#materialselection

Explore tagged Tumblr posts

Text

Sofa Making: Avoid These Common Mistakes for a Perfect Build!

Want to build a sofa that’s comfy, stylish, and built to last? Then steer clear of these common mistakes when choosing materials and designing your sofa! From selecting the right foam to avoiding poor fabric choices, Qube Interiors shares expert tips to help you craft a sofa that’s both durable and beautiful. Watch now to make sure your next sofa project is a success!

#SofaMaking#DIYFurniture#QubeInteriors#SofaDesign#InteriorDesign#FurnitureTips#MaterialSelection#HomeDecor#ComfortableSofa#StylishSofa#FurnitureMaking#SofaBuilding#interiordesigninspiration#designwithqube#falseceiling#hometransformation#interiordesignerhyderabad#dreamhome#falseceilingdesign

2 notes

·

View notes

Text

Selecting the Right Shim Material for Optimal Performance

Choosing the right material for your shims is essential for ensuring optimal performance and longevity in industrial machinery. Stainless steel shims are an excellent choice for environments that demand corrosion resistance, making them ideal for applications in industries like automotive and manufacturing. On the other hand, brass shim sheet provides added strength and are commonly used in high-load applications where durability is critical.

Many shim manufacturers in India offer a variety of shim materials, including ss shim plate and shim sheet metal, in different thicknesses. This ensures you can select the best option for your specific needs, whether you're working with heavy machinery or requiring precise adjustments for alignment.

Precut shims are a great time-saving solution, as they are ready for immediate installation and ensure accurate alignment in industrial machinery. By opting for these pre-made shims, you can streamline maintenance processes and improve operational efficiency.

Whether you need stainless steel shims, brass shim sheet, or shim sheet metal, partnering with reliable shim manufacturers in India guarantees that you get high-quality materials tailored to your industry’s requirements, ensuring smooth machinery operation and reduced downtime.

#ShimMaterial#OptimalPerformance#EngineeringSolutions#IndustrialMaterials#PerformanceMaterials#MaterialSelection#ShimDesign#ManufacturingEfficiency

0 notes

Text

Stay updated with the latest changes in the Interior Design course syllabus for 2025. This guide covers key topics, including design theory, space planning, material selection, sustainability practices, and advanced software techniques that will be part of the curriculum. Whether you're a student or a professional looking to enhance your skills, understanding these updates will help you stay on top of industry standards and prepare effectively for your exams and projects.

#InteriorDesignSyllabus2025#InteriorDesignCourse#InteriorDesignCurriculum#DesignTheory#SpacePlanning#MaterialSelection#SustainabilityInDesign#InteriorDesignSoftware#AdvancedInteriorDesign#InteriorDesignEducation#2025SyllabusUpdates

0 notes

Text

🌟 Polyurethane vs. Rubber: Choosing the Right Material for Your Needs! 🌟

🤔 Struggling to decide between polyurethane and rubber for your next project? Our latest blog post breaks down their differences, benefits, and ideal applications to help you make an informed choice.

🔧 Plus, explore our custom processing services tailored for large-scale plastic procurement and OEM custom plastic products.

👉 Read more here:

#polyurethane#rubber#materialselection#customprocessing#engineering#manufacturing#oem#plastic products#innovation#sustainability#industrial design#technology#futuretech#ecoideas

0 notes

Text

How do you do a montessori lesson plan

Creating a Montessori lesson plan is different from traditional lesson planning because it centers around the needs, interests, and developmental stages of the child. Instead of a rigid schedule, it focuses on providing a prepared environment and allowing the child to engage with materials at their own pace. Here's a step-by-step guide to creating a Montessori lesson plan:

1. Observation

Purpose: Begin by observing the child to understand their interests, developmental stage, and needs.

Method: Spend time watching the child during activities. Take notes on what captures their attention, challenges they face, and how they interact with materials and peers.

2. Prepared Environment

Purpose: Ensure the environment is ready to support the child’s learning.

