#mbr technology

Explore tagged Tumblr posts

Text

Advanced MBR Wastewater Treatment in the USA – Oxymotec

Oxymotec provides high-performance MBR wastewater treatment solutions across the USA. Experience cleaner, more efficient water treatment today. Feel free to contact us; we are here for you 24/7. Call us at +86-130-0635-3124.

0 notes

Text

Best MBR Plant Manufacturers in USA

Looking for the best MBR plant manufacturers and services in the USA? Look no further than Oxymo Technology. We provide top-quality MBR plants and reliable services for your wastewater treatment needs. Call us at +86-130-0635-3124.

#MBR#MBR Plant#MBR Technology#MBR Reactor#MBR System#mbr process#mbr membrane#mbr suppliers#mbr membrane suppliers#mbr membrane china#mbr membrane manufacturer

0 notes

Text

Best STP Plant Manufacturer/Supplier for Pharma Industry

In the pharmaceutical industry, managing wastewater is a complex and critical task. The nature of pharmaceutical production involves the use of various chemicals, solvents, and biologically active substances that pose unique challenges for wastewater treatment. Ensuring that this wastewater is treated effectively is essential not only for compliance with stringent regulations but also for…

#3D Aqua#activated carbon adsorption#AOPs#India STP supplier#MBBR technology#MBR technology#pharmaceutical wastewater management#pharmaceutical wastewater treatment#sewage treatment plant supplier#STP plant manufacturer#Water Treatment Technology

0 notes

Text

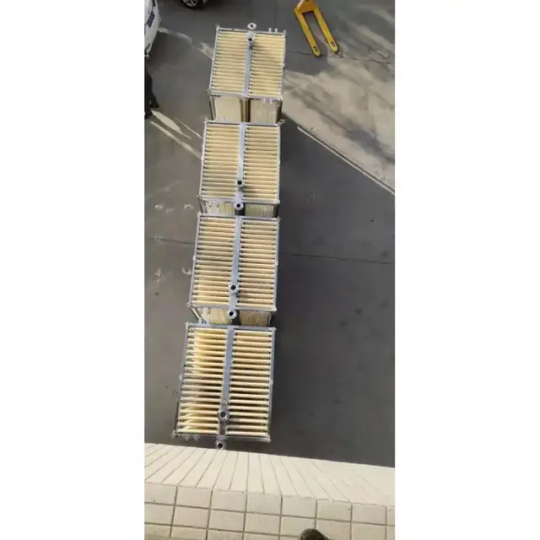

Hinada Water Treatment Tech Co., Ltd. has been one of China's top manufacturers of Submerged MBR membranes, Ultra-Fine membranes, and Membrane Filtration Systems.

#ultrafiltration systems water treatment#wastewater treatment equipment#edi electrodeionization#ultra filtration system#electrodeionization system#pvdf ultrafiltration membrane#UF System#hollow fiber uf membrane#uf membranes#ultrafiltration membrane#ultrafiltration unit#uf ultrafiltration#ultrafiltration membrane manufacturers#mbr reactor#mbr technology#mbr membrane bioreactor#mbr membrane manufacturers#membrane bioreactor for wastewater treatment#mbr wastewater#mbr membrane#mbr wastewater treatment#Water Treatment Equipment Suppliers.

0 notes

Text

Membrane bioreactor or MBR technology is a wastewater remedy procedure that combines an organic remedy manner with a membrane filtration gadget. The natural remedy technique, commonly an activated sludge, removes organic count and nutrients from the wastewater. The membrane filtration machine removes suspended solids, micro organism, and viruses from the handled wastewater. source:https://hinada-china.blogspot.com/2023/07/what-is-mbr-technology-and-why-it-must.html

#ultrafiltration systems water treatment#wastewater treatment equipment#edi electrodeionization#ultra filtration system#electrodeionization system#pvdf ultrafiltration membrane#UF System#hollow fiber uf membrane#uf membranes#ultrafiltration membrane#ultrafiltration unit#uf ultrafiltration#ultrafiltration membrane manufacturers#mbr reactor#mbr technology#mbr membrane bioreactor#mbr membrane manufacturers#membrane bioreactor for wastewater treatment#mbr wastewater#mbr membrane#mbr wastewater treatment#Water Treatment Equipment Suppliers.

