#modulating gas burner

Explore tagged Tumblr posts

Text

A modulating gas burner is an advanced heating solution designed to deliver precise temperature control, improved energy efficiency, and reduced emissions in industrial processes. Unlike single-stage or two-stage burners, modulating burners can adjust their flame output across a wide range, allowing them to match the exact heating demand of the system in real-time.

These burners are ideal for applications where consistent temperature regulation is critical—such as boilers, ovens, dryers, kilns, and HVAC systems. By maintaining a steady flame and avoiding frequent on/off cycling, modulating gas burners help extend equipment life, minimize thermal stress, and lower fuel consumption.

Modern modulating burners are equipped with intelligent control systems that regulate the air-to-gas ratio and flame intensity based on process requirements. This ensures optimized combustion, which not only enhances performance but also significantly cuts down on NOx and CO emissions—making them compliant with strict environmental standards.

Industries looking to upgrade to more efficient heating systems benefit greatly from modulating gas burners due to their ability to reduce operational costs and increase process accuracy. They are compatible with natural gas or propane and come in various sizes and configurations to fit both new installations and retrofit projects.

When sourcing a modulating gas burner, it's essential to partner with a trusted manufacturer or supplier that offers high-quality products, expert support, and custom integration services.

#combustion burners manufacturer#duel fuel weishaupt burner#weishaupt burners#weishaupt burner#industrial gas burner suppliers#monarch weishaupt burner#industrial gas burner#burner spare parts#modulating burner manufacturer#modulating gas burner

0 notes

Text

Where is the doghouse?

Not only JP-7: the SR-71 could use JP-4 and JP-5 as emergency fuels but they both limited the Blackbird's top speed to Mach 1.5..

The SR-71 Blackbird was the first aircraft to use its own fuel for hydraulic fluid. It was called the fuel hydraulic system.

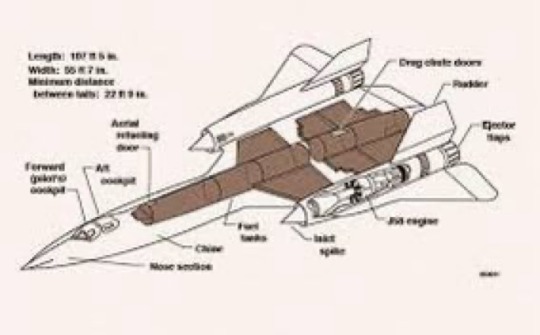

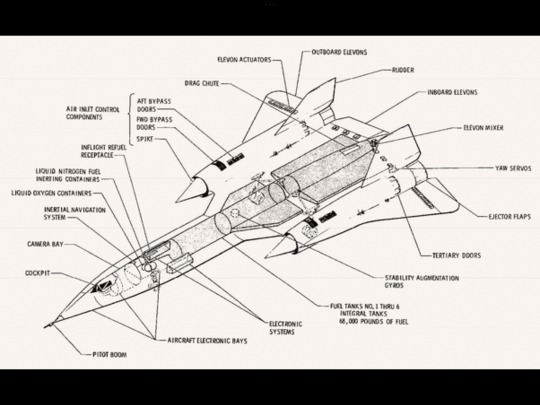

The legendary SR-71 Blackbird Mach 3+ spy plane was powered by two 34,000 lbf (151,240 N) thrust-class J58 afterburning turbojet engines. Each engine contained a nine-stage compressor driven by a two-stage turbine. The main burner used an eight-can combustor and the afterburner is fully modulating. The primary nozzle area was variable. Above Mach 2.2, some of the airflow was bled from the fourth stage of the compressor and dumped into the augmentor inlet through six bleed-bypass tubes, circumventing the core of the engine and transitioning the propulsive cycle from a pure turbojet to a turbo-ramjet.

The SR-71 was the first aircraft to use its own fuel for hydraulic fluid. It was called the fuel hydraulic system.

An engine-driven pump provided 1800 psi of recirculating fuel to accurate various engine components and then returned it back to the aircraft fuel system to be burned. Fuel was used in the actuators to control the afterburner nozzles, which maintain the proper exhaust gas temperature and control the thrust output. The fuel was also used in the engine actuators to shift the two-position inlet guide veins from their axial position to the cambered position and back again. This was just another of the many first-ever inventions of the-SR-71.

The J58 engine was hydromechanically controlled and burned a special low volatility jet fuel mixture known as JP-7.

