#magnetic contactor

Explore tagged Tumblr posts

Text

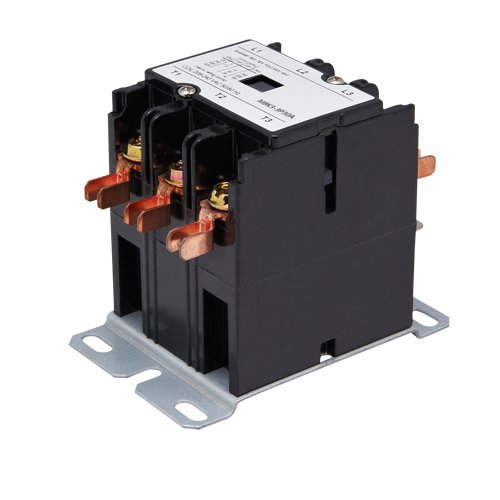

The Hyundai UMC 100 Magnetic Contactor is a reliable and high-performance electrical control device designed to switch electrical circuits on and off in industrial applications. With a current rating of up to 100A, it is ideal for controlling heavy-duty equipment such as motors, pumps, and compressors. The contactor is built with a compact design, making it suitable for installations in space-constrained control panels while maintaining high operational efficiency. It features durable construction that ensures long-lasting performance even in demanding environments, with quick make-and-break capabilities for fast and reliable switching. The UMC 100 offers flexibility with various coil voltage options and includes auxiliary contacts for additional control or monitoring functions. Designed for easy maintenance, the contactor ensures minimal downtime and optimal system performance, making it an essential component for industrial automation, motor control, and other electrical systems.

0 notes

Text

The Hyundai UMC 100 Magnetic Contactor is a dependable device designed for controlling electric motors and other heavy electrical loads in industrial settings. Known for its robust construction and reliable performance, it ensures safe and efficient operation, making it a key component in power distribution and automation systems. The UMC 100 is easy to install and built to last, providing long-term, trustworthy service in demanding environments.

0 notes

Text

Understanding AC Magnetic Contactors: A Crucial Component in Electrical Systems

AC magnetic contactors play a pivotal role in electrical systems, serving as reliable switches that control the flow of electricity to various devices and equipment. These devices are essential in industrial, commercial, and residential applications where the switching of electrical loads is required.

What is an AC Magnetic Contactor?

An AC magnetic contactor is an electromechanical device designed to establish or interrupt an electric circuit by physically separating the contacts within the device. Unlike manual switches, contactors are typically controlled remotely through a control circuit, often using a lower voltage than the main power circuit they control. This feature allows them to handle much higher currents and voltages than a simple switch.

Structure and Functionality

Coil: The core component of an AC magnetic contactor is its coil, which, when energized, generates a magnetic field that pulls the contacts together, closing the circuit. This mechanism allows for the controlled activation or deactivation of electrical loads.

Contacts: AC contactors feature multiple sets of contacts, typically made of durable materials such as silver alloy. These contacts are designed to handle significant electrical currents without welding or sticking, ensuring reliable operation over extended periods.

Auxiliary Contacts: Many contactors also include auxiliary contacts that are mechanically linked to the main contacts. These auxiliary contacts provide additional control functions, such as signaling the status of the main contacts or facilitating interlocking between multiple contactors.

Applications

AC magnetic contactors find application in a wide range of scenarios:

Industrial Machinery: Used to control motors, pumps, compressors, and other heavy-duty equipment.

HVAC Systems: Essential for switching heating elements, fans, and other HVAC components.

Elevators and Escalators: Control systems that manage the operation of motors and safety features.

Lighting Control: Often used in large-scale lighting systems to manage circuits efficiently.

Advantages

Reliability: Contactors are designed for frequent operation and can withstand high electrical loads.

Remote Operation: This can be controlled from a distance via control circuits, enhancing safety and convenience.

Longevity: Built with durable materials to ensure a long operational life span in demanding environments.

Considerations

When selecting an AC magnetic contactor, factors such as current rating, voltage rating, and environmental conditions should be carefully evaluated to ensure compatibility and optimal performance. Additionally, proper maintenance and periodic inspection are crucial to prevent issues like contact wear or coil degradation.

In conclusion, AC magnetic contactors are indispensable components in electrical systems, providing efficient and reliable control over electrical loads across various industries. Their robust construction, remote operability, and versatility make them essential for ensuring the safe and effective operation of electrical equipment and machinery. Understanding their role and functionality is key to leveraging their benefits effectively in any electrical application.

