#monel bar stock

Explore tagged Tumblr posts

Text

Monel 400 Bar Supplier & Exporter | High-Quality Monel 400 Round Bars

Would you be interested in a premium Monel 400 bar? Reliable Overseas is a trusted supplier and exporter of Monel 400 round bars, which offer exceptional strength and corrosion resistance and are perfect for your industrial needs. Contact us today!

#monel 400 round bars#monel 400 round bar#monel 400 bar#monel 400 rod#monel bar stock#Stainless Steel 304 Round Bar#ASTM A276 Type 304 Rod#Stainless Steel Round Bar Suppliers#304 Stainless Steel Round Bars#Stainless Steel 304 Round Bars

0 notes

Text

Top Factors to Consider When Selecting MS Plate Suppliers

Choosing the appropriate MS Plate suppliers for the specific Project work is one of the most important decisions in construction or manufacturing industry. With high tensile strength, and overall considerably low cost, mild steel (MS) plates are used in construction, engineering, and manufacturing industries. However, not all MS plate suppliers are the same as in this world, there are varying qualities and types of MS plates.

1. The Quality of Material and Standards

The quality of the MS plates is one of the most important things to look at when choosing the MS Plate suppliers. Precise specifications are not met when manufacturing steel plates. Superior Grade MS plates are of substantial tensile strength and are capable to meet the pressure of the project. Search for suppliers who provide materials that have an international standard. For instance, most of the industries need Monel plate or Inconel plate because both are strongly protected and resistant to corrosion. Some of these plates are made with special high-performance alloys ideally used in harsh environments.

There should also be some conditions that guarantee high quality; so, when dealing with the supplier, it is recommended to require certification or material test reports. This makes it easy for you to confirm the chemical analysis and mechanical characteristics of the plates. If you do not have these certificate then it becomes hard to determine if the particular product is of the required quality and performance.

2. Range of Available Products

In addition to the cost of the material, there are noted other important criteria when choosing MS plate suppliers, which is the available portfolio. Judging from the convenience point of view, suppliers who stock up an array of materials, sizes and grades are more convenient to deal with. Maybe you require Monel Round Bar or Hastelloy plate or Inconel Round Bar, all you need is a supplier who can provide you all these products at one go. This is helpful to you because it reduces the amount of time you have to spend on such work and also the possibility of a project being delayed.

It’s also a plus to be able to source from suppliers who can offer what is commonly referred to as ‘special buys’, or sizes that are not standard. For example, if you are developing an application which would require Hastelloy Fasteners or Inconel Fasteners, you need a supplier who can offer the same fastener material to avoid change in the material sources.

3. Reliability and Reputation

The issue of selecting a supplier with a good reputation for being reliable is very critical. The last thing you need is to be held up by delays or compromised quality of the materials you used in your project. You can easily find a company that has certain reputation for delivering their products on time and within the customer’s expectations. If you want to verify a supplier’s honesty, read his or her customers’ feedback and reviews. To gather as much information as possible, try to get in touch with the past or current clients, any associate of the supplier.

Further, suppliers with experience will know what the industry requires and can give good advice. They can assist you in choosing the most ideal products depending on your need; be it MS Pipe suppliers or Inconel tube.

4. Pricing and Cost-Effectiveness.

However, cost should not be the main contributing factor while at the same time it is still a factor. Pricing should relate to the quality of the product to be produced and the reputation of the supplier. Seek out the MS Plate suppliers who are offering their products at reasonable rates but at the same time they should not compromise of the quality of the products. One may even opt to purchase better quality products because in the long run it may turn out to be cheaper you won’t have to deal with corrosion or have to replace a product which has worn out early.

Check that the supplier offers obvious and clear price and does not include extra costs. It will also assist you in making wiser financial decisions because you will not be blindsided by such information. For example, when procuring Monel Fasteners for a specific application, you want to know the total cost as it determines your cost constrain.

5. Customer Service and Support

Last but not least, friendly and reliable suppliers are hard to discover when choosing the best MS Plate. A supplier that is willing to talk to you, willing to be of assistance and prepares to respond to your questions will ease the procurement process. This is particularly pertinent where items like Monel plate or Inconel plate are used where such users may need assistance in their application.

Conclusion

Therefore, the various qualities of the suppliers which should be considered when choosing the MS Plate suppliers are quality of material used, range of products, reliability of the suppliers, costs and customer relations. PipingMaterial is the leading supplier of Hastelloy tube, Inconel Round Bar, Monel Fasteners and other high-performance materials.

0 notes

Text

Round Bar Exporters In India: A Full Overview For Industry And Trade

With Indian round bar exporters being well-known worldwide for their superior goods, Nippon Alloys Inc. has emerged as a major force in the steel sector. Round bars are crucial structural and equipment elements that are used extensively in the industrial, automotive, and building sectors. To meet the varied needs of customers throughout the world, our exporters provide a broad range of round bars made of alloy steel, carbon steel, and stainless steel. They have established a strong reputation in markets across Europe, Asia, and the Middle East because of their dedication to affordable prices and strict quality standards.

Round bars are cylindrical, long goods used in a wide range of sectors, including construction, automobile manufacture, heavy machinery, and infrastructure development. These round bars manufactured from a number of materials, including stainless steel, carbon steel, alloy steel, and copper, among others. Round bars are vital in contemporary manufacturing and construction because to their strength, durability, and adaptability.

Another important market for round bars is the automobile sector. India, one of the biggest automakers in the world, had an exponential increase in demand for premium round bars for usage in axles, chassis, and engine parts. Large amounts of round bars were also needed for the building of train stock, signalling equipment, and tracks in the nation's expanding railway network.

For More Detail

Website: nipponalloys.com

Product: Round Bar Exporter in India

Other Product: Alloy Round Bar Supplier in India, Monel Round Bar Importer in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

Regent Steel & Engineering Co.: Your Only Solution to the Best Inconel Plate and Round Bars

There has always been a constant demand for industrial products everywhere. Steel product manufacturers play a crucial role in completing these demands. One of the products that asks for a consistent supply is steel plates. The Inconel 600 plate is highly versatile. The major applications of these plates are making drums and vessels. Drums are required in every industry for storage purposes. The plates are also used to make pipes and tubes with different properties. Another product that is prominently used in many sectors is bars. The bars come in various shapes and sizes. However, the Alloy 825 round bar provides structural support to many areas of an industry. There is a huge variety of bars and plates, each with different use cases. For a newcomer, it might be challenging to select the perfect materials for a project. But you need not worry about that, as the expert staff of Regent Steel & Engineering Co. will guide you through the process of selecting the perfect Alloy 825 round bar and plates for your project.

