#lead alloys manufacturers

Explore tagged Tumblr posts

Text

#pewter metals#white babbitt bearing metals#tin sheet manufacturers#high purity indium tin oxide#tin zinc wire#fusible alloys manufacturer#low melting point alloys#gallium based liquid alloys#cadmium sheet suppliers#radiation shielding products manufacturers#metal foils manufacturer#tin foil manufacturer#indium sheet#fusible alloys#Lead Alloys#radiation shielding products#silver brazing alloys#Solder Alloys#indium wire#indium tin oxide#radiation shielding material#thermal interface materials#lead alloys manufacturers

1 note

·

View note

Text

Battery Scrap Buyer | Gravita India

Gravita India is a trusted global leader in battery scrap recycling. As a premier battery scrap buyer, we ensure competitive pricing, eco-friendly processing, and compliance with global standards. Partner with us for sustainable recycling solutions.

#ABS Regrind#ADC12 manufacturers in India#Aluminium Alloy Ingot#Aluminium alloy manufacturers#aluminium suppliers#Battery Breaking Machine#Battery Recyclers in India#battery recycling companies in India#Battery Recycling in India#Battery Recycling Plant#battery scrap buyer in India#Biggest recycling company in India#circular economy#Green Aluminium#Lead acid battery disposal#lead acid battery scrap buyer#Lead Alloy for battery manufacturers#Lead Alloys for Radiation Shielding#lead alloys manufacturers in India#Lead Antimony alloy#Lead Calcium Alloy#Lead Oxide Plant#Lead Powder#Lead Recycling Plant#Lead Refining Plant#Lead Sheathing Alloy#Lead Sheet#lead sheet manufacturers in India#Lead Smelting Plant#Plastic Compounding

0 notes

Text

Leading Metals Manufacturer Company in India | Sarda Metals & Alloys Ltd

In the vast landscape of India's industrial sector, Sarda Metals and Alloys stands tall as a prominent metals manufacturer company. With a strong commitment to quality, innovation, and customer satisfaction, Sarda Metals and Alloys has cemented its position as a reliable provider of metal products in the country. In this blog post, we will delve into the company's history, product offerings, manufacturing capabilities, and contributions to the Indian metals industry.

A Rich History of Excellence:

Sarda Metals and Alloys was founded with a vision to cater to the growing demand for high-quality metal products in India. Established in [year], the company has since embarked on a journey of excellence, consistently delivering top-notch products and services to its customers. Over the years, Sarda Metals and Alloys has earned a reputation for its commitment to technological advancements, ethical practices, and sustainable manufacturing processes.

Wide Range of Metal Products:

Sarda Metals and Alloys offers a diverse range of metal products to cater to various industries and applications. The company specializes in manufacturing steel, stainless steel, aluminum, copper, and other non-ferrous metal products. From raw materials to finished products, Sarda Metals and Alloys ensures strict quality control at every stage of the manufacturing process. Whether it's sheets, coils, rods, pipes, or custom-made metal components, the company's product portfolio is designed to meet the diverse needs of its customers.

State-of-the-Art Manufacturing Facilities:

To maintain its high standards of quality and precision, Sarda Metals and Alloys operates state-of-the-art manufacturing facilities equipped with advanced machinery and technology. The company's production units are spread across strategic locations in India, allowing for efficient distribution and prompt delivery of products to customers nationwide. Sarda Metals and Alloys' manufacturing processes adhere to international quality standards, ensuring consistency and reliability in their products.

Focus on Research and Development:

Sarda Metals and Alloys places a strong emphasis on research and development to stay ahead of market trends and customer requirements. The company invests in cutting-edge technologies and employs a team of skilled engineers and metallurgists who continuously innovate and develop new products. By staying at the forefront of technological advancements, Sarda Metals and Alloys consistently introduces innovative metal solutions that cater to evolving industry demands.

Commitment to Sustainability:

Sarda Metals and Alloys is committed to sustainable manufacturing practices and environmental responsibility. The company strives to minimize its ecological footprint by optimizing resource consumption, reducing waste generation, and implementing eco-friendly production processes. Through the use of renewable energy sources and the adoption of recycling and waste management practices, Sarda Metals and Alloys actively contribute to India's sustainable development goals.

Customer-Centric Approach:

At the core of Sarda Metals and Alloys' success lies its customer-centric approach. The company values long-term partnerships with its clients and strives to understand their specific requirements. By providing personalized solutions, prompt delivery, and reliable after-sales support, Sarda Metals and Alloys ensures customer satisfaction at every step of the way.

Sarda Metals and Alloys has emerged as a leading metals manufacturer company in India, renowned for its commitment to quality, innovation, and sustainability. With a diverse product portfolio, advanced manufacturing facilities, and a customer-centric approach, the company continues to shape the Indian metals industry. As Sarda Metals and Alloys look towards the future, its unwavering dedication to excellence positions it as a trusted partner for businesses across various sectors, both in India and beyond.

For More Info: Call: +91 9493549632Visit: https://sardametals.com/

#metals manufacturer in india#metal suppliers in india#metals suppliers#metals manufacturer india#ferro alloys suppliers in india#ferro alloys suppliers#ferro alloys in india#silico manganese#ferro manganese#ferro alloys producer in india#sarda metals and alloys ltd#sarda#ferro alloys producer#leading metals manufacturer company in india#metals manufacturer company in india#best metal manufacture company india#leading manufacturers of silico manganese#silico manganese india#silico manganese manufactures#sarda metals alloys#sarda metals#sarda metals and alloys

0 notes

Text

November 24th is the start of Thanksgiving Week! For today, Howard letterpress printed a little reminder to get you ready for the big day. The print was made from a piece of lead alloy type, also called a sort, and depicts a pilgrim carrying a blunderbuss and turkey.