Method: Set up the environment with materials that are appropriate for the child’s developmental stage. Materials should be accessible, aesthetically pleasing, and organized to encourage independence. Examples include practical life activities (e.g., pouring water, tying shoes), sensorial materials (e.g., cylinder blocks, color tablets), and academic materials (e.g., sandpaper letters, number rods).

3. Material Selection

Purpose: Choose specific materials that align with the child’s interests and developmental needs.

Method: Select materials from the Montessori curriculum areas (Practical Life, Sensorial, Language, Math, and Cultural subjects). For instance, if a child shows an interest in language, you might introduce sandpaper letters or a movable alphabet.

4. Presentation

Purpose: Introduce the material to the child through a demonstration.

Method: Present the material to the child in a simple, clear, and slow manner. For example, if introducing cylinder blocks, demonstrate how to remove each cylinder, mix them up, and place them back in the correct order, ensuring the child sees the process clearly.

5. Independent Work

Purpose: Allow the child to work with the material independently.

Method: After the presentation, give the child the opportunity to explore the material on their own. Encourage repetition and exploration, which helps deepen their understanding and mastery of the task.

6. Observation and Adjustment

Purpose: Monitor the child’s progress and adjust the environment or materials as needed.

Method: Continue observing how the child engages with the materials. If a child masters a material, introduce the next level of challenge. If they struggle, either offer guidance or allow them to explore at their own pace without pressure.

7. Follow the Child

Purpose: Let the child's interests guide the learning process.

Method: Be flexible in your planning. If a child shows a new interest, be ready to shift your focus to support that interest with appropriate materials and activities.

8. Record Keeping

Purpose: Track the child’s progress and plan future activities.

Method: Maintain a record of the child’s work, noting which materials they have mastered, what still challenges them, and any emerging interests. This will help in planning future presentations and selecting new materials.

Example of a Simple Montessori Lesson Plan:

Observation: Child is interested in pouring water but struggles with control.

Prepared Environment: Set up a Practical Life station with a small pitcher and cups.

Material Selection: Practical Life pouring exercise.

Presentation: Demonstrate how to hold the pitcher, pour the water into a cup without spilling, and return the pitcher to its place.

Independent Work: Child practices pouring, refilling the pitcher, and trying again.

Observation and Adjustment: Monitor the child’s progress. If they succeed easily, introduce a more challenging task, like pouring from a pitcher with a spout.

Follow the Child: If the child shows interest in other pouring activities (e.g., with different materials like beans or rice), introduce those.

Record Keeping: Note the child’s progress and plan to introduce more complex Practical Life activities.

This approach allows for flexibility, personalization, and responsiveness to each child’s unique developmental journey, which is at the core of Montessori education

#Montessori#LessonPlan#PreparedEnvironment#ChildCentered#Observation#PracticalLife#Sensorial#IndependentLearning#FollowTheChild#MaterialSelection#ChildDevelopment#HolisticEducation#IntrinsicMotivation#ChildLedLearning#MontessoriMaterials#SelfGuidedLearning#LearningByDoing#MontessoriMethod#EducationForLife

0 notes

Text

Custom Fabrication Services in Haryana

Company Overview: Meghmani Metal Industries is a prominent Manufacturer and Supplier of Custom Fabrication Services in Haryana, India. Established in 2011, Meghmani Metal Industries has consistently prioritized customer satisfaction and environmental responsibility in its operations. We handle a diverse range of projects, from high-volume production to single-unit designs. Meghmani Metal Industries offers a diverse range of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats. Capabilities and Services: Design Expertise: Specialized design services tailored to meet project requirements. Material Selection: Expertise in selecting the best materials for each fabrication project. Precision Machining: Ensures high accuracy in all fabricated parts. Welding and Joining: Proficiency in a variety of welding and joining techniques. Custom Tooling: Development of custom tooling solutions based on specific needs. Custom Finishes: A wide array of finishes to meet aesthetic and functional demands. Applications: Architectural and structural elements Automotive components Industrial machinery Equipment for the food and beverage industry Medical and healthcare devices Art and sculpture projects Meghmani Metal Industries Custom Fabrication Services in Haryana, covering cities such as Ambala, Bhiwani, Chandigarh, Faridabad, Firozpur Jhirka, Gurugram, Hansi, Hisar, Jind, Kaithal, Karnal, Kurukshetra, Panipat, Pehowa, Rewari, Rohtak, Sirsa, Sonipat. For more details, please have a professional conversation with you / your team. Read the full article

