#Battery Recyclers in India

Explore tagged Tumblr posts

Text

Battery Scrap Buyer | Gravita India

Gravita India is a trusted global leader in battery scrap recycling. As a premier battery scrap buyer, we ensure competitive pricing, eco-friendly processing, and compliance with global standards. Partner with us for sustainable recycling solutions.

#ABS Regrind#ADC12 manufacturers in India#Aluminium Alloy Ingot#Aluminium alloy manufacturers#aluminium suppliers#Battery Breaking Machine#Battery Recyclers in India#battery recycling companies in India#Battery Recycling in India#Battery Recycling Plant#battery scrap buyer in India#Biggest recycling company in India#circular economy#Green Aluminium#Lead acid battery disposal#lead acid battery scrap buyer#Lead Alloy for battery manufacturers#Lead Alloys for Radiation Shielding#lead alloys manufacturers in India#Lead Antimony alloy#Lead Calcium Alloy#Lead Oxide Plant#Lead Powder#Lead Recycling Plant#Lead Refining Plant#Lead Sheathing Alloy#Lead Sheet#lead sheet manufacturers in India#Lead Smelting Plant#Plastic Compounding

0 notes

Text

The Future of Lithium-Ion Battery Recycling and its Impact on Sustainable Energy Solutions

The electric vehicle (EV) revolution is undeniably reshaping the future of transportation and energy storage. Central to this transformation is the lithium-ion battery, a critical component in powering everything from electric vehicles to renewable energy storage solutions. As the world accelerates towards electrification, a pressing issue looms large: the end-of-life management of these batteries. With rising demand for EVs and clean energy storage systems, we must ask: what happens when these batteries reach the end of their useful life?

The Growing Need for Battery Recycling

By 2030, it is estimated that over 2 million metric tonnes of lithium-ion batteries will be retired annually, including those from electric vehicles, consumer electronics, and large-scale energy storage systems. As these batteries reach their end of life, the importance of recycling, reuse, and material recovery cannot be overstated. According to industry forecasts, the global battery recycling market is expected to grow significantly, driven by the increasing adoption of electric vehicles (EVs) and the need to mitigate the environmental impact of mining for critical materials like cobalt, nickel, and lithium.

Lithium-ion battery disposal has historically been problematic, with many batteries ending up in landfills or incinerators, where valuable materials are lost. However, advancements in recycling technologies and the push towards a circular economy have the potential to address these challenges. For instance, current research is focused on improving the efficiency of recycling processes, particularly the recovery of high-value minerals from battery cathodes, which make up the core of a battery's energy capacity.

Lithium-Ion Battery Residual Value Analysis

As electric vehicle batteries age, their performance gradually declines. However, even when these batteries are no longer suitable for use in EVs, their residual value remains significant. A lithium-ion battery residual value analysis can help determine the potential for repurposing or reusing these batteries in secondary applications, such as stationary energy storage or grid stabilization. By extending the life of EV batteries in these lower-demand applications, we reduce the need for new batteries, lessen environmental impacts, and create an economically viable pathway for battery manufacturers.

One promising avenue for extending the life of these batteries is through second-life applications, such as large-scale energy storage systems. For instance, retired EV batteries can store excess energy generated from renewable sources like solar or wind. In these applications, batteries may continue to provide reliable service for an additional 6 to 10 years, contributing to energy stability and reducing the need for new energy storage systems.

The Economic Value of Recycling and Material Recovery

Recycling lithium-ion batteries offers several advantages, including reducing the need for new mining operations, lowering the environmental impact, and providing an alternative source for valuable materials. Through processes such as lithium-ion battery disposal value assessments, companies can determine the profitability of recycling batteries and recover critical minerals like cobalt, nickel, and lithium, which make up nearly 50% of the total cost of a battery.

In addition, recent innovations in direct recycling technologies have shown great promise. By refurbishing battery cathodes rather than fully breaking down the battery, researchers have been able to retain more of the original battery structure and improve the performance of recycled batteries. The new cathode material is as efficient as newly mined materials, with the added benefit of being cheaper and more sustainable.