This very small sort from a handy pack, which is less than an inch square, is from the Frank Cowsert Collection. This is from a handy pack made by the American Type Founders in the 1920s. Handy packs contain small symbols for informational or advertising purposes for printers in the letterpress trade. This was printed with black rubber base ink using our Washington hand press, which was manufactured in 1852.

#thanksgiving#turkey#museum#sacramento#history#printing#letterpress#art#printmaking#asmr#old sacramento

202 notes

·

View notes

Note

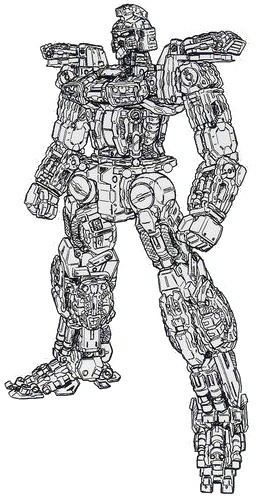

What materials is Biohazard made of? I guess not everything resists radiation

Indeed! No material is totally resistant to radiation; it always depends on the amount of radiation and the exposure time.

Let me get a little nerdy

I clarify and repeat: I'm not an expert on the subject. I did research for this AU in general and thus determined the right materials for the construction of Biohazard. I may be wrong. But this is sci-fi, and some things are improbable but intentional, like Biohazard's melting rays!

Endoskeleton and joints: titanium alloys, stainless steel, and aluminum reinforced with carbon fiber.

Internal components:

Microchips and components: specifically designed to withstand high doses of radiation and encased in a dense layer of ceramic material within a tungsten protective box.

Sensors made with materials resistant to radiation and high temperatures. Integrated into the endoskeleton and protected by a dense covering material.

Actuators: electric or hydraulic motors made with corrosion- and wear-resistant materials. Located within the joints and protected by the endoskeleton.

Metallic lithium-Ion batteries specially designed to operate in extreme environments, housed in a tungsten protective box, away from sensitive components.

Cooling system: copper tubes and non-flammable, radiation-resistant cooling fluids integrated into the endoskeleton to dissipate heat generated by electronic components and shielding.

Protection systems:

Primary shielding: lead sheets and boron-based composite materials, 1.5 centimeters thick.

Secondary/Exterior shielding: tungsten sheets, 1 cm thick.

Biohazard has numerous limbs and components functioning as redundant systems. In the event of a failure, he can continue operating with backups.

He used to integrate cameras and sensors for remote monitoring and data collection. These are no longer operational.

Being made of very dense materials, he's extremely robust and heavy! You practically couldn't lift one of his arms if he were off!

He was very, very expensive to manufacture as well. The frustration was very great when the project "didn't work".

#long post#Biohazard oc#GC Biohazard#Gamma Code AU#Gamma Code fic#GC concepts#fnaf eclipse#fnaf sun#fnaf moon#sundrop#moondrop#fnaf dca fandom#dca community#fnaf#fnaf security breach#security breach#five nights at freddy's#beloved moot#asks

114 notes

·

View notes

Text

Sixaluminium - Devasa+

Aluminum extrusion is a process used to create parts with specific cross-sectional profiles by pushing heated alloy material through a die. This process allows for the creation of various shapes and sizes, making it a versatile method for manufacturing aluminum profiles. Despite its importance, many people may not even notice the prevalence of aluminum extrusions in their homes. In Turkey aluminium manufacturer, companies like Aluminance Aluminum Industry and Trade Inc. and ��. are leading manufacturers of aluminum extrusion profiles and composite panels. These companies play a crucial role in providing high-quality aluminum extrusion products for various industries, including construction. The construction industry greatly benefits from the use of aluminum extrusion profiles. Aluminum construction are lightweight, strong, and corrosion-resistant, making them ideal for construction applications. They are commonly used in windows, doors, and other architectural elements due to their structural integrity and cost benefits. Additionally, aluminum extrusions offer sustainability advantages as they are recyclable and can be repurposed for other projects . The use of aluminum extrusions in construction also contributes to faster construction timelines, as they can be easily fabricated and installed. Overall, aluminium systems profiles have become an essential component in the construction industry, offering a range of benefits for architects, builders, and homeowners alike. In Turkey aluminium extrusion manufacturers like Ş. have played a significant role in supplying the construction industry with high-quality aluminum profiles. These profiles are used in various applications, including aluminum systems for windows, doors, and facades . The 40-Series Aluminium Extrusion Profile produced in the EU is a popular choice for construction pr aluminium veranda ojects due to its quality and durability. The use of aluminum extrusion profiles in construction not only enhances the aesthetics of buildings but also provides structural stability and longevity. With the continued advancements in aluminum extrusion technology, the construction industry can expect further innovation and development in the utilization of aluminum profiles for various architectural and structural applications.

2K notes

·

View notes

Text

#gallium based liquid alloys#indium tin oxide#solder alloys#silver brazing alloys#lead alloys#tin alloys#radiation shielding products#radiation shielding material#tin sheet manufacturers#low melting point alloys#indium wire#indium sheet

1 note

·

View note

Text

Lead Alloys | Gravita India

Gravita India specializes in high-quality lead alloys, tailored for industries like batteries, cables, and radiation shielding. With cutting-edge recycling technology and a commitment to sustainability, we deliver reliable, eco-friendly solutions to meet your lead alloy requirements globally.

