#InstrumentationNeedleValves

Explore tagged Tumblr posts

Text

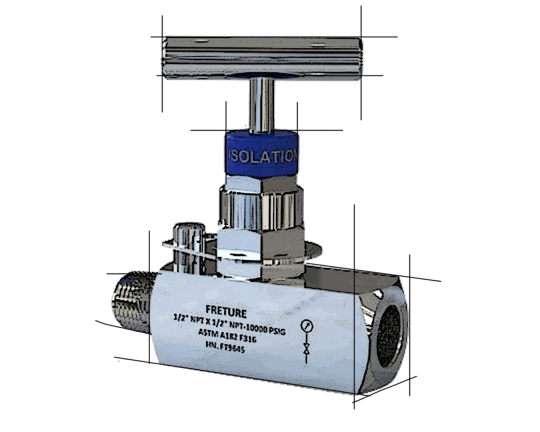

High Pressure Needle Valves: Precision Flow Control in Demanding Applications

In the realm of fluid control systems, high pressure needle valves stand out as indispensable components, offering precise regulation of flow in some of the most challenging industrial environments. These valves, characterized by their ability to withstand extreme pressures while providing accurate flow control, play a crucial role across various sectors, from oil and gas to chemical processing and hydraulic systems.

Understanding High Pressure Needle Valves

A high pressure needle valve is a type of linear motion valve designed to regulate flow with high precision, particularly in systems operating under significant pressure. The valve's name derives from its key component: a slender, tapered pin (the "needle") that moves in and out of a small orifice to control flow. This design allows for extremely fine adjustments, making needle valves ideal for applications requiring meticulous flow regulation.

Key Features and Advantages

Precise Flow Control: The gradual taper of the needle and its fine-threaded stem allow for minute adjustments, enabling operators to achieve exact flow rates.

High Pressure Capability: Engineered to withstand pressures ranging from several hundred to thousands of bar, these valves maintain their integrity in extreme conditions.

Tight Shut-off: When fully closed, the needle forms a metal-to-metal seal with the seat, ensuring minimal to zero leakage.

Durability: Constructed from high-strength materials, these valves offer long service life even in harsh operating environments.

Compact Design: Despite their high pressure capabilities, needle valves are relatively small, making them suitable for installations with space constraints.

Versatility: Available in various configurations to suit different mounting requirements and flow directions.

Construction and Materials

The effectiveness of a high pressure needle valve largely depends on its construction and the materials used:

Body: Typically made from forged steel, stainless steel, or special alloys like Monel or Hastelloy for corrosive applications.

Needle (Stem): Usually constructed from hardened stainless steel or other wear-resistant alloys to ensure longevity and maintain a tight seal.

Seat: Often integrated into the valve body, but may be replaceable in some designs. Material choice depends on the application but is generally a hardened alloy compatible with the body material.

Packing: High-quality packing materials like PTFE or graphite are used to prevent leakage around the stem while allowing smooth operation.

Bonnet: Secures the packing and guides the stem. In high pressure applications, a bolted bonnet design is common for added strength.

The choice of materials is critical and depends on factors such as operating pressure, temperature, media compatibility, and environmental conditions.

Types of High Pressure Needle Valves

Several variations of high pressure needle valves exist, each designed to meet specific application requirements:

Standard Needle Valves: The most common type, suitable for a wide range of general applications.

Micro-Metering Valves: Feature an exceptionally fine needle taper for ultra-precise flow control, often used in laboratory or analytical equipment.

Multi-Port Needle Valves: Incorporate multiple inlets or outlets for complex flow control scenarios.

Angle Pattern Needle Valves: Designed with the inlet and outlet at right angles, useful in certain piping configurations.

Bar Stock Needle Valves: Machined from solid bar stock for maximum pressure handling capability.

Cryogenic Needle Valves: Specially designed to maintain functionality at extremely low temperatures.

Applications Across Industries

The versatility and precision of high pressure needle valves make them indispensable in numerous industrial applications:

Oil and Gas: Used in wellhead control panels, sampling systems, and pressure reduction stations.

Chemical Processing: Crucial for precise chemical injection and reactor feed control.

