#marine air compressor

Explore tagged Tumblr posts

Text

Invictus provides the best service for equipment rental in the UAE for the oil and gas, marine, power, and construction industries. Our rental fleet covers a wide range of light and heavy equipment, catering to your needs and requirements. With over a decade of experience, we have established ourselves as a reliable partner for our clients’ energy needs, providing top-quality equipment and services.

The main backbone of any energy project are generators and power plants, and we offer a wide range of options to suit your specific needs. Whether you require a small generator for backup power or a large power plant for your operations, we’ve got you covered. Our generators are efficient, reliable, and easy to operate, ensuring an uninterrupted power supply for your operations.

Diesel tanks are essential for storing and transporting fuel, and we offer a range of options to suit your needs. Our diesel tanks are built to last, ensuring the safe and efficient storage of fuel for your operations.

Load banks and transformers are critical components for the testing and commissioning of electrical systems. We offer a range of load banks and transformers that are built to the highest standards, ensuring accurate and reliable testing of your electrical systems.

Portable air compressors are essential for a range of applications, from powering pneumatic tools to providing compressed air for equipment. Our air compressors are built to last, ensuring reliable and efficient operation for your operations.

Mobile tower lights are essential for providing illumination in remote locations, and we offer a range of options to suit your needs. Our tower lights are portable, easy to operate, and built to withstand harsh environments, ensuring reliable lighting for your operations.

High-pressure triplex pumps are essential for a range of applications, from well drilling to pressure testing. Our triplex pumps are built to the highest standards, ensuring reliable and efficient operation for your operations.

Cementing units are essential for the oil and gas industry, and we offer a range of truck and skid-mounted options to suit your needs. Centrifugal pumps are essential for a range of applications, from water transfer to chemical processing. Our centrifugal pumps are available in engine and motor-driven options, ensuring reliable and efficient operation for your operations.

Reverse osmosis plants and storage tanks are essential for the oil and gas industry, and we offer a range of options to suit your needs. Our reverse osmosis plants are built to the highest standards, ensuring reliable and efficient water treatment for your operations.

At Invictus Oil Field, we are committed to providing the best possible service and support to our clients. We offer a range of services, from equipment installation and commissioning to maintenance and repair. Our team of experts is always on hand to provide technical support and advice, ensuring that your operations run efficiently.

In conclusion, Invictus Oil Field is your one-stop destination for all your energy needs. With our extensive range of products and services, we are committed to providing reliable, efficient, and cost-effective solutions for the oil and gas industry. If you are looking for industrial equipment rental in the UAE or across the world, contact us for the best deal.

Generators

Power Plants

Diesel Tanks

Load Banks & Transformers

Portable Air Compressors

Mobile Tower Lights

High Pressure Triplex Pumps

Cementing Units (Truck and Skid Mounted)

Centrifugal Pumps (Engine and Motor driven)

Reverse Osmosis Plant, Storage Tanks (Water and Acid)

2 notes

·

View notes

Text

Dasset Engineering: Your Trusted Partner for High-Performance Crankshafts in India

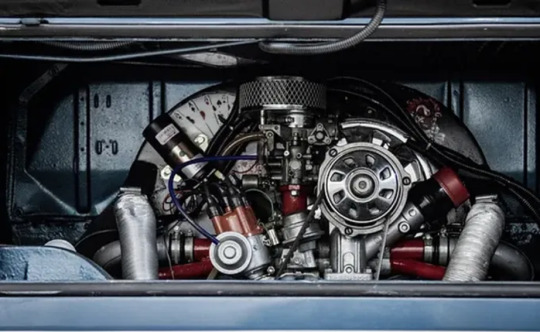

Crankshafts are a critical engine component, serving as the backbone of power transmission and converting linear piston motion into rotational motion. Whether you’re running an automotive engine, stationary machinery, marine engines, or agricultural equipment, the quality of the crankshaft can significantly impact performance, efficiency, and reliability. At Dasset Engineering, we specialize in providing top-tier crankshafts tailored to meet the diverse needs of various industries, making us the best crankshafts manufacturer and supplier in India.

Why Choose High-Quality Crankshafts?

The crankshaft is subjected to immense pressure, high temperatures, and constant motion. Therefore, it must be designed with the utmost precision and constructed from high-quality materials to withstand these stresses. A well-engineered crankshaft minimizes vibrations, reduces engine wear, and ensures optimal performance. That’s where Dasset Engineering comes in, offering a wide range of forged and cast crankshafts to suit every requirement.

