#liquid nitriding treatment

Explore tagged Tumblr posts

Text

What is nitriding?

Nitriding refers to a chemical heat treatment process that allows nitrogen atoms to penetrate into surface of workpiece at a certain temperature and in a certain medium. Products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. 01 Introduction to Nitriding Aluminum, chromium, vanadium and molybdenum elements in…

View On WordPress

#air nitriding#gas nitriding#industrial nitriding#Ion nitriding#Ion nitriding treatment#Liquid nitriding#liquid nitriding treatment#Nitriding#nitriding treatment#What is nitriding

0 notes

Text

https://blwenginevalves.com/liquid-nitriding-service-provider-in-india/

Liquid Nitriding: A Versatile Surface Treatment Solution by BLW Engine Valves

Liquid nitriding, also known as L.C.N, Oxy-nitrocarburizing, Sursulf, Isonite, Pulsonite, Arcur, Teniffer, Oxynite, Nopo, Tuff-Riding, and Nitrocarburizing, is a top alternative to chrome, especially in rod form. After establishing our new plant in the Indian and overseas markets for BLW Engine Valves and automobile parts, we have become the go-to choice for surface treatment services as a tier 2 vendor. Our advanced Nopo nitriding process significantly enhances corrosion resistance, clearing salt spray tests for up to 200 hours, ensuring superior quality and performance in demanding environments.

0 notes

Text

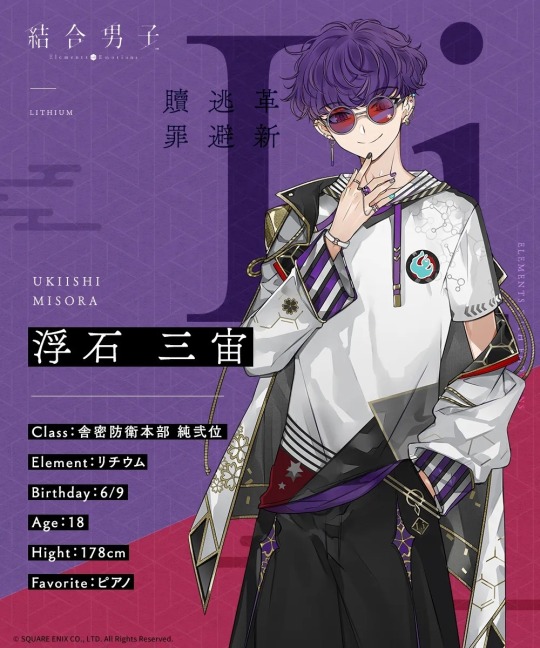

This is Lithium from the game Elements with Emotions! I take Lithium as my medication for BP-II

Some fun facts about the actual element!

Its atomic number is 3

It's the least dense metal and least dense solid element

Like all alkali metals, lithium is highly reactive and flammable, and must be stored in vacuum, inert atmosphere, or inert liquid such as purified kerosene or mineral oil

It never occurs freely in nature, but only in compounds

It's present in ocean water and is commonly obtained from brines

It's an exception to the trend that heavier nuclei are less common

Lithium is present in biological systems in trace amounts; its functions are uncertain

Lithium salts have proven to be useful as a mood stabilizer and antidepressant in the treatment of mental illness such as bipolar disorder

It reacts vigorously with water

Lithium metal is made into alloys with aluminium and magnesium, improving their strength and making them lighter

A magnesium-lithium alloy is used for armour plating. Aluminium-lithium alloys are used in aircraft, bicycle frames and high-speed trains

Lithium has no known biological role. It is toxic, except in very small doses

Lithium was discovered from a mineral, while other common alkali metals were discovered from plant material. This is thought to explain the origin of the element’s name; from ‘lithos’ (Greek for ‘stone’).

The most important use of lithium is in rechargeable batteries for mobile phones, laptops, digital cameras and electric vehicles. Lithium is also used in some non-rechargeable batteries for things like heart pacemakers, toys and clocks. It keeps grease running at arctic temperatures

Lithium does not occur as the metal in nature, but is found combined in small amounts in nearly all igneous rocks and in the waters of many mineral springs. Spodumene, petalite, lepidolite, and amblygonite are the more important minerals containing lithium

Observed to give an intense crimson flame when thrown onto a fire

Rare in the Universe, although it was one of the three elements, along with hydrogen and helium, to be created in the Big Bang

Present in all kinds of things such as grapes, seaweed, tobacco, vegetables, milk and blood

It cannot be kept under oil, as sodium can, because it is less dense and floats. So it is stored by being coated with petroleum jelly. Somewhat surprisingly it does not react with oxygen unless heated to 100oC, but it will react with nitrogen from the atmosphere to form a red-brown compound lithium nitride, Li3N

The hydrogen of hydrogen bombs is actually the compound lithium hydride, in which the lithium is the lithium-6 isotope and the hydrogen is the hydrogen-2 isotope (deuterium). This compound is capable of releasing massive amounts of energy from the neutrons released by the atomic bomb at its core. These are absorbed by the nuclei of lithium-6 which immediately disintegrates to form helium and hydrogen-3 which then go on to form other elements and as they do the bomb explodes with the force of millions of tonnes of TNT

0 notes

Photo

Industrial technology mainly involves smelting, casting, forging, welding, heat treatment, physical and chemical testing, etc., supplemented by knowledge of mechanical processing and computer design. Most people now know that stainless steel precision casting, also known as investment casting wax film casting, is widely applicable to various castings. However, in the casting process, it will also inevitably encounter a series of problems.