Hydraulic Systems: Employed in pressure control and hydraulic test benches.

Power Generation: Found in steam sampling systems and turbine control.

Aerospace: Used in fuel systems and hydraulic controls of aircraft.

Research and Development: Essential in high pressure testing equipment and experimental setups.

Water Jet Cutting: Control water flow in high pressure cutting systems.

Considerations for Selection and Installation

Choosing the right high pressure needle valve requires careful consideration of several factors:

Pressure Rating: Must exceed the maximum system pressure with an appropriate safety margin.

Temperature Range: Ensure compatibility with both the minimum and maximum expected temperatures.

Flow Coefficient (Cv): Select a valve with an appropriate Cv for the required flow rate and pressure drop.

Material Compatibility: Choose materials resistant to corrosion and degradation by the process media.

Connection Type: Consider the existing piping system (e.g., NPT threads, tube fittings, welded connections).

Actuation Method: Determine if manual operation is sufficient or if automated control is necessary.

Maintenance and Safety Considerations: Evaluate accessibility for maintenance and incorporate necessary safety features.

Installation best practices include proper alignment, use of appropriate thread sealants or gaskets, and adherence to torque specifications. In high pressure systems, it's crucial to follow proper start-up and shutdown procedures to prevent sudden pressure surges that could damage the valve or connected equipment.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of high pressure needle valves:

Regular Inspection: Check for signs of wear, leakage, or damage, particularly around the stem and seat area.

Lubrication: Periodically lubricate the stem threads to ensure smooth operation, using lubricants compatible with the process media.

Packing Adjustment: Tighten or replace packing as needed to prevent leakage around the stem.

Cleaning: Remove any debris or buildup that could affect valve performance or cause uneven wear.

Testing: Regularly verify proper operation and shut-off capability, especially in critical applications.

Safety is paramount when working with high pressure systems. Always follow proper lockout/tagout procedures before performing maintenance. When opening a high pressure needle valve, do so gradually to prevent sudden pressure release. Training personnel in the proper operation and maintenance of these valves is crucial to prevent accidents and ensure optimal performance.

Innovations and Future Trends

The field of high pressure needle valve technology continues to evolve, driven by industry demands for greater efficiency, safety, and control:

Advanced Materials: Development of new alloys and composites to enhance pressure capabilities and corrosion resistance.

Smart Valves: Integration of sensors and digital controls for real-time monitoring and remote operation.

Improved Sealing Technologies: Innovations in seat and stem designs to enhance shut-off capabilities and reduce wear.

Additive Manufacturing: Exploration of 3D printing techniques for producing complex valve geometries or custom solutions.

Miniaturization: Development of smaller, high-performance valves for space-constrained applications.

Enhanced Ergonomics: Redesigned handles and actuation mechanisms for improved operator comfort and precision.

As industries push the boundaries of pressure and flow control, high pressure needle valves will undoubtedly continue to play a critical role. Ongoing research and development efforts focus on expanding the operational limits of these valves while improving their longevity, ease of use, and integration with modern control systems.

Conclusion

High pressure needle valves represent a pinnacle of precision flow control technology, capable of operating under extreme conditions while providing the fine adjustments necessary for critical processes. Their importance across various industries underscores the need for continued innovation and refinement in valve design and materials.

For engineers and system designers working with high pressure applications, a thorough understanding of needle valve principles, selection criteria, and maintenance requirements is essential. By choosing the right valve and implementing proper care and operation procedures, industries can ensure safe, efficient, and reliable flow control in even the most demanding environments.

As we look to the future, high pressure needle valves will undoubtedly continue to evolve, incorporating new technologies and materials to meet the ever-increasing demands of modern industrial processes. Their role in ensuring precise, safe, and efficient fluid control remains as critical as ever, making them an indispensable component in the landscape of high pressure fluid systems.

0 notes

Photo

Bleed Valve

Visit For More Features: https://bit.ly/2K6lgQK

#Instrumentationneedlevalve #Manifoldvalves #Valvemanufacturers

#Bleed Valve Manufacturers#Instrumentation Fittings Manufacturers#Forged Fittings Manufacturers#Pressure Snubber Manufacturers

0 notes