Our Crankshaft Solutions: Forged and Cast Crankshafts

At Dasset Engineering, we pride ourselves on delivering high-performance crankshafts that cater to a broad spectrum of applications:

Forged Crankshafts: Forged crankshafts are manufactured through a process that compresses and molds the metal, resulting in a denser, more durable component. These crankshafts are ideal for high-performance engines, such as those in race cars, heavy-duty trucks, and industrial machinery, where strength and resistance to fatigue are paramount. The forging process ensures minimal internal defects, offering excellent structural integrity and superior tensile strength.

Cast Crankshafts: Cast crankshafts are produced by pouring molten metal into a mold, allowing it to cool and solidify into shape. They are suitable for applications where moderate performance and cost-effectiveness are essential. Our advanced casting techniques produce crankshafts with uniformity, precision, and a smooth surface finish. Cast crankshafts are often used in standard automotive engines, air compressors, and other moderate-duty applications.

Both types of crankshafts are available in fully finished or semi-finished conditions. This flexibility allows us to cater to your specific needs, whether you require a crankshaft ready for installation or one that can be customized further to fit unique engine requirements.

Applications of Dasset Engineering Crankshafts

Our crankshafts are designed to deliver optimal performance across various industries and applications:

Automotive Engines: Our crankshafts provide the strength and balance necessary for passenger cars, commercial vehicles, and racing engines, ensuring smooth operation and longevity.

Stationary Engines: For generators, pumps, and industrial equipment, we supply crankshafts that deliver consistent power and reliability.

Marine Engines: In harsh marine environments, our crankshafts offer superior corrosion resistance and durability.

Agricultural and Industrial Engines: Used in tractors, earthmovers, and heavy machinery, our crankshafts are built to handle tough conditions with ease.

Air and Refrigeration Compressors: We provide crankshafts for compressors that demand high precision and balance to maintain performance and reduce vibration.

Why Dasset Engineering Stands Out

Dasset Engineering has earned a reputation as the best crankshaft manufacturer and supplier in India for several reasons:

Commitment to Quality: We use only the finest materials and the latest technologies to produce crankshafts that meet international quality standards.

Expert Engineering: Our team of skilled engineers ensures each crankshaft is meticulously designed and manufactured to deliver peak performance.

Customization Options: We provide both standard and custom solutions to fit the specific needs of our clients, offering flexibility in terms of design, materials, and finishes.

Stringent Testing: Every crankshaft undergoes rigorous quality control tests to ensure it meets our high standards for durability, performance, and reliability.

Conclusion

Dasset Engineering is your trusted partner for high-performance crankshafts in India. Whether you need forged crankshafts for a high-power application or cast crankshafts for cost-effective solutions, we provide products that promise quality, performance, and longevity. Our crankshafts are designed to drive efficiency and reliability, making us the preferred choice for automotive, marine, industrial, and agricultural applications.

Choose Dasset Engineering for all your crankshaft needs and experience unmatched quality and service. Contact us today to learn more about our offerings and how we can support your business!

#Best crankshaft manufacturer in India#High-performance crankshafts for automotive engines#Forged crankshafts supplier for industrial engines#Cast crankshafts for marine and agricultural applications#Crankshaft manufacturer for air compressors in India#Top crankshaft suppliers for tractors and earthmovers#Buy high-quality forged crankshafts in India#Custom crankshafts for industrial and stationary engines#Durable crankshafts for refrigeration compressors#Crankshafts for heavy machinery engines in India#High-strength crankshafts for race cars and heavy-duty trucks#Fully finished and semi-finished crankshafts suppliers#Affordable cast crankshafts for automotive applications#Leading supplier of crankshafts for agricultural equipment#Customized crankshaft manufacturing services in India

0 notes

Text

Below filters we have in stock worldwide delivery

ALL ORIGINAL PRODUCTS OF TMC / TAMROTOR

*NT0063 - 4PCS OIL SEPARATOR Item 3, 032 677 28

*NT7141 - 5PCS Oil change kit 301657

*NT4561 - OIL FILTER T25 -243898-295244

*NT0728 - 4PCS V Belt

*NT8160 - 6 Pcs OIL SEPARATOR ELEMENT( 297003

-NT4935- O RING,297003-NT1612 Filter,297003-*NT1228-O-RING, NT1679 supporting bushing W 1.5mm orifice

