#nitrile gloves manufacturer CA

Explore tagged Tumblr posts

Text

Outdoor Gloves Guide

Outdoor Gloves Guide

When it comes to outdoor tasks that demand durability, protection, and a reliable grip, nitrile-coated outdoor gloves are a must. Designed to withstand rough surfaces, sharp objects, and varying weather conditions, these gloves are essential for any outdoor enthusiast, gardener, construction worker, or DIY hobbyist. Here, we'll explore some of the best nitrile-coated outdoor gloves with grip, highlighting their unique features and benefits.

youtube

What Goes into a Good Outdoor Glove?

When it comes to outdoor tasks, having the right gear can make a significant difference in your performance, safety, and overall enjoyment. Nitrile coated outdoor gloves with grip are essential tools that provide protection, durability, and excellent traction for a wide range of activities. To ensure you invest in the best pair of gloves for your needs, follow this comprehensive guide to buying the perfect nitrile coated outdoor gloves with grip.

Consider Your Outdoor Activities

Start by identifying the specific outdoor activities you'll be engaging in regularly. Are you an avid gardener, a construction professional, or do you enjoy DIY projects? Different activities may require gloves with varying levels of protection, grip, and flexibility. By understanding your needs, you can narrow down your options and find gloves tailored to your preferred tasks.

Safer Grip Gloves by OPNBar

10053 Whittwood Dr, Suite 11284 Whittier,

CA 90603 USA

657-667-6227

Grip Technology

The primary feature that sets nitrile coated gloves apart is their enhanced grip. Look for gloves with a textured nitrile coating that offers excellent traction even in wet or oily conditions. The grip should allow you to maintain control over tools and materials, preventing accidents and improving efficiency. Prioritize gloves with multiple grip zones for added versatility and adaptability to different tasks.

Material Quality and Durability

Check the quality of the base material and the thickness of the nitrile coating. Opt for gloves made from high-quality nylon, polyester, or other durable materials that can withstand regular wear and tear. The nitrile coating should be thick enough to provide ample protection against cuts, scrapes, and punctures. Investing in gloves with reinforced fingertips and palms can further enhance their longevity and resistance to abrasion.

Size and Fit

A proper fit is crucial for comfort and dexterity during outdoor tasks. Choose gloves that are available in various sizes to ensure you find the one that fits your hands perfectly. A snug fit prevents the gloves from slipping off during use while allowing your hands to move freely. Be sure to consult the sizing chart provided by the manufacturer to find the most appropriate size for your hands.

Comfort and Flexibility

Outdoor tasks can be physically demanding, so prioritize gloves that offer comfort and flexibility. Look for gloves with a breathable design that allows air circulation and prevents excessive sweating. A flexible base material enables better hand movement and reduces hand fatigue, especially during extended use.

Water and Chemical Resistance

Depending on your activities, you may need gloves that are water-resistant or offer protection against specific chemicals. Consider the environments in which you'll be using the gloves and choose a pair that meets those requirements. Some gloves have specialized coatings that repel water and oils, ensuring a secure grip even in wet conditions.

Eco-Friendly Options

If environmental sustainability is a priority for you, consider opting for eco-friendly nitrile coated gloves made from sustainable materials and manufactured using environmentally conscious processes. Several brands are now offering eco-friendly options that reduce their impact on the environment.

Read Reviews and Recommendations

Before making a final decision, read reviews and seek recommendations from other users. Online reviews provide valuable insights into the performance and durability of the gloves, helping you make an informed choice.

Choosing the best nitrile coated outdoor gloves with grip involves considering your specific outdoor activities, grip technology, material quality, size and fit, comfort, water and chemical resistance, and eco-friendliness. By following this guide, you can confidently select a pair of gloves that will serve as a reliable companion for all your outdoor adventures, providing the protection, durability, and grip you need to excel in every task.

Materials that Enhance Grip

Various materials and technologies contribute to the grip-enhancing properties of hiking gloves. Some of the most popular choices include:

Silicone patterns: Many high-quality gloves incorporate silicone patterns on the palms and fingers, offering an impressive grip on multiple surfaces.

Textured synthetic materials: Gloves made with textured synthetic materials, such as polyurethane or rubber, provide an excellent balance between grip and durability.

Innovative grip technologies: Some gloves utilize cutting-edge technologies to enhance their grip capabilities, such as strategically placed padding, ergonomic design, or moisture-wicking materials.

Benefits of Hiking Gloves with Grip

Hiking gloves with superior grip features offer numerous advantages, including:

Safety: A firm grip helps prevent accidents and injuries resulting from slips or loss of balance.

Versatility: Gripping gloves enable secure handling of various gear and equipment, making them suitable for different outdoor activities.

Comfort: Gloves with exceptional grip often boast ergonomic designs and materials, providing comfort during extended hikes.

Improved performance: Enhanced grip contributes to better control and dexterity, allowing hikers to tackle challenging trails with confidence.

Investing in hiking gloves with outstanding grip capabilities is a game-changer for outdoor enthusiasts. These gloves provide safety, versatility, and comfort while enhancing your overall performance on the trail. Before embarking on your next adventure, consider upgrading to gripping hiking gloves for a more enjoyable and secure experience.

Grip gloves are specialized gloves designed to provide an enhanced grip when handling objects. They are widely used in various industries, including construction, manufacturing, and automotive, to improve productivity and reduce the risk of accidents. In this article, we will discuss the benefits of using grip gloves and explore the different types of grip gloves available in the market.

Types of Grip Gloves

Latex Grip Gloves: Latex grip gloves are made of a latex coating over a knit or woven base material. They are lightweight and offer excellent grip in wet or dry conditions. Latex grip gloves are commonly used in the healthcare industry, where they provide protection against infectious materials.

Nitrile Grip Gloves: Nitrile grip gloves are made of a synthetic rubber material that is resistant to punctures, cuts, and chemicals. They offer excellent grip in wet or oily conditions and are commonly used in the automotive and manufacturing industries.

PVC Grip Gloves: PVC grip gloves are made of a PVC coating over a knit or woven base material. They are lightweight and offer good grip in wet or oily conditions. PVC grip gloves are commonly used in the food processing and janitorial industries.

Leather Grip Gloves: Leather grip gloves are made of high-quality leather and offer superior grip and durability. They are commonly used in the construction and landscaping industries, where workers need to handle heavy tools and materials.

Cut-Resistant Grip Gloves: Cut-resistant grip gloves are made of specialized materials that offer protection against cuts and abrasions. They are commonly used in industries where workers handle sharp tools and materials, such as the construction and manufacturing industries.

Choosing the Right Grip Gloves:

When choosing grip gloves, there are several factors to consider, including the type of work being performed, the level of grip required, and the potential hazards present in the workplace. Some important factors to consider include:

Material: The material of the gloves should be chosen based on the type of work being performed. For instance, latex grip gloves are suitable for healthcare workers, while nitrile grip gloves are better for automotive and manufacturing workers.

Grip: The level of grip required will depend on the nature of the work being performed. Workers who handle heavy or slippery objects may require gloves with a stronger grip, while those who handle smaller components may require gloves with a more delicate grip.

Size: The gloves should fit snugly to ensure maximum grip and protection. It is essential to choose gloves that fit properly to avoid slipping or sliding while working.

Durability: The durability of the gloves should be considered when choosing grip gloves. Workers who handle sharp or abrasive materials may require gloves that are more durable to prevent punctures or tears.

Employee Safety

Employee safety should be a top priority in any company. Apart from the obvious pain and suffering with worker deaths and injuries, workers who are injured on the job could sue a company for financial damages. Injuries may make them less productive when they return to work. It is important that employers effectively communicate safety standards to every employee, and train them properly.

Safer Grip Gloves by OPNBar™️ are ideal work grip gloves for all-day use for light manufacturing, warehouse operators, and for use in maintenance areas.

