#magnetite powder

Explore tagged Tumblr posts

Text

How to Use Herbs: Basil (Sweet Basil)

Hwello again! This time we shall be talking about how to use basil in different forms. If you want more information about basil, please click this link to get to my basil post: Basil Let's get started.

Alchemist Formulas:

*Remember always try to see one part as a teaspoon before going into other measurements. Doing a smaller amount first and then trial and error is better than making too much and a mess.

Mars:

two parts red sandalwood

one part honeysuckle flowers

one part basil

one part ginger oil

one part juniper oil

Health

one part frankincense (Sun; vitality)

one part basil (Mars; energy)

one part cinnamon (Mercury; nervous system)

one part bay oil (Sun; health)

one part sandalwood oil (Moon; Inner Self)

Oils

Basil Essential Oil:

Ingredients

12 ounces olive oil

2 ounces basil, 1 packed cup

Remove basil leaves from stems.

Place olive oil in a pint sized mason jar.

Carefully stuff basil into mason jar and close the lid.

Store on a sunny windowsill for 1 day.

Use a funnel to strain oil and a spoon to smash last bits of oil out of leaves and discard the leaves.

Transfer oil to a decorative jar and refrigerate for up to 1 week.

Prosperity Oil:

1 part mint

1 part basil

1 part cinnamon

1 part pine

Carrier oil of your choice (olive oil, jojoba oil and etc)

Simply take a small mason jar and fill it a 1/4 of the way up with your chosen oil.

Add in your herbs while thinking of your intentions of prosperity and abundance and swirl the jar around clockwise.

Then add a little bit more of the oil before closing the lid.

Awakening Oil:

*This needs to crafted on a full moon

1/4 cup carrier oil

Mason jar

2 drops of basil oil

2 drops of thyme oil

Pour your carrier oil into the mason jar and then added the drops of thyme and basil

Swirl it gently in a clockwise direction so it will mix thoroughly. Say, "I awaken, I listen, I see. Enlightenment come to me. Awareness, mindfulness, clarity. Illumination come to me."

Anoint your temples on your head and pulse points with your oil before doing divination work.

Spells

Basil Growth Spell

Chop fresh basil into fine threads.

Warm honey gently over the stove. (A double boiler or bain-marie is recommended, as honey scorches easily.)

Add the basil to the honey and simmer.

Remove the basil-enhanced honey from the source of heat and murmur over it something like this: "Flies flocks to honey, Customers flock to me, Bears flock to honey, Business flocks to me, Ants flock to honey, Contracts flock to me."

Run a warm bath for yourself.

Rub the honey over your body, and then enter the bath.

Soak in the water for a while. When you emerge, before you drain the water, reserve some of the used bathwater.

Toss this on the grounds of your business.

Sex Worker’s Better Business Spell

Dress a lodestone , a magnetite rock, with essential oils of basil, bergamot, and lavender. (In theory, the lodestones' gender may be coordinated with the gender of the clientele you wish to draw.)

Sprinkle with magnetic sand and a pinch of ground cinnamon.

Carry or wear to charm up added business.

Exorcism Powder

Blend the following ingredients together and grind into a fine powder:

Dried basil

Frankincense

Rosemary

Rue

Yarrow

2. Blend this powder with arrowroot powder.

3. Sprinkle as needed.

Basil Cleansing Bath

Pour approximately one cup of boiling water over one heaped teaspoon of dried basil.

Allow this to stand until the water cools, creating a strong infusion.

Add this to your bath.

Financial Dreams (For Solutions)

Sprinkle either infused basil oil or essential oil of basil onto a lodestone, just before going to sleep.

Get into bed, turn out the lights and gently rub the scented lodestone in a sunwise direction on your forehead. (When you awake, your forehead will probably be dirty. Don’t panic; lodestone dust is lucky.)

Keep the lodestone near the bed, so that you can inhale the basil

Since two of these spells ask for lodestone, here is where you can get some and arrowroot powder. Lodestone , Arrowroot Powder

Kitchen Witch Recipe:

Wisdom Soup

Serves: 4

Prep Time: 30 minutes

Cooking Time: 30 minutes, plus a little bit until it’s just right

1 cup red lentils

2 cloves garlic, minced

1 can coconut milk

1 lime, sliced into thin wheels

Oil Options: Olive oil, toasted sesame oil

Sour Options: lemon juice, lime juice, rice vinegar

1 onion, diced

Sweet Options: Sugar, honey, agave

2 sprigs basil, de-stemmed and chopped

Salt Options: Soy sauce, sea salt, sweet miso (make a paste with miso and water before adding)

2 inches fresh ginger, minced

2 cups water

2 sprigs cilantro, de-stemmed and chopped

2 sprigs mint, de-stemmed and chopped

1/4 teaspoon cayenne pepper

In a pot, place the lentils, coconut milk, and water, and bring to a boil.

Reduce heat and simmer.

Add the onion, garlic, ginger, cayenne.Stir. Do not cover.

Once the lentils are cooked and not firm (about 15–20 minutes), add one thing from the sour category, one from the sweet category, one from the salty, and some oil (add about a teaspoon of oil at a time). Taste. Repeat with a different item from each category.

Garnish with sliced wheels of lime and minced-up basil, mint, and cilantro.