*NT4921 - 1PC AIR FILTER ELEMENT 300567

*NT5701 separator Kit 3pcs -301790- 295696 NT8160 OIL SEPARATOR ELEMENT with oring NT1228-NT1612 filter -, NT4935 O-ring, NT1679 supporting bushing W 1.5mm orifice (6pcs filter)

WE ARE STOCKIST OF MARINE FILTERS

WORLDWIDE DELIVERY

Exporter of machinery and parts Worldwide

IDEAL DIESEL MARINE

E-MAIL: [email protected] (Primary)

[email protected] ( cc )

#NT0728#NT8160#NT4935#NT7141#NT4921 - 1PC AIR FILTER ELEMENT 300567#NT5701 separator Kit 3pcs -301790- 295696 NT8160 OIL SEPARATOR ELEMENT with oring NT1228-NT1612 filter -#NT4935 O-ring#NT1679 supporting bushing W 1.5mm orifice (6pcs filter)#NT4561 - OIL FILTER T25 -243898-295244#NT8160 - 6 Pcs OIL SEPARATOR ELEMENT( 297003#NT0063 - 4PCS OIL SEPARATOR Item 3#032 677 28#NT7141 - 5PCS Oil change kit 301657#NT4935- O RING#297003-NT1612 Filter#297003-*NT1228-O-RING#NT1679 supporting bushing W 1.5mm orifice#TMC FILTER TAMROTOR NT0063 NT7141 NT4561 NT0728#TMC MARINE COMPRESSOR FILTER-#TMC MARINE COMPRESSOR FILTER

0 notes

Text

Adamsllc - Devasa+ (3)

For a reliable and durable product, Adams International is the perfect option. Its engines offer products that guarantee quality and performance. With over 80 years of experience in industrial motor production, CSM MOTORI is one of the most reliable brands in the world today. They offer a wide range of products including marine, industrial and agricultural engines. MARELLI MOTORI is another well-known brand in the motor industry. Its products are known for their innovative designs and high quality materials. They specialize in manufacturing motors for a variety of applications including air compressors, electric vehicles, small machinery and more. MARELLI MOTORI is a leader in the engine industry with over 60 years of experience. HIGEN MOTOR is a reliable and energy efficient motor for any application. Their products are designed to provide maximum efficiency and performance while still being cost effective. The motors have advanced features such as quiet operation and long life expectancy. It's the perfect choice for those who need a reliable and efficient engine that won't break the bank. Whatever your needs, our company offers you reliable and cost-effective solutions. With their long history in the industry, you can be sure that every engine is designed to last and meet all your requirements.

2K notes

·

View notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

Latest Update on Whipchek for Industrial Use & Importance

In industrial settings, high-pressure hoses play a crucial role in air, water, hydraulic, and chemical transfer operations. However, unexpected hose failures can lead to dangerous whipping actions, posing serious safety risks. Whipcheks are a critical safety measure designed to prevent hoses from whipping uncontrollably in case of a sudden rupture or coupling failure.

With new advancements in design and durability, Whipcheks are now more efficient than ever, providing enhanced protection and workplace safety in industries such as construction, mining, oil & gas, and manufacturing.

Latest Updates on Whipchek Technology

The latest Whipcheks are designed with improved materials, better flexibility, and enhanced pressure resistance, making them a must-have safety feature for industrial hose applications.

1. Reinforced High-Tensile Steel Cable

Stronger and more durable than previous versions.

Provides superior resistance to sudden hose bursts and pressure surges.

2. Enhanced Pressure Handling Capacity

Designed to withstand higher pressure levels in industrial operations.

Suitable for air, hydraulic, water, and chemical hose applications.

3. Improved Flexibility & Compatibility

Updated design allows for easy installation on hoses of various diameters.

Available in different sizes and configurations for customized use.

4. Quick & Secure Installation

Tool-free installation ensures fast and secure attachment.

Helps minimize downtime and maximize safety in industrial setups.

5. Meets & Exceeds Industry Safety Standards

Compliant with OSHA, MSHA, and API safety regulations.

Helps industries meet legal safety requirements and reduce workplace hazards.

Importance of Whipchek in Industrial Use

A Whipchek serves as a safety net against hose whip accidents, preventing severe injuries, equipment damage, and operational downtime.

1. Preventing Hose Whip Injuries

Stops high-pressure hoses from whipping dangerously upon failure.

Prevents life-threatening injuries to workers in close proximity.

2. Protecting Equipment & Workspaces

Prevents damage to machinery, pipelines, and nearby structures.