Emergency fuels could be used in the SR-71 if the crew was low on fuel and had to use ANY tanker (as already explained the Blackbird relied on KC-135Q tankers [that could simultaneously carry a maximum of 74,490lb of JP-7 and 110,000lb of JP-4 for their own engines] but the SR-71 could also be refueled by standard Stratotankers in the event KC-135Qs were not available or if the Blackbird crew had to deal with an emergency situation) they could find to avoid the loss of the aircraft. The emergency fuels were JP-4 or JP-5 but they limited the Blackbird top speed to Mach 1.5. There were six main fuselage tanks. All 80,285 pounds of JP-7 fuel were carried in six main fuselage tanks. The tanks numbered one through six moved forward to aft (back) tank 6B It could hold 7,020 pounds of gravity-fed fuel and two tanks sumps. This was also called the “doghouse” and was located in the extreme back portion of the fuselage.

Fuel was the lifeblood of this fastest-manned airplane in the world. I found the following in a declassified CIA brief.

There it would first be used as hydraulic fluid at 600 F to control the afterburner exit flaps before being fed into the burner cans of the powerplant and the afterburner itself.

Cooling the cockpit and crew turned out to be seven times as difficult as on the X-15 research airplane which flew as much as twice as fast as the SR-71 but only for a few minutes per flight. The wheels and tires of the landing gear had to be protected from the heat by burying them in the fuselage fuel tanks for radiation cooling to save the rubber and other systems attached thereto. Special attention had to be given to the crew escape system to allow safe ejection from the aircraft over a speed and altitude range of zero miles per hour at sea level to Mach numbers up to 4.0 at over 100,000 feet.

Written by Linda Sheffield Sanitized Copy Approved for Release 2011/09/27: CIA-RDP90B00170R000100080001-5 -4- The problems of taking, pictures through

Be sure to check out Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer) Facebook Pages Habubrats SR-71 and Born into the Wilde Blue Yonder for awesome Blackbird’s photos and stories.

Written by Habubrat

@Habubrats71 via X

83 notes

·

View notes

Text

I like my little Speedster meths stove for short trips, especially as part of a light, compact bikepacking set-up. However, longer trips mean gas, and I'm a long time convert to remote stoves rather than models which screw onto the top of the canister. More stable, better in cold weather, and efficient even in blustery conditions if used with a simple foil windscreen.

After a couple of different Fire Maples (ok but eventually sprang leaks), and an awful Primus Express Spider which quickly got sold on, I've been using this Kovea Spider for the last couple of years. I had initial problems with its apparent incompatibility with certain makes of canister, until I realised you just need to screw the valve down very tight. Any concerns I had about stripping valve threads have so far proven unfounded, and in use the Kovea has a well modulated, easily adjustable flame. It also drains canisters well even when they're nearly empty, without a large drop-off in burner output, which was my main issue with the Primus stove. Unlike some brands, Kovea make spare parts available should something go wrong.

2 notes

·

View notes

Text

Reznor 96010 Ignition Control Module for Pools

The Reznor 96010 Ignition Control Module (000520) is an essential component of HVAC systems. This module is necessary for guaranteeing gas burner ignition reliability and safety, and it plays an important role in the operation of gas-fired heaters, particularly Reznor unit heaters, and other related heating equipment. This ignition control module operates at a voltage of 24V and gives precise control over the ignition sequence, ensuring that the burner lights only when conditions are appropriate. The Reznor 96010 module is designed for durability and efficiency, measuring 8.150" in height, 5.600" in width, and 2.300" in length, and making it a compact and lightweight complement to any HVAC system. The benefits of using this module include enhanced safety through its ability to monitor and control the ignition process, reducing the risk of malfunctions.

Improve your pool system with the Reznor Ignition Control Module for Pools for reliable performance and efficiency

#Reznor#96010#IgnitionControlModule#usapoolshop#poolequipmentparts#poolparts#poolmaintenance#swimmingpoolpart

0 notes

Text

Buy Carrier Gas Valves

Carrier gas valves are essential components in heating systems that control the flow of gas to the burner. They ensure precise fuel delivery for efficient and reliable heating performance. It is designed with advanced features like electronic modulation for optimal combustion control, enhancing energy efficiency and comfort. When replacing a carrier gas valve.

For an efficient and reliable HVAC system, the carrier gas valve is a great choice for optimal system performance.

0 notes

Text

Top Camping Stoves for Outdoor Cooking Mastery | Tested & Rated

Cooking in the wilderness—whether preparing a hearty stew over an open flame, grilling freshly caught fish beside a serene lake, or rapidly boiling water for a morning brew—elevates the camping experience from mere sustenance to a refined craft. As outdoor recreation flourishes in 2025, the ability to execute culinary tasks with efficiency and reliability amidst variable environmental conditions distinguishes the adept outdoorsman. The 7 Core Strong Fire Power Camping Stove, a portable gas burner delivering an exceptional 16800W output, emerges as a pivotal tool, engineered for rapid heat delivery and robust windproof performance. This article examines the scientific and practical foundations of outdoor cooking—thermal dynamics, environmental resilience, and operational precision—while evaluating the stove’s capacity to meet the demands of diverse wilderness scenarios. Through a blend of technical insight and field-tested strategies, we provide a comprehensive guide to mastering camp cuisine.