#ABS Regrind#ADC12 manufacturers in India#Aluminium Alloy Ingot#Aluminium alloy manufacturers#aluminium suppliers#Battery Breaking Machine#Battery Recyclers in India#battery recycling companies in India#Battery Recycling in India#Battery Recycling Plant#battery scrap buyer in India#Biggest recycling company in India#circular economy#Green Aluminium#Lead acid battery disposal#lead acid battery scrap buyer#Lead Alloy for battery manufacturers#Lead Alloys for Radiation Shielding#lead alloys manufacturers in India#Lead Antimony alloy#Lead Calcium Alloy#Lead Oxide Plant#Lead Powder#Lead Recycling Plant#Lead Refining Plant#Lead Sheathing Alloy#Lead Sheet#lead sheet manufacturers in India#Lead Smelting Plant#Plastic Compounding

0 notes

Text

Researchers Ibuki Taniuchi, Ryota Akiyama, Rei Hobara, and Shuji Hasegawa of the University of Tokyo have demonstrated that the direction of the spin-polarized current can be restricted to only one direction in a single-atom layer of a thallium-lead alloys when irradiated at room temperature. The discovery defies conventions: single-atom layers have been thought to be almost completely transparent, in other words, negligibly absorbing or interacting with light. The one-directional flow of the current observed in this study makes possible functionality beyond ordinary diodes, paving the way for more environmentally friendly data storage, ultra-fine two-dimensional spintronic devices, in the future. The findings were published in the journal ACS Nano. Diodes are fundamental building blocks of modern electronics by restricting the flow of currents to only one direction. However, the thinner the device the more complicated it becomes to design and manufacture these functional components. Thus, demonstrating phenomena that might make such developmental feats possible is critical. Spintronics is an area of study in which researchers manipulate the intrinsic angular momentum (spin) of electrons, for example, by applying light.

Read more.

16 notes

·

View notes

Text

Woman Discovers Over 2,150 Silver Coins From Middle Ages in Czech Republic

Historians have started the process of putting these ancient coins through X-rays to determine what material they are made from.

A woman, out for a walk, was in for a surprise when she stumbled upon a buried treasure from the Middle Ages -- more than 2,150 silver coins -- in the Kutna Hora town of the central Bohemian region in the Czech Republic.

Described by experts as a "once-in-a-decade discovery", these silver coins were minted between 1085 and 1107, according to a press release translated into English by the Institute of Archaeology of the Czech Academy of Sciences (ARUP).

Experts believe these coins were manufactured in Prague and were imported to Bohemia.

ARUP explained that the coins were made of "coin alloy, which, in addition to silver, also contains an admixture of copper, lead and trace metals”.

Once the experts determine the composition used in making these coins, they will also be able to tell the origins of the silver used, it added.

Political instability

The treasure was hidden when the region witnessed political instability, archaeologist Filip Velimsky said.

These coins were stored in a ceramic container that was destroyed over time. However, the archaeologists did manage to discover the bottom of the container.

Recalling history, Velimsky asserted that back then there were disputes in the country "between the members of the Přemysl dynasty about the princely throne of Prague."

Noting that battles were common during the period, ARUP, in its release, claimed that the depot could have been cash “for paying wages or spoils of war.”

The value of these ancient coins was “unimaginable” during the time, the historian said.

“Unfortunately, for the turn of the 11th–12th century, we lack data on the purchasing power of contemporary coins… But it was a huge, unimaginable – and at the same time, unavailable – amount for an ordinary person. It can be compared to winning a million in the jackpot," Velimsky explained.

Officials in the country have called the discovery “one of the largest finds of the last decade.”

What next?

For now, historians have started to process the coins. This includes putting them through X-rays to determine what material these coins are made from.

There are plans to put these coins up for display during an exhibition next year.

#Woman Discovers Over 2150 Silver Coins From Middle Ages in Czech Republic#silver#silver coins#collectable coins#metal detector#ancient artifacts#archeology#archeolgst#history#history news#ancient history#ancient culture#ancient civilizations#middle ages

39 notes

·

View notes

Text

Leading Metals Manufacturer Company in India | Sarda Metals & Alloys Ltd

In the vast landscape of India's industrial sector, Sarda Metals and Alloys stands tall as a prominent metals manufacturer company. With a strong commitment to quality, innovation, and customer satisfaction, Sarda Metals and Alloys has cemented its position as a reliable provider of metal products in the country. In this blog post, we will delve into the company's history, product offerings, manufacturing capabilities, and contributions to the Indian metals industry.

A Rich History of Excellence:

Sarda Metals and Alloys was founded with a vision to cater to the growing demand for high-quality metal products in India. Established in [year], the company has since embarked on a journey of excellence, consistently delivering top-notch products and services to its customers. Over the years, Sarda Metals and Alloys has earned a reputation for its commitment to technological advancements, ethical practices, and sustainable manufacturing processes.

Wide Range of Metal Products:

Sarda Metals and Alloys offers a diverse range of metal products to cater to various industries and applications. The company specializes in manufacturing steel, stainless steel, aluminum, copper, and other non-ferrous metal products. From raw materials to finished products, Sarda Metals and Alloys ensures strict quality control at every stage of the manufacturing process. Whether it's sheets, coils, rods, pipes, or custom-made metal components, the company's product portfolio is designed to meet the diverse needs of its customers.

State-of-the-Art Manufacturing Facilities:

To maintain its high standards of quality and precision, Sarda Metals and Alloys operates state-of-the-art manufacturing facilities equipped with advanced machinery and technology. The company's production units are spread across strategic locations in India, allowing for efficient distribution and prompt delivery of products to customers nationwide. Sarda Metals and Alloys' manufacturing processes adhere to international quality standards, ensuring consistency and reliability in their products.

Focus on Research and Development:

Sarda Metals and Alloys places a strong emphasis on research and development to stay ahead of market trends and customer requirements. The company invests in cutting-edge technologies and employs a team of skilled engineers and metallurgists who continuously innovate and develop new products. By staying at the forefront of technological advancements, Sarda Metals and Alloys consistently introduces innovative metal solutions that cater to evolving industry demands.

Commitment to Sustainability:

Sarda Metals and Alloys is committed to sustainable manufacturing practices and environmental responsibility. The company strives to minimize its ecological footprint by optimizing resource consumption, reducing waste generation, and implementing eco-friendly production processes. Through the use of renewable energy sources and the adoption of recycling and waste management practices, Sarda Metals and Alloys actively contribute to India's sustainable development goals.