Our new and improved Safer Grip nitrile coated grip gloves by OPNBar are ideal multi-purpose work grip gloves for various applications like trucking and delivery, warehouses, maintenance areas, light manufacturing and carpentry. They are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Coated Grip Gloves

Safer Grip nitrile coated gloves are made of 15-Gauge nylon polyester engineered yarn. The glove conforms to the operator’s hand and offers maximum flexibility and comfort. Safer Grip spandex nylon glove palms are coated in micro-foam nitrile, and are quite flexible, making Safer Grip nitrile coated grip gloves the perfect nitrile foam gloves for working with tools and protecting your hands and products. The latest glove offers a durable thumb crotch for extra grip and protection.

Coated foam grip gloves are extremely popular, primarily because they have a good price point. They are effective and comfortable, provide great dexterity, and protect operator hands from hazards, as well as protect products from workers’ hands.

Foam coatings can be applied and used in wet, oily, cold, and normal situations. Safer Grip spandex gloves with a long lasting microfoam nitrile coating are breathable with a coarse surface that can suck up oil and liquid, and maintain grip and tactility even when wet.

Nitrile Foam Grip Gloves Coating

Safer Grip Gloves by OPNBar™️ grip gloves are dipped in a special longer lasting formula, with a durable nitrile foam coating that improves tactility and dexterity. The foam coating resists cuts, abrasions, and tears, and is also a good alternative for people with latex allergies or want an alternative to leather. Safer Grip gloves are dipped in an improved nitrile microfoam formula in a three-quarter palm dip. Micro-foam technology offers great breathability, making them cool and comfortable to wear, in any environment.

Lots of Features

15-Gauge Nylon/Spandex Liner

Tough Micro-Foam Nitrile Coating

Touchscreen Compatible Grip Gloves that Work with Phone

Superior Grip, Dexterity & Protection

Ultra Soft Fitting, Breathable

Abrasion Resistance: 40,000 cycles, EN388:4131X

Oeko-Tex Standard 100, Skin Friendly, Latex Free

Machine Washable

CE Compliance

Safer Grip nitrile coated grip gloves are CE Certified, EN388 4131 compliant, and have an abrasion resistance of 40,000 cycles. Safer Grip gloves are Oeko Tek Standard 100, are skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

STANDARD 100 by OEKO-TEX® is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety.

SAFER GRIP Gloves by OPNBAR™️ apparel carries the STANDARD 100 label. You can be certain that every component has been tested for harmful substances and are harmless for human health.

In the test, they take into account numerous regulated and non-regulated substances, which may be harmful to human health. In many cases, the limit values for the STANDARD 100 go beyond national and international requirements.

More Features of Safer Grip

Touchscreen Compatible Grip Gloves that Work with Phone

These work gloves are also touchscreen compatible on 4 fingers!

Ultra Soft Fitting, Breathable

These lightweight work gloves offer superior breathability and are quite form fitting.

Superior Grip, Dexterity & Protection

Nitrile coated work gloves offer versatile protection for many environments.

Reinforced Thumb Crotch

The thumb crotch on these work gloves provides a firm grip for these grip gloves.

Abrasion Resistance: 40,000 cycles, EN388:4131X

SAFER GRIP gloves are tested to have an abrasion resistance of 40,000 cycles!

Tough Micro-Foam Nitrile Coating

SAFER GRIP nitrile dipped work gloves and nitrile coated in a special, long lasting formula.

Versatile Weather Protection

These safety gloves can offer protection not only for your hands and products, but also weather elements as well.

Latex Free, Skin Friendly

Skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

Industrial Use Features of Safer Grip

Construction, Carpentry, Roofing

Woodworking/Carpentry Gloves

These construction gloves are also great for being woodworking gloves and roofing gloves.

Warehouse Gloves

These warehouse gloves also make great moving gloves or box handling gloves.

Mechanic Gloves

These mechanics gloves also make great shop gloves or gloves for home improvement.

Truck Driver Gloves

SAFER GRIP gloves are popular truck driver gloves for their versatility and comfort.

Versatile Outdoor Uses of Safer Grip Gloves

Gardening Gloves

SAFER Grip gloves make great outdoor gloves and gardening gloves.

Hiking Gloves

These are great for everyday use in the outdoors and also make excellent hiking gloves.

Boating Gloves

Nitrile coated gloves provide dexterity in wet environments making them great boating gloves and fishing gloves.

Biking and Outdoor Gloves

These firm grip gloves are also great as biking gloves or daily outdoor gloves.

Protecting your hands should be your top priority, and the best way is to use work gloves. Yes, these work gloves are great as they provide a layer of protection to the knit gloves and give a non-slippery experience.

Gloves can be made of nylon, cotton, and even polyester or engineered yards called Kevlar or Dyneema. This material is an excellent alternative for expensive leather gloves.

The palm-coated industrial work gloves are great for different use in the automotive industry, construction, or even in sampling and handling products, which offer a better, and anti-slip grip.

Glove Coatings

The dip coating is applied on the knit gloves to give a good layer of protection. However, the amount of coating can be customized as follows:

Full Dip

The full dip allows covering the whole hand including the lower wrist.

Palm Dip

The palm dip will cover the whole palm including the fingertips for a better shield.

¾ Dip

The ¾ dip protects the palm, knuckles, and fingers.

What’s Grip Gloves Do you Prefer?

These tough coatings will give a perfect experience for handling tough materials filled with grease and chemicals. These gloves will enhance durability, chemical resistance, and even cut protection.

Many coatings can be used on knit gloves which are as follows:

Nitrile Foam

Latex

PVC

Neoprene

Zed coat

Micropore Nitrile

Polyurethane (PU)

Now, let us have a brief look at all these types of coating.

Nitrile Foam Coated Gloves

Industrial environments of today carry many activities that have risks. Governments and businesses in many countries define guidelines that benefit the safety of their workers. Many industrial applications promote the use of nitrile foam grip gloves for industry workers as a means of safety.

For Those with Allergy Concerns

Nitrile foam grip gloves are a type of glove made from nylone and coated with synthetic rubber. Nitrile is a polymer compound with a production process similar to that of making rubber. Unlike rubber however, nitrile is a 100% synthetic substance and typically does not create any type of allergic reaction on the human body and as a result, is accepted and used in many businesses. Nitrile is the synthetic form of latex and is commonly chosen for its strength.

Nitrile Latex vs Rubber

Just like natural rubber, Nitrile latex does not contain latex proteins. Nitrile rubber provides excellent resistance to tears and punctures and is almost 3 times stronger than natural rubber. Nitrile stands up well to oil, and makes it is a good choice for handling small wet/oily parts.

Features of Nitrile Foam Gloves

The main feature of knit nylon gloves coated with nitrile is their good grip and dexterity. Nitrile coated palm and fingers provide protection from abrasion, excellent grip, are extremely thin and durable, are breathable, comfortable, cut resistant, have great dexterity, tactility, and sensitivity.

There are various types of Nitrile coated glove dips available, some of them which include Nitrile palm coated grip gloves, foam Nitrile coated gloves, and fully coated Nitrile gloves.

All-Weather Grip Gloves

Many businesses use nitrile work grip gloves for their workers and most of these companies, especially in cold weather areas of the world. Nitrile foam gloves can keep worker’s hands warm in cold weather conditions and allow them to move their hands freely and easily even in cold conditions as well as protect their hands from harmful substances, cuts, and abrasion.

Works Well with Wet Conditions and Oil

Nitrile foam gloves withstand oils and have tactility even when wet. Nitrile coatings protect hands by preventing oil from penetrating through the gloves. Some applications include working with small or oily parts, as nitrile coating provides a secure grip.