#Ambala#Architecturalandstructuralelements#Artandsculptureprojects#Automotivecomponents#Bhiwani#Chandigarh#CustomFabricationServices#CustomFabricationServicesinHaryana#CustomFabricationServicesinIndia#CustomFabricationWork#CustomFabricationWorkinHaryana#CustomFabricationWorkinIndia#CustomFinishes#CustomTooling#DesignExpertise#Equipmentforthefoodandbeverageindustry#Faridabad#FirozpurJhirka#Gurugram#Hansi#Hisar#Industrialmachinery#Jind#Kaithal#Karnal#Kurukshetra#Manufacturer#MaterialSelection#Medicalandhealthcaredevices#Panipat

0 notes

Text

From Concept to Shelf: The Journey of Packaging Label Printing

Packaging label printing is a crucial aspect of the packaging industry, playing a pivotal role in conveying vital information, ensuring brand recognition, and enticing consumers to make a purchase. This article explores the fascinating journey of packaging label printing, from the initial concept to the moment a product sits proudly on the store shelf.

Understanding the Significance of Packaging Label Printing

1. The First Point of Contact

Packaging labels are often the first point of contact between a consumer and a product. They provide essential information about the product, its ingredients, usage instructions, and branding. An attractive and informative label can create a positive impression and influence purchasing decisions.

Example: Consider a bottle of premium olive oil. The elegant label not only displays the product's quality but also provides details about its origin, flavor notes, and usage recommendations, all of which influence the consumer's decision.

2. Branding and Identity

Packaging labels are a powerful tool for establishing and reinforcing a brand's identity. The design, colors, typography, and overall aesthetics of a label are carefully chosen to align with the brand's image and values. Consistency in labeling across a product line helps build brand recognition.

Transparent Label Manufacturer: Brands looking for a modern, sleek, and minimalistic label design often collaborate with a Transparent Label Manufacturer. These labels provide a clear and clean look, allowing the product to be the focal point.

The Process of Packaging Label Printing

The journey of packaging label printing involves several intricate steps, each contributing to the creation of a label that communicates effectively and appeals to the target audience.

1. Design and Conceptualization

The process begins with the design and conceptualization phase. Designers and brand owners work together to create a label that encapsulates the product's essence. This includes choosing the right colors, fonts, imagery, and layout. The label must be visually appealing while conveying essential information clearly.

2. Material Selection

Once the design is finalized, the next step is material selection. The choice of label material is essential, as it affects the label's appearance and durability. Options include paper, plastic, or even special materials like foil for a premium look. The choice also depends on the product's environment and usage conditions.

3. Printing Techniques

Packaging label printing involves several printing techniques, with the most common ones being:

Offset Printing: Ideal for high-quality images and colors, often used for intricate label designs.

Flexographic Printing: Suitable for large production runs and labels with simple designs.

Digital Printing: Offers flexibility, allowing for on-demand printing and variable data.

The selection of the printing technique depends on the label's design, quantity, and budget considerations.

Example: A boutique chocolate manufacturer may opt for offset printing to showcase the intricate details of their label design, which features hand-painted chocolate pieces.

4. Color Management

Accurate color management is crucial to ensure consistency across different label printing runs. Color profiles are established to ensure that the label's colors match the approved design, whether it's a vibrant red for a soft drink or a muted pastel for a skincare product.

