#modified atmosphere packaging (MAP)

Explore tagged Tumblr posts

Text

Modified Atmosphere Packaging (MAP) Explained | Crystal Media

Know what is Modified Atmosphere Packaging (MAP) and its benefits. Explore MAP packaging types, applications, and how they preserve freshness in food packaging.

0 notes

Text

Mastering MAP Leak Testing: A Comprehensive Guide by Seal Tick

In the fast-paced world of food packaging, ensuring the integrity of Modified Atmosphere Packaging (MAP) is paramount. MAP offers extended shelf life and freshness, but any leaks can compromise product safety and quality. That's where MAP leak testing comes into play, and Seal Tick is here to guide you through the process.

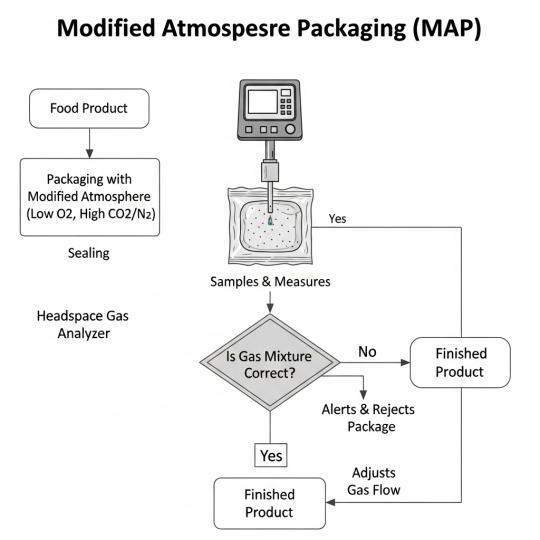

Understanding Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves altering the atmosphere inside a package to extend the shelf life of perishable products. By adjusting gas compositions, typically with a mix of oxygen, carbon dioxide, and nitrogen, MAP slows down the deterioration process, preserving freshness and quality.

Importance of MAP Leak Testing

MAP leak testing is essential to ensure the integrity of the packaging. Even a tiny leak can lead to an influx of oxygen or other gases, accelerating spoilage and compromising product safety. Leak testing helps identify and rectify any issues before products reach consumers, maintaining brand reputation and reducing product waste.

Types of MAP Leak Testing

Several methods are used for MAP leak testing, each with its advantages and limitations:

Bubble Emission Testing: Submerging packages in water and observing bubble formation indicates leaks.

Vacuum Decay Testing: Applying a vacuum to packages and monitoring pressure changes to detect leaks.

Pressure Decay Testing: Measuring pressure changes within a sealed package to identify leaks.

Gas Analysis Testing: Analyzing gas composition within packages to detect any deviations.

Electronic Sensing: Using electronic sensors to detect changes in gas composition or pressure.

Choosing the right method depends on factors like package size, material, and production volume.

Seal Tick: Your Partner in MAP Leak Testing

Seal Tick specializes in providing reliable and efficient MAP leak testing solutions. With years of experience in the industry, Seal Tick understands the unique challenges of MAP packaging and offers tailored testing equipment to meet your specific needs.

Our Range of MAP Leak Testing Equipment

Seal Tick offers a diverse range of MAP leak testing equipment, including:

Seal Tick MAP Leak Testers: High-precision instruments designed for accurate and efficient leak detection.

Portable Leak Testing Devices: Compact and portable solutions for on-the-go testing.

Customized Testing Solutions: Tailored systems to accommodate unique packaging requirements.

Benefits of Seal Tick MAP Leak Testing Equipment

Choosing Seal Tick for your MAP leak testing needs offers numerous benefits:

Accuracy: Our equipment ensures precise leak detection, minimizing false positives and negatives.

Efficiency: Streamlined testing processes save time and resources, improving productivity.

Reliability: Seal Tick equipment is robust and dependable, providing consistent results.

Versatility: Our testing solutions are adaptable to various packaging formats and materials.

Compliance: Meet regulatory standards and customer expectations with confidence.

Conclusion

Mastering MAP leak testing is crucial for maintaining the quality and safety of packaged products. With Seal Tick as your partner, you can ensure the integrity of your Modified Atmosphere Packaging, safeguarding your brand reputation and consumer satisfaction. Choose Seal Tick for reliable and efficient MAP leak testing solutions tailored to your unique requirements.

Click Here For Information: https://sealtick.com/modified-atmosphere-packaging-testing/

Contact Us For More Information

Phone Number: 0395405100

Fax Number: 0395515541

Email: [email protected]

Address: Unit 14 44 Garden Blvd Dingley VIC Australia 3172

0 notes

Text

From Plastic to Plant-Based: The Frozen Food Packaging Shift You Didn’t See Coming

Frozen Food Packaging Market Introduction:

The frozen food packaging market industry is undergoing a profound transformation, driven by technological innovation, evolving consumer behaviors, and regulatory pressure for sustainable solutions. With the frozen food packaging market poised to exceed USD 79.2 billion by 2032, stakeholders must align with emergent trends, embrace cutting-edge materials, and position themselves to thrive in a landscape increasingly shaped by eco-conscious demand and intelligent packaging.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40599-global-frozen-food-packaging-market-trends

📈 Market Growth Trajectory: Trends Shaping the Frozen Food Packaging Sector

We anticipate a steady CAGR of over 5.9% through 2032, propelled by an upsurge in demand for ready-to-eat meals, convenience-oriented lifestyles, and the evolution of sustainable packaging technologies. This growth is underpinned by several macro and microeconomic forces:

Urbanization and Dual-Income Households: Higher time constraints are fostering dependence on frozen food solutions.

Technology-Driven Packaging: Innovations in smart packaging such as time-temperature indicators and modified atmosphere packaging (MAP) are setting new quality benchmarks.

Global Sustainability Mandates: Regulatory frameworks and environmental awareness are fueling the shift toward recyclable and compostable materials.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40599-global-frozen-food-packaging-market-trends

🛠️ Material Innovation in Packaging: Dominance, Disruption, and Direction

Plastic Packaging: Efficiency Meets Environmental Scrutiny

Plastic remains the cornerstone of frozen food packaging due to its flexibility, moisture resistance, and cost-effectiveness. Representing 63% of market share in 2023, the segment is evolving through the integration of bio-based polymers, mono-material films, and closed-loop recycling systems.

However, environmental pressure is catalyzing the adoption of low-impact alternatives:

Polylactic Acid (PLA)

Polyhydroxyalkanoates (PHA)

Recyclable Polyethylene (rPE)

Paper & Paperboard: Recyclable and Renewable

Emerging as a viable substitute to plastics, paper-based materials are gaining favor in applications like tray linings, cartons, and wraps—particularly when paired with biopolymer coatings that enhance barrier properties without sacrificing recyclability.

🍽️ Product Segmentation: Custom Packaging Solutions for Diversified Categories

Ready-to-Eat Meals: Packaging for Speed and Shelf Stability

Comprising 39.2% of the frozen food packaging market in 2023, this segment continues its upward trajectory. The packaging solutions here demand:

High barrier properties to retain flavor and freshness

Microwave-safe formats

Portion-controlled trays

Meat, Poultry & Seafood: Insulation and Integrity

These high-protein, perishable goods require advanced materials with anti-leak features, odor barriers, and puncture resistance, along with vacuum-sealed and skin pack options to extend freshness.

Bakery, Dairy, Fruits & Vegetables: Freshness Lock and Visual Appeal

Resealable pouches, gusseted bags, and printed films dominate here, balancing product visibility with functional features like moisture barriers, anti-fog coatings, and nitrogen flushing.