0 notes

Text

Packaged MBR Sewage Treatment Plant | MBR STP

Wipro Water's Packaged MBR Sewage Treatment Plant (MBR STP) is an most reliable & efficient solution for treating & recycling sewage. With advanced technology and compact design, it ensures the effective removal of organic contaminants, reducing operational costs and thus environmental impact. With asthetic design and auto operation Package MBR STP are widely used for Sewage treatment and recycling

0 notes

Text

حمدان بن محمد: طموحاتنا دوماً نحو قمم أعلى وترك بصمات إ��اراتية واضحة على الأرض وبعيداً حيث النجوم

سجل سمو الشيخ حمدان بن محمد بن راشد آل مكتوم، ولي عهد دبي نائب رئيس مجلس الوزراء وزير الدفاع رئيس المجلس التنفيذي لإمارة دبي، في آخر تدوين لسموه عبر حسابه في «إكس» 🔻

شهدنا توقيع اتفاقية تطوير مركبة الهبوط “المستكشف محمد بن راشد” ضمن مهمة الإمارات الطموحة لاستكشاف حزام الكويكبات بين كوكبي المريخ والمشتري، والتي تهدف إلى الهبوط على كويكب “جوستيشا”.... يمثل هذا المشروع ثمرة تعاون استثنائي بين مؤسساتنا الوطنية والقطاع الخاص، ويجسد فلسفتنا في تعزيز الجهود الدولية المشتركة من خلال التعاون مع معهد الابتكار التكنولوجي (TII)...

بطموح إماراتي متجدد وبمركبة تحمل اسم الرجل الذي علم شعبه قهر المستحيل، سنمضي في رحلة تستمر 13 عاماً تتضمن 6 سنوات لتطوير المركبة ورحلة تستمر 7 سنوات تقطع خلالها 5 مليارات كيلومتر ... طموحاتنا دوماً نحو قمم أعلى وترك بصمات إماراتية واضحة على الأرض وبعيداً حيث النجوم.

_____________

His Highness Sheikh Hamdan bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai, Deputy Prime Minister and Minister of Defence of the UAE, and Chairman of The Executive Council of Dubai, in his latest tweet on his «X» account 🔻

I witnessed the signing of an agreement to develop the MBR Explorer’s lander for the Emirates Mission to the Asteroid Belt (EMA), a key milestone in the UAE’s ambitious journey to explore the asteroid belt between Mars and Jupiter, with the goal of landing on the asteroid Justitia. This project represents an exceptional collaboration between our national institutions and the private sector, reinforcing our commitment to international cooperation through our partnership with the Technology Innovation Institute (TII).

With renewed Emirati ambition and a spacecraft named after the man who taught his people to defy the impossible, we embark on a 13-year journey—a six-year spacecraft development phase followed by a seven-year voyage to the main asteroid belt beyond Mars, covering 5 billion kilometers. Our aspirations continue to rise, leaving a lasting Emirati mark on Earth and beyond, among the stars.

Thursday, 09 January 2025 الخميس

7 notes

·

View notes

Text

The Essential Guide to Wastewater Treatment Plants: Turning Waste into Resource

Wastewater treatment plants (WWTPs) are the unsung heroes of urban infrastructure. As they work tirelessly behind the scenes, they transform contaminated water into a clean resource that can be safely returned to the environment or even reused. In this article, we’ll explore the critical role of wastewater treatment plants, their processes, and the benefits they bring to our communities and ecosystems.

Understanding Wastewater: What Is It?

Before delving into the intricacies of treatment plants, it’s vital to understand what wastewater is. Wastewater is any water that has been adversely affected by human activity. This can include:

Domestic Wastewater: From sinks, toilets, and showers in households.

