#metal core pcb supplier

Explore tagged Tumblr posts

Text

Top Reasons to Use Metal Core PCBs in High-Power Electronics

When it comes to high-power electronics, metal core PCBs (Printed Circuit Boards) offer an unmatched solution for efficient heat management and enhanced durability. Designed with a metal substrate, typically aluminum or copper, metal core PCBs outperform standard boards by effectively dissipating heat, which is crucial for maintaining the longevity and performance of high-power devices. Here’s why metal core PCBs are a top choice for high-power electronics and the benefits they bring to demanding applications.

1. Superior Thermal Management

One of the main reasons metal core PCBs are essential in high-power electronics is their superior thermal conductivity. Unlike traditional PCBs, which may struggle with heat buildup, metal core PCBs are designed to pull heat away from heat-generating components, reducing the risk of damage. This makes them ideal for applications like LED lighting, power supplies, and automotive electronics, where components are subjected to high temperatures.

2. Enhanced Durability and Stability

The metal layer in metal core PCBs provides additional strength and stability, making them more robust than standard PCBs. This added durability allows the board to withstand mechanical stress, vibrations, and thermal cycling. For high-power electronics, where devices may be exposed to extreme conditions, this durability ensures reliable performance over time.

3. Improved Efficiency for High-Power Applications

High-power electronics need to operate at optimal efficiency, and metal core PCBs play a critical role in achieving this. By effectively managing heat, metal core PCBs allow components to operate within their safe temperature range, reducing power loss and boosting efficiency. This is especially beneficial for applications like RF amplifiers and motor drives, where consistent power delivery is crucial.

4. Compact and Lightweight Designs

Despite their strength, metal core PCBs can be manufactured in compact, lightweight designs, making them ideal for modern electronic devices. The metal core allows for thinner boards without compromising thermal management capabilities, which is advantageous in applications where space is limited.

Discover High-Quality Metal Core PCBs

For high-performance metal core PCBs designed to meet the demands of high-power electronics, explore American Standard Circuits. Their RF metal-backed PCB solutions offer the reliability and efficiency required in demanding applications, from LED lighting to power electronics, ensuring your devices run cooler and last longer. Choose American Standard Circuits to experience the full benefits of advanced metal core PCB technology.

0 notes

Text

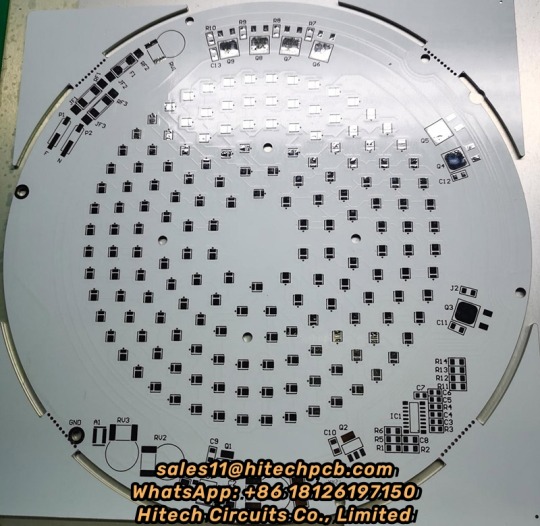

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

Premium Metal Core PCB Design Experts Offer Overall Quality to Patrons

Best Technology has been the market leader for nearly two decades and manufactures aluminum core and copper core PCB. Apart from the product array, the company also provides services like MCPCB design, prototype, mass production, aluminum PCB assembly, and procurement of raw materials. The company serves customers in more than 66 countries.

0 notes

Text

Copper core PCB is a copper substrate + Insulated layer + copper

Copper core PCB is a copper substrate + Insulated layer + copper circuits layer PCB,also, it is called copper substrate pcb, copper based pcb,copper clad pcb.

A copper base PCB is a metal core PCB with a copper substrate. If a hybrid PCB whose substrate is a copper plate inlay in the FR4 board, it is also a copper base PCB.

Usually, copper-base PCBs have the same structure as aluminum PCBs - single-layer, double-layer with single component-mounting side, double-layer with dual component-mounting sides, and four-layer with dual component-mounting sides. Even they use the same prepreg material to insulate the copper layers. However, the copper substrate (398W/mK) has better thermal conductivity than the aluminum substrate (237W/mK).

#pcb#pcba#pcb manufacturer#aluminium pcb#ceramic pcb#pcb assembly#heavy copper pcb#mpcb#Metal core pcb#Copper core PCB#fpcb

0 notes

Text

Here are some well-known laser engraving machine suppliers and manufacturers:

Trotec Laser: Offers high-end laser equipment for precise engraving, marking, and cutting. With over 25 years of experience, they develop innovative and comprehensive laser systems. Their laser devices, powerful software, and high-quality materials are perfectly matched.