Regent Steel & Engineering Co.

Regent Steel & Engineering Co. manufactures multiple plates and round bars for industrial applications. You will receive test reports and analytics of the products you order. Each round bar and plate must pass a series of quality tests. The products that pass the test with favorable results are available for sale. The Inconel plate they manufacture is very versatile. This plate is used to make stress-resistant pipes and tubes. Various international standards, including ASTM, are followed while manufacturing plates and round bars. Another great feature of their service is their timely deliveries. All the products are delivered at the time mentioned when you place the order.

Round Bars

There is a huge collection of plates and round bars at Regent Steel & Engineering Co. The monel round bar has high electrical conductivity. This bar also has high tensile strength. Another specification of this round bar is the Monel 400 round bar. This bar has superior corrosion resistance. This bar has high strength and works well in subzero conditions in the ocean. The Hastelloy C276 round bar has high-performance applications. It works perfectly in acidic conditions and harsh environments. The bars are used for their excellent strength. But they can also be used to make shafts on different machines.

Plates

Plates have major industrial applications. Sometimes gaps are present while making a large vessel. The Alloy 800 plate is applied in such areas to fill such gaps. These plates have superior resistance to high temperatures. An alloy 20 plate has applications in making fasteners and flanges for mixing tanks, agitators, valves, etc. They have applications in the food processing industry. Their inventory has the Hastelloy Plate as well. This plate is made from a corrosion-resistant alloy. Some plates crack due to corrosion. However, the Hastelloy plate can withstand such conditions without showing any sign of cracking.

The whole staff of Regent Steel & Engineering Co. is equipped with knowledge about every plate and round bar in their stock. They aim to deliver only the best-quality products to their customers. You can contact them at regentsteel.com.

0 notes

Text

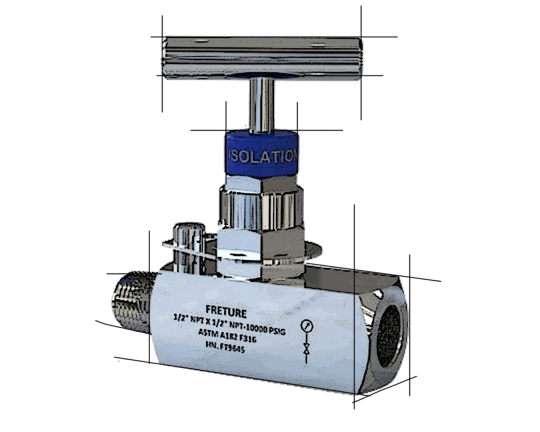

High Pressure Needle Valves: Precision Flow Control in Demanding Applications

In the realm of fluid control systems, high pressure needle valves stand out as indispensable components, offering precise regulation of flow in some of the most challenging industrial environments. These valves, characterized by their ability to withstand extreme pressures while providing accurate flow control, play a crucial role across various sectors, from oil and gas to chemical processing and hydraulic systems.

Understanding High Pressure Needle Valves

A high pressure needle valve is a type of linear motion valve designed to regulate flow with high precision, particularly in systems operating under significant pressure. The valve's name derives from its key component: a slender, tapered pin (the "needle") that moves in and out of a small orifice to control flow. This design allows for extremely fine adjustments, making needle valves ideal for applications requiring meticulous flow regulation.

Key Features and Advantages

Precise Flow Control: The gradual taper of the needle and its fine-threaded stem allow for minute adjustments, enabling operators to achieve exact flow rates.

High Pressure Capability: Engineered to withstand pressures ranging from several hundred to thousands of bar, these valves maintain their integrity in extreme conditions.

Tight Shut-off: When fully closed, the needle forms a metal-to-metal seal with the seat, ensuring minimal to zero leakage.

Durability: Constructed from high-strength materials, these valves offer long service life even in harsh operating environments.

Compact Design: Despite their high pressure capabilities, needle valves are relatively small, making them suitable for installations with space constraints.

Versatility: Available in various configurations to suit different mounting requirements and flow directions.

Construction and Materials

The effectiveness of a high pressure needle valve largely depends on its construction and the materials used:

Body: Typically made from forged steel, stainless steel, or special alloys like Monel or Hastelloy for corrosive applications.

Needle (Stem): Usually constructed from hardened stainless steel or other wear-resistant alloys to ensure longevity and maintain a tight seal.

Seat: Often integrated into the valve body, but may be replaceable in some designs. Material choice depends on the application but is generally a hardened alloy compatible with the body material.

Packing: High-quality packing materials like PTFE or graphite are used to prevent leakage around the stem while allowing smooth operation.

Bonnet: Secures the packing and guides the stem. In high pressure applications, a bolted bonnet design is common for added strength.

The choice of materials is critical and depends on factors such as operating pressure, temperature, media compatibility, and environmental conditions.

Types of High Pressure Needle Valves

Several variations of high pressure needle valves exist, each designed to meet specific application requirements:

Standard Needle Valves: The most common type, suitable for a wide range of general applications.

Micro-Metering Valves: Feature an exceptionally fine needle taper for ultra-precise flow control, often used in laboratory or analytical equipment.

Multi-Port Needle Valves: Incorporate multiple inlets or outlets for complex flow control scenarios.

Angle Pattern Needle Valves: Designed with the inlet and outlet at right angles, useful in certain piping configurations.

Bar Stock Needle Valves: Machined from solid bar stock for maximum pressure handling capability.

Cryogenic Needle Valves: Specially designed to maintain functionality at extremely low temperatures.

Applications Across Industries

The versatility and precision of high pressure needle valves make them indispensable in numerous industrial applications:

Oil and Gas: Used in wellhead control panels, sampling systems, and pressure reduction stations.

Chemical Processing: Crucial for precise chemical injection and reactor feed control.

Hydraulic Systems: Employed in pressure control and hydraulic test benches.

Power Generation: Found in steam sampling systems and turbine control.

Aerospace: Used in fuel systems and hydraulic controls of aircraft.