I hope you enjoy these spells, recipes, and formulas and put them to good use. Use them wisely and bye byes~

Sources

#baby witch#witchblr#green witch#witchcraft#witch community#plants and herbs#herbalist#occulltism#paganblr#nature#kitchen witch#witch tips#witchcraft 101#apothecary#alchemy#occultism#basil#culinary#recipes#witches of tumblr#witchcraft resources#witch blog#beginner witch

200 notes

·

View notes

Text

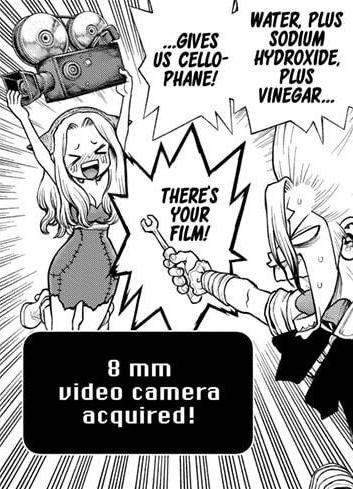

Chapter 222 Trivia (Part 1)

Fun fact: this chapter is from issue #2 of WSJ's 2022 collection!

The Apollo mission had spacesuits tailor-made to each astronaut, but these days it's easier to use interchangeable parts and switch them out according to the size of the wearer, rather than having the whole suit fitted.

However, the gloves are always custom-sized for dexterity.

Vinyl fabric doesn't seem to have ever been used as part of a spacesuit, however spandex and nylon have, especially in the inner layers.

Outer layers include Teflon, Kevlar, and aluminized Mylar.

It's possible that rather than being used for the fabric, the vinyl is used for the suit's interior cooling tube system, and the aluminum is used for the Mylar rather than for the exterior metal parts, as pure aluminum is easily scratched.

You probably recognize this panel from the end of chapter 219. The only difference is Ryusui's head has been swapped with Stanley's.

Japanese doesn't have a "V" sound, which is why Chrome says "by" rather than "vi" or "vy".

Generally English words used in Japanese make this switch, for example "violin" becoming "baiorin" due to the lacking of "V" and "L" sounds.

This building may be where they're assembling the SENKU 11 rocket, however in this first panel it appears completed, but in later ones it's still under construction.

The PS5 was first announced in April 2019, and released November 2020. First images of the console were revealed on June 11th 2020.

The first global petrification happened in June 2019, so this person would know about the console but not known what it was meant to look like.

The robot maid request is most likely a reference to "Me and Roboco", another manga currently being published in Weekly Shonen Jump alongside Dr. Stone. It's a comedy series that follows a powerful-but-clumsy maid robot in a grade schooler's service.

(Later, Me and Roboco came out with a Dr. Stone parody for the 15th volume cover)

The vacuum tubes are back in the form of cavity magnetrons. These produce the microwaves that bounce around the microwaves' interior body.

The cooking effect was first discovered in 1945 when Percy Spencer noticed a candy bar had melted in his pocket after testing magnetrons.

Plastic wrap is vinyl that has been flattened to between 8-12 μm thick, (approximately 0.001 cm). For context, this is about as thick as a spider's web or the size of a droplet of water in fog.

The film Senku makes here is cellulose triacetate film, which is less flammable than earlier celluloid film, earning it the nickname "safety film".

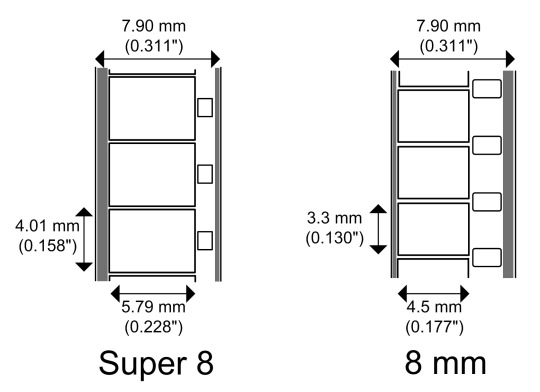

The 8 mm part is the width of the film strip.

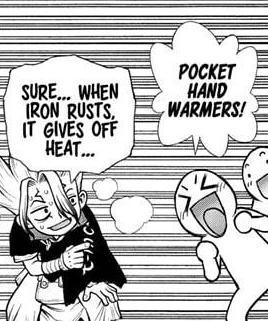

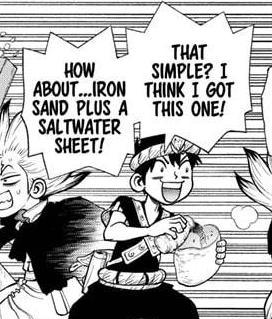

Unlike reusable hand-warmers that use supersaturated sodium acetate, these are one-time use and rely on oxidation to create heat. Once the packaging is opened, air penetrates the bag, oxidizing the iron. Vermiculite is added to remove moisture & salt is added as a catalyst.

Chrome's design wouldn't work properly because he uses iron sand rather than iron powder. Iron sand is mostly magnetite, which is already an iron oxide and thus won't have the oxidation reaction or create heat.

The fridge (or maybe mini wine cellar/fridge?) design is a parody of Smeg, a kitchen appliance brand.