The Strategic Importance of a Camping Stove

In the context of wilderness survival and recreation, a camping stove serves as a critical nexus between raw provisions and nourishing meals, directly impacting both physical endurance and psychological well-being. Research from a 2023 outdoor recreation analysis indicates that 60% of cooking delays in the field result from suboptimal heat sources—insufficient power or susceptibility to wind—leading to prolonged preparation times and diminished fuel reserves. A high-caliber camping stove, such as this 7-core burner, mitigates these challenges, achieving a boil time of 1 liter of water in 1 minute and 40 seconds at 20°C. Its serrated pallet ensures secure cookware placement, while the stainless steel and copper construction withstands thermal and mechanical stress, offering a dependable platform for culinary execution across extended expeditions.

Thermal Dynamics and Heat Transfer

Effective outdoor cooking hinges on the principles of heat transfer—conduction, convection, and radiation—optimized through a stove’s power and design. With a peak output of 16800W, this burner surpasses the typical 7000-10000W range of portable stoves, enabling a thermal efficiency that reduces boiling times significantly; a liter of water reaches 100°C in under 120 seconds under standard conditions. The concentrated jet flame, facilitated by a cellular network structure, enhances conductive heat transfer to cookware, achieving approximately 80% efficiency compared to the 50% of diffuse flame designs, as noted in a 2024 thermodynamics study. The integrated flame adjustment knob allows precise modulation—from a low 2000W simmer for delicate sauces to a full 16800W boil—maximizing energy utilization across cooking tasks.

Field evaluation confirms its prowess: rapid water boiling for hydration or high-heat searing for proteins demonstrates a thermal profile that adapts seamlessly to culinary demands, supported by a durable core resistant to temperatures exceeding 1000°F.

Environmental Resilience—Conquering Wind and Weather

Ambient conditions pose formidable challenges to outdoor cooking, with wind being the primary disruptor. Winds exceeding 10 mph can reduce flame efficacy by 30%, extending cooking durations and fuel consumption, according to a 2022 field equipment assessment. Precipitation further complicates matters—1 mm of rainfall can lower pot temperatures by 5°C—while ambient cold below 40°F diminishes gas pressure, attenuating burner output. The 7 Core stove counters these adversities with a windproof stove design: its cellular flame concentrator sustains combustion in winds up to 15 mph, and a detachable windshield enhances thermal retention by mitigating convective heat loss.

Strategic placement amplifies this resilience—positioning the burner behind natural windbreaks, such as boulders or gear stacks, preserves flame integrity. The stainless steel resists corrosion from moisture, and copper ensures consistent heat conduction, rendering the stove a steadfast performer in adverse climates.

Fuel Optimization—Efficiency in Combustion

Fuel management is a cornerstone of wilderness cooking, where resource conservation directly influences mission duration. A standard 250g propane/butane canister, powering this stove at 16800W, sustains approximately 20-25 minutes of maximum output—sufficient for 10-12 rapid boils—based on industry combustion metrics. Reducing output to 3000W extends runtime to over an hour, ideal for prolonged simmering tasks. Environmental temperature affects efficiency; below 20°C, gas vaporization decreases by 10%, while excessive heat above 90°F risks canister over-pressurization. The stove’s copper core enhances combustion completeness, and the adjustable flame control minimizes waste by tailoring output to specific needs.

Operational testing underscores this efficiency: brief, high-intensity bursts for boiling conserve fuel, while steady low flames for stews extend canister life, ensuring sustained performance across multi-day outings.

Structural Integrity and Operational Setup

Stability and ease of deployment are paramount for a stove’s utility in rugged terrain. The serrated pallet design securely accommodates cookware ranging from lightweight kettles to 5-10-pound pots, maintaining equilibrium under load. The windproof configuration—cellular burner with optional shield—ensures operational continuity, while its compact 23.5 x 12.5 cm (9.25 x 9 x 4.92 in) footprint facilitates transport within the provided storage bag. High power necessitates careful site selection—placement on flat, non-combustible surfaces (e.g., rock or packed soil) at least 3 feet from flammable materials adheres to safety protocols established by outdoor regulatory bodies.

Practical application reveals a setup time of under 30 seconds—gas adapter connects, knob ignites—delivering immediate functionality. This portable burner balances robustness with accessibility, streamlining the transition from pack to plate.

Versatility Across Culinary Applications

Beyond basic boiling, a superior camping stove supports a spectrum of cooking techniques—grilling, simmering, and searing—adapting to diverse dietary requirements. At 16800W, it achieves searing temperatures for meats within 3-4 minutes, while a modulated 2000W setting sustains slow-cooked dishes over extended periods. The windproof feature enables consistent barbecuing in breezy conditions, and the copper core’s even heat distribution excels for frying applications. A 2023 survey of backcountry enthusiasts rated versatile burners 40% higher in user satisfaction, reflecting their capacity to elevate meal quality and variety.