📦 Packaging Types: The Era of Flexibility and Functionality

Flexible Packaging: Lightweight, Low-Cost, and Logistics-Friendly

Holding a commanding 59% share, flexible packaging supports streamlined transportation and storage, while minimizing material usage. Innovations include:

Stand-up pouches

Laminated films

Vacuum bags with oxygen scavengers

Rigid & Semi-Rigid Formats: Premium Presentation with Protection

Rigid containers, often made from polypropylene or PET, are preferred for premium products requiring structural support. Semi-rigid solutions bridge cost and functionality, offering stackability and enhanced sealing performance.

🌍 Regional Leadership: Frozen Food Packaging Market Penetration by Geography

North America: Innovation and Infrastructure

Accounting for 38% of global share in 2023, North America remains a powerhouse due to:

Established cold chain logistics

High per-capita frozen food consumption

Retail giants like Walmart and Kroger expanding private label offerings

Europe: Regulatory Pressure Spurs Eco-Packaging

The EU’s stringent single-use plastic regulations have catalyzed a shift toward fiber-based packaging, home-compostable films, and carbon-neutral production cycles.

Asia-Pacific: Rapid Expansion, Rising Middle Class

Emerging economies like India and China are witnessing explosive growth, with increased penetration of organized retail and online grocery platforms. The region is a hotspot for low-cost sustainable innovation, including cassava starch films and palm fiber trays.

🧠 Smart Packaging: The Next Frontier

The rise of intelligent packaging is revolutionizing frozen food preservation and consumer trust. Examples include:

Time-temperature indicators (TTIs)

QR-coded traceability

Color-changing freshness labels

IoT-enabled tracking for e-commerce logistics

These technologies not only enhance shelf life but also provide real-time data visibility across the supply chain.

🌱 Sustainability Focus: Towards a Circular Packaging Economy

Modern consumers expect more than functionality—they demand environmental stewardship. Frozen food brands are increasingly adopting:

Compostable films derived from corn starch and sugarcane

Mono-material flexible films for improved recyclability

Recycled PET (rPET) and Post-Consumer Resin (PCR) content

Carbon-neutral manufacturing commitments

🧭 Strategic Partnerships & M&A: Market Consolidation and Innovation

The $8.4 billion merger of Amcor Plc and Berry Global Group, Inc. reflects a broader trend of consolidation aimed at enhancing R&D capabilities and global market reach. These mega-alliances are pivotal in:

Accelerating the commercialization of sustainable solutions

Expanding global distribution networks

Optimizing material sourcing through scale economies

Other key players making strategic moves include Sealed Air Corporation, Sonoco Products, and Huhtamaki Group, all of whom are aligning product development with eco-compliance mandates and evolving consumer preferences.

🚚 E-Commerce & DTC: The Packaging Challenge in Cold Logistics

The surge in direct-to-consumer frozen food delivery is redefining packaging requirements:

Insulated liners and phase-change materials

Reinforced outer packaging for last-mile durability

Minimalist design to reduce dimensional weight (DIM weight) charges

These shifts necessitate packaging that balances thermal integrity with cost-efficiency and curbside recyclability.

🧩 Key Takeaways: Market-Ready Strategies

Adopt smart, sensor-integrated packaging to enhance transparency and shelf life.

Invest in R&D for bio-based polymers and recyclable mono-material formats.

Optimize packaging for e-commerce logistics and direct-to-consumer shipment durability.

Align packaging strategies with global regulatory trends and sustainability benchmarks.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40599-global-frozen-food-packaging-market-trends

🔮 Forecast: The Future of Frozen Food Packaging Market

By 2032, the frozen food packaging market landscape will be defined by zero-waste designs, AI-enabled supply chain integration, and hyper-personalized consumer experiences. Companies that innovate toward eco-efficiency, intelligent traceability, and consumer convenience will lead the next evolution of the market.

Now is the time to reimagine packaging—not just as a necessity, but as a strategic differentiator in a dynamic and competitive global market.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Food Processing Revolution: Innovations Shaping the Industry

In the dynamic domain of food processing, innovation serves as the fundamental basis for advancement. The food processing business has seen a significant evolution over time, mostly influenced by technological improvements, shifting customer preferences, and an increasing recognition of the importance of sustainability and health. The revolution in question has had a profound impact on the methods employed in the production, packaging, and consumption of food. Make Vadodara the hub of your efficient food processing. Explore solutions for improved productivity, quality, and compliance at Modern Food Products - ranked among the top companies in the Food processing industry in Vadodara!

This blog post aims to explore the noteworthy advancements that are now affecting the food processing industry and their impact on its overall trajectory.

· Automation and Robotics:

In the dynamic domain of food processing, innovation serves as the fundamental basis for advancement. The food processing business has seen a significant evolution over time, mostly influenced by technological improvements, shifting customer preferences, and an increasing recognition of the importance of sustainability and health. The revolution in question has had a profound impact on the methods employed in the production, packaging, and consumption of food. This blog post aims to explore the noteworthy advancements that are now affecting the food processing industry and their impact on its overall trajectory.

· Internet of Things (IoT) and Data Analytics:

The incorporation of Internet of Things (IoT) technology in the food processing industry enables the continuous monitoring of production lines in real time, hence facilitating the achievement of optimal performance and the reduction of wastage. Internet of Things (IoT) devices have the capability to gather significant data, which can be subjected to analysis in order to enhance process optimisation, forecast maintenance requirements, and enhance overall quality control. The utilisation of data analytics offers significant insights into customer behaviour, hence empowering enterprises to customise their products in accordance with specific tastes.

· 3D Printing in Food Manufacturing:

The utilisation of 3D printing technology in the realm of food manufacturing has garnered significant attention due to its ability to provide novel and tailored solutions for the creation of complicated and personalised food designs. The utilisation of 3D printing technology has the capacity to significantly transform our understanding and production of food, encompassing the creation of distinctive shapes and textures, as well as the printing of customised nutritional profiles. This technological advancement presents promising prospects for fostering culinary innovation and addressing specific nutritional needs.

· Food Preservation and Packaging Innovations:

The primary objectives of advancements in food preservation and packaging are to prolong the duration of shelf life, minimise food wastage, and preserve the nutritious content of food products. In the field of packaging, notable advancements include Modified Atmosphere Packaging (MAP), hoover packaging, and intelligent packaging equipped with embedded sensors for freshness monitoring. These technologies are designed to ensure that consumers are provided with products that are both safe and of high quality, while simultaneously mitigating the environmental consequences associated with packaging.

· Clean Label and Natural Ingredients:

The demand for clean-label products is on the rise among consumers, prompting the food processing industry to embrace natural ingredients that have undergone little processing. The driving force behind this transition is motivated by a strong inclination towards openness and a predilection for nourishing healthful dietary options. Food processors are engaging in the process of reformulation in order to remove artificial additives, preservatives, and synthetic colours from their goods. This strategic action is in accordance with the growing customer preference for healthier alternatives. Join the league of successful Food processing companies in Gujarat. Implement state-of-the-art technologies and witness unprecedented growth. Get in touch with Modern Food Products today!

· Plant-Based and Alternative Proteins:

The emergence of plant-based and alternative protein sources represents a notable transformation in consumer dietary preferences. Food processors are utilising innovative techniques to create plant-based meat alternatives that mimic the sensory attributes, such as taste and texture, of conventional meat products. These inventions play a significant role in promoting sustainability since they effectively mitigate the environmental consequences associated with traditional meat production, all the while accommodating the needs of an expanding group of individuals who follow vegetarian or flexitarian diets.