Durable and Long Lasting

Nitrile foam gloves do not easily break down, delaminate or blister-like other coating materials in the presence of oils and in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Other Information on Nitrile Foam Gloves

Nitrile foam gloves are perfect for general work because of their durability and robustness. The nitrile coating will prevent cuts, tears, and even abrasions. These grip gloves work well between -25 F and 350 F.

Nitrile foam gloves are durable, but they will not provide a robust grip in oily and wet conditions compared to micropore nitrile gloves.

Nitrile foam coating may not be ideal for liquids and adhesives because they may seep inside the gloves.

Latex Coated Gloves

Latex-coated gloves are soft and flexible. These soft gloves give a perfect grip and an anti-slip experience. Latex-coated gloves work well in all circumstances and temperatures, and they are a perfect choice for high temperatures too.

Latex gloves fall in the category of the most durable gloves, but you may experience low abrasion and oil resistance. Latex gloves can resist the use of alcohol and some categories of ketones, but they won’t work well for organic solvents and hydrocarbons.

Latex gloves are perfect to use in construction, masonry, and even landscaping.

Micropore Nitrile Gloves

Micropore nitrile gloves work best for oily grip. These gloves consist of different suction cups which absorb all the oil and liquid providing a firm grip.

This coating doesn’t work well with adhesives, but the outcome is highly abrasion-resistant.

Polyurethane Coated Gloves

Polyurethane-coated gloves come with the best stretch and flexibility. These gloves work well for delicate applications, and the coating offers flexibility.

Polyurethane-coated gloves are resistant to all kinds of liquids, including oil. It is also heat resistant, but these gloves are not recommended to use above 79 degrees celsius. These polyurethane gloves work perfectly well for aerospace, fine part handling, and even with assembly and inspection.

PVC Gloves

PVC gloves work the best with adhesives, and they are abrasion-resistant. The adhesives won’t stick on the gloves so that you can work without any hassle. These gloves are best when working with furniture, automotive assembly, and trim applications.

These PVC gloves are perfect to use within cold conditions, and these PVC gloves are flexible but not tactile with rubber products.

Neoprene Coating Gloves

Neoprene coating gloves are synthetic rubber that also comes with chemical stability and heat resistance. These gloves are suitable for chemical-resistant and fire-retardant installations.

Neoprene coating will provide a dry, oily, and wet grip, but it has low resistance towards abrasion.

Final Verdict!

Nitrile foam grip gloves are more versatile do not easily break down, delaminate or blister-like other coating materials in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Looking for comfortable grip gloves should be your topmost priority so that there is no chance of removing these grip gloves and damaging your skin and hands.

Nitrile foam grip gloves will become your new favorite with a long-lasting experience.

2 notes

·

View notes

Text

Nitrile Butadiene Rubber (NBR) Prices Trend | Pricing | News | Database | Chart

Nitrile Butadiene Rubber (NBR) is a key material widely utilized across various industries due to its impressive resistance to oil, fuel, and other chemicals. Over recent years, NBR prices have undergone noticeable fluctuations driven by a variety of factors, including supply chain dynamics, raw material costs, global demand, and macroeconomic trends. The evolving pricing environment for NBR is a reflection of broader economic influences that shape the production and consumption of this essential synthetic rubber.

One of the primary factors affecting NBR prices is the cost of its raw materials, mainly butadiene and acrylonitrile. The prices of these raw materials are highly dependent on crude oil prices since both are petrochemical derivatives. As a result, NBR prices often display a degree of correlation with fluctuations in the oil market. When oil prices increase, the production costs for butadiene and acrylonitrile also rise, leading to an uptick in NBR prices. Conversely, a decline in crude oil prices tends to exert downward pressure on NBR costs. The volatility of the oil market, influenced by geopolitical tensions, production quotas by major oil-producing countries, and shifts in global energy policies, makes predicting NBR prices a challenging endeavor.

Get Real Time Prices for Nitrile Butadiene Rubber (NBR): https://www.chemanalyst.com/Pricing-data/nitrile-butadiene-rubber-71

Demand for NBR across key end-use sectors is also a major factor influencing price trends. The automotive industry, one of the largest consumers of NBR, heavily impacts demand. NBR is used in the production of seals, gaskets, hoses, and other components. When the automotive industry experiences growth, such as during economic expansions or due to government incentives for vehicle purchases, demand for NBR increases, often resulting in price hikes. Alternatively, when the automotive sector contracts, as seen during economic downturns or shifts in consumer preferences, NBR demand and prices may decline. Additionally, demand from sectors like healthcare, oil and gas, and construction also contributes to fluctuations in NBR pricing. For instance, the demand for NBR gloves surged during the pandemic due to their extensive use in personal protective equipment, temporarily pushing prices up due to increased consumption.

Another key factor in the pricing dynamics of NBR is regional market trends and competition. Different regions have varying levels of production capacity, trade policies, and consumption rates, which collectively impact pricing. For example, Asia-Pacific, particularly China, has become a major hub for NBR production and consumption. High levels of production in this region often lead to competitive pricing, while any disruption, such as stricter environmental regulations in China, can lead to price increases. On the other hand, regions with lower production capacities may experience higher prices due to a reliance on imports and associated logistics costs. Trade tariffs, international agreements, and local regulations further complicate regional pricing strategies and create disparities in global NBR market prices.

Environmental regulations and sustainability initiatives have increasingly influenced NBR prices. Efforts to reduce carbon footprints and implement eco-friendly practices have led some manufacturers to invest in sustainable production processes, which may entail higher initial costs. These costs are often passed on to consumers, influencing the overall price structure. Additionally, as regulatory bodies continue to tighten standards regarding emissions and the handling of chemicals, manufacturers may face increased compliance costs, further driving price volatility.

Technological advancements in NBR production also play a role in shaping prices. Innovations that improve production efficiency or create more durable, high-performance NBR products can impact pricing dynamics. As technology advances, new processes may reduce production costs, potentially leading to more competitive pricing. However, investment in new technology can be expensive, and the costs associated with research and development might lead to price increases in the short term.

Macroeconomic factors, including inflation, currency exchange rates, and global economic conditions, have significant ramifications for NBR prices. Inflation can lead to increased costs for labor, energy, and other inputs, all of which contribute to higher NBR prices. Currency fluctuations also impact the competitiveness of exports, influencing demand and, by extension, prices. For example, a strong domestic currency can make NBR exports more expensive, reducing demand and applying downward pressure on prices. Conversely, a weaker currency can boost exports and raise demand, thereby supporting higher prices.

In conclusion, Nitrile Butadiene Rubber (NBR) prices are influenced by a complex interplay of factors, including raw material costs, supply chain dynamics, demand fluctuations across various industries, regional market differences, environmental regulations, technological advancements, and macroeconomic conditions. Understanding these influences is critical for stakeholders across the value chain, from producers to end-users, as they navigate a constantly shifting market landscape. Future trends in NBR pricing will likely continue to be shaped by these multifaceted forces, requiring continuous monitoring and adaptation to changing conditions.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#NBR Pricing#Nitrile Butadiene Rubber#Nitrile Butadiene Rubber Price#Nitrile Butadiene Rubber Prices#Nitrile Butadiene Rubber Pricing

0 notes

Text

Roofing Gloves Guide

Roofing Gloves Guide

youtube

Nitrile-coated roofing gloves are a specialized type of work glove designed to provide roofing professionals with superior grip, protection, and durability. In this comprehensive guide, we will delve into the key features, benefits, applications, and maintenance tips for nitrile-coated roofing gloves.

Safer Grip Gloves by OPNBar 10053 Whittwood Dr, Suite 11284 Whittier, CA 90603 USA 657-667-6227 [email protected]/ https://safergrip.net/roofing-gloves/

Understanding Nitrile-Coated Roofing Gloves:

Material: Nitrile is a synthetic rubber compound known for its excellent resistance to punctures, chemicals, and abrasions.