Customer-Centric Approach:

At the core of Sarda Metals and Alloys' success lies its customer-centric approach. The company values long-term partnerships with its clients and strives to understand their specific requirements. By providing personalized solutions, prompt delivery, and reliable after-sales support, Sarda Metals and Alloys ensures customer satisfaction at every step of the way.

Sarda Metals and Alloys has emerged as a leading metals manufacturer company in India, renowned for its commitment to quality, innovation, and sustainability. With a diverse product portfolio, advanced manufacturing facilities, and a customer-centric approach, the company continues to shape the Indian metals industry. As Sarda Metals and Alloys look towards the future, its unwavering dedication to excellence positions it as a trusted partner for businesses across various sectors, both in India and beyond.

For More Info: Call: +91 9493549632Visit: https://sardametals.com/

#sarda metals and alloys ltd#silico manganese#ferro alloys in india#metal suppliers in india#ferro alloys suppliers#metals manufacturer in india#ferro manganese#ferro alloys producer in india#ferro alloys suppliers in india#sarda#metals suppliers#sarda metals and alloys#leading manufacturers of silico manganese#silico manganese manufactures#ferro alloys india#ferro alloys producer#ferro alloys manganese manufacturers in india#sarda metals

0 notes

Text

The Hound of the Baskervilles: The Man on the Tor

E. Remington and Sons, founded in 1816, was an American company known for firearms and typewriters, manufacturing the first commercial model of the latter. The typewriter part of the business was sold off in 1886 and via a series of corporate changes, the company is now part of Unisys. Not that it makes typewriters anymore.

The earliest known use of the word "sexy" comes from a letter by Arnold Bennett in 1896.

This is a period where people, especially of class, very much cared about avoiding scandal. A married woman visiting a single man late at night would be a scandal.

At this time Laura Lyons would have to prove that her estranged husband had committed both adultery and abandoned her. Proving the former would usually require a private detective of some form, beyond the means of most people.

A red letter day is one of special significance. In the UK, there are certain days where English High Court judges wear scarlet robes instead of the normal black. This would include religious festivals and the Sovereign's birthdays (official and actual), but I am unable to find an updated official list to reflect the situation with the current King.

Red Letter Days is also the name of a company that sells "experiences" like tank driving days or a cream tea at a posh hotel.

While Franklin possibly isn't aware of it as it was a common turn of phrases, the term "double event" was used in a postcard purporting to be from Jack the Ripper sent the day after that serial killer murdered two women in the space of an hour.

The Court of Queen’s Bench, now the Court of King's Bench, is the division of the High Court dealing with things like personal injury, libel and breach of contract:

Frankland clearly does not remember that you cannot sue the Sovereign. He could sue the Devon County Constabulary though, which has since become the Devon and Cornwall Police.

Tins for food were widespread at this time. They were made of iron, soldered with a tin-lead alloy, which could lead to poisoning by the latter until Max Ams developed a seam in 1888 that only required the solder on the outside.

A pannikin is a metal cup coated in enamel.

"Spartan" means austere. The city state of Sparta in ancient Greece was known, in a rather mythologicalised fashion, for its heavily militarised society, eschewing personal comfort for this. It attracted a lot of admirers as a result, including playing a big part in fascist beliefs. Their reputation for physical prowess has also seen several sports teams adopt their name, like AC Sparta Prague, who dominate the Czech association football game.

There is also of course 300...

#letters from watson#sherlock holmes#history#factoids#acd canon#houn#the hound of the baskervilles#this is dartmoor!