Linxuan Laser: With more than 18 years of experience in the laser industry, it is one of the top industrial laser marking/carving machine manufacturers in China. They provide customized and cost-effective laser marking + carving solutions.

Shenzhen Algo Technologies Co., Ltd: An innovative technology company focusing on commercial laser engraving machines, founded by Justin Tan, a renowned expert in the laser engraving machine industry.

DEMARK: Specializes in laser technology for over 20 years, including laser marking, laser engraving, laser welding, and laser cutting applications. It is now one of the leading suppliers in the Chinese laser industry.

Han's Laser: A very popular and trusted laser cutting machine manufacturer in China, known for its laser marking equipment and a wide range of laser devices. Established in 1996, it has become a highly trusted and professional laser machinery manufacturer for many enterprises worldwide.

HGLASER: A pioneer and leader in the application of laser industry in China, it is a world-leading provider of laser equipment and intelligent manufacturing solutions, and a core subsidiary of the famous national high-tech listed company HGTECH.

These laser engraving machine suppliers offer a wide range of laser engraving machines suitable for various materials and applications, including metals, non-metals, PCB boards, ICs, and semiconductor wafers. They not only guarantee the quality of the equipment but also provide quick solutions and operational support. If you need more information or wish to purchase a laser engraving machine, you can visit their official websites or contact them directly.

0 notes

Text

LED PCB Assembly

LED PCB Manufacturer & Assembly – One-stop service

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED Pcb Board, LED pcb Assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

0 notes

Text

By choosing Saasin Electronics Pvt. Ltd. as your PCB manufacturer and supplier, you can take advantage of our expertise in creating compact, high-performance Metal Core PCBs that meet the demands of your projects.

#PCBsupplier#bestpcbmanufacturer#metalcorepcbmanufacturer#metalcorepcbsolutions#saasinelectro#metalcorepcbsolution#pcbsuppliers

0 notes

Text

Hitechpcb is a professional manufacturer of copper based printed circuit board (PCB). We produce metal-based MCPCB, aluminum substrate and copper substrate PCBs. with short delivery time, strict quality and excellent service. What is Copper Based PCB? Copper base PCB is a type of metal-based PCB, it is PCBs made of copper substrate. As the leader of the thermal conductivity in the metal substrate MCPCB(metal core PCB), the copper core PCB has a thermal conductivity of up to 400 watts. It can meet the needs of higher power LED light sources after the aluminium substrate, and solve the various heat problems such as high power dead light, serious light decay, and high heat generation. As the more active star products in the metal substrate, copper base PCBs and aluminium substrate PCBs have their advantages and are widely used, which are common in cars, stage lights, control panels, photographic lights, projection lights, Stage laser lamps and other products are excellent high-power accessories.

0 notes

Text

The Surge of Mandarin PCB Distributors: Exactly How They're Molding the Future of Modern Technology

When you think about sophisticated electronic tools like Apple's apples iphone, you may certainly not promptly connect them along with China's printed circuit board (PCB) distributors. Nevertheless, business like Taiwan's Wistron and China's Shenzhen Kaifa Technology have actually been silently performing an important job in making the complicated PCBs that power these devices. Over the past 3 years, Mandarin PCB providers have actually swiftly expanded their capabilities, and their influence on the international technology field is actually palpable. However what drives their excellence, and how will they form the future of modern technology? The response exists in understanding their exceptional rise.

Past History of Chinese PCB Business

Exactly how did China cheer come to be a prevalent player in the international PCB market? You might be actually startled to find out that China's PCB industry has a past history extending over three decades. In the 1980s, China's federal government launched a collection of financial reforms, leading the technique for international investment and technological move. This triggered the facility of providers like Hitech Circuits Co. Limited, an introducing PCB producer in China. As the business grew, Chinese PCB makers began to focus on creating modern PCB boards, dealing with the demands of worldwide electronics companies. Today, China is home to various PCB board makers, including ceramic PCB manufacturers and light weight aluminum PCB providers. The country's huge production capabilities, coupled along with its reasonable costs and advantageous business setting, have produced it a desirable destination for PCB production.

Benefits of Mandarin PCB Distributors

As China's PCB industry has matured, its own suppliers have actually ended up being considerably attractive to providers seeking reliable, premium PCBs. When trying to find a pcb board distributor, you expect quick delivery, affordable rates, and adherence to quality criteria. Chinese pcb board suppliers have cheered meet these desires, offering a wide array of PCB kinds, including ceramic pcb and aluminum pcb. Their competence in generating complicated PCBs, like double sided pcb supplier, has actually gotten all of them a track record as a best destination for companies requiring high-volume, top notch PCBs. Furthermore, lots of Chinese pcb board distributors have actually invested heavily in trial and error, guaranteeing they remain at the cutting edge of PCB modern technology. Do not choose usual when you may attain remarkable results-- find the unparalleled quality and performance of Hitech PCB and boost your ventures with the most up to date in PCB technology.