The first problem about the solution of the hammer jamming: In production, we should often measure the temperature to avoid excessive temperature of the hammer head and barrel and also select high-quality impurity-free alloy materials to avoid impurities sticking to the hammer head.

The second problem happens when the injection gun is stuck in the gooseneck. When the device is at room temperature, try to turn the hammer, if it can’t turn, then replace the barrel and remove the hammer. If you want to quickly solve the stuck problem, it is best to replace the material tank.

The third problem is that dozens of molds are impossible. It will take a few minutes to continue punching. See if there are any bright spots on the top. If all parts are gray, then the nozzle may be clogged. You should properly increase the nozzle temperature, reduce the nozzle knocking time by 0.1 to 0.2 seconds, and close the fixed mold cooling water slightly.

The fourth problem is on how to solve the problem of easy cracking of thin-walled die-casting products. This problem may be due to material problems, poor mold settings or improper selection of process parameters. Pls try to control the proportion of scrap products not to exceed 30%. If it is too long and the wall thickness is about 3 seconds per millimeter, the ejection delay is not very long, which is 0.5-2 second.

The fifth problem: the material is too hard, and the tool is easy to wear.

The sixth problem is on the black spots when polishing aluminum alloy die casting solutions: reduce the concentration of spraying agent, change to other spraying agent, or increase the blowing time after spraying.

The seventh problem is on metal splash solution in the die casting process: reinstall the mold; increase the clamping force and adjust the die casting machine to keep the moving fixed plate parallel; increase the support plate on the moving mold to improve the mold Stiffness.

The eighth problem is on flow pattern generation solution after die-casting anodizing: spraying, uneven walking of injection oil, inappropriate high-speed switching position, or excessive copper ion content in the oxidation tank will cause flow pattern problems, so spraying And injection oil can be evenly dispersed, not concentrated in local areas, or set high-speed switch position to reduce shortages. Casting phenomenon.

The ninth problem is about the solution of the die-casting mold adhesive: check whether the mold temperature is normal, reduce the casting temperature and mold temperature of the alloy liquid properly; check whether the release agent ratio is abnormal, try to replace the release agent; debug the surface of the sprayed part , And carefully polish the nitride mold to prevent damage. The surface nitriding layer forms more throwing sticking phenomenon; improve the design structure of the casting system to avoid the continuous corrosion of the cavity wall or the core by the alloy liquid; modify the mold cooling system; adjust the die casting process parameters, appropriately reduce the injection speed, shorten the double Speed travel.

www.bonlycasting.com

Email:[email protected]

welcome your consults for any casting parts.

1 note

·

View note

Text

Several surface treatment methods of titanium bolt

The appearance of titanium bolt is like steel, with silver white luster. It is a transition metal. Titanium bolt has high strength, small density, high hardness, high melting point and strong corrosion resistance. Due to its stable chemical properties, it has good high temperature resistance, low temperature resistance, strong acid resistance, strong alkali resistance, high strength and low density.

The color of titanium bolt is silver gray without any surface treatment, as shown in the following photo

Sometimes, we find many colorful titanium bolts on top grade bicycles or cars. The surface of these bolts is so bright and colorful after some surface treatment. Today, we will briefly introduce the surface treatment of titanium bolts

1. Removal of reaction layer on the surface of titanium bolt

Due to the low density of titanium bolt, the inertia of titanium liquid flow is small, and the flow performance is poor. In the process of production, it is easy to cause defects such as pores on the surface and inside of titanium bolt. In order to make the titanium bolt bright and colorful, it is necessary to remove the reaction layer on the surface of the titanium bolt. There are two ways to remove the reaction layer on the surface of titanium bolt:

1) Sand blasting: sand grains are blasted on the surface of titanium bolts by sand blasting, resulting in intense sparks. When the temperature rises, the surface of titanium bolts will react, forming secondary pollution and affecting the surface quality. The time is 15-30 seconds, only removing the sand sticking, surface sintering layer and part of oxide layer on the casting surface. The rest of the surface reaction layer structure should be removed quickly by chemical pickling.

2) Acid pickling: the surface reaction layer of titanium bolt can be removed quickly and effectively by the method of cleaning and acid pickling, and other metal elements will not be polluted.

2. Treatment of casting defects of titanium bolts

In the production process of titanium bolts, there may be internal porosity and shrinkage internal defects: at this time, it can be removed by hot isostatic pressing technology.