11 notes

·

View notes

Text

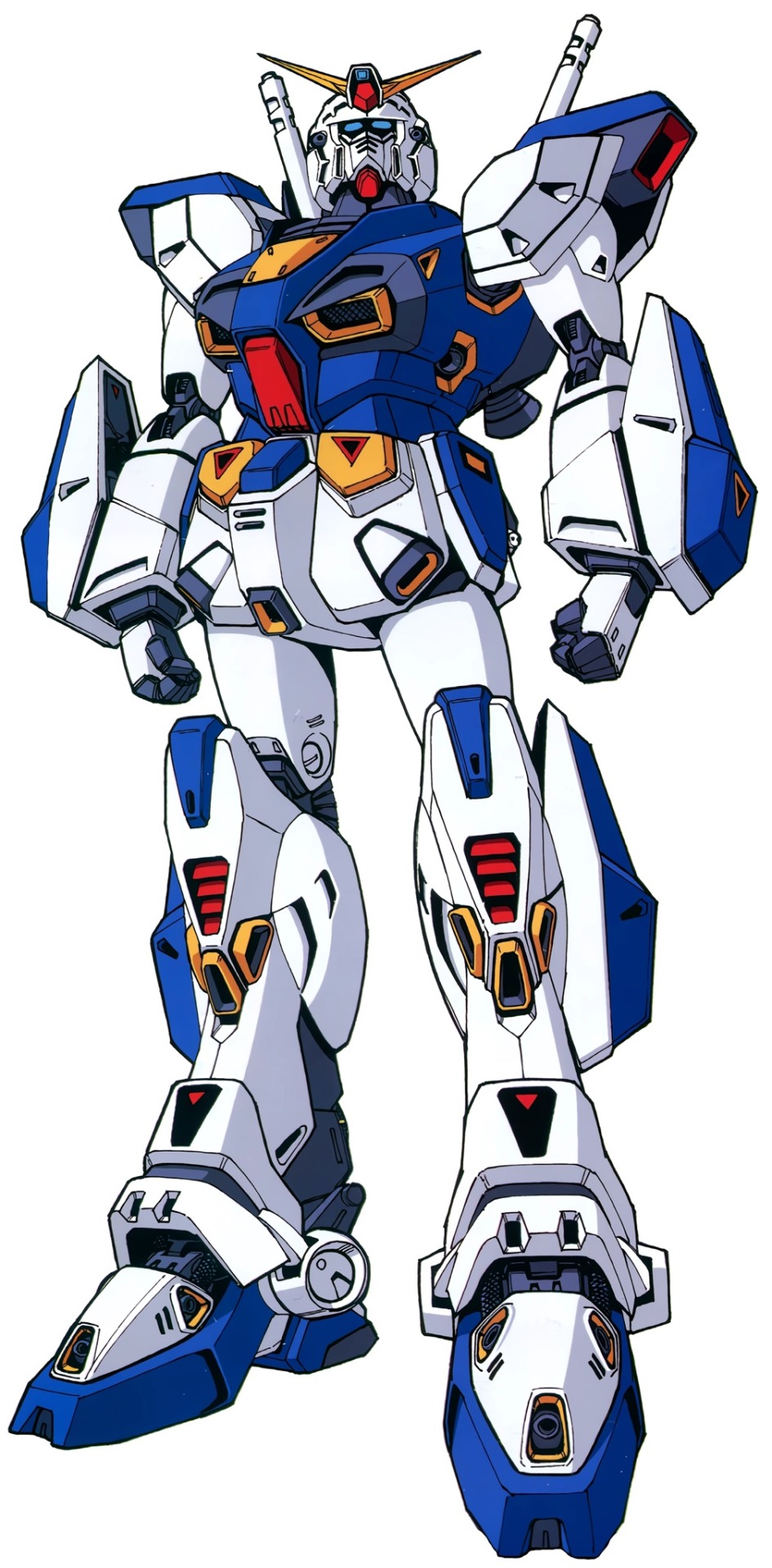

Mobile Suit Generations in the Universal Century

Alright, another lineage post, kinda (I will finish that 00 one eventually).

Now in my post about how the Zaku series changed over time, I mentioned briefly that I don’t really see the Universal Century Gundam series as being much of a lineage, primarily because it’s an absolute mess. However, I do want to do a post talking about the Gundam “line” in some more detail at some point. So I thought I’d make this post beforehand as a sort of preliminary excercise. Because it’s rather difficult to talk about Gundams in universal century without talking about Mobile Suit Generations themselves.

So, What are Mobile Suit Generations?

In brief; as mobile suit technology in Universal Century developed, there were a number of concepts that would revolutionise the entire field, and lead to mobile suit design being completely different as time went on. New technologies, new theories, new design ethos, that sort of thing. And because Gundam units were so often cutting-edge, these new ideas would typically be applied to them. A new generation represents a massive leap forward for the technology, meaning that development occurred very quickly. I’ve thrown around the terms before, typically when talking about fourth-generation mobile suits, but I figured I’d do a post outlining the different mobile suit generations, what their characteristics are, give some examples and talk about any noteworthy oddities.

Disclaimer: as it ever is with UC, there’s a lot that doesn’t divide cleanly here. Some mobile suits are easier to categorise than others, and there can be a lot of overlap between the generations, so I’ll be looking more at broad trends than categorising everything. I’m also gonna skip over a lot of detail here in the name of this post actually being of reasonable length.

First Generation Mobile Suits

Named retroactively and also the easiest to categorise. First-Generation mobile suits encompasses every mobile suit built prior to the Gryps War - Zaku’s, GM’s, RX-78’s, Pale Riders, the Gundam Development Project - all First-Gen mobile suits. First-Gen’s a broad category because it’s every suit on both sides of the OYW, and because mobile suits were still a very new technology there was an absolute range on design ethos and styles. First-Generation mobile suits really only share a timeframe of manufacture, there isn’t really much else to tie them together.

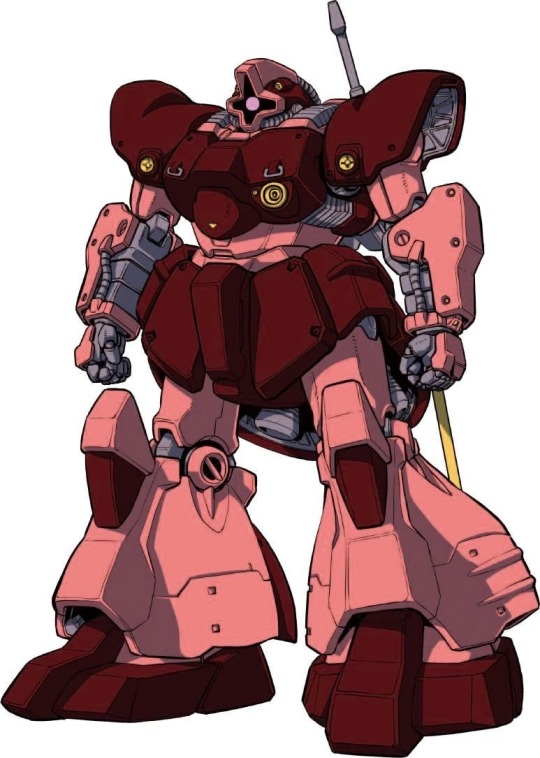

Second Generation Mobile Suits

The only (technically) Mobile Suit Generation to straight-up replace its predecessor and also one of only two generations to incorporate actual definitions (at least as far as I can tell). While the later generations tended to focus on one aspect of mobile suits, Second-Generation mobile suits were an all-around improvement over the second generation. They were characterised by three main features:

The movable frame - rather than just providing structure as was the case previous, the movable frame incorporates all the critical components required to actually move the unit, with the weapons armour and propellant tanks being externalised. This allows for easier maintenance, greater mobility and improved energy efficiency.

360-degree panoramic cockpit and linear seat - technically two improvements, but a “better cockpit” in a nutshell. The 360-degree panoramic cockpit allowed for a much greater field of view for the pilot, especially when compared to the old, cramped cockpits of the OYW, while the linear seat helped reduce the effect of g-forces on the pilot (and also made it easier to eject in the case of being shot down).

