#manufacturers of irrigation systems in India

Explore tagged Tumblr posts

Text

When it comes to selecting the best manufacturers of irrigation systems in India, there are several vital factors that need to be considered. Firstly, assessing the reputation and experience of the manufacturer is crucial. Look for companies with a track record of providing high-quality irrigation systems and long-standing expertise in the industry.

Secondly, it is essential to evaluate the range of products offered by manufacturers of irrigation systems in India. A diverse portfolio indicates their capability to cater to various customer requirements. Ensure that they offer a wide selection of irrigation systems suitable for different agricultural practices and landscapes.

Thirdly, evaluating the technology and innovation employed by manufacturers is important. Opting for manufacturers who continuously invest in research and development ensures access to advanced and efficient irrigation systems that can enhance productivity and conserve resources.

Furthermore, considering the manufacturer's after-sales service is vital. Choose companies with a strong customer support network, including technical assistance and warranty provisions. This guarantees prompt assistance if any issues arise after installation or during system operation.

Moreover, examining certifications and quality standards complied with by the manufacturers of irrigation systems in India is critical. Manufacturers who abide by international quality regulations reflect their commitment towards delivering reliable products.

Another aspect to consider is pricing and affordability. It's recommended to compare prices among different manufacturers while taking into account the quality, durability, and efficiency of their irrigation systems.

Delivery timelines should also be taken into consideration as delays could impact project schedules negatively. Opt for manufacturers with a reputation for consistent on-time deliveries.

Lastly, customer reviews are an excellent source of insight into a manufacturer's reliability and overall satisfaction level among its clientele. Researching online testimonials or seeking recommendations from other farmers or professionals in the agriculture sector can provide valuable feedback regarding specific manufacturers' performance in India's irrigation system market.

By evaluating these factors comprehensively, one can make an informed decision when choosing the best manufacturer of irrigation systems in India that aligns with their requirements seamlessly reaffirming reliability and exceptional performance.

#manufacturers of irrigation systems in India#Irrigation Drip kits India#drip irrigation system suppliers in India#drip irrigation company India#Treadle pump exporter in India

0 notes

Text

When it comes to agricultural appliances, you will find a wide variety. These are primarily used to enhance farming production and ensure the healthy growth of crops. From irrigation to dust suppression, you will find devices with specific operations. Among them, impact sprinklers have a significance of their own.

#sprinkler manufacturers in india#impact sprinkler manufacturers in india#oasis irrigation systems#irrigation equipment company#sprinkler irrigation#irrigation equipment#sprinkler system garden#sprinkler material#sprinker irrigation#oasis sprinkler service#sprinkler system for agriculture#sprinkler system irrigation#sprinkler spare parts#sprinkling machine#irrigation companies in india#irrigation manufacturers

0 notes

Text

What makes Indian rice manufacturers the top choice for global importers?

Indian rice manufacturers have built a strong global reputation for their quality, variety, and consistent supply. As one of the largest rice exporting countries, India supplies premium and affordable rice varieties to over 150 countries. But what makes them the preferred choice for international buyers? Let’s look at the factors that make Indian rice exporters stand out in the global market.

Introduction to Indian Rice Manufacturing

India has long been a global leader in rice production, exporting over 40% of the world’s total rice supply (Source: FAO). The country’s manufacturing capacity is supported by its vast paddy fields, skilled workforce, and advanced milling facilities. Indian rice manufacturers cater to the market’s diverse needs, offering everything from high-quality Basmati to cost-effective bulk options.

This adaptability and focus on quality ensures that Indian rice continues to dominate the global market.

Quality Standards and Certifications

Quality assurance is the cornerstone for rice suppliers in India. They follow international guidelines to ensure that rice meets the expectations of global importers. Some of the key certifications include:

ISO 22000 and HACCP: highlighting their commitment to food safety.

Organic certifications: ensuring compliance with USDA and EU standards.

Fair trade and sustainability practices: signifying ethical production.

Many manufacturers use state-of-the-art milling techniques and conduct strict quality checks. These efforts make Indian rice a reliable choice for consumers around the world.

Wide variety of rice types

India offers an unmatched variety of rice, enabling manufacturers to meet the diverse preferences of global markets. Popular choices include:

Basmati rice: Famous for its aroma and long-grained texture, it is widely in demand in Europe and the Middle East.

Non-Basmati Rice: Varieties such as IR64 and Sona Masuri are staples in Africa and Asia.

Specialty and Organic Rice: Catering to niche markets focused on health and sustainability.

This broad portfolio allows Indian exporters to meet the needs of a variety of customers, from gourmet chefs to wholesale distributors.

Cost-effectiveness and supply reliability

Indian rice manufacturers maintain a balance between quality and affordability. This is achieved through:

High production efficiency: Leveraging large-scale operations and advanced machinery.