For instance, the development of methods that preserve the integrity of the cathode material not only results in a lower cost for producing new batteries but also reduces the energy-intensive processes involved in refining raw materials. This innovation offers a promising solution to address the increasing demand for battery materials and reduce dependency on mining operations, especially in regions that suffer from environmental degradation due to resource extraction.

Policy and Infrastructure Challenges

Despite the promising developments in battery recycling, several challenges remain. First, the infrastructure for recycling is still underdeveloped, particularly in regions where EV adoption is growing rapidly. To ensure that the lithium-ion battery disposal value is fully realized, governments and private industries must invest in the development of efficient collection, sorting, and recycling technologies.

Governments also play a key role in facilitating the growth of this sector by implementing policies that promote sustainable battery disposal practices and incentivize the recycling of EV batteries. California, for instance, is actively working to establish policies that ensure 100% of EV batteries sold in the state are recycled or reused at their end of life. Policy mechanisms such as extended producer responsibility (EPR), responsible sourcing, and deposit fees can help improve the economics of battery recycling and accelerate the transition to a circular economy.

The Road Ahead: A Sustainable Future for EV Batteries

Looking ahead, the future of lithium-ion battery recycling appears promising. As battery technologies continue to improve and recycling infrastructure expands, the residual value of lithium-ion batteries will become increasingly important. More efficient recycling and repurposing techniques, coupled with strong policy support, can help to mitigate the environmental impacts of battery disposal and create a sustainable, circular supply chain for battery materials.

By investing in research, infrastructure, and policies that promote battery recycling, we can ensure that the EV revolution is both environmentally and economically sustainable. As the demand for electric vehicles and renewable energy storage continues to grow, it is crucial that we address the challenges of battery disposal, recycling, and material recovery to secure a greener, more sustainable future.

Conclusion

As the market for electric vehicles continues to expand, understanding the lithium-ion battery residual value analysis and lithium-ion battery disposal value will become essential for both manufacturers and consumers. The key to a sustainable future lies not only in innovations in battery technology but also in creating systems that efficiently recycle and repurpose the materials within those batteries. By closing the loop on battery materials, we can reduce our dependence on mining and make the transition to a greener economy more cost-effective and environmentally responsible.

At LOHUM, we are dedicated to advancing the future of sustainable battery solutions and contributing to the development of a circular economy. Through ongoing innovation and collaboration, we are committed to helping create a future where lithium-ion battery disposal, recycling, and reuse play a central role in achieving global sustainability goals.

Visit us at: Recycling of ev batteries in India

Originally published on: Medium

0 notes

Text

Explore the India Lithium-Ion Battery Recycling Market trends, share, revenue, outlook, future market insights, forecast, and analysis up to 2028.

#India Lithium-Ion Battery Recycling Market research report#India Lithium-Ion Battery Recycling Market report#India Lithium-Ion Battery Recycling Market size#India Lithium-Ion Battery Recycling Market trends#India Lithium-Ion Battery Recycling Market share#India Lithium-Ion Battery Recycling Market revenue#India Lithium-Ion Battery Recycling Market outlook#India Lithium-Ion Battery Recycling future market#India Lithium-Ion Battery Recycling Market insights#India Lithium-Ion Battery Recycling Market forecast#India Lithium-Ion Battery Recycling Market analysis#India Lithium-Ion Battery Recycling Market top players#India Lithium-Ion Battery Recycling Market major players#India Lithium-Ion Battery Recycling Market leading players#India Lithium-Ion Battery Recycling Market emerging players#India Lithium-Ion Battery Recycling Market players#India Lithium-Ion Battery Recycling Market competitors#India Lithium-Ion Battery Recycling Market growth#India Lithium-Ion Battery Recycling Market growth factors#India Lithium-Ion Battery Recycling Market development#India Lithium-Ion Battery Recycling Market challenges

0 notes

Text

Best Lithium-Ion Battery Recycling Company in India | ReBAT

ReBAT is a leading provider of eco-friendly battery materials, specializing in Lithium-Ion battery recycling. Committed to simplifying sustainability. Enquire today!