Gundarium y alloy - one of several refined versions of the original Gundarium used in the RX-78 series, Gundarium y was lightweight and durable, making it the armour of choice for second-generation mobile suits, allowing them to shrug off blows that would be lethal to earlier models, while remaining manoeuvrable enough that they could dodge such blows.

The most famous Second-Generation mobile suits would be the Gundam Mk-II and the Rick Dias, despite the fact that they each lacked one feature from the above list (the Mk-II had the older titanium alloy ceramic composite armour, whereas the Rick Dias lacked a movable frame). As previously mentioned, Second-generation mobile suits became the benchmark going forwards, and this wasn’t changed until the advent of miniaturised mobile suits in the U.C. 110’s. The Jegan, which would be the mainline mobile suit for the federation for over sixty years, was a Second-Generation mobile suit, typically likened to a mass-produced Gundam Mk-II.

Which brings us to our first oddity I want to talk about - the Dowas Custom. The original Dowas was the final production unit of the Zeon’s Dom line during the One Year War. The precise shakedown of their use and deployment is unclear - the Dowas is derived from the Rick Dom II, which was part of the latewar United Maintenance Plan, but there are reports of Dowas Desert types conducting operations in the wake of the Battle of Odessa - they could be early prototypes, or the Desert units came first and were later refined into the regular Dowas, or the Pezun Dowadge doesn’t count because it wasn’t a production unit…….

Anyway, at least one Dowas unit was brought to Axis by Zeon remnants fleeing A Baoa Qu, where it would be refined and upgraded with Axis’ latest technologies, and then supplied to the nascaent AEUG. That unit was the MS-09SS Dowas Custom, seen in Anaheim Laboratory Log. I won’t spoil the precise details of the hand-off, but you can probably guess from the colour scheme that it involves a certain individual who’s never heard of this Char Aznable fella, dear me no.

But the reason I’m talking about the Dowas Custom here is that it would be reverse-engineered in order to create the Rick Dias, one of the first Second-Generation Mobile suits. But where does that leave the Dowas Custom? Is it First-Gen, or Second-Gen? Well, it’s got Gundarium Alloy Armour (presumably y, since it’s the best one), however we know it doesn’t have a movable frame - neither the original Dom, nor its successor the Rick Dias incorporate one, so it’s very unlikely it has one. So then we come to the cockpit, and I’ve genuinely no idea what kind it employs. So I tend to consider it as an in-between, generation wise.

Third-Generation Mobile Suits

Transformable mobile suits, in a nutshell. Transformable mobile suits were considered an huge advantage during the gryps war, as they allowed for faster deployment, increased scouting range and, in many cases, were able to be transferred from Earth to space more easily than standard mobile suits. The latter half of the Gryps War and early stages of the First Neo Zeon War (Zeta Gundam to ZZ Gundam), are typically considered the golden age of Transformable mobile suits, with such luminaries such as the Zeta Gundam, Bawoo, Messala and Gabthley. Due to the aforementioned advantages, Third-Gen suits continued to develop after this period, giving rise to the Rezel and Delta Plus seen during Unicorn.

Interestingly, what is technically the first Third-Generation mobile suit, the Delta Gundam, was laid down during the early stages of the Gryps War but never built, simply because Anaheim couldn’t figure out how to make the frame work until Kamille Bidan managed to fix the problems with the Zeta, at which point Anaheim was so busy with other projects (like the Zeta Project) that they didn’t have time to review the Delta Gundam until after the war.

However, it is nice to have at least one generation with the relatively simple description of “if it transforms, it’s probably a third-generation suit”

Right?

If it wasn’t for this fucking thing.

Cards on the table, I really like the Gundam Mk-V. It’s nice. But, maddeningly, it’s also one of the only suits that we have an actual, in-universe definition for which mobile suit generation it falls into - “A third-generation mobile suit with the firepower of a fourth”. So it’s a third-generation mobile suit that doesn’t transform. What. Also, It’s the only thing that’s like this - The Gaza-C is a third-gen, because it can transform - The Jegan is a second-gen, because it doesn’t fit into third or fourth-gen categories. Why is a non-transforming suit a third-gen? Very annoying. Based on this, I’m led to conclude that what qualifies a suit as a member of the Third-Generation *has* to be something to do with frame structure, not necessarily transformation, given that the Mark-V doesn’t transform (Or it’s an error on the part of whoever wrote the description).

Fourth Generation Mobile Suits

Speaking of, I should really define fourth generation mobile suits, shouldn’t I? In one word: firepower. Fourth-Generation mobile suits were a product of greatly improved generator output, plus several noteworthy developments in Newtype tech. Any Newtype-specialist mobile suit after the gryps war is most likely part of the Fourth-Generation. The best-known fourth-generation mobile suits would be the ZZ Gundam, S Gundam and Döven Wolf. Axis was a major leader in Fourth-Gen tech, with such units as the Hamma-Hamma and, of course, the Qubeley. Several of these mobile suits were also combiners, such as the aforementioned Gundam’s, though this was later dropped as it led to compatibility and maintenance issues. Fourth-Generation mobile suits were also comparatively rare compared to those of earlier generations - likely due to the rarity of the newtypes that were typically their favoured pilots. The Döven Wolf has the distinction of being one of the few mass-produced Fourth-Generation mobile suits, likely because Axis had the resources to devote to it. Fourth-Generation mobile suits are also unique in that we (arguably) see an upper limit to the technology - the Gundam Unicorn, which is pretty goddamn scary.