You can also see the Senku-brand PlayStation, robot maid, and protein powder.

(Next part)

18 notes

·

View notes

Text

Research blog until GSA: Day 2 of 25

Folks... I slept exactly 1 hour and 30 minutes last night and would love if Monster/Red Bull could sponsor my Ph.D.

Anyway... I began dissolving my samples today, the first step of three is to put my rock powder in a mixture of 3:1 Nitric to HF acid. This is usually the most aggressive step, the subsequent steps are really just to get rid of the fluorides that form after this (they just look like white flecks at the bottom of the beaker).

You have to rotate putting them on heat and sonicating the samples for the first three hours that you begin this process, so it is very time consuming on the first day. Below is a picture of my samples after 2 hours in the solution, there was still plenty of magnetite in some of my samples and the orange/brown you see in the beakers is the gas produced from the dissolution process.

In between all of that I began modifying my Perplex file I made yesterday to ensure I was using the correct solution models.

I know I promised yesterday to explain how Perplex works slightly, so here it goes. Each rock can be broken up into the major elements that are found within it, these are typically represented by oxides like FeO, MgO, etc., you can plug those concentrations into the program and set a specific range of pressure and temperature conditions you desire (typically you start with a big range and refine it later on), and Perplex will spit out what minerals would be stable anywhere in that Pressure Temperature space. Its incredibly overwhelming but you at least know your end goal, which is whatever minerals that are in your rock sample.

Put simply, when you find your known assemblage in the program, you can get a pressure and temperature range for your rocks, However, to make it a bit 'easier' for the program, you can put in 'solution models' which basically just lets it know to look for those specific minerals, while, maybe, specifically excluding others (exclusions aren't necessary and I frequently try to avoid it).

*This is just one use of Perplex, it is really extensive the amount of cool things you can do with it, but what I am currently doing is making what is called a 'pseudosection', you may have made one in your petrology course if you have taken it*

I also looked at my thin section a little more today, and the last thing on my list today is to handpick more.

(As a side note unrelated to research, the first week of TAing is going pretty well this semester. Also I am not proofreading this wall of text I am sorry in advance, I just do not have the concentration)

#geology#stem#rocks#grad school#women in stem#science#geologist#science education#studying#studyblr#geochemistry

3 notes

·

View notes

Text

my roommate ruined my dark beads with the aura from his magnetite powder

7 notes

·

View notes

Text

Magnetite Powder Manufacturers In India | Magnetite Powder Manufacturers

We are one of the finest Magnetite Powder Manufacturers and Suppliers in India Our Magnetite is processed from Premium quality raw material with magnetic content of over 97 Browse us online for more details.

0 notes

Text

Demir Tozu Metalurjisi ile Yüksek Performanslı Bileşen Elde Etme!

Net şekilli parçaların karmaşık bir hale getirilmesinde demir tozu metalurjisi (ferrous powder metallurgy P/M) düşük maliyetli ve verimli bir işleme tekniği olarak görülmektedir. Bu teknikle üretilen parçalar diğer tekniklere oranla; •damgalama, •döküm •dövme gibi geleneksel işleme teknikleriyle, •maliyet, •geri dönüşüm ortamı ve özellikleri bakımından rekabet etmektedir. Hatta ikincil işlemleri ortadan kaldırması ya da minimuma indirmesi nedeniyle (işleme gibi) demir tozu metalurjisi oldukça çekici bir işleme tekniği olmaktadır.Toz, tozun kimyasal bileşimi, sıkıştırma ve sinterleme, bileşenlerin mekanik özellikleri üzerinde büyük bir etkiye sahiptir Otomotiv sektöründe metalürjinin uygulanması (göbekler, halkalar, kayan manşonlar, debriyaj konileri ) FeCrMoC, FeCrC, FeNiMoCuC gibi yeni yüksek performanslı malzemelerin gelişmesine yol açmıştır. Bu malzemelerin optimum kullanılması için en önemli kriter yorgunluk performansıdır. Mikro yapının çeşitli homojenliği, malzemenin yorulma performansını etkileyebilir. Sinterleme koşulları da, mikro yapıyı iyileştirmek ve bu nedenle yorulma dayanımını iyileştirmek için değiştirilebilir.

Toz

Demir tozu Demir tozu iki farklı toza ayrılabilir: Sünger demir tozu Bir magnetit kaygan (Fe3O4 ) ve kok ve kireçtaşı (Hoganas Süreci) indirgenmesinden oluşur. •Bantlı fırında öğütme, •eleme, •tavlama ve •dengeleme, toz büyüklüğünün 150 um'nin altında bir partikül ile üretilmesinin farklı aşamalarıdır. Toz güçlüdür ancak düşük bir sıkıştırılabilirliğe sahiptir ve <6.8 g / cm³ yoğunluğa sahip bileşen için kullanılır. Su atomize toz Su jetleri ile eritilip atomize edildikten sonra, tozlanma otomizasyon sırasında aşırı hızlı soğutma nedeniyle istenenden daha zordur. Susuzlaştırılmış, kurutulmuş, manyetik olarak ayrılmış, elenmiş, bir ısıl işlemden sonraki adımlar. Bunları yumuşatmak ve oksijen ve karbon içeriğini azaltmak için, tozlar kontrollü bir atmosferde tavlanır. Bu toz yaklaşık partikül büyüklüğü yaklaşık 85 um olan yüksek basınçtadır ve manşon kovanı, eşleyici göbeği, eşleyici halkası gibi > 6,8 g / cm³ yoğunluğa sahip bileşenler için kullanılır.

