#mould manufacturer company in pune

Explore tagged Tumblr posts

Text

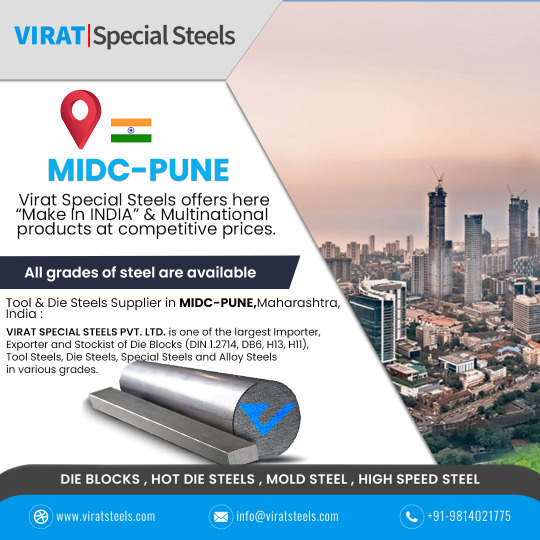

Looking for a Tool and Die Steel Supplier in MIDC Pune? Here's Your Solution Virat Special Steels delivers excellence!

Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Pune, Maharashtra!

Pune, the thriving city nestled in the state of Maharashtra, is a bustling hub of industrial activity. Known for its deep-rooted cultural heritage, rapid urbanization, and status as the "Oxford of the East" due to its prestigious educational institutions.

Pune also plays a crucial role in India's manufacturing sector. As the second-largest city in Maharashtra and a significant contributor to the nation's industrial development, Pune hosts numerous industries, including the ever-growing tool and die steel sector.

If you're searching for a reliable Tool and Die Steel supplier in the MIDC (Maharashtra Industrial Development Corporation) Pune area, you've come to the right place. VIRAT SPECIAL STEELS PVT. LIMITED , INDIA , headquartered in Gurugram.

This company has carved a niche for itself as a premier supplier of tool and die steels in India. With a product list that boasts of high-quality steels ranging from DIE STEEL to ALLOY STEELS and EN-SERIES.

Available Grades:- Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6. Hot Work Steels: DIN 2343, 2344, AISI H11, and H13. Plastic Mould Steels: DIN 2738, 2311, and AISI P20. High-Speed Steels: DIN 3243, 3343, AISI M2, and M35. Cold Work Steels (HCHCr): DIN 2379, 2080, AISI D2, and D3. Alloy Steels, EN-Series, and More.

Virat Special Steels is not just a supplier; it's a beacon of innovation and quality.

You can explore their offerings here. Contact us today to learn more! https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-pune/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#midc industrial area#MIDCPune#Maharashtra#H13DieSteel#AluminumIndustry#ToolAndDie

2 notes

·

View notes

Text

Plastic Injection Molding Pune. India

At Precious Enterprises, we take great satisfaction in manufacturing mould bases with the highest accuracy and dependability possible, which makes us one of the most reliable plastic injection moulding companies in Pune.

#plastic injection moulding companies in Pune#Plastic Injection Molding Pune#Best Molding Companies India#Gun Drilling Machine Pune

0 notes

Text

Injection Moulding Machine Manufacturer

Pune, a vibrant industrial city in Maharashtra, India, has established itself as a crucial hub for manufacturing and technology. Among the diverse industries flourishing in Pune, the field of plastic processing, particularly injection molding, stands out. Injection molding machines, essential for producing plastic parts with high precision and efficiency, are integral to Pune's industrial landscape. This article provides an overview of the injection molding industry in Pune, highlighting key players, technological advancements, and the industry's impact on the local economy.

Understanding Injection Molding

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. This process is known for its efficiency, precision, and ability to produce complex shapes with high repeatability. It is commonly used for producing plastic components in various industries, including automotive, consumer goods, electronics, and medical devices.

The Injection Molding Landscape in Pune

Pune's strategic location, skilled workforce, and supportive infrastructure make it an attractive destination for injection molding machine manufacturers and users. The city's industrial ecosystem supports a wide range of applications, from small-scale enterprises to large multinational corporations.

Key Players in the MarketSeveral prominent companies and suppliers are active in the injection molding machine sector in Pune:

Milacron India: Milacron is a global leader in injection molding technology, known for its innovative solutions and extensive service network. The company’s presence in Pune strengthens the city’s position in the injection molding industry.

Arburg: With a reputation for high-quality machines and advanced technology, Arburg provides state-of-the-art injection molding solutions and has a strong presence in Pune.

Husky Injection Molding Systems: Husky is renowned for its expertise in high-performance injection molding machines, catering to various industrial needs in Pune.

KraussMaffei: Offering cutting-edge technology and comprehensive support, KraussMaffei serves a diverse range of industries in Pune.

Plastics Machinery & Parts: Specializing in a wide range of plastic processing equipment, this company provides injection molding machines tailored to local market needs.

Battenfeld-Cincinnati: Known for its technological innovations, Battenfeld-Cincinnati contributes to Pune’s advanced injection molding capabilities.

Santec Group: A key player in manufacturing injection molding machines, Santec Group supports Pune's growing demand for plastic components.

Cosmos Engineering: Offering a variety of plastic processing machines, Cosmos Engineering plays a significant role in Pune’s injection molding sector.

Technological AdvancementsThe injection molding industry in Pune benefits from continuous technological advancements. Modern machines are equipped with features such as:

Energy Efficiency: Advanced machines consume less power, reducing operational costs and environmental impact.

Precision Control: Enhanced control systems ensure high accuracy and consistency in production.

Automation: Integration with robotics and automation technologies improves efficiency and reduces manual labor.

Smart Technology: IoT-enabled machines allow for real-time monitoring and predictive maintenance, enhancing operational reliability.