Coating: These gloves feature a nitrile coating on the palm and fingers, providing exceptional grip and protection.

Versatility: Nitrile-coated gloves are versatile and suitable for various roofing tasks, including handling roofing materials, nails, and other sharp objects.

Benefits of Nitrile-Coated Roofing Gloves:

Superior Grip: The nitrile coating offers an outstanding grip on roofing materials, even in wet or oily conditions, reducing the risk of slipping.

Protection: Nitrile is puncture-resistant, safeguarding your hands against nails, sharp debris, and other potential hazards on the roof.

Chemical Resistance: These gloves are resistant to a wide range of chemicals commonly found in roofing materials, such as asphalt and tar.

Comfort: Nitrile-coated gloves are flexible, providing good dexterity and comfort, which is essential for precision work.

Applications:

Installing Shingles: Nitrile-coated gloves are perfect for handling shingles and fasteners during roof installation.

Handling Metal Roofing: Roofers working with metal roofing sheets benefit from the gloves' grip and protection.

Roof Repairs: Whether you're patching up leaks or replacing damaged sections, these gloves keep your hands safe and secure.

General Roof Maintenance: Nitrile-coated gloves are suitable for various maintenance tasks, such as gutter cleaning and inspections.

Choosing the Right Pair:

Size: Ensure a proper fit that allows dexterity while preventing the gloves from being too tight or loose.

Coating Thickness: Consider the thickness of the nitrile coating, as thicker coatings provide enhanced durability.

Grip Pattern: Different gloves may have varying grip patterns, so choose one that suits your specific roofing tasks.

Cuff Length: Opt for gloves with an appropriate cuff length for your needs, which can range from short cuffs for dexterity to gauntlet-style cuffs for added wrist protection.

Maintenance and Care:

Clean your nitrile-coated gloves regularly to remove dirt and debris.

Inspect for any signs of wear, tear, or punctures, and replace damaged gloves promptly.

Store gloves in a cool, dry place away from direct sunlight to prevent premature deterioration.

Nitrile-coated roofing gloves are an indispensable tool for roofing professionals, offering a winning combination of grip, protection, and comfort. By selecting the right pair and practicing proper maintenance, you can ensure your hands stay safe and agile while tackling roofing projects with confidence.

Employee Safety

Employee safety should be a top priority in any company. Apart from the obvious pain and suffering with worker deaths and injuries, workers who are injured on the job could sue a company for financial damages. Injuries may make them less productive when they return to work. It is important that employers effectively communicate safety standards to every employee, and train them properly.

Safer Grip Gloves by OPNBar™️ are ideal work grip gloves for all-day use for light manufacturing, warehouse operators, and for use in maintenance areas.

Our new and improved Safer Grip nitrile coated grip gloves by OPNBar are ideal multi-purpose work grip gloves for various applications like trucking and delivery, warehouses, maintenance areas, light manufacturing and carpentry. They are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Coated Mechanic Grip Gloves

Safer Grip nitrile coated gloves are made of 15-Gauge nylon polyester engineered yarn. The glove conforms to the operator’s hand and offers maximum flexibility and comfort. Safer Grip spandex nylon glove palms are coated in micro-foam nitrile, and are quite flexible, making Safer Grip nitrile coated grip gloves the perfect nitrile foam gloves for working with tools and protecting your hands and products. The latest glove offers a durable thumb crotch for extra grip and protection.

Coated foam grip gloves are extremely popular, primarily because they have a good price point. They are effective and comfortable, provide great dexterity, and protect operator hands from hazards, as well as protect products from workers’ hands.

Foam coatings can be applied and used in wet, oily, cold, and normal situations. Safer Grip spandex gloves with a long lasting microfoam nitrile coating are breathable with a coarse surface that can suck up oil and liquid, and maintain grip and tactility even when wet.

Nitrile Foam Mechanic Grip Gloves Coating

Safer Grip Gloves by OPNBar™️ grip gloves are dipped in a special longer lasting formula, with a durable nitrile foam coating that improves tactility and dexterity. The foam coating resists cuts, abrasions, and tears, and is also a good alternative for people with latex allergies or want an alternative to leather. Safer Grip gloves are dipped in an improved nitrile microfoam formula in a three-quarter palm dip. Micro-foam technology offers great breathability, making them cool and comfortable to wear, in any environment.

Lots of Features

15-Gauge Nylon/Spandex Liner

Tough Micro-Foam Nitrile Coating

Touchscreen Compatible Grip Gloves that Work with Phone

Superior Grip, Dexterity & Protection

Ultra Soft Fitting, Breathable

Abrasion Resistance: 40,000 cycles, EN388:4131X

Oeko-Tex Standard 100, Skin Friendly, Latex Free

Machine Washable

CE Compliance

Safer Grip nitrile coated grip gloves are CE Certified, EN388 4131 compliant, and have an abrasion resistance of 40,000 cycles. Safer Grip gloves are Oeko Tek Standard 100, are skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

STANDARD 100 by OEKO-TEX® is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety.

SAFER GRIP Gloves by OPNBAR™️ apparel carries the STANDARD 100 label. You can be certain that every component has been tested for harmful substances and are harmless for human health.

In the test, they take into account numerous regulated and non-regulated substances, which may be harmful to human health. In many cases, the limit values for the STANDARD 100 go beyond national and international requirements.

More Features of Safer Grip

Touchscreen Compatible Grip Gloves that Work with Phone

These work gloves are also touchscreen compatible on 4 fingers!

Ultra Soft Fitting, Breathable

These lightweight work gloves offer superior breathability and are quite form fitting.

Superior Grip, Dexterity & Protection

Nitrile coated work gloves offer versatile protection for many environments.

Reinforced Thumb Crotch

The thumb crotch on these work gloves provides a firm grip for these grip gloves.

Abrasion Resistance: 40,000 cycles, EN388:4131X

SAFER GRIP gloves are tested to have an abrasion resistance of 40,000 cycles!

Tough Micro-Foam Nitrile Coating

SAFER GRIP nitrile dipped work gloves and nitrile coated in a special, long lasting formula.

Versatile Weather Protection

These safety gloves can offer protection not only for your hands and products, but also weather elements as well.

Latex Free, Skin Friendly

Skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

Industrial Use Features of Safer Grip

Construction, Carpentry, Roofing

Woodworking/Carpentry Gloves

These construction gloves are also great for being woodworking gloves and roofing gloves.

Warehouse Gloves

These warehouse gloves also make great moving gloves or box handling gloves.

Mechanic Gloves

These mechanics gloves also make great shop gloves or gloves for home improvement.

Truck Driver Gloves

SAFER GRIP gloves are popular truck driver gloves for their versatility and comfort.

Versatile Outdoor Uses of Safer Grip Gloves

Gardening Gloves

SAFER Grip gloves make great outdoor gloves and gardening gloves.

Hiking Gloves

These are great for everyday use in the outdoors and also make excellent hiking gloves.

Boating Gloves

Nitrile coated gloves provide dexterity in wet environments making them great boating gloves and fishing gloves.

Biking and Outdoor Gloves

These firm grip gloves are also great as biking gloves or daily outdoor gloves.

Protecting your hands should be your top priority, and the best way is to use work gloves. Yes, these work gloves are great as they provide a layer of protection to the knit gloves and give a non-slippery experience.

Gloves can be made of nylon, cotton, and even polyester or engineered yards called Kevlar or Dyneema. This material is an excellent alternative for expensive leather gloves.

The palm-coated industrial work gloves are great for different use in the automotive industry, construction, or even in sampling and handling products, which offer a better, and anti-slip grip.

Glove Coatings

The dip coating is applied on the knit gloves to give a good layer of protection. However, the amount of coating can be customized as follows:

Full Dip

The full dip allows covering the whole hand including the lower wrist.