3. Grinding and polishing

1) Titanium bolts have high chemical reactivity, low thermal conductivity, high viscosity, low mechanical grinding ratio, and are easy to react with abrasive Abrasives. Ordinary abrasives are not suitable for the grinding and polishing of titanium screws. It is better to use super hard abrasives with good thermal conductivity, such as diamond, CBN, etc,

2) Chemical polishing: chemical polishing is to achieve the purpose of leveling and polishing through the oxidation-reduction reaction of metal in the chemical medium. It has the advantages that chemical polishing has nothing to do with the hardness of metal, polishing area and structure shape. All parts contacting with polishing fluid are polished without special and complex equipment. It is easy to operate and is more suitable for polishing of precision titanium screws with complex structure. However, chemical polishing is difficult to control in process parameters. It is required to have good polishing effect on titanium bolts without affecting the precision of titanium bolts.

4. Coloring

In order to increase the aesthetic feeling of titanium bolt, make the surface of titanium bolt more colorful and bright, and prevent the continuous oxidation of titanium bolt under natural conditions. General bolt manufacturers will adopt surface nitriding treatment, atmospheric oxidation and anodizing surface coloring treatment to form a light yellow or golden yellow surface and improve the aesthetic feeling of titanium bolts. The anodizing method uses the interference of titanium oxide film on the light to produce natural color, which can form colorful color on the titanium surface by changing the cell voltage.

Of course, titanium bolt customization is mainly based on the different needs of users for different surface treatment methods. The practical application environment of titanium bolt is the main reason for the surface treatment of titanium bolt, which is just the conventional treatment of titanium screw fastener.

This Article from Baoji HOSN Titanium Co., Ltd.

www.hosnti.com

1 note

·

View note

Text

JWELL Extruder Screw and Barrel

Zhoushan Jwell Screw&barrel Co.,Ltd has been founded in 1978 and produced first good quality screw in China. It covers 80,000m2 with professional heating treatment factory and manufacturing factory. Our screw company is professional in designing and making screw and barrel. With two generations' hard working, our screw and barrel choose good alloy material, processed by the latest technology and inspection equipment of European and US, have win high appreciation around the world. For many years, we always put our customers first, making our product perfect with innovation as well as advanced management system, our goal is to make and as the best screw brand in China.

We provide various structure screws to meet different production requirements of different polymer. Our main products include: single screw, conical twin screw and parallel screw.

The high-efficiency screw and barrel designed by JWELL company adopts optimized screw structure, it can separate the material into solid and liquid part quickly, and increase the temperature uniformity of melted material, reduce the internal stress of raw material, achieve high capacity with low speed.

Material of Extruder Screw and Barrel

High quality alloy-steel

38CrMoAlA(JIS SACM645)

42CrMo(JIS SCM440)

9 Cr18MoV

SKD11

C276

GH113

Heat Treatment of Extruder Screw and Barrel

Nitriding treatment

Electroplated hard-chrome finish

Medium-high frequency quenching

Spray bimetallic coating

Vacuum quenching

The Application of JWELL Extruder Screw and Barrel

1) For plastic product extrusion: Blow film, sheet, plate, profile, pipe extrusion.

2) For chemical fiber extrusion: PET, PA6, film, non-woven fabric, rope fiber.

3) For plastic recycling and pelletizing.

For cable extrusion: PVC, PE, PBT and rubber fluoride.

0 notes

Text

What Factors Impacting Industrial Nitrogen Market Growth?

Industrial Nitrogen Market Top Companies

The major players operating in the global industrial nitrogen market include Air Products and Chemicals, Inc.; Axcel Gases; Dubai Industrial Gases; Ellenbarrie Industrial Gases Ltd; Gulf Cryo; Linde plc; Messer Group; nexAir; Omega Air; Parker Hannifin Corp.; Praxair; Southern Industrial Gas; Taiyo Nippon Sanso; Universal Industrial Gases, Inc.; and Yingde Gases Group.

According to a new report published by Allied Market Research, the industrial nitrogen market was valued at $3.47 billion in 2021, and is estimated to reach $5.71 billion by 2031, growing at a CAGR of 5.2% from 2022 to 2031.

Asia-Pacific was the highest revenue contributor, accounting for a CAGR of 6.2%. China was the highest revenue contributor, accounting for CAGR of 6.8%.

Get Report Sample PDF @ https://www.alliedmarketresearch.com/request-sample/17502

By form, the compressed gas segment was the highest revenue contributor to the market in 2021.

By application, the food & beverages segment was the highest revenue contributor to the market in 2021.

The market is categorized into metal manufacturing & fabrication, oil & gas, pharmaceutical & healthcare, chemical, food & beverage, electronics, and others.

The industrial nitrogen market size is provided in terms of revenue.

The industrial nitrogen market analysis includes top players and regions operating in the market.

The report outlines the current industrial nitrogen market trends and future scenario of the market from 2022 to 2031 to understand the prevailing opportunities and potential investment pockets.

The growth of the global industrial nitrogen market is majorly attributable to its wide applications in various industries such as pharmaceutical & healthcare, oil & gas, metal manufacturing & fabrication, food & beverage, electronics, and chemical.