Economic ImpactThe injection molding industry significantly contributes to Pune’s economy by:

Job Creation: The industry supports a wide range of jobs, from machine operators to engineers and technicians.

Supporting Industries: Injection molding drives growth in related sectors such as raw material suppliers, mold makers, and maintenance services.

Export Potential: Pune’s injection molding machines and components are increasingly being exported, enhancing the city’s international trade profile.

Challenges and Future Prospects

While the injection molding industry in Pune is thriving, it faces challenges such as fluctuating raw material costs and the need for continuous technological upgrades. However, the city's robust industrial infrastructure and commitment to innovation position it well for future growth.

Looking ahead, the industry is likely to see increased adoption of sustainable practices, including the use of recycled materials and energy-efficient technologies. Pune’s growing focus on smart manufacturing and Industry 4.0 will further drive advancements in injection molding technology.

Conclusion

Pune’s injection molding industry is a vital component of its industrial sector, marked by a dynamic landscape of leading companies, technological innovation, and significant economic contributions. As the industry continues to evolve, Pune remains a key player in shaping the future of plastic processing and manufacturing.

1 note

·

View note

Text

Soap mould washing and drying Pune India

Streamlining Soap Mould Washing and Drying Solutions Pune India: NexGen Drying Pvt. Ltd. Leads the Way

In the bustling city of Pune, India, where innovation meets tradition, the soap manufacturing industry stands as a testament to the blend of modern techniques and age-old craftsmanship. Within this vibrant sector, one essential aspect often overlooked is the meticulous process of washing and drying soap moulds. However, with the emergence of NexGen Drying Pvt. Ltd., this crucial phase of soap production is receiving the attention it deserves, revolutionizing efficiency and quality across the industry.

Soap mould washing and drying might seem like a straightforward task, but for soap manufacturers in Pune and beyond, it presents a unique set of challenges. Traditional methods often involve manual labor, consuming time, energy, and resources. Moreover, inconsistencies in cleaning and drying can lead to compromised hygiene and product quality. Recognizing these pain points, NexGen Drying Pvt. Ltd. has emerged as a beacon of innovation, offering cutting-edge solutions tailored to the specific needs of soap manufacturers in Pune and beyond.

At the heart of NexGen's approach lies a commitment to precision and efficiency. Leveraging advanced technology and expertise, NexGen has developed state-of-the-art washing and drying systems designed to streamline the soap mould cleaning process. These systems boast intelligent features such as automated cleaning cycles, precise temperature control, and customizable settings, ensuring optimal results with minimal manual intervention.

One of the key advantages of NexGen's solutions is their adaptability to diverse manufacturing environments. Whether operating on a small scale or managing large-scale production facilities, soap manufacturers in Pune can benefit from NexGen's versatile equipment, seamlessly integrating into existing workflows and maximizing operational efficiency. With customizable configurations and scalable options, NexGen empowers businesses of all sizes to elevate their cleaning and drying processes to new heights.

In addition to efficiency, NexGen prioritizes hygiene and product integrity. The company's washing and drying systems are engineered to meet the highest standards of cleanliness, effectively removing residues, contaminants, and bacteria from soap moulds. By ensuring optimal hygiene throughout the production process, NexGen helps manufacturers uphold quality standards, safeguarding the reputation and trust of their brands.

Furthermore, NexGen's commitment to sustainability sets it apart as a leader in the industry. Recognizing the environmental impact of traditional cleaning methods, NexGen has developed eco-friendly solutions that minimize water and energy consumption while maximizing efficiency. Through innovations such as water recycling systems and energy-efficient technologies, NexGen enables soap manufacturers in Pune to reduce their carbon footprint and contribute to a more sustainable future.

Beyond the tangible benefits of NexGen's products, the company's dedication to customer satisfaction is evident in its comprehensive support services. From installation and training to ongoing maintenance and technical support, NexGen partners with its clients every step of the way, ensuring smooth implementation and continued success. With a team of experienced professionals committed to excellence, NexGen stands as a trusted ally for soap manufacturers seeking to optimize their operations.

In Pune's dynamic soap manufacturing landscape, NexGen Drying Pvt. Ltd. emerges as a catalyst for progress, reshaping the way Soap Mould Washing and Drying Solutions Pune India are approached. By combining cutting-edge technology, unwavering quality, and exceptional service, NexGen empowers businesses to thrive in an increasingly competitive market. As Pune's premier provider of washing and drying solutions, NexGen is not just revolutionizing production processes; it's shaping the future of the industry.

In conclusion, NexGen Drying Pvt. Ltd. represents a paradigm shift in the soap manufacturing industry, offering innovative solutions tailored to the unique needs of businesses in Pune, India, and beyond. With a focus on efficiency, hygiene, sustainability, and customer satisfaction, NexGen stands at the forefront of progress, driving the evolution of soap mould washing and drying practices. As Pune's trusted partner for cutting-edge solutions, NexGen is poised to lead the industry into a new era of excellence.

0 notes

Text

The amazing story of a PET bottle mould

The journey of a PET bottle begins in the mind of an entrepreneur who wishes to cater to the ever-growing beverage market, pharma industry or home care product industry by introducing a new product. The idea consists of the shape, size, product application and target customer. This idea is translated into a PET bottle by AwantiPolymoulds, the leading PET bottle mould manufacturer based in Pune.

Awanti is an end-to-end solutions provider to PET blow moulds for a wide variety of product applications and catering beverage companies in India and abroad.Awanti is a one-stop shop for converting an idea into a bottle, starting with bottle designing to mould manufacturing to mould and bottle testing.

Step 1– Bottle Designing

Understanding the customer’s requirements and translating them into a feasible bottle shape is what Awanti’s design team specializes in. Aspects like blow-ability, strength and stability are taken into consideration before finalising the bottle design.