Effect On International Tech Market

The global tech market is actually watching a significant change in its own source establishment characteristics, along with Mandarin PCB vendors significantly becoming the basis of the multibillion-dollar business. As you examine the marketplace, you'll notice that Mandarin vendors are right now efficient in producing high quality printed motherboard, including complicated concepts including ceramic PCB panels and metal core PCBs. This shift is actually possessing a profound effect on the worldwide tech market. You are actually observing lowered manufacturing expenses, faster turn-around opportunities, and improved accessibility to a large variety of PCB board production services. Dual sided PCBs, the moment a particular niche product, are actually today extensively available and budget-friendly.

Developments in PCB Manufacturing

You're most likely knowledgeable about the essentials of PCB manufacturing, but what's steering the field ahead are technologies that drive the boundaries of what's feasible. Chinese PCB providers, particularly, are investing greatly in experimentation to remain in advance of the curve. One key area of development resides in using alternative products, including ceramic and aluminum. Hi-tech ceramic PCBs, for example, provide strengthened thermal conductivity and security, making all of them suitable for high-frequency requests. Meanwhile, aluminum PCBs supply a cost-effective solution for applications that demand high thermal abandonment.

Potential of PCB Modern Technology Trends

Expecting the future of PCB technology trends, one trait is actually crystal clear: suppliers like you will be driving need for much more ingenious and specific PCB solutions. As the IoT and 5G innovations proceed to advancement, state-of-the-art PCBs are going to play a necessary part in assisting their efficiency. You'll demand PCBs that use higher speeds, lower latency, and improved reliability. This is where hitech PCBs, such as dual sided PCBs and hitech LED PCBs, will become increasingly vital. A double sided PCB maker along with expertise in hitech PCBs will certainly be actually vital in complying with these needs. They'll require to supply PCBs with sophisticated materials, including high-frequency laminates and low-loss dielectrics, to assist the much higher rates and frequencies.

Conclusion

As you aim to the future of innovation, it's clear that Mandarin PCB providers are leading the charge. Their unrelenting drive for development has stired up a firestorm of developments, transforming the worldwide specialist landscape forever. With the ability to produce complex PCBs at unparalleled rates and costs, they are actually catapulting the field forward at lightning-fast speed, creating it feel like the future is actually getting to a million miles every hr.

3F, Bldg B5, Zhimeihuizhi Industrial Park

FuYong, Bao'an Dist. Shenzhen, GuangDong, China

+86-755-29630063

0 notes

Text

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

The Future of Electronics - The Role of Metal Core PCB Technology

As technology continues to advance at a rapid pace, the demand for electronic devices that are smaller, faster, and more powerful than ever before continues to grow. In this ever-evolving landscape, the role of metal core PCB technology is becoming increasingly prominent. Metal core PCBs, also known as MCPCBs, offer a range of benefits that make them an essential component in the future of electronics. In this blog post, we'll explore the role of metal core PCB technology and the importance of choosing the right metal core PCB supplier.

Metal Core PCBs: A Game-Changing Solution

Metal core PCBs are a specialized type of printed circuit board that feature a metal core, typically made of aluminum or copper. This metal core acts as an efficient heat sink, dissipating heat away from sensitive electronic components and ensuring optimal thermal management. As electronic devices become smaller and more compact, the need for effective thermal management becomes increasingly critical, making metal core PCBs an essential component in the future of electronics.

The Advantages of Metal Core PCBs

There are several key advantages to using metal core PCBs:

Enhanced Thermal Management: Metal core PCBs offer superior heat dissipation capabilities, allowing for more efficient cooling of high-power components.

Improved Reliability: By keeping operating temperatures low, metal core PCBs can help improve the reliability and lifespan of electronic devices.

Compact Design: Metal core PCBs enable the integration of complex circuitry and high-power components in compact form factors, saving space and reducing overall system size.

Choosing the Right Metal Core PCB Supplier

When it comes to metal core PCBs, choosing the right supplier is crucial. Look for a supplier that offers high-quality products, customizable solutions, and excellent customer service. At [Metal Core PCB Supplier], we pride ourselves on delivering top-notch metal core PCBs that meet the highest standards of quality and performance. With our state-of-the-art manufacturing facilities and dedicated team of experts, we're here to help you navigate the future of electronics with confidence.