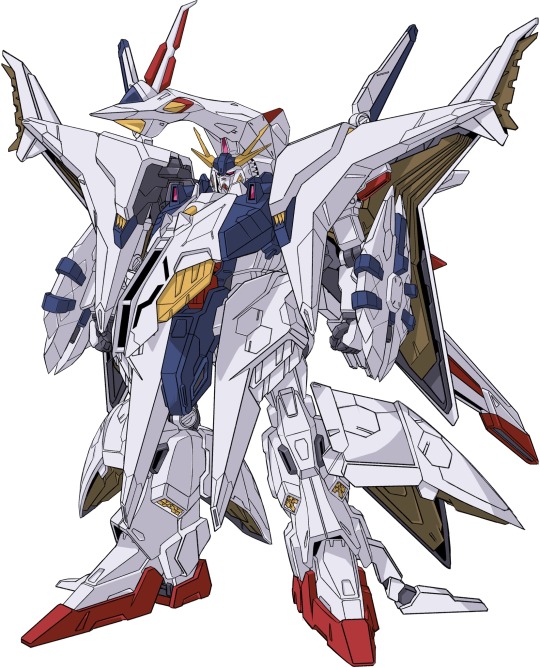

Fifth-Generation Mobile Suits

A very easy one here, a) there’s only two mobile suits classed as fifth-generation at present - the Xi Gundam and the Penelope; and b) it’s got a nice, simple definition - fifth-generation mobile suits are equipped with a Minovsky craft system, allowing for unrestricted flight within the atmosphere.

The Minovsky Craft system is essentially how Gundam deals with all those horribly un-aerodynamic flying mobile armours - they incorporate minovsky craft systems, allowing for flight within the atmosphere (like the Psycho Gundam and the Adzam). The Xi Gundam and Penelope however, are actually light and aerodynamic, meaning that they can function more as mobile interceptors as opposed to flying city blocks. Honestly, I don’t have much more to say on this one.

Miniaturised Mobile Suits

Not really a generation per se, but I figured I’d cover my bases here. Miniaturised mobile suits were pioneered by SNRI, the Earth Federation’s in-house weapon development team, in around the UC 90’s to UC 100’s (such as the Loto and Heavygun). It eventually became standard practice after SNRI development data was stolen in UC 116, allowing other manufacturers to develop miniaturised mobile suits.

The main distinctions between miniaturised mobile suits and their forebears is, well, they were smaller. The Gundam F90 stood at only 14.8 meters tall compared to the original RX-78’s 18 meter height. This was due to a miniaturisation of the thermonuclear reactor used in mobile suits, and the development on new armour materials that allowed the armour and mobile frame to be made lighter without compromising its structural strength. Miniaturised mobile suits also used less resources than traditional ones to construct, allowing militaries to get more bang-for-their-buck, as it were (though given the prevalence of large mobile armours in late UC, being able to spend those resources elsewhere may also have something to do with it).

#apologies I really didn’t know how to describe the Penelope#I’ve really been looking forward to talking about the Dowas Custom#gundam#ramblings#mobile suit gundam#zeta gundam#gundam mk ii#Delta Gundam#Rick Dias#Tem Ray#gundam zz#Doven Wolf#Dowas Custom#Rezel#Gundam mk v#Gundam Penelope#Xi Gundam#Odysseus Gundam#Gundam F90#mobile suit generations#Gundam unicorn#Anaheim Laboratory Log#Autocorrect wanted Cher Aznable

9 notes

·

View notes

Text

Transat Jacques Vabre - Wikipedia

CARTE BLANCHE & ART DE VIVRE EST DE BEERS

The expression is of military origin, referring to unconditional surrender, but it is now used solely in a figurative sense, so that to give someone carte blanche is to grant them absolute freedom of action."

The art of living is the way of living - of being and thinking - of a person or a group of individuals.

AUTHENTIC MOVEMENT DIAÇAMIEUX [DIAMOND AND PREMIER]

Of Undisputed Origin and First in Importance, Order, or Position; Leading.

Periodic Table Metallurgy Cultivator with Artisanal Primitive Anthropology, Nationalist, Art Intellect with Athletic Ability, Riverbanks Farmland, Real Estate Investment Trust and Real Estate Brokerage Trust Account, Pool-Live Monopoly Turf Accountant Board Game Tournament, Rugby and Kickboxing, Eagle Conservation, Painting and Polyrhythm Syncopated Progressive Drum Loops with Rhythm Flag (Bass Clef; Anacrusis; Staccato and Legato; Barcarolle; Tonic and Dominant; Triple G Positions; Distortion Theory; Syncopated Call and Response Café Drum and Bass, Riff Melody, Imitation Vocals, and Drum & Bass Licks), and (Diamond; Decapods; Mollusk; Opium; Deliriants; Tobacco; Coffee; and Arms) Black Market

(Artisanal Primitive King) Pedagogy: King Anthropology; Mixing a form of Royalty Title with Anthropology. CRAFT SOCIETY Sensory Processing Anthropology Artisan Primitive: Sensory Play of the Sensory Ethnography, Sensory Modulits CNS; Artisanal Plantation Metallurgy Cash Crops Spectrum; Evolution; Savagery, Emerging Markets, Civilianization, ECONOMICS OF FINANCIAL MARKETS; Economic Science (Supply-side Economics), Economic Geography (Artisanal Plantation), Economic Mathematics (CFD Probabilistic Model Exchange), Microeconomics (Contract Theory, Purchasing Theory, Portfolio Theory, Producer Price Index, Profit Sharing Plan, Lipstick Effect, Opportunity Cost, Private Limited Partnership, Public-Private Sectors, Pyramid Marketing, Minor Purchase Group) for Sensory Geography (5 Senses City); Prenatal Hormones with Fetus Alcohol Consumption for Sensory Overload Savant;

Randlords Agronomics Spirit: Economic Expansion, Economic Bubble, Supply-Side Economics, FX Counter Trading Party Interdependence Economics, Intermodal Port Economics, Horizontal Integration, Soil Chemistry;

Meturllnomics: Periodic Table Element Manufacturing, Covalent Bonds Fertilizer with Soil Chemistry Ex. Carbon Compounds, Covalent Bonds Fertilizer with Soil Chemistry, Chandelier Tree for Bontonical Indicator; Diamond Vowels: A (Accessories Auctions), E (Exchange Probabilistic Model), I (Sensual Insurance), O (Open-pit Mines), U (Unanimous Laser Cutters and Laser Pressure); Metal Exchange Probabilistic Model for Derivatives CFDS; Crystalline Structure of Elements of the Periodic Table Covalent Bonds Fertilizer, The oxide mineral class includes those minerals in which the oxide anion (O2−) is bonded to one or more metal alloys. I treat my Fertilizer as a Mixing Agent.