Government policies: Subsidies for farm equipment and fertilizers reduce production costs.

Geographical advantage: Fertile land and favorable weather ensure consistent yields.

Their ability to handle bulk orders while adhering to strict timelines makes Indian rice exporters reliable partners for global importers.

Commitment to sustainability and innovation

Sustainability has become a priority for Indian rice manufacturers. Many companies are adopting environmentally friendly practices such as:

Water conservation: Using innovative irrigation techniques to reduce water consumption.

Renewable energy: Integrating solar and bioenergy into milling processes.

Waste utilization: Converting rice husk into biofuels and fertilizers.

Such practices align with the values of environmentally conscious consumers, strengthening India’s position in the global market.

Additionally, advances in traceability and quality control, including digital systems, enhance transparency and trust between manufacturers and importers.

India’s global prominence in rice exports is supported by its strong manufacturing base, diverse offerings, and commitment to quality. By choosing Indian rice manufacturers, importers benefit from reliable, high-quality rice that meets a variety of market demands. Whether it’s aromatic basmati for fine eating or affordable bulk varieties for everyday use, Indian exporters continue to set benchmarks in the global rice trade.

2 notes

·

View notes

Text

How has Col. Rajyavardhan Rathore contributed to the development of Rajasthan?

1. Infrastructure Development

Roads and Connectivity: Col. Rathore has focused on improving the region’s connectivity by advocating for the construction and expansion of highways, rural roads, and bridges. These initiatives have boosted trade and accessibility for remote areas.

Smart Cities and Urban Renewal: He has supported urban development projects, modernizing cities like Jaipur and Jodhpur to meet global standards while preserving cultural heritage.

2. Water Resource Management

Water Accessibility: Col. Rathore has been a vocal supporter of initiatives like the Jal Jeevan Mission, which aims to provide piped water to every household. His efforts have been pivotal in addressing water scarcity, especially in Rajasthan’s arid regions.

Irrigation Projects: Promoting sustainable irrigation practices and modern systems to empower farmers and improve agricultural productivity.

3. Focus on Rural Development

Basic Amenities: His leadership has ensured improved access to electricity, clean water, and healthcare in rural areas.

Skill Development: Launching programs for rural youth to enhance employability and foster entrepreneurship in villages.

4. Economic Growth Through Investments

Rising Rajasthan Global Investment Summit: Col. Rathore played a key role in attracting domestic and international investments. His efforts have brought industrial projects, IT hubs, and manufacturing units to Rajasthan, creating jobs and spurring economic growth.

MSME Empowerment: Advocating policies to support small and medium enterprises, which are the backbone of the state’s economy.

5. Promotion of Renewable Energy

Green Energy Initiatives: Rajasthan has emerged as a leader in solar and wind energy under his guidance. He supports large-scale renewable energy projects to ensure sustainable development.

6. Education and Skill Development

Kalwad Mahavidyalaya Land Allotment: Col. Rathore facilitated the allotment of land for the development of educational institutions to provide better learning opportunities.

Tech-Driven Education: Promoting digital literacy and introducing smart classrooms to prepare students for a competitive world.

7. Support for Sports and Youth Development

Sports Infrastructure: Leveraging his background as an Olympian, Col. Rathore has advocated for sports facilities, promoting athletic talent across Rajasthan.

Youth Engagement: Organizing programs to inspire and involve young people in the development of their communities.

8. Tourism Promotion

Cultural Preservation: Encouraging eco-tourism and cultural tourism while preserving Rajasthan’s rich heritage.

Infrastructure for Tourism: Supporting the development of tourist-friendly facilities to boost the state’s economy.

9. Digital Transformation

IT Hubs and Startups: His initiatives have led to the establishment of IT cities and startup incubation centers near key urban areas like Jaipur, bringing innovation and employment.

Smart Villages: Integrating technology into rural areas to improve governance and service delivery.

10. Advocacy for Women Empowerment and Social Welfare

Empowering Women: Supporting schemes that provide women with access to education, healthcare, and skill development.

Social Upliftment: Advocating for programs to aid underprivileged communities and improve their standard of living.

Conclusion

Col. Rajyavardhan Rathore has consistently championed initiatives that aim for a holistic transformation of Rajasthan. His contributions span across sectors, ensuring that the state achieves balanced development while empowering its people. Through his leadership and commitment, Rajasthan is on a trajectory toward becoming a model state in India.

3 notes

·

View notes

Text

GI Flanges at Lowest Prices in Delhi NCR

If you're looking for GI flanges at the lowest price in Delhi NCR, several manufacturers and suppliers in the region offer competitive pricing while ensuring high quality and reliability. GI flanges are essential for connecting pipes in water supply, firefighting, plumbing, and industrial piping systems due to their corrosion resistance and durability.