· Nanotechnology in Food Processing:

The utilisation of nanotechnology in food processing allows for the meticulous manipulation of food characteristics on a molecular scale, resulting in improved sensory attributes such as taste and texture, as well as enhanced nutritional composition. Nanoencapsulation is a technique that facilitates the precise delivery of nutrients to specific targets, hence enhancing the nutritional content of food products through the addition of vital vitamins and minerals. Furthermore, the application of nanosensors is being employed to enhance quality control measures, thereby guaranteeing the safety and freshness of food products across the whole supply chain.

· High-Pressure Processing (HPP):

HPP is a food preservation method that uses elevated pressure levels to eliminate pathogenic microorganisms and prolong the shelf life of food products. This technology achieves these objectives without subjecting the food to thermal treatments, hence preserving its nutritional composition and sensory attributes. The utilisation of this approach is increasingly being recognised for its ability to generate newly produced, secure, and minimally treated goods, thereby satisfying the growing need for uncontaminated and consumer-friendly food items.

Final Thoughts:

The food processing business is currently experiencing a significant transformation propelled by technological advancements, a focus on sustainability objectives, and the changing demands of consumers. These developments are not only exerting a significant influence on the sector but also fundamentally altering our perspectives and patterns of food consumption. The future of food processing encompasses a range of cutting-edge technologies, including automation, robotics, 3D printing, and nanotechnology.

These innovations hold great potential to revolutionise the global food industry and significantly impact the methods by which we sustainably nourish our growing population. Please remain engaged as we see the gradual progression of this transforming expedition into the forthcoming realm of sustenance. Ready to secure a top place in the Food processing industry in Vadodara? Modern Food Products’ expert team in Vadodara is prepared to optimize your operations. Reach out for personalized advice and solutions.

#Food processing companies in Gujarat#Food processing industry in Vadodara#Best food product company in Vadodara#Food product industry in Vadodara#Food Product company in Gujarat#Food product company in India

8 notes

·

View notes

Text

China Medical Plastic Packaging Market Size, Share, Growth, Trends, Revenue, Competitive Analysis, Forecast 2033

The burgeoning demand for medical products, including advanced medical packaging solutions, in China is fueled by its rapidly aging population and increased healthcare expenditure. Moreover, the Chinese government is proactively fostering the growth of the healthcare sector, including the medical packaging market, through policy incentives and substantial investments.

Stringent regulatory standards enforced by the Chinese government regarding medical packaging, focusing on safety and effectiveness, serve as catalysts for the creation of innovative and regulatory-compliant packaging solutions in the country.

Read More: https://www.factmr.com/report/medical-packaging-market#:~:text=What%20was%20the%20Global%20Medical,US%24%2087.5%20billion%20in%202022.

In the realm of healthcare, ensuring the safety and efficacy of medical products is paramount. Among the critical components in maintaining these standards is the packaging used to store and transport medical supplies. China, a global leader in manufacturing, has been at the forefront of innovations in medical plastic packaging, combining safety, functionality, and sustainability to meet the demands of the rapidly evolving healthcare industry.

Medical plastic packaging serves multiple purposes, including protecting products from contamination, ensuring sterility, extending shelf life, and providing user-friendly features. With advancements in technology and materials, China has been able to address these needs effectively while also focusing on sustainability, a growing concern in today's world.

One of the significant advancements in medical plastic packaging is the development of materials with enhanced barrier properties. These materials act as a shield, preventing the permeation of moisture, oxygen, and other gases that can compromise the integrity of medical products. China has invested heavily in research and development to create packaging solutions that offer superior barrier protection, thereby extending the shelf life of pharmaceuticals, medical devices, and other healthcare products.

Moreover, China has been proactive in adopting innovative technologies such as modified atmosphere packaging (MAP) and active packaging systems. MAP involves modifying the atmosphere inside the packaging to create optimal conditions for preserving the quality and safety of the enclosed products. Active packaging systems incorporate elements such as oxygen scavengers or desiccants to actively remove or neutralize harmful substances within the packaging environment. These technologies play a crucial role in maintaining the efficacy of sensitive medical products, especially those prone to degradation or contamination.

In addition to functionality, sustainability has become a key focus in the development of medical plastic packaging. China recognizes the importance of reducing the environmental impact of healthcare packaging, given the significant volume of waste generated by the industry. As such, there has been a shift towards the use of eco-friendly materials and manufacturing processes.

Bio-based plastics derived from renewable sources such as corn starch or sugarcane have gained traction as alternatives to traditional petroleum-based plastics. These materials offer comparable performance while significantly reducing carbon emissions and reliance on finite fossil fuel resources. China has been actively promoting the adoption of bio-based plastics in medical packaging through incentives and regulations aimed at encouraging manufacturers to embrace sustainable practices.

Furthermore, recycling and waste management initiatives have been implemented to minimize the environmental footprint of medical plastic packaging. China has established comprehensive recycling infrastructure and regulations to ensure the proper disposal and recycling of medical waste, including packaging materials. By promoting the circular economy model, wherein materials are recycled and reused to minimize waste generation, China aims to create a more sustainable healthcare ecosystem.

Collaboration between industry stakeholders, including manufacturers, regulators, and healthcare providers, has been instrumental in driving progress in medical plastic packaging in China. By fostering an environment of innovation and collaboration, China has positioned itself as a global leader in this critical sector, contributing to advancements in healthcare delivery and sustainability.

Looking ahead, the future of medical plastic packaging in China holds even greater promise. Continued investments in research and development, coupled with advancements in material science and technology, will enable the development of even more advanced packaging solutions. Moreover, as sustainability becomes an increasingly pressing issue, China will continue to lead the way in implementing eco-friendly practices and driving towards a more sustainable healthcare industry.

In conclusion, China's medical plastic packaging industry stands as a testament to innovation, safety, and sustainability. Through advancements in materials, technology, and environmental stewardship, China has positioned itself as a global leader in providing packaging solutions that meet the evolving needs of the healthcare sector. As the industry continues to grow and evolve, China remains committed to driving progress and ensuring the safety and efficacy of medical products for patients worldwide.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Agriculture Packaging Market Size, Share, Trends, Forecast & Growth Analysis 2034

Agriculture Packaging Market is rapidly evolving, set to grow from $7.19 billion in 2024 to $11.72 billion by 2034, expanding at a CAGR of approximately 5%. As global agricultural activity intensifies to meet the rising food demand, the need for durable, efficient, and sustainable packaging solutions has never been greater. This market encompasses the design and distribution of packaging for seeds, fertilizers, pesticides, grains, fruits, and vegetables. Beyond functionality, modern agriculture packaging emphasizes sustainability, waste reduction, and product shelf life, supporting the transformation of traditional farming into a tech-forward, environmentally conscious industry.

Market Dynamics

Several key forces are shaping the trajectory of the agriculture packaging market. One of the most significant drivers is the rising demand for flexible packaging — especially films, sacks, and pouches — thanks to their lightweight, cost-effectiveness, and ease of handling. Rigid plastics follow closely, favored for their strength and protective qualities.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS33040

An emerging trend that’s reshaping the market is the adoption of biodegradable and recyclable packaging. Environmental concerns, along with increasingly strict regulations, are pushing manufacturers to explore eco-friendly materials such as paper, jute, and bioplastics. Additionally, smart packaging technologies — including vacuum sealing, modified atmosphere packaging (MAP), and intelligent labeling — are gaining ground, offering better traceability, product monitoring, and safety assurance throughout the supply chain.

On the other hand, the market faces challenges such as fluctuating raw material prices, regulatory compliance costs, and the lack of infrastructure for recycling and composting in several regions. Despite these hurdles, innovation continues to drive growth and adaptability within the industry.