Follow our Facebook and Twitter for more information about our product.

1 note

·

View note

Text

Discover everything you need to know about Fuji Electric magnetic contactors. From installation guides and key features to expert tips on maintenance and the latest innovations, our comprehensive overview will help you understand why Fuji Electric magnetic contactors are a top choice for enhancing electrical systems. Explore the benefits and applications of these reliable and efficient devices today!

#fuji electric magnetic contactor#Fuji Electric Magnetic Contactor 32A#Fuji Electric Magnetic Contactor 13A

0 notes

Text

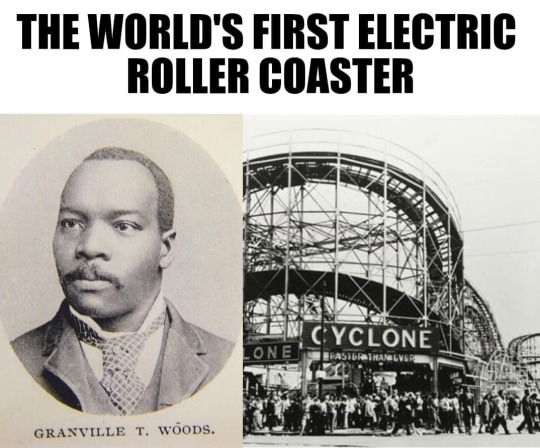

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

511 notes

·

View notes

Text

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

#granville t woods#black inventor#invented#world's first#electric roller coaster#1893#read about him#read about his invention#reading is fundamental#knowledge is power#black history

123 notes

·

View notes

Text

The Hyundai HiMC 22 Magnetic Contactor is a reliable and efficient solution for industrial automation needs. Designed for controlling electric motors and other high-power loads, this contactor ensures safe and stable operation in various applications. It features a compact design, durable construction, and superior performance, making it ideal for harsh industrial environments. The HiMC 22 supports easy installation, reduced maintenance, and excellent electrical insulation for enhanced safety. With Hyundai’s trusted engineering, this magnetic contactor delivers dependable switching and extended lifespan. Perfect for use in automation systems, the HiMC 22 optimizes operational efficiency and ensures seamless control.

#industrial automation#auto2mation#marine spare parts#industrial equipment#industrial spare parts#marine automation#industrial and marine automation#industrial and marine automation equipment#industrial automation equipment#automation#contactor#industrial parts supplier

0 notes

Text

What is a Contactor and How Does It Enhance Electrical Systems?

In the world of electrical control systems, a contactor plays a vital role in managing power efficiently and safely. But what exactly is a contactor, and how does it improve the performance of your system? Let’s dive into its functions and benefits.

1. What is a Contactor?

A contactor is an electromechanical switch used to control high-voltage circuits by receiving low-voltage signals. It is commonly used to switch electrical power in motors, heating systems, and lighting, making it a critical component in industrial and commercial setups.

2. How Does a Contactor Work?

Electromagnetic Operation: When an electrical current passes through the contactor's coil, it creates a magnetic field, closing the circuit and allowing current to flow.

Switching Mechanism: It can open or close circuits, allowing safe power control without requiring direct manual operation.

High Durability: Contactors are designed to handle frequent switching cycles, ensuring long-term reliability.

3. Where Are Contactors Used?

Industrial Applications: Controlling heavy-duty machinery and conveyor belts.

Motor Control: Managing the start and stop functions of motors in HVAC systems.

Lighting Systems: Automating large-scale lighting setups in commercial buildings.

Power Distribution: Protecting and managing circuits in power distribution systems.

4. Why Should You Use a Contactor?

Improved Safety: Separates control circuits from power circuits, minimizing risks of direct contact.

High Efficiency: Ensures smooth and reliable switching for optimal system performance.

Versatility: Compatible with a wide range of electrical devices and systems.

Durability: Built to withstand high loads and frequent switching.

Discover More About Contactors

A contactor is an indispensable tool for modern electrical systems, offering enhanced safety and efficiency. To explore more about contactors and how they can optimize your setup, visit Schneider Electric's Contactor Page.

0 notes

Text

How Contactors Work and Their Role in Motor Control?

When we think about motor control, we often imagine large machines in industries or the electric motors that power everyday appliances. But behind these motors is a critical component that manages their operation, controls the power, and ensures safe handling of electrical currents: the contactor. In this blog, we will dive into what contactors are, how they work, and their vital role in motor control systems.