Best Sources for GI Flanges at Lowest Prices in Delhi NCR:

1. Udhhyog

Udhhyog is a leading supplier in India, known for offering GI flanges at the lowest prices while maintaining high product standards. They supply a wide range of galvanized iron flanges suited for water supply, HVAC systems, and more. Udhhyog focuses on providing reliable products to MSMEs, ensuring both affordability and quick delivery.

Why Udhhyog?

Competitive Prices: Known for offering the best rates on bulk orders.

Quality Assurance: Strict quality control and durable GI flanges.

Customer Focus: Easy procurement process with timely delivery.

Check out their offerings:

GI Flanges

GI Blind Flanges

2. Sanjay Metal India

Sanjay Metal India offers GI flanges at economical rates with a strong focus on product quality. They serve various industries, including water pipelines, fire suppression systems, and irrigation systems. Their prices are competitive for both standard and custom-made flanges.

Why Sanjay Metal India?

Affordable pricing for standard GI flanges.

High customer satisfaction with bulk and wholesale orders.

3. Regal Sales Corporation

Regal Sales Corporation is known for providing a wide selection of GI flanges at competitive prices. They supply flanges that meet global standards and are known for their precision and durability. Bulk discounts and fast delivery make them a popular choice in Delhi NCR.

Why Regal Sales Corporation?

Competitive bulk order rates.

Wide range of flange types available at economical prices.

4. Metal Udyog

Metal Udyog offers some of the most affordable GI flanges in the Delhi NCR region, catering to industries that require durable, cost-effective solutions. Their products are widely used in water distribution systems and industrial piping applications.

Why Metal Udyog?

Low-cost options for standard GI flanges.

Excellent delivery network across Delhi NCR.

5. Suryadeep Industries

Suryadeep Industries provides affordable GI flanges with a focus on budget-friendly solutions for construction, water pipelines, and fire protection systems. Their cost-effective pricing makes them a top contender for companies looking for high-quality, low-priced GI flanges.

Why Suryadeep Industries?

Competitive pricing without compromising on quality.

Suitable for large-scale and small-scale projects.

#GIFlanges#LowestPriceFlanges#DelhiNCRFlanges#PipeFittings#IndustrialSuppliers#Udhhyog#GalvanizedFlanges#AffordableFlanges#PipeConnections#DelhiManufacturers

2 notes

·

View notes

Text

GI Flanges Manufacture in Delhi

Galvanized Iron (GI) flanges are crucial components in various piping systems, offering both durability and corrosion resistance. As a leading GI flanges manufacturer, Udhhyog provides high-quality products that cater to diverse industrial requirements. Whether you need flanges for water pipelines, gas distribution, or construction applications, Udhhyog ensures top-notch quality and performance. In this article, we’ll explore the benefits, applications, and why Udhhyog is your trusted partner for GI flanges.

What are GI Flanges?

GI flanges are made from galvanized iron, which undergoes a zinc coating process to prevent rust and corrosion. These flanges are used to connect pipes, valves, and other equipment, creating a secure and leak-proof seal. The galvanization process enhances the flange's resistance to harsh environmental conditions, making it suitable for both indoor and outdoor applications.

Key Features of GI Flanges

Corrosion Resistance: The zinc coating provides excellent protection against rust and corrosion, even in aggressive environments.

Durability: GI flanges are strong and robust, capable of withstanding high pressure and temperature variations.

Easy Installation: Designed for a secure fit, these flanges are easy to install and maintain, reducing downtime.

Benefits of Using GI Flanges

Long Service Life: The galvanization process ensures that the flanges last longer, reducing the need for frequent replacements.

Cost-Effective: Compared to other materials, GI flanges offer a good balance of performance and affordability.

Versatility: Suitable for a wide range of applications, including water supply, gas distribution, and structural projects.

Applications of GI Flanges

Water Supply Systems: Used extensively in municipal water distribution and irrigation systems due to their resistance to rust.

Gas Distribution: Ideal for use in natural gas and propane distribution networks.

Construction Industry: Used in structural applications and building frameworks where strong and reliable connections are required.

Why Choose Udhhyog as Your GI Flanges Manufacturer?

Udhhyog is dedicated to delivering high-quality GI flanges that meet industry standards and exceed customer expectations. Here’s why you should choose us:

Top-Quality Products: As a leading GI flanges manufacturer, we ensure that our products are manufactured using the best materials and processes.

Competitive Pricing: We offer high-quality flanges at the most competitive prices in the market, making us the preferred choice for many industries.

Exceptional Service: Our team is committed to providing excellent customer support and timely delivery across India.

How to Order GI Flanges from Udhhyog

Ordering from Udhhyog is simple and convenient. Visit our website and click on GI flanges manufacture to place your order. We guarantee a seamless shopping experience with quick delivery to your desired location.