Industrial Wastewater: Generated from manufacturing processes and commercial activities.

Stormwater: Rainwater that collects pollutants as it flows over surfaces.

Proper management of these types of wastewater is crucial for public health and environmental protection.

The Importance of Wastewater Treatment Plants

Wastewater treatment plants are essential for several reasons:

Public Health: Proper treatment of wastewater prevents the spread of waterborne diseases.

Environmental Protection: Treated water reduces pollution in rivers, lakes, and oceans, preserving aquatic ecosystems.

Resource Recovery: Many plants can recover valuable resources, such as nutrients and energy, from wastewater.

Sustainable Practices: Modern WWTPs incorporate technologies that promote sustainability, reducing their carbon footprint.

The Process of Wastewater Treatment

The treatment of wastewater is a complex process that typically involves several stages. Let’s break down these stages:

1. Preliminary Treatment

In this initial stage, large debris such as sticks, leaves, and plastic are removed from the wastewater. This is usually done through screening and grit removal processes.

2. Primary Treatment

After preliminary treatment, wastewater moves to primary treatment, where solids settle to the bottom, forming sludge. This process removes about 50-70% of suspended solids and approximately 30% of biological oxygen demand (BOD).

3. Secondary Treatment

Secondary treatment is crucial for further reducing organic matter. This stage usually involves biological processes, where microorganisms break down organic pollutants. There are various methods used in secondary treatment, including:

Activated Sludge Process: In this method, air is pumped into the wastewater, allowing microorganisms to feed on the organic material.

Trickling Filters: Wastewater is distributed over media, allowing microorganisms to grow and treat the water as it trickles through.

4. Tertiary Treatment

Tertiary treatment is an advanced stage that further polishes the water. This can involve filtration, nutrient removal, and disinfection processes like chlorination or ultraviolet (UV) light treatment. The goal is to ensure that the water is safe for discharge or reuse.

5. Sludge Management

Throughout the treatment process, sludge is generated. This sludge must be treated separately to reduce its volume and make it safer. Common methods include anaerobic digestion, which produces biogas, and composting, which can create a valuable soil amendment.

Innovations in Wastewater Treatment

The landscape of wastewater treatment is evolving, thanks to technological advancements. Here are some innovations transforming the industry:

1. Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, allowing for higher quality effluent and smaller footprint operations. This technology is ideal for areas with limited space.

2. Constructed Wetlands

These engineered ecosystems mimic natural wetlands to treat wastewater. They are cost-effective and environmentally friendly, providing additional habitats for wildlife.

3. Resource Recovery Facilities

Modern WWTPs are increasingly focusing on recovering valuable resources from wastewater. This includes extracting nutrients like nitrogen and phosphorus, which can be used as fertilizers, and capturing biogas for energy production.

The Benefits of Wastewater Treatment Plants

Investing in wastewater treatment has far-reaching benefits:

1. Economic Advantages

Efficient wastewater treatment supports local economies by ensuring clean water for industries and agriculture. It also creates jobs in engineering, operations, and maintenance.

2. Environmental Sustainability

By reducing pollution and conserving water resources, wastewater treatment plants contribute to a healthier planet. They play a critical role in combating climate change by mitigating greenhouse gas emissions from untreated wastewater.

3. Improved Public Health

Access to treated wastewater prevents health risks associated with untreated sewage. This is especially crucial in developing regions where sanitation infrastructure may be lacking.

Challenges Facing Wastewater Treatment Plants

Despite their importance, wastewater treatment plants face several challenges:

1. Aging Infrastructure

Many WWTPs are outdated and require significant investment to upgrade. Aging systems may lead to inefficiencies and increased pollution.

2. Climate Change Impacts

Extreme weather events and rising sea levels can impact the operation of wastewater treatment facilities. Adapting to these changes is crucial for future resilience.