Reduces costly repairs and equipment downtime.

3. Essential for High-Risk Industrial Environments

Used in oil refineries, mining sites, manufacturing plants, and construction zones.

Ensures safety during high-pressure fluid and air transfer operations.

4. Compliance with Industry Regulations

Meets OSHA, MSHA, and API safety standards to help industries avoid legal penalties.

Enhances workplace safety programs by integrating preventive measures.

5. Cost-Effective Safety Solution

Low-cost investment with high safety returns.

Reduces the risk of expensive accident claims and liability lawsuits.

Industrial Applications of Whipchek

Whipcheks are widely used in high-risk industries where hoses operate under extreme pressure conditions.

1. Oil & Gas Industry

Used for high-pressure drilling, fracking, and fuel transfer.

Prevents hose failures in offshore and onshore rigs.

2. Construction & Demolition

Ensures safety when using pneumatic hoses for jackhammers and compressors.

Reduces the risk of hose failure in high-impact environments.

3. Manufacturing & Chemical Processing

Prevents accidents in fluid transfer operations.

Essential for chemical plants handling corrosive and volatile materials.

4. Mining & Heavy Machinery

Protects hydraulic and pneumatic hose connections in mining sites.

Enhances safety during heavy-duty material transport.

5. Marine & Shipyard Operations

Provides critical hose restraint solutions for ship fuel and water transfer.

Reduces risks in marine maintenance and offshore engineering projects.

Key Features of Whipchek

✔ Heavy-Duty Steel Cable Construction – Ensures maximum durability and strength. ✔ High-Pressure Resistance – Prevents hose whip in air, water, and hydraulic applications. ✔ Quick & Easy Installation – No tools required, enabling fast deployment. ✔ OSHA-Compliant Safety Solution – Meets global industrial safety standards. ✔ Available in Multiple Sizes – Customizable for various hose diameters. ✔ Enhances Workplace Safety – Protects workers from hose failure hazards.

Benefits of Using Whipchek

Upgrading to Whipchek provides numerous safety, operational, and financial advantages.

1. Maximum Workplace Safety

Eliminates the risk of hose whip-related injuries.

Prevents catastrophic equipment failures and downtime.

2. Improved Hose Performance & Longevity

Keeps hoses securely in place, reducing unnecessary stress.

Extends the lifespan of industrial hoses by preventing excessive movement.

3. Cost-Effective & Durable Solution

Reusable design offers long-term cost savings.

Reduces expensive workplace accident claims and machinery repairs.

4. Quick Installation & Maintenance-Free

No tools required for setup, ensuring efficient deployment.

Low maintenance requirements, making it a cost-effective safety measure.

5. Supports Compliance & Safety Standards

Meets OSHA, MSHA, and API requirements for industrial safety.

Helps businesses avoid legal issues and workplace hazards.

Why Choose Whipchek from NewE Traders?

The Whipcheks available from NewE Traders are engineered for durability, reliability, and enhanced industrial safety.

Why Buy from NewE Traders?

✔ High-Quality Industrial-Grade Materials – Built for tough, high-pressure environments. ✔ Innovative & Reliable Safety Design – Ensures maximum protection in critical applications. ✔ Custom Fit for Various Hose Sizes – Available in multiple configurations. ✔ Compliant with Safety Regulations – OSHA-approved for industrial use. ✔ Fast & Efficient Procurement – Quick order fulfillment and bulk availability.

Conclusion

Whipcheks are a vital safety tool in high-risk industrial operations, preventing hose whip accidents and ensuring worker safety. By investing in high-quality Whipcheks, industries can enhance workplace safety, minimize accidents, and improve operational efficiency.

📢 Protect your workplace today! Get the latest Whipcheks and eliminate hose whip hazards now!

0 notes

Link

Experience unparalleled performance with the Schumacher Electric SL1562 Lithium Jump Starter and Portable Power Station. This compact and lightweight jump starter fits effortlessly in your purse, tote bag, or trunk, providing powerful, dependable performance when you need it most. Powerful 1200 Amp Starting Power: Jump-starts up to 8.0L gas and 6.0L diesel engines with ease. […] The post Schumacher Electric Lithium Jump Starter and Portable Power Station SL1562, 4-in-1, 1200 Amp, 150-PSI Air Compressor, 12V – Works on Cars, Trucks, Motorcycles, Marine Batteries, SUVs, ATVs, and More appeared first on Automotive Parts.