#GIFlanges#FlangeManufacture#IndustrialFlanges#PipingSolutions#GalvanizedIronFlanges#Udhhyog#FlangeSupplier#ConstructionMaterials

5 notes

·

View notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

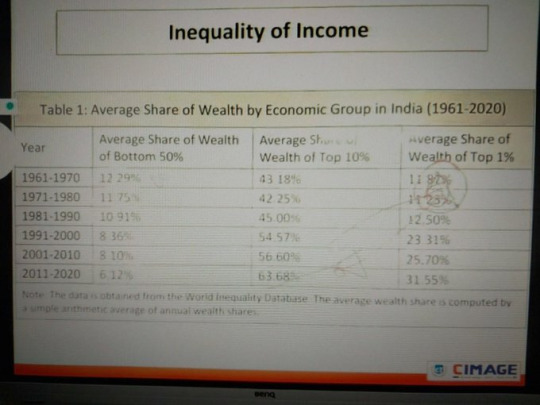

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

Top PVC Pipe Manufacturers in Ambala: Surya Roshni

When it involves first rate PVC pipes in Ambala, Surya Roshni sticks out as a trusted name within the industry. With a dedication to excellence and innovation, we have earned recognition as one of the most popular PVC pipe manufacturers in Ambala. Our merchandise is designed to meet the diverse desires of customers, ranging from residential to agricultural and business programs.

Why Choose Surya Roshni for PVC Pipes?

Premium Quality: As a leading PVC pipe enterprise in Ambala, we use superior era and top-grade uncooked materials to manufacture long lasting and reliable pipes.

Wide Range of Products: Whether you need PVC pipes for plumbing, irrigation, or business functions, we offer a complete variety to suit all necessities.

Affordable Pricing: Our products integrate quality with affordability, making us a preferred preference for PVC pipes in Ambala.

Applications of Surya Roshni PVC Pipes

Plumbing Solutions: Our pipes ensure leak-evidence and efficient water delivery systems for residential and business residences.

Agricultural Use: Designed for sturdiness, our pipes are best for irrigation structures, making sure dependable water waft for farming needs.

Industrial Applications: Surya Roshni PVC pipes are suitable for transporting chemicals and other materials, providing excellent resistance to corrosion.

Key Features of Surya Roshni PVC Pipes

Durability: Built to remaining, our pipes are proof against wear and tear, ensuring long-term overall performance.

Eco-Friendly: Our PVC pipes are designed with sustainability in mind, minimizing environmental impact.

Customizable Solutions: We provide pipes in numerous sizes and specifications to meet unique customers’ wishes.

Contact Surya Roshni Today

If you are seeking out the first-class PVC pipe manufacturers in Ambala, Surya Roshni is your cross-to solution. With a focus on first-class, innovation, and consumer pleasure, we try to provide products that exceed expectations.

Website: https://surya.co.in/pvc-pipes/upvc-swr-pipes-fittings/

Email: [email protected]

Phone: 91-11-47108000

Address: Padma Tower - 1, Rajendra Place, New Delhi – 110008, India

#best branded lighting manufacturer#best branded lighting company#best lighting store#lighting products provider#largest branded lighting manufacturer#best-branded lighting manufacturer#surya light distributor#surya lighting#best-branded lighting manufacturers#best lighting company in india

0 notes

Text

"Top Drip Irrigation System Manufacturer in India - Kothari Group"

Kothari Group is a leading drip irrigation system manufacturer in India, offering innovative and water-efficient solutions for agriculture. Our high-quality systems ensure optimal irrigation, saving water and boosting crop yields for farmers across India.

#water-efficient irrigation#drip irrigation india#indian irrigation manufacturers#drip irrigation solutions

0 notes

Text

Cotton is an industrial fiber that can be spun into manufacturing products used throughout the early twenty-first century world (e.g. thread and cloth). Cotton is farmed on an industrial basis. Historically it is associated with Egypt, India, and the Southern United States, and its cheap industrial manufacture is associated with Britain. The cotton industry shaped much of 18th and 19th century colonial politics and was a major part of both the industrial revolution and the transatlantic slave trade.

Being a living organism, cotton requires water for its biological processes. As a plant, water is required to transform sunlight into sugars via photosynthesis. Some farmers rely entirely on rain and groundwater (which is refreshed by rain) to water their crops. Other have irrigation systems, but rain is still effective at reducing the cost of irrigation. As such, farmers desire a healthy mix of sunny days and rainy days for optimal plant growth, and a break in a drought with rain is seen as desirable.

Cotton candy is spun sugar. Heating and spinning sugar into thin, light strands makes it appear like spun cotton, giving rise to the name. Cotton candy is produced with specialized machinery that heats and spins sugar which will gather around any stick placed inside it. It is a common festival treat, being cheap, convenient, and tactile to eat. Cotton Candy is often flavored beyond the pure sugar, often with an eponymous "Cotton Candy" flavor, which is used for other flavored items like ice cream, bubble gum, and flouride. Artificial flavor blends like Blue Raspberry and Pink Vanilla are common.