3. Public Awareness and Engagement

Many communities are unaware of the vital role that WWTPs play. Increasing public engagement can foster support for necessary investments and improvements.

Conclusion: The Future of Wastewater Treatment

Wastewater treatment plants are more than just facilities for cleaning water; they are essential components of sustainable urban development. As technology continues to evolve, these plants will become even more efficient and capable of recovering resources, ultimately contributing to a circular economy.

By recognizing the importance of wastewater treatment and supporting innovations in the field, we can ensure that our communities remain healthy and our environment is preserved for future generations. Investing in wastewater treatment Plant is not just about managing waste; it’s about embracing a sustainable future.

2 notes

·

View notes

Text

Fenton Technologies Pvt. Ltd. is a professional Engineering equipment’s Manufacturing and Environmental research and development, production and sales of science and technology enterprises. Since its inception, we always adhere to the spirit of craftsmanship, to provide the industry with water treatment equipment and services and systematic solutions, Company Work in Three Verticals- Sewage Water Projects , Wastewater Products, Swimming Pools Products include MBR Membrane , Oil Skimmer, Screw Press, MBR STP Plant, Bar Screen, Dissolved Air Flotation (DAF) many More water treatment Equipment’s . Fenton is also Associating with Overseas partners to Keep in Forefront . Our Water Treatment Equipment Company always welcome innovation & Advance Technologies Developers for Association in Market . In product quality improvement, the water treatment equipment company “customer first” philosophy for the development, adhering to the “quality, innovation and service” business purposes, the establishment of a set of international standards of quality assurance management system.

youtube

MBR Membrane Manufacturer

Sewage treatment plant manufacturer in india

water Treatment Equipment Manufacturer

water Treatment Equipment Supplier

Belt Type Oil Skimmer Manufacturer

swimming pool manufacturer in india

2 notes

·

View notes

Text

Why Every Hotel Needs a Sewage Treatment Plant: A Smart Step Towards Sustainability

Water is a critical resource, and managing wastewater efficiently is essential for any business—especially in the hospitality sector. For hotels, sustainability, hygiene, and regulatory compliance are non-negotiable. One of the most effective ways to achieve all three is by installing a sewage treatment plant for hotels. These systems not only handle wastewater effectively but also contribute significantly to cost savings and environmental protection.

The Importance of Sewage Management in Hotels

Hotels generate a substantial amount of wastewater daily through activities like bathing, washing, laundry, cooking, and cleaning. If this wastewater is not treated properly, it can lead to serious environmental and health issues. A sewage treatment plant for hotels is designed to treat this wastewater using physical, chemical, and biological processes to remove harmful contaminants and make the water safe for reuse or safe disposal.

Benefits of Installing a Sewage Treatment Plant in Hotels

1. Environmental Compliance

Every hotel must comply with local and national pollution control regulations. Having an in-house sewage treatment facility ensures the hotel meets the required discharge standards, avoiding penalties or operational interruptions.

2. Water Reuse and Conservation

Modern STPs purify wastewater to a level where it can be reused for gardening, flushing toilets, and even cooling systems. This significantly reduces the hotel’s dependency on fresh water sources, helping in water conservation and reducing utility bills.

3. Operational Cost Savings

Though the initial investment in a sewage treatment plant for hotels may seem significant, the long-term savings are substantial. Reduced water bills, lower fines for non-compliance, and decreased environmental impact all contribute to a better bottom line.

4. Enhanced Brand Image

Guests today are increasingly eco-conscious. A hotel that demonstrates sustainable practices—like treating and recycling its wastewater—can attract more customers and build a stronger brand reputation.

How Does a Hotel STP Work?

A typical sewage treatment plant for hotels includes primary treatment (screening and sedimentation), secondary treatment (biological processing), and tertiary treatment (filtration and disinfection). The treated water is odorless, colorless, and safe for reuse. The plant can be fully automated and designed with energy-efficient technologies to minimize manual intervention and electricity consumption.