Alaşım Elementlerinin Etkisi

Sert etkin sinterlenmiş demirli malzemelerin elde edilmesi için, •Bakır •Nikel, •Molibden, •Krom, •Manganez, •Silisyum •Karbon Gibi diğer alaşım elementlerinin eklenmesi gerekir. Preslenmiş ve sinterlenmiş P/M bileşenleri için, alaşım elemanlarının yanı sıra ekleme modunun (karıştırılmış, önceden alaşımlı veya difüzyon alaşımlı) karışım, sıkıştırma ve sinterleme adımlarının her biri üzerindeki etkisi çok önemlidir. Karbon (ağırlıkça% 0.1-0.7) Çelik ve PM çeliği için temel elemandır. Martensitik dönüşümün sıcaklığındaki artış nedeniyle karbon, gerilme mukavemetini ve sertliğini arttırır, ancak sonuç olarak uzamayı azaltır. Ağırlıkça> 0,8'lik bir konsantrasyon için. -% artık östenit oluşumu meydana gelir ve çekme dayanımı düşer. Nikel (ağırlıkça% 1-4) Darbe dayanımı, yorulma dayanımı ve iyi aşınma dayanımı vardır. Sinterleme sırasında bir büzülme gözlenebilir. Molibden (ağırlıkça% 0.4-1.4), Krom (ağırlıkça% 0.5-3.0) Krom, molibden gibi alaşım elementleri sertlik, kuvvet ve tokluk gibi özellikleri geliştirmek için karbonlu demire eklenir. Bakır (ağırlıkça % 1.0-3.0) Genellikle, diğer alaşım elementleri ile birlikte kullanılır. Bakır ve grafit ilaveleri sinterlenmiş kompaktda büyümeye neden olur. Manganez (ağırlıkça% 0.1-2.0) Molibden ile birlikte gücü ve sertliği arttırın. Silisyum (ağırlıkça% 0.5-3.0) Silisyumun demire eklenmesi, demirin manyetik özellikleri üzerinde etkilidir. Silikon, direnci arttırır ve doygunluk endüksiyonunu azaltır. Sinterleme sırasında sıvı faz gerçekleşir. Fosfor (genellikle ağırlıkça% 0.45) Ütüye fosfor eklenmesi yumuşak manyetik özellikler üzerinde olumlu bir etkiye sahiptir. Elemanlar daha açık alfa fazını dengeler ve 1050 ℃ civarında bir sıvı faz oluşturur. Sinterleme, 1120 ℃ yaygın olarak kullanılan sıcaklıkta gerçekleşir. Fosfor doygunluk indüksiyonunda bir artışa, zorlayıcı alanda bir azalmaya ve dirençte bir artışa neden olur.

Alaşım teknolojisi

Saf demirin mekanik özelliklerini geliştirmek için alaşım elementlerinin eklenmesi, yani mukavemet, sertlik, süneklik, darbe dayanımı, yorulma dayanımı bileşenlerin üretimi için çok önemlidir. Farklı alaşım teknolojisinin grafiksel gösterimi Şekil 1'de gösterilmektedir.

Toz karakterizasyonu

Metal tozlarının imalat sırasındaki davranışı büyük ölçüde, aşağıdaki gibi farklı özellik kategorisi ile karakterize edilebilen, tozun özelliklerine bağlıdır: 1. Metalurjik özellikler: kimyasal bileşim ve safsızlıklar, mikro sertlik 2. Geometrik özellikler: parçacık boyut dağılımı, parçacık şekli 3. Mekanik özellikler: akış süresi, sıkıştırılabilirlik, geri yay, görünür yoğunluk, doldurma faktörü 4. Tozun özellikleri, sıkıştırma ve sinterleme davranışına ve mekanik özelliklerine karar verir.

Sıkıştırma

Metal tozları yağlayıcılarla karıştırıldıktan sonra (örneğin ağırlıkça% 0,4 ila 1,4 arası balmumu ve grafit karışımı )Premix diye adlandırılır. Karışım hassas bir kalıba beslenir ve genellikle oda sıcaklığında sıkıştırılır Normal olarak, istenen yeşil yoğunluğu elde etmek için 400 ila 700 MPa arasındaki basınçlar kullanılır. Bir bileşenin yeşil yoğunluğu ve yeşil gücü; •sıkıştırma basıncına, •bileşen geometrisine •toz bileşimine bağlıdır. Önceden pürüzlendirilmiş tozlar, tamamen alaşımlı tozlara kıyasla yüksek bir sıkıştırılabilirliğe sahiptir. Toz seçimi ve sinterleme koşulları, numunelerin mekanik özellikleri üzerinde büyük bir etkiye sahiptir. Kaynak : 1-Scholarlypages 2-Vibgyorpublishers Read the full article