Nitrogen liquid is used to maintain flammable or explosive substances and liquids away from air. Certain chemicals, solid surfaces, and stored food products have qualities that must be safeguarded from degradation caused by environmental oxygen and moisture.

Nitrogen is used in the manufacturing of steel and other metals to treat the melt and as a shield gas in the heat treatment of iron, steel, and other metals. It is also utilized as a process gas in conjunction with other gases for carbonization and nitriding reduction.

Nitrogen is used in large quantities to anneal stainless steel and other steel mill products. Annealing is a thermal treatment that improves steel processing.

COVID-19 Analysis:

In regions such as North America, Europe, Asia-Pacific, and LAMEA, industrial nitrogen is used as a metal manufacturing & fabrication, oil & gas, pharmaceutical and healthcare, chemical, and food & beverage. Because of the importance of liquid nitrogen and compressed nitrogen following the COVID-19, industrial nitrogen is primarily used in health care & pharmaceutical industry and hence positively impacting the industrial nitrogen market growth during the pandemic.

Browse Complete Report @ https://www.alliedmarketresearch.com/industrial-nitrogen-market-A17114

Nitrogen is a non-metallic element employed in multiple industrial manufacturing processes. Gaseous nitrogen is used in food processing, brewery, beverage, oil & gas recovery, and other applications owing to its inert nature.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa 5933 NE Win Sivers Drive #205, Portland, OR 97220 United States USA/Canada (Toll Free): +1-800-792-5285, +1-503-894-6022 UK: +44-845-528-1300 Hong Kong: +852-301-84916 India (Pune): +91-20-66346060 Fax: +1(855)550-5975 [email protected]

Web: www.alliedmarketresearch.com

Allied Market Research Blog:

https://blog.alliedmarketresearch.com

Follow Us on | Facebook | LinkedIn | YouTube

0 notes

Text

Carburizing and nitriding surface treatment process for mold material

Carburizing and nitriding surface treatment process for mold material

Carburizing and nitriding generally refer to chemical heat treatment of surface of steel. Carburization Carburizing must use low carbon steel or low carbon alloy steel, which can be divided into three types: solid, liquid and gas carburizing. Widely used gas carburizing, heating temperature 900-950℃. Carburizing depth mainly depends on holding time, which is generally estimated at 0.2-0.25 mm…

View On WordPress

0 notes

Text

The global market for air separation plants was valued at USD 4.5 billion in 2021 and is projected to reach USD 5.9 billion by 2026, at a CAGR of 4.9% between 2021 and 2026. The global market for air separation plants is driven by strong growth in demand, especially from the iron & steel, oil & gas, chemical, healthcare, and other end use industries.

On the basis of process, the cryogenic process segment is projected to grow at the highest CAGR from 2021 to 2026. Cryogenic technology was commercialized in 1902 and has since been used extensively by companies across multiple industries that require gases such as nitrogen, oxygen, and others. Being the oldest air separation technology available, it has evolved considerably over the years, resulting in improved efficiency and high purity of yield gases. The growing demand for fabricated metals and alloys across the globe, the increasing dependency on pure gases for enhancing metal properties, and rapid industrialization are expected to drive the air separation plant market during the next five years. Technological advancements to control toxic emissions from plants are compelling companies to devise energy-efficient designs.

Among gas types, the Nitrogen segment is projected to grow at the highest CAGR from 2021 to 2026. The inert properties of nitrogen make it a good blanketing gas in many applications. Nitrogen blanketing is used to protect flammable or explosive solids and liquids from contact with air. Certain chemicals, surfaces of solids, and stored food products have properties that must be protected from degradation by the effects of atmospheric oxygen and moisture. This is achieved by keeping these items in a nitrogen-enriched atmosphere. Nitrogen is used to treat melt in the manufacturing of steel and other metals and as a shielding gas in the heat treatment of iron, steel, and other metals. It is also used as a process gas, together with other gases for the reduction of carbonization and nitriding.

#Air Separation Plant#Air Separation Plant market#COVID-19 Impact on Air Separation Plant Market#Global Air Separation Plant market#Air Separation Plant Market Overview#Air Separation Plant Research Report#Air Separation Plant research insights#Air Separation Plant business research report#Air Separation Plant Industry Trends#Air Separation Plant Market Share#Air Separation Plant market Analysis#Air Separation Plant market growth

0 notes

Text

Anti-corrosion measures for industrial valves

Valve corrosion is generally considered for damage to the metal material of the valve caused by the chemical or electrochemical environment. Since "corrosion" occurs in the spontaneous interaction between metal and the surrounding environment, corrosion prevention focuses on isolating the metal from the surrounding environment or using more non-synthetic materials. Here 3 way stainless steel ball valve manufacturer in india will discuss the ways to prevent valve corrosion.

Electrochemical protection: Cathodic and anode protection provide electrochemical protection. So-called anode shielding involves adding a direct external current to the metal shield to increase the anode potential in the positive direction. When it is raised to a certain point, a dense protective film forms on the surface of the metal anode, which is a passive film. Safety Concerns Anodic material is easy to deactivate.