Key Players Analysis

The agriculture packaging market features a competitive landscape filled with established names and emerging disruptors. Amcor, Mondi, and Sonoco Products Company lead the charge, known for their extensive product portfolios and strong global presence. These companies invest heavily in research and development, focusing on sustainable packaging materials and advanced manufacturing techniques.

Other influential players include Sealed Air, Smurfit Kappa, DS Smith, Berry Global, and Bemis Company. These organizations are exploring next-gen solutions such as biodegradable films, compostable trays, and IoT-integrated packaging to improve operational efficiency and sustainability.

Emerging players like Greif, Huhtamaki, and Winpak are entering the arena with focused innovations in customized packaging formats and region-specific products, catering to the evolving needs of farmers and agribusinesses.

Regional Analysis

Asia-Pacific dominates the agriculture packaging market, led by countries like China and India, where agricultural expansion and modernization are on a fast track. Government support, growing food demand, and increasing awareness of sustainable practices contribute to strong market performance in this region.

North America comes in second, primarily driven by the United States, where the agricultural sector is highly industrialized and technologically advanced. The region sees significant adoption of biodegradable materials and smart packaging technologies, driven by regulatory pressures and eco-conscious consumers.

Europe is another key region, with countries such as Germany and France leading due to their strong emphasis on environmental responsibility. The European Union’s stringent packaging waste directives have encouraged companies to invest in greener alternatives and innovative product designs.

Latin America, especially Brazil and Argentina, presents high growth potential due to the expansion of agri-exports and increased investment in value-added packaging. Middle East and Africa are emerging markets, where countries like South Africa and Egypt are beginning to adopt better packaging technologies to reduce post-harvest losses and improve food supply chains.

Recent News & Developments

The agriculture packaging landscape is buzzing with innovation. Amcor recently partnered with a leading agri-tech firm to develop packaging solutions that reduce environmental impact. Mondi Group launched a new line of fully recyclable paper-based bags, while Smurfit Kappa expanded its operations in Eastern Europe with a facility focused solely on agricultural packaging.

Moreover, BASF has entered a joint venture with a packaging technology company to create advanced biodegradable packaging solutions, signaling a shift toward green transformation across the industry. Meanwhile, the European Union’s new regulations on single-use plastics are pushing packaging companies to accelerate innovation and compliance strategies.

Browse Full Report : https://www.globalinsightservices.com/reports/agriculture-packaging-market/

Scope of the Report

This report provides a deep dive into the global agriculture packaging market, covering market segmentation by material type, product form, application, technology, and geography. It offers a detailed look at market drivers, challenges, competitive landscape, and emerging trends, helping stakeholders understand the evolving dynamics of this critical industry.

As sustainability, technology, and efficiency continue to reshape agriculture packaging, businesses that embrace innovation, eco-conscious practices, and smart solutions will thrive in this expanding landscape.

#agriculturepackaging #sustainablepackaging #greenagriculture #smartpackaging #biodegradablematerials #foodsecuritysolutions #agritech #packaginginnovation #farmtotable #ecofriendlypackaging

Discover Additional Market Insights from Global Insight Services:

Caraway Seeds Market : https://www.globalinsightservices.com/reports/caraway-seeds-market/

Cashew Milk Market : https://www.globalinsightservices.com/reports/cashew-milk-market/

Chinese Takeout Market : https://www.globalinsightservices.com/reports/chinese-takeout-market/

Cognac and Brandy Market : https://www.globalinsightservices.com/reports/cognac-and-brandy-market/

Dehydrated Garlic Market : https://www.globalinsightservices.com/reports/dehydrated-garlic-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

How Linpack’s Solutions Help the Dairy Industry Stay Fresh

In the fast-paced and highly perishable world of dairy products, freshness isn’t just a preference—it’s a necessity. From milk and cheese to yogurt and butter, every dairy product demands strict quality control, temperature regulation, and protective packaging to preserve its shelf life. This is where Linpack, a leading name in vacuum packaging technology, steps in with innovative solutions tailored for the dairy industry. Let’s dive into how Linpack’s packaging solutions play a pivotal role in maintaining freshness, reducing waste, and enhancing safety in dairy production and distribution.

The Challenges of the Dairy Industry

The dairy industry faces unique challenges when it comes to product preservation:

Short Shelf Life: Milk and many other dairy items spoil quickly due to microbial growth.

Temperature Sensitivity: Dairy must be stored and transported at consistent, cold temperatures.

Oxygen Sensitivity: Exposure to air leads to oxidation and spoilage.

Contamination Risk: Products must be sealed hygienically to avoid bacterial contamination.

Sustainability Demands: Consumers and retailers are pushing for environmentally friendly packaging solutions.

To address these challenges, dairy processors need more than just good refrigeration—they need advanced, reliable packaging solutions that work in tandem with the cold chain.

Linpack’s Vacuum Packaging: A Game Changer

Linpack has developed a range of vacuum packaging machines and systems that directly tackle the issues above. vacuum packaging machine Here’s how their technology benefits the dairy sector:

1. Extended Shelf Life through Vacuum Sealing

Oxygen is the enemy of dairy freshness. Linpack’s vacuum packaging machines remove air from the package before sealing, effectively slowing down microbial activity and oxidation. This process significantly extends the shelf life of products like:

Hard and semi-hard cheeses

Yogurt cups and pouches

Butter blocks

Milk-based snacks and desserts

By creating an oxygen-free environment, Linpack’s vacuum solutions help preserve the taste, texture, and nutritional value of dairy products.

2. Hygienic Packaging Environments

In dairy processing, hygiene is non-negotiable. Linpack’s machines are designed to meet the highest standards of cleanliness and food safety:

Stainless steel frames prevent rust and corrosion.

Smooth surfaces ensure easy cleaning and sanitation.

Machines support HACCP and other international food safety protocols.

This minimizes the risk of cross-contamination and aligns with industry standards for sanitary design.

3. Modified Atmosphere Packaging (MAP)

Linpack doesn’t stop at vacuum packaging. For specific dairy products, they offer Modified Atmosphere Packaging (MAP) systems. These systems replace oxygen with inert gases like nitrogen or carbon dioxide, which help inhibit spoilage without the need for preservatives.

For example:

Cream cheese and soft cheese benefit from MAP to maintain their creamy texture and prevent mold growth.

Yogurt-based drinks and probiotic items retain their live cultures better with the right atmosphere mix.

This customized approach gives dairy producers greater control over product freshness and appeal.

Real-World Applications of Linpack Technology

Here are a few examples of how Linpack’s packaging systems are applied in real-world dairy scenarios:

A. Cheese Packaging

Vacuum-sealed cheese blocks are a staple in supermarkets. Linpack machines are used to package both bulk and retail-size cheese portions in film that conforms tightly to the product shape. This keeps the cheese protected from drying out, molding, or developing off-flavors.

B. Milk Pouch Packing

Linpack’s form-fill-seal machines are ideal for packing pasteurized milk in pouches. These machines offer high-speed automation with precision sealing, reducing leakage and ensuring consistent output for large dairy processors.

C. Yogurt Cup Sealing

For single-serve yogurts, Linpack’s cup sealing machines offer tamper-evident, airtight seals that keep the product fresh and safe on store shelves. These systems also support branding with printed lidding films, enhancing visual appeal.

D. Butter and Ghee Blocks

Linpack vacuum chambers are widely used to package butter and ghee in bricks or blocks. These machines ensure minimal exposure to air and moisture, powder packaging machines which is crucial for products stored at room temperature in some regions.