Factors Affecting Cost and Design

The cost of an STP for a hotel depends on various factors such as:

Capacity (based on the number of rooms and expected occupancy)

Type of treatment technology (MBR, MBBR, SBR, etc.)

Space availability and layout

Level of automation required

It is important to consult with wastewater treatment experts who can assess the hotel’s needs and suggest a suitable, cost-effective, and sustainable solution.

Final Thoughts

Installing a sewage treatment plant for hotels is no longer just an option—it’s a necessity. It ensures compliance, promotes sustainability, enhances hygiene, and ultimately leads to long-term savings. Whether you’re building a new property or upgrading an existing one, an efficient STP should be a part of your infrastructure planning.

Choose a smart, eco-friendly solution that serves your guests, your budget, and the environment.

Original Source:- https://a3tecnocrafts.blogspot.com/2025/04/why-every-hotel-needs-sewage-treatment.html

#waste water treatment#a3technocrafts#zero liquid discharge plant#sewer treatment plant#industrial wastewater management

0 notes

Text

MBR Technology: The Key to Sustainable Water Solutions in the USA

MBR membrane systems provide cutting-edge wastewater treatment in the USA, enhancing the quality of effluent while promoting sustainability and resource conservation. Feel free to contact us; we are here for you 24/7. Call us at +86-130-0635-3124.

#MBR Technology#MBR Membrane#Membrane Bioreactor#Membrane Bioreactor for Wastewater Treatment#MBR Wastewater Treatment#Membrane Bioreactor Technology#MBR Water Treatment

0 notes

Text

Premium MBR Membrane Manufacturer in USA

Looking for a reliable MBR membrane manufacturer in the USA? Oxymo Technology offers top-notch, high-performance membranes for all your water treatment needs. Feel free to contact us; we are here for you 24/7.

#MBR#MBR Plant#MBR Technology#MBR Reactor#MBR System#mbr process#mbr membrane#mbr suppliers#mbr membrane suppliers#mbr membrane china#mbr membrane manufacturer

1 note

·

View note

Text

Best STP Plant Manufacturer/Supplier for Restaurants

In the bustling world of restaurants, managing wastewater efficiently is crucial for maintaining hygiene, complying with regulations, and ensuring a seamless dining experience. Restaurants generate significant amounts of wastewater, which includes everything from food scraps and grease to detergents and cleaning agents. Properly treating this wastewater is essential for safeguarding public…

#3D Aqua#DAF systems#India STP supplier#MBBR technology#MBR technology#restaurant wastewater management#restaurant wastewater treatment#sewage treatment plant supplier#STP plant manufacturer#Water Treatment Technology

0 notes

Text

The Hinada Company: A Case Study in Ultrafiltration Membrane Production

When it comes to delivering potable water, ultrafiltration membranes play a critical role in the water treatment and purification industry. Hinada is well recognized as a premier ultrafiltration membrane producer among the sector's elite. Hinada has made a name for itself by consistently exceeding customer expectations in terms of innovation, quality, and environmental friendliness. We'll explore ultrafiltration membranes and the work of Hinada, a pioneer in the field.

Hinada: An Industry Leader in Ultrafiltration Membrane Production

Hinada is a frontrunner in the manufacture, distribution, and marketing of ultrafiltration membranes. Water treatment, food and beverage, pharmaceuticals, and other sectors all benefit from the innovative membrane technologies developed by the company thanks to its commitment to R&D.

Hinada's ultrafiltration membranes stand out due to their efficiency at filtering out pollutants such as suspended solids, bacteria, and viruses. With such exactitude, even the purest water may be manufactured with confidence. Hinada's membranes are highly sought after by those in need of dependable water treatment solutions due to its longevity, efficient filtration, and constant performance.

Hinada's ultrafiltration membranes have several advantages.

Modern Science- When it comes to ultrafiltration membranes, Hinada is at the forefront of innovation since it uses state-of-the-art production procedures and state-of-the-art research to create its products.