#Bakır#DemirTozunununÖzellikleri#Fosfor#GeometrikÖzellikler#Karbon#Krom#Manganez#MekanikÖzellikler#MetalurjikÖzellikler#Molibden#Nikel#Silisyum

0 notes

Text

Harnessing Sustainable Practices in the Ilmenite Market: An In-depth Study

Ilmenite is a naturally occurring titanium-iron oxide mineral which is used as the primary source of titanium dioxide. Ilmenite is smelted to produce titanium dioxide, which is a widely used whitening pigment due to its non-toxic properties. Titanium dioxide has high demand in the paints and coatings industry where it is used to provide opacity, whiteness and brightness to various paints, plastics, papers and other applications. The growing construction industry across the world has fueled the demand for paints and coatings in recent years. The global ilmenite market is estimated to be valued at US$ 13.38 Bn in 2023 and is expected to exhibit a CAGR of 3.9% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: The rising demand from the paints and coatings industry is a major driver for the ilmenite market. As mentioned earlier, titanium dioxide obtained from ilmenite is used extensively in the formulation of various paints and coatings. The booming construction industry globally has augmented the consumption of paints and coatings in buildings, infrastructure and other construction applications. According to statistics, the global construction industry experienced a growth rate of over 3% during the period 2013 to 2018. The burgeoning construction sector in developing economies such as China, India etc. is anticipated to boost the paints demand, thereby favoring the market for ilmenite over the forecast period from 2023 to 2030. Another factor propelling the ilmenite market is its use as a natural mineral supplement for livestock. Ilmenite contains mineral iron which is an essential nutrient for animals. Many farmers add ilmenite grit or powder to animal feed in order to meet their iron requirements. The thriving livestock industry, especially in Americas and Asia Pacific is expected to drive the consumption of ilmenite in the coming years. SWOT Analysis

Strength: Ilmenite has wide industrial applications which helps drive its demand. It is a major source of titanium dioxide which is used in paints, plastics, papers and other applications. Many countries have sizeable Ilmenite reserves which ensures stable supply.

Weakness: Ilmenite has lower TiO2 content compared to other titanium minerals which increases production costs. Production of titanium dioxide from Ilmenite is capital intensive and energy intensive which affects its profitability.

Opportunity: Growing construction and infrastructure activities are increasing the use of paints and coatings which will boost demand for titanium dioxide and subsequently Ilmenite. Expanding applications in automotive, aerospace and other industries also present new growth opportunities.

Threats: Fluctuations in raw material prices and foreign currency exchange rates pose risks. Stringent environmental regulations for mining activities could increase production costs. Key Takeaways The global Ilmenite market is expected to witness high growth. The global ilmenite market is estimated to be valued at US$ 13.38 Bn in 2023 and is expected to exhibit a CAGR of 3.9% over the forecast period 2023 to 2030.

Regional analysis related content comprises growing demand from China, India and other Asian countries will drive the Asia Pacific region's market share over the forecast period. Countries like India, China, Vietnam have witnessed highest growth in infrastructure development and construction activities in recent years which is increasing consumption of paints, plastics and other end use industries thereby augmenting demand for Ilmenite in the region. Key players related content comprises Key players operating in the Ilmenite market are Abbott Blackstone, China Vanadium Titano-Magnetite Mining, Illuka Resources Limited, Jiangxi Jingshibao Mining Manufacturing Co., Ltd, Kenmare Resources, PT Monokem Surya, Rio Tinto, V.V Mineral, Yucheng Jinhe Industrial Co., Ltd. These players are focused on capacity expansion plans and strategic partnerships to meet rising demand for Ilmenite. For instance, Rio Tinto signed a multi-year Ilmenite supply agreement with Chemours to support growth in its titanium technologies business.

0 notes

Text

Basalt is a natural rock formation known for its hard and dense texture. Its dark, bumpy surface is often likened to coarse, nappy hair when scratched by a tool. This picturesque and fascinating rock formation has captivated geologists and the public for centuries.

On a geological level, basalt occurs when molten rock, called magma, is released from the Earth's mantle as lava. Layers of the lava slowly cool and solidify over time to form the bumpy basalt. Its bumpy surface is magnified as additional lava flows into the formation, creating extra bumps or ridges.

The dense and heavy texture is a result of its composition, which is made mostly of the minerals pyroxene, olivine, and plagioclase. All three minerals, together with scarce amounts of magnetite, quartz, and feldspar are known as mafic minerals, a type of mineral that is exceptionally dense and dark due to its high density mineral composition.

When scratched, basalt releases a dark gray powder, its original, unweathered color. This makes the rock resemble coarse, nappy hair. In some areas in the United States and abroad, light-colored rocks are often mistaken for basalt, but they are in fact deposits that are not as dense as basalt.

Basalt’s unique textures and rock composition have fascinated geologists for centuries. Its true beauty is seen best when its dark color contrast against the bright shades of geological layers next to them.

0 notes

Text

With a disclaimer that working from photos is always difficult because a lot of diagnostic features are hard to see in photos or involve other things (weight, hardness, cleavage angles etc...) for separating similar looking minerals

1. Most likely calcite (if you have hcl or muriatic acid you can test to see if it fizzes... Because most non geologists don't if you scratch a part of it into a little powder and drop some warm vinegar on it, it should also fizz a bit if it's calcite.