What is a Contactor?

A contactor is an electrically controlled switch designed to handle high currents. Unlike standard switches, which can only manage low currents, contactors are built to switch electrical circuits with much higher current loads. This makes them suitable for applications like motor control, lighting systems, and heating systems, where they protect equipment and ensure safe operation.

In simple terms, an electrical contactor works as an intermediary between the power source and the motor. It allows a small electrical signal to control a much larger power flow, making it ideal for automated control. By managing the connection between the motor and the power source, contactors enable machines and equipment to turn on or off safely, without manually handling large electrical currents.

Basic Structure of a Contactor

To understand how contactors work, let's break down their basic structure:

Electromagnetic Coil: The heart of the contactor is the electromagnetic coil. When powered, this coil creates a magnetic field that activates the switching mechanism within the contactor. The coil voltage can vary depending on the application and requirements.

Contacts: Contacts are the parts of the contactor that actually open and close the electrical circuit. There are three main types:

Power Contacts: These are the main contacts responsible for handling the high current load to power equipment.

Auxiliary Contacts: These smaller contacts handle additional functions, such as signaling or interlocking with other devices.

Arc Suppressors: Located around the contacts, these components help control and reduce electrical arcs when the contacts open, preventing damage and prolonging contactor life.

Enclosure or Housing: The contactor’s enclosure protects its internal components from dust, moisture, and other environmental factors. It also ensures safety, keeping the high-voltage parts away from accidental touch.

How Does a Contactor Work?

Now that we understand the contactor’s structure, let’s look at how it operates.

Activation of the Coil: When an electrical current flows through the electromagnetic coil, it generates a magnetic field. This magnetic field pulls a movable armature towards the coil, closing the main contacts. This allows the electrical current to flow through the contactor to the motor or load.

Current Flow to the Motor: With the contacts closed, the contactor enables current to flow through the motor circuit. The motor receives the necessary power to start and run.

Deactivation: When the control circuit interrupts the power to the coil, the magnetic field collapses. This causes the contacts to return to their original, open position, breaking the current flow. The motor stops as a result.

Arc Suppression: When the contacts open, an arc of electricity often forms between them. This arc can damage the contactor and motor if not controlled. Contactors are designed with arc suppressors and other features that minimize the impact of these arcs, making them safer and extending their life.

This process of opening and closing happens quickly and repeatedly, allowing the contactor to control the motor’s operation without exposing users to the high electrical currents involved.

Role of Contactors in Motor Control

In motor control, contactors are essential for several reasons. Let’s break down their role in more detail:

Starting and Stopping Motors Safely: One of the primary roles of a contactor is to start and stop motors safely. By controlling the connection between the motor and the power source, the contactor lets operators turn motors on and off without manually handling high-current connections.

Protection from Electrical Overloads: Contactors often work alongside other protective devices like overload relays. The contactor itself may not detect an overload, but it plays a role in the overall safety of the system. When an overload relay senses a current spike, it signals the contactor to open, disconnecting the motor and preventing damage.

Remote and Automated Control: Contactors allow for remote or automated motor control, making them ideal for industrial automation. For example, a control signal from a PLC (Programmable Logic Controller) can activate the contactor, starting the motor. This automation is essential in industries where machinery operates continuously and needs precise control.

Interlocking and Sequence Control: Contactors are frequently used in interlocking systems, where multiple devices must operate in a specific sequence. For example, in a conveyor belt system, one motor must start only after another completes its task. Contactors, with their auxiliary contacts, help create these interlocking arrangements.

Energy Efficiency and Safety: By controlling when and how long a motor runs, contactors help improve energy efficiency. They allow the motor to operate only when needed, saving electricity. Moreover, contactors reduce the risk of electrical shock or fire by isolating high currents within a secure enclosure, making the environment safer for operators.

Types of Contactors Used in Motor Control

There are various types of contactors, each suited for specific applications. In motor control, some of the most common include:

Electromagnetic Contactors: These are the standard type, using an electromagnetic coil to open and close the contacts. They’re versatile and can handle high currents, making them ideal for motor control applications.

Definite Purpose Contactors: These are specially designed for specific applications, such as HVAC systems, compressors, or pumps. They are reliable and more economical but have limited uses compared to general-purpose contactors.