Boosting Sustainability in Dairy Packaging

Sustainability is more important than ever. Linpack supports eco-conscious dairy brands with several initiatives:

Recyclable films: The company offers packaging material options that are 100% recyclable or biodegradable.

Minimal material use: Vacuum packaging reduces the need for bulky containers, lowering plastic consumption.

Energy-efficient machines: Linpack’s latest models are designed to consume less energy while maximizing output.

This helps dairy companies meet environmental goals without compromising product integrity.

Enhanced Branding and Shelf Appeal

In addition to preserving freshness, Linpack packaging systems also help dairy brands stand out on the shelf:

Clear vacuum-sealed films showcase the product quality.

Custom shapes and sizes give flexibility in branding.

High-definition printed films allow logos, nutrition info, and QR codes to be added seamlessly.

With Linpack, companies don’t have to choose between protection and presentation—they get both.

Supporting Small and Large Dairy Businesses Alike

Linpack’s wide product range includes compact machines for local dairies and high-throughput systems for large-scale operations. Whether you're a small artisanal cheese maker or a multinational milk processor, Linpack has a solution to match your production scale, budget, and packaging format.

Table-top vacuum sealers for small batches

Automatic vacuum chamber lines for industrial use

Rotary and inline cup fillers for continuous yogurt production

This versatility makes Linpack a reliable partner across the entire dairy ecosystem.

The Linpack Advantage

What sets Linpack apart from competitors?

Over two decades of experience in packaging innovation

Global presence with customer support and service across continents

Customized machine solutions tailored to specific dairy needs

Commitment to R&D for continually improving machine performance

Their mission is not just to sell machines, but to help dairy brands deliver consistently fresh, safe, and high-quality products to consumers.

Final Thoughts

In the dairy industry, freshness is the foundation of consumer trust. With the help of Linpack’s cutting-edge vacuum and MAP packaging solutions, dairy businesses can confidently protect their products from spoilage, contamination, and waste. From farm to fridge, Linpack ensures every drop of milk, every slice of cheese, and every spoon of yogurt reaches the customer as fresh as the moment it was made.

If you're in the dairy industry and looking to future-proof your packaging operations, Linpack is the partner you need to stay fresh, competitive, and sustainable in today’s evolving marketplace.

0 notes

Text

Freshness Sealed: How Headspace Gas Analyzers Revolutionize Food Packaging

Why Headspace Analysis Matters More Than Ever

Every bite of packaged food relies on an invisible atmosphere. Even tiny amounts of leftover oxygen can trigger spoilage, off-flavors, or mold long before the “best-by” date. Headspace gas analyzers measure O₂, CO₂, and N₂ right inside sealed packages—without opening them—so you catch packaging faults or gas-mix errors in real time.

Ensuring MAP Integrity on the Line

Modified Atmosphere Packaging (MAP) swaps ambient air with a tailored mix of nitrogen and carbon dioxide to slow oxidation and microbial growth. But without verification, a misaligned sealing head or faulty gas flush can let oxygen sneak back in. Inline headspace analyzers automatically sample each pack, flagging deviations instantly so you reject bad product—not an entire production run.

Products That Benefit Most

Certain foods demand heroic protection:

Meats & Poultry: Prevent discoloration and rancidity in red meat by keeping O₂ below critical thresholds.

Dairy & Cheese: Maintain precise CO₂ levels to inhibit unwanted bacteria without altering taste or texture.

Bakery & Snacks: Lock in crispness by displacing oxygen with nitrogen, cutting mold and staleness.

Fresh Produce & Salads: Balance O₂ and CO₂ to slow respiration—extending shelf life without soggy leaves.

Ready-to-Eat Meals: Ensure multi-ingredient stability in sandwiches, sushi, and more.

Compliance, Traceability & Brand Trust

Regulatory bodies like the FDA and EU regulators require documented evidence that packaging processes meet safety standards. Headspace analyzers seamlessly integrate into HACCP plans, creating digital audit trails for every batch. This not only safeguards against recalls but also builds consumer confidence when you prove “freshness guaranteed” with hard data.

Boost Production Efficiency & Cut Waste

Manual sampling leaves blind spots. Inline headspace analysis delivers continuous feedback—catching leaks or gas-mix drifts the moment they occur. Automated alerts stop the line, reject faulty packs, and prompt instant adjustments. The result? Dramatic reductions in spoiled product, fewer material costs, and optimized gas usage that shrinks your bottom-line impact.

From Reactive QA to Proactive Quality

With headspace data in hand, operations teams shift from firefighting to fine-tuning. Historical gas profiles reveal trends—maybe you’re over-flushing gas or running sealing temperatures too low. Armed with these insights, you calibrate your line for peak performance: lower cycle times, less wasted protective gas, and consistently flawless packaging.

Conclusion: In today’s competitive food market, “fresh” is a promise—and a responsibility. Headspace gas analyzers deliver the real-time, non-destructive checks you need to protect flavor, extend shelf life, and meet every regulatory bar. When every package leaves your line verified, you’re not just sealing in freshness—you’re sealing in trust.

Contact Us : 0086–15071131907

Email Us : [email protected]

0 notes

Text

The Essential Guide to Meat Pouches: A Revolution in Food Packaging

In the modern world of food packaging, convenience, freshness, and sustainability are key priorities for consumers and manufacturers alike. Meat pouches have become a significant innovation in this sector, offering a practical and efficient solution for packaging meat products. These flexible, durable pouches provide an optimal environment to preserve the freshness of the meat while enhancing ease of handling and storage. In this article, we’ll delve into the various aspects of meat pouches, including their types, benefits, applications, and environmental impact. We will offer an in-depth look at why they have become a popular choice for meat packaging.

1. What Are Meat Pouches?

1.1 Definition and Composition

Meat pouches are flexible, sealed packaging made from a variety of materials, such as plastic films, laminated films, or a combination of both. These pouches are designed to contain and preserve meat products, maintaining their quality during storage and transportation. The materials used in meat pouches are specifically chosen for their strength, flexibility, and barrier properties, ensuring that the meat inside remains safe from contaminants.

1.2 How Do Meat Pouches Differ from Traditional Packaging?

Unlike traditional meat packaging, such as trays or vacuum-sealed plastic, meat pouches offer more flexibility and adaptability. They take up less space, are lightweight, and can be used for various meat products, from raw cuts to ready-to-eat meals. Furthermore, pouches can be easily modified to include features like zip-locks or tear strips, improving convenience for consumers.

2. Types of Meat Pouches

2.1 Vacuum Pouches

Vacuum-packed meat pouches are a popular option in the food industry. These pouches are designed to remove air from the inside, creating a vacuum seal that helps preserve the meat's freshness for extended periods. The absence of air helps prevent oxidation, which can lead to spoilage.

2.2 Modified Atmosphere Packaging (MAP) Pouches

MAP pouches use a combination of gases to create an environment that slows spoilage. These pouches are often used for fresh meat products, as the modified atmosphere helps maintain the meat's appearance and taste for more extended periods.

2.3 Stand-Up Pouches

Stand-up pouches are a more recent innovation in meat packaging. With a flat bottom, these pouches are designed to stand upright on shelves, offering a more attractive display in retail settings. They also provide additional space for branding and product information, making them a preferred choice for packaging ready-to-eat meat products.

3. Benefits of Using Meat Pouches

3.1 Freshness and Shelf Life

One of the primary advantages of meat pouches is their ability to extend the shelf life of meat products. The pouches' tight seals and barrier properties help protect the meat from contamination, spoilage, and moisture loss. This is particularly important for preserving the freshness of fresh cuts, as well as ready-to-eat meals.