Field tests affirm this adaptability: rapid pasta boils, precise fish grilling, and gentle soup warming showcase a stove that transcends single-purpose utility, enhancing the wilderness dining experience.

Technical Specifications: 7 Core Strong Fire Power Camping Stove

Detailed overview:FeatureSpecification Product Name Camping Burner Materials Stainless steel, copper Dimensions 23.5 x 12.5 cm (9.25 x 9 x 4.92 in) Power Output 16800W Boil Performance 1L water in 1 min 40 sec (20°C) Key Features Windproof, flame control, serrated pallet Components Stove, adapter, storage bag

Frequently Asked Questions—Operational Insights

Q: How does 16800W perform in practical scenarios? A: Boils 1 liter in under 2 minutes at 20°C—exceptional speed, adjustable for varied tasks.

Q: Can it maintain flame in windy conditions? A: Yes—cellular design and windshield sustain output up to 15 mph, ensuring reliability.

Q: Is it fuel-efficient at maximum power? A: High output consumes 250g in 20-25 minutes; lower settings extend duration significantly.

Q: Does it support heavy cookware? A: Serrated pallet secures 5-10-pound loads—stable on firm, level surfaces.

Q: How durable is it under intense use? A: Stainless steel and copper withstand high temperatures and weight, ensuring longevity.

Outdoor cooking in 2025 demands a synthesis of technical proficiency and dependable equipment. The 7 Core Strong Fire Power Camping Stove—boasting 16800W, windproof engineering, and durable construction—emerges as a cooking stove exemplar, tested and rated for its capacity to deliver precision and resilience. From rapid boiling to nuanced simmering, it empowers campers to conquer culinary challenges, transforming wilderness provisions into exceptional meals with professional-grade efficiency.

0 notes

Text

Samsung Dg94-03979a Cooktop-Frame Module Hnkparts

The Samsung DG94-03979A Range-Cooktop Frame Module provides stable support for the gas range and increases the safety and reliability of the appliance. This part helps to support the burners and offers the framework for the cooktop. It is simple and it has a clamping system that keeps components in place to ensure even heat and proper cooking.

If you're looking for a reliable replacement, the Samsung Cooktop-Frame Module is an excellent choice for the smooth operation of your home appliance

0 notes

Text

The Complete Guide to Spare Parts for Commercial Gas and Electric Fryer Systems

In a busy commercial kitchen, commercial electric fryers and commercial gas fryers are essential for producing crispy, golden delights in record time. But like any hardworking equipment, they need regular maintenance and occasional part replacements to keep running smoothly. Whether you rely on a commercial electric fryer or a commercial gas fryer, understanding the essential spare parts can save you from unexpected breakdowns and costly downtime. Let’s dive into the world of commercial electric fryer spare parts and commercial gas fryer spare parts.

, understanding the essential spare parts can save you from unexpected breakdowns and costly downtime. Let’s dive into the world of commercial electric fryer spare parts and commercial gas fryer spare parts.

The Importance of Regular Maintenance

Maintaining your commercial fryer isn’t just about extending its lifespan — it’s about ensuring safety, consistency, and efficiency in every batch of fried food. Replacing worn-out commercial electric fryer spare parts and commercial gas fryer spare parts in a timely manner prevents breakdowns and minimizes the risk of accidents in a high-heat environment.

Commercial Electric Fryer Spare Parts

Commercial electric fryers heat oil with electric elements and require several specialized parts to function properly. Some key commercial electric fryer spare parts to keep in stock include:

Heating Elements: These are responsible for heating the oil and are crucial for maintaining the right cooking temperature.

Thermostats: Regulate the oil temperature, ensuring consistent frying results.

Control Panels: House the buttons, digital displays, and settings — crucial for user control.

Power Switches: Allow you to turn the fryer on and off; a malfunctioning switch can disrupt your entire workflow.

Indicator Lights: Offer visual feedback on the fryer’s status and may burn out with regular use.

Wiring and Connectors: Ensure a stable power connection, which is vital for safe and consistent performance.

Commercial Gas Fryer Spare Parts

Commercial gas fryers use a direct flame to heat the oil, requiring a different set of components for proper functioning. Essential commercial gas fryer spare parts include:

Gas Valves: Regulate the flow of gas to the burner, making them critical for safety and efficiency.

Burner Assemblies: Provide the heat source for the oil, ensuring even cooking.

Thermocouples: Automatically shut off the gas supply if the pilot light goes out, preventing gas leaks.

Pilot Lights: Ignite the burner and keep the flame steady; essential for proper operation.

Pressure Regulators: Maintain steady gas pressure, ensuring consistent heating.