5. Die-Cutting and Finishing

After the labels are printed, the next step is die-cutting. This process shapes the label into its final form, whether it's a simple rectangle or a custom shape that complements the product's packaging. Labels may also undergo additional finishing processes such as embossing, laminating, or varnishing for added visual and tactile appeal.

6. Quality Control

Quality control is a critical part of the process. Labels are inspected for color accuracy, consistency, and defects. This step ensures that labels meet the highest standards of quality and aesthetics.

7. Application to Packaging

Once the labels are approved and quality-checked, they are applied to the product's packaging. This can be done manually for small batches or automatically for large production runs.

Example: A local artisan jam maker may apply labels to each jar of jam by hand, emphasizing the handmade and personal touch of their products.

The Importance of Compliance and Information

In addition to aesthetics and branding, packaging label printing must comply with various regulations and provide essential product information. This includes:

Ingredients: Clearly listing all ingredients used in the product, particularly important for allergen information.

Nutrition Facts: Providing accurate nutrition information, including calories, fats, proteins, and more.

Barcodes: Adding barcodes for inventory and sales tracking.

Safety Warnings: Including safety warnings, usage instructions, and any relevant legal information.

Sustainability and Environmental Considerations

In recent years, there has been a growing emphasis on sustainable packaging label printing. Many brands are opting for eco-friendly label materials, inks, and printing processes. This shift aligns with the broader goal of reducing the environmental footprint of the packaging industry.

Conclusion

The journey of packaging label printing is a meticulously planned process that combines aesthetics, information, and compliance. From concept to shelf, packaging labels serve as the bridge between brands and consumers. They convey a product's identity, entice potential buyers, and provide essential information. As the packaging industry continues to evolve, so too does the art and science of label printing, adapting to changing consumer preferences, environmental considerations, and the ever-increasing demand for creative and informative labeling. Credits : https://letragraphix.blogspot.com/2023/10/Packaging%20Label%20Printing.html

#PackagingLabels#LabelPrinting#Branding#Design#MaterialSelection#PrintingTechniques#ColorManagement#Compliance#Sustainability#ConsumerInformation#ProductIdentity

0 notes

Text

Choosing the Right Stud Bolts: Factors to Consider

Introduction

When it comes to fastening heavy-duty applications, stud bolts are the unsung heroes that provide stability and strength. These mighty bolts play a crucial role in various industries, including construction, manufacturing, and oil and gas. However, choosing the right stud bolts can be a daunting task, given the wide range of options available. Fear not! In this blog, we'll guide you through the essential factors to consider, making your selection process a breeze.

Understand Your Application

The first step in choosing the right stud bolts is to have a clear understanding of your specific application. Consider the load requirements, operating conditions, and environmental factors that the stud bolts will be subjected to. Are you fastening structural steel in a building construction project, or securing flange connections in an oil refinery? Understanding the demands of your application will help you select stud bolts that can withstand the intended load and environmental challenges.

Material Selection

Selecting the appropriate material for your stud bolts is vital to ensure their durability and longevity. Common materials for stud bolts include carbon steel, stainless steel, and alloy steel. Carbon steel is a cost-effective choice for general applications, while stainless steel offers excellent corrosion resistance in harsh environments. Alloy steel is often preferred for high-temperature applications. Consider the specific requirements of your project and consult with experts or suppliers to determine the best material option for your stud bolts.

Bolt Grade and Strength

Stud bolts come in various grades, denoting their strength and performance capabilities. The most commonly used grades are ASTM A193 and ASTM A320. Each grade has specific tensile and yield strength requirements, as well as temperature limitations. It's crucial to match the bolt grade with the load requirements of your application. Consult engineering specifications or seek advice from professionals to ensure you choose the appropriate bolt grade that can handle the intended load without compromising safety.

Thread Type and Fit

The thread type and fit of stud bolts are essential considerations. Stud bolts typically have either coarse threads (UNC) or fine threads (UNF). Coarse threads are more common and provide better resistance against loosening due to vibrations. Fine threads, on the other hand, offer higher strength in tension and are suitable for applications with limited space. Additionally, ensure that the stud bolt's thread fit matches the mating component, such as the nut or tapped hole, to ensure a secure and reliable connection.