2. Dark crystals might actually be tourmaline. If the rock feels heavier than you were expecting the white mineral may be barite. The red is probably hematite staining (iron-oxide, rust basically) of other minerals but hard to say from the photo.

3. Pyrite for sure. The grey one, my first thought was Galena but it doesn't look as sharp cubic as I'd expect. Rub it with your thumb if it comes away grey like soft pencil lead it may be graphite. If not scratch it, if the colour of the scratched powder is red or brown = specular hematite. If grey try a magnet, if it's magnetic = magnetite. If not any of those it's probably a sulphide of some flavour but more tests needed.

4. I'm definitely no paleontologist. Bivalves and coral but have no more detail to add.

5. If it was heavy for the size I'd say barite. But it's not so... Maybe gypsum, try scratching it to see if it's really soft and easy to scratch. Could also be bladed calcite? It's really hard to tell from the photo. There's a few options.

6. Hard to tell from the photos. Could be fluorite or apatite? If you have a black light and it fluoresces its likely fluorite. But there are other options too.

7. Could be mica or gypsum (if you can scratch with fingernail is the second). The shiny on the granite is probably pyrite. Possibly chalcopyrite.

Part 2 to come.

Who wants to help me ID some rocks?

So one of the cool things that got left at the new house is the former owner's rock and fossil collection, which they meticulously catalogued by which I mean they left them out under some junipers in the back yard. The power is out, so I'm spraying some of the dirt and leaves off with the hose, but if anyone has guesses I'd love to hear them.

1. The Big Fucker:

(10 in screwdriver for scale)

First clue that there was a secret collection, this was the only one really visible. Pale translucent blue-green cubic crystals and skinny, more opaque/white ones on top of a heavy dull white rock. Pretty, whatever she is.

2. Salt n Peppa

Pretty sure the black stuff is smoky quartz, but what are the white cubes and the red rock it's on?

3. Sparkly Bois:

Two of these- I think the little cubes are pyrite, but what's the dark, shiny/metallic stuff? Very heavy for their size.

4. Assorted Dead Things!

Fossil clams and a coral I think, but if anyone knows anything more specific I'd love to hear it. Pretty sure most of these things are from the Rockies/front range area but genuinely, I don't know where they got them.

5. IDK what she is, but her name is Helen:

Like a bunch of criss-crossing wafers. Not very heavy for her size.

6. Green Stuff:

What are the green crystals coming out of this rock? They're cool, whatever they are.

7. Miscellaneous Shinies:

Assorted small rocks I found while digging. Small dead clam, I think some of that is mica, and I'm really curious about the shiny stuff on the granite (?).

Part 1/2, gonna hose some more rocks while y'all speculate.

2K notes

·

View notes

Link

#Stainless Steel Pipes#telescopic channels#drawer slider#auto hinges#stainless steel telescopic channel#soft close telescopic channel#Silica Ramming Mass#Cenospheres#magnetite powder#Tundish Board#Quartz Powder#khetan group#khetan udyog#khetan viniyog#khetan enterprises#stainless steel pipes suppliers#stainless steel pipes manufacturer#stainless steel pipes distributors#Stainless Steel Telescopic Channel manufacturer#telescopic channels for wooden fittings

0 notes

Text

Black Iron Oxide Powder Manufacturer in India

Vijit Worldwide is a reputed manufacturer, exporter and supplier of premier quality black iron oxide, red iron oxide, yellow iron oxide, garnet sand and glass powder for varied industrial purposes. We always strive to produce best quality products and offer prompt services across the globe. We are a trustworthy destination for high quality mineral powder and chemical. We take pride in introducing ourselves as one of India’s leading exporters of processed mineral and chemicals as well.

Being a well-known name in the industry our products are highly appreciated by the reliable customers. Our company gives high integrate focus to create value for the benefit of the customers and dedicated itself always to retain the best quality of the products by maintaining operational hi-tech infrastructure. Today, we are recognized as one of the authentic manufacturer, supplier and exporter of raw materials for finishing industries in the world.

Please visit our website at https://vijitinternational.com/ for more information.

With Best regards,

Vijit Singh Parmar

Cell phone : + 91-9109676454

Email: [email protected]

1 note

·

View note

Link

Emery (n, often attributive) 1. A dark granular mineral that consists of corundum with iron oxide impurities (such as magnetite) and is used as an abrasive also : a hard abrasive powder

"Shoal-shell-ization" is just as ridiculous as it sounds. At least you can endear yourself to your to-be fianceé.

And her brother's there too, you guess.