0 notes

Text

Sauer Air Compressor | ftm.gr

Sauer Air Compressor brought to you by Fortune Trading Marine. Learn more at https://www.ftm.gr/products/

0 notes

Text

Introduction The salt spray machine plays a critical role in the evaluation of material resistance to corrosion, particularly in industrial applications. One of the industry-standard tools for this purpose is the LISUN YWX/Q-010 Salt Spray Test Chamber, which enables precise testing under controlled conditions. This article provides a comprehensive look at how salt spray machines work, their applications, and a detailed review of the LISUN YWX/Q-010 Salt Spray Test Chamber. What is a Salt Spray Machine? A salt spray machine, also known as a salt fog chamber, is designed to simulate harsh, corrosive environments to assess the durability of materials and coatings. These machines are commonly used to test metals, coatings, and other materials for resistance to salt-induced corrosion. The Importance of Salt Spray Testing Corrosion is a major concern in industries such as automotive, electronics, and marine engineering, where products are exposed to salty or humid environments. Salt spray testing is one of the most widely used methods to predict how materials and coatings will perform in these environments. The key advantage of using a salt spray machine is its ability to simulate decades of exposure within days or weeks. How Salt Spray Machines Work A salt spray machine like the LISUN YWX/Q-010 Salt Spray Test Chamber works by spraying a saline solution (typically a mix of water and sodium chloride) onto the sample materials. The chamber controls the temperature, humidity, and concentration of the solution, maintaining constant conditions that mimic corrosive environments. Key components of a salt spray machine include: • Control system: Monitors and adjusts conditions like temperature and humidity. • Spray system: Disperses the saline solution as a fine mist. • Sample racks: Holds the materials being tested in place to ensure uniform exposure. LISUN YWX/Q-010 Salt Spray Test Chamber Overview The LISUN YWX/Q-010 Salt Spray Test Chamber is a highly reliable and widely used model for salt spray corrosion tests. It complies with several international standards such as ASTM B117, ISO9227, and GB/T 2423.17. The chamber is equipped with a variety of advanced features that enhance its precision and ease of use. Some notable features of the LISUN YWX/Q-010 include: • Corrosion-resistant material: The interior is made from corrosion-resistant polypropylene (PP) to ensure long-term durability. • Automatic control system: Provides precise regulation of temperature and spray time. • Uniform spray distribution: Ensures consistent exposure across all samples. • High-performance air compressor: Supplies a stable flow of air to the spray nozzle, ensuring a fine and consistent mist. Applications of Salt Spray Machines Salt spray machines are essential for assessing the corrosion resistance of materials used in various industries. Some key applications include: • Automotive industry: Testing the corrosion resistance of car components such as body panels, frames, and electrical connectors. • Marine industry: Assessing how materials used in shipbuilding and offshore platforms withstand the corrosive effects of seawater. • Electronics industry: Evaluating the performance of coatings and enclosures that protect sensitive electronic components. YWX/Q-010_Salt Spray Test Machine Salt Spray Test Standards Various standards govern salt spray testing, and the LISUN YWX/Q-010 Salt Spray Test Chamber complies with the following: • ASTM B117: The most widely recognized standard for salt spray testing, used to assess the corrosion resistance of paints, coatings, and metals. • ISO 9227: Specifies methods for neutral salt spray tests (NSS), acetic acid salt spray tests (AASS), and copper-accelerated acetic acid salt spray tests (CASS). Test Procedures and Data Analysis The testing process involves several critical steps: • Preparation of the sample: Cleaning and drying the samples before placing them in the chamber. • Saline solution preparation: The solution typically contains 5% sodium chloride and is sprayed at a constant rate. • Test duration: Depending on the material, the test can last anywhere from 24 hours to several weeks. • Post-test evaluation: After the test, the samples are analyzed for signs of corrosion, such as pitting, blistering, or coating degradation. Table 1: Sample Salt Spray Test Results Using LISUN YWX/Q-010 Material Coating Type Test Duration (hours) Corrosion Observed Steel Zinc coating 48 Minor pitting Aluminum Anodized 72 No corrosion Copper Painted 24 Severe blistering Plastic (ABS) No coating 120 No corrosion Advantages of Using LISUN YWX/Q-010 Salt Spray Machine The LISUN YWX/Q-010 Salt Spray Test Chamber offers several advantages over other models: • Precise environmental control: Ensures accurate and repeatable results. • Durability and reliability: The corrosion-resistant construction ensures a long service life. • Compliance with international standards: Meets all major standards, including ASTM and ISO, making it suitable for a wide range of industries. Conclusion The salt spray machine, particularly the LISUN YWX/Q-010 Salt Spray Test Chamber, is an invaluable tool for assessing the corrosion resistance of materials in various industries. By simulating corrosive environments, companies can predict the long-term performance of materials and coatings, ensuring product reliability and safety. Whether for automotive, marine, or electronics applications, salt spray machines are critical for maintaining high-quality standards in production and research. Read the full article