Specialized Answers– The company understands that specialized products are required for certain uses. Hinada provides its varied clients with a selection of membrane types, pore sizes, and materials to meet their individual requirements.

Durability and Longevity:- Thanks to Hinada's attention to detail, you may rest assured that their membranes will last for a long time without breaking down.

Attention to the Environment:-Hinada's membranes encourage responsible water use by cutting down on waste and saving energy during the filtration process, two factors that are very important in today's focus on sustainability.

Compliance and Certification:- Customers may be assured that Hinada's ultrafiltration membranes are of the highest quality and performance because they have been tested and certified in accordance with international standards.

FAQs-

Q1-What is it and how does it function?

In order to remove impurities from liquids, ultrafiltration employs a semi-permeable membrane. Because it functions on the size exclusion principle, it lets through water molecules but traps bacteria and viruses.

2- For what applications are Hinada's ultrafiltration membranes useful?

Hinada's ultrafiltration membranes are used in many different fields, from the production of food and drink to the processing of pharmaceuticals and biotechnology.

3- When it comes to industrial use, how scalable are Hinada's membranes, and can they be used in smaller-scale applications as well?

Hinada does, in fact, provide a selection of ultrafiltration membranes that may be scaled to meet the needs of any business. Hinada has alternatives whether you need a large-scale system to treat water for an entire town or a small-scale system for a single factory.

4- To what extent does Hinada's membrane production process take into account environmental concerns?

Sustainability and eco-friendliness are priorities for Hinada. The company's membranes are created with economy in mind, using less power and producing less trash than comparable products on the market. Hinada's membranes are built to last, so they won't need to be replaced as often throughout the course of their service life.

Conclusion

Hinada is an industry leader in ultrafiltration membranes thanks to its commitment to innovation, quality, and sustainability. Its dedication to R&D and wide selection of membrane solutions make it a go-to for businesses in need of cutting-edge water purification technology. Hinada's commitment to a sustainable future is shown in the ultrafiltration membranes it uses to guarantee the production of pure water.

Also Read: mbr membrane bioreactor, mbr membrane manufacturers, membrane bioreactor for wastewater treatment,

#ultrafiltration systems water treatment#wastewater treatment equipment#edi electrodeionization#ultra filtration system#electrodeionization system#pvdf ultrafiltration membrane#UF System#hollow fiber uf membrane#uf membranes#ultrafiltration membrane#ultrafiltration unit#uf ultrafiltration#ultrafiltration membrane manufacturers#mbr reactor#mbr technology#mbr membrane bioreactor#mbr membrane manufacturers#membrane bioreactor for wastewater treatment#mbr wastewater#mbr membrane#mbr wastewater treatment#Water Treatment Equipment Suppliers

0 notes

Text

The future of hospital sewage treatment plant is driven by innovation and sustainability. By adopting advanced treatment methods such as MBRs, electrocoagulation, AI-powered monitoring, and Zero Liquid Discharge systems, hospitals can ensure the safe and efficient management of wastewater. With ongoing advancements in technology, the goal of achieving cleaner effluent, reduced environmental impact, and cost-effective operations is becoming a reality for healthcare facilities worldwide.

0 notes

Text

Find The Best Sewage Treatment Plant Manufacturer In Gurgaon ?

Sewage treatment is very critical when it comes to the simple matter of cleaning up our environment. Commercial RO Plant is your Sewage Treatment Plant Manufacturer in Gurgaon which offers proficient and efficient sewage treatment solutions.

Introduction:

Sewage treatment is very important aspect in order to keep the area clean and healthy. The population of Gurgaon, one of the emerging urban metro cities in India, is growing day by day, for which the demands for proper sewage treatment system also increasing. For this, high demand of Sewage Treatment Plants (STPs) is observed. Commercial RO Plant is the Sewage Treatment Plant Manufacturer in Gurgaon, providing efficient Sewage Treatment Plants to treat waste water and conserving environment.

Why Sewage Treatment?