Coatings and Surface Treatments

Applying coatings or surface treatments to stud bolts can enhance their performance and protection against corrosion. Common coatings include zinc plating, hot-dip galvanising, and epoxy coatings. These coatings provide a barrier against moisture and corrosive elements. Surface treatments like lubrication or anti-seize compounds can also aid in ease of installation and prevent galling during tightening. Consider the environmental conditions and consult industry standards to determine the most suitable coating or treatment for your stud bolts.

Quality and Certification

Last but not least, ensure that the stud bolts you choose are of high quality and meet industry standards. Look for reputable manufacturers or suppliers that provide certified products. Quality assurance certifications such as ISO 9001 ensure that the stud bolts undergo rigorous testing and adhere to strict quality control measures. Investing in high-quality stud bolts will guarantee their performance, reliability, and long-term safety in your application.

Top Stud Bolt Manufacturers in India

Delta Fitt Inc. (An Extended Unit of WMI Group) is a well-known Stud Bolt Manufacturer in India. We pride ourselves on being one of the leading manufacturers of stainless steel bolts in the industry. We use only the highest quality materials and the latest manufacturing techniques to create bolts that are strong, durable, and corrosion-resistant.

But not all stainless steel bolts are created equal. That's why it's important to choose a reputable Stainless Steel Bolts Manufacturer in Germanythat specialises in creating high-quality bolts that will stand the test of time.

Whether you're building a small structure or a large commercial building, you can trust Delta Fitt Inc and their stud bolt suppliers to provide you with the bolts you need to create a strong and durable structure.

At Delta Fitt Inc. we specialise in producing a wide range of high-quality bolts, including customised stud bolts,Eye Bolts, High Tensile Bolts, HSFG Bolts, Heavy Hex Bolts

So why wait? Contact Delta Fitt Inc and their stud bolt manufacturers today to learn more about our products and services, and see how we can help you build the structure of your dreams.

We are also Stainless Steel Bolts Manufacturer in India, Stainless Steel Bolts Manufacturer in Poland, Stainless Steel Bolts Manufacturer in France, Heavy Hex Bolts Manufacturer in Poland and High Tensile Bolts Manufacturer in Germany

Conclusion

Choosing the right stud bolts is a critical step in ensuring the stability and safety of your projects. By considering factors such as load requirements, material selection, bolt grade, thread type, coatings, and quality assurance, you can make an informed decision. Remember to consult with experts, refer to industry standards, and rely on reputable suppliers to guide you in selecting the best stud bolts for your specific application.

#Studbolts#Fasteners#Construction#Manufacturing#Industrialapplications#Heavy-dutyfastening#Loadrequirements#Materialselection#Boltgrades#Threadtypes#Coatings#Surfacetreatments#Qualityassurance#Safety#Engineering#Corrosionresistance#Structuralintegrity#Choosingtherighthardware#Installationtips#Industrystandards

0 notes

Video

tumblr

Quality takes patience, but it’s always worth the wait! ✨ #fashionbusiness #qualityoverquantity #textiledesign #fashionproduction #fashionjourney #materialselection #fashiondevelopment #fashionindustry #designprocess #textilequality #fashiondesigner #fashioninspo #apparelproduction #fashionmanufacturing #productionready #sourcingfabrics #fashionstudio #fashionlessons #qualitymatters #fashionentrepreneur #fashionbrand #trusttheprocess #fashioninnovation #fashiontrends #creativejourney #materialtesting #fashionbuyers #fabricselection #qualitycontrol #fabricreview #fashiondesignerslife

1 note

·

View note

Photo

How to Choose the Right Angle Bar for Your Project

When embarking on a construction project, one of the key decisions you'll need to make is choosing the right materials. One essential component that often gets overlooked is the angle bar. Angle bars are versatile and commonly used in various construction projects, from building frameworks to supports and braces. But with so many options available, how do you know which angle bar is the right choice for your project?