Vacuum Contactors: These contactors use vacuum-sealed contacts to extinguish arcs, making them highly reliable in environments with high voltages or where arcs can be hazardous. They are commonly used in heavy-duty industrial motor control systems.

Solid-State Contactors: Instead of mechanical contacts, solid-state contactors use electronic components to control current. They are fast, quiet, and wear-resistant, making them useful in applications requiring precise control, although they’re often more expensive.

Contactors play a fundamental role in motor control by providing a reliable and safe way to start, stop, and manage motors. Their ability to control high currents through a relatively simple electromagnetic process makes them invaluable for various industries. Whether used in industrial automation, heating systems, or lighting applications, contactors bring safety, efficiency, and convenience to motor control.

Understanding how contactors work helps us appreciate their function within complex motor control systems. By managing high electrical currents efficiently, they ensure our equipment operates smoothly, securely, and with minimal risk. As industries continue to grow and automation becomes more common, the role of contactors in motor control will only increase, making them a cornerstone of modern electrical engineering.

0 notes

Text

Siemens Industrial Controls 75D73070A-110-120/220-240V Coil Sz00-2.5 | PartsHnC

The Siemens Industrial Controls 75D73070A is an electromagnetic coil designed for use in size 00-2.5 contactors, commonly employed in HVAC systems for controlling the flow of electricity to various components. This coil provides the magnetic force required to activate the contactor and enable or interrupt the electrical circuit as needed, operating on voltages between 110 and 120 volts or 220-240 volts.

#partshnc#partshncbuzz#airconditionerparts#furnaceparts#hvacparts#SiemensIndustrialControls#75D73070A#electromagneticcoil

0 notes

Text

Invertek Drives Optidrive E3 General Purpose

Variable Frequency Drive (VFD) that provides sensorless vector control for induction motors, AC permanent magnet motors, brushless DC motors, synchronous reluctance motors, and line start PM motors.

Simple Comissioning 14 parameter basic setup. Default settings suitable for most applications. Contactor style connection for simple wiring.

Intuitive Keypad Control Precise digital control at the touch of a button.

Application Macros Switch between Industrial, Pump & Fan modes to optimize Optidrive E3 for your application.

Internal Category C1 EMC Filter An internal filter in every Optidrive E3 saves cost and time for installation. Cat C1 according to EN61800-3:2004

#hvac#agriculture#automation#mining#watersupply#wastewater#refrigeration#printing#conveyor#mixer#treadmill#pumps#dosing#borehole#swimmingpool#spa#fountain#fans#ventilation

0 notes

Text

Selecting the Right Motor Protection Circuit Breaker

In the dynamic world of industrial automation and control, ensuring the longevity and efficiency of motors is paramount. One of the most critical components in this regard is the Motor Protection Circuit Breaker (MPCB). As a leading Schneider contactor supplier, Balaji Switchgears understands the importance of selecting the right MPCB to safeguard your motors from potential damage and ensure optimal performance. This blog delves into the essential factors to consider when choosing the perfect MPCB for your application.

Understanding Motor Protection Circuit Breakers

Motor Protection Circuit Breakers are specialized devices designed to protect motors from overloads, short circuits, and phase failures. They are essential for maintaining the operational integrity and safety of electric motors.

MPCBs combine the functionalities of a circuit breaker and an overload relay into a single compact unit, providing comprehensive protection and simplifying the wiring process.

Key Considerations for Selecting the Right MPCB

Motor SpecificationsThe first step in selecting the right MPCB is to understand the specifications of the motor it will protect. Key parameters include the motor’s power rating (in kilowatts or horsepower), operating voltage, full load current, and service factor. These details help in determining the appropriate current and voltage ratings for the MPCB.

Type of Motor LoadDifferent applications place varying demands on motors. It’s crucial to consider whether the motor will be driving a constant load, variable load, or a load with high starting currents. For example, pumps and fans typically have constant loads, while compressors and conveyors may experience variable loads. Selecting an MPCB that can handle the specific load type ensures better protection and performance.

Overload ProtectionOverload protection is a fundamental feature of MPCBs. They are designed to trip and disconnect the motor from the power supply if the current exceeds a predetermined level for a specified duration. This prevents overheating and potential damage to the motor. Ensure the MPCB’s overload protection settings are adjustable to match the motor’s characteristics.

Short Circuit ProtectionShort circuits can cause severe damage to motors and other connected equipment. MPCBs with built-in short circuit protection can quickly interrupt the current flow in the event of a short circuit, preventing catastrophic failures. When selecting an MPCB, verify its short circuit interrupting capacity to ensure it meets or exceeds the maximum fault current of the system.

