#magnetic coolant separator

Explore tagged Tumblr posts

Text

Disassembly Drone Headcanons! >:3

For your viewing pleasure!

~••••••~

• DDs have more animalistic behavior than worker drones do. While they do maintain their social acceptance and respect when in public spaces with workers and humans, their primary forms of showing affection generally involve things like nuzzling, purring, and even sharing parts of their hunt with their partners - This can be disconcerting for DD/WD couples, though it’s usually a token of affection from the DD partner to the WD partner.

• Internal fans in the chest area used for cooling certain components will sometimes make a purring sound, which is often associated with comfort and contentment.

• VERY cuddly. Expect lots of nuzzles, kisses, hugs, snuggles, massages, hand holding, etc. from a DD partner. They seriously CANNOT keep their hands off you

• DDs like roughhousing. It’s a form of play for them - wrestling, play-fighting… They’re predators, and for them it’s a game of who is the strongest and who can pin down who first. This can also be used as a form of flirting between DDs, for… obvious reasons.

• Shiny Drones! Different colors of lights are uncommon, but not unheard of in DDs. Yellow is the standard, though blue is used as a way to show ownership by a lab or research team - These drones’ data is collected remotely for use in research and engineering. The color does not influence how the drones work in any way, though they might be picked on by others for being unique.

• DDs are social creatures, often living in groups of 3 to 6 individuals. These groups are often closely bonded together, and if they become separated the lost individual will more than likely become depressed and anxious. It’s also relatively common for DDs to engage in a sort of polyamory or queer-platonic relationships within these groups, though this definitely depends on the individuals involved.

• DDs in general prefer Drone-Grade oil, though in reality they can consume any kind of oil and derive sustenance from it. Some DDs who chose to integrate with WD society participate in a sort of ‘robot veganism’ in which they only drink pre-bottled or canned motor oil, rather than hunting it themselves out of respect for their peers.

• In that same vein, Overheating is a canon issue for DDs. The symptoms and aftermath often look similar to a stroke - Confusion, weakness, changes in eyesight, slurred speech, loss of balance… The effects can range from more milder complications such as some impaired motor skills all the way to severe cognitive deficits and even death, all of which are caused by the fusing or shorting of wires and circuits in the body.

• Coolant has the same effects as alcohol on Drones. Magnets have the same effect as sedative drugs such as weed, and in larger quantities can be a substitute for a nerve block or anesthesia.

• Both DDs and WDs can switch voice modules at any time should they please, but DDs in particular have the ability to swap parts, due to their models having sex characteristics. Some DDs do this for a day as a fun challenge, but it can be treated as a sort of gender-affirmation repair for drones who identify as trans. It is also possible to mix and match parts, for those who identify as non-binary!

• Many DDs will place a cork or similar on the end of their tail when they sleep in a bed rather than hanging upside-down to avoid injuries.

• On occasion, DDs will offer a taste of each other’s oil. This is usually something reserved only for romantic partners, as knowing someone’s flavor is considered one of the most intimate things you can share with someone in their culture.

• Will chase the red dot

~••••••~

Spicy headcanons ahead, you’ve been warned

~••••••~

• DDs have a programmed enjoyment of primal play. A mating pair might “hunt” each other, commencing the act when the more submissive of the two is caught by the other.

• Although they can do it how humans and workers do, male DDs generally prefer to mount from behind, and will sometimes spread their wings during the act in a display of dominance when they do this.

• Biting and scratching are ON THE TABLE. It is commonplace to the point of being expected, but DDs are usually more careful about this with a WD partner.

• DD culture takes a rather relaxed approach to intimacy, treating it as more of a fun bonding activity with close friends and partners. They’re robots and cannot get pregnant, and therefore don’t generally have the same reservations about the act - for them, it’s purely for the physical sensation alone.

• Tails are sensitive and a bit of an erogenous zone when held or touched in certain ways. When the DD is excited, their acid will typically form a bead at the tip of the needle.

#murder drones#murder drones headcanon#disassembly drone#disassembly drone headcanons#md headcanons#headcanon#murder drones fandom#fandom#disassembly drones#Disassembly drones are like giant cats#Idk I thought it was cute#I may have picked some of these up from others#I hope that’s okay#anyway enjoy#I will probably cover Worker Drones later

5 notes

·

View notes

Text

Smart Auto Recycling Industry Challenges Nowadays

Auto recycling, also known as automotive recycling, is the process of dismantling vehicles for spare parts and recycling materials. It plays a significant role in the automotive industry and the environment, providing both economic and ecological benefits. This essay will delve into the history, process, benefits, challenges, and future trends of auto recycling.

History of Auto Recycling

The concept of auto recycling dates back to the early 20th century when automobiles became more common. Initially, the practice was informal, with small scrap yards dismantling cars and selling usable parts. As the automotive industry grew, so did the need for more structured and efficient recycling methods. By the mid-20th century, formal auto recycling facilities emerged, equipped to handle the increasing volume of end-of-life vehicles (ELVs).

The Auto Recycling Process

Auto recycling involves several steps, each designed to maximize the recovery of usable parts and materials while minimizing environmental impact.

1. **Collection**: The process begins with the collection of ELVs. These can come from various sources, including individual owners, insurance companies, and fleet operators. Vehicles are either towed to recycling facilities or driven there if they are still operational.

2. **Depollution**: Once at the recycling facility, the vehicle undergoes a depollution process. This step involves draining all fluids, such as oil, gasoline, coolant, and brake fluid, to prevent environmental contamination. Hazardous materials like batteries and airbags are also removed and safely disposed of or recycled.

3. **Dismantling**: After de-pollution, the vehicle is dismantled to salvage reusable parts. Components such as engines, transmissions, alternators, and electronic systems are carefully removed, tested, and refurbished for resale. This stage is critical as it extends the lifecycle of parts and reduces the need for new manufacturing.

4. **Shredding and Material Recovery**: The remaining vehicle shell, primarily composed of metal, is sent to a shredder. The shredding process breaks down the vehicle into smaller pieces, which are then sorted using magnets, air classification, and other techniques to separate ferrous and non-ferrous metals, plastics, and other materials.

5. **Recycling and Disposal**: Recovered materials are sent to specialized recycling facilities. Metals are melted down and repurposed for manufacturing new products. Plastics, glass, and rubber are also processed and reused in various industries. Any residual waste that cannot be recycled is disposed of in an environmentally responsible manner.

Benefits of Auto Recycling

Auto recycling offers numerous benefits, spanning environmental, economic, and social dimensions.

1. **Environmental Benefits**:

- **Resource Conservation**: Recycling metals and other materials from vehicles reduces the demand for virgin resources, conserving natural reserves and lowering the environmental impact of mining and manufacturing.

- **Energy Savings**: Manufacturing products from recycled materials generally requires less energy than producing them from raw materials. For example, recycling steel saves about 60% of the energy needed to produce new steel from iron ore.

- **Pollution Reduction**: Proper disposal of hazardous materials and fluids prevents soil and water contamination. Additionally, recycling reduces greenhouse gas emissions associated with the production of new materials.

2. **Economic Benefits**:

- **Job Creation**: The auto recycling industry supports a significant number of jobs, from collection and transportation to dismantling, refurbishing, and material processing.

- **Cost Savings for Consumers**: Recycled auto parts are often more affordable than new ones, providing cost savings for vehicle repairs and maintenance.

- **Revenue Generation**: Auto recycling generates revenue through the sale of salvaged parts and recycled materials, contributing to the economy.

3. **Social Benefits**:

- **Community Support**: Auto recycling facilities often engage in community initiatives, such as environmental education and support for local charities.

- **Safety Improvements**: By ensuring that hazardous materials are properly handled and disposed of, auto recycling enhances community safety and health.

Challenges in Auto Recycling

Despite its benefits, the auto recycling industry faces several challenges that must be addressed to improve its effectiveness and sustainability.

1. **Technological Advancements**: Modern vehicles are increasingly complex, incorporating advanced materials and electronic systems. This complexity makes dismantling and recycling more challenging, requiring continual adaptation of techniques and technologies.

2. **Economic Viability**: Fluctuations in the market prices of scrap car pick up and other recycled materials can impact the profitability of auto recycling operations. Maintaining economic viability in the face of these fluctuations is a persistent challenge.

3. **Regulatory Compliance**: Auto recycling is subject to numerous regulations aimed at protecting the environment and public health. Compliance with these regulations can be costly and requires ongoing investment in training and infrastructure.

4. **Consumer Awareness**: Increasing consumer awareness about the benefits of auto recycling is essential for its growth. Many vehicle owners are still unaware of the environmental and economic advantages of recycling their old cars.