Research and Development: Essential in high pressure testing equipment and experimental setups.

Water Jet Cutting: Control water flow in high pressure cutting systems.

Considerations for Selection and Installation

Choosing the right high pressure needle valve requires careful consideration of several factors:

Pressure Rating: Must exceed the maximum system pressure with an appropriate safety margin.

Temperature Range: Ensure compatibility with both the minimum and maximum expected temperatures.

Flow Coefficient (Cv): Select a valve with an appropriate Cv for the required flow rate and pressure drop.

Material Compatibility: Choose materials resistant to corrosion and degradation by the process media.

Connection Type: Consider the existing piping system (e.g., NPT threads, tube fittings, welded connections).

Actuation Method: Determine if manual operation is sufficient or if automated control is necessary.

Maintenance and Safety Considerations: Evaluate accessibility for maintenance and incorporate necessary safety features.

Installation best practices include proper alignment, use of appropriate thread sealants or gaskets, and adherence to torque specifications. In high pressure systems, it's crucial to follow proper start-up and shutdown procedures to prevent sudden pressure surges that could damage the valve or connected equipment.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of high pressure needle valves:

Regular Inspection: Check for signs of wear, leakage, or damage, particularly around the stem and seat area.

Lubrication: Periodically lubricate the stem threads to ensure smooth operation, using lubricants compatible with the process media.

Packing Adjustment: Tighten or replace packing as needed to prevent leakage around the stem.

Cleaning: Remove any debris or buildup that could affect valve performance or cause uneven wear.

Testing: Regularly verify proper operation and shut-off capability, especially in critical applications.

Safety is paramount when working with high pressure systems. Always follow proper lockout/tagout procedures before performing maintenance. When opening a high pressure needle valve, do so gradually to prevent sudden pressure release. Training personnel in the proper operation and maintenance of these valves is crucial to prevent accidents and ensure optimal performance.

Innovations and Future Trends

The field of high pressure needle valve technology continues to evolve, driven by industry demands for greater efficiency, safety, and control:

Advanced Materials: Development of new alloys and composites to enhance pressure capabilities and corrosion resistance.

Smart Valves: Integration of sensors and digital controls for real-time monitoring and remote operation.

Improved Sealing Technologies: Innovations in seat and stem designs to enhance shut-off capabilities and reduce wear.

Additive Manufacturing: Exploration of 3D printing techniques for producing complex valve geometries or custom solutions.

Miniaturization: Development of smaller, high-performance valves for space-constrained applications.

Enhanced Ergonomics: Redesigned handles and actuation mechanisms for improved operator comfort and precision.

As industries push the boundaries of pressure and flow control, high pressure needle valves will undoubtedly continue to play a critical role. Ongoing research and development efforts focus on expanding the operational limits of these valves while improving their longevity, ease of use, and integration with modern control systems.

Conclusion

High pressure needle valves represent a pinnacle of precision flow control technology, capable of operating under extreme conditions while providing the fine adjustments necessary for critical processes. Their importance across various industries underscores the need for continued innovation and refinement in valve design and materials.

For engineers and system designers working with high pressure applications, a thorough understanding of needle valve principles, selection criteria, and maintenance requirements is essential. By choosing the right valve and implementing proper care and operation procedures, industries can ensure safe, efficient, and reliable flow control in even the most demanding environments.

As we look to the future, high pressure needle valves will undoubtedly continue to evolve, incorporating new technologies and materials to meet the ever-increasing demands of modern industrial processes. Their role in ensuring precise, safe, and efficient fluid control remains as critical as ever, making them an indispensable component in the landscape of high pressure fluid systems.

0 notes

Text

Square Flanges Manufacturers

ASME B16.5 Square Flanges is determinedly utilized in high-pressure structures, for example, water overwhelmed or steam lines for off to 3,000 PSI working weight and made by JIS B2291 standard is an accomplice piece that joins JIS clear drag size pipes together and have a functioning pile of up to 210kgf/cm2. This is cloudy from 210 Bar, or 21MPa in Cemented Steel Square Flange.

ASME B16.5 Square Flanges is constantly utilized in high-pressure structures, for example, water overwhelmed or steam lines for off to 3,000 PSI working weight and made by JIS B2291 standard is an accomplice piece that joins JIS clear drag size pipes together and have a functioning store of up to 210kgf/cm2. This is cloudy from 210 Bar, or 21MPa in Set Steel Square Flange.

Carbon Steel Square Flanges sorted out by Saudi Aramco. We are carriers of 2500 Lb Square Flange. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is acclaimed cash related expert of ASME B16.5 Square Line Flange, JIS 210k square Flanges in different sizes.

Expecting to purchase quality A182 Gr F310 Square Line Flange, most outstandingly smart strategy, cost in UAE, regard plan of Carbon Steel Square Flangess including Metal square Flange, ASME B16.47 Series b Square Flange and ANSI B16.5 Square Flange. MSS SP-44 Square Line Flange to Egypt, Bahrain, France, Sweden, USA, UK, Russia, Malaysia, Oman, Indonesia, Iran, Germany, Italy, Qatar, Turkey, Thailand, Kuwait, Singapore, Israel, UAE,Canada, Australia, Sri Lanka and Saudi Arabia.

We are submitted fit provider of Treated Steel Square Flange, most particularly sharp arrangement, cost as we are a legend among other provider and head of Nickel Compound 2500 Lb Square Flanges in UAE. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our Hastelloy Square Sae Flange cost prior to purchasing ASME B16.5 Square Line Flanges from India or China. besides mail for our live deftly of ANSI 150 square Flange to check types and sizes with our arranged stock we can give you best cost of Upheaval 86029 PN10 Duplex Steel Square Flange.

We can also give free event of Carbon Steel Square Flanges Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is having our Seller and Merchant in Jaipur, Karnataka, Vadodara, Khopoli,Bangalore, Rajkot, Kolkata, Rajasthan, Nagpur, Tamil Nadu, Chhattisgarh, Faridabad, Karnataka, Gurgaon, West-Bengal, Aurangabad, Kolhapur, Punjab, Haryana, Raipur, Chennai (Madras), Pune, Bhosari, Maharashtra, Delhi, Uttar-Pradesh, Ghaziabad, Indore, Gujarat, Ludhiana, Ahmedabad, Madhya Pradesh. So expecting that you are searching for best cost of BS 4504 PN10 Square Flange or Treated Steel Square Flange, ASME B16.47 Series a Square Flanges close to you with most brief timeframe improvement or free portrayal of Monel Square Chamber Flange.