Palm Dip

The palm dip will cover the whole palm including the fingertips for a better shield.

¾ Dip

The ¾ dip protects the palm, knuckles, and fingers.

What’s Grip Gloves Do you Prefer?

These tough coatings will give a perfect experience for handling tough materials filled with grease and chemicals. These gloves will enhance durability, chemical resistance, and even cut protection.

Many coatings can be used on knit gloves which are as follows:

Nitrile Foam

Latex

PVC

Neoprene

Zed coat

Micropore Nitrile

Polyurethane (PU)

Now, let us have a brief look at all these types of coating.

Nitrile Foam Coated Gloves

Industrial environments of today carry many activities that have risks. Governments and businesses in many countries define guidelines that benefit the safety of their workers. Many industrial applications promote the use of nitrile foam grip gloves for industry workers as a means of safety.

For Those with Allergy Concerns

Nitrile foam grip gloves are a type of glove made from nylone and coated with synthetic rubber. Nitrile is a polymer compound with a production process similar to that of making rubber. Unlike rubber however, nitrile is a 100% synthetic substance and typically does not create any type of allergic reaction on the human body and as a result, is accepted and used in many businesses. Nitrile is the synthetic form of latex and is commonly chosen for its strength.

Nitrile Latex vs Rubber

Just like natural rubber, Nitrile latex does not contain latex proteins. Nitrile rubber provides excellent resistance to tears and punctures and is almost 3 times stronger than natural rubber. Nitrile stands up well to oil, and makes it is a good choice for handling small wet/oily parts.

Features of Nitrile Foam Gloves

The main feature of knit nylon gloves coated with nitrile is their good grip and dexterity. Nitrile coated palm and fingers provide protection from abrasion, excellent grip, are extremely thin and durable, are breathable, comfortable, cut resistant, have great dexterity, tactility, and sensitivity.

There are various types of Nitrile coated glove dips available, some of them which include Nitrile palm coated grip gloves, foam Nitrile coated gloves, and fully coated Nitrile gloves.

All-Weather Grip Gloves

Many businesses use nitrile work grip gloves for their workers and most of these companies, especially in cold weather areas of the world. Nitrile foam gloves can keep worker’s hands warm in cold weather conditions and allow them to move their hands freely and easily even in cold conditions as well as protect their hands from harmful substances, cuts, and abrasion.

Works Well with Wet Conditions and Oil

Nitrile foam gloves withstand oils and have tactility even when wet. Nitrile coatings protect hands by preventing oil from penetrating through the gloves. Some applications include working with small or oily parts, as nitrile coating provides a secure grip.

Durable and Long Lasting

Nitrile foam gloves do not easily break down, delaminate or blister-like other coating materials in the presence of oils and in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Other Information on Nitrile Foam Gloves

Nitrile foam gloves are perfect for general work because of their durability and robustness. The nitrile coating will prevent cuts, tears, and even abrasions. These grip gloves work well between -25 F and 350 F.

Nitrile foam gloves are durable, but they will not provide a robust grip in oily and wet conditions compared to micropore nitrile gloves.

Nitrile foam coating may not be ideal for liquids and adhesives because they may seep inside the gloves.

Latex Coated Gloves

Latex-coated gloves are soft and flexible. These soft gloves give a perfect grip and an anti-slip experience. Latex-coated gloves work well in all circumstances and temperatures, and they are a perfect choice for high temperatures too.

Latex gloves fall in the category of the most durable gloves, but you may experience low abrasion and oil resistance. Latex gloves can resist the use of alcohol and some categories of ketones, but they won’t work well for organic solvents and hydrocarbons.

Latex gloves are perfect to use in construction, masonry, and even landscaping.

Micropore Nitrile Gloves

Micropore nitrile gloves work best for oily grip. These gloves consist of different suction cups which absorb all the oil and liquid providing a firm grip.

This coating doesn’t work well with adhesives, but the outcome is highly abrasion-resistant.

Polyurethane Coated Gloves

Polyurethane-coated gloves come with the best stretch and flexibility. These gloves work well for delicate applications, and the coating offers flexibility.

Polyurethane-coated gloves are resistant to all kinds of liquids, including oil. It is also heat resistant, but these gloves are not recommended to use above 79 degrees celsius. These polyurethane gloves work perfectly well for aerospace, fine part handling, and even with assembly and inspection.

PVC Gloves

PVC gloves work the best with adhesives, and they are abrasion-resistant. The adhesives won’t stick on the gloves so that you can work without any hassle. These gloves are best when working with furniture, automotive assembly, and trim applications.

These PVC gloves are perfect to use within cold conditions, and these PVC gloves are flexible but not tactile with rubber products.

Neoprene Coating Gloves

Neoprene coating gloves are synthetic rubber that also comes with chemical stability and heat resistance. These gloves are suitable for chemical-resistant and fire-retardant installations.

Neoprene coating will provide a dry, oily, and wet grip, but it has low resistance towards abrasion.

Final Verdict!

Nitrile foam grip gloves are more versatile do not easily break down, delaminate or blister-like other coating materials in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Looking for comfortable grip gloves should be your topmost priority so that there is no chance of removing these grip gloves and damaging your skin and hands.

Nitrile foam grip gloves will become your new favorite with a long-lasting experience.

1 note

·

View note

Text

Mechanic Gloves Guide

Mechanic Gloves Guide

In the world of mechanical work, having the right tools is crucial to ensure efficiency, precision, and safety. Among these essential tools are coated mechanic gloves with grip, designed to provide an optimal balance of dexterity, protection, and enhanced grip.

youtube

With a specialized coating applied to the gloves, they offer a range of advantages that make them indispensable for professionals and enthusiasts in various industries. Here, we will explore the numerous benefits of coated mechanic gloves with grip and their significance in mechanical tasks.

Enhanced Grip and Precision

Coated mechanic gloves with grip are engineered with a specialized coating, often made of materials such as latex, nitrile, or polyurethane. This coating acts as an additional layer, providing exceptional grip and adhesion to various surfaces. Whether handling oily components, slippery tools, or delicate parts, these gloves offer a reliable grip, allowing for improved control, precision, and accuracy. The enhanced grip minimizes the risk of slippage and accidents, ensuring the smooth execution of tasks.

Safer Grip Gloves by OPNBar

10053 Whittwood Dr, Suite 11284 Whittier,

CA 90603 USA

657-667-6227

Protection from Hazards

Mechanical work involves exposure to potential hazards, such as sharp objects, rough surfaces, and chemicals. Coated mechanic gloves act as a protective barrier, safeguarding the hands from cuts, abrasions, burns, and chemical contact. The coating provides an additional layer of defense, enhancing resistance to punctures, tears, and abrasive materials. This protection minimizes the risk of injuries and promotes a safer working environment.

Durability and Longevity

Coated mechanic gloves are designed to withstand demanding conditions and extended use. The coating not only enhances grip but also contributes to the overall durability of the gloves. It provides resistance to wear and tear, extending the lifespan of the gloves and reducing the need for frequent replacements. The gloves' durability ensures that they can withstand the rigors of mechanical work, providing reliable protection and grip for prolonged periods.

Flexibility and Comfort

While protection and grip are crucial, comfort and flexibility are equally important. Coated mechanic gloves are engineered to offer a snug fit, allowing for natural hand movement and flexibility. The coating materials used are often lightweight and flexible, ensuring optimal dexterity and tactile sensitivity. Additionally, many coated gloves are designed with breathable materials, allowing for adequate airflow, reducing hand fatigue, and maintaining comfort during prolonged use.