Step 2- Mould manufacturing

Mould Design-

Understanding the technical specifications of the customer’s blowing equipment is of paramount importance before proceeding with mould designing and manufacturing. High-grade raw material, a well-defined and sequential machining process and stringent quality checks at every stage are what goes into each mould manufactured at Awanti.

Step 3- Mould testing and bottle testing

As per requirement, the mould is tested on in-house blowing equipment and the bottles are put through internationally defined quality tests like bottle burst, stress crack, top load and thermal testing among many others.

The result:

Each mould is capable of producing millions of bottles having consistent quality for years together, leading to ultimate customer delight and repeat orders! Awanti is humbled to be associated as an approved vendor for global beverage giants like Coca-Cola and Pepsi and Indian leaders like Parle and Bisleri.

0 notes

Text

Tips for Buying a Quality Circular Saw Machine

Table of Content:

What Is Circular Saws Machine?

Benefits of Circular Saw Machine

Types of Circular Blades

Tips to Buy the Right Circular Saw for Your Job

Conclusion

What Are The Circular Saws?

Circular saws are power tools that use a toothed or abrasive disc or blade to cut various materials, including wood, metal, and plastic. They are versatile and can be used for a wide range of applications, from cutting lumber for construction to trimming metal pipes for plumbing.

Circular saws come in different types, including handheld and stationary models. Handheld circular saws are compact and portable, making them ideal for cutting materials on job sites or in tight spaces. Stationary circular saws, on the other hand, are larger and more powerful, and are designed for heavy-duty cutting tasks in workshops or factories.

Circular saw Machines are an essential tool in many industries, including construction, woodworking, metalworking, and manufacturing.

Learning how to use a circular saw machine and understanding its capabilities can be a valuable skill for anyone looking to pursue a career in these fields.

Zeal Tech Automation is a well-known Circular Saw Machine Manufacturer in India. When using circular saws, it is important to follow proper safety guidelines, such as wearing eye and ear protection, keeping the blade guard in place, and securing the material being cut. With proper use and maintenance, circular saws can be a valuable tool for any DIY enthusiast or professional contractor

Benefits Of Circular Saw Machines:

1. Accurate Cuts:

Circular saw machines are known for their precision and accuracy in making straight cuts. They are designed to deliver smooth and clean cuts, making them ideal for various types of cutting tasks.

Zeal Tech Automation is a leading Circular Saw Machine Manufacturer In Pune, India. The company offers a wide range of high-quality circular saw machines that are designed for various industrial applications.

2. Versatility:

Circular saw machines are versatile, as they can be used to cut various types of materials such as wood, metal, plastic, and more. This makes them an essential tool for professionals and DIY enthusiasts alike.

3. Speed:

Circular saw machines are designed to cut at high speeds, making them ideal for projects that require quick and efficient cutting. They are also equipped with powerful motors that allow them to handle tough materials with ease.

4. Portability:

Circular saw machines are lightweight and portable, making them ideal for on-site jobs or projects that require moving the saw from one location to another. This feature makes them a popular choice for contractors and construction workers.

5. Safety:

Circular saw machines are designed with safety features such as blade guards, anti-kickback mechanisms, and safety switches, which help to prevent accidents and injuries during use.

6. Cost-effective:

Circular saw machines are relatively affordable compared to other types of saws, making them an excellent investment for those on a budget.

7. Easy to Use:

Circular saw machines are easy to use, even for beginners.

Types of Circular Blades

Circular blades are cutting tools that have a circular shape. They are used in a variety of industries, from woodworking to metalworking, and even in the food industry. There are different types of circular blades, each designed for specific purposes.

1. Rip Blades

Rip blades are used for cutting along the grain of the wood. They have fewer teeth than other circular blades, which makes them more efficient at removing material. Rip blades are ideal for cutting boards, planks, and other large pieces of wood.

2. Crosscut Blades

Crosscut blades are used for cutting across the grain of the wood. They have more teeth than rip blades, which make them more precise. Crosscut blades are ideal for cutting smaller pieces of wood, such as trim and mouldings.

3. Combination Blades

Combination blades are designed to be versatile. They have alternating teeth that can be used for both ripping and crosscutting. Combination blades are ideal for woodworkers who need to switch between ripping and crosscutting frequently.

4. Plywood Blades

Plywood blades are designed to cut through plywood and other composite materials. They have a high tooth count and are designed to produce clean cuts without splintering the material.

5. Dado Blades

This type of blade is used for cutting a groove in wood. These blades have two outer blades and multiple inner blades that can be adjusted to cut different widths of grooves. Dado blades are available in different sizes, and the size of the blade depends on the width of the groove being cut.

TIPS TO BUY THE RIGHT CIRCULAR SAW FOR YOUR JOB

A circular saw is an essential tool in any workshop, whether you are a professional woodworker or a DIY enthusiast. It is a versatile tool that can cut through different materials, including wood, metal, and plastic, with ease. However, not all circular saws are created equal, and choosing the right one for your job can be a daunting task. In this article, we will share some Tips for Buying a Quality Circular Saw Machine for your job.

1. Consider the Type of Blade

The type of blade you choose will depend on the material you intend to cut. There are different types of blades, including those for cutting wood, metal, and masonry. If you plan to cut wood, then a carbide-tipped blade is ideal. For metal cutting, a blade with fewer teeth is better, while a diamond blade is suitable for masonry and concrete cutting. A High-Quality Saw Made by Experienced Manufacturers at Zeal Tech Automation.

2. Blade Size

The size of the blade you choose will depend on the depth of the cut you need to make. A larger blade will cut deeper, and a smaller blade will cut shallower. Most circular saws come with a blade size of between 5-1/2 to 7-1/4 inches. If you plan to cut thicker materials, then a larger blade is ideal.