3.2 Convenience and Portability

Meat pouches are lightweight and easy to handle, making them an ideal packaging solution for both consumers and food manufacturers. Their compact nature allows them to be transported more easily and stored efficiently. For consumers, pouches are convenient for portion control, with resealable options available for added convenience.

3.3 Cost-Effectiveness

Compared to traditional packaging methods, such as rigid plastic containers or cans, meat pouches are generally more cost-effective to produce and ship. The materials used in pouches are less expensive, and the lightweight nature of the pouches helps reduce shipping costs, making them an attractive choice for manufacturers.

4. Applications of Meat Pouches

4.1 Fresh and Frozen Meat

Meat pouches are commonly used for packaging fresh and frozen meat products. Whether it’s steaks, sausages, or poultry, these pouches help maintain the quality of the meat during freezing or refrigeration. The barrier properties of the pouches prevent freezer burn, ensuring that the meat retains its flavour and texture.

4.2 Ready-to-Eat Meals

With the increasing demand for convenience foods, meat pouches are also used to package ready-to-eat meals that include meat. These meals often come with pre-cooked or marinated meat inside the pouches, providing a quick and easy meal solution for busy consumers.

4.3 Processed Meat Products

Processed meats like deli meats, jerky, and meat snacks are often packaged in meat pouches. The flexible nature of these pouches allows for easy sealing, while the strong barrier properties prevent contamination and extend shelf life.

5. Environmental Impact and Sustainability

5.1 Eco-Friendly Materials

As sustainability becomes a growing concern, the packaging industry has begun to embrace more eco-friendly solutions. Many manufacturers are now producing meat pouches from recyclable or biodegradable materials. These innovations aim to reduce the environmental impact of plastic waste and promote a more sustainable food packaging solution.

5.2 Reducing Food Waste

Another benefit of meat pouches is their ability to reduce food waste. By providing superior protection from air and moisture, meat pouches help to preserve the quality of meat products for more extended periods, ultimately reducing the likelihood of spoilage and waste.

Conclusion

Meat pouches have revolutionised how meat products are packaged and distributed, offering numerous benefits in freshness, convenience, and sustainability. As technology improves, the packaging industry will likely see even more innovative solutions, with meat pouches providing consumers and businesses with flexible, cost-effective, and environmentally friendly packaging options. For manufacturers looking to enhance their product offerings, meat pouches represent a modern, efficient, and consumer-friendly solution that is here to stay.

0 notes

Text

Hygienic and Sustainable Packaging Demands Drive Equipment Upgrades in Bakery Sector

June 2025 — The global bakery packaging machine market is entering a promising growth phase, propelled by increasing consumer demand for convenience foods, the growing bakery industry, and the urgent need for automation in packaging processes. As food safety regulations tighten and aesthetic presentation gains importance, bakery producers are turning to technologically advanced packaging machines to ensure quality, efficiency, and compliance.

According to a comprehensive market analysis, the bakery packaging machine market was valued at USD 2.6 billion in 2023 and is expected to expand at a CAGR of 3.6% from 2024 to 2034, reaching USD 3.8 billion by the end of 2034. This steady growth highlights the market’s resilience and adaptability to changing consumer behaviors and industry trends.

What is Fueling Growth in the Bakery Packaging Machine Market?

Bakery packaging machines are used for the automated packing of products such as bread, cakes, pastries, muffins, cookies, and more. From flow wrappers and vacuum sealers to cartoners and labeling systems, these machines offer enhanced speed, precision, and hygiene.

Request Sample Copy of the Report- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=75867

Several forces are shaping the future of this industry:

1. Expansion of the Global Bakery Industry

The global bakery sector is experiencing healthy growth, fueled by increasing consumption of packaged baked goods across developing and developed economies alike. Urbanization, busy lifestyles, and growing awareness of ready-to-eat snacks are expanding the market for baked items—directly boosting the demand for specialized packaging equipment.

2. Emphasis on Food Safety and Hygiene

In a post-pandemic world, safety and hygiene are at the forefront of food production and packaging. Bakery producers are investing in automated packaging systems to reduce human handling, extend shelf life, and ensure product integrity. Machines that offer contamination-free, sealed, and tamper-evident packaging are in particularly high demand.

3. Shift Toward Sustainable Packaging

Sustainability is now a key consideration in packaging decisions. Machines compatible with recyclable films, compostable trays, and minimal packaging designs are being prioritized by manufacturers. This trend is driving innovation in both machine functionality and materials handling.

4. Rise of Automation and Smart Packaging Solutions

The integration of smart technologies such as AI, IoT-enabled sensors, and robotics in packaging machinery is transforming production lines. Bakery manufacturers are increasingly adopting automated systems with real-time diagnostics, predictive maintenance, and remote monitoring to improve operational efficiency and reduce waste.

Key Applications and Packaging Types

Bakery packaging machines serve a wide range of product categories, including:

Bread and Rolls: Packaged in flow wrap, pillow packs, or shrink films.

Cookies and Biscuits: Often packed in horizontal form-fill-seal (HFFS) systems or trays with film sealing.

Cakes and Pastries: Require delicate handling with protective packaging to maintain shape and texture.

Frozen Bakery Products: Require vacuum-sealed or modified atmosphere packaging (MAP) to ensure freshness.

Types of machines in demand include flow wrappers, vertical form-fill-seal (VFFS) machines, thermoformers, cartoners, and tray sealers, each tailored to different packaging needs and volumes.

Regional Insights

Europe Leads with Strong Demand for Premium Packaging

Europe dominates the bakery packaging machine market, owing to its established bakery industry and stringent food safety norms. Consumers in the region also show a strong preference for sustainable and aesthetically pleasing packaging, pushing bakeries to invest in advanced machinery.

Asia Pacific Emerging as a High-Growth Region

Asia Pacific is expected to witness the fastest growth in the bakery packaging machine market over the forecast period. Rising disposable incomes, growing urban populations, and increased demand for convenience foods in countries such as China, India, and Indonesia are creating significant opportunities for packaging automation.

North America Focuses on Innovation and Efficiency

In North America, bakeries are increasingly adopting integrated packaging lines with real-time monitoring, improved traceability, and faster changeovers to meet shifting consumer preferences and SKU diversity.

Competitive Landscape

The bakery packaging machine market features a combination of established global players and emerging regional innovators. Key players are focused on expanding their product lines, enhancing energy efficiency, and integrating digital solutions to stay ahead of the curve.

Prominent Companies in the Market Include:

GEA Group AG

Bosch Packaging Technology (Syntegon)

MULTIVAC Group

Ishida Co., Ltd.

ULMA Packaging

PAC Machinery

Heat and Control, Inc.

IMA Group

Rovema GmbH

ILAPAK International S.A.

These companies are investing in R&D to develop machines capable of handling a wide variety of product sizes and shapes while delivering consistent speed, seal integrity, and minimal material waste.

Recent Developments and Trends

MULTIVAC recently launched a new generation of compact tray sealers with reduced energy consumption and improved sealing precision.

ULMA Packaging introduced smart HFFS systems with built-in sensors for better film tension control and automated troubleshooting.

Bosch Packaging Technology (now Syntegon) is emphasizing modular machine designs to enable rapid changeovers and customized solutions for small bakeries.

GEA Group is integrating AI into its packaging lines to support predictive maintenance and reduce unplanned downtime.

hallenges to Consider

Despite a promising outlook, the bakery packaging machine market is not without its challenges:

High Capital Investment: Advanced packaging machinery requires a significant upfront investment, which may be a barrier for small or mid-sized bakery operations.

Skilled Labor Shortage: Operating and maintaining modern, digitized machines demands trained technicians—a gap in many emerging markets.