Versatility in Applications

Coated mechanic gloves with grip find applications in various industries and tasks. From automotive repairs and maintenance to assembly line work, these gloves are versatile tools that adapt to different environments. The coating's grip properties make them suitable for handling small parts, tools, and equipment, improving productivity and efficiency. Additionally, the protective qualities of the gloves make them invaluable in construction, manufacturing, and other industries where hand safety is paramount.

Coated mechanic gloves with grip provide a winning combination of enhanced grip, protection, durability, and comfort. These gloves are essential tools for professionals and enthusiasts involved in mechanical work, offering improved performance, safety, and productivity. By investing in high-quality coated mechanic gloves, individuals can enhance their grip, reduce the risk of injuries, and tackle challenging tasks with confidence

About Coated Mechanic Gloves

Grip gloves are specialized gloves designed to provide an enhanced grip when handling objects. They are widely used in various industries, including construction, manufacturing, and automotive, to improve productivity and reduce the risk of accidents. In this article, we will discuss the benefits of using grip gloves and explore the different types of grip gloves available in the market.

Benefits of Mechanic Grip Gloves:

Enhanced Grip: The primary benefit of using grip gloves is that they provide an enhanced grip on objects. The gloves are designed with specialized materials that offer superior traction, making it easier to hold and manipulate objects. This is particularly useful in situations where the objects are heavy or slippery.

Increased Productivity: The improved grip provided by the gloves can help increase productivity in various industries. For instance, construction workers can handle heavy tools and materials with ease, reducing the time and effort required to complete tasks. Similarly, manufacturing workers can handle small components with greater precision, resulting in faster assembly times.

Reduced Risk of Accidents: Grip gloves can also help reduce the risk of accidents in the workplace. With a better grip on tools and materials, workers are less likely to drop them, reducing the risk of injury to themselves and others.

Types of Mechanic Grip Gloves:

Latex Grip Gloves: Latex grip gloves are made of a latex coating over a knit or woven base material. They are lightweight and offer excellent grip in wet or dry conditions. Latex grip gloves are commonly used in the healthcare industry, where they provide protection against infectious materials.

Nitrile Grip Gloves: Nitrile grip gloves are made of a synthetic rubber material that is resistant to punctures, cuts, and chemicals. They offer excellent grip in wet or oily conditions and are commonly used in the automotive and manufacturing industries.

PVC Grip Gloves: PVC grip gloves are made of a PVC coating over a knit or woven base material. They are lightweight and offer good grip in wet or oily conditions. PVC grip gloves are commonly used in the food processing and janitorial industries.

Leather Grip Gloves: Leather grip gloves are made of high-quality leather and offer superior grip and durability. They are commonly used in the construction and landscaping industries, where workers need to handle heavy tools and materials.

Cut-Resistant Grip Gloves: Cut-resistant grip gloves are made of specialized materials that offer protection against cuts and abrasions. They are commonly used in industries where workers handle sharp tools and materials, such as the construction and manufacturing industries.

Choosing the Right Mechanic Grip Gloves:

When choosing grip gloves, there are several factors to consider, including the type of work being performed, the level of grip required, and the potential hazards present in the workplace. Some important factors to consider include:

Material: The material of the gloves should be chosen based on the type of work being performed. For instance, latex grip gloves are suitable for healthcare workers, while nitrile grip gloves are better for automotive and manufacturing workers.

Grip: The level of grip required will depend on the nature of the work being performed. Workers who handle heavy or slippery objects may require gloves with a stronger grip, while those who handle smaller components may require gloves with a more delicate grip.

Size: The gloves should fit snugly to ensure maximum grip and protection. It is essential to choose gloves that fit properly to avoid slipping or sliding while working.

Durability: The durability of the gloves should be considered when choosing grip gloves. Workers who handle sharp or abrasive materials may require gloves that are more durable to prevent punctures or tears.

Employee Safety

Employee safety should be a top priority in any company. Apart from the obvious pain and suffering with worker deaths and injuries, workers who are injured on the job could sue a company for financial damages. Injuries may make them less productive when they return to work. It is important that employers effectively communicate safety standards to every employee, and train them properly.

Safer Grip Gloves by OPNBar™️ are ideal work grip gloves for all-day use for light manufacturing, warehouse operators, and for use in maintenance areas.

Our new and improved Safer Grip nitrile coated grip gloves by OPNBar are ideal multi-purpose work grip gloves for various applications like trucking and delivery, warehouses, maintenance areas, light manufacturing and carpentry. They are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Coated Mechanic Grip Gloves

Safer Grip nitrile coated gloves are made of 15-Gauge nylon polyester engineered yarn. The glove conforms to the operator’s hand and offers maximum flexibility and comfort. Safer Grip spandex nylon glove palms are coated in micro-foam nitrile, and are quite flexible, making Safer Grip nitrile coated grip gloves the perfect nitrile foam gloves for working with tools and protecting your hands and products. The latest glove offers a durable thumb crotch for extra grip and protection.

Coated foam grip gloves are extremely popular, primarily because they have a good price point. They are effective and comfortable, provide great dexterity, and protect operator hands from hazards, as well as protect products from workers’ hands.

Foam coatings can be applied and used in wet, oily, cold, and normal situations. Safer Grip spandex gloves with a long lasting microfoam nitrile coating are breathable with a coarse surface that can suck up oil and liquid, and maintain grip and tactility even when wet.

Nitrile Foam Mechanic Grip Gloves Coating

Safer Grip Gloves by OPNBar™️ grip gloves are dipped in a special longer lasting formula, with a durable nitrile foam coating that improves tactility and dexterity. The foam coating resists cuts, abrasions, and tears, and is also a good alternative for people with latex allergies or want an alternative to leather. Safer Grip gloves are dipped in an improved nitrile microfoam formula in a three-quarter palm dip. Micro-foam technology offers great breathability, making them cool and comfortable to wear, in any environment.

Lots of Features

15-Gauge Nylon/Spandex Liner

Tough Micro-Foam Nitrile Coating

Touchscreen Compatible Grip Gloves that Work with Phone

Superior Grip, Dexterity & Protection

Ultra Soft Fitting, Breathable

Abrasion Resistance: 40,000 cycles, EN388:4131X

Oeko-Tex Standard 100, Skin Friendly, Latex Free

Machine Washable

CE Compliance

Safer Grip nitrile coated grip gloves are CE Certified, EN388 4131 compliant, and have an abrasion resistance of 40,000 cycles. Safer Grip gloves are Oeko Tek Standard 100, are skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

STANDARD 100 by OEKO-TEX® is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety.

SAFER GRIP Gloves by OPNBAR™️ apparel carries the STANDARD 100 label. You can be certain that every component has been tested for harmful substances and are harmless for human health.

In the test, they take into account numerous regulated and non-regulated substances, which may be harmful to human health. In many cases, the limit values for the STANDARD 100 go beyond national and international requirements.

More Features of Safer Grip

Touchscreen Compatible Grip Gloves that Work with Phone

These work gloves are also touchscreen compatible on 4 fingers!

Ultra Soft Fitting, Breathable

These lightweight work gloves offer superior breathability and are quite form fitting.

Superior Grip, Dexterity & Protection

Nitrile coated work gloves offer versatile protection for many environments.

Reinforced Thumb Crotch

The thumb crotch on these work gloves provides a firm grip for these grip gloves.

Abrasion Resistance: 40,000 cycles, EN388:4131X

SAFER GRIP gloves are tested to have an abrasion resistance of 40,000 cycles!

Tough Micro-Foam Nitrile Coating

SAFER GRIP nitrile dipped work gloves and nitrile coated in a special, long lasting formula.

Versatile Weather Protection

These safety gloves can offer protection not only for your hands and products, but also weather elements as well.

Latex Free, Skin Friendly

Skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

Industrial Use Features of Safer Grip

Construction, Carpentry, Roofing

Woodworking/Carpentry Gloves

These construction gloves are also great for being woodworking gloves and roofing gloves.