3. Power

The power of the circular saw is measured in amps or volts higher amps also mean the saw will consume more electricity and generate more heat, which can lead to faster wear and tear and potentially overheat the motor. If you plan to cut through thick materials, then a saw with a higher power rating is ideal. However, keep in mind that a more powerful saw will be heavier and may be more challenging to handle.

4. Corded or Cordless

Circular saws come in two types: corded and cordless. Corded saws are more powerful and are ideal for heavy-duty cutting jobs. They are also more reliable since they do not rely on batteries. Cordless saws, on the other hand, are more portable and are ideal for small cutting jobs. They are also safer since they do not have a power cord that can get in the way.

5. Ergonomics

The ergonomics of the saw are essential, especially if you plan to use it for extended periods. Look for a saw with a comfortable grip that is easy to hold. The weight of the saw is also crucial, and you should choose one that is easy to handle.

6. Safety Features

It is important to follow all safety guidelines and precautions when using power tools to prevent accidents and injuries. Look for a circular saw with safety features such as a blade guard that covers the blade when not in use. The saw should also have a safety switch that prevents accidental start-up.

7. Brand Reputation

The brand reputation is also an essential factor to consider when buying a circular saw. Look for a reputable brand that has a track record of producing high-quality tools. Read reviews from other users to get an idea of the saw’s performance and reliability.

Conclusion

If you are looking to buy a circular saw machine, there are several factors that you should consider, including the type of material you will be cutting, the size of the blade, and the power of the motor.

Zeal Tech circular saw machines are known for the high-quality construction and reliability.

Zeal Tech automation offers a range of models to choose from, each designed for specific applications. By selecting the right Zeal Tech circular saw machine for your job, you can ensure that you get the best results possible.

#Circular Saw Machine#Circular Saw Machine Manufacturers#Circular Saw Machine Manufacturer in Pune#Circular Saw Machine Manufacturer in India#Circular Saw#Fully Automatic Circular Saw#Semi-Automatic Circular Saw Machine

0 notes

Text

How to Choose Perfect 3D Printing Service?

Why is 3D printing required? Do you know 3d Printer Price In India? This is required for fast prototyping and manufacturing. It is a relatively new technology capable of making new prototypes from CAD models. This type of printing could be used to make automobile parts, fashion items, artificial limbs, as well as medical tools.

Some benefits

There are numerous ways to apply this technology to the production of your product. Let's go through some of the advantages of employing Best 3d Printer In India.

Significant financial savings

The use of traditional machinery gets more expensive with time. Online 3d printing service in pune, in contrast, could result in the fabrication of things at a variety of economical prices.

Time wasting can be avoided.

This type of technology allows for speedier idea formulation. As quickly as the idea is completed, you can print it the next day within a few hours. This reduction in processing time from weeks to a few days allows businesses to keep ahead of the competition.

Risk reduction

It is always more cost effective to 3D print a test prototype rather than rework a mould. It is a better idea to test a concept before investing much in pricey instruments.

Open lines of connection

A theatrical exposition of a product cannot communicate the complete image. There are some locations that could be misconstrued. A picture of the product is preferable than a general overview, but it becomes even more appealing if you can handle it in your hands. It eliminates all forms of ambiguity and eliminates any possibility of confusion. You may have a physical representation of the commodity.

Market testing

It is incredibly advantageous that you may test the market with this prototype. If you exhibit this 3D model at a trade event, you will learn about the reactions of potential clients, investors, and the general public. It allows you to determine whether the product has market potential even before goes into production.

Feeling tangible

You cannot get a sense of a product from an image or an online portrayal of it on a computer. You should be able to grasp the thing in your hands and assess it if you would like to feel the ergonomics or acquire a sense of a tangible product.

Suitable service provider selection

It is difficult to select an effective and Cheap 3d Printing Service India. There are various businesses that provide these services. As a result, you must take caution while picking a service provider. The 3D technology should be built to meet the objectives of your project. Request recommendations from friends and family. You should also visit the websites of numerous businesses. You will gain a comprehensive understanding of the level of services provided by the various companies. You should attend numerous printing meet-ups and inquire about different service contracts from service bureaus.

A commercial printing service's principal goal is to impress potential clients and customers. People are more impressed by a readable, tidy, and clear business card than by an expensive business outfit.

0 notes

Link

Conformal cooling is a process in which the cooling passageway follows the shape of the cavity and moulds core to promote temperature uniformity and perform rapid uniform cooling process for injection molding process.

#conformal cooling in 3d printing#conformal cooling application#additive manufacturing company in India#3d printing pune#metal 3d printing services#advantages of metal 3d printing#benefits of metal 3d printing#metal 3d printing in India#mould and die tool manufacturing