construction #anglebar #buildingmaterials #projectmanagement #structuralengineering

The importance of selecting the right angle bar cannot be overstated. Choosing the wrong type or size can lead to structural weaknesses, compromising the integrity and safety of your project. To help you make an informed decision, here are some key factors to consider when choosing the right angle bar for your project:

Material: Angle bars are typically made from either carbon steel, stainless steel, or aluminum. The material you choose will depend on the specific requirements of your project. Carbon steel angle bars are the most common choice for general construction projects, while stainless steel is preferred for applications requiring corrosion resistance. Aluminum angle bars are lightweight and ideal for projects where weight is a concern.

Size: Angle bars come in a variety of sizes, ranging from small, lightweight angles to larger, heavier-duty options. The size of the angle bar you choose will depend on the load-bearing requirements of your project. Consider factors such as the weight of the materials being supported and the overall structure of the project when selecting the size of the angle bar.

Thickness: The thickness of the angle bar is another important consideration. Thicker angle bars are more durable and can withstand heavier loads, making them ideal for structural supports and braces. Thinner angle bars are suitable for lighter applications where weight is a concern. Be sure to consult with a structural engineer to determine the appropriate thickness for your project.

Finish: Angle bars come in a variety of finishes, including galvanized, painted, and plain. The finish you choose will depend on the aesthetic requirements of your project as well as the environmental conditions it will be exposed to. Galvanized angle bars are corrosion-resistant and suitable for outdoor applications, while painted angle bars offer a customizable appearance.

Cost: Finally, cost is always a factor to consider when choosing building materials for your project. While it may be tempting to opt for the cheapest option, it's important to weigh the cost against the quality and durability of the angle bar. Investing in a higher-quality angle bar may save you money in the long run by reducing the need for repairs and replacements.

By taking these factors into consideration, you can ensure that you choose the right angle bar for your project. Remember, the angle bar is a crucial component of your construction project, so it's important to select the best option for your specific needs. If you're unsure about which angle bar is right for your project, don't hesitate to consult with a structural engineer or construction professional for guidance.

Choosing the right angle bar may seem like a small detail, but it can have a big impact on the success of your project. By carefully considering the material, size, thickness, finish, and cost of the angle bar, you can ensure that your construction project is built to last.

Next time you're planning a construction project, don't overlook the importance of choosing the right angle bar. It may be a small piece of the puzzle, but it plays a crucial role in the overall strength and stability of your structure. Make the right choice and set your project up for success.

constructiontips #structuralintegrity #buildingstrong #materialselection #projectplanning #buildingsuccess

0 notes

Text

Why Material Selection is Critical When Choosing Your Shims

When choosing a shim, the material is a key factor that determines its performance. Shims are used to fill gaps, align components, and provide spacing in a wide range of applications. Selecting the right material ensures that the shim functions effectively and lasts longer. In this article, we’ll explore the most common materials used in shim manufacturing, including stainless steel shims, brass shim sheets, precut shims, and shim sheet metal, and help you understand why choosing the right one is crucial for your specific application.

Stainless Steel Shims:

Stainless steel shims are the go-to option when resistance to rust, wear, and high pressure is needed. These shims are ideal for harsh environments, such as automotive, industrial machinery, and construction. Stainless steel offers excellent durability and strength, making it a popular choice for heavy-duty applications. It also provides good corrosion resistance, which is vital in wet or outdoor conditions. If you’re looking for reliable shim manufacturers in India, stainless steel shims are often their most requested option due to their long-lasting qualities and versatility.

Brass Shim Sheets:

Brass shims are known for their flexibility and high conductivity. These properties make brass shim sheets ideal for electrical applications, where conductivity is critical. Brass is also used in decorative applications because of its attractive appearance and ease of use. Its malleability allows it to fit various shapes, making it versatile for precision applications. If you require brass shim sheet for your specific needs, sourcing from a trusted shim manufacturer in India can ensure quality and precision.