0 notes

Text

Introduction The salt spray machine plays a critical role in the evaluation of material resistance to corrosion, particularly in industrial applications. One of the industry-standard tools for this purpose is the LISUN YWX/Q-010 Salt Spray Test Chamber, which enables precise testing under controlled conditions. This article provides a comprehensive look at how salt spray machines work, their applications, and a detailed review of the LISUN YWX/Q-010 Salt Spray Test Chamber. What is a Salt Spray Machine? A salt spray machine, also known as a salt fog chamber, is designed to simulate harsh, corrosive environments to assess the durability of materials and coatings. These machines are commonly used to test metals, coatings, and other materials for resistance to salt-induced corrosion. The Importance of Salt Spray Testing Corrosion is a major concern in industries such as automotive, electronics, and marine engineering, where products are exposed to salty or humid environments. Salt spray testing is one of the most widely used methods to predict how materials and coatings will perform in these environments. The key advantage of using a salt spray machine is its ability to simulate decades of exposure within days or weeks. How Salt Spray Machines Work A salt spray machine like the LISUN YWX/Q-010 Salt Spray Test Chamber works by spraying a saline solution (typically a mix of water and sodium chloride) onto the sample materials. The chamber controls the temperature, humidity, and concentration of the solution, maintaining constant conditions that mimic corrosive environments. Key components of a salt spray machine include: • Control system: Monitors and adjusts conditions like temperature and humidity. • Spray system: Disperses the saline solution as a fine mist. • Sample racks: Holds the materials being tested in place to ensure uniform exposure. LISUN YWX/Q-010 Salt Spray Test Chamber Overview The LISUN YWX/Q-010 Salt Spray Test Chamber is a highly reliable and widely used model for salt spray corrosion tests. It complies with several international standards such as ASTM B117, ISO9227, and GB/T 2423.17. The chamber is equipped with a variety of advanced features that enhance its precision and ease of use. Some notable features of the LISUN YWX/Q-010 include: • Corrosion-resistant material: The interior is made from corrosion-resistant polypropylene (PP) to ensure long-term durability. • Automatic control system: Provides precise regulation of temperature and spray time. • Uniform spray distribution: Ensures consistent exposure across all samples. • High-performance air compressor: Supplies a stable flow of air to the spray nozzle, ensuring a fine and consistent mist. Applications of Salt Spray Machines Salt spray machines are essential for assessing the corrosion resistance of materials used in various industries. Some key applications include: • Automotive industry: Testing the corrosion resistance of car components such as body panels, frames, and electrical connectors. • Marine industry: Assessing how materials used in shipbuilding and offshore platforms withstand the corrosive effects of seawater. • Electronics industry: Evaluating the performance of coatings and enclosures that protect sensitive electronic components. YWX/Q-010_Salt Spray Test Machine Salt Spray Test Standards Various standards govern salt spray testing, and the LISUN YWX/Q-010 Salt Spray Test Chamber complies with the following: • ASTM B117: The most widely recognized standard for salt spray testing, used to assess the corrosion resistance of paints, coatings, and metals. • ISO 9227: Specifies methods for neutral salt spray tests (NSS), acetic acid salt spray tests (AASS), and copper-accelerated acetic acid salt spray tests (CASS). Test Procedures and Data Analysis The testing process involves several critical steps: • Preparation of the sample: Cleaning and drying the samples before placing them in the chamber. • Saline solution preparation: The solution typically contains 5% sodium chloride and is sprayed at a constant rate. • Test duration: Depending on the material, the test can last anywhere from 24 hours to several weeks. • Post-test evaluation: After the test, the samples are analyzed for signs of corrosion, such as pitting, blistering, or coating degradation. Table 1: Sample Salt Spray Test Results Using LISUN YWX/Q-010 Material Coating Type Test Duration (hours) Corrosion Observed Steel Zinc coating 48 Minor pitting Aluminum Anodized 72 No corrosion Copper Painted 24 Severe blistering Plastic (ABS) No coating 120 No corrosion Advantages of Using LISUN YWX/Q-010 Salt Spray Machine The LISUN YWX/Q-010 Salt Spray Test Chamber offers several advantages over other models: • Precise environmental control: Ensures accurate and repeatable results. • Durability and reliability: The corrosion-resistant construction ensures a long service life. • Compliance with international standards: Meets all major standards, including ASTM and ISO, making it suitable for a wide range of industries. Conclusion The salt spray machine, particularly the LISUN YWX/Q-010 Salt Spray Test Chamber, is an invaluable tool for assessing the corrosion resistance of materials in various industries. By simulating corrosive environments, companies can predict the long-term performance of materials and coatings, ensuring product reliability and safety. Whether for automotive, marine, or electronics applications, salt spray machines are critical for maintaining high-quality standards in production and research. Read the full article