0 notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- China cnc engineering prototyping parts factory customization cheapest price manufacturing mill engineering parts list,engineering parts supplier,engineering parts catalog,engineering parts website,engineering parts and services,engineering parts hs code,engineering parts manufacturers,engineering parts online,engineering parts accessories company,engineering parts and services puerto rico,engineering parts aircraft,parts engineering and manufacturing,tissue engineering parts a b & c,tissue engineering parts a,hunter engineering parts and service,engineering parts brisbane,engineering parts buy,engineering brake parts,engineering parts sdn bhd,hamilton engineering boiler parts,ireland engineering bmw parts,engineering replacement body parts,combustion engineering boiler parts,b.t. engineering parts co. ltd,engineering parts companies in karachi,parts engineering company,engineering car parts,engineering compass parts,engineering custom parts,parts engineering compressor,h & c engineering parts supplies,engineering parts diagram,engineering drawing parts,engineering drawing parts list,engineering design parts,engineering parts list definition,plastic parts engineering drawing,dema engineering parts,dk engineering parts,hamilton engineering evo parts,precision engineering engine parts,engineering diesel engine parts,electrical engineering parts,europa engineering parts,electronic engineering parts,enduro engineering parts,environmental engineering parts,engineering parts for projects,engineering for parts,hill engineering ferrari parts,triangle engineering fan parts,gto engineering ferrari parts,surface engineering for parts made by additive manufacturing,pbs engineering fiat parts,better engineering parts washer for sale,extreme engineering gun parts,coleman engineering generator parts,kato engineering generator parts,reverse engineering gun parts,gto engineering parts,genetic engineering parts,giltrap engineering parts,gloucester engineering parts,engineering spare parts hs code,vulcan engineering harley parts,custom parts engineering hospers ia,mace engineering holden parts,engineering machinery spare parts hs code,engineering goods spare parts hs code,hunter engineering parts,h-e parts engineering pty ltd,h-e parts engineering,engineering parts item,ace engineering parts (india) private limited,jet parts engineering inc,kauffman engineering inc parts,better engineering impulse parts washer,cambridge engineering inc parts,boeing spares engineering parts interchangeability,zero engineering parts japan,xk engineering jaguar parts,ace engineering jeep parts,jancy engineering parts,jetline engineering parts,pt asia parts engineering jakarta,j&r engineering m68 parts,azusa engineering kart parts,keene engineering parts,kato engineering parts,engineering parts list template,engineering lathe parts,mechanical engineering parts list,engineering spare parts list,mason engineering parts llc,engineering parts mechanical,parts engineering meaning,engineering moulded parts,engineering motorsport parts,engineering machined parts,engineering materials parts,engineering many parts,engineering parts near me,engineering parts naming conventions,mechanical engineering parts name,nc engineering parts,neb engineering parts,engineering of parts,civil engineering parts of a building,merkur engineering parts order,reverse engineering obsolete parts,engineering definition of parts list,parts of engineering drawing,parts of engineering report,engineering parts products,engineering plastic parts,engineering plastic parts manufacturers in pune,chill parts engineering pte ltd,ames engineering pontiac parts,wright engineering plough parts,reverse engineering plastic parts,q-engineering��sierra engineering rv parts,base engineering remote parts,randolph engineering replacement parts,aerospace engineering racing parts,hunter engineering replacement parts,viking engineering rover parts,wheeler engineering replacement parts,jet parts engineering revenue,engineered parts supply,engineering parts & services,engineering spare parts,engineering spare parts management,engineers transit parts,lc engineering toyota parts,transit engineering trailer parts,bond engineering turned parts ltd,aircon parts engineering thailand co,sprint engineering triumph parts,engineering and technology parts,engineering used parts,uk engineering parts,engineering parts vector,interstate engineering vacuum parts,creative engineering vw parts,integrated engineering vw parts,rothenbacher engineering vw parts,viking engineering parts,v1 engineering parts,v1 engineering parts list,engineering parts washer,engineering works parts,better engineering parts washer,better engineering parts washer manual,better engineering parts washer pump,kenco engineering wear parts,yuyao engineering & parts sdn b

2 notes

·

View notes

Text

Why Virat Special Steels?

At Virat Special Steels, we are more than just a steel supplier – we are your trusted partner in quality and reliability. With a strong foothold in the industry, we are known as a preferred dealer, wholesaler, and supplier of top-notch Steel Blocks.

Our comprehensive range includes Flats, Squares, and Bars, all manufactured using quality-tested raw materials sourced from reliable vendors in the market.

What sets VIRAT SPECIAL STEELS PVT. LIMITED , INDIA apart is our commitment to excellence. We import Tools & Die Steels from the world's top manufacturing companies, including M/s. Schmiedewerke Groditz Thyssen and Deutsche Edelstahlwerke from Germany, and M/s. Thyssen Krupp from France. This ensures that our customers receive only the best quality products that meet international standards.

We supply steel bars to forging companies across #Ludhiana, #Faridabad, #Bhiwadi, #Sonipat, #Rohtak, #Haryana, #Punjab, #Jamshedpur, #Trichy, #Aurangabad, #Pune, #Gurgaon, #Noida, #Ghaziabad, #Indore, and all locations in India.

Our goal is to support the tool and steel products industry by providing high-quality materials that enable our customers to excel in their businesses.

Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us : 🌐https://viratsteels.com 📨 [email protected] 📞 +91 098140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#db6 steel#h13diesteel#h13toolsteels#h11steel#din2714#din 2344#din2343#p20steels#din2738#Jamshedpur#gaziabad#manesar

2 notes

·

View notes

Text

Electronics Company in Pune | GIC India

Founded in 1972, General Industrial Controls Private Limited (GIC) is a Top electronics company in Pune, India, that manufactures Electronic Control and Timing devices. What began as a small venture, is now a company that gives an array of world-class products. Process Controller devices, Monitoring Devices, including Instrumentation devices are any of the product categories in which GIC produces excelled and made a standing in the market.

Today, we are an ISO 9001:2015, IATF 16949 certified business with a state-of-the-art plant producing integrated facilities for everything from ‘idea to delivery’ under one roof.

Our high-performance products for Process Control and Automation utilization, collectively with our intelligent tooling resolutions, have garnered us excellent fame the world over.

OUR PRODUCT CATEGORIES INCLUDE:

Lighting Automation: Time Switches and Light Energy Management Systems. Process Control: Timers, Mini PLCs, GSM Controller, Protocol Converters, Interface Converters, Signal Transducer, Power Supplies, Temperature Controllers. Low Energy Protection and Switchgear: Voltage, Frequency, and Current Monitoring Devices, Earth Leakage Relays, Temperature Monitoring devices, & Liquid Level Controllers. Instrumentation: Hour Meters, Impulse Counters, Rate Indicator, and Totalisers. Injection Moulded Plastic Components.