Cotton candy, being made of sugar crystals strung together, will dissolve in water, just like normal sugar crystals. This undoes the preparation completely, 'melting' it.

Cotton candy is not grown in a field (the sugar cane it is made from might be). Cotton candy farmers do not exist. The joke is based on the absurd premise of a cotton candy farmer, in contrast to a regular cotton farmer. In this humorous absurd scenario where cotton candy is farmed, the reader would understand that rain (and water in general) would be quite distressing for this hypothetical farmer, as their entire crop would be ruined. This enhances the absurdity of the impossible scenario, and the humor with it. The introduction with a realistic concept (a cotton farmer relieved by the rain) is integral for the humor. An individual in the early twenty-first century would not find the joke as funny on its own without the setup.

#period novel details#explaining the joke ruins the joke#not explaining the joke means people 300 years from now won't understand our culture#thank you for tagging me#why does the cotton candy farmer not just grow their crop in a dehumidified greenhouse?#I struggle to understand how the cotton candy crop would survive if it melted in rain#I imagine it must be a desert based organism#but wouldn't it just be eaten by all the desert animals? where can its seeds persist?#perhaps it is like a tumbleweed...#thinking about it too much

26K notes

·

View notes

Text

End Suction Pumps are a versatile and efficient choice for fluid handling across a wide range of industries. Known for their compact design and reliable performance, these pumps are ideal for applications in water supply, irrigation, industrial processing, and HVAC systems.

Designed with precision, End Suction Pumps offer high efficiency and reduced energy consumption, making them a cost-effective solution for your pumping needs. Their robust construction ensures durability and long-term reliability, even in demanding operating conditions.

One of the key advantages of End Suction Pumps is their ease of maintenance. The back pull-out design allows quick servicing without dismantling the entire system, minimizing downtime and ensuring uninterrupted operations. These pumps are compatible with a variety of fluids, including water, light chemicals, and mild slurries, making them a versatile option for diverse industries. Available in various sizes and configurations, End Suction Pumps can be customized to meet specific application requirements.

0 notes

Text

Best PVC Pipe Manufacturing Companies in India

Introduction

This blog is authored by Mr. Rajesh Menon, a seasoned expert with more than 40 years of experience in the Indian pipe manufacturing industry. Throughout his career, Rajesh has developed a deep understanding of the evolving landscape of the pipe industry, from the days of metal pipes to the current shift towards advanced plastic solutions. Having started as a junior engineer, Rajesh worked his way up to senior management, overseeing operations and product development at one of India's leading pipe manufacturers. His expertise in mechanical engineering, coupled with decades of hands-on experience, has made him a respected figure in the industry.

Now retired, Rajesh has turned to blogging to share his wealth of knowledge with homeowners, builders, and developers. His goal is to help them make informed decisions amidst the many pipe brands available in the market. Through his blog series on India’s top pipe manufacturers, Rajesh offers unbiased insights into the strengths and weaknesses of various brands, ensuring readers can select the most reliable options for their needs.

PVC Pipe Industry in India

The Indian pipe industry has undergone a remarkable transformation in recent decades, transitioning from traditional materials like metal and cement pipes to modern plastic solutions, such as PVC, which cater to the country’s plumbing, sanitation, and drainage needs. The market for plastic pipes has grown rapidly, becoming a ₹40,000 crore industry in the last decade. As infrastructure and construction projects continue to rise across India, the demand for durable, safe, and reliable pipes has surged. Consumers now face a wide array of options, each promising superior performance. Therefore, it is essential to choose the right brand that guarantees safety, longevity, and value for money.

Whether for residential, commercial, or industrial purposes, selecting the right PVC pipes ensures a trouble-free, leak-proof plumbing system. This blog will help guide your decision-making by comparing factors like quality standards, durability, distribution reach, and product range.

Factors for Evaluating the Top Companies

Several key factors have been considered when selecting the top PVC pipe companies in India:

Durability: Ensures pipes remain intact without cracking, corrosion, or leakage under challenging conditions, minimizing the need for replacements.

Performance: High-quality pipes that can handle water pressure, temperature fluctuations, and varying water qualities ensure smooth and efficient plumbing.

Low Maintenance: Pipes requiring minimal maintenance save time and costs, making them ideal for residential and commercial use.

Value for Money: Offering long-lasting reliability at a reasonable price, providing an optimal balance of cost and performance.

India-Wide Availability: Accessibility across urban and rural regions ensures timely delivery and efficient project execution, no matter the location.

These criteria ensure that consumers choose a PVC pipe brand that offers consistent performance, cost-effectiveness, and long-term satisfaction.