Aluminum and Plastic Shims:

For lighter applications, aluminum shims are a great choice due to their lightweight nature and corrosion resistance. They are commonly used in industries where weight reduction is important, such as aerospace and electronics. On the other hand, plastic shims are used in non-load-bearing applications where strength is not the main concern. These shims are cost-effective and suitable for industries like packaging and light assembly. For precut shims, manufacturers typically offer customizable options to suit specific dimensions and weight requirements.

How to Choose the Right Material:

When selecting a shim, consider the specific demands of your application. If you require high strength and corrosion resistance, stainless steel shim plates are your best option. For applications where conductivity is important, choose brass shim sheets. If weight is a priority, aluminum is the ideal choice, while plastic shims are perfect for non-load-bearing uses. Shim sheet metal can be used in a variety of applications, ensuring durability and functionality. By understanding the needs of your project, you can choose the perfect material for your shim and ensure optimal performance.

In summary, material selection plays a crucial role in ensuring the efficiency and durability of shims across industries. Choose wisely based on your specific requirements for corrosion resistance, conductivity, strength, or weight. Whether you need stainless steel shims, brass shim sheets, or shim sheet metal, working with trusted shim manufacturers in India guarantees that you receive high-quality and reliable components.

#MaterialSelection#Shims#EngineeringMaterials#PrecisionEngineering#IndustrialSolutions#MechanicalEngineering#ManufacturingInsights#CustomShims#AutomotiveParts#IndustrialDesign

1 note

·

View note

Video

youtube

Mastering Party Bunting Banner Creation

Are you ready to master the art of creating stunning party bunting banners? Look no further! This comprehensive course is perfect for anyone looking to elevate their event planning game with personalized and stylish decorations. From color coordination to material selection, you'll learn all the essential skills needed to design and craft eye-catching bunting banners that are perfect for any occasion. Join us and unleash your creativity in the world of bunting banner creation!

In this course, you will learn:

· How to design and create party bunting banners from scratch

· Techniques for choosing color schemes and patterns for impactful designs

· Tips for selecting the right materials for indoor and outdoor settings

· Understanding the importance of bunting banners in event decor

· Creating mood boards for design inspiration

· Crafting triangle and swallowtail bunting banners with step-by-step guidance

· Styling and presentation techniques for maximum visual impact

· Troubleshooting common design issues and personalizing bunting banners for specific events

Skills you'll gain:

· Designing and crafting bunting banners for parties

· Understanding color coordination and patterns

· Choosing the appropriate materials for different settings

Detailed Course Outline:

· Module 1: Introduction to Party Bunting Banners

· Module 2: Design Principles for Bunting Banners

· Module 3: Material Selection for Bunting Banners

· Module 4: Triangle Bunting Banner Creation

· Module 5: Swallowtail Bunting Banner Creation

· Module 6: Size and Dimension Considerations

· Module 7: Styling and Presentation Techniques

· Module 8: Advanced Bunting Banner Tips and Tricks

YouTube Video Tags:

bunting banners, party decorations, event planning, DIY crafts, design principles, color coordination, pattern selection, materials for banners, triangle banner tutorial, swallowtail banner tutorial, banner sizing, banner styling, crafting techniques, visual impact, event decor, personalized banners, creative designs, hands-on activities

YouTube Hashtags:

#buntingbanners #partydecorations #eventplanning #diycrafts #designideas #colorcoordination #materialselection #bannerstyling #craftingtutorial #eventdecor #personalizedbanners #creativestyle #handsonactivities #trianglebanners #swallowtailbanners #visualimpact #bannerdesigns #stylingtips #diyprojects