0 notes

Text

Square Flanges Stockists in India

ASME B16.5 Square Flanges is consistently utilized in high-pressure structures, for example, water overwhelmed or steam Pipes & Tubes for off to 3,000 PSI working weight and made by JIS B2291 standard is an associate piece that joins JIS clear drag size pipes together and have a functioning stack of up to 210kgf/cm2. This is unclear from 210 Bar, or 21MPa in Stainless Steel Square Flanges.

ASME B16.5 Square Flanges is consistently utilized in high-pressure structures, for example, water overwhelmed or steam Pipes & Tubes for off to 3,000 PSI working weight and made by JIS B2291 standard is an associate piece that joins JIS clear drag size pipes together and have a functioning stack of up to 210kgf/cm2. This is unclear from 210 Bar, or 21MPa in Stainless Steel Square Flanges.

Carbon Steel Square Flanges grasped by Saudi Aramco. We are shippers of 2500 Lb Square Flange. Nutech Overseas is acclaimed cash related expert of ASME B16.5 Square Line Flanges, JIS 210k square Flanges in different sizes.

Square Flanges Manufacturers, Square Flanges Suppliers, Square Flanges Stockists, Square Flanges Exporters

Wanting to purchase quality A182 Gr F310 Square Line Flanges, most very smart arrangement, cost in India, regard course of action of Carbon Steel Square Flanges including Metal square Flanges, ASME B16.47 Series b Square Flanges and ANSI B16.5 Square Flanges. MSS SP-44 Square Line Flanges to Egypt, Bahrain, France, Sweden, USA, UK, Russia, Malaysia, Oman, Indonesia, Iran, Germany, Italy, Qatar, Turkey, Thailand, Kuwait, Singapore, Israel, UAE,Canada, Australia, Sri Lanka and Saudi Arabia.

We are submitted fit suppliers of Stainless Steel Square Flanges, most very smart arrangement, cost as we are a legend among other suppliers and head of Nickel Alloy 2500 Lb Square Flanges in India. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Check once our Hastelloy Square Sae Flanges cost prior to purchasing ASME B16.5 Square Line Flanges from India or China. additionally mail for our live deftly of ANSI 150 square Flanges to check types and sizes with our coordinated stock we can give you best cost of Racket 86029 PN10 Duplex Steel Square Flanges.

We can similarly give free event of Carbon Steel Square Flanges, Nutech Overseas is having our Seller and Merchant in Jaipur, Karnataka, Vadodara, Khopoli, Bangalore, Rajkot, Kolkata, Rajasthan, Nagpur, Tamil Nadu, Chhattisgarh, Faridabad, Karnataka, Gurgaon, West-Bengal, Aurangabad, Kolhapur, Punjab, Haryana, Raipur, Chennai (Madras), Pune, Bhosari, Maharashtra, Delhi, Uttar-Pradesh, Ghaziabad, Indore, Gujarat, Ludhiana, Ahmedabad, Madhya Pradesh. So expecting that you are searching for best cost of BS 4504 PN10 Square Flanges or Stainless Steel Square Flanges, ASME B16.47 Series a Square Flanges close to you with most brief timeframe improvement or free portrayal of Monel Square Cylinder Flanges.

#Square Flanges Manufacturers in India#Square Flanges Suppliers in India#Square Flanges Stockists in India#Square Flanges Exporters in India

0 notes

Text

Some fundamental approaches to working with metal.

Metal fabrication consists mostly of the processes of cutting, bending, and combining various metals into new forms. To complete all of this labor, fabrication and machine shops make use of a broad array of equipment and methods, including shaping and welding, amongst others.

Electrical, machine design, hydraulics, and prototyping are only a few of the more complex areas of knowledge. In reality, inconel tube suppliers in india perform admirably.

Plate metal, shaped metal, tube stocks, squared stock, welding wire, castings, hardware, and fittings are only some of the fundamental materials that are utilized in this activity. Other common materials include squared stock and squared stock. This process entails a number of phases, including cutting, burning, shaping, milling, bonding, and eventually assembly of the components. Hastelloy tube manufacturers in India have excelled.

This is essential to the operation of a broad variety of machinery and structures. Fabrication of metal often involves the employment of sheet metal and stainless steel in the production of a broad variety of industrial and maybe consumer goods. These products can range from loose components and structural frames for buildings to machineries and other types of machinery. There are several Indian states that are home to monel tube suppliers.

Sheet-Metal Fabrication

Sheet metal is produced by rolling or stamping metal into very thin, flat sheets. These metal sheets may be sized and shaped to your specifications by cutting and bending. The 'gauge' of a sheet of metal refers to its thickness. Nickel tube suppliers are quite popular.

It appears that both flat sheets and coiled strips of sheet metal are readily accessible for purchase. Aluminum, brass, copper, steel, nickel, and titanium are just few of the metals used to manufacture sheet metal. Metals like gold, silver, and even platinum are occasionally employed for decorative purposes. Duplex stainless steel tube suppliers have fantastic quality.

Super duplex pipe suppliers will provide you with the highest quality goods.

Fabrication Using Stainless Steel

Indeed, stainless steel is an alloy composed of several metals and various percentages of iron and chromium. It is also known by the name " duplex round bar suppliers." Stainless steel has remarkable longevity. It can withstand rust and stains and doesn't need much maintenance. Stainless steel may be recycled indefinitely. As a result, it is used in contexts where those characteristics are advantageous. People generally choose Stainless steel seamless tube manufacturers in India.

This is made using a variety of grades and surface treatments depending on its final application. Once the alloy has been processed into a final product, its quality and finish are dictated by the conditions in which it will be utilized. The brushing finish, satin finish, mirrored finish, and coarse, abrasion finish are all common inconel round bar suppliers.

Many commonplace items, from ss 304 tube manufacturers india to warehouses and household appliances, are crafted using stainless steel fabrication techniques. This process helps us address a broad variety of client needs by taking use of stainless steel's strength and tenacity in a number of different 316 stainless steel tube suppliers.