Future Trends in Auto Recycling

The future of auto recycling is poised for significant developments, driven by technological advancements, regulatory changes, and shifting consumer attitudes.

1. **Technological Innovations**:

- **Automation and Robotics**: The use of automation and robotics in dismantling and sorting processes is expected to increase efficiency and precision, reducing labor costs and improving material recovery rates.

- **Advanced Material Recovery**: New technologies for recovering materials from complex automotive components, such as batteries and composite materials, are being developed. These innovations will enhance the recyclability of modern vehicles.

2. **Regulatory Developments**: Stricter environmental regulations and extended producer responsibility (EPR) policies are likely to shape the future of auto recycling. EPR policies hold manufacturers accountable for the end-of-life management of their products, encouraging the design of more recyclable vehicles.

3. **Sustainable Design**: The automotive industry is increasingly focusing on sustainable design principles, such as using recyclable materials and designing for disassembly. These efforts will make future vehicles easier to recycle and reduce the environmental impact of the automotive sector.

4. **Circular Economy**: The concept of a circular economy, which aims to minimize waste and maximize the reuse of resources, is gaining traction. Auto recycling plays a crucial role in this paradigm by keeping materials in use for as long as possible and reducing the need for new resource extraction.

Conclusion

Auto recycling is a vital component of the automotive used tires industry and environmental conservation efforts. By recovering valuable parts and materials from end-of-life vehicles, auto recycling conserves resources, reduces energy consumption, and mitigates pollution. Despite facing challenges such as technological complexity and market fluctuations, the industry is evolving with innovations in automation, material recovery, and sustainable design. As regulatory frameworks and consumer awareness continue to improve, auto recycling will play an increasingly important role in building a sustainable and circular economy.

#auto recycling#hamilton junkyard#scrap cars hamilton#scrap yard hamilton#scrap yard in hamilton#scrap car removal aurora

0 notes

Text

Customised Reed Switch Sensor Solutions for Automotive Industry

Have you wondered how a same type of component can be modified into different types of sensors, then without further delay read this article explores how customised reed switch sensor solutions are driving innovations in the automotive industry, providing tailored solutions to meet the unique demands of this sector.

Understanding Reed Switch Sensors

Reed switch sensors consist of two ferromagnetic blades enclosed in a hermetically sealed glass tube. When exposed to a magnetic field, these blades either come together or separate, closing or opening an electrical circuit. This fundamental mechanism offers numerous benefits, including high durability, low power consumption, and the ability to operate in harsh environments.

Why Customise Reed Switch Sensors for Automotive Applications?

Customization allows reed switch sensors to be tailored to specific automotive applications, ensuring optimal performance and integration. Here are some key reasons why customization is essential:

Precision Fit: Customise sensors can be designed to fit specific spaces within vehicle systems, ensuring seamless integration.

Enhanced Performance: Tailoring sensor specifications, such as sensitivity and activation points, improves overall performance and reliability.

Environmental Adaptability: Custom sensors can be designed to withstand extreme temperatures, vibrations, and other harsh conditions typical in automotive environments.

Regulatory Compliance: Ensuring sensors meet industry standards and regulations is critical for automotive applications.

Key Applications of Customized Reed Switch Sensors in Automotive Industry

1. Anti-Lock Braking Systems (ABS)

Reed switch sensors play a crucial role in ABS, providing real-time feedback on wheel speed to prevent skidding and maintain control during sudden braking. According to Grand View Research, the global ABS market is expected to reach $37.2 billion by 2027, highlighting the importance of reliable sensors in these systems.

2. Gear Position Sensing

Customized reed switch sensors are used to detect the position of gears, ensuring accurate transmission control. This precision is vital for both manual and automatic transmission systems, enhancing driving performance and safety.

3. Fluid Level Monitoring

In applications such as fuel tanks, brake fluid reservoirs, and coolant systems, reed switch sensors monitor fluid levels, providing alerts for low levels to prevent potential damage. The automotive fluid market, as reported by MarketsandMarkets, is projected to reach $43.5 billion by 2025.

4. Door and Window Positioning

Reed switch sensors are used to detect the open or closed position of doors and windows, contributing to vehicle security and safety. These sensors ensure that doors are properly latched and windows are closed, providing peace of mind to drivers and passengers.

5. Seat Belt Detection

Customised reed switch sensors are employed in seat belt detection systems to ensure passengers are securely fastened. This is a critical safety feature, as seat belts significantly reduce the risk of injury during accidents.

Benefits of Customised Reed Switch Sensor Solutions

Enhanced Reliability

Customized reed switch sensors are designed to meet the specific demands of automotive applications, ensuring high reliability and long operational life. This reliability is essential for maintaining the safety and performance of vehicles.

Cost-Effectiveness

By tailoring sensors to specific applications, manufacturers can optimise production processes and reduce costs. Custom sensors eliminate the need for additional modifications or adjustments, streamlining the manufacturing process.

Improved Safety

Safety is a top priority in the automotive industry. Customized reed switch sensors enhance vehicle safety systems, such as ABS and seat belt detection, providing drivers and passengers with greater protection on the road.

Environmental Resistance

Automotive environments can be harsh, with exposure to extreme temperatures, moisture, and vibrations. Custom reed switch sensors are designed to withstand these conditions, ensuring consistent performance and durability.

Real-World Examples of Custom Reed Switch Sensor Solutions

Tesla Model S

The Tesla Model S utilises customised reed switch sensors in its advanced driver-assistance systems (ADAS). These sensors provide precise feedback for various functions, including gear position sensing and fluid level monitoring, contributing to the vehicle's high performance and safety standards.

Ford F-150

The Ford F-150, one of the best-selling trucks in the world, incorporates custom reed switch sensors in its door and window positioning systems. These sensors ensure that all doors and windows are properly closed, enhancing vehicle security and passenger safety.

Future Trends in Customised Reed Switch Sensors

The future of reed switch sensors in the automotive industry is bright, with ongoing advancements driving innovation and expanding their applications. Here are some key trends to watch:

Integration with IoT

The integration of reed switch sensors with Internet of Things (IoT) platforms is set to revolutionize automotive applications. This integration allows for real-time data collection and analysis, enabling predictive maintenance and enhanced vehicle performance. A McKinsey report estimates that IoT applications could have an economic impact of $3.9 trillion to $11.1 trillion per year by 2025.

Miniaturisation

As automotive technology evolves, the demand for smaller, more compact sensors continues to grow. Miniaturisation efforts are leading to the development of even smaller reed switch sensors, expanding their application range and improving vehicle design flexibility.

Wireless Connectivity

Advancements in wireless technology are paving the way for reed switch sensors with built-in wireless connectivity. These sensors can communicate with other vehicle systems and external devices, providing seamless integration and enhanced functionality.

Conclusion

Customized reed switch sensor solutions are transforming the automotive industry, offering tailored solutions that enhance performance, reliability, and safety. By understanding the unique needs of automotive applications and leveraging the benefits of customization, manufacturers can stay ahead of the curve and drive innovation in this dynamic sector.

Investing in customised reed switch sensors is not just about improving existing systems; it's about shaping the future of automotive technology. As the industry continues to evolve, these sensors will play an increasingly important role in ensuring vehicles are safer, more efficient, and more reliable.

0 notes

Text

Significance of Magnetic Coolant Separator in Industry

Use of magnetic coolant separator in trade these days has become dominant owing to high level of demands. Coolants not solely facilitate in dashing up the assembly however conjointly give several blessings within the metal operating operation.

The Process in the Consumption of Coolants

Because the consumption of coolants is extremely high a system is badly in want, therefore on recirculate the used agent. Conjointly the number of venturesome wastes generated by industrial plants has become a progressively expensive drawback for the manufactures and a further stress on the setting. Since the acquisition and disposal of the spent cutting fluids is turning into progressively high-ticket, fluid employment may be a viable possibility for minimizing the price. Separation of aluminiferous chips from the agents by exploitation magnetic coolant separation has established a decent management and maintenance of the cutting fluid.