Conclusion

In conclusion, metal core PCB technology is playing an increasingly important role in the future of electronics. With their superior thermal management capabilities, improved reliability, and compact design, metal core PCBs are revolutionizing the way electronic devices are designed and built. Partner with a trusted metal core PCB supplier like [Metal Core PCB Supplier] to ensure that your electronic designs are equipped to meet the challenges of tomorrow's technology landscape.

0 notes

Text

Tips For Optimal Business With Top Metal Core PCB Manufacturer

It is as much the responsibility of the corporate client to attain the best quality services products, and support from their vendors through a systematic business code. Working with some of the best metal core PCB manufacturers is no different. In this discussion, we will look at the tips and guidelines that will help you to do optimal business with your mcpcb manufacturer and suppliers.

0 notes

Text

Hitechpcb is a professional manufacturer of copper based printed circuit board (PCB). We produce metal-based MCPCB, aluminum substrate and copper substrate PCBs. with short delivery time, strict quality and excellent service. What is Copper Based PCB? Copper base PCB is a type of metal-based PCB, it is PCBs made of copper substrate. As the leader of the thermal conductivity in the metal substrate MCPCB(metal core PCB), the copper core PCB has a thermal conductivity of up to 400 watts. It can meet the needs of higher power LED light sources after the aluminium substrate, and solve the various heat problems such as high power dead light, serious light decay, and high heat generation. As the more active star products in the metal substrate, copper base PCBs and aluminium substrate PCBs have their advantages and are widely used, which are common in cars, stage lights, control panels, photographic lights, projection lights, Stage laser lamps and other products are excellent high-power accessories.

#pcb#pcb assembly#pcb manufacturer#Copper PCB#heavy copper pcb#aluminium pcb#ceramic pcb#pcba#flex pcb

0 notes

Text

Turn-key PCB Assembly

As GreensTone CEO said, GreensTone has over 10 years of experience in the PCB industry. Our core values are centered around customer service, engineering, manufacturing, and product solutions. In the beginning, we gained a stellar reputation through PCB assembly services and our customers pushed us to help them find solutions for PCB Fabrication, Components, Interconnect, Cables, Packaging Systems, and Mechanical parts in plastic or metal. Our expansion into these areas has allowed us to provide our customers with a wide range of engineering and manufacturing capabilities. Our core business is PCB assembly!

Turn-key PCB Assembly Quality Control Process

Assembly manual instruction

The PCBA engineer make the assembly manual instruction to norm the manufacturing process in advance, guide the production, and improve the quality from the process technology.

IQC Incoming Quality Control

Check all the components values, pads size, brands, manufacturing date and code.

SPI Solder Paste Inspection

Solder paste inspection can check the solder paste is sufficient and uniform to prevent assembly quality problems in advance caused by poor solder paste soldering.

Online AOI Inspection

The AOI can check the short circuit, offset, wrong solder, reverse solder, false solder, empty solder, incomplete solder, etc. It also can check excessive solder, less solder, continuous solder and solder joints.

First sample confirm

Check the first sample with Gerber, BOM and coordinate files, test it’s function with the testing program. Only sample confirmed by PCBA engineer, it can go for mass production.

Off-line AOI inspection

Check the soldered surface mount assembly for errors, omissions, and false connections.

X-Ray welding inspection

Inspect the solder joints of invisible components like BGA.

QC manual inspection

The assembled board is visually inspected to ensure 100 % ok.

Specification of Turn-key PCB Assembly

Item name

Turn-key PCB Assembly Capability

PCB Type

Rigid PCB

PCB Shape

Rectangular, Circular and any Odd Shapes

PCB Dimension

Min Board Size: 50mm x 100mm (Boards smaller than this size need to be panelized)

Max Board Size: 250mm x 500mm

Types of solder

leaded and lead-free (RoHS Compliant) assembly

Components Size

Passive Component: components as small as 01005, 0201,0402.

BGA: handle BGA of 0.25mm pitch with X-ray testing.

Fine Pitch to 0.25mm

UBGA, QFN, POP, leadless chips, connectors and terminals.

Components package

in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk.

Components Source

Turn-key/partial turn-key

Stencils

laser cut stainless steel stencils

Quantities

1-50000pcs

0 notes

Text

Leading PCB Manufacturer in Delhi | Shree Ram Electronics

If you are searching for a PCB machine then you may get many manufacturing stores but Shree Ram Electronics is the best landing place in Delhi. We have designed our machine from the customer's center of view because our first priority is the customer. We are leading PCB manufacturer in Delhi of different types of PCB like single side printed circuit boards, Double side printed circuit boards, Metal Core and Multilayer PCBs. Shree Ram Electronics is the supplier of PCB machines gives the accurate result because we are fabricating high-quality PCB with CNC.

1 note

·

View note