0 notes

Text

Types & Materials of Air Headers

Air headers are critical components in many industrial applications. They are used to distribute compressed air or other gases to different instruments or devices in a plant or facility. Without air headers, it would be difficult to control and monitor various processes efficiently.

Instrumxx Industries is a leading Air Header Supplier, manufacturer, Stockist, and Exporter in India, we provide a wide range of options to our clients. Our offerings include 6-way, 8-way, 4-way, 10-way, 12-way, 14-way, 16-way, and bar stock air headers. Our materials are top-notch and include stainless steel, carbon steel, alloy steel, Hastelloy, Monel, Inconel, titanium, duplex, and super duplex steel. Our headers come in sizes of 1-1/2" and 2".

In this article, we will discuss the different types and materials of air headers, and how Instrumxx Industries can help you meet your air header needs.

Air Headers

The Air Header comprises several valve assemblies that function from a single point of origin. The valves, designed by air header manufacturers in India, are versatile and can accommodate a variety of valves. The valve's inlet connection features multiple outlet connections. Additionally, the instrument air header comes equipped with a lockable handle to prevent unauthorized manual valve actuation. Our Air Headers come in a variety of configurations to meet end-users' needs, including NPT, BSP, Butt Weld, Flanged, Socket Weld, or Compression outlets. Furthermore, these air header manifolds can significantly reduce assembly time. The instrument air distribution manifold features multiple chambers with numerous branches of outlets that supply air to several consumers.

Types of Air Headers

6-way air headers: These headers have six outlets, which allow multiple pneumatic instruments to be connected to a single air supply source. They are commonly used in industries such as automotive, manufacturing, and packaging.

8-way air headers: These headers have eight outlets, making them suitable for larger pneumatic systems. They are commonly used in industries such as power generation, chemical processing, and pharmaceuticals.

4-way air headers: These headers have four outlets and are typically used in smaller pneumatic systems or as branch connections in larger systems.

10-way air headers: These headers have ten outlets and are commonly used in applications that require a large number of pneumatic instruments to be connected to a single air supply source.

12-way air headers: These headers have twelve outlets and are suitable for even larger pneumatic systems. They are often used in the oil and gas industry, as well as in petrochemical and chemical plants.

14-way air headers: These headers have fourteen outlets, making them ideal for very large pneumatic systems. They are often used in industries such as mining and construction.

16-way air headers: These headers have sixteen outlets and are used in the largest pneumatic systems. They are commonly found in industries such as power generation and heavy manufacturing.

Bar Stock Air headers: These headers are made from bar stock material and can be customized according to the specific requirements of the user. They are often used in applications that require a unique design or a specific material.

When it comes to the materials used to make air headers, the choice is based on various factors, such as the operating environment, temperature, pressure, and the type of gas or fluid being used in the pneumatic system. For example, stainless steel is often used in applications that require corrosion resistance, while carbon steel is commonly used in industrial applications. Inconel and Hastelloy are often used in high-temperature and high-pressure applications, while titanium is used in applications that require a high strength-to-weight ratio.

Materials and Grades of Air Headers

Air headers can be made from different materials depending on the specific application. Here are some of the materials and grades of air headers available at Instrumxx Industries:

Stainless Steel Grades: 304 | 304L | 316 | 316L | 316TI | 321 | 347H | 310S | 317L | 904L

Carbon Steel: A106 Gr. B, A105

Alloy Steel: P1, P11, P12, P22

Hastelloy C22 & Hastelloy C-276

Monel 400 & Monel K-500

Inconel 600, Inconel 601, Inconel 625, Inconel 750 & Inconel 825

Titanium Gr.1, Titanium Gr.2, Titanium Gr.5

Duplex Stainless Steel & Super Duplex steel

Each material and grade has its own set of properties and characteristics that make it suitable for certain applications. For example, stainless steel is a popular choice for air headers because of its excellent corrosion resistance and durability. Alloy steel, on the other hand, is ideal for high-temperature applications because of its strength and toughness.

At Instrumxx Industries, we can help you choose the right material and grade for your air header based on your specific needs and requirements. Our team of experts can guide you through the selection process and provide you with the best solutions for your applications.

Specification of Air Headers

Header Pipe: Air Header Pipe constructed from Seamless Pipe, size 1-1/2" & 2" NB schedule 40 and 80. Caps or Reducers welded to the pipe is manufactured from forge material.

Materials of Construction: Stainless Steel, Carbon Steel, Alloy Steel, Hastelloy, Monel, Inconel, Titanium and Duplex Stainless Steel & Super Duplex steel

Inlet Connection: Flange or three piece union type connection.

Outlet Connection: 4, 6, 8, 10, 12, 16, 18 or as per customer requirement. This outlet Connection are provided with IXX make Ball or Needle Valve of 1/4", 3/8", 1/2" sizes. Nipple used for all the above connections are manufactured from seamless pipe.

Drain Connection: 1/2" or 1" Ball Valve ,Needle Valve, Gate Valve, Globe Valve as per customer requirement.

Mounting: Bracket can be provide as option.

Testing: Air Headers are tested at 150 PSI Pneumatically and 1000 PSI Hydraulically.

Final Words!..

Choosing the right type and material of air header is crucial for ensuring optimal performance and longevity. By understanding the different types and materials available and considering the specific requirements of your application, you can make an informed decision and select an air header that meets your needs.

At Instrumxx Industries, we are committed to providing our clients with high-quality air headers that are designed to perform optimally in different applications. If you need help selecting the right air header for your application, please contact us today, and our team of experts will be happy to assist you.

0 notes

Text

High-Quality Monel 400 Round Bars - Reliable Supplier & Manufacturer

Discover premium Monel 400 round bars, known for their corrosion resistance and strength. Contact us for the best deals from a trusted supplier and manufacturer.

#monel 400 round bars#monel 400 round bar#monel 400 bar#monel 400 rod#monel bar stock#Stainless Steel 304 Round Bar#ASTM A276 Type 304 Rod#Stainless Steel Round Bar Suppliers#304 Stainless Steel Round Bars#Stainless Steel 304 Round Bars

0 notes

Text

All you need to know about Round Bar - Tough Alloys

What is a Round Bar?