AgCurrency: Economic Table, Barter Economics, NIRP Supply-side Fixed Rate Pegged De Facto; AgIndex: Commodities Portfolio Management; Agronomics CFDS//Option Exchange (Credit Spread Options, FX-CFD Interest Rates Beta-Arbitrage w/PPP and Supply-side Economics Currency Pair)

The 2023 of the Transat Jacques Vabre was the 16th edition edition and was raced from Le Havre, France, to Fort de France, Martinique.

CÔTE L’AMBRE PROCESS CERTIFICATE FOR EXPORT AND MARKET VOLUME

Open-pit Mines Economic Geography

Banking System and Probabilistic Model Exchange

Intermodal Cargo Countyline Trafficking Infrastructure

port authority (less commonly a port district) is a governmental or quasi-governmental public authority for a special-purpose district usually formed by a legislative body (or bodies) to operate ports and other transportation infrastructure.

De facto SLL/SDM FX Counter Trading Party for Diamond And Oil CFD; SLL 5% AND SDM -0.5% Interest Rates Contract for Difference. Gold laundering is the process whereby illegally obtained gold is melted and recast into another form. The recasting is performed to obscure or conceal the true origin of the gold. The recast gold is then sold, thus laundering it into cash.

Diamond enhancements are specific treatments, performed on natural diamonds (usually those already cut and polished into gems), which are designed to improve the visual gemological characteristics of the diamond in one or more ways. These include clarity treatments such as laser drilling to remove black carbon inclusions, fracture filling to make small internal cracks less visible, color irradiation and annealing treatments to make yellow and brown diamonds a vibrant fancy color such as vivid yellow, blue, or pink.

the crystalline structures of the elements of the periodic table which have been produced in bulk at STP and at their melting point (while still solid) and predictions of the crystalline structures of the rest of the elements.

Closed oligopoly is where there are prominent barriers to market entry which preclude other firms from easily entering the market.[14] Entry barriers include high investment requirements, strong consumer loyalty for existing brands, regulatory hurdles and economies of scale.

Imperfect (or 'differentiated') oligopolies, on the other hand, involve firms producing commodities which are heterogenous. Where companies in an industry need to offer a diverse range of products and services, such as in the manufacturing and service industries,[12] such industries are subject to imperfect oligopoly.[13]

Sierra Certificate; with Diamond Laser Cutter

A brokerage account is an investment account held at a licensed brokerage firm. An investor deposits funds into their brokerage account, and the broker executes orders for investments such as stocks, bonds, mutual funds, and exchange-traded funds (ETFs) on behalf of the investor.

THOMAS CROWN AFFAIR CHECKING

Barter Economics Guns for Diamonds

Smash and Grab Thomas Crown Affair

Re sale to clientele

CURRENCY, OIL, & GOLD COMMODITIES CANDLESTICK CHARTS

Swing Trading: Use mt4/mt5 With Heiken Ashi Charts, Setting at 14 or 21 Momentum Indicator above 0 as Divergence Oscillator and Volume Spread Analysis as Reversal Oscillator and Trade when bullish candlesticks above 200 exponential moving average and/or 20 exponential moving average (EMA) on H1 (Hourly) Time Frame; use H4 (4 Hours) and D1 (1 Day) as reference.

CAFÉ AFRICAÍ SPICE TRADE//SOLVENT ECONOMIC GEOGRAPHY

Spice Fragrance Spice Shea Butter

Robusta et Robusta Tabaque

Nutmeg

All-Spice

Cinnamon

Cacao-Hazelnut

Cinnamon Flour

Dairy-Caramel Factory

MINING SOIL SOLEVENT ECONOMIC GEOGRAPHY

African Mines

European Rural Areas Soil Chemistry Riverbanks

Real Estate Brokerage Trust Account Offshored Embezzlement (Tax Merger Corporate and Capital Gains) Real Estate Investment in exchange for Supply Horizontal Integration

MATTHIEU ALEV΂I IS WITH INTERPOL

🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🇨🇮🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🗼🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹🌹💎💎💎💎💎💎💎💎💎💎💎💎💎💎💎💎💎💎⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️⚜️

4 notes

·

View notes

Text

#silver brazing alloys#tin sheet manufacturers#solder alloys#radiation shielding material#lead alloys#tin alloys#indium tin oxide#low melting point alloys#gallium based liquid alloys#thermal interface materials

1 note

·

View note

Text

Pure Lead / Refined Lead Ingots | Gravita India

Gravita India delivers premium-quality Pure Lead and Refined Lead Ingots, crafted through sustainable recycling processes. Trusted globally, our lead products meet international standards, ensuring unmatched quality for diverse industries. Choose Gravita for reliability and eco-conscious innovation.

#ABS Regrind#ADC12 manufacturers in India#Aluminium Alloy Ingot#Aluminium alloy manufacturers#aluminium suppliers#Battery Breaking Machine#Battery Recyclers in India#battery recycling companies in India#Battery Recycling in India#Battery Recycling Plant#battery scrap buyer in India#Biggest recycling company in India#circular economy#Green Aluminium#Lead acid battery disposal#lead acid battery scrap buyer#Lead Alloy for battery manufacturers#Lead Alloys for Radiation Shielding#lead alloys manufacturers in India#Lead Antimony alloy#Lead Calcium Alloy#Lead Oxide Plant#Lead Powder#Lead Recycling Plant#Lead Refining Plant#Lead Sheathing Alloy#Lead Sheet#lead sheet manufacturers in India#Lead Smelting Plant#Plastic Compounding

0 notes