Top 10 PVC Pipe Companies in India

1. Ajay Pipes

Ajay Pipes, part of the Ajay Group, brings over 60 years of experience to the piping industry. Known for introducing plastic piping solutions in India, the company specializes in CPVC, uPVC, SWR, and UDS pipes. With a reputation for producing durable and low-maintenance products, Ajay Pipes serves residential, commercial, and industrial plumbing needs.

2. Apollo Pipes Ltd.

Part of the APL Apollo Group, Apollo Pipes has swiftly gained prominence in the PVC pipe sector. The company offers a wide range of products, including CPVC, uPVC, and HDPE pipes, and caters to sectors like irrigation, plumbing, and infrastructure. Apollo Pipes is recognized for its cost-effective solutions and robust distribution network, making it a popular choice across India. Read more

0 notes

Text

PVC Ball Valve Trusted Supplier to Yemen

KANA Valves Pvt. Ltd. is a reliable and trusted PVC Ball Valve Supplier catering to Yemen’s plumbing and irrigation needs. As a leading manufacturer and exporter of various plumbing and irrigation products, KANA Valves Pvt. Ltd. is based in Ahmedabad, Gujarat, India. We specialize in providing a wide range of high-quality PVC Ball valve, including: PVC Ball Valve- White, Black, Gray in (Socket-Din, Threded-BS) Standards UPVC Ball Valve (Socket-Din, ANSI) Standards CPVC Ball Valve (Socket-ANSI, ASTM D-2846, ASTM D-2467) Standards Irrigation Ball Valves Union Ball Valves in (Socket-Din, Threded-BS) Standards P.P. Hose Fittings in Size range of (DN 15 to DN200) KANA PVC Ball Valves are designed with precision to meet the specific needs of plumbing and irrigation systems in Yemen, ensuring reliability and top-tier performance in diverse conditions. Adhering to ANSI & DIN standards with pressure ratings of PN6, PN10 & PN16, our valves are available in sizes ranging from DN15 to DN200. Engineered for durability, efficiency, and cost-effectiveness, KANA Valves is your trusted partner for high-performance plumbing and irrigation solutions in Yemen and beyond. Features of KANA PVC Ball Valves: Global Standards Compliance: Our valves meet ANSI and DIN standards, ensuring exceptional performance and longevity. Versatile Pressure Ratings: Available with PN6, PN10 & PN16 ratings for different application needs. Compact Sizes: Offered in sizes ranging from DN15 to DN200, perfect for various plumbing and irrigation needs. Durable Materials: Made from high-quality PVC, P.P., and CPVC, ideal for the harsh climate of Yemen. Easy Integration: Designed to fit seamlessly into existing systems for simple and quick installation. Corrosion-Resistant: Built to handle Yemen’s water and irrigation systems without degradation. Leak-Proof Operation: Ensures zero leakage, making the valves reliable and dependable. Smooth Operation: Advanced engineering provides excellent torque for effortless and smooth operation. Benefits of Choosing KANA PVC Ball Valves: Reliable Solution: A trusted name for Yemen’s plumbing and irrigation infrastructure. Cost-Effective: Affordable pricing while maintaining top-notch international quality. Sustainable Design: Built for long-term use with minimal maintenance requirements. Applications of KANA PVC Ball Valves: Agricultural Irrigation: Ideal for controlling water flow in farms, greenhouses, and irrigation systems. Residential Plumbing: Perfect for use in homes and commercial buildings in Yemen. Municipal Water Supply: Reliable for large-scale water distribution networks in urban areas. Industrial Use: Suitable for chemical and manufacturing plants needing efficient water control. Desalination Plants: Durable and resistant to saltwater, perfect for Yemen’s desalination facilities. KANA Valves Pvt. Ltd. is your reliable Supplier of PVC Ball Valves for Yemen, serving cities such as Sana'a, Ta'izz, Al Hudaydah, Aden, Ibb, Dhamar, Mukalla, Seiyun, Zinjibar, Sayyan, Ash Shihr, Sahar, Zabid, Hajjah, Bajil District, Dhi as-Sufal, Rada'a, Socotra, Bait al-Faqih, al-Marawi'a, Yarim, Al Bayda', 'Amran, Lahij, Abs, Harad, Dimnat Chadir, Ataq, al-Mahabischa, Baihan, Marib, Thula, Az Zaydiyah, Mudiyah, Khamir, Hais, ad-Dahi, Mocha, Al Ghaydah, Al Mahwit. We are committed to providing high-quality solutions tailored for the plumbing and irrigation sectors in Yemen, ensuring timely delivery and customer satisfaction. Contact us today to learn more about our products, request a quote, or schedule a consultation for your next project. Read the full article

0 notes

Text

Top 5 GI Flanges Manufacturers in Delhi

Galvanized Iron (GI) flanges are essential components in various industries for connecting pipes, valves, and other fittings. These flanges are coated with a layer of zinc, offering superior corrosion resistance, durability, and a cost-effective solution for industrial and domestic applications. Delhi, being a major industrial hub in India, is home to several leading GI flange manufacturers that cater to industries such as water supply, construction, gas pipelines, and more.