Cathodic protection means that the protected metal is used as the cathode, and direct current is applied in the negative direction to reduce the potential. When a potential value is reached, the current wear rate decreases and the metal is protected. Also, you can protect a metal protected by cathodic protection from metal with a higher electrode potential than the protected metal. If zinc is used to conserve iron, then zinc and zinc are considered sacrificial metals. This cathodic protection method is used by cryogenic ball valves manufacturers in india for large valves and core valves and is an inexpensive, simple and effective procedure.

Metal surface treatment: Metal surface treatment processes include plating, surface penetration, surface oxidation passivation, etc. Its objective is to improve the corrosion resistance of metals and improve the mechanical energy of metals. Surface treatments are commonly used in the valve area. The wear-resistant valve stems is a problem that people pay attention to, and people have gained a lot of experience in manufacturing. Surface treatment methods such as nitriding, boron, chrome plating, and nickel plating are also used to improve corrosion resistance, wear resistance, and corrosion resistance. The valve precipitates on contact with air-filled asbestos, water vapour and gas nitride and hard chrome plating (stainless steel is not suitable for ionic nitride).

Choose wear-resistant materials according to the corrosive environment: Corrosion in the actual processing is very complex. Even if you use the valve material for the same medium, the liquid's resistance, pressure, and temperature will be special, and the corrosion of the medium on the substrate will be different. The corrosion rate increases 1 to 3 times for every 10 ° C increase in material temperature. The intensity of the medium has a significant influence on the corrosion of the valve material. When the concentration exceeds 6%, wear is significantly reduced. For example, aluminium is highly corrosive at concentrations of 80 per cent or more in concentrated nitric acid but highly corrosive at medium and low concentrations of nitric acid. While stainless steel is resistant to nitric acid dilution, corrosion is more severe in more than 95% concentrated nitric acid. The above examples show that the correct selection of stainless steel needle valve manufacturers in india will depend on certain conditions. Various wear factors must be evaluated and materials selected following the corresponding anti-corrosion manual.

0 notes

Text

Best Liquid Nitriding Services in India | BLW Engine Valves

After establishing our sales in Indian & overseas Mrket of engine valves, We have become the ultimate choice for surface treatment services for OEM customers like BAJAJ Motors, Varroc, HERO, Honda Scooters, Endurance, Wipro, Ucal Pump, LPS and many More. Liquid Carbo Nitriding (LCN) is a common term for a diffusion process that is actually liquid nitro carburizing; a thermo-chemical reaction whereby nitrogen, primarily, and some carbon are diffused into the surface of iron-based materials. The nitrogen combines with the iron to form an iron-nitride compound layer that provides improved surface properties; e.g. resistance to wear, friction, corrosion, and fatigue.

for more information: https://blwenginevalves.com/liquid-nitriding/

0 notes

Text

Advantages,Application and Types of wear-resistant ceramic coating

Advantages of wear-resistant ceramic coating

Wear-resistant ceramic coating experts point out that a 300,000 kilowatt boiler will generate 7.2 million degrees less electricity per day of shutdown. But if the metal substrate coated with a layer of high-temperature wear-resistant coating will play a protective role on the metal substrate, thereby extending the service life of the metal substrate. In the chemical industry, metallurgy, electric power and other industries will often encounter metal high temperature wear phenomenon.

Hard wear-resistant ceramic coating usually refers to the cover layer applied to the surface in order to improve the surface wear resistance, corrosion resistance and high temperature resistance of structural parts. The thickness of the cover layer can vary depending on the role, usually from a few nanometers to tens of microns, and sometimes up to millimeters depending on special requirements. In order to achieve the purpose of wear resistance, corrosion resistance, heat resistance and oxidation resistance, the material of hard wear-resistant ceramic coating is often some transition group metal and non-metal composition of compounds, intermetallic compounds, etc.These compounds not only have high melting point and high hardness, but also tend to be less susceptible to chemically corrosive atmosphere or liquid corrosion, and have good chemical stability and thermal stability.

In addition, due to the high melting point of wear-resistant ceramic coating materials, especially when the wear-resistant coating is added to the metal that can generate a dense oxide thin layer at high temperature oxidation such as Al, Cr or Ni and other elements, the high temperature oxidation resistance and high temperature corrosion resistance of the wear-resistant ceramic coating can be significantly improved.

Application of wear-resistant ceramic coating

In the industrial environment, high temperature wear-resistant ceramic coating is used to prevent vapor corrosion friction, hardness friction and impact friction on all kinds of objects in the wear-resistant environment, so that the coal conveyor is subjected to the frictional impact of coal for a long time, the long time vibration friction of machinery, the frictional loss of fan blades, the extrusion friction of heavy machinery on the road, the equipment in the wind and sand, the metal in the flue, etc. These industrial working conditions are well solved for a long time, so that Industrial environment for a long time can not cure the knotted disease no longer exists. The company produces wear-resistant products with high wear resistance, high strength, high hardness, high corrosion resistance characteristics, widely used in: thermal power, steel, smelting, machinery, coal, mining, chemical industry, ports, terminals and other industries with serious wear.