Phase Failure and Imbalance ProtectionMotors are sensitive to phase failures and imbalances, which can lead to overheating and reduced efficiency. Many MPCBs come with phase failure and imbalance protection features that detect abnormal conditions and trip the circuit to protect the motor. This is especially important in three-phase motor applications.

Environmental ConditionsThe operating environment plays a significant role in the performance and longevity of an MPCB. Consider factors such as ambient temperature, humidity, and the presence of dust or corrosive substances. Choose an MPCB with appropriate environmental ratings to ensure reliable operation in challenging conditions.

The Role of a Trusted Schneider Contactor Supplier

As a leading Schneider contactor supplier, Balaji Switchgears provides a comprehensive range of MPCBs that meet the highest standards of quality and reliability. Schneider Electric, a global leader in energy management and automation, offers innovative motor protection solutions that cater to diverse industrial needs.

Why Choose Schneider Electric MPCBs?

Advanced Protection FeaturesSchneider Electric MPCBs are equipped with advanced protection features, including thermal and magnetic trip units, adjustable overload settings, and short circuit protection. These features ensure robust and precise motor protection, enhancing the overall efficiency and lifespan of your motors.

Compact and Modular DesignSchneider Electric MPCBs boast a compact and modular design, making them easy to install and integrate into existing systems. Their space-saving design allows for flexible mounting options, reducing installation time and costs.

High Reliability and DurabilityBuilt to withstand harsh industrial environments, Schneider Electric MPCBs are known for their high reliability and durability. They undergo rigorous testing to ensure they can handle extreme conditions and provide consistent performance over time.

Global Standards ComplianceSchneider Electric MPCBs comply with international standards, including IEC and UL, ensuring they meet the stringent safety and performance requirements of global markets. This makes them a trusted choice for industries worldwide.

Conclusion

Selecting the right Motor Protection Circuit Breaker is crucial for the safety, efficiency, and longevity of your motors. By considering factors such as motor specifications, load type, and environmental conditions, you can choose an MPCB that provides optimal protection. As a trusted Schneider contactor supplier, Balaji Switchgears offers a wide range of high-quality MPCBs from Schneider Electric, ensuring you have access to reliable and advanced motor protection solutions. Invest in the right MPCB today and safeguard your motors for a sustainable and efficient future.

Originally Published at:

0 notes

Link

Magnetic Contactor are electromagnetically operated switches that provide a safe and convenient means for repeatedly making and breaking

0 notes

Text

Everything You Need To Know About Electrical Contactors

Electrical contactors consist of a coil and a set of contacts that open and close to control the flow of electrical power. When an electric current passes through the coil, it generates a magnetic field, causing the contacts to either close or open, depending on the design and purpose. Contactors are often used in conjunction with overload relays and other protective devices to ensure the safety and efficiency of electrical systems.

Read more: https://smartshop.lk-ea.com/blog-articles/post/everything-you-need-to-know-about-electrical-contactors.html

1 note

·

View note

Text

Fuji Electric Magnetic Contactor 32A | Electrical Lighting Co. LLC

Discover the Fuji Electric Magnetic Contactor 32A at Electrical Lighting Co. LLC in Dubai. This high-quality contactor ensures reliable performance for electrical systems, ideal for various applications. Designed for durability and efficiency, it provides excellent control and protection in demanding environments. Visit us for your electrical solutions.

0 notes

Text

Schneider Electric (Square D) 8536Sbo2V02S-120V 3P Open Full Volt Starter | PartsHnC

The Schneider Electric (Square D) 8536SBO2V02S is a 120-volt, 3-phase, open full voltage starter intended for operating AC squirrel cage motors in a variety of industrial and commercial settings. For manual start and stop, the starter usually has a push button or toggle switch. A magnetic contactor is activated when the start button is pressed, energising a coil inside the starter. By directly connecting the motor to the entire line voltage, this contactor functions as a switch and enables the motor to run. Thermal overload relays that keep an eye on the motor's current consumption are included into the starter. The relays automatically trip, de-energizing the contactor and stopping the motor to avoid overheating and possible damage, if the current exceeds safe limits for a prolonged amount of time.

#airconditionerparts#furnaceparts#hvacparts#partshnc#partshncbuzz#SchneiderElectric#8536SBO2V02S#Starter

0 notes