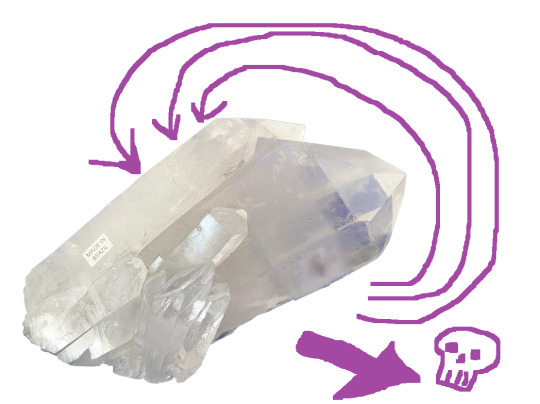

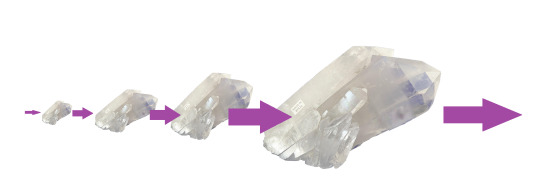

The Removal of Aluminiferous Chips

By removing the aluminiferous chips, the agent life is greatly extended, will increase the machining quality and reduces period. A magnetic agent filter is developed that uses very high energy magnets to develop a field of force that is dense on a slim flow path into that the contaminated agent is directed. The magnetic attraction particles captured and aligned by the dense field of force, from the economical filter medium. this permits the unit to get rid of magnetic attraction particles from the agent. Magnetic agent filters use the principle of magnetic separation to purify the used agent.

The developed magnetic coolant separator has the potential of purifying forty liters per minute of agent with the scale of the contaminants starting from 1 µm to 30 µm. The filter is going to be useful in saving the assembly price because the price related to the planned style is well even by the price savings in production. The field of force made by permanent magnets are going to be throughout the realm beneath the reservoir.

The Production of Field of Force

This produces field of force 30mm on top of the agent reservoir. Very small particles are in remission with no slip. The material used won't lose its strength even range of years of use. Dirty agent is fed to the reservoir of the filter from the machines either by gravity or a pump and flows underneath the receptacle. This attracts the metallic element particles and builds up a cake of metallic element material and at last got rid of by the hand tool.

The moving magnets on the shaft attracts metallic element chips and slide them on to plate then to the discharge finish or sludge bin. The agent separated from chips flow back to the agent tank. Well during this quick dynamic growth of metal operating operation the employment of cutting fluids become important for the management of agent.

With the assistance of this developed model of magnetic coolant separator setup we will get extremely economical approach of filtration guarantying fine end, dimensional accuracy and enlarged tool life. the foremost vital role of this filter is that, it'll scale back the waste disposal of agent and a profit for the assembly industries.

0 notes

Text

Little late, but here’s my take on a Swap!Au for Robots! It’s still a WIP, so bare with me!

(Shout out to @kalifiah and @themadauthorshatter for their Swap and Dead End Friends Au respectively, since their takes on the idea inspired me to make my own!)

Main differences:

-Ratchet was built in Rivet Town and had Madame and Monsieur Gasket to raise him.

-Madame Gasket in particular is known for her loving and passionate personality, with Monsieur Gasket being a pure sweetheart for all to enjoy. He was also known for needing constant repairs. Despite this, he keeps up his optimism.

-Ratchet messed up his leg when he was 17. I’m still working on what happened, but whatever happened wasn’t catastrophic, so he built himself a crutch to save money. He can’t really run with it, so the magnetized chance scene is way shorter then in the movie.

-Ratchet never cared for the sleek and shiny upgrades, much to his parents joy. He works with his dad at Gunks’s to help pay for repairs.

-Like cannon Rodney, he picked up tinkering after learning about Bigweld. Unlike Rodney, however, Ratchet also looked into becoming a repair bot for a career so he could simply repair his dad himself and save money.

-Ratchet used an old vase to make the wonderbot (you can actually see her in the sketch). She’s pretty chatty, even if she can only talk in bleeps and squeaks.

-Ratchet’s story isn’t much different from this point on, he goes to the city, meets the rusties, saves the day, etc. Only real notable difference is that he’s kind of a dumbass. He’s got zero sense of self preservation and it shows. He also kinda falls for the villain like a chad and has to deal with that sob story.

-Rodney, however, oh boy that’s an entirely different story.

-His parents own the Chop Shop, with his mother in charge and his father taking the role of caregiver to Rodney. Herb is still Herb here, but takes cannon Monsieur’s “Bye son, good luck with your dastardly plans!” Personality to a whole new level.

-Herb’s pretty laid back about the whole evil plan thing as long as his son is home in time for dinner. That, and his morning coffee. (Morning oil? Coolant?)

-Rodney’s mom (Lydia I think?) acts as a creeper Madam Gasket. Lots inspiration from The Other Mother from Coraline (we’ll see a full body someday). Other than that, she isn’t entirely fleshed out yet, so I’ll definitely make separate posts for each of the characters.

-Out of everyone in this Au, Rodney has changed completely. He’s seductive, manipulative, and is the brains behind the business. When he wants something, he’ll get it one way or another. It doesn’t help that he’s currently in charge of one of the largest companies in the city. He’s in charge and he fucking knows it.

-He’s also known to do a lot of model work during his free time, so he’s got a whole arsenal of upgrades and heels (yes he has heels in this Au) for him to run the runway with and to flex. If you’re gonna sell something, why not advertise it yourself?

I’m still working on this Au, so any comments or feedback would help me out and I’d really appreciate it in the long run.

✨~Ciao! ✨

154 notes

·

View notes

Text

@sparkvoid “Lace drop your favourite mods list.”

Okay. Keep in mind these are all for FORGE on 1.16.5. Let’s go.

Powah! A really fun power generation mod that is easy on the game and based on tiered technology. There’s no penalty for forgetting something, as even reactors just shut down if you forget a coolant. The colours are gorgeous, the ideas are fun, and the cable system is A-Tier.

Mining Gadgets. A really fun laser mining mod that lets you create one of three tiers of mining laser. It is charged with RF/FE, and you can add upgrades onto it to give it fortune, magnets, etc. I love this thing so much.

Mekanism. Easily the most complex tech mod in 1.16.5. Mekanism let’s you mine JUST ores, separate liquids into their component parts, create gases, and even quintuple your ores in processing. It has so many little parts that setting up a factory is just a whole lot of nonsense but in a REALLY good way.

Sophisticated Backpacks. My favourite backpack mod. You start with a low tier backpack and upgrade it all the way to Netherite. It even has upgrades that let it void items, magnet items, and auto collect into its inventory rather than your basic inventory. It also has a keybind to let you open it without taking it off.

Curios. The successor to Baubles, Curios let’s you equip non-armored items into specialized slots, like necklace, back, etc. It lets you carry more trinkets around, usually from other mods, and the backpack from the above mod can go into the back slot and you can SEE IT.

Double Slabs. This might be the best thing in Minecraft. You can stack different slabs together. No more shall you suffer with decisions! Not only that, it also allows for vertical slabs and you can orient them in anyway you want either on the edge or CENTRE of a block. And the lighting! Works! No weird shadows! I could scream.

The entire Macaw collection. Macaw makes amazing decorative mods - doors, gates, fences, furniture, windows, roofs, trapdoors, and more. They’re all gorgeous, they all go into the game beautifully, and they all have fantastic logic. The windows OPEN and you can GO THROUGH THEM. It’s brilliant. Just brilliant.

Easy Hammers. Plenty of mods have their own hammers, but I like to be thorough. Hammers break a 3x3 space, with the block you focus on being the centre. They’re made with 5 of the same material and two sticks and they are fast, gorgeous, and have a TON of durability. Hammers. For making mining more fun.

EmendatusEnigmatica. Okay, so hear me out. This mod was made for Engimatica 6, a modpack, but it allows you to manipulate your ore gen, both modded and vanilla in a way you can’t with other mods. Turn off the ore gen in all your other mods (provided EE has the ore), then open the config on this and go wild. I have iron almost doubled in my configs from the default because modded takes so much.

Cooking for Blockheads. Build a functional kitchen in Minecraft. Oven, fridge, etc., and you can use the counter to see everything you can currently make. The sink is an infinie water source and probably the most infamous item in here because it attaches to pipes from all mods and takes up one block.

Ocean Floor. Hey you know how finding sand/gravel/clay is a pain in the ass and modded needs all three for some reason? This changes all oceans to have these three as its primary floor. Some dirt, too, but lord is this so good and useful.

Pam’s HarvestCraft 2. All parts. One of the best food mods out there. It’s got so many CROPS and so many TREES and it’s got a MARKET BLOCK and it’s just so much fun. I love making all the different foods just because I can. And having such a diverse farm just feels right, you know?

Silent’s Gems. Gemstones! They make weapons. They make pretty blocks. They add MORE ORES to your world. What else could you want? Pretty!

Peaceful Surface. So, I am a coward. The mobs in Minecraft upset me deeply but I cannot play on Peaceful because I need the DROPS. So, this mod helps with that. It makes it so monsters can only spawn at Light Level 0. This makes the surface WAY more peaceful and also makes caves with lava in them easier to handle. It’s much less scary.

Biomes O Plenty. The OG biome mod is still my favourite, by far. I love the autumn forest biome and I hunt one down in every world I make. It’s so gorgeous. I love all the different biomes and how different they are, while still working in the scope of Minecraft.