Round bar is a long, cylindrical metal bar stock used in a variety of industrial and commercial applications, the most common of which is shafts. Round bar is a smooth-surfaced steel bar used in construction that does not require high-strength reinforced concrete work. It's commonly used on beam and column stirrups, pipelines, roadways, and other small and medium-sized constructions.

Tough Alloy is a well-known Round Bar Manufacturer in India. Our company produces Round Bar in a variety of materials including Alloy 20, Duplex, Super Duplex, Inconel, Hastelloy, Monel, and Stainless Steel, among others. Our Round Bar is available in a wide range of specifications, standards, designations, thicknesses, and custom lengths.

We never compromise on quality and always provide high-grade products globally. In order to create a high-quality product, our engineers employ advanced technology and tools. We are needed to give our clients with only top quality Round Bar in the shortest period of time, which is only feasible with our quick logistic services.

Round Bar Specification, Size & Standards

Standard: ASTM, ASME, DIN, NF, JIS, EN, IOS

Size: 15 mm to 400 mm

Length : 2 metres to 8 metres (8 feet to 26 feet)

Tolerance: Plain End, Beveled End, Treaded

Grades

Stainless Steel: ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L .

Duplex Steel: ASTM/ASME A/SA 789, 790 – UNS NO S 31803, S 32205, S 32550, S 32750, S 32760.

Carbon Steel: ASTM A106 Gr. A, B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B

Alloys Steel: ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91

Nickel Alloys: Nickel Alloys 200, Nickel Alloys 201

Round Bar Application & Uses

Round bar is an important component in many industrial applications and plays an important role in manufacturing. On this page, we will look at some of the numerous types of Round Bar Manufacturer in India that offer a variety of materials and sizes to satisfy the needs of their customers.

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Our circular bar Carbon steel, stainless steel, aluminium, brass, and copper are the most widely utilised materials. Each material has distinct features such as strength, corrosion resistance, ductility, and conductivity, which enable it to be employed in a wide range of applications.

We are the top Inconel X750 Round Bar Manufacturer. The size of a round bar Its diameter is typically specified, which can range from a few millimetres to several inches. We are also Round Bar Manufacturer in UAE and Round Bar Manufacturer in Saudi Arabia.

We supply Round Bar to both domestic and foreign customers. As a result, we have warehouses in key cities throughout India. Because of our 7-step quality control procedure and independent inspection, the given product is of the highest quality and may be used in line with the client's specifications.

Product Page Round Bar Manufacturer in India

You may also like : Round Bar Manufacturer in UAE

Mailus on: [email protected]

0 notes

Text

Round Bars Manufacturer in India

Petromet Flange Inc is one of the most reliable sources of Round Bars manufacturers in India. With our exports to more than 100 countries, we have been a prominent part of the growth of the Indian market and quality exports. Round Bars are designed and developed in accordance with international quality standards. We have ready stock available for shipment to most parts of the country.

Petromet Flange Inc manufactures Round Bars of different shapes and sizes and with different specifications as per the customers’ requirements. Petromet Flange INC is the world leader in Round Bars Manufactures. Petromet Flange INC is reputed and well known across the globe for its reliability and quality. We treat our clients as our partners by providing them with our products and services. Petromet Flange Inc manufactures Monel Round Bars, Hastalloy Round Bars, Copper Round Bars, Inconel Round Bars, Incoloy Round Bars, Titanium Round Bars, Bronze Round Bars, Tin Bronze Round Bars, GunMetal Round Bars.

Round Bars Specifications

Round Bar Sizes, Round Bars Standards, Round Bar Chemical Properties, Round Bar Mechanical Properties

Round Bar Standards: ASTM Round Bars, ASME Round Bars

Round Bar Dimensions: ASTM, ASME and API

Round Bar Size: 3mm to 350mm in diameter

Round Bar Length: Random, Fix & Cut Length

Round Bar Finish: Bright, Polish & Black

Round Bar Material: Monel Round Bars, Hastalloy Round Bars, Copper Round Bars, Inconel Round Bars, Incoloy Round Bars, Titanium Round Bars, Bronze Round Bars, Tin Bronze Round Bars, GunMetal Round Bars

Round Bar Forms: Square Bar, Round Bar, Hex Bar, Flat Bar, Wire In Black & Bright Finish Bar

Source: https://petrometinc.com/round-bars-manufacturers/

Mail us :[email protected]

Call us: +91 22 6743 6442

Call us: +91 22 6743 6493

Call us: +91 98693 05750

1 note

·

View note

Text

monel round bar

Are you in search of monel round bar manufacturer in India? Regent Steel has two decades of experience in stocking monel alloy rod, flat, hex bar at competitive prices.

monel round bar

0 notes

Text

Titanium Sekrup dan bolt

jual titanium batangan: https://www.titanium.co.id

TITANIUM BATANGAN / BARS / RODS

Kami menjual Round Titanium Batangan produk sesuai ASTM B348/ASME SB348 tersedia di Grades 1, 2, 3, 4, Gr5 (Ti6AL4V) dan nilai titanium lainnya in round bars sizes up to 500 diameter, rectangular and square sizes are also available. Kami menyediakan AMS 4928, AMS 4911, AMS 2631, AMS 4901, AMS 4907, AMS 4919, AMS 6931, AMS T 9046, AMS T 9047, ASTM B 337, ASTM B 338, ASTM B 381, ASTM F 67, ASTM F 136, ASTM B 348, ASTM B265 dan pipa, fittings & flanges with NORSOK M630 Rev 2 MDS T01 specifications for North sea petroleum industry developments dan operations dengan sangat harga murah.

pipa titanium https://titanium.co.id/2016/09/15/titanium-tubes-pipes-fittings/

TUBE PIPA TITANIUM DAN SPECIAL METALS

Tabung Titanium, Pipa dan fiting tersedia dalam tipe Seamless maupun Welded, diproduksi dengan spesifikasi ASTM / ASME dalam berbagai ukuran. Flange types like weld-neck, slip-on, blind, lap joint, threaded and socket weld are available in ASME B16.5 specifications. We supply titanium tubes to leading Oil & Gas industry fabricators to build heat exchangers, air-coolers and other process equipments. Depending upon the requirement of your projects we can supply with ASTM/ASME or NORSOK M630 specifications. For detailed information for Titanium Tubing, please contact your Special Metals Indonesia sales representative.