Ignition Modules: Create the spark necessary to ignite the gas, keeping your fryer ready to cook.

Pro Tips for Fryer Maintenance

Regular Inspections: Catch wear and tear early by checking commercial electric fryer spare parts and commercial gas fryer spare parts frequently.

Deep Cleaning: Prevent buildup around heating elements and burners.

Stock Up on Spares: Keep key commercial electric fryer spare parts and commercial gas fryer spare parts on hand to avoid long downtimes.

Call the Pros: Schedule regular checkups with a qualified technician to keep your fryer in peak condition.

By staying on top of fryer maintenance and keeping the right commercial electric fryer spare parts and commercial gas fryer spare parts in stock, you can ensure your kitchen runs smoothly day in and day out. Don’t let a simple part failure slow you down — be prepared and keep those fryers sizzling!

0 notes

Text

A reputable modulating burner manufacturer offers cutting-edge heating solutions designed for precision, energy efficiency, and environmental compliance. Modulating burners are essential in industries where consistent temperature control and variable heat demand are critical — such as food processing, pharmaceuticals, petrochemicals, and HVAC systems.

Unlike traditional on-off or two-stage burners, modulating burners adjust the flame continuously, allowing seamless control of the burner output based on the exact heating load. This results in lower fuel consumption, reduced emissions, and extended equipment life. Leading manufacturers design modulating burners to work with natural gas, propane, biogas, and dual-fuel systems.

Top-tier modulating burner manufacturers focus on innovation, integrating advanced control systems, electronic servos, and precise fuel-air ratio monitoring. These features help minimize temperature fluctuations and improve process consistency, making modulating burners a smart investment for long-term performance.

When selecting a modulating burner manufacturer, look for companies that offer custom solutions, energy audits, technical support, and compliance with international safety standards such as CE, UL, or ISO certifications. The best manufacturers provide burners in various capacities to meet the specific needs of industrial ovens, boilers, dryers, and kilns.

Choosing the right modulating burner manufacturer ensures maximum efficiency, reduced operational costs, and optimal performance in even the most demanding environments. Whether you're upgrading an outdated system or installing a new one, a quality modulating burner is key to achieving precise, reliable heat control.

#industrial gas burner#duel fuel weishaupt burner#weishaupt burner#combustion burners manufacturer#monarch weishaupt burner#industrial gas burner suppliers#industrial burner repair#weishaupt burners#burner spare parts#modulating burner manufacturer#modulating gas burner#monoflame oil burner spares

0 notes

Text

Not only JP-7: the SR-71 could use JP-4 and JP-5 as emergency fuels but they both limited the Blackbird top speed to Mach 1.5

JP-7, the fuel that powered the SR-71 Blackbird caused a nationwide shortage of bug spray. Here’s why.

The SR-71 Blackbird was the first aircraft to use its own fuel for hydraulic fluid. It was called the fuel hydraulic system.

The legendary SR-71 Blackbird Mach 3+ spy plane was powered by two 34,000 lbf (151,240 N) thrust-class J58 afterburning turbojet engines. Each engine contained a nine-stage compressor driven by a two-stage turbine. The main burner used an eight-can combustor and the afterburner is fully modulating. The primary nozzle area was variable. Above Mach 2.2, some of the airflow was bled from the fourth stage of the compressor and dumped into the augmentor inlet through six bleed-bypass tubes, circumventing the core of the engine and transitioning the propulsive cycle from a pure turbojet to a turbo-ramjet.

The SR-71 was the first aircraft to use its own fuel for hydraulic fluid. It was called the fuel hydraulic system.

An engine-driven pump provided 1800 psi of recirculating fuel to accurate various engine components and then returned it back to the aircraft fuel system to be burned. Fuel was used in the actuators to control the afterburner nozzles, which maintain the proper exhaust gas temperature and control the thrust output. The fuel was also used in the engine actuators to shift the two-position inlet guide veins from their axial position to the cambered position and back again. This was just another of the many first-ever inventions of the-SR-71.

The J58 engine was hydromechanically controlled and burned a special low volatility jet fuel mixture known as JP-7.

SR-71 print

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. SR-71A Blackbird 61-7972 “Skunkworks”

Emergency fuels could be used in the SR-71 if the crew was low on fuel and had to use ANY tanker (as already explained the Blackbird relied on KC-135Q tankers [that could simultaneously carry a maximum of 74,490lb of JP-7 and 110,000lb of JP-4 for their own engines] but the SR-71 could also be refueled by standard Stratotankers in the event KC-135Qs were not available or if the Blackbird crew had to deal with an emergency situation) they could find to avoid the loss of the aircraft. The emergency fuels were JP-4 or JP-5 but they limited the Blackbird top speed to Mach 1.5. There were six main fuselage tanks. All 80,285 pounds of JP-7 fuel were carried in six main fuselage tanks. The tanks numbered one through six moved forward to aft (back) tank 6B It could hold 7,020 pounds of gravity-fed fuel and two tanks sumps. This was also called the “doghouse” and was located in the extreme back portion of the fuselage.