1 note

·

View note

Text

#India battery recycling market size#India battery recycling market share#India battery recycling market trends#India battery recycling market growth

0 notes

Text

battery recycling companies in india

battery recycling companies in india

Battery recycling companies in india has emerged as a crucial practice in India to address environmental concerns and promote sustainability. Several companies have stepped up to provide innovative solutions for recycling various types of batteries, contributing to a cleaner and greener future.

Eco-Battery Solutions Pvt. Ltd. Eco-Battery Solutions specializes in recycling lead-acid batteries, which are commonly used in automobiles and industrial applications. The company employs advanced technologies to extract lead, plastic, and other materials from spent batteries, ensuring efficient resource utilization and minimizing environmental impact.

battery recycling companies in india

GreenTech Recycling Industries GreenTech Recycling Industries focuses on recycling lithium-ion batteries, prevalent in electronic devices and electric vehicles. Through a combination of mechanical and chemical processes, the company safely recovers valuable metals like lithium, cobalt, and nickel, promoting circular economy principles and reducing reliance on finite resources.

RenewPower Recycling Pvt. Ltd. RenewPower Recycling offers comprehensive solutions for battery recycling companies in india including nickel-cadmium and nickel-metal hydride batteries. With state-of-the-art facilities and a commitment to responsible recycling practices, the company contributes significantly to reducing hazardous waste and conserving natural resources.

EnviroVolt Technologies Ltd. EnviroVolt Technologies specializes in innovative recycling processes for a wide range of batteries, including alkaline and zinc-carbon batteries. By adopting environmentally friendly techniques, the company ensures efficient material recovery while adhering to stringent safety standards and regulatory requirements.

Conclusion: Battery recycling companies in India play a pivotal role in mitigating environmental pollution and conserving valuable resources. Through their expertise and commitment to sustainability, these companies contribute to a cleaner and more sustainable future for generations to come.

#battery recycling companies in india#e waste disposal hyderabad#battery recycling plant#electronic scrap buyers in hyderabad#e waste recycling chennai

1 note

·

View note

Text

The Rise of Battery Recycling in India: From Waste to Wealth

In the age of technology, where batteries power everything from our smartphones to our cars, the importance of battery recycling cannot be overstated. As India stands on the verge of an energy revolution, recycling has emerged as a critical component of the country’s sustainable future.

Recycling batteries is the process of converting used batteries into reusable materials, thereby reducing the need for new raw materials and the environmental impact of waste disposal. It’s a practice that not only conserves resources but also prevents old batteries, which can be toxic and made economically useful, instead of ending them in landfill sites.

India, with its huge population and rapidly growing economy, generates a significant amount of battery waste. The rise of electric vehicles and renewable energy storage solutions has further amplified the need for effective battery recycling. Recognizing this, the Indian government has implemented policies and regulations to encourage the proper disposal and recycling of batteries.

The Need for Recycling Batteries

Recycling Batteries is not just a matter of environmental responsibility; it’s a necessity. The improper disposal of batteries can have severe environmental and economic implications.

Environmental Impact of Improper Battery Disposal

Batteries contain a variety of heavy metals and toxic chemicals, including lead, mercury, cadmium, and lithium. When disposed of improperly, these substances can leak into the soil and water, causing significant environmental harm. This contamination can disrupt ecosystems, harm wildlife, and even pose risks to human health through the contamination of food and water supplies.

Moreover, the improper disposal of batteries contributes to the growing problem of electronic waste, or e-waste. E-waste is one of the fastest-growing waste streams globally, posing a significant challenge for waste management and leading to the loss of valuable resources that could be recovered and reused.

Economic Benefits of Battery Recycling

On the other side, recycling batteries offers substantial economic benefits. The process of recycling recovers valuable materials like lead, nickel, and lithium, which can be reused to manufacture new batteries or other products. This reduces the demand for new and unused materials, leading to cost savings and a lower environmental footprint.

In addition, the battery recycling industry can create jobs and stimulate economic growth. As the demand for batteries continues to rise, particularly with the growth of electric vehicles and renewable energy storage, so does the potential for a thriving battery recycling industry.

In India, the battery recycling sector is still in its infant stages, but it holds immense potential. With the right policies and infrastructure, battery recycling can become a significant industry, contributing to India’s economy while helping to address environmental challenges.