Types of wear-resistant ceramic coating

Polymer composite wear-resistant anti-corrosion coating mainly consists of base material, filler and other additives. Among them, organic polymer, such as high-performance wear-resistant particles (pure alumina corundum porcelain ball, silicon carbide, zirconium oxide, titanium, etc.) and modified toughened heat-resistant resin to composite high-performance wear-resistant anti-corrosion polymeric materials, construction of other components bonded to the surface of the friction parts to form a continuous film, thereby greatly improving the wear resistance of the material, reducing the wear of the material surface. The coating has the ability of wear resistance as well as corrosion resistance, construction is convenient, after the shutdown of the equipment can be coated with the product after a simple treatment, heating and curing 2 hours, the equipment can be put into use, but also without heating, without heating in general 24 hours curing.

There are many kinds of wear-resistant coatings, such as oxide wear-resistant coatings, carbide, nitride, boride and silicide ceramic coatings, intermetallic compound ceramic coatings, plastic ceramic composite coatings, etc.. Among them, metal wear-resistant coatings are being used more and more widely due to their composition and good overall performance.

Metal wear-resistant coating is a coating material made of metal and alloy as the bonding phase and ceramic particles as the reinforced hard phase, which is processed by spraying, sintering, agglomeration, coating and other processes. The combination of different metal and alloy components and ratios with different ceramic end materials can make a series of metal-ceramic end materials, so that the strong toughness, thermal conductivity, processability and other characteristics of metals and ceramic materials such as high hardness, high chemical stability, insulation and thermal insulation and functional properties are organically combined, giving full play to the comprehensive advantages of the two engineering materials.

Due to the addition of the metal component, the bonding strength of the metal wear-resistant coating and the base material increases, the adhesion strength between the ceramic particles of the coating increases, the porosity of the coating decreases, and the denseness increases, so that the metal-ceramic coating has mechanical properties than the pure ceramic coating, and can be applied to greater stress and fatigue and other working conditions and obtain the desired results.

The performance of metal wear-resistant coatings depends on several factors, such as the composition and properties of the metal base, the properties, composition, percentage of the ceramic phase, particle size, etc., the degree of mutual infiltration of the metal base and ceramic, and the degree of infiltration of the entire metal-ceramic coating and the metal surface. Because the degree of infiltration determines the adhesion between the various components of the coating and the size of the bonding force between the coating and the metal substrate.

1 note

·

View note

Text

Gallium Nitride Market Overview Highlighting Major Drivers, Trends, Growth and Demand Report 2020- 2027

The global gallium nitride market is projected to be worth USD 320.4 Million by 2027, according to a current analysis by Emergen Research. The gallium nitride market is observing high demand attributed to the growing demand for gallium nitride devices in consumer electronics. Gallium nitride is garnering significant traction in the market and is replacing silicon for use in fast chargers for laptops and smart devices. In the last couple of years, the screen and battery size of smartphones have witnessed a significant increase, which, in turn, is causative of increased power consumption for smartphones, thereby pushing the market for fast chargers.

The latest market intelligence report underscores the impact of the COVID-19 pandemic on the global Gallium Nitride market, offering deep insights into the pandemic’s adverse effects on the global economy and, consequently, this particular business sector. The report carefully gauges the key market-influencing factors and considers the COVID-19 pandemic as one of the contributing elements for this industry’s potential downturn. Following the pandemic, drastic changes have been observed in the market dynamics and demand trends, which have caused financial difficulties for the businesses operating in this sector. Additionally, the report assesses the COVID-19 impact on the overall growth of the Gallium Nitride market, besides preparing a future impact assessment to help readers make informed business decisions.

Get a free sample copy of the report @ https://www.emergenresearch.com/request-sample/317

The prominent players of the global Gallium Nitride market are expected to contribute significantly to the revenue generation owing to increasing demand for the Gallium Nitride products in the industry.

Prominent Players Profiled in the Gallium Nitride Market:

DOWA Electronics Materials Co. Ltd., Cree Inc., American Elements, Furukawa Co. Ltd., Mitsubishi Chemical Corporation, Kyma Technologies Inc., Soitec, IQE PLC, Infineon Technologies, and Nitride Semiconductors Co. Ltd., among others.

Emergen Research has segmented the global gallium nitride market on the basis of substrate type, distribution channel, application, and region:

Substrate Type Outlook (Revenue, USD Billion; 2017-2027)

GaN-on-SiC

GaN-on-Si

GaN-on-Sapphire

Others

Distribution Channel Outlook (Revenue, USD Billion; 2017-2027)

Online

Offline

Application Outlook (Revenue, USD Billion; 2017-2027)

Radio Frequency Devices

Power Electronics

Optoelectronics

Wireless Infrastructure

Satellite Communication

Military & Defense

Others

Power Supply

Electric Vehicle

LiDAR

Servers & Data Centers

Wireless Power

Solar Photovoltaic Technology

Envelope Tracking

Others

LED

LASER

Others

Key Regions of the Gallium Nitride Market:

North America (U.S., Canada)

Europe (U.K., Italy, Germany, France, Rest of EU)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)

Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

Request customization of the report @https://www.emergenresearch.com/request-for-customization/317

Research Methodology

Our team of analysts has performed an accurate analysis of significant market elements leveraging advanced primary and secondary research tools. They have deployed well-known analytical tools like SWOT Analysis and Porter’s Five Forces Analysis for the comprehensive market study. A great deal of vital data &information related to the Gallium Nitride market has been gathered in the report from various reliable sources. Under the primary research study, detailed supply chain analysis, value chain analysis, several industry experts’ interviews, and a brief analysis of the Gallium Nitride market’s vendor landscape have been covered. Therefore, as part of secondary research, the report offers vital information pertaining to the company profiles of the key market contenders. Hence, the report’s market segmentation section looks at the global sector to scrutinize key trends, regional markets, and recent industry developments.

Reasons to Purchase this Report:

The report performs qualitative and quantitative analyses of the Gallium Nitride market based on both the economic and non-economic factors.

It accurately indicates the regional segments expected to witness the fastest market growth rate.

The report endows the reader with an in-depth understanding of the competitive landscape of the Gallium Nitride market, with the market ranking of the major players and their new product launches, partnerships, and various other business expansion strategies.

Highlights of the Table of Contents:

Report Overview 1.1 Research Scope 1.2 Key Gallium Nitride market segments 1.3 Major players 1.4 Market analysis by product type 1.5 Market analysis by application 1.6 Report timeline

Global Growth Trends 2.1 Global Gallium Nitride market size 2.2 Latest trends of the Gallium Nitride market by region 2.3 Key growth trends

Competitive Outlook 3.1 Global Gallium Nitride market key players 3.2 Global Gallium Nitride size by manufacturers 3.3 Products of major players 3.4 Entry barriers in the Gallium Nitride market 3.5 Mergers, acquisitions, joint ventures, and strategic alliances

Gallium Nitride Market by product type

4.1 Global Gallium Nitride Sales by Product

4.2 Global Gallium Nitride by Product Revenue

Gain access to the full report by clicking here on the link @ https://www.emergenresearch.com/industry-report/gallium-nitride-market

Thank you for reading our report. Please connect with us to know more about the report and its customization feature. Our team will ensure your queries are solved, and the report is customized to meet your requirements.

Read similar reports by Emergen Research:

Polysorbate Market@ https://www.emergenresearch.com/industry-report/polysorbate-market

Liquid Hydrogen Market@ https://www.emergenresearch.com/industry-report/liquid-hydrogen-market

Agricultural Pheromones Market@ https://www.emergenresearch.com/industry-report/agricultural-pheromones-market

Surface Treatment Chemicals Market@ https://www.emergenresearch.com/industry-report/surface-treatment-chemicals-market

Super Absorbent Polymers Market@ https://www.emergenresearch.com/industry-report/super-absorbent-polymers-market

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research | Web: www.emergenresearch.com

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Facebook | LinkdIn | Twitter | Blogs

1 note

·

View note

Link

Salt Bath Furnace

JR FURNACE involved in manufacturing, exporting and supplying Industrial Salt Bath Furnace that is generally used for hardening of various steel components.

Applications:

Atmosphere controlled, liquid heat treatment furnaces are excellent for Hardening, Tempering, Quenching, Normalizing, Annealing, etc., of H.S.S. Cutting tools, HC, HVR, die-punches, slitting cutters, E. N. Series Steels, Mill rolls, Ball bearing, Auto, Railway and Aircraft parts an alloy steels. These furnaces are free from scaling, pitting and de-carburizing. This furnace can also be utilized for pre-heating, case hardening and forging.

#heattreatment#heattreatmentfurnace#heattreatmentofmetals#heattreatments#heattreatmentfurnaces#heattreatmentequipment#heattreatmentprocess#heattreatmentofmetal#industrialfurnace#industrialfurnaces#aircraftparts#aircraftpartsforsale#aircraftpartssupplier#furnace#saltpotfurnace#saltbathfurnace#furnaces#ovens#saltpot#jigsandfixtures#heattreat#heattreatingoven

0 notes

Text

Application of vacuum sintering furnace in sintering process

The main factor that affects the carbon content of alloy in vacuum sintering furnace is the concentration of carbon atmosphere in vacuum sintering furnace. The cracking temperature of molding agent is about 450C, which produces a large amount of hydrocarbon gas, and the hydrocarbon gas will also be cracked, that is, CxHy - > H2 + C, leaving a large amount of carbon, which causes the instability of carbon atmosphere in vacuum sintering furnace. The structure of the vacuum sintering furnace affects the distribution of carbon atmosphere in the furnace. The cross-sectional area of the furnace should not be too large, especially not too high. The distribution of air inlet and exhaust port should be reasonable, which can make the gas flow unimpeded, so as to ensure the uniform distribution of atmosphere in the furnace. The carbon parts in the furnace (including carbon fiber insulation layer, heating body, graphite plate, graphite boat plate, etc.) are the sources of carbon, especially the poor quality carbon parts have a greater impact, so the quality of carbon parts should be very good (need to be burned at 2000 ° C). If the product is directly installed on the graphite boat, it will cause carburization and adhesion of the product. Therefore, the isolation material is coated (plated) on the bottom of the boat to ensure that the product does not stick to the boat, carburize or decarbonize, and its performance is stable at high temperature. The size and structure of the boat dish, round or square, sealed or open, will affect the quality of the product. Different boat dishes should be designed according to different products; the purity of the gas used should be high, and the water content should be low. PCD / PCBN / CBN / CVD Diamond Vacuum Brazing Furnace Process Flow Of Sintering NdFeB Piston QPQ Liquid Nitriding Heat Treatment