These are just a few interesting facts that I found by reading Rich Graham’s “SR 71 Revealed the inside story.” This book was published in 1996 before some of the facts about the SR-71 became unclassified. Last year when I was visiting SR-71 #972 one of my Grandson’s friends asked me “Why is this airplane so big? My immediate answer was… they needed the room to hold as much fuel as possible.

Fuel was the lifeblood of this fastest-manned airplane in the world.

Be sure to check out Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer) Facebook Pages Habubrats SR-71 and Born into the Wilde Blue Yonder for awesome Blackbird’s photos and stories.

19 notes

·

View notes

Text

Raypak 007374F Hot Surface Ignition Module

The Raypak 007374F Hot Surface Ignition Module, also known as part number 35-673902-561, is a crucial component in modern HVAC systems, particularly for gas-fired heating applications. Measuring 9" × 9" × 9" this module operates at a voltage of 24V. It is designed to ignite the burner in gas-fired units using hot surface ignition technology. This technology involves a heated element that lights the gas burner, ensuring a reliable and efficient start-up of the heating system. The Raypak 007374F is ideal for use in residential and commercial HVAC systems that require precise and reliable ignition for optimal performance. Its benefits include increased reliability in ignition, reduced maintenance needs, and improved heating system efficiency. By ensuring a consistent ignition process, this module helps maintain stable operation and extends.

Improve your pool system with the Raypak Hot Surface Ignition Module for reliable performance and efficiency.

#Raypak#007374F#HotSurfaceIgnitionModule#usapoolshop#poolequipmentparts#poolparts#poolmaintenance#swimmingpoolparts

0 notes

Text

Gas Structured Heating Melbourne: Smart Solutions for a Sustainable Winter

Melbourne winters are notorious for their biting winds and damp chill. The search for effective and sustainable heating solutions is a constant pursuit for homeowners and businesses alike. Forget the days of inefficient and costly heating systems; the future of winter warmth lies in innovative approaches like Gas Structured Heating Melbourne, a system designed for both performance and environmental responsibility. It's about more than just staying warm; it's about doing so intelligently and sustainably. This blog will explore how gas structured heating can revolutionize your winter experience.

Finding the right climate control solution in Melbourne can be tricky. When winter hits, the need for a reliable heating system becomes paramount. Choosing the right system means balancing performance with energy efficiency. This is where gas structured heating excels. However, many people overlook the convenience and efficiency of a Reverse Cycle Heating and Cooling Melbourne system for year-round climate control. This approach combines both heating and cooling into a single unit, maximizing space and offering cost-effective operation across all seasons. Considering this option alongside gas structured heating is crucial for a comprehensive home comfort strategy.

Beyond the initial comfort factor, the rising cost of energy is a significant concern for many Melburnians. Traditional heating methods can be incredibly expensive, putting a strain on household budgets. Gas Structured Heating Melbourne offers a compelling alternative. This system operates by distributing warm air evenly throughout your home, eliminating cold spots and ensuring consistent temperatures in every room. This uniform heating contributes to better energy efficiency. Less energy used means lower utility bills and a smaller environmental footprint. Let’s delve into the specific benefits of choosing gas structured heating for your Melbourne home.

The Advantages of Gas Structured Heating in Melbourne:

Energy Efficiency: Gas structured heating systems are designed for optimal fuel consumption. Modern units incorporate features like modulating burners and smart thermostats, allowing them to adjust their output based on the actual heating demand. This prevents overheating and minimizes wasted energy, resulting in significant cost savings over time. The initial investment may be higher than traditional systems, but the long-term savings often outweigh the upfront cost.

Consistent and Comfortable Heating: Unlike some heating systems that create hot and cold spots, gas structured heating provides a consistent flow of warm air throughout your home. The strategic placement of vents and ducts ensures that every room is evenly heated, creating a comfortable and inviting environment for you and your family. This consistent temperature control is particularly beneficial for households with young children or elderly individuals who are more susceptible to temperature fluctuations.

Environmentally Conscious: While gas is still a fossil fuel, modern gas structured heating systems are significantly more environmentally friendly than older, less efficient models. They produce lower emissions and consume less fuel, helping to reduce your carbon footprint. Furthermore, many systems are compatible with renewable energy sources, such as solar panels, allowing you to further reduce your reliance on fossil fuels.

Enhanced Air Quality: Gas structured heating systems can be integrated with air filtration systems to improve indoor air quality. These filters remove dust, pollen, and other allergens from the air, creating a healthier living environment for allergy sufferers and individuals with respiratory conditions. Many modern systems also feature air purification technology that eliminates bacteria and viruses, further enhancing indoor air quality.