The journey of recycling batteries in India can be a fascinating tale of turning waste into wealth. It can build a story of how a country can leverage policy, technology, and entrepreneurship to transform a challenge into an opportunity.

Indian Government’s Policy on Battery Recycling

Recognizing the importance of recycling batteries, the Indian government has implemented a series of policies and regulations aimed at promoting responsible battery disposal and recycling.

Overview of the Battery Waste Management Rules 2022

Battery Waste Management Rules 2022 replaces the earlier Battery Management and Handling Rules 2001, providing a unified structure for the management of battery waste in India. They cover all types of batteries and apply to manufacturers, importers, assemblers, re-conditioners, consumers, and recyclers.

The 2022 rules introduce several significant changes, including stricter Extended Producer Responsibility (EPR) obligations, a focus on environmentally sound management of battery waste, and provisions for the formalization of the informal battery recycling sector.

Role of Extended Producer Responsibility (EPR)

Extended Producer Responsibility (EPR) is a policy approach under which producers are given significant responsibility for the treatment or disposal of post-consumer products.

Under the Battery Waste Management Rules 2022, producers are required to ensure that used batteries are collected and sent for recycling in an environmentally sound manner. They are also required to create awareness among consumers about the importance of proper battery disposal.

Government’s Initiatives to Promote Battery Recycling

The Indian government has launched several awareness campaigns, incentives for battery recycling businesses, and research and development programs to improve battery recycling technologies.

Furthermore, the government is also working to strengthen the infrastructure for battery collection and recycling and to formalize the informal battery recycling sector, which currently handles a significant portion of battery waste in India.

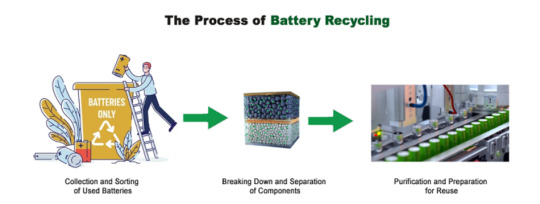

The Process of Recycling Batteries

Recycling Batteries is a complex process that involves several stages, each of which plays a crucial role in transforming used batteries into reusable materials. Here’s a closer look at how it works:

Collection and Sorting of Used Batteries

The first step in the recycling process is the collection of used batteries. This can be done through various means, including collection boxes at retail stores, community recycling events, and dedicated battery recycling facilities.

Once the batteries are collected, they are sorted based on their chemistry. Different types of batteries such as lead-acid, nickel-cadmium, and lithium-ion require different recycling processes, so accurate sorting is crucial.

Breaking Down and Separation of Components

After sorting, the batteries are broken down, often through a process called mechanical treatment. This involves crushing the batteries into small pieces, which makes it easier to separate the different components.

The crushed batteries are then separated into different streams. For example, in the case of lead-acid batteries, the lead and plastic components are separated from the electrolyte.

Purification and Preparation for Reuse

The separated materials then undergo further treatment to purify them and prepare them for reuse. This can involve a variety of processes, depending on the type of material.

For example, lead from lead-acid batteries is often smelted and refined to remove impurities, after which it can be used to manufacture new batteries. Similarly, plastic components can be cleaned and converted into pellets for use in new plastic products.

The recycling process not only recovers valuable materials from used batteries but also ensures that potentially harmful substances are managed in an environmentally sound manner.

The Business of Battery Recycling in India

Current State of Battery Recycling Industry in India

As the demand for batteries continues to grow, so does the potential for a thriving battery recycling industry. The Industry of recycling batteries in India is still in its infancy stages, but it’s growing rapidly.

Currently, the industry is dominated by the unorganized sector, which handles a significant portion of battery waste. However, as the market grows, more and more companies will enter the market and invest in advanced recycling technologies.

Major Companies Involved in Recycling Batteries

Several companies are leading the way in recycling batteries in India. These include Gravita India Ltd., a leading lead recycling company, and Attero Recycling, which specialises in e-waste management and recycles various types of batteries. Other players include Ecoreco, which offers solutions for e-waste and battery waste management, and Exigo Recycling, which provides recycling services for electronic waste, including batteries.