EnderStorage mixed with some kind of chunk loader let’s you drain the nether of its lava. What more do you need? Basically, it creates a more sophisticated version of the Ender Chest and a Tank, which have three colour bars. Set the chest/tank to a string of three colours, with Minecraft dyes, and it’ll link to every chest/tank (must be same) with the same colours. Even across dimensions!

Refined Storage. Y’all sick of CHESTS? This makes your storage DIGITAL. ENTER THE NEW AGE. It’s so much simpler than Applied Energistics and I love it so much more. It’s fun, it’s easy, and it’s highly expandable and has lots of good add-ons.

Item Zoom. When you hover over an item in your inventory screen, or any screen that is a menu, it shows a bigger version on the left hand side of the screen. No longer do I struggle with textures.

There are the ones I adore the most, but I’m sure that’ll change as I get deeper into playing again. It’s been a while. Thank you for asking!

22 notes

·

View notes

Text

Magnetic Separator, Magnetic Destoner, Coolant Separator Manufacturer

We are Leading Manufacturer of Magnetic Separator, Magnetic Destoner, Rare Earth Magnetic Drums, Rare Earth Tube Magnet, Lifting Magnets, Hopper Magnets, Permanent Magnetic Drum, Magnetic Floor Sweeper, Permanent Magnetic Drum Separator, Double Deck Vibrating Screening Machine, Magnetic Coolant Separator, Hump Magnetic Separators, Inline Drum Type Magnetic Separators, Permanent Magnetic Pulley, Rare Earth Magnets.

For More Details, Visit:-https://www.kumarmagnetics.com/ Contact us:-+91-9824022397/+91-8000202090

1 note

·

View note

Text

Having the Time of My Life Overanalyzing Voltron Science, A Visual Novel

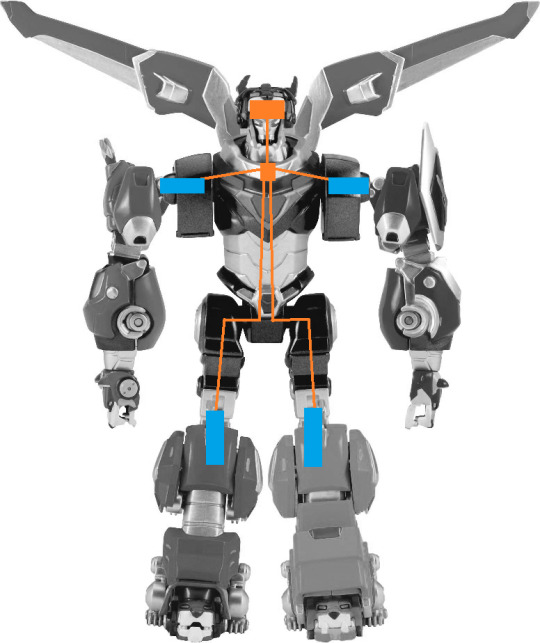

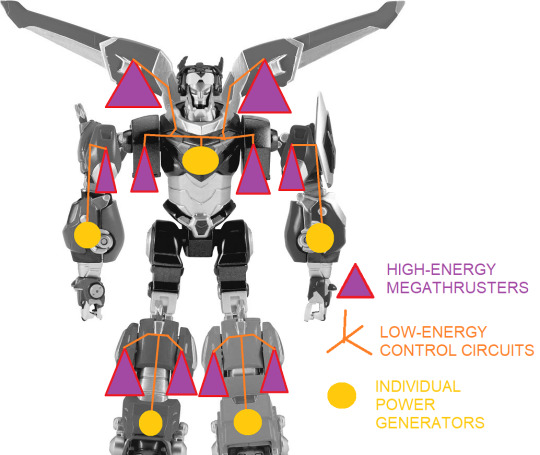

The team’s little mantra in the original show was “ Activate interlock! Dynotherms connected! Infracells up! Mega thrusters are go! Let’s go Voltron Force!” And they said this each and every single time their 5 lions formed together into the combined robot.

In today’s essay I will be deeply examining and wildly speculating about what exactly interlocks, dynatherms, infracells, and mega thrusters are, why it’s entirely crucial that these 4 items be part of the Voltron preflight checklist, and explaining why (or at least inferring that) you should take it all seriously.

Interlock

The Interlock is easy. It’s probably whatever system is used to attach the 5 lions together. So what are they? Magnets? Docking rings like on spacecraft? Just mechanical latches? Hard to say. But something as simple as a mechanical latch isn’t something you’d have to ‘activate’ or actively call out during pre-flight, so I would suspect ‘interlock’ is likely a catch-all term for not only the mechanical attachments, but also the control circuit used to synchronize the computers onboard all 5 lions. It would be a complex integrated system within the black lion, which also explains why they refer to it in the singular instead of plural.

Without the interlock, Voltron would just be the 5 lion with their individual brains tied together like duct-taped dogs. The interlock synchronizes them into a common intelligence, under the direction of the centralized black lion.

I don’t know what the mechanical structure of the interlocks would be. Conventional material science would suggest that a robot as large as Voltron wouldn’t be able to even stand, let alone run and jump and fight, so even if we assume nearly-indestructible exotic alien materials, I think you would still want something more than hooks and pins to connect the various pieces together. It would be best if the actual structural elements could somehow fuse at the molecular level. Welding is the most obvious method for that, but there’s also Vaan-Der-Waals forces, which could bond together flat surfaces that could then be slid apart. And maybe if you had superconducting cables running between the elements and then ran a ton of current through them, then you could use magnetic binding? I’m not sure if that would work, but it sounds futuristic enough to be true. IDK.

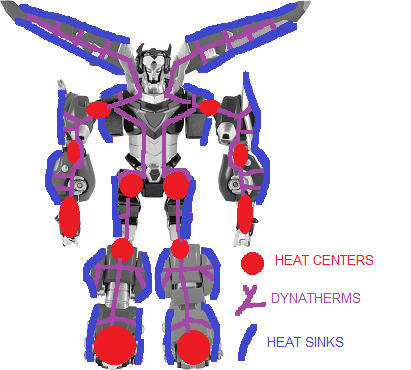

Dynatherms

I can’t tell if this is ‘dynatherms’ or ‘dinotherms’, but the first sounds less prehistoric, so I’ll go with that. So it sounds like pieces of the words ‘dynamic’ and ‘thermal’ mashed together, which don’t really mean anything except in the context of thermodynamics, so.... What is this? A reactor? A steam engine?

Of all the various components this one puzzled me longest, but I think I’ve got it.

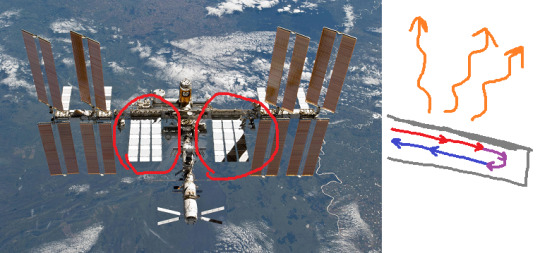

The dynatherms are the cooling system, meant to radiate away the massive amounts of heat its engines and motors would generate. Most spacecraft, heck most vehicles in general, have a system analogous to this. Here’s the one the ISS uses:

Voltron doesn’t have any weird extendo-wings like this, but it’s conceivable that they could be built directly into the outer layer of its armor. The black lion’s little red wings are likely a part of the system too. If you ask me, the surface area of its armor isn’t nearly enough to dissipate enough heat to keep a thing like this cool, but I think I can ignore that.

So anyway. At first this explanation doesn’t seem to fit, since they say ‘dynatherms connected’, not ‘coolant pumps started’ or ‘refrigerant levels maximum’ or something. You don’t ‘connect’ the heat radiators, they’re always connected. You just pump water through them. Right?

Wrong! Here’s my sufficiently futuristic explanation: Voltron’s cooling system doesn’t use coolant and pumps or any type of conventional refrigeration at all! Instead, the ‘dynatherms’ are a network of thermally superconductive cables connecting all its motors and engines to radiative armor panels on the exterior. Thermal superconductivity is a concept I learned from Star Wars and later found out is a real-ish thing. Basically any vibrations in any part of a thermally-superconductive material can frictionlessly travel to any other part of the material. Since temperature is based on vibrations, this means that if a hot thing touches one part of the material, everything else touching the material can instantly feel that heat, and even dissipate that heat. You can think of it as Marvel vibranium or as warmth communism.

Since there’s no fluid flow, the only way to control this cooling system or increase or decrease its dissipation is to connect and disconnect individual cables. Hence why they would have to connect the dynatherms before forming Voltron; combat in combined robot mode is one of the most taxing conditions of the machine’s operation, so they need all the cooling they can get.