Zoning Capabilities: Gas structured heating systems can be divided into zones, allowing you to control the temperature in different areas of your home independently. This is particularly useful for large homes or homes with multiple levels, as it allows you to heat only the areas that are being used, further reducing energy consumption. For example, you can set a lower temperature in bedrooms during the day and a higher temperature in the living room in the evening.

Considerations When Choosing Gas Structured Heating:

Installation Costs: The initial cost of installing a gas structured heating system can be higher than that of other heating options, such as electric heaters or window air conditioners. However, it's essential to consider the long-term cost savings associated with energy efficiency. Request quotations from several installers to compare pricing and discover the best bargain.

Professional Installation: Gas structured heating systems must be installed by qualified and licensed professionals. This ensures that the system is installed correctly and safely and that it complies with all relevant building codes and regulations. Improper installation might result in safety risks and lower efficiency.

Maintenance: Like all heating systems, gas structured heating systems require regular maintenance to ensure optimal performance and longevity. Schedule annual checkups with a qualified technician to inspect the system, clean the burners, and check for leaks or other issues. Proper maintenance will help to prevent costly repairs and extend the lifespan of your system.

Looking Ahead: The Future of Sustainable Heating

The future of heating in Melbourne is undoubtedly moving towards more sustainable and energy-efficient solutions. Gas structured heating, with its ability to integrate with renewable energy sources and offer precise temperature control, is at the forefront of this trend. As technology continues to advance, we can expect even more innovative heating solutions that prioritize both comfort and environmental responsibility. Embracing gas structured heating in Melbourne is a step towards a more sustainable and comfortable winter. By choosing an energy-efficient system and taking advantage of features like zoning and air filtration, you can create a warm and inviting home environment while reducing your carbon footprint and saving money on energy bills. If you’re looking for reliable and efficient heating solution contact Hitech Air Solution, we will guide you in best way possible. So, this winter, consider investing in gas structured heating for a warmer, greener, and more comfortable future.

#gas ducted heating installation melbourne#aircon installation company melbourne#gas ducted heating melbourne#duct work installation melbourne#split air-conditioning installation melbourne#air conditioning maintenance melbourne#aircon repair shop melbourne#heating repair melbourne#reverse cycle ducted heating and cooling melbourne#air conditioning repair melbourne

1 note

·

View note

Text

The Krom Schroder VK 40R10MXA43D Motorized Valve is a high-performance industrial valve designed for precise gas flow control. Engineered for reliability and efficiency, it is ideal for combustion systems, heating applications, and industrial automation. This motorized valve ensures smooth operation, enhanced safety, and long-lasting durability. Its advanced design allows for accurate modulation, making it a trusted choice in the automation industry. Whether used in gas burners or process heating, the VK 40R10MXA43D guarantees optimal performance. Explore more high-quality industrial equipment at Auto2mation. Get the best in manufacturing automation today!

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Automation#manufacturing#control valve#krom schroder

0 notes

Text

Southbend 1175723 Ignition Control Module | PartsFe

The Southbend 1175723 Ignition Control Module is a high-performing and essential part made for commercial kitchen ranges. Approximately 5 inches in length, 3.25 inches in width, and 1.5 inches in height, this guarantees safe and proper lighting of burners. It does this by providing specific signals to fire the gas in the kitchen without frequent blips, which improves the safety of the kitchen. Designed for high work load, it offers maximum performance in conditions that require higher levels of output. Advantages include increased energy conservation, low maintenance, and increased product longevity, making it a worthy addition to any professional kitchen.

To keep your restaurant running smoothly, it's crucial to invest in Southbend Ignition Control Module that ensure long-lasting performance.

#1175723#Southbend#Ignition Control Module#partsfe#partsfebuzz#restaurantowner#restaurantequipmentparts#kitchenequipmentparts#foodserviceparts

0 notes

Text

Gas Steam Boilers and Sustainability: A Greener Heating Option

Gas steam boilers are an efficient and reliable heating solution for residential, commercial, and industrial applications. Compared to traditional coal or oil-fired boilers, modern gas steam boilers produce lower emissions, reducing their environmental impact. They operate with high energy efficiency, utilizing natural gas or biogas to generate steam for heating and other processes. Advanced condensing models further enhance efficiency by capturing and reusing heat from exhaust gases. With stricter environmental regulations and the growing demand for sustainable energy solutions, gas steam boilers provide a cleaner alternative while maintaining performance. By integrating smart controls and renewable energy sources, they contribute to reduced carbon footprints and energy conservation, making them a key component of eco-friendly heating systems.