Opportunities and Challenges in the Battery Recycling Business

Read the full article at: https://dsb.edu.in/the-rise-of-battery-recycling-in-india-from-waste-to-wealth/?utm_source=tumblr&utm_medium=tumblr&utm_campaign=tumblr+battery+recycling

#waste management#battery#recycling#battery recycling market trend#battery recycling#ai#india#blockchain#fintech#jobs#education#google

0 notes

Text

water pollution control in india

WATER POLLUTION CONTROL

#incinerator manufacturer in india#industrial waste incinerator manufacturers#force draft cooler#recuperator manufacturer in india#ladle manufacturers in india#aluminium extrusion plant manufacturers in india#turnkey projects companies in india#hot air generator manufacturers in india#plate bending machine manufacturers in india#Rotary kiln manufacturers#furnace manufacturers in india#calciner manufacturers#bag filter manufacturers in india#bag filter manufacturers#cartridge filter manufacturers in india#cyclone dust collector#Battery Cutting Machine#battery cutting machine manufacturers#battery cutting machine manufacturers in india#Battery Recycling Plant#battery recycling plant in india#battery recycling plant manufacturers#Battery Recycling Technology#battery recycling technology india#lead acid battery recycling companies in india#Disposal technology for Lead Acid Battery Waste#disposal technology for lead acid battery waste india#cyclone dust collector manufacturers#cyclone dust collector manufacturer in india#baghouse manufacturers

1 note

·

View note

Text

extended producer responsibility consultation

Extended Producer Responsibility consultation refers to a regulatory process where manufacturers and producers are held accountable for the entire lifecycle of their products, including disposal and recycling. It involves seeking input and feedback from stakeholders to develop effective EPR policies for sustainable waste management and environmental protection.

#epr for battery#best epr consultant in india#electronic refurbishing in delhi#epr certification services#e waste recycling in delhi#e waste certificate in delhi

0 notes

Text

Lead Alloys | Gravita India

Gravita India specializes in high-quality lead alloys, tailored for industries like batteries, cables, and radiation shielding. With cutting-edge recycling technology and a commitment to sustainability, we deliver reliable, eco-friendly solutions to meet your lead alloy requirements globally.

#ABS Regrind#ADC12 manufacturers in India#Aluminium Alloy Ingot#Aluminium alloy manufacturers#aluminium suppliers#Battery Breaking Machine#Battery Recyclers in India#battery recycling companies in India#Battery Recycling in India#Battery Recycling Plant#battery scrap buyer in India#Biggest recycling company in India#circular economy#Green Aluminium#Lead acid battery disposal#lead acid battery scrap buyer#Lead Alloy for battery manufacturers#Lead Alloys for Radiation Shielding#lead alloys manufacturers in India#Lead Antimony alloy#Lead Calcium Alloy#Lead Oxide Plant#Lead Powder#Lead Recycling Plant#Lead Refining Plant#Lead Sheathing Alloy#Lead Sheet#lead sheet manufacturers in India#Lead Smelting Plant#Plastic Compounding

0 notes

Text

Unleashing Potential: Battery Waste Recycling Strategies

Battery recycling is not only essential for the environment but also a strategic step directed towards a sustainable future. The elevating adoption of electric vehicles (EVs) and renewable energy storage systems has led to a noticeable increase in battery recycling. While batteries are indispensable for lessening greenhouse gas emissions, they also pose a significant challenge for waste management due to their dangerous elements and limited lifespan.

One prime strategy for battery authorization is resource recovery. Batteries comprise important materials like cobalt, lithium, nickel, and more, which are highly demanding for the production of fresh batteries. Recycling lessens the environmental footprint of mining and processing these materials and preserves finite resources. There is an increasing emergence of recycling technologies, making it feasible to extract and reuse important resources from spent batteries properly.

Another crucial aspect of battery recycling is minimizing environmental harm. Batteries can leak hazardous chemicals if not disposed of properly. Recycling facilities employ strict protocols to handle, neutralize, and dispose of these toxic substances safely. Proper disposal and recycling also prevent the release of heavy metals into the environment, safeguarding ecosystems and human health.