Below is a look at the top 5 GI flange manufacturers in Delhi:

1. Udhhyog

Udhhyog is a well-established name in the B2B marketplace, specializing in high-quality GI flanges. The company has earned a reputation for delivering premium industrial products to MSMEs across India. Udhhyog’s flanges are known for their strength, precise dimensions, and long-lasting performance, making them a top choice for water supply systems, firefighting installations, and industrial pipelines. With a customer-centric approach, Udhhyog ensures competitive pricing and fast delivery.

Product Offerings:

GI Flanges

GI Blind Flanges

Why Choose Udhhyog:

High-quality zinc-coated flanges

Competitive pricing

Reliable supply chain for MSMEs

2. Sanjay Metal India

Sanjay Metal India is a prominent manufacturer and supplier of GI flanges in Delhi. They offer a wide range of galvanized iron flanges with different specifications that meet industry standards. Sanjay Metal India is known for its strong customer support, adherence to international quality standards, and timely delivery of products. The company’s GI flanges are widely used in water distribution, oil, and gas pipelines.

Why Choose Sanjay Metal India:

Wide variety of flange types

Products meet international quality certifications

Strong industry reputation for customer service

3. Regal Sales Corporation

Regal Sales Corporation has become a leader in manufacturing and exporting high-quality GI flanges in Delhi. Their flanges are produced using advanced machinery and meet global standards like ASME, ANSI, and DIN. Regal Sales Corporation serves industries such as oil & gas, petrochemicals, and construction, offering both standard and custom-made GI flanges that ensure corrosion resistance and durability.

Why Choose Regal Sales Corporation:

Advanced manufacturing technology

Compliance with international standards

Custom-made flange solutions

4. Metal Udyog

Metal Udyog is a well-known supplier of GI flanges, catering to various industrial applications. Their range of flanges is highly regarded for its durability, corrosion resistance, and precision. The company offers a variety of galvanized flanges, including slip-on, weld neck, and blind flanges, which are designed to withstand the rigors of high-pressure applications. Metal Udyog’s commitment to quality has made them one of the preferred suppliers in Delhi.

Why Choose Metal Udyog:

Focus on quality control and precision manufacturing

Comprehensive range of GI flanges

Fast delivery and industry-wide recognition

5. Suryadeep Industries

Suryadeep Industries is one of the leading manufacturers of galvanized iron flanges in Delhi, offering a wide selection of flanges suitable for various applications. Their products are crafted with precision and undergo stringent quality checks to ensure they meet industry requirements. The company is known for its affordable yet high-performance GI flanges, making them a popular choice among clients in the water treatment, plumbing, and irrigation sectors.

Why Choose Suryadeep Industries:

Affordable pricing without compromising on quality

Broad range of GI flange products

Extensive industry expertise

#GIFlanges#GalvanizedFlanges#PipeFittings#IndustrialFlanges#FlangeManufacturers#DelhiSuppliers#CorrosionResistant#WaterPipeline#ConstructionSupplies#IndustrialPipeFittings#Udhhyog#MSMESupplier#DelhiManufacturers#PipeConnections

2 notes

·

View notes

Text

Jindal GI ERW Pipe: A Reliable Choice for Your Projects

When it comes to selecting the right pipe for your construction or industrial projects, reliability and durability are key factors. The Jindal GI ERW pipe is known for its high-quality standards and longevity. At Udhhyog, we offer the Jindal GI ERW pipe at competitive prices, making it an excellent choice for your next project. In this article, we’ll dive into the benefits, applications, and why you should consider Udhhyog for your procurement needs.

What is Jindal GI ERW Pipe?

Jindal GI ERW (Electric Resistance Welded) pipes are galvanized iron pipes manufactured using high-quality materials and advanced technology. These pipes are coated with a layer of zinc to protect them from corrosion, ensuring long-term durability. The ERW process also gives the pipes excellent strength and reliability, making them suitable for a wide range of applications.

Key Features of Jindal GI ERW Pipe

Corrosion Resistance: The galvanization process provides a protective layer of zinc, making the pipes highly resistant to rust and corrosion.

High Strength: The ERW manufacturing process results in strong and robust pipes, capable of withstanding high pressure.

Versatile Use: Available in various sizes and thicknesses to meet different project requirements.

Benefits of Using Jindal GI ERW Pipe

Long-Lasting Performance: The galvanized coating ensures that the pipes last longer, even in harsh environments.

Cost-Effective: Investing in Jindal GI ERW pipes can save you money in the long run due to their durability and low maintenance.

Wide Range of Applications: Suitable for plumbing, irrigation, water supply, and structural applications.