Understanding Gas Steam Boilers

A gas steam boiler is a heating system that uses natural gas or propane as fuel to generate steam. The process involves burning gas in a combustion chamber, which heats water in a boiler to produce steam. This steam is then distributed for various heating applications, such as space heating, industrial processes, and power generation.

Modern gas steam boilers come with advanced control systems, improved burner designs, and high-efficiency heat exchangers, making them an ideal choice for sustainable heating.

Energy Efficiency of Gas Steam Boilers

Energy efficiency is a crucial factor in determining the sustainability of any heating system. Gas steam boilers are designed to maximize heat output while minimizing fuel consumption. Key efficiency features include:

Condensing Technology: Captures and utilizes latent heat from exhaust gases, improving overall efficiency.

Modulating Burners: Adjust fuel supply based on demand, reducing wastage.

Heat Recovery Systems: Reuse waste heat to enhance energy efficiency.

With these advancements, modern gas steam boilers can achieve efficiency levels of over 90%, making them a cost-effective and environmentally friendly option.

Environmental Benefits of Gas Steam Boilers

Compared to traditional coal or oil-fired boilers, gas steam boilers produce significantly lower emissions. The environmental advantages include:

Reduced Carbon Dioxide (CO₂) Emissions: Natural gas burns cleaner than coal and oil, leading to lower CO₂ output.

Lower Nitrogen Oxide (NOₓ) Emissions: Advanced burner technology helps minimize NOₓ, a major contributor to air pollution.

Minimal Sulfur Dioxide (SO₂) Emissions: Unlike coal, natural gas has negligible sulfur content, reducing acid rain risks.

By using gas steam boilers, businesses and homeowners can reduce their carbon footprint while maintaining reliable heating.

Gas Steam Boilers and Renewable Energy Integration

One of the key aspects of sustainability is the ability to integrate with renewable energy sources. Gas steam boilers can complement green energy systems in the following ways:

Hybrid Heating Systems: Can work alongside solar thermal or biomass heating systems to optimize energy use.

Green Hydrogen Compatibility: Some modern gas steam boilers can be modified to run on hydrogen, reducing reliance on fossil fuels.

Waste Heat Utilization: Industries can use waste heat from gas steam boilers to generate electricity, further improving sustainability.

By incorporating renewable energy sources, gas steam boilers become even more environmentally friendly.

Cost Savings and Economic Benefits

Apart from sustainability, gas steam boilers offer significant economic benefits:

Lower Fuel Costs: Natural gas is often cheaper than oil or electricity for heating.

Government Incentives: Many countries provide tax credits or rebates for installing high-efficiency gas steam boilers.

Reduced Maintenance Expenses: Modern gas steam boilers require less maintenance compared to older models, saving long-term costs.

These factors make gas steam boilers a financially viable choice for both commercial and residential users.

Regulations and Standards for Sustainable Boiler Use

Governments and environmental organizations have implemented strict regulations to ensure sustainable boiler operations. Compliance with these standards is essential for businesses and homeowners using gas steam boilers. Key regulations include:

Energy Efficiency Standards: Mandates for higher boiler efficiency ratings.

Emission Control Policies: Limits on CO₂ and NOₓ emissions from boilers.

Periodic Inspections and Maintenance: Regular checks to ensure optimal performance and environmental compliance.

Adhering to these standards helps users maximize efficiency while minimizing environmental impact.

Future of Gas Steam Boilers in a Sustainable World

The future of gas steam boilers lies in continuous innovation and adaptation to cleaner energy sources. Some emerging trends include:

Hydrogen-Powered Boilers: Development of boilers that run entirely on hydrogen to eliminate carbon emissions.

Smart Boiler Technology: AI-driven control systems that optimize fuel usage and maintenance schedules.

Carbon Capture and Storage (CCS): Techniques to capture CO₂ emissions and prevent them from entering the atmosphere.

As technology advances, gas steam boilers will play a vital role in the transition toward a greener and more energy-efficient world.

Conclusion

Gas steam boilers represent a sustainable heating option due to their high efficiency, lower emissions, and adaptability to renewable energy sources. With ongoing advancements in technology, they are becoming even more environmentally friendly and cost-effective. As regulations push for cleaner energy solutions, the future of gas steam boilers remains promising in creating a greener and more sustainable heating industry.

0 notes

Text

Lincoln 369532 Single Trial Ignition Control | PartsFe Canada

The Lincoln 369532 is a single trial ignition control module, designed for Lincoln commercial ovens. This module initiates the ignition sequence for the oven's burners, generating the high voltage spark needed to ignite the gas.

To keep your restaurant running smoothly, it's crucial to invest in Lincoln Single Trial Ignition Control That ensure long-lasting performance

#Lincoln#LincolnParts#369532#Ignitioncontrol#Partsfe#PartsFeCanada#Partsfebuzz#restaurantowner#restaurantequipmentparts#kitchenequipmentparts

0 notes