OUR BELIEF

We at GIC, understand how important it is to provide our customers with the greatest experience. It is essential that we create such an experience that they seem completely connected to our brand, time and again.

We understand that for our customers to excel, we need to excel in everything that we offer. The foundation of excellence lies in being relevant to market needs, ensuring excellence in our products, a deep understanding of customer satisfaction, ensuring dependable services, and encouraging our people to excel, thus ensuring innovation and quality. We stay committed to being Excellent.

1 note

·

View note

Text

Our Future Plan is to Manufacture Skids, Intervalve Poonawalla Ltd

Intervalve Poonawalla Limited and El-O-Matic India have been taking giant strides in the sector of valves and actuators. In this interview with Huned Contractor, Yohan Poonawalla, chairman and managing director of both these companies elaborates about products, expansion plans and the growth potential of the industry

Pune-based Poonawalla Group is one of India’s most respected and leading business houses with interests in the sectors of engineering, biotech, thoroughbred horse breeding, hospitality, finance and real estate. Of their various companies, Intervalve Poonawalla Limited and El-O-Matic India are engaged in the engineering sector for the production of world-class valves and actuators, providing reliable flow-control solutions to a wide spectrum of industries worldwide spanning over 46 countries and with an impressive track record of supplying to various industry sectors like oil and gas, petrochemical, power (nuclear, thermal, hydro), chemicals, agrochemicals, steel, paper and pulp, fertilizer, edible oil, pharmaceuticals, paint, tyre, water treatment, effluent treatment, utilities, food and beverages, and so on. Excerpts from the interview:

Q. Could you elaborate about the operations of Intervalve Poonawalla Limited and El-O-Matic India?

The current manufacturing programme of Intervalve Poonawalla Limited includes butterfly valves produced in technical collaboration with BV Holland (variants: soft-seated/metal-seated, centric, eccentric, replaceable liner/moulded liner). We also manufacture gate valves, globe valves, check valves (variants: wafer/DPCV/swing/piston), ball valves (variants: floating/trunnion, soft-seated/metal-seated) and Skotch yolk actuators. The size range starts from 1/2” up to 112”.

El-O-Matic India was established in 1989 in collaboration with El-O-Matic International, Holland which was subsequently acquired by the Emerson Group. El-O-Matic India (P) Ltd. is synonymous with safety and high efficiency. El-O-Matic India manufactures pneumatic actuators in both single acting and double acting variants. Along with manufacturing and selling of bare actuators, we are also an experienced and qualified system integrator delivering the entire on/off valve systems comprising valve, actuator, solenoid valve, limit switch, tubing, positioner and similar components since valves and actuators are our in-house products. Our actuators are suitable for over half a million operations.

Q. What is the infrastructure status of the company and its manufacturing capacity?

The Poonawalla Group of engineering companies has three world-class state-of-the-art manufacturing facilities in Pune that are spread across 15 acres. These companies have the latest machinery and equipment, including facilities to manufacture valves up to 112”. This includes in-house facilities for special testing like Helium leak test, fire-safe test, proof of design test, cyclic test, non-destructive test, etc. We inaugurated a new facility in May 2017 to focus on manufacturing of metal-seated ball valves for petrochemical industries and refineries and the product portfolio includes large-sized ball valves up to 42” and handling weights up to 20 tons.

Q. What is the product(s) USP that gives Intervalve an edge in the industry?

Intervalve Poonawalla Limited is committed to maximizing customer satisfaction by consistently improving the quality of its products, services and delivery. We strive for the growth of our clients, employees, society and all our associates with passion, perfection and performance: the passion to maintain leadership in everything we do, perfection in what we promise and performance in what we produce. Our consistent endeavour is to exceed our customer expectations in our brand and products. Our engineering companies have been associated with the manufacturing of high-quality products with total customer satisfaction. The companies have always emphasized on investing in the right assets to deliver value.

The butterfly valves of Intervalve Poonawalla Limited are designed as per international standards and benefit from a technical collaboration with B V Holland. They have been tried, tested and proven for the last 30 years. El-O-Matic’s actuators have the advantage of a technical collaboration with El-O-Matic, Holland. The company has also been manufacturing ball valves and gate, globe and check valves for the last 10 years and has supplied to industries across all sectors like chemicals, water, steel, oil and gas, fertilizers, petrochemicals, food and beverages, power, and so on.

Both the companies have wide range of approvals from end users like EIL, IOCL, BPCL, HPCL, APGENCO, GE, Reliance, Larsen & Toubro, Essar Group, Adani Group, VaTech Wabag, BGR Group, United Phosphorus, Cipla, Asian Paints, Henkel, Tata Steel, Jindal Group, ITC and certifications of various international standards like IBR, API, ISO, OHSAS, CE, ATEX, PED, etc. With this product portfolio that is manufactured under one umbrella, the company has positioned itself as a one-stop solution and single source responsibility, as for example, valves and actuators under a single source for automated systems. And as mentioned earlier, this is our unique selling proposition (USP) that translates into tangible benefits for our esteemed customers.

Q. What kind of research and development is carried out?

We have a strong and highly qualified team in our engineering and research and development departments. This team ensures compliance to all international designs of our products and undertakes lot of development activities. Design validations and prototyping are carried out before the release of the final manufacturing design, which ensures ruggedness of our in-house designs. We use the latest design software like ProEngineer and Solidworks. Our design team is flexible and capable of customisation as per the requirement of our customers.

Q. What is the company’s expansion plan for 2017-18?

The company has decided to expand its manufacturing base as it intends to add new products like metal-seated ball valves for petrochemicals and refinery, large-sized ball valves up to 42”, cryogenic ball valves, gate globe check valves and a world-class assembly and testing plant for valves. These products would address a wider range of products coupled with system integration with actuators for greater automation that will make us a ‘single-stop’ solution provider and more so ‘single source responsibility’ for our existing and new customer base.