Volatility in Raw Material Prices: Fluctuations in the cost of packaging materials and components can impact profit margins and procurement strategies.

However, as packaging becomes a critical component of brand identity and product differentiation, these challenges are likely to be offset by long-term benefits in productivity, compliance, and consumer satisfaction.

Outlook and Opportunities

Over the next decade, the bakery packaging machine market will be shaped by innovation, customization, and a continued shift toward sustainable practices. Opportunities lie in:

Eco-Friendly Packaging Compatibility: Machines designed to work seamlessly with paper-based films, biodegradable trays, and monomaterial laminates.

AI and Robotics Integration: Further enhancement of machine intelligence for autonomous decision-making and operational optimization.

Emerging Market Penetration: Untapped potential in regions such as Latin America, the Middle East, and Africa, where bakery production is expanding rapidly.

Conclusion

The global bakery packaging machine market is steadily rising as automation, hygiene, and sustainability become vital pillars in the food production ecosystem. As bakeries evolve from small-scale operations to large-scale manufacturers, the demand for reliable, smart, and flexible packaging solutions will continue to grow.

With the market projected to reach USD 3.8 billion by 2034, stakeholders who align with emerging trends—particularly digitalization, material innovation, and regulatory compliance—will be best positioned to capture a competitive edge.

Whether it’s ensuring the freshness of a croissant, the shelf life of sandwich bread, or the visual appeal of premium pastries, modern packaging machines are playing a central role in shaping the future of the global bakery sector.

0 notes

Text

US Coal Market Size, Drivers, Challenges & Innovations Forecast 2032

US Frozen Food Packaging Market Overview The US frozen food packaging market is experiencing substantial momentum, driven by evolving consumer lifestyles and heightened demand for convenience foods. As of 2025, the market is valued at approximately USD 9.8 billion and is projected to grow at a compound annual growth rate (CAGR) of 5.2% over the next 5–10 years. Increasing urbanization, expanding cold chain logistics, and the rise in ready-to-eat meals have significantly propelled market expansion. A shift toward single-serve and portion-controlled packaging formats is further fueling demand, especially among the millennial and working-class populations. Industry players are also investing in smart and active packaging to enhance shelf life and preserve product quality, aligning with modern packaging trends. US Frozen Food Packaging Market Dynamics Market Drivers: One of the primary growth drivers is the surging demand for frozen snacks, meals, and vegetables. Technological innovations in packaging materials, such as multi-layer films and recyclable plastics, contribute to the market's growth. Consumer preference for extended shelf-life and sustainable packaging solutions also drives innovation. Market Restraints: The market faces challenges including rising raw material costs and concerns regarding plastic waste, which may hinder widespread adoption of traditional packaging formats. Additionally, regulatory compliance around food safety and materials used in packaging poses constraints for manufacturers. Opportunities: Opportunities lie in biodegradable and compostable packaging solutions that address environmental concerns. The growing e-commerce food delivery ecosystem opens new channels for frozen food packaging, creating avenues for smart labeling and tamper-proof designs. Increased investment in automation and AI for packaging operations also presents future growth potential. Download Full PDF Sample Copy of US Coal Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=481606&utm_source=PR-News&utm_medium=387 US Frozen Food Packaging Market Trends and Innovations Innovations in frozen food packaging are centered around sustainability, user convenience, and product integrity. Modified Atmosphere Packaging (MAP), vacuum sealing, and nano-coating technologies are transforming how products are preserved and presented. Recyclable and plant-based packaging materials are being increasingly adopted to meet environmental standards and consumer expectations. Smart packaging with QR codes for traceability and freshness indicators are gaining traction. Collaborative ventures between packaging manufacturers and frozen food brands are accelerating innovation pipelines. For instance, co-development of custom-fit packaging solutions for niche frozen food products helps in reducing food waste and enhancing consumer experience. Furthermore, flexible packaging formats such as pouches and resealable bags are trending due to their lightweight and user-friendly nature. US Frozen Food Packaging Market Challenges and Solutions Key challenges include supply chain disruptions, particularly in raw materials and cold chain logistics, which can lead to delayed deliveries and higher operational costs. Pricing pressures from fluctuating resin and film costs also affect profit margins. Regulatory hurdles concerning packaging waste and food-grade compliance continue to impose restrictions on material usage. Solutions involve diversifying supply sources and investing in local material production to reduce dependency on imports. Leveraging automation and AI in packaging lines can improve efficiency and reduce labor costs. Implementing sustainable practices, such as closed-loop recycling systems and biodegradable alternatives, helps address regulatory and environmental concerns effectively. US Frozen Food Packaging Market Future Outlook The future of the US frozen food packaging market is promising, with a strong trajectory toward digital transformation, sustainability, and customization.

By 2030, the market is expected to exceed USD 16 billion, driven by evolving dietary habits, increased female workforce participation, and a growing preference for home-cooked frozen meals. Brands that adopt eco-friendly materials and invest in consumer-centric innovations will capture significant market share. Technological advancements in smart packaging, coupled with regulatory support for sustainable initiatives, will shape the next phase of market development. Overall, the US frozen food packaging market is set for dynamic growth, characterized by innovation, resilience, and an emphasis on environmental stewardship. Key Players in the US Coal Market US Coal Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. Peabody Energy Corporation Arch Resources Inc. Alliance Resource Partners L.P. Cloud Peak Energy Contura Energy Inc. Consol Energy Inc. Foresight Energy Ramaco Resources Inc. Warrior Met Coal Inc. Alpha Metallurgical Resources Inc. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=481606&utm_source=PR-News&utm_medium=387 US Coal Market Segments Analysis and Regional Economic Significance The US Coal Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The US Coal Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. By Type •Online Service• Offline Service By Application •Construction Site• Industrial Factory By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/us-coal-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/automated-parking-systems-market/ https://www.verifiedmarketresearch.com/ko/product/plasma-protein-therapeutics-market/

https://www.verifiedmarketresearch.com/ko/product/concrete-bonding-agents-market/ https://www.verifiedmarketresearch.com/ko/product/automotive-ethernet-market/ https://www.verifiedmarketresearch.com/ko/product/turkey-underfloor-heating-hydronic-system-market/

0 notes

Text

Ensuring Freshness: The Role of Modified Atmosphere Packaging Leak Testers

Introduction: Modified atmosphere packaging (MAP) is a popular method used in the food industry to extend the shelf life of perishable products by altering the atmosphere within the packaging. However, ensuring the integrity of MAP is crucial to prevent spoilage and maintain product freshness. In this blog post, we'll explore the importance of modified atmosphere packaging leak testers, their working principles, applications in the food industry, and the benefits they offer in preserving product quality.

Understanding Modified Atmosphere Packaging Leak Testers:

Modified atmosphere packaging leak testers are specialized devices designed to detect and quantify leaks in MAP systems. These testers utilize various methods, such as pressure decay, vacuum decay, or tracer gas detection, to identify any leaks that may compromise the integrity of the packaging and allow the entry of oxygen or other gases.

Working Principles of Modified Atmosphere Packaging Leak Testers:

Pressure Decay: Pressure decay testers measure the change in pressure within the packaging over a specified period. Any decrease in pressure indicates the presence of a leak, as gas molecules escape from the packaging.

Vacuum Decay: Vacuum decay testers create a vacuum inside the packaging and monitor any changes in pressure. Similar to pressure decay testers, a decrease in pressure indicates the presence of a leak.

Tracer Gas Detection: Tracer gas testers inject a small amount of tracer gas, such as helium or carbon dioxide, into the packaging. A sensitive detector then analyzes the surrounding atmosphere for traces of the tracer gas, allowing the detection of even tiny leaks.