0 notes

Text

The degree of heat resistance and manufacturing technology of heat - resistant steel furnace

Heat resistant steel furnace is used in heat treatment furnace accessories, it is commonly used material is CrMnN, Ni7N, 2520 and other heat resistant steel, the degree of heat resistance of different materials are also different. For example, cr-Mn-N furnace tank is suitable for 850℃ ~ 900℃; ZG35Cr24Ni7N heat treatment equipment vacuum furnace suitable for 900℃ ~ 1050℃; ZG40Cr25Ni20Si2 furnace tank is suitable for 1050℃ ~ 1150℃.

High temperature strength refers to the ability of steel to withstand mechanical loads for a long time at high temperatures. Steel is softened under mechanical load at high temperature, that is, its strength decreases with increasing temperature. The second is creep, that is, under the action of constant stress, the plastic deformation increases slowly with the extension of time, and the plastic deformation of steel at high temperature is caused by intra - grain slip and grain boundary slip. Alloying is usually used to increase the high temperature strength of steel. It is also the addition of alloying elements to steel to enhance the bonding strength between atoms and to form favorable structures. By adding chromium, molybdenum, tungsten, vanadium, titanium, etc., the matrix of steel can be strengthened, the recrystallization temperature can be raised, and enhanced phase carbide or intermetallic compounds can be formed, such as Cr23C6, VC, TiC, etc. These hardened phases are stable at high temperatures, insoluble, do not aggregate and grow, and maintain their hardness. Nickel was added mainly to get austenite. Austenitic atoms are more closely arranged than ferrite atoms, and the bonding force between atoms is stronger. So austenite is stronger at high temperatures. It can be seen that the high-temperature strength of heat-resistant steel is not only related to the chemical composition, but also related to the structure.

Heat resisting steel furnace can be divided into cover furnace, nitriding furnace, carburizing furnace, star anise furnace, cylinder furnace, heat treatment furnace, CRMNN furnace, centrifugal furnace, etc. It can also produce non-standard furnace tank according to customers' requirements, which can withstand 1150 degree high temperature, and not easy to denatured, heat and corrosion resistant.

At present, there are two kinds of heat-resistant steel furnace tank, one is casting, one is welding, welding material, Swedish plate 310S as the best, the life can go to 2-5 years, and this material of heat-resistant steel furnace tank weight is lighter, heat faster, more energy saving, quality is the best.

Heat resistant steel furnace tank, of course, also can use the centrifugal casting process, apply for centrifugal casting process of the seamless pipe in tank top casting furnace, tube wall tissue density high, uniform wall thickness fluctuation, more solid and durable, not easy appear high temperature deformation, the service life of the warranty in more than one year, product advantages more apparent.

Among the many heat-resistant steel brands, the following factors must be considered comprehensively when choosing heat-resistant steel that meets the working conditions of the cement plant:

(1) The working temperature of heat-resistant steel castings. Operating temperature refers to the highest, normal and lowest temperatures and the rate of change of temperature.

(2) Mechanical load of heat-resistant steel castings.

(3) Gas in contact with heat-resistant steel castings and their conditions (including wind speed dust content, chemical composition, etc.).

(4) The price should be low, where can use chromium, nickel content low cast heat resistant steel, not high chromium, nickel content.

The experience of using heat-resistant steel castings should be constantly summarized and accumulated in cement plant. If there is failure problem in use and it is proved by analysis that the abnormal scrap of heat-resistant steel castings is caused by improper material selection, the manufacturer can contact with the manufacturer to prevent failure by studying the material selection. The manufacturer should provide the material selection data and indicate the direction to the using factory.

In a word, heat-resistant steel furnace and tank products have a series of advantages, such as high temperature resistance, high strength, not easy to deformation, good oxidation resistance, etc., so the furnace and tank are widely used in heat treatment, can also meet the special casting requirements of metallurgy, mining, petrochemical, shipping, building materials, electric power, light industry, machinery, military industry and other industries.

In fact, in addition to heat resistant steel pot, similar to the heat resistant steel workpiece there are many, are to meet the special requirements of the processing was introduced. Metal heat treatment equipment as a specific special properties of material, heat resistant steel has many USES, can play an important role in various industries.

Related products:

Heat Resistant Steel Castings Tools For Machining

Why Do Stripes Appear In Heat Resistant Steel Casting

Other related products:

Liquid ring vacuum pump Oil Diffusion Vacuum Pump

Dry screw vacuum pump

0 notes