Q. What about exports?

Currently Intervalve Poonawalla Limited is exporting to 46 countries with a focus on countries in the Southeast Asian region, the Middle Eastern region, the European continent and the American continent. The company is trying to expand its network to the Far East region and Africa.

Q. What is your perception about the Indian valve market? Will it accelerate? If so, what would be the driving factors?

The Indian valve market would outpace the growth of the world valve market, which is growing at 5% per annum. The Indian government’s ‘Make in India’ campaign has triggered investments coupled with opportunities in infrastructure development projects and this, among others, will be the key growth driver for the Indian valve industry. The ‘Smart Cities’ project is another growth driver for the valve industry in India. In addition, opportunities in the oil and gas industry in GCC countries, rising demand for energy in APAC and major investments in the African continent will be the other growth drivers for the Indian valve industry.

Q. What are the opportunities that the company would like to tap in the coming future?

Our future plan is to manufacture skids for the industrial and natural gas segments. Skids are an integration of valves, actuators and electronic accessories. Skids of three types would be manufactured: pressure-reducing skids, gas conditioning skids and gas metering skids. This would have many of our in-house products such as butterfly valves, ball valves, gate, globe and check valves and actuators.

Q. What are your activities in terms of corporate social responsibilities?

The Poonawalla Group is engaged in several CSR activities. We have received many accolades and recognition from government bodies and NGOs for our contribution and continued association towards social causes. Be it medical aid or education for the underprivileged, developing gardens for the beautification of Pune or its basic infrastructure, we strive to put in our best to support all possible social endeavours. For instance, Intervalve Poonawalla Limited has been associated with the Poona Leprosy Committee since 1990 and has been instrumental in almost eradicating the disease.

The Poonawalla Group has financially supported the Zavaray Poonawalla Cancer Building at the Ruby Hall Hospital. Apart from beatifying and maintaining the Gool Poonawalla Garden we sponsored and took active participation in the construction of the Soli Poonawalla Road at Hadapsar in Pune. We are also committed to supporting better education for the underprivileged through promoting English medium education at the Soli Poonawalla Memorial High School at Hadapsar.

Source: engmag

1 note

·

View note

Text

Pre-Launch Property by Mahindra Lifespaces in Pimpri - A Prime Location

Here we have a pre-send off of another forthcoming undertaking by Mahindra Lifespaces in Pimpri is a notable exceptionally quickly developing industrial area known for the IT and assembling organizations.

Mahindra Group is an extremely old land heritage viewed as in 1999 known for their stunning framework and engineering and moulded plans also rank 2nd in the 'Expanded'/'Recorded' classification of land organizations, in the Global Real Estate Sustainability Benchmarking (GRESB) report and won different honours like World Architect and Builder Awards times.

Location Benefits:

Pimpri goes under the PCMC region with wonder a network to rails, streets, and air like 136 Municipality schools and 208 non-public schools and well-known ICSE and CBSE instructive organizations like Hindustan Antibiotics and Dr D. Y. Patil, Vidya Niketa and Elpro International School, VIBGYOR School.

Significant automobile companies like Tata Motors, Mercedes Benz, Bajaj Auto, Force Motors, Eaton, and Times of India.

Top-notch medical clinics like YCM Hospital and D. Y. Patil Hospital.

Cinema Halls and lifestyle malls like City One Mall, Elpro City Square, Premier Plaza Mall, Spine City Mall, Spot18, Xion Mall.

Upcoming Infrastructure:

Metro connectivity to Pimpri under the Pune Metro project.

Rainbow BRTS transport system.

New airport near Chakan.

Outer ring road.

Public attractions in Pimpri:

The Major Dhyanachand Stadium.

Annasaheb Magar PCMC Stadium

Rangmandir Auditorium.

Public Parks like – Durga-Tekdi, Bhakti-Shakti Garden,

Pawna River – Boat Club.

Pimpri-Chinchwad Science Park.

So don't stand by any further to pick the undertaking with Mahindra Lifespaces known for their convenient conveyance and client-driven approach the task is to establish an arranged climate for the functioning populace nearby their workplace.

Pimpri is the home of automotive and manufacturing companies and IT organizations. Mahindra Lifespaces will offer you 1/2/3 BHK with open and rich houses available to be purchased like Pune with a soothing climate. Having a home in Pune is a dream of each home tracker and inhale taking plan. So recommend you to affiliate with the Mahindra Lifespaces.

0 notes

Text

Pre-Launch Property by Mahindra Lifespaces in Pimpri - A Prime Location

Here we have a pre-send off of another forthcoming undertaking by Mahindra Lifespaces in Pimpri is a notable exceptionally quickly developing industrial area known for the IT and assembling organizations.

Mahindra Group is an extremely old land heritage viewed as in 1999 known for their stunning framework and engineering and moulded plans also rank 2nd in the 'Expanded'/'Recorded' classification of land organizations, in the Global Real Estate Sustainability Benchmarking (GRESB) report and won different honours like World Architect and Builder Awards times.

Location Benefits:

Pimpri goes under the PCMC region with wonder a network to rails, streets, and air like 136 Municipality schools and 208 non-public schools and well-known ICSE and CBSE instructive organizations like Hindustan Antibiotics and Dr D. Y. Patil, Vidya Niketa and Elpro International School, VIBGYOR School.

Significant automobile companies like Tata Motors, Mercedes Benz, Bajaj Auto, Force Motors, Eaton, and Times of India.

Top-notch medical clinics like YCM Hospital and D. Y. Patil Hospital.

Cinema Halls and lifestyle malls like City One Mall, Elpro City Square, Premier Plaza Mall, Spine City Mall, Spot18, Xion Mall.