Applications of Modified Atmosphere Packaging Leak Testers:

Modified atmosphere packaging leak testers are widely used in the food industry to ensure the quality and safety of packaged products. Common applications include:

Fresh Produce: MAP is commonly used to package fruits, vegetables, and salads. Leak testers help ensure that the packaging maintains the desired atmosphere to extend the shelf life of these perishable products.

Meat and Poultry: MAP is used to package meat and poultry products to prevent spoilage and maintain freshness. Leak testers ensure that the packaging remains airtight, preserving the quality and flavor of the meat.

Dairy Products: MAP is employed for packaging dairy products such as cheese, yogurt, and butter. Leak testers help prevent the entry of oxygen, which can cause oxidation and spoilage of these products.

Benefits of Modified Atmosphere Packaging Leak Testers:

Quality Assurance: Leak testers ensure the integrity of MAP systems, preventing leaks that could compromise the freshness and safety of packaged products.

Extended Shelf Life: By detecting and repairing leaks, modified atmosphere packaging leak testers help extend the shelf life of perishable products, reducing waste and maximizing product availability.

Compliance: Leak testers help food manufacturers comply with regulatory requirements and industry standards for food packaging safety and quality.

Cost Savings: By minimizing product spoilage and waste, modified atmosphere packaging leak testers help reduce costs associated with product recalls and replacements.

Brand Reputation: Ensuring the freshness and quality of packaged products enhances consumer trust and loyalty, strengthening the brand reputation of food manufacturers and retailers.

Conclusion: Modified atmosphere packaging leak testers play a vital role in ensuring the freshness, safety, and quality of packaged food products. By detecting and repairing leaks in MAP systems, these testers help extend the shelf life of perishable products, minimize waste, and enhance brand reputation. With their ability to provide accurate and reliable leak detection, modified atmosphere packaging leak testers are essential tools for food manufacturers seeking to deliver superior-quality products to consumers.

0 notes

Text

Canned Food Packaging: How It’s Evolving to Meet Consumer Demands

Executive Summary

The global canned food packaging market is experiencing remarkable growth, driven by evolving consumer preferences, technological advancements, and increasing demand for convenience foods. The market, valued at USD 40.1 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.8%, potentially surpassing USD 62.1 billion by 2032. Key drivers behind this growth include the increasing popularity of ready-to-eat meals, advancements in packaging technologies, and a growing emphasis on sustainability.

As consumer habits shift towards long-shelf-life products, packaging solutions that ensure product integrity, safety, and freshness have become essential. Furthermore, the demand for environmentally friendly packaging options, such as biodegradable and recyclable materials, has surged. The competitive landscape is marked by the presence of prominent industry players who are focusing on sustainable innovations to address both consumer and regulatory expectations.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40600-global-canned-food-packaging-market

Canned Food Packaging Market Dynamics: Drivers, Challenges, and Opportunities

Rising Consumer Demand for Convenience Foods

With the acceleration of urbanization and busy lifestyles, the demand for canned food products, particularly those offering convenience and longer shelf life, is on the rise. Canned foods, such as ready-to-eat meals, soups, and vegetables, have become staple products due to their ease of storage and minimal preparation time. Additionally, canned food products preserve nutritional value, ensuring that consumers can enjoy high-quality meals at home or on the go.

Advancements in Packaging Technologies

The shift towards sustainable, innovative, and functional packaging technologies plays a crucial role in expanding the market. Packaging solutions such as smart packaging, temperature-sensitive labels, vacuum-sealed cans, and modified atmosphere packaging (MAP) help maintain food safety and product quality throughout the supply chain. These technologies enhance consumer confidence in canned products and improve overall product appeal.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40600-global-canned-food-packaging-market

Environmental Concerns and the Push for Sustainability

Environmental concerns surrounding the excessive use of non-recyclable materials, particularly plastics and aluminum, have created a strong demand for eco-friendly packaging alternatives. Companies are increasingly investing in biodegradable, recyclable, and lightweight materials that do not compromise the integrity or shelf life of the packaged food.

Sustainability is no longer a trend but a significant market force. The industry is shifting towards materials that reduce carbon footprints and plastic waste, which aligns with growing consumer demand for environmentally conscious products.

Innovations in Packaging Formats and Materials

The evolution of packaging materials has made a significant impact on the canned food packaging industry. Metal remains the dominant material in canned food packaging, accounting for over 70% of the market share due to its durability and ability to protect the contents from external elements. However, the glass and plastic segments are experiencing growth, driven by their premium appeal and versatility.

The use of aluminum, glass, and plastic packaging is steadily increasing, especially in premium food segments. Glass packaging, valued for its high-quality preservation capabilities, appeals to health-conscious consumers who prefer non-toxic, eco-friendly options. Meanwhile, plastic packaging is gaining traction due to its lightweight and cost-effective nature.

Health and Safety Concerns

Health consciousness is one of the primary factors influencing consumer behavior towards canned food. Consumers are becoming more aware of the implications of packaging materials on their health, leading to an increased demand for BPA-free, non-toxic, and food-safe materials. Packaging technologies that maintain food quality and safety without the need for artificial preservatives are becoming more popular, especially in the dairy and beverage sectors.

E-commerce Growth and Changing Retail Dynamics

With the rise of e-commerce platforms and online grocery delivery services, there has been a marked shift in consumer buying habits. The need for durable and secure packaging that can withstand the rigors of transit while maintaining product quality has increased. As online shopping becomes an integral part of the retail landscape, the demand for effective, consumer-friendly packaging solutions has also risen.

Canned Food Packaging Market Segmentation Analysis:

By Material Type

The global canned food packaging market is segmented into several material types, each offering distinct advantages:

Metal Packaging: Metal packaging, primarily in the form of aluminum and steel cans, dominates the market due to its excellent barrier properties, durability, and ability to preserve food for extended periods. This segment held a market share of approximately 73% in 2023 and is expected to maintain steady growth throughout the forecast period.

Glass Packaging: Glass packaging is witnessing steady growth due to its premium appeal and its ability to preserve food quality without the use of synthetic chemicals. Glass jars are typically used for high-end products such as jams, sauces, and some soups, where product quality is paramount.

Plastic Packaging: Although less common in the canned food sector, plastic packaging is growing in popularity due to its lightweight nature and cost-effectiveness. Flexible plastic pouches, often used for soups and meals, are increasingly being adopted as a convenient, space-saving solution.

Other Materials: This category includes composite packaging materials such as paper-based containers and hybrid solutions that combine several materials for enhanced durability and eco-friendliness.

By Food Type

The canned food packaging market is segmented by food type, with the following key categories:

Meat and Poultry: The meat and poultry segment accounts for the largest share in the canned food packaging market, driven by the growing demand for convenient protein-rich meals. This segment is expected to maintain its dominance with a projected CAGR of 5% from 2024 to 2032.

Soups and Stews: The soups and stews segment is growing at a CAGR of 6.37% during the forecast period, as consumers increasingly seek easy-to-prepare meal options. Canned soups are an essential part of the convenient food sector and continue to see strong demand.

Fruits and Vegetables: Canned fruits and vegetables offer long shelf lives, and their usage remains widespread. This segment benefits from the increasing desire for healthy, convenient food options that retain nutritional content.

Other Categories: Other canned food products include dairy-based canned goods, ready-to-eat meals, and beverages, all of which contribute to market diversity.

By End-User

The key end-users in the canned food packaging market are:

Retail: The retail segment dominates the market, accounting for more than 50% of the market share. Supermarkets, convenience stores, and online platforms are the primary channels for consumer sales of canned food products.