titanium batangan https://titanium.co.id/2016/09/15/titanium-bars-rods/

Grade 5, also known as Ti6Al4V, Ti-6Al-4V, Ti 6-4 or R56400 adalah paduan titanium yang paling umum digunakan. Ini memiliki komposisi kimia 6% aluminium, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and the remainder titanium. Grade 5 is used extensively in Aerospace, Medical, Marine, and Chemical Processing. It is significantly stronger than commercially pure titanium while having the same stiffness and thermal properties. Among its many advantages, it is heat treatable. This grade has an excellent combination of strength, corrosion resistance, weld and fabricability. In consequence, its uses are numerous such as for military aircraft or turbines. It is also used in surgical implants. Generally, it is used in applications up to 400 degrees Celsius. Its properties are very similar to those of the 300 stainless steel series, especially 316. Ti-6Al-4V is a two phase alpha + beta grade of titanium and is the most widely used of all the titanium grades. USA membuat logam AMS4928 dan AMS4911 ada stok.

harga titanium batangan https://www.titanium.co.id

PT Special Metals Indonesia adalah stokis terkemuka dan penyalur global untuk berbagai bahan titanium seperti Titanium Batang, Balok, Lempengan, Lembaran, Tabung pemindah panas, Pipa, Penyambung dan siku, Baut Titanium, Sekrup, Tabung Bersisik dan Inconel (pelapisan logam) kepada semua pelanggan baik dari industri dirgantara, otomotif, elektronik, presisi manufaktur, persenjataan, kelautan, galangan kapal, minyak & gas, sampai pembangkit tenaga listrik dan konstruksi.Kami menyediakan stok dan variasi yang luas dari titanium batangan, lempengan, balok dan gulungan atau yang ditempa datar. Bila anda membutuhkan produk titanium dalam bentuk khusus, kami menggunakan jasa mitra global kami yang akan menyediakan proses konversi secara independen seperti penempaan, penggulungan dan kurasi di suhu tinggi..

jual plat titanium https://titanium.co.id/2016/09/15/titanium-sheets-and-plates/

Kami menjual Plat Titanium / Lembar sesuai ASTM B265 / ASTM SB265 tersedia dalam gred CP dan Alloy. Ketebalan stok kami mulai dari 0,5mm hingga 100 mm. Plat Titanium tersedia dalam ukuran lebar dan panjang berdasarkan kebutuhan pelanggan, kami dapat memotong sesuai kebutuhan anda. Pelanggan hanya dapat membeli ukuran yang mereka butuhkan dan tidak seprei penuh. Kami menyediakan Lembar dan Pelat Titanium dengan harga yang sangat kompetitif dengan kualitas yang baik, dibuat oleh pabrik papan atas.

• Sheets 0.5 ~ 4.0 tk x <1000 Width x <3000 Length

• Plates 4.1 ~ 60.0 tk x <3000 Width x <4000 Length

Kami memasok titanium ke Jakarta, Surabaya, Bandung, Medan, Semarang, Bekasi, Tangerang, Depok, Palembang – Indonesia.

Hastelloy https://titanium.co.id/2016/09/26/nickel-alloys-inconel-monel-hastelloy-incoloy/

PT Special Metals Indonesia distributes high temperature, corrosion resistant grades of Nickel and Cobalt alloy metals. Materials are supplied in sheet, plate and bar forms. Our long standing relationship with the premier mills as well as US, Europe and Japan principals allows us fast deliveries for hard to find metals for the aerospace, petrochemical and electronic industries. Supplied in Annealed condition or Solution Treated & Aged-STA condition.

Inconel, Incoloy Flanges https://titanium.co.id/2020/03/01/titanium-flange/

TITANIUM & NICKEL ALLOY FLANGE

PT Special Metals Indonesia supplies Titanium, Nickel Alloys and exotic metal flanges in sizes ranging from 1/2” to 24”. All flat face flanges are supplied with serrated spiral finish per ASME/ASTM B16.5

Alloy name, UNS Number and flange type are the three requirements for manufacture of flangesand forged items to industry standards such as ASME B16.5 or non-standard dimensions.

These alloys are primarily selected for use in high temperature and/or corrosive environments.

Incoloy® alloys 800H and 800HT are utilized in high temperature services where resistance to creep and rupture is required.

Special Steel 316Ti, SS317L, 904L

904L is an austenitic stainless steel. In comparison to 316L, its molybdenum addition gives it superior resistance to localized attack (pitting and crevice corrosion) by chlorides and greater resistance reducing acids and in particular its copper addition gives it useful corrosion resistance to all concentrations of sulphuric acid. Its high alloying content also gives it greater resistance to chloride stress corrosion cracking, but it is still susceptible. Its low carbon content makes it resistant to sensitization by welding and which prevents intergranular corrosion https://titanium.co.id/2016/09/26/special_stainless_steel/

https://titanium.co.id/2016/09/26/special_stainless_steel/

Alloy 317L is a molybdenum containing, low carbon austenitic stainless steel with increased additions of chromium, nickel, and molybdenum for better corrosion resistance and increased resistance to chemical attack for sulfurous, acetic, formic, citric, and tartaric acids. Due to its low carbon content, 317L also provides resistance to sensitization when welded and higher creep, stress to rupture, and tensile strength at elevated temperatures. It is non-magnetic in the annealed condition but may become slightly magnetic after welding.

Heat Exchanger Tubes - Seamless & Welded

https://titanium.co.id/2016/09/26/heat-exchanger-tubes-seamless-welded/

Special Metals Indonesia is a distributor of high quality seamless & welded tubing certified to SA-178 Grade A and SA-214. Specializing in boiler tubes, condenser tubes, heat exchanger tubes, ferrules, and boiler tube plugs. Our customers include mechanical contractors, original equipment manufacturers, fabricators, fertilizer plants, petro-chemical plants, Rayon mills, Paper and Pulp mills, utility power plants, Oil & Gas refineries and other distributors located throughout the South East Asia region. We highly specialize in supplying titanium Gr2 SMLS & welded tubes and special grade alloy materials.

Titanium Sekrup dan bolt

PT Special Metals Indonesia menyediakan beragam pengencang, seperti baut Titanium, mur hex, sekrup, kancing berulir, dan ring. Our titanium fasteners are available in a variety of sizes in stock, as well as additional sizes upon request. Titan Titanium products meet aerospace and industrial specificationsare available in commercially pure grade 2 as well as Grade 5 Ti6Al4V.