Sewage treatment is not only a process that has to do with the environment and disposal of wastes. Proper treatment of wastewater also helps in:

1. Conserving water resources

2. Measures to enhance Quality of Water for Irrigation

3. Protection from pollution of the rivers, lakes, and ground water Source Type: The source of the water that we are to safeguard is the rivers, lakes, and even the groundwater. Compliance: One way we can prevent pollution of rivers, lakes and ground water is to follow the following options.

4. Protecting public health

Sewage treatment is very important for the health of the people and at Commercial RO Plant, we have dedicated ourselves to fulfill the requirements of customers in Gurgaon with excellent solutions.

Types of Sewage Treatment Plants:

Commercial RO Plant offers a wide range of STPs tailored to different requirements:

1. Domestic Sewage Treatment Plants: Suitable for installation in homes, apartments, and small offices and commercial buildings

2. Commercial Sewage Treatment Plants: Most suitable for use in malls, offices and other medium-scale enterprises.

3. Industrial Sewage Treatment Plants: Constructed to meet the markets of industrial scale needs.

4. Municipal Sewage Treatment Plants: This is basically meant to address challenges of sewerage produced by cities and towns.

Our STPs are capable of treating a range of sewage consisting of domestic, commercial and industrial wastewater; Our Organization is therefore the most reliable Sewage Treatment Plant Manufacturer in Gurgaon.

Advanced Sewage Treatment Technology:

Commercial RO Plant is committed to providing cutting-edge solutions and uses the latest in sewage treatment technology:

1. Membrane Bioreactors (MBR): Another type of filtration technology we used in MBR employs microfiltration membranes to essentially ‘strainer out’ the solids from liquid where bacterial action on organic matter would be much more effective.

2. Sequencing Batch Reactors (SBR): The SBR systems we provide incorporate treatment processes in one tank which has cyclic action to properly treat sewage.

3. Anoxic and Aerobic Systems: STPs of Commercial RO Plant employ both anoxic and aerobic conditions to enhance the production efficiency of microbial degradation processes.

State-of-art technologies on sewage treatment are utilized to provide one of the most effective and consistent solutions to the problems of wastewater treatment in Gurgaon.

Why Commercial RO Plant should be the Sewage Treatment Plant Manufacturer of your choice in Gurgaon?

This is a company with a core business of water treatment and circulation in various organizations, and at Commercial RO Plant we hold the values of quality, reliability and customer satisfaction to the greatest esteem. Here are a few reasons why you should choose us as your Sewage Treatment Plant Manufacturer in Gurgaon:

1. Innovative and Advanced Technology: In designing and development of STPs, we employ advanced technology.

2. Customized Solutions: We can further deploy a team of experts to help you develop sewage treatment plants that are right for your enterprise.

3. Cost-Effective: Both our advanced STPs are economical and low on power consumption as well as do not demand much attention in terms of maintenance.

4. Eco-friendly: Commercial RO Plant’s STPs have always aimed at discharge of purified water safely so as to contribute towards the stabilization of environment and water.

5. Timely Delivery and Installation: It is our promise to deliver and install our STPs in Gurgaon and the neighboring regions as soon as possible.

6. Comprehensive After-Sales Service: We have experienced technical persons on call for routine service and repair works of your STP system.

Contacting Commercial RO Plant for Your Sewage Treatment Plant Needs:

On the official website of Commercial RO Plant, we have made it our mission to deliver the Sewage Treatment Plants that Gurgaon deserves. If you have further questions or require any help with filling in the form, kindly contact our helpful and professional staff. You can contact us through:

1. Phone: +91 921-092-1327

2. Email: [email protected]

Commercial RO Plant is your solution partner to customize sewage treatment solutions that handles your problem in the most efficient and reliable way. Rely on us, the top Sewage Treatment Plant Manufacturer In Gurgaon and get a healthy, clean, and safe environment!

#sewage treatment plant#sewage treatment plant manufacturer in gurgaon#water is life#netsol water#save water#water treatment plant

0 notes