New chapter up in time for 4/13! Merry stuck at home day, all. Fic info under the cut

Chapters: 4/15 Fandom: Homestuck Rating: Teen And Up Audiences Warnings: Major Character Death Relationships: Mituna Captor/Latula Pyrope, Mituna Captor & Kankri Vantas, Mituna Captor/Kankri Vantas, Mituna Captor & Meenah Peixes Characters: Mituna Captor, Kankri Vantas, Meenah Peixes, Beforus Feferi Peixes, Beforus Eridan Ampora, Latula Pyrope Additional Tags: A1 Session, Beforus (Homestuck), Beforus Culling (Homestuck), SGRUB, Implied/Referenced Self-Harm, Implied/Referenced Animal Death, Personal Growth, Angst, Body Horror, Canon-Typical Profanity, Pre-Accident Mituna Captor, Major Character Undeath, Sibling Rivalry

10 notes

·

View notes

Text

Research blog until GSA: Day 1 of 25

I am not really good at maintaining these, but it is the last 25 days until GSA connects and I still have some data I wanted to collect before then (not necessary, I just want it). So welcome to 'Metamorphic petrologist/geochemist getting her shit together for the final dash'.

note: all of this work is part of one project! What does that mean? It means that everything I will write about in the next 25 days is related to one story. So by the end of this I will explain the full story of these rocks and why doing all of this was important. (This is really the final collect of data for my first paper)

Also: I will try to explain everything I am doing if I feel like explanation is needed for, like, why I am doing the tasks I am doing when necessary because otherwise it is just going to sound like a laundry list of bullshit, so here goes.

Today, I had to clean some beakers today, our lab uses Teflon (fancy plastic) beakers because we work with HF (used to dissolve silicates). It takes at least five days to properly clean beakers, but we usually have some at some halfway stage of cleaning I can pick up from.

I then made sure all the materials I would need to begin dissolving my samples was available (is there enough clean beakers, dissolution sheets, are my samples powdered, do I know how much of each sample I have to dissolve, etc.) This is for running isotopes, in particular I am looking at Sr and Nd to help determine fluid sourcing in my rocks.

A new Miniminuteman video came out, so I put that on while I handpicked garnets crumbs from magnetite and ilmenite crumbs. These garnet crumbs are from the mantle (Middle) part of one very large garnet that I drilled out the individual parts of before grinding up. Why am I doing this? Surprisingly not because I am a masochist but because I also need to liquify them so I can measure Lu/Hf ratios to get ages from the core, mantle, and rim of the garnet to learn

✨the rate that it grew at✨.

After that I reviewed my pelitic schist thin section so I could check if I still agreed with my notes I made on the sample from 5 months ago, so I could begin making a thermodynamic model of these rocks (I use the program perplex. The name speaks volumes...). I will put the initial data in tonight, and revise the model more in depth tomorrow, so I will try to explain it more then.

In this thin section of my rock, you can see a very sad garnet (In black) that gave up (The gray/white stuff and iridescent junky looking stuff around it a.k.a. mica and quartz)

I will try to add an image everyday for the ✨aesthetic✨

2 notes

·

View notes

Text

What is the black coating outside the black knife made of ?

The coating outside the black knife is usually a black oxide .

The use of black coating not only makes the knife more beautiful, but also protects the knife from corrosion.Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance, and to minimize light reflection. To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax. One of its advantages over other coatings is its minimal buildup.

A black oxide solution includes salts that act as an oxidizer. That solution reacts with the iron in the steel to create a coating over the surface. On products like knife blades, manufacturers coat the blade before putting on a final edge.

It is worth noting that the longer we use the knife, the more broken the black coating will be.

There are three types of black oxide

Hot black oxide

Hot baths of sodium hydroxide, nitrates, and nitrites at 141 °C (286 °F) are used to convert the surface of the material into magnetite (Fe3O4). Water must be periodically added to the bath, with proper controls to prevent a steam explosion.

Mid-temperature black oxide

Like hot black oxide, mid-temperature black oxide converts the surface of the metal to magnetite (Fe3O4). However, mid-temperature black oxide blackens at a temperature of 200–245 °F (93–118 °C), significantly less than hot black oxide. This is advantageous because it is below the solution’s boiling point, meaning there are no caustic fumes produced.

Cold black oxide

Cold black oxide, also known as room temperature black oxide, is applied at a temperature of 65–85 °F (18–29 °C). It is not an oxide conversion coating, but rather a deposited copper selenium compound. Cold black oxide offers higher productivity and is convenient for in-house blackening. This coating produces a similar color to the one the oxide conversion does, but tends to rub off easily and offers less abrasion resistance.

So, what the advantages of the black coating?

Black blades typically are designed for tactical, low light situations, such as military combat. Since it also won’t reflect a big glare of sunlight, the coating also draws less attention if you pull it out during the day. I’ve also heard that in blade steels that are prone to rusting, it helps seal the steel from moisture. Finally, a lot of people just like the tactical look that black blades have. So there are probably a few various reasons that people get them.

And , as time flies , the coating will drop off gradually . What I want to say is that , anyway, the scratches are a feature. It makes your knives cooler, doesn’t it ?

WHY CHOOSE YIERCITY?

We do authentic professional knife sets wholesale business. We want to be your stable global supporter and partner.

We are an enterprise integrated factory and trade, specializing in designing, manufacturing and selling knife sets and other kitchen supplies. We are dedicated to providing customers with high-quality knife sets and great service.

We always make every effort to supervise the manufacturing of every nice knife.

WHY CHOOSE YIERCITY

●We have a huge selection of authentic professional knife sets.

●Excellent customer service before and after sales.

●Return guarantee on all products.

●Free shipping and tax/custom clearance service.

●Made of premium high-quality materials to ensure safety and durability.

●Continuously optimize the manufacturing process and design style, and pursue product innovation.

●We listen to our customer’s needs and adopt their feedback.