Warehouse Gloves

These warehouse gloves also make great moving gloves or box handling gloves.

Mechanic Gloves

These mechanics gloves also make great shop gloves or gloves for home improvement.

Truck Driver Gloves

SAFER GRIP gloves are popular truck driver gloves for their versatility and comfort.

Versatile Outdoor Uses of Safer Grip Gloves

Gardening Gloves

SAFER Grip gloves make great outdoor gloves and gardening gloves.

Hiking Gloves

These are great for everyday use in the outdoors and also make excellent hiking gloves.

Boating Gloves

Nitrile coated gloves provide dexterity in wet environments making them great boating gloves and fishing gloves.

Biking and Outdoor Gloves

These firm grip gloves are also great as biking gloves or daily outdoor gloves.

Protecting your hands should be your top priority, and the best way is to use work gloves. Yes, these work gloves are great as they provide a layer of protection to the knit gloves and give a non-slippery experience.

Gloves can be made of nylon, cotton, and even polyester or engineered yards called Kevlar or Dyneema. This material is an excellent alternative for expensive leather gloves.

The palm-coated industrial work gloves are great for different use in the automotive industry, construction, or even in sampling and handling products, which offer a better, and anti-slip grip.

Glove Coatings

The dip coating is applied on the knit gloves to give a good layer of protection. However, the amount of coating can be customized as follows:

Full Dip

The full dip allows covering the whole hand including the lower wrist.

Palm Dip

The palm dip will cover the whole palm including the fingertips for a better shield.

¾ Dip

The ¾ dip protects the palm, knuckles, and fingers.

What’s Grip Gloves Do you Prefer?

These tough coatings will give a perfect experience for handling tough materials filled with grease and chemicals. These gloves will enhance durability, chemical resistance, and even cut protection.

Many coatings can be used on knit gloves which are as follows:

Nitrile Foam

Latex

PVC

Neoprene

Zed coat

Micropore Nitrile

Polyurethane (PU)

Now, let us have a brief look at all these types of coating.

Nitrile Foam Coated Gloves

Industrial environments of today carry many activities that have risks. Governments and businesses in many countries define guidelines that benefit the safety of their workers. Many industrial applications promote the use of nitrile foam grip gloves for industry workers as a means of safety.

For Those with Allergy Concerns

Nitrile foam grip gloves are a type of glove made from nylone and coated with synthetic rubber. Nitrile is a polymer compound with a production process similar to that of making rubber. Unlike rubber however, nitrile is a 100% synthetic substance and typically does not create any type of allergic reaction on the human body and as a result, is accepted and used in many businesses. Nitrile is the synthetic form of latex and is commonly chosen for its strength.

Nitrile Latex vs Rubber

Just like natural rubber, Nitrile latex does not contain latex proteins. Nitrile rubber provides excellent resistance to tears and punctures and is almost 3 times stronger than natural rubber. Nitrile stands up well to oil, and makes it is a good choice for handling small wet/oily parts.

Features of Nitrile Foam Gloves

The main feature of knit nylon gloves coated with nitrile is their good grip and dexterity. Nitrile coated palm and fingers provide protection from abrasion, excellent grip, are extremely thin and durable, are breathable, comfortable, cut resistant, have great dexterity, tactility, and sensitivity.

There are various types of Nitrile coated glove dips available, some of them which include Nitrile palm coated grip gloves, foam Nitrile coated gloves, and fully coated Nitrile gloves.

All-Weather Grip Gloves

Many businesses use nitrile work grip gloves for their workers and most of these companies, especially in cold weather areas of the world. Nitrile foam gloves can keep worker’s hands warm in cold weather conditions and allow them to move their hands freely and easily even in cold conditions as well as protect their hands from harmful substances, cuts, and abrasion.

Works Well with Wet Conditions and Oil

Nitrile foam gloves withstand oils and have tactility even when wet. Nitrile coatings protect hands by preventing oil from penetrating through the gloves. Some applications include working with small or oily parts, as nitrile coating provides a secure grip.

Durable and Long Lasting

Nitrile foam gloves do not easily break down, delaminate or blister-like other coating materials in the presence of oils and in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Other Information on Nitrile Foam Gloves

Nitrile foam gloves are perfect for general work because of their durability and robustness. The nitrile coating will prevent cuts, tears, and even abrasions. These grip gloves work well between -25 F and 350 F.

Nitrile foam gloves are durable, but they will not provide a robust grip in oily and wet conditions compared to micropore nitrile gloves.

Nitrile foam coating may not be ideal for liquids and adhesives because they may seep inside the gloves.

Latex Coated Gloves

Latex-coated gloves are soft and flexible. These soft gloves give a perfect grip and an anti-slip experience. Latex-coated gloves work well in all circumstances and temperatures, and they are a perfect choice for high temperatures too.

Latex gloves fall in the category of the most durable gloves, but you may experience low abrasion and oil resistance. Latex gloves can resist the use of alcohol and some categories of ketones, but they won’t work well for organic solvents and hydrocarbons.

Latex gloves are perfect to use in construction, masonry, and even landscaping.

Micropore Nitrile Gloves

Micropore nitrile gloves work best for oily grip. These gloves consist of different suction cups which absorb all the oil and liquid providing a firm grip.

This coating doesn’t work well with adhesives, but the outcome is highly abrasion-resistant.

Polyurethane Coated Gloves

Polyurethane-coated gloves come with the best stretch and flexibility. These gloves work well for delicate applications, and the coating offers flexibility.

Polyurethane-coated gloves are resistant to all kinds of liquids, including oil. It is also heat resistant, but these gloves are not recommended to use above 79 degrees celsius. These polyurethane gloves work perfectly well for aerospace, fine part handling, and even with assembly and inspection.

PVC Gloves

PVC gloves work the best with adhesives, and they are abrasion-resistant. The adhesives won’t stick on the gloves so that you can work without any hassle. These gloves are best when working with furniture, automotive assembly, and trim applications.

These PVC gloves are perfect to use within cold conditions, and these PVC gloves are flexible but not tactile with rubber products.

Neoprene Coating Gloves

Neoprene coating gloves are synthetic rubber that also comes with chemical stability and heat resistance. These gloves are suitable for chemical-resistant and fire-retardant installations.

Neoprene coating will provide a dry, oily, and wet grip, but it has low resistance towards abrasion.

Final Verdict!

Nitrile foam grip gloves are more versatile do not easily break down, delaminate or blister-like other coating materials in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Looking for comfortable grip gloves should be your topmost priority so that there is no chance of removing these grip gloves and damaging your skin and hands.

Nitrile foam grip gloves will become your new favorite with a long-lasting experience.

1 note

·

View note

Text

Fume Hood Safety Series- FHSS 1

In the realm of laboratory safety, the occurrence of fume hood catastrophes continue to perplex and concern researchers and industry professionals alike. The pressing question remains: Why do these incidents persist, and how can we effectively prevent them?

At Metrolabs, our expertise lies in the design, manufacturing, and installation of a wide range of laboratory furniture, including fume hoods, anti-vibration tables, and storage cupboards, among others. With decades of experience in the field, we have come to realize that a significant number of our inquiries stem from fume hoods manufactured by various brands that have experienced failures. Significantly, while there seems to be a loose correlation between the age of the fume hood system, this does not appear to be a causative factor. Quite surprisingly, despite the scale of the issue, there seems to be a dearth of discussion on its causative factors, autopsies of incidents, and possible preventative measures. In this inaugural article of the Fume Hood Safety Series, we delve into two case studies, examining the preventive measures and general practices crucial for the safe operation of fume hoods within a laboratory environment.