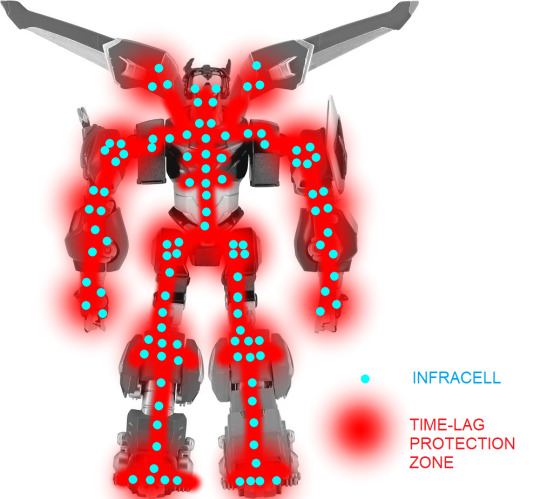

Infracells

Now HERE’S where it starts to get interesting. ‘Infra’ roughly means ‘below’. To take the most common example, take ‘infrared’ light, that is, light existing at frequencies lower red light, which is itself the lowest frequency in the visible spectrum. Infrared is invisible, so the only way to describe its color is ‘somewhere below red’.

So as far as I can tell, ‘infracells’ could mean one of three things. They could be some kind of infrared light sensors, like FLIR imagers used for night vision and targeting on modern military equipment (which I consider unlikely, since that’s not the type of thing you would specifically call out during the preflight, or something intrinsically useful to the Voltron assembly process.) Or it could be an armor layer consisting of some kind of cells literally ‘below’ the rest of the armor (which I also consider unlikely, because why would that be important to the Voltron assembly either? You wouldn’t need to even worry about it until you take damage to the outer armor layer, right?) Or, finally and most interestingly, it could have something to do with lower frequencies or lower speeds in general.

Here’s my theory:

The infracells cause time itself to run differently. You all saw the movie Interstellar, where time aboard the spacecraft passed slower for the crew whenever they were inside powerful gravity wells. If you had high buildups of negative energy within cells inside Voltron, it would produce the opposite effect, causing time to move faster inside the cells than outside. Anything inside would experience the rest of the universe in slower motion, meaning lower acceleration, lower forces, and lower stress.

Therefore, if such ‘infracells’ were installed around Voltron’s skeletal frame and motors, it may explain the machine’s great strength and indestructibility. And it would make sense that this would be the type of thing they would call out during the pre-flight, as even one down infracell could spell disaster once that section of the frame is attempting to support the entire weight of the robot; it would buckle and break. Every infracell needs to be up before forming Voltron.

Mega thrusters

Now, this just sounds silly. They’re likely the engines that Voltron uses to fly, but the show creators put ‘mega’ in front of the name to sound cool. Might as well call them ‘super rockets’ or ‘the ultra drive’, right? But mega is an interesting word, as it’s actually a scientific term in the metric system meaning to multiply by a million. Like a kilometer is a thousand meters and a kilogram is a thousand grams, a megameter is a million meters, and a megagram is a 1000 kilograms. You may have heard of ‘megaton’ when referring to nuclear explosives; a three-megaton bomb is a bomb with the explosive yield equivalent to three million tons of TNT. A lot.

So, uh,

Why would you call a thruster a ‘mega thruster’, then?

Well, I know approximately jack-diddly about the original show, but I know that in the newer show, most large spacecraft in the universe get their energy not from nuclear reactors or solar cells, but rather from Balmeran crystals. The crystals are able to produce apparently infinite energy so long as you don’t damage them or overtax them. I don’t know where the crystals get their infinite energy, but that’s not what I’m here to speculate about, so I’ll just treat that as one of the universe’s rules, like bending in Avatar.

So! How do you set that up to make an engine? Well, infinite power is good! Higher power to the engine means hotter, faster exhaust, and hotter, faster exhaust means higher fuel efficiency and higher thrust. So the question becomes, how do you get the most power in the safest and most efficient way possible?

For the sake of some rules, let’s say that you need to give the crystals a little bit of stimulating energy to make them produce energy. That seems fair, I think. Let’s say they produce 5 times the energy they absorb.

So you give a crystal 1 watt, you get 5. That’s great; that means if we need 50 billion watts to run the thruster, we just need to get a big crystal, and feed it 10 billion watts. However! Where do we get that initial 10 billion watts? Well we could just take a portion of the crystal’s own output and cycle it back around to the input, but that’s a dangerous game to play, since if the percentage you cycle around is even slightly more than 20%, you could create a “positive feedback loop” where more input means more output, which leads to greater input which leads to even greater output, and so on and so on until the crystal breaks or the ship blows up or something generally unfavorable happens. This is approximately the experience of the people at Chernobyl, and is not recommended.

So instead of having crystals feed themselves, you’d instead want them to be fed exclusively by an external source, like a battery or an entirely separate smaller crystal. So the initial crystal would feed larger ones, which would feed larger ones, and so on, each stage in the chain becoming more powerful, but always stable and dependent on some initial external input, so as to never go out of control.

And now, I’m thinking it would be nice from an engineering perspective to have all the crystals together in one shielded location. And from a tactical perspective, it would be nice not to have a bunch of bulky, vulnerable, high-energy cables running around the entire vehicle. So, you would want as many crystal stages as possible in the places where the power is needed most. Namely, the engines.

Therefore, a big part of the engines would be made of armored shells to contain dozens of stacks of crystal beds. They would accept a small amount of power at the top, and multiply it internally to get enormous output at the bottom. Hence, ‘mega’ thruster. It multiplies input by a million.

Boom.

Done.

Headcanon deployed.

So now the next time you’re watching some stupid show and think that something doesn’t make sense, pause to consider that maybe you’re just not using enough imagination, or else I will be with you in spirit to wrong-shame you.

(If you use your imagination and it still doesn’t make sense, then don’t worry. This means that the show is trash and you are right.)

Now go to bed.

#Boom#Voltron#voltron: legendary defender#lion#fan theory#engineering#some cool food for thought#I don't even watch this show what am I doing

9 notes

·

View notes

Text

aft - butts

- audial, audio receptor - ear

- berth, recharge slab - bed, a place to recharge

- bond - marry. Involves "spark merging" and possibly a ceremony, or at least personal vows of devotion.

- cables - muscles. Sometimes refers to an interface cable.

- calipers - (look up a diagram) a channel of internal “muscles” inside of intakes and valves.

- chassis - main body, torso

- CPU - attention span, memory capacity

- coolant - runs through fuel lines (or something?) to reduce overheating. - cooling fans activate when flustered, like blushing. Used to expel excess heat from the frame and moderate internal temperature.

- circuits/circuitry - circulatory or cardiovascular system

- communication link (“comm link” or “comm”) - wireless communications system in which mechs choose a specific radio frequency and use it like a phone line. Can be privately or inclusively broadcasted.

- cord - a cable with a jack at the end, used for interfacing.

- digit - finger

- dentae - teeth

- derma, dermal plating - skin, outer armor

- electromagnetic field (EM field) - (definitely research this, its cool stuff!) An aura. Simply put, it’s the charged particles (electrons) surrounding an object which conducts electricity. When different EM fields come into contact, they slightly alter each other, causing interference of sorts. Using your imagination, you can presume Cybertronians use fields to communicate. Different levels, intensities, amount of charge etc are likely associated with different moods and emotions. EM fields likely expand and contract depending on social and emotional situations. They are essentially someone’s “bubble.” One can feel disturbances in the air around them if another mech brushes against or stands in their field. In a way they are like whiskers, judging spacial awareness and reading energy currents/air currents. It’s fun to make them into a method of emotional communication akin to body language.

- engine - will rev when excited. Can also growl when angry, sputter when exasperated, etc.

- frag - v. or n. (opposite of “defragment”) Crude word for “interface.” Also an interjection.

- frame - whole body

- frame type - overall shape and style of the Cybertronian’s model. Examples include jet, race car, truck, helicopter, etc

- fuel pump - Pumps fuel throughout the body the same way a heart circulates blood.

- glossa - tongue

- helm - head

- host/carrier - a frame type which relies on a symbiotic relationship to other mechs (i.e, Soundwave and Blaster).

- intake, fuel intake - throat

- interface - v. Two or more mechanisms connecting either physically or mentally, in a manner that is generally perceived to be sexual. (Depends on personal interpretation!)

There are 3 main categories for interfacing, “sticky,” "plug n’ play,“ and “tactile”.

Sticky interface uses concepts analogous to human anatomy (spike, valve, fluids)

Plug n’ play focuses on a cord/port connection, along with the transfer of energy, files, emotions, and memories.