Upcoming Infrastructure:

Metro connectivity to Pimpri under the Pune Metro project.

Rainbow BRTS transport system.

New airport near Chakan.

Outer ring road.

Public attractions in Pimpri:

The Major Dhyanachand Stadium.

Annasaheb Magar PCMC Stadium

Rangmandir Auditorium.

Public Parks like – Durga-Tekdi, Bhakti-Shakti Garden,

Pawna River – Boat Club.

Pimpri-Chinchwad Science Park.

So don't stand by any further to pick the undertaking with Mahindra Lifespaces known for their convenient conveyance and client-driven approach the task is to establish an arranged climate for the functioning populace nearby their workplace.

Pimpri is the home of automotive and manufacturing companies and IT organizations. Mahindra Lifespaces will offer you 1/2/3 BHK with open and rich houses available to be purchased like Pune with a soothing climate. Having a home in Pune is a dream of each home tracker and inhale taking plan. So recommend you to affiliate with the Mahindra Lifespaces.

0 notes

Text

Blow Moulds For Rotary Machines

Blow Moulds for Rotary Machines turn out to be an excellent choice for high output production of various types of containers. The outcome of this type of machine usually leads to a wide variety of plastic extrusion blow molded products.These rotary blow molding machines have a set of ‘wheels’ in them, which are many times sized according to the volume and dimensional demands of a specific product.

The wheels come in varied combinations, thereby putting forward continuous motion and indexing wheels. Here, even horizontal and vertical variations are observed. Wheel machines are available in single as well as double parisons, which result in faster, more versatile and cost efficient outcome. Though the production speed is high, the rotation speed is kept low so as to cause minimum damage and wear and tear of the products.

What is Blow Molding? The process comes under the manufacturing line of containers, where forming and joining of hollow plastic or glass parts takes place. It commences with melting the plastic and then forming it into a parison. A parison is a tube of plastic that is later formed into a hollow object, using the processes like Blow Molding.

Rotary blow molding systems can produce bottles for a range of utilities including normal and carbonated water, aerated drinks, fruit juices, sport drinks, tea, milk and milk-based products, oil and alcoholic drinks. PET bottles are also made using the service.

Rotary wheels usually contain over six to thirty molds which have constantly extruded parisons. The revolving of blow moulds seize the parisons as the extrusion head passes by. Stations are set where the revolving molds are set. For the rotation of the wheel, an electric motor is used. Very detailed and tight outputs can be obtained as the pinching is done accurately.

One of the perks of rotary wheel blow molding is the continuous extrusion that happens. A machine with continuous extrusion has rotatable wheels. When the parison is continuously extruded, the parts are isolated and are cut off by a suitable knife. The parisons can be programmed accordingly, depending on the desired thickness.

When rotary wheel blow molding is used, multi- layer coextrusion can be done. This process combines two textures in a single operation. Moreover, this machine has the power to give multiple outputs in single working. That is, the cost per bottle is extremely low. The production’s efficiency is also high when compared to other processes. High speed bottle moulds are guaranteed with this system.

All these perks are placed at one station- Awanti Polymoulds. Awanti specializes in various functionalities related to moulding service. Being a leading mould manufacturing company in India, Awanti promises the best of quality to cater your needs. Awanti is the company you can rely on, and when you do that, only the best will come at your desk!

#blow mold manufacturers#blow mould#mould manufacturer#blow#Mould Manufacturer in india#Blowing machine manufacturer in india#mould manufacturer in pune#mould makers in Pune india#mould manufacturer company in pune#mould maker in pune

0 notes

Text

Pre-Launch Property by Mahindra Lifespaces in Pimpri - A Prime Location

Here we have a pre-send off of another forthcoming undertaking by Mahindra Lifespaces in Pimpri is a notable exceptionally quickly developing industrial area known for the IT and assembling organizations.

Mahindra Group is an extremely old land heritage viewed as in 1999 known for their stunning framework and engineering and moulded plans also rank 2nd in the 'Expanded'/'Recorded' classification of land organizations, in the Global Real Estate Sustainability Benchmarking (GRESB) report and won different honours like World Architect and Builder Awards times.

Location Benefits:

Pimpri goes under the PCMC region with wonder a network to rails, streets, and air like 136 Municipality schools and 208 non-public schools and well-known ICSE and CBSE instructive organizations like Hindustan Antibiotics and Dr D. Y. Patil, Vidya Niketa and Elpro International School, VIBGYOR School.

Significant automobile companies like Tata Motors, Mercedes Benz, Bajaj Auto, Force Motors, Eaton, and Times of India.

Top-notch medical clinics like YCM Hospital and D. Y. Patil Hospital.

Cinema Halls and lifestyle malls like City One Mall, Elpro City Square, Premier Plaza Mall, Spine City Mall, Spot18, Xion Mall.

Upcoming Infrastructure:

Metro connectivity to Pimpri under the Pune Metro project.

Rainbow BRTS transport system.

New airport near Chakan.

Outer ring road.

Public attractions in Pimpri:

The Major Dhyanachand Stadium.

Annasaheb Magar PCMC Stadium

Rangmandir Auditorium.

Public Parks like – Durga-Tekdi, Bhakti-Shakti Garden,

Pawna River – Boat Club.

Pimpri-Chinchwad Science Park.

So don't stand by any further to pick the undertaking with Mahindra Lifespaces known for their convenient conveyance and client-driven approach the task is to establish an arranged climate for the functioning populace nearby their workplace.

Pimpri is the home of automotive and manufacturing companies and IT organizations. Mahindra Lifespaces will offer you 1/2/3 BHK with open and rich houses available to be purchased like Pune with a soothing climate. Having a home in Pune is a dream of each home tracker and inhale taking plan. So recommend you to affiliate with the Mahindra Lifespaces.

0 notes