0 notes

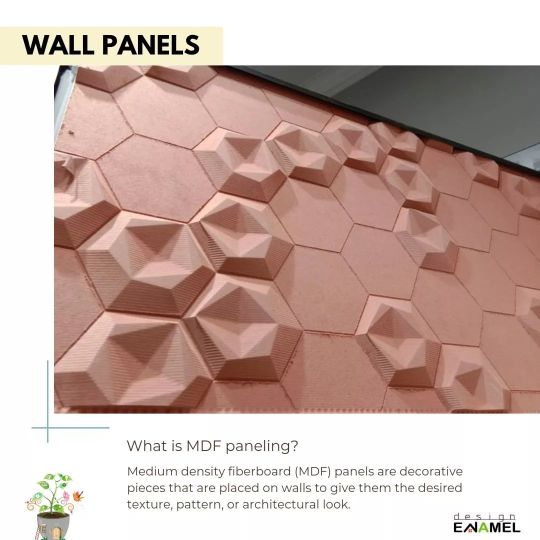

Photo

This Mdf panel we will use in our ongoing residential project so please keep in touch with us to see the magic. . . . . . #mdfpanel #mdfpanelling #mdf #mdfdecor #mdfpanels #wallpanels #wallpanelingideas #wallpaneling #walltreatment #wallideas #walldecor #wallsurface #surfacefinishing #interiorwalltreatment #interiorwall #interiormaterials #materialselection #interiormaterialtrend #interiortrend #interiorinspirations #interiorinspo #interiorideas #viralinterior #interiorinfo #information #materialknowledge #interiorstudents #archistudent #interiorarchitect #interiorarchitecturedesign (at Bhawani Peth) https://www.instagram.com/p/CgbFpG7ojZt/?igshid=NGJjMDIxMWI=

#mdfpanel#mdfpanelling#mdf#mdfdecor#mdfpanels#wallpanels#wallpanelingideas#wallpaneling#walltreatment#wallideas#walldecor#wallsurface#surfacefinishing#interiorwalltreatment#interiorwall#interiormaterials#materialselection#interiormaterialtrend#interiortrend#interiorinspirations#interiorinspo#interiorideas#viralinterior#interiorinfo#information#materialknowledge#interiorstudents#archistudent#interiorarchitect#interiorarchitecturedesign

1 note

·

View note

Photo

Posted @withregram • @aloma_homestaging_design Love how this came together! #materialselection #alomahsd #design #newbuild https://www.instagram.com/p/CPePUBqlxxV/?utm_medium=tumblr

0 notes

Photo

A short Guide of Window blinds.... . . . . .#windowblinds #blind #widnowtreatments #interiormaterials #materialguide #materialselection #blindselection #interiordecorating #interiorblogger #interiordesign #interiortips #interiordesigner #interiorguide #interiormaterials #interiorstyling #interiordecor #interiordesignjob #interior #interiornotes #studentofinterior #studentguides #studentofarchitecture #architectureprofession #interiorprofessionals #architecturedesign #learninteriordesign #homedecor (at Delhi, India) https://www.instagram.com/p/COJd6J_p3uZ/?igshid=1nsiabi88nwuq

#windowblinds#blind#widnowtreatments#interiormaterials#materialguide#materialselection#blindselection#interiordecorating#interiorblogger#interiordesign#interiortips#interiordesigner#interiorguide#interiorstyling#interiordecor#interiordesignjob#interior#interiornotes#studentofinterior#studentguides#studentofarchitecture#architectureprofession#interiorprofessionals#architecturedesign#learninteriordesign#homedecor

0 notes

Photo

Scrolling around for new items 🥥 earth tones! . . #interiordesign #materialselection #bali #baliindonesia #fabricselection #furnitureselection #interiordesigner #maitegranda #designstudio #interiorsbymaitegranda #miami #nyc https://www.instagram.com/p/BthSGncHPCE/?utm_source=ig_tumblr_share&igshid=v7s2u8kt8gkv

#interiordesign#materialselection#bali#baliindonesia#fabricselection#furnitureselection#interiordesigner#maitegranda#designstudio#interiorsbymaitegranda#miami#nyc

0 notes