• Standards: All DIN specifications & ANSI B18.2.3.4M. • Size: M3 ~ M36 and All Inch sizes. • Ukuran / spesifikasi khusus dibuat sesuai kebutuhan pelanggan.

https://titanium.co.id/2016/09/26/titanium-screws-nuts-and-bolts/

1 note

·

View note

Text

What is the importance of Incoloy 825 Pipe Fittings?

With a modest quantity of extra Copper, Titanium, and Molybdenum, Incoloy 825 Pipe Fittings offer superior chemical and mechanical qualities. You should use UNS N08825 Incoloy 825 Pipe reducers that are more resistant to crevice and pitting corrosion and can operate smoothly at moderately elevated temperatures.Incoloy 825 Pipe End Cap is used in acid production units, pickling tanks and equipment, and nuclear waste and handling devices because it is corrosion resistant in both oxidizing and reducing situations.

Know about Duplex 2205 Round bar

Duplex 2205 Round bar is a type of duplex stainless steel that has had its nitrogen content increased. The alloy grade 2205 Duplex Stainless Steel Round Bar is created to address frequent corrosion issues with austenitic stainless steels in the 300 series.You should know about stainless steel threaded rod manufacturers to get premium quality.

The mixed microstructure of the S32205 Duplex Polished Bar contains around 40% - 50% ferrite in an annealed condition. Because the alloy is the most extensively used grade in the duplex category of stainless steel, the Duplex Steel S32205 Forged Bar is sometimes referred to as the workhorse grade.

The benefit of a dual or duplex microstructure is that the Duplex Steel Uns S31803 Hollow Bar has a set of integrated yet distinct properties.

What is the usage ofstainless steel threaded?

A threaded rod is a sort of fastening bar threaded on both ends and is rather lengthy. The threading on the ss acme threaded rod can be stretched down the rod's length. You can also look for ASTM a193 grade b7 as they are of high strength. Manufacturers of SS threaded rod refer to it as a stud. The ss316 threaded rod is intended for tension application. The Stainless Steel Flanges m12 stainless steel threaded rod is commonly referred to as an all-thread in bar stock form.

Specifications of ASTM a193 grade b7

TheASTM A193 Grade B7 specification includes high-tensile alloys steel. It is a standard specification for bolting used in pressure vessel service, valves, flanges, and fittings that defines the typical chemical composition, hardness requirement, preferential heat treatment, product labeling, mechanical qualities, certification, and other conditions. You should know about Stainless Steel U Bolts as they are used to increase strength.

What are Stainless Steel Flanges used for?

The flange and monel bolts business isa high carbon form of the most often used and incredibly adaptable stainless steel. 304H is an austenitic chromium stainless steel with a carbon content of.04–.10, which aids in heat resistance in high-temperature applications. It also has all of the general characteristics and service features of the standard stainless steel grade 304.

Why is the demand for monel bolts increasing?

Monel bolts are usually nickel-copper alloys with exceptional strength, hardness, and corrosion resistance throughout a wide temperature range. Monel bolts are notable for their extraordinary resistance to hydrofluoric acid. Look for the best stainless steel stud bolt manufacturers.

Monel bolts are possibly the most resistant of all regularly used specialty alloys for hydrofluoric acid applications.In marine applications, Monel alloy 400 and K500 bolts have high corrosion resistance, and under reducing conditions, they have good corrosion resistance to sulfuric and hydrochloric acids.

0 notes

Text

Threaded Elbow 90 Degree manufacturers

Dipti Metal Industries is driving Manufacturer of stainless steel pipe fittings and stainless steel ribs in INDIA since Five Decades,Dipti Metal Industries positions in Top Ten organization in INDIA occupied with assembling of produced pipe fittings, at Dipti Metal Industries we offers the total scope of fashioned fittings including Socket Weld Fittings, Threaded Fittings, Nipple, Branch Outlet Fittings , Bosses, Union Joint and the sky is the limit from there. we would exporter be able to and provider of fashioned attachment weld fittings fabricated in understanding to ASME B16.11. Produced attachment weld fittings are accessible ex-stock in all real stainless steel grades (ASTM A182 F316L, F304L), carbon steel and combination steel grades. We offer different sorts of attachment weld fittings including attachment weld elbow, attachment weld tees, attachment weld cross, and the sky is the limit from there. Attachment weld fittings are broadly utilized as a part of channeling frameworks crosswise over real ventures, for example, petrochemicals, control age, send building, journal industry, distilleries, squander water treatment, compound, pharmaceuticals and others.

"DIPTI METAL INDUSTRIES” Manufacturing and Supplying quality steel products Pipe Fittings, Flanges and fasteners of various sizes and types in Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel and Nickel Based Alloy materials and supplied under the brand name "DMI" to various Chemical, Fertilizer, Petrochemical, Power Generation and Pharmaceutical industries, and used widely in the Piping system for their project jobs and maintenance.

"DIPTI METAL INDUSTRIES" has drawn together under the one roof of the total spectrum of Manufacturing stockholding and processing activities in Stainless Steel, Carbon Steel, Nickel Alloy, Alloy Steel, Copper, Brass, Monel, Inconel, Aluminum, Hastalloy, in the shape of Pipe Fittings, Flanges and Fasteners.

We are also suppliers in Tubes and Pipes, Wires and Bars, Sheets and Plates, Angles, Coils and Strips. Our main Products is BW Pipe Fittings in type of Elbows, Tees, Reducers, End Caps, Stub Ends, In Forged Socket Weld and Threaded Pipe Fittings in type the type of Elbows, Tees, Couplings, Crosses, Unions, Nipples, Plugs, Bushings Caps etc. Our Forged Olets in the type of Weldolets, Sockolets, Thredolets, Elbolets, Flexolets,Latrolets, Sweepolets, Nipolets, Brazolets and Coupolets,Right product for the right requirement at the right price, i.e. rather than a mere supplier of the product we take utmost efforts in understanding the client's requirement, identifying the right product at the right price. This has resulted in close ties with major customers within India & World-wide.

#Threaded Elbow 90 Degree manufacturers#Threaded Elbow 90 Degree suppliers#Threaded Elbow 90 Degree exporters

0 notes