Tactile interface focuses on physical (and sometimes electrical) touch

Personal suggestion: combine all three!

Colloquial terms for interface include: jack in, plug in, link up, fileshare.

- interface housing - an area of the body (your choice!) that houses interface equipment, be it cables/ports or spikes/valves). Generally the equipment is kept safe behind separate panels (one for spike/cord, one for valve/port)

- olfactory sensors, chemoreceptors/chemosensors - sense of smell. Detects chemical stimuli in the environment.

- optics/optical sensors - eyes

- offline - unconscious, asleep. Sometimes means “dead.” (I don’t use it that way).

- online - conscious, awake, alive.

- oral cavity, oral component - mouth

- oral lubricant - saliva

- overheating - body becomes uncomfortably warm, possibly to a harmful degree. Causes of overheating include embarrassment, anger, arousal, etc

- overload - the climax of interfacing (orgasm), achieved by excessive electrical charge within the frame. May involve shorted circuits, being knocked offline, systems crashing, blacking out, temporarily shutting down, rebooting in some form.

- panel, interface panel, interface hatch/manual hatch - the panel behind which lies the interface equipment. May be automatically or manually operated (or both!)

- pede - foot, leg

- port - receptive end for an interface cable.

- processor - brain

- recharge - sleep

- sealed/factory sealed - Essentially a virgin. One who retains the protective seals over their interface equipment they were constructed with. Most will agree that seals should be medically removed, but some mechs romanticize “breaking their lover’s seals.”

- sensory input modules - nerves (things that relay information to the processor)

- slag - basically “shit”.

- spark - heart/soul/lifeforce. Located in the chest.

- spark merging - a profusely intimate act in which mechs open their chest compartments, revealing their sparks, and press together until the sparks resonate at the same frequency, pulse in synchronicity, etc. Likely this leads to overloading. Generally spark merging is an act reserved for bonded mechs, as it involves one to expose themselves to absolute vulnerability.

- spike - phallus component utilized in sexual interface. Upon arousal, spikes will “come online” by heating up, extending from interface housing, stiffen by means of magnetism or hydraulics (probably?), and likely will self-lubricate. Connecting to a valve forms a circuit between mechs and energy can be shared in a feedback loop. Thrusting in-and-out movements stimulate internal tactile and electrical sensors, accumulating electrical charge.

- struts/spinal struts - back

- symbiote/symbiont - a mech smaller than a mini which lives on or inside its designated host/carrier mech. (i.e., the cassetticons)

- valve - interface equipment resembling a vagina. Internal components include calipers, a ceiling node, various tactile sensory nodes, various electrical nodes. Outer components include a rim and at least one external node resembling a clitoris. Valves will “come online” and start to heat and self-lubricate upon arousal.

- ventilation - breathing

3 notes

·

View notes

Photo

SOFIA Reveals How the Swan Nebula Hatched

One of the brightest and most massive star-forming regions in our galaxy, the Omega or Swan Nebula, came to resemble the shape resembling a swan’s neck we see today only relatively recently. New observations reveal that its regions formed separately over multiple eras of star birth. The new image from the Stratospheric Observatory for Infrared Astronomy, or SOFIA, is helping scientists chronicle the history and evolution of this well-studied nebula.

“The present-day nebula holds the secrets that reveal its past; we just need to be able to uncover them,” said Wanggi Lim, a Universities Space Research Association scientist at the SOFIA Science Center at NASA’s Ames Research Center in California’s Silicon Valley. “SOFIA lets us do this, so we can understand why the nebula looks the way it does today.”

Uncovering the nebula’s secrets is no simple task. It’s located more than 5,000 light years away in the constellation Sagittarius. Its center is filled with more than 100 of the galaxy’s most massive young stars. These stars may be many times the size of our Sun, but the youngest generations are forming deep in cocoons of dust and gas, where they are very difficult to see, even with space telescopes. Because the central region glows very brightly, the detectors on space telescopes were saturated at the wavelengths SOFIA studied, similar to an over-exposed photo. SOFIA’s infrared camera called FORCAST, the Faint Object Infrared Camera for the SOFIA Telescope, however, can pierce through these cocoons.

The new view reveals nine protostars, areas where the nebula’s clouds are collapsing and creating the first step in the birth of stars, that had not been seen before. Additionally, the team calculated the ages of the nebula’s different regions. They found that portions of the swan-like shape were not all created at the same time but took shape over multiple eras of star formation.

The central region is the oldest, most evolved and likely formed first. Next, the northern area formed, while the southern region is the youngest. Even though the northern area is older than the southern region, the radiation and stellar winds from previous generations of stars has disturbed the material there — preventing it from collapsing to form the next generation.

“This is the most detailed view of the nebula we have ever had at these wavelengths,” said Jim De Buizer, a senior scientist also at the SOFIA Science Center. “It’s the first time we can see some of its youngest, massive stars, and start to truly understand how it evolved into the iconic nebula we see today.”

Massive stars, like those in the Swan Nebula, release so much energy that they can change the evolution of entire galaxies. But less than one percent of all stars are this enormous, so astronomers know very little about them. Previous observations of this nebula with space telescopes studied different wavelengths of infrared light, which did not reveal the details SOFIA detected.

SOFIA’s image shows gas in blue as it’s heated by massive stars located near the center, and dust in green that is warmed both by existing massive stars and nearby newborn stars. The newly-detected protostars are located primarily in the southern areas. The red areas near the edge represent cold dust that was detected by the Herschel Space Telescope, while the white star field was detected by the Spitzer Space Telescope.

The Spitzer Space Telescope will be decommissioned on January 30, 2020, after operating for more than 16 years. SOFIA continues exploring the infrared universe, studying wavelengths of mid- and far-infrared light with high resolution that are not accessible to other telescopes and helping scientists understand star and planet formation, the role magnetic fields play in shaping our universe, and the chemical evolution of galaxies.

JPL manages the Spitzer Space Telescope mission for NASA's Science Mission Directorate in Washington. Science operations are conducted at the Spitzer Science Center at Caltech in Pasadena. Space operations are based at Lockheed Martin Space in Littleton, Colorado. Data are archived at the Infrared Science Archive housed at IPAC at Caltech. Caltech manages JPL for NASA.

Herschel is a European Space Agency mission, with science instruments provided by consortia of European institutes and with important participation by NASA. While the observatory stopped making science observations in April 2013, after running out of liquid coolant as expected, scientists continue to analyze its data. NASA's Herschel Project Office is based at NASA's Jet Propulsion Laboratory, Pasadena, California. JPL contributed mission-enabling technology for two of Herschel's three science instruments. The NASA Herschel Science Center, part of IPAC, supports the U.S. astronomical community. Caltech manages JPL for NASA.

SOFIA, the Stratospheric Observatory for Infrared Astronomy, is a Boeing 747SP jetliner modified to carry a 106-inch diameter telescope. It is a joint project of NASA and the German Aerospace Center, DLR. NASA’s Ames Research Center in California’s Silicon Valley manages the SOFIA program, science and mission operations in cooperation with the Universities Space Research Association headquartered in Columbia, Maryland, and the German SOFIA Institute (DSI) at the University of Stuttgart. The aircraft is maintained and operated from NASA’s Armstrong Flight Research Center Building 703, in Palmdale, California.

Picture above: Composite image of the Swan Nebula. SOFIA detected the blue areas (20 microns) near the center, revealing gas as it’s heated by massive stars located at the center and the green areas (37 microns) that trace dust as it’s warmed both by massive stars and nearby newborn stars. The nine never-before-seen protostars were found primarily in the southern areas. The red areas near the edge represent cold dust that was detected by the Herschel Space Telescope (70 microns), while the white star field was detected by the Spitzer Space Telescope (3.6 microns). The space telescopes could not observe the blue and green regions in such detail because the detectors were saturated. SOFIA’s view reveals evidence that parts of the nebula formed separately to create the swan-like shape seen today. Credits: NASA/SOFIA/De Buizer/Radomski/Lim; NASA/JPL-Caltech; ESA/Herschel

https://www.nasa.gov/feature/sofia-reveals-how-the-swan-nebula-hatched

9 notes

·

View notes

Text

Magnetic Coolant Separator

Magnetic Coolant Separator

In magnetic coolant separator (magnetic dust separator), the coolant fluid with iron dust particles falling by gravity to the inlet of the separator from the precision machine tools such as grinders, milling machines, automates etc. The coolant with iron impurities come into contact directly with magnetic drum and extracts all iron particles. The magnetic drum is kept…

View On WordPress

#coolant magnetic separators#Magnetic coolant separator#Magnetic Drum#magnetic dust separator#Magnetic Separators