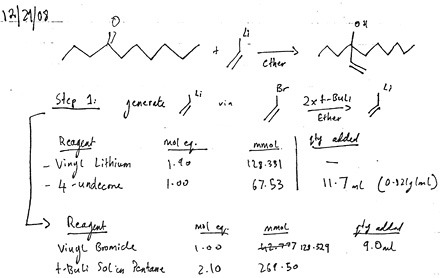

Case Study 1University of California, Los Angeles (UCLA) Laboratory Explosion (2008):

In 2008, a fume hood explosion at UCLA resulted in the unfortunate death of a research assistant. Sangji, 23, research assistant, was working with a nitrogen manifold in a fume hood on the fourth floor of UCLA’s Molecular Sciences Building. Unexpectedly, the syringe plunger dislodged from the barrel, exposing tBuLi to the atmosphere. Inadvertently, Sangji also knocked over an open flask of hexane in the hood. The tBuLi ignited, causing a fire that spread to the solvent and Sangji’s clothing. It is unclear whether Sangji wore eye protection, but was not wearing a lab coat and had nitrile gloves on. Despite the presence of a safety shower in the lab, Sangji could not utilize it. Sangji was promptly taken to the hospital but unfortunately succumbed to injuries a few days later.

Analysis: The explosion at UCLA was caused by the reactive nature of tBuLi, along with the accidental presence of hexane which led to an uncontrolled cross-reaction and subsequent explosion inside the fume hood. Improper handling techniques in the handling of the tBuLi and improper storage practices- the accidental presence of hexane, which was negligently left inside the hood could be theorised to be the main cause of the accident. Not wearing PPE such as the lab coat or eye protection definitely contributed to the severity of the consequences of the accident.

Prevention: Proper training on handling reactive chemicals, implementing rigorous safety protocols, wearing of proper personal protective incidents (PPE), ensuring appropriate storage conditions and protocols, ensuring the absence of other substances that might cross-react catastrophically, and conducting regular risk assessments can help prevent similar incidents.

Case Study 2Evacuation at the University of Utah Lab after Fume Hood Explosion (2023):

A small explosion in room 328 of the Fletcher Building at the University of Utah led to the evacuation of the facility. The incident, contained within a fume hood, occurred during laboratory work in the Physics & Astronomy Department. No injuries were reported, and damage was limited to the fume hood and the lab. Authorities, including the university’s Environmental Health and Safety Department, are investigating the cause of the explosion. There is no ongoing risk to the surrounding area.

Analysis: Education on proper synthesis methods, strictly abiding by the chemical incompatibility charts, frequent fume hood assessment & maintenance activities in accordance with the IQ/OQ charts, and proper chemical storage protocols might have prevented this mishap.

Why talk about Fume Hood safety in particular?

There have been increasingly numerous fume hood-related catastrophic accidents across India, and many of them have been preventable. It wouldn’t be an exaggeration to state that it is truly due to gods grace that there aren’t a much greater number of accidents that occur, because of many of the poor lab techniques, safety practices and poor engineering practices in the design and manufacture of the hood being followed. To prevent any such devastating but perfectly preventable accidents from happening at all, we must autopsy such incidents, and implement good lab practices and good engineering practices in the design, manufacturing and usage of such hoods. This will increase the safety of personnel inside the laboratory, increase work efficiency, mitigate risk in case of accidents and also prove to be more environmentally friendly. To address the need for Fume Hood Safe Practices is the need of the hour for us all.

Proper Usage of Fume Hoods: Guidelines for Accident Prevention and risk mitigation

Material of Construction: Compatible material of construction for each part of the fume hood. The reactions and processes undergone in the fume hood, the reagents used, and the temperatures reached, etc. must be kept in mind- the chosen material of construction in every aspect of the fume hood must withstand all these conditions that occur during the due course of usage.

Scrubber compatibility and maintenance: Scrubbers must be chosen in accordance with the type of reactions and the type of reactions and care must be taken to ensure that incompatible reactions are not undergone inside the fume hood. Prompt, regular maintenance must take place according to the IQ/OQ protocol.

Proper reagent storage: Reagents must be clearly labeled and properly stored within the appropriate storage area. Care must be taken to keep the container lids closed tightly, and that photosensitive substances are kept in a sufficiently dark location. Incompatible reagents must be stored separately from each other to prevent accidental cross-reactions. Unused substances and spillage must NEVER be left or stored in the fume hood, for any reason.

Plan and organize experiments: Before starting any experiment, the procedures and ensuring proper segregation of substances must be planned. The workspace for each chemical must be clearly defined and overcrowding must be avoided to minimize the risk of accidental reactions.

Follow safety protocols and proper lab techniques: Established safety protocols and guidelines for the use of fume hoods must be adhered to. Proper technique must be followed for the handling of all reactions and processes. Proper training must be provided for all personnel for safety protocols, proper technique, and good laboratory practices.

Why talk about Fume Hood safety in particular?

Fume hood explosions in laboratory settings can have severe consequences for both personnel and infrastructure. By examining real incidents, we can better understand the causes and work toward implementing effective preventive measures. To prevent fume hood explosions, it is crucial to prioritize proper chemical handling, storage, and disposal practices, conduct thorough risk assessments, ensure proper ventilation, and maintain electrical safety protocols. By prioritizing laboratory safety and adhering to these preventive measures, we can minimize the risks of fume hood explosions and create a safer working environment for researchers. More about each factor will be discussed in the upcoming articles in the Fume Hood Safety Series (FHSS).

Sources and Citations

[1] Vellutato, A. (2021). Cleaning and Disinfecting Laminar Flow Workstations, Bio Safety Cabinets and Fume Hoods. In Handbook of Validation in Pharmaceutical Processes (pp. 419-428). CRC Press.

[2] “Deadly UCLA lab fire leaves haunting questions” Los Angeles Times, 2009

[3] “Learning From UCLA: Details of the experiment that led to a researcher’s death prompt evaluations of academic safety practices” Chemical & Engineering News, 2009

[4] National Academies of Sciences, Engineering, and Medicine. (2016). Chemical Laboratory Safety and Security: A Guide to Developing Standard Operating Procedures.

#metrolabs#lab furniture#lab safety#safety#workplace#osha compliant#osha#ppe#safety equipme#stem#science#chemistry#chemical manufacturing#osha noncompliant#osha approved#health and safety#health care#safety education#safety accessories

1 note

·

View note

Text

Fishing Gloves Guide

Nitrile coated fishing gloves offer a better grip compared to their uncoated counterparts. This is important when handling rods, nets and especially fish, which can be slippery and difficult to control. The added grip reduces the chance of accidental slips and ensures a more successful and less frustrating fishing experience.

Why Choose Fishing Gloves with Grip?

Superior Grip and Control

Nitrile coated fishing gloves offer an enhanced grip compared to their non-coated counterparts. This is crucial when handling fishing rods, nets, and, most importantly, the fish themselves, which can be slippery and difficult to control. The added grip reduces the chances of accidental slips, ensuring a more successful and less frustrating fishing experience.

10053 Whittwood Dr, Suite 11284 Whittier,

CA 90603 USA

657-667-6227

Protection Against the Elements

The nitrile coating on these gloves acts as a protective barrier against various elements. It is resistant to oils, chemicals, and certain types of abrasion, making it particularly beneficial for fishing in diverse environments. Whether you're fishing in saltwater, freshwater, or brackish environments, these gloves can help to protect your hands from potential harm.

Enhanced Durability

Nitrile coated gloves are known for their durability. The coating adds an extra layer of protection, reducing wear and tear on the gloves and ensuring they last longer. This makes them a cost-effective choice in the long run, especially for those who fish frequently.

Comfort and Sensitivity

Despite the robust protection they offer, nitrile coated gloves do not compromise on comfort or sensitivity. They are flexible and often designed to fit snugly, allowing for a high level of dexterity. This is particularly important in fishing, where precision and fine motor control can be the difference between a successful catch and a missed opportunity.