Applications of Jindal GI ERW Pipe

Water Supply Systems: Commonly used in municipal and residential water supply lines due to their corrosion resistance.

Irrigation: Ideal for agricultural applications, providing reliable water distribution.

Construction: Used in structural applications, scaffolding, and fencing due to their high strength.

Why Choose Udhhyog for Jindal GI ERW Pipe?

Udhhyog is committed to providing high-quality industrial products at competitive prices. By choosing us, you get:

Authentic Products: We offer genuine Jindal GI ERW pipes that meet industry standards.

Competitive Pricing: Get the best value for your money with our affordable pricing structure.

Reliable Service: Our team ensures timely delivery and excellent customer support.

How to Order

Purchasing from Udhhyog is simple and convenient. Visit our website and place your order for Jindal GI ERW Pipe to enjoy quality products at competitive prices. We deliver across India, ensuring a smooth and hassle-free experience.

#JindalGIPipe#ERWPipe#PipeSupplier#IndustrialPipes#ConstructionMaterials#WaterSupply#Udhhyog#ReliablePipingSolutions

5 notes

·

View notes

Text

Understanding FRP Pipes: Features, Applications, and Benefits.

D Chel Oil & Gas is a reputed FRP pipe manufacturer in India. FRP pipe is corrosion-resistant, easy to build and transport, has a long service life, and requires minimal maintenance. It transports sewage and wastewater from homes and businesses. Our FRP pipe operates well under a variety of soil and weather conditions. When put in harsh environments, they may have to perform at high temperatures and pressures. FRP pipes are often utilised in a wide range of sectors, including power production, irrigation, gas, and chemical facilities.They are often regarded as the most effective petrochemical industry commodity solutions.

What Are FRP Pipes?

FRP pipes are composite materials made by combining a polymer matrix with reinforcing fibers, typically glass fibers. The polymer matrix can be thermosetting resins like epoxy, polyester, or vinyl ester, which bind the fibers together and provide the desired shape and chemical resistance. The result is a lightweight yet robust pipe with excellent mechanical and thermal properties.

Key Features of FRP Pipes

Corrosion Resistance: One of the most significant advantages of FRP pipes is their resistance to corrosion. Unlike traditional materials like steel, FRP pipes can withstand exposure to harsh chemicals, acids, and salts, making them ideal for industrial applications.

High Strength-to-Weight Ratio: Despite being lightweight, FRP pipes offer exceptional strength. This property makes them easy to transport and install without compromising performance.

Thermal and Electrical Insulation: FRP pipes exhibit excellent thermal and electrical insulating properties, making them suitable for high-temperature and electrical applications.

Customization: FRP pipes can be customized in terms of size, shape, and composition to meet specific project requirements. This flexibility allows for tailored solutions in various industries.

Longevity: With a lifespan of several decades, FRP pipes require minimal maintenance, reducing long-term operational costs.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes have a wide range of applications across various industries, including:

Water and Wastewater Management: FRP pipes are widely used in sewage systems, water treatment plants, and irrigation systems due to their resistance to chemicals and ease of installation.

Chemical Processing Plants: Their ability to withstand corrosive chemicals makes FRP pipes a preferred choice for transporting acids, alkalis, and other reactive substances.

Oil and Gas Industry: FRP pipes are used for transporting petroleum products and in offshore platforms where resistance to saltwater corrosion is crucial.

Power Generation: They are employed in cooling water systems, flue gas desulfurization, and other applications in thermal and nuclear power plants.

Marine and Offshore Applications: FRP pipes are used in shipbuilding, desalination plants, and other marine environments due to their resistance to seawater and lightweight nature.

Advantages of Using FRP Pipes

Cost-Effectiveness: Although the initial cost of FRP pipes might be higher than some traditional materials, their long lifespan and low maintenance requirements result in significant cost savings over time.

Environmental Benefits: FRP pipes have a lower carbon footprint during production and are recyclable, making them an eco-friendly choice.

Ease of Installation: The lightweight nature of FRP pipes simplifies handling and installation, reducing labor and equipment costs.

Safety: The non-conductive properties of FRP pipes make them safe for use in electrical and thermal applications.

Durability: FRP pipes can withstand extreme weather conditions, high pressures, and temperatures, ensuring reliable performance even in challenging environments.

FRP Pipe Manufacturers in India

India is home to various well-known FRP pipe manufacturers who produce high-quality products that meet international criteria.FRP Pipe Suppliers in India provide a wide selection of solutions adapted to specific industrial needs, guaranteeing that clients obtain durable and effective pipe systems. These manufacturers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the product of contemporary manufacturing techniques and stringent quality control measures. We are also one of the largest FRP grating manufacturers in India.

#FRP Pipe Manufacturers in India#FRP pipe manufacturers#FRP Pipe Suppliers in India#FRP Grating Manufacturers in India

0 notes