0 notes

Text

Repton

The inside of the dome is a hothouse; your optics fog the moment you cut inside. The ground shifts and gives slightly under your feet. Nothing is paved here, except with what you’re guessing is piles of chipped rubber strewn across a concrete foundation. The whole place feels like you’ve wandered into a nightmare version of a playground; a hopeless tangle of brightly-painted metal and plastic, some entirely abstract and some molded in crude imitation of jungle foliage, weaves around and above you. Featureless black domes break up the terrain, some the size of houses. And then there’s the noise, the inescapable wall of sound this place throws at you. Synthetic insect chirring, the hiss and hum of climate regulators, a distant rumble of turbines and churning coolant somewhere far below, and a repetitive, ear-splitting whoop. Which, you’re realizing, is almost certainly an alarm. Your hosts are well camouflaged against the terrain; bright, many-colored scales gleam under the half-light that catches in the heady atmosphere like insects in amber. They dangle from bars and false branches, then drop to the ground and pace tight circles around you, watching the graphics flit across the inner surface of the dusky orange domes fused over their eyes. Some break formation to get a closer look, then flee back into the labyrinthine reaches above. “Are they supposed to be cute?” says Dak. Weapon racks pop loose from hidden chambers in the floor and out of “trees,” clattering into place. The Reptons rush them, squabbling for the prime pickings before some unseen force goads them to break away and take the next gun down. “You tell me,” you say.

HD 1 MV 180’ climb AC 14 AT bite (d4+1) or by weapon Special network

Network—all Reptons are networked to each other and their devices. Unless their comms are jammed, a Repton soldier always has a precise understanding of their distance relative to their squadmates and all Repton-aligned tech, and can communicate with both. Furthermore, all Reptons have access to their network’s algorithmic assistance. If the Reptons in question are in combat with a target that has fought networked Reptons before, they gain +1 to attack and initiative rolls for every one of these prior encounters (up to 6).

1d6 Repton Weapons

1. Lance caster. 3d3 kinetic, 90’ range, six-shot clip. Semi-automatic magnetic bolt-thrower. Individual bolts are about as long as a human forearm, brightly colored to stand out for easy recovery and reload. Reptons struggle with tracking ammunition in high-tension situations, and also with aiming; lance casters tend to be assigned to top-percentile fighters.

2. Buddy gun. 1d4+3 heat, 240’ range, battery exhausts and needs to be re-cranked for 1d3 rounds on a max-damage roll. Onboard AI provides procedurally generated moral support. Weapon of choice for the average Repton grunt.

3. Bughucker. Xd10 explosive, 400’ range, can house and fire up to three shells at once, dealing damage equal to shells fired. Launches a suicide drone resembling an overfed beetle that chases its target using impenetrable precognitive algorithms. The damage from a successful attack roll with a Bughucker “arrives” 2d3 rounds after the round is actually fired. It takes 1 round to arm and load a shell. The definition of a fire-and-forget weapon.

4. Mega-cuffs. 2d6 kinetic, melee weapon. Allows an extra 60’ rocket-assisted charge in a straight line as part of an attack. Fuel explodes for 3d6 damage in a 15’ radius on a critical miss (Dex check for half for everyone but the Repton wearing it).

5. Rad-hoser. 30’ cone, 2d4 Rads (Dex check for half). Sprays goopy, luminescent reactor discharge. Widely used to clear ground for development.

6. Slough cannon. 60’ cone, 1d8+1 damage from abrasion and hemorrhaging (Con check for half). Damage die implodes each round: roll damage at the top of the round and apply if the damage is less than the damage dealt last round; otherwise the effect ends. Deals no damage to targets in airtight armor. Weapon reaches dangerous operating temperatures; on firing the wielder takes 1d3 heat damage. Fires an expanding cloud of nanoassemblers designed to revert living tissue to uncommitted stem cells and package it for future use.

1d8 Repton Devices

1. Black cylinder the size of a coffee maker held aloft on a dirty yellow repulsor field. Synthesized voice squawks instructions in decidedly un-reptilian but still unrecognizable language in time with strobes of decorative light piping. Neural-network assisted targeting means that each consecutive missed shot grants a +1 to the next attack made by any Repton. AC 8, hp 12, MV 90’ hover

2. Modular railgun. Takes three dedicated team members and a full round to assemble, aim & fire, hucks anything that fits in the barrel and can hold a charge for 10d10 kinetic damage in a 600’ straight line (Dex check to dodge). All pieces emblazoned with thorough visual aids that walk the user through the assembly process.

3. Egg-shaped plastic housing the size of a football with a set of neural interface leads coiled around a magnetic support stand. When wired up, user enters a hypnagogic state for six hours, after which leads detach and user wakes with no memory of their state of unconsciousness. For the subsequent 48 hours, user has instantaneous and entirely subconscious grasp of Repton engineering, will service Repton devices without noticing if their hands are not kept otherwise occupied. Reptons will ignore anyone who sticks close to one of these things, and actively assist a user. Continuous use risks permanent nerve damage.

4. Short brass rod ending in t-shaped prong. So long as it remains aimed at a single biological target, the target’s sensory faculties are greatly reduced (disadvantage to all tests of perception), and pain, fatigue, and sickness register only as a faint, pleasurable itch (so long as effect is sustained, player has no knowledge of their hit point total and is immune to penalties from distraction/pain/morale).

5. Repton-sized metal pylon ringed with sturdy levers. Interface panel shows map of local terrain and best-fit route from current location to resource-rich zone. Requires a team of ten Reptons (or three to four reasonably strong humans) to open, revealing opalescent, filigreed structure, like a fossil basket star curled around a flickering, barely perceptible mote of solid black. Upon release, computronium seed begins to unfold and put down roots. Surrounding six-mile radius will become a fully functional and populated Repton habitat within a month.

6. Amoeboid drone; flexile smart-matter body around hard-framed central storage armatures. Absorbs wounded Reptons and deposits them in “care spheres” where internal limbs mend/foam over wounds and dose the patient with combat amphetamines. One round to recover an incapacitated Repton, 2d3 rounds to redeploy with a rerolled hit die and +4 to hit and damage. MV 120’, AC 10, hp 14.

7. Mobile terrarium. Looks like a Rainforest Café stapled to the back of a mechanical crab. Reptons stationed in one never flee; they defend their home to the death. “Trees” extrude clone mealworm paste and simulation fruit flesh in narcotic, mildly hallucinogenic, and blue raspberry flavors. Guided by competent but nonverbal AI. Personalities tend to be grudgingly servile to overseers, pleasantly exasperated with crew in a way that should be familiar to any cat owner. MV 90’, AC 16, hp 80

8. Meta-Rover. Modular all-terrain vehicle, top operable combat speed of 300’/round. Like a pile of motorized, armored bigwheels bolted together into a single day-glo abomination, until it separates into a swarm of single-seaters. Vehicles can hypothetically link indefinitely, but for every unit after the 6th there’s a 1 in 10 chance at the end of each round that the drivers fall catastrophically out of sync and the assemblage spins out.

The Reptons were the first species we encountered in the Contact War, and if it had only ever been them, things might have been different.

The average individual Repton is about as canny as an especially dull chimp in most regards. They’re reasonably talented tool-users, but if you were to raise one from the egg, away from their infrastructure, their at-birth implants, and mainline Repton culture, it would take some serious goading to get them to so much as flint-knap.

And yet as a group, Reptons are deadly. They fight tactically, often making unexpected gambits, and they fight with little regard for their individual well-being. They communicate constantly, though no-one has yet been able to decipher Repton script or spoken language; Repton “writing” features six thousand plus distinct characters and counting and doesn’t seem to have any fixed direction you’re supposed to read it. And their war effort is driven by arms and manufacturing tech that is sometimes leagues ahead of what humanity is capable of, or founded on utterly inscrutable scientific principles, even if the interfaces often seem designed for preschoolers.

But nobody has a clear, substantiated explanation for how they wound up with their tech in the first place. A camp in Freestar One’s strategic research division theorizes that they are the leftovers of a species that lost its evolutionary pressures towards sapience; another argues that they are an uplifted species whose patrons abandoned them, died out, or supervise them from a distance. Stranger explanations exist.

What is known is that their computers are frighteningly powerful and all of their machines talk to each other. Their industrial society is kept afloat purely by the power of their algorithms and the constant influx of resources provided by their ongoing conquest of the planet—the Reptons themselves are merely the hands that authorize and facilitate the intricate automatic processes of invention and fabrication that build their domed cities, develop their food, medicine, entertainment, and weapons, grow and indoctrinate their children, and schedule their lives.

They are vestigial components in a vast machine with no capacity to recognize itself or any part within, operating on the sprawling organic logic of a dream instantiated by engineers lost to time.