We are an official knife vendor who are verified on the knife forum with lots of third party five star reviews…and not one negative review to date.

2 notes

·

View notes

Text

Magnetite Powder Manufacturers In India | Selective Minerals

Discover premium magnetite powder from Selective Minerals, one of India's leading manufacturers. Our high-quality magnetite powder is renowned for its purity and consistency, making it ideal for a variety of applications, including industrial, chemical, and agricultural uses. With a commitment to excellence, Selective Minerals ensures that our magnetite powder meets stringent quality standards. Trust us to provide reliable and efficient solutions for your needs. Visit our website to learn more and find the perfect magnetite powder for your projects.

0 notes

Note

I love Lucien very much now thank you for sharing, what are your OCs like?

Oh man there’s so many I couldn’t easily talk about all of them in one post. I’ll go with one I don’t talk about on tumblr as often as the others.

So his name is Haruki Himura. He’s from a Pathfinder game based on the video game Shin Megami Tensei 4. I played Haruki intending him to be a fallen hero archetype, someone who originally wanted to do good but who had things go wrong over and over until he became jaded and spiteful.

So Haruki is only 17. He was the son of a powerful noble family, but he was also a bit of an outcast amongst his peers because as a child people thought he was cursed, because his mother died in child birth and he was too sickly to be brought out of the home for nearly a year after. He’s still a bit small for his age. Everyone who did get close to him were other nobles who wanted what benefits befriending him could bring. So Haruki wasn’t looking forward to an empty life as a noble, and instead dreamed of being chosen to be one of the Samurai. Because in his eyes the Samurai were there to make the world better for everyone, and were basically heroes. This turned out to be a very naive and rose colored point of view.

On his 17th birthday he did in fact get chosen to become a Samurai. He was paired up with a girl named Dreama, who was of the lower class, hated that she’d been chosen and therefore forced into the Samurai position, and was resentful of both that and the fact she had to work with Haruki, who she viewed as a silver spoon rich kid.

Then it turned out that the real purpose of the Samurai were to fight demons in the underground caverns of Naraku, which were constantly trying to escape to the surface. Then one of the other noble kids got killed in Naraku. Then a ‘dark Samurai’ came up from the deepest caverns and turned an innocent hurting woman into a demon they were forced to kill. Then when they went into the deepest caverns of Naraku they broke an ancient seal and were cursed. Dreama was turned into a half-angel aasimar, and became basically worshipped by the people back home, who declared her their savior against the demons. At the same time Haruki got turned into a drow, or Adodaki as they call themselves. He was viewed as a demon and would have been killed if his fellow Samurai Walter hadn’t smuggled him back to his father’s estate.

Since then it’s been a downward spiral for Haruki. The people he wanted to help and protect view him as a monster, while the woman who wants nothing to do with being a hero is being hailed as their savior. He can’t go out into sunlight without being blinded. Even a literal angel of their god the Nameless Father said that his bloodline was tainted and basically it would be better for everyone if he died. And when he tried to touch Dreama’s holy sword to keep her from hurting herself, it burned his hand to the bone, scarring it.

So he’s angry. He feels like his entire life and everything he’s ever reached for has been shattered and destroyed and twisted. And as a result he’s started lashing out, becoming more violent against the demons they face, and being willing to fight against angels when it comes to it, because he’s completely lost his faith in the Nameless Father after He abandoned Haruki. And because in the world below Naraku, which is post apocalyptic modern Tokyo, angels are seen as the bad guys by the locals who are considered tainted by the heavens. And he likes the people in sunken Tokyo better than the people up top, because they treat him like a normal person despite being a drow now. Although he is violently murderous against a faction that’s basically the yakuza, due to some very messed up things he and Dreama found some of their members doing. He feels like he has less control over his emotions than he did as a human and tends to act on his emotions more and is in general a bit of a powder keg (this is not true—the drow aren’t any more violent than anyone else, it’s just him excusing his own actions that he wouldn’t have taken before the change because he feels justified in being a monster when others treat him like one)

He tried to find out more about the Adodaki/drow, but then one threatened to kill him for reasons unknown, and another cut him with a dagger tainted with a poisonous crystal that’s eating him from the inside. But, hey, he got cool powers from it. Namely a big crystalline claw that forms around his hand sometimes when he’s fighting, which infects and devours his enemies rapidly.

We’ve put this particular game on hiatus because it was a bit grimdark alongside the real events of 2020, so his story isn’t finished yet. But last time we played, he refused the offer of an angel for a cure for the magnetite crystal which would have turned him into an angel as well and taken his free will. He struggled with his answer, almost chose to take it, and only didn’t because he realized Walter wouldn’t have agreed with that choice. He believes he just gave up his only chance to save himself, but he wants to be strong and stand on his own, not lean on a god that’s already forsaken him once.

Random note, he and Walter are in something of a relationship. I don’t know that I’d say they’re dating, I don’t know if either want the commitment of that, but they definitely have some sort of romance going on.

#thank you anon#Haruki Himura#in the actual game Walter is voiced by Matt Mercer#so of course my character caught feelings for him#to be fair Walter DID save his life#and WAS the only person who treated him like a person initially when he was changed#despite Walter not liking the nobility any more than Dreama does

2 notes

·

View notes