Furthermore, recycling can be economically viable. As demand for batteries grows, the market for recycled materials is expanding. This creates a financial incentive for recycling companies and promotes circular economy where materials are reused and waste is minimized.

To fully unleash the potential of battery waste recycling, it's vital to establish efficient collection systems, promote public awareness, and encourage manufacturers to design batteries with recycling in mind. Additionally, governments can play a crucial role by implementing regulations and incentives to support recycling initiatives.

#Battery Customs#Battery Authorization#battery recyling india#Batteries recycling#battery epr#EPR battery waste management

0 notes

Text

E-Waste Annual Returns Filing Services

To submit e-waste returns, the exact process can vary depending on the specific regulations and requirements of your jurisdiction. However, I can provide you with a general overview of the steps involved in submitting e-waste returns:

Gather necessary information: Collect all the relevant data and information required for the e-waste return filing. This may include details about the types and quantities of e-waste generated, recycled, or disposed of during the reporting period, as well as any supporting documentation or records.

Understand the reporting period: Determine the reporting period for which you need to submit the e-waste return. This could be a calendar year, a fiscal year, or a specific period defined by the regulatory authorities.

Complete the required forms: Depending on the regulations in your jurisdiction, you may need to fill out specific forms or templates provided by the regulatory authorities. These forms typically require you to provide detailed information about your e-waste management activities during the reporting period.

Ensure accuracy and completeness: Review the completed forms and supporting documentation to ensure accuracy and completeness. Double-check that all required information has been provided and that calculations and data are consistent.

Submit the e-waste return: Once the forms are completed, submit them to the appropriate regulatory body or government agency responsible for e-waste management. The submission process can vary but is often done electronically through a designated online portal or by mailing physical copies to the relevant address. It's important to meet any specified deadlines for submission.

Retain records: Keep a copy of the submitted e-waste return and any supporting documentation for your records. This is important for future reference, audits, or compliance checks.

#waste disposal#waste management#battery-waste plastic-waste#deshwal waste management#e-waste management in india#batteryrecycling#wastemanagement#recycling

0 notes

Text

Lithium ion Battery Recycling Companies in India | ATTERO

Attero offers top-class Li-ion Battery recycling solutions in India by extracting pure grade metals and having a positive impact on the environment.

#e-waste#e-waste management#ewaste#lithium ion battery market trends#Lithium ion Battery Recycling Companies in India#lithium ion battery#li ion battery recycling

1 note

·

View note

Text

Good Climate News: Headline Roundup April 1st through April 15th, 2023

Contrary to what you might expect, there's actually way more good climate news stories than I have time to post about individually. (Especially now that my health is better and I'm back to working more!) Which itself is fantastic news!

Some stories are big, some are small, but they all add up. All over the world, people are doing far more than we realize to help save the planet - and ourselves.

I'm posting this is mid-May bc I've gotten really behind on news posts, but trust me, there will be more roundups coming. And this is SO FAR from all the good climate news in April 2023. I may do weekly roundups in the future.

So, without further ado, some reasons to have hope, all from just April of 2023:

^Article date: 4/15/23

^Article date: 4/14/23. And to clarify, the cleanup will NOT be temporary, they are building infrastructure and changing laws for the long term.

^Article date: 4/13/23

^Article date: 4/12/23

^Article date: 4/10/23

^Article date: 4/12/23

^Article date: 4/11/23

^Article date: 4/8/23

^Article date: 4/5/23

More roundup posts to come!

#climate#sustainability#climate change#biodiversity#marshes#sparrows#india#united states#united kingdom#wales#france#senegal#madagascar#georgia#texas#milkweed#rivers#conservation#conservation news#water pollution#electric vehicles#reforestation#trees#good news#hope

208 notes

·

View notes

Text

Innovations in Textile Products: What Exporters Need to Know

The textile industry is undergoing a wave of transformation, fueled by innovation and technological advancements. As consumer preferences shift and the global market becomes more competitive, staying updated on the latest trends and innovations in textile products is essential for exporters. For textiles products exporters in Gujarat, keeping pace with these changes can offer a significant edge in