Anyone who’s been deployed in Repton territory can attest to the uncanny atmosphere they carry with them. No individual part of a Repton crew behaves like a person. But there is something that emerges in the interplay, as they fumble with their devices and their devices fumble with them, that suggests an intellect inherent to neither. If you watch them from the right distance—not too far, not too close—they resolve into something distressingly like us.

#frp#frpg#ttrpg#trpg#rpg#D&D#Dungeons and Dragons#monster#monster design#homebrew#ruleslight#statblock#game design#fantasy#bestiary#worldbuilding#sf#scifi#sci-fi#sci fi#science fiction#postapoc#postapocalyptic#post apocalyptic#alien#reptile#lizard#uplift#cyborg#cybernetic

15 notes

·

View notes

Text

How Car Scrap Yard in Auckland Recycle Your Car

You may decide to have your automobile recycled for a variety of reasons, but you've come to the perfect location whether it's because of a failed engine or MOT, crash damage, or simply old age.

We can arrange for your automobile to be recycled, and we've also put together this guide to explain to you the various processes a vehicle goes through during a safe and environmentally responsible recycling process.

What Is The Car Recycling Process?

A vehicle will be sent to an authorized treatment facility once it has reached the end of its useful life, where it will go through the following three stages:

1: Depollution

2: Dismantle

3. Destruction.

DEPOLLUTION

When a vehicle undergoes the depollution procedure at a car scrap yard in Auckland, the Environmental Agency's requirements for the safe removal of all hazardous materials or components are followed.

Depollution is crucial since old vehicles contain a variety of substances that could be harmful to the environment. To safeguard the environment and people, contaminants including windscreen wash, coolants, antifreeze, batteries, oil, and fuel must be disposed of carefully.

If one of these compounds gets into the food chain or water supply, it would lead to a variety of health issues. So that they can be disposed of correctly, these compounds must be removed by experts. When a car has been properly depolluted, the parts are kept and given to experts so they can be disassembled and used again.

DISMANTLE

The car will be disassembled when the dangerous liquids have been eliminated at a car scrap yard in Auckland. This procedure entails:

Catalytic converter recycling

Catalytic converters contain a variety of precious metals, including platinum, rhodium, and palladium. These metals are extracted and then reused in jewelry, electronics, and even pharmaceutical items, including wedding bands!

As an alternative, they can be used again to create fresh catalytic converters. Regardless of the catalytic converter's intended usage, it should only ever be recycled by a qualified specialist because hazardous waste status is applied after the ceramic interior has been unsealed and exposed to air.

Car Tire recycling

Tires have traditionally been one of the more difficult materials to find a second use for. The tires can be used again on another vehicle if they are just partially worn, but if not, recent discoveries have discovered intriguing new uses for them.

Tires are frequently utilized as playground mulch, as roadbed on racetracks, as running track material, or in their raw condition, before they are melted down.

Glass recycling

Due to the composition of glass, it is a remarkably adaptable material that can be recycled endlessly. Glass can be used for a variety of things, including making more glass, decorations, tiles, doorknobs, and builder's sand.

DESTRUCTION

Once the car has been cleaned up and disassembled at a car scrap yard in Auckland, it's time to destroy it. Which we take rather literally because the car's metal body will be crushed and transported to a metal mill after it has been disassembled. A vehicle will undergo the following steps when it is destroyed:

Magnetic Separation

Steel is typically magnetic to a large extent, making it very simple to separate from other recyclable materials like plastic.

Detinning

To keep most cars from rusting, a thin layer of tin is placed on top of them. This is fantastic for an automobile, but when a car is scrapped and repurposed, it is not required, so the thin covering of tin is taken off.

This is accomplished using a procedure known as "detinning," which involves submerging the scrap in a hot caustic soda solution to dissolve the tin covering. After that, there are several ways to recover the tin, including electrolysis, hydrous stannic oxide and acid, and evaporation and crystallization using sodium stannate.

Melting

After the tin, coating has been peeled off and the steel has been separated, it is melted down in a furnace. The steel will then be poured into casters and rolled into fresh steel flat sheets after this is finished. The steel can be used repeatedly in this process without losing any of its strength.

Once it has been transformed into flat sheets, it can be used to make a variety of items, such as automobiles and building materials like Rebar, which is frequently used in the construction sector to reinforce and frame concrete structures.

0 notes

Text

Automotive Solenoid Valve Market Estimated to Surpass $6.5 Billion Mark by 2026

The global Automotive Solenoid Valve Market is estimated to surpass $6.5 billion mark by 2026 growing at an estimated CAGR of more than 6.9% during the forecast period 2021 to 2026. Automotive solenoid valves are electromechanically controlled valves. These valves control the rate of flow of air or fluid in systems and motors in automobiles. Solenoids are devices that convert electrical energy into mechanical energy, creating a magnetic reaction, this occurs when electric current makes its way through the wire in the solenoid. These are usually used to hydraulic systems and power fluid. Different types of solenoid valves include direct-acting valves which is utilized to prevent the development of too much pressure in a device, pilot-operated valves also called as indirect valves or servo operated used for one flow direction, two-way valves which have one inlet and one outlet used to permit and stop the fluid flow.

Automotive Solenoid Valve Market Segment Analysis - By Application

Intake systems are the major application of solenoid valves in the automotive context. A range of solenoid valves are used in motor vehicle systems. They are usually used to regulate the flow of automotive fluids such as oil, anti-skid brake fluid or even fuel. In some of these functions, a variable solenoid valve is often utilized. It allows a medium to be controlled instead of shutting it off completely. A good example of this is when limiting the flow of fuel to the engine to reduce vehicle speed. The fuel solenoid valve is common in countries that have regulatory rules for speed. Other automobile solenoid valves include the type used to shut off fuel flow and stop a vehicle, the type to drain water from a water fuel separator automatically, and the coolant control solenoid valve in a vehicle’s HVAC system.

Request for Sample Report @ https://www.industryarc.com/pdfdownload.php?id=9594

Report Price: $ 4500 (Single User License)

Automotive Solenoid Valve Market Segment Analysis - By Vehicle Type

The passenger vehicles sector dominates the Automotive Solenoid Valve market driven by significant adoption in luxury and high end vehicles. Key drivers for Automotive Solenoid Valve segment were the increase in the number of electronic components used in cars and the increase in demand for automotive safety systems. From the last decades the increasing use of electrical components in the engine and gearbox compartment is projected to increase demand for Automotive Solenoid Valves over the forecast period. This is especially prevalent in Commercial vehicles where the number of electronic components is rising at a significant rate.

Automotive Solenoid Valve Market Segment Analysis - By Geography

APAC remains the major market for Automotive Solenoid Valve driven by significant automotive production in the region. Despite the effect of Covid-19, China will remain the major market for Automotive Solenoid Valves in the APAC market. It is expected that the demand profile for vehicle sales in China is promising in the medium to long term, and that the country will remain the largest car market in the world in the coming future, directly increasing the growth of the Asia-Pacific’s Automotive Solenoid Valve market. In automobile industry, the solenoid valves are used in critical components such as ignition systems, gear box drive selectors, air conditioning controls, security systems and others. According to International Organization of Motor Vehicle Manufacturers (OICA), the production of cars and commercial vehicles has been increased from 4.48 million units to 5.17 million units during 2016-2018 period in India. Increase in production vehicles has been driving the solenoid valves industry in India and will drive the market in the global context as well, despite the short term decline due to Covid-19.

Automotive Solenoid Valve Market Drivers

Rising Electric Vehicle Adoption driving new applications of Solenoid Valves

Keeping pace with the current rapid development of clean energy, hybrid cars and electric vehicles are receiving extensive attention. In electronic control brake systems, which are essential to these vehicles, a solenoid valve is used to control the hydraulic pressure, which boosts the driver's braking force. Solenoid valve technology is also vital in handling the thermal management and cooling aspects of Electric Vehicles. Despite the lack of fuel intake valves, the adoption of Electric Valves is continuing to drive the Solenoid Valves market growth during the forecast period.

Rising Vehicle Demand in North America

North America dominates the global automotive solenoid valve market owing to the growing adoption of automotive vehicles and increased investments for vehicle production by major OEMs such as Ford and General Motors. In 2019, Ford has committed to invest more than $1.5 billion in U.S to increase the production of vehicles. Similarly, General Motors is investing heavily for the production of vehicles. In addition, the US is home to leading aftermarket suppliers, such as Borgwarner and Curtiss Wright for automotive solenoid valves. On the other hand the lack of adequate public transport and the wide geographical area of the country have compelled people to travel in their own vehicles. Increased focus on improving fuel efficiency in this region is compelling the manufacturers to make improved solenoid valves for fuel intake applications.