non-regulation fights and practice times, they can use them to train, and they get given back to you when you go home, to be put in a safe location.

Even if they’re 100% mudkip, there’s a literal flame in that Pokemon, channel it, help it use that passion in a controlled manner. I’ve seen water Pokemon practice safe fire breathing before, It’s not unheard of, and you should give some thought to it as an option. Should you ever battle with this technique, it’s a real game changer to pull out.

The alternative is to try to go spend some time at a fire station open day. Kids and young Pokemon get given tours for fun, and to learn about fire safety. It might be that the little dude can’t fully grasp human language yet, and doesn’t understand the severity of what fire is. Again, other Pokemon will do a better job at explaining something quite complex than a human, language is hard sometimes, not every Pokemon will get it fully, or as easily as others. I guess try a child safe lighter instead of matches too, mudkip don’t have thumbs and find these difficult to use.

There’s something in my gut that says do it, just do it safely. Invest in extinguishers, fire blankets, good smoke alarms, and lessons for your mudkip, who clearly has an interest.

#maybe I’m crazy#but I’d encourage it#makes for an interesting fighter#and happy partner#prof.peach#pokemon#peach talks

246 notes

·

View notes