0 notes

Text

Why Hamworthy Air Compressors are a Trusted Choice in the Maritime Industry?

In the maritime industry, reliability, efficiency, and durability are paramount when it comes to the equipment that powers a ship's operations. One of the most critical pieces of machinery on board is the air compressor—a vital component that ensures smooth functioning of everything from engine starters to pneumatic tools and cargo systems. Among the leading names in air compressor technology, Hamworthy Air Compressors stand out as a trusted choice for maritime applications. With a legacy of providing robust, high-performance solutions, Hamworthy compressors have earned a reputation for excellence in the demanding environment of the maritime industry.

1. Proven Track Record of Reliability

One of the key reasons Hamworthy air compressors are a trusted choice in the maritime industry is their proven reliability. Ships are often at sea for extended periods, and downtime can result in costly delays and operational setbacks. Hamworthy compressors are designed to withstand the harsh conditions of marine environments, including exposure to saltwater, extreme temperatures, and constant vibrations.

Engineered with high-quality materials and advanced technology, these compressors provide continuous performance without the risk of failure. This reliability ensures that critical ship systems—such as engine starting systems, cargo handling, and pressurized air for tools—continue to function smoothly, minimizing the risk of unexpected maintenance or breakdowns. This level of dependability is crucial for keeping ships running efficiently and safely.

2. Energy Efficiency and Cost Savings

Another reason Hamworthy air compressors are widely preferred in the maritime industry is their exceptional energy efficiency. As fuel costs continue to rise and the push for sustainability becomes stronger, ships are under increasing pressure to reduce energy consumption and operating expenses. Hamworthy compressors are designed with energy-saving features that help lower fuel consumption and reduce overall operational costs.

By optimizing compressed air generation and minimizing energy losses, Hamworthy air compressors reduce the amount of energy required to maintain the required air pressure for ship systems. This results in cost savings in the long term, particularly for vessels that operate over long distances or have high-demand air systems. The energy efficiency of Hamworthy compressors also aligns with the maritime industry's growing focus on reducing emissions and minimizing environmental impact.

3. Durability and Longevity

Hamworthy air compressors are built to last. The maritime industry demands equipment that can handle tough conditions and maintain high performance over time. Hamworthy compressors are crafted with durability in mind, using corrosion-resistant materials and heavy-duty components that can endure the wear and tear of continuous use.

Their robust construction ensures that these compressors require minimal maintenance and experience fewer breakdowns, even in harsh maritime environments. This durability translates into lower maintenance costs and longer intervals between repairs, which is a significant advantage for ship owners and operators who want to keep their vessels running efficiently without the burden of frequent maintenance.

4. Versatility for Various Marine Applications

Hamworthy air compressors are designed to serve a wide range of applications, making them a versatile choice for many different types of vessels. Whether it’s a cargo ship, tanker, offshore platform, or passenger cruise liner, Hamworthy compressors can be customized to meet the specific needs of any shipboard operation.

The compressors are used for a variety of vital functions, including starting marine engines, supplying air for pneumatic systems, controlling cargo systems, and supporting ventilation. Their adaptability means that Hamworthy compressors can provide a reliable air supply across multiple systems, reducing the need for different compressors for each application and simplifying shipboard operations.

5. Advanced Technology and Innovation

Hamworthy is committed to staying at the forefront of compressor technology, constantly improving the performance and features of their products to meet the evolving demands of the maritime industry. With innovations in energy efficiency, noise reduction, and system integration, Hamworthy air compressors offer advanced capabilities that improve overall ship performance.

For instance, Hamworthy’s compressors are equipped with smart control systems that monitor and adjust air pressure levels in real-time, ensuring that the ship's systems are always running at optimal conditions. These technological advancements enhance the overall efficiency of ship operations, providing further value to ship owners, operators, and engineers.

6. Strong Support Network and After-Sales Service

When it comes to maintaining and servicing critical equipment like air compressors, having a reliable support network is essential. Hamworthy provides excellent after-sales support, including routine maintenance, technical assistance, and repair services. Their team of experienced technicians ensures that any issues are quickly resolved, minimizing downtime and maximizing the operational lifespan of the compressors.

The brand’s strong presence in the maritime industry, coupled with their global service network, ensures that ship operators have access to timely and efficient support, no matter where they are operating.

Conclusion

Hamworthy air compressors have become a trusted choice in the maritime industry due to their reliability, energy efficiency, durability, versatility, and innovative technology. With their ability to handle the demanding conditions of the sea and deliver consistent performance, Hamworthy compressors are integral to the efficient operation of ships worldwide. Whether for engine starting, cargo handling, or other vital systems, Hamworthy air compressors provide ship operators with peace of mind, knowing that their equipment is built to last and operate effectively in all conditions.

By investing in a Hamworthy air compressor, ship owners and operators can reduce operational costs, improve energy efficiency, and ensure the longevity of their vessels—making them a wise choice for any maritime operation.

0 notes

Text

Success Stories Sikdar Marine Services Chittagong

Sikandar Marine Service is a company that specializes in marine spare parts supplier. We can supply all of expendable parts in Main Engine, Aux Engine etc. Also Air Compressor, Oil Separator, Automation-Navigation goods and other requested parts by your component crews are provided rapidly and accurately.

>> Main Engine >> Aux Engine >> Air Compressor >> Oil Separator >> Automation >> Navigation

https://sikandarms.com/

#successstories #wordpress #marinelife#marinespares #websiteDevelopment #HTML5

1 note

·

View note

Text

Marine Excellence Solutions and Services

We provide comprehensive marine services, delivering expert solutions in vessel maintenance and repairs. Our experienced team ensures smooth operations for maritime industries. To more details, reach our website.

#marine services#hydraulic cylinder#air compressors#pneumatic pump repair#centrifugal pumps#air controls

0 notes

Text

Choosing Between Pneumatic and Hydraulic Systems

Selecting the right system is vital for industrial automation. Pneumatic and hydraulic systems are two popular power transmission methods, each with unique strengths and limitations. Here’s a brief overview to help you decide.

Pneumatic Systems

Pneumatic systems use compressed air to generate motion and force. These systems are ideal for industries requiring fast, clean, and low-maintenance solutions.

Advantages:

Clean and Safe: Suitable for contamination-sensitive industries like food and pharmaceuticals.

Fast and Responsive: Ideal for quick, repetitive operations.

Low Maintenance: Fewer components and no fluids reduce upkeep.

Cost-Effective: Air is free, and components are affordable.

Common Uses:

Material handling, packaging, and robotics. RAM Automations supplies valves, actuators, and air compressors from Bosch and Siemens.

Hydraulic Systems

Hydraulic systems use pressurized fluids, typically oil, for high-power and precision applications.

Advantages:

High Power: Capable of handling heavy-duty tasks.

Precision and Control: Fine-tuned performance for demanding operations.

Durable: Withstands high pressure and harsh conditions.

Common Uses:

Construction equipment, manufacturing, and aerospace industries. RAM Automations provides pumps, motors, and cylinders from ABB and Schneider Electric.

Key Comparisons

Power: Hydraulic systems offer greater force; pneumatic systems are faster but less powerful.

Precision: Hydraulics provide superior accuracy, while pneumatics excel in speed.

Maintenance: Pneumatics are simpler and cheaper to maintain; hydraulics require more upkeep.

Environmental Impact: Pneumatics are cleaner; hydraulics pose risks like oil spills.

Which System Is Right for You?

Choose hydraulic systems for heavy loads, precision, and high power.

Opt for pneumatic systems for speed, cleanliness, and cost efficiency.

At RAM Automations, we offer tailored solutions to meet your specific industrial needs. Explore our diverse catalog of pneumatic and hydraulic products, featuring top brands and cutting-edge technologies.

Why RAM Automations?

Our power transmission systems enhance efficiency and give your business a competitive edge. Visit ramautomations.com to discover our range of genuine industrial and marine spare parts. Trust RAM Automations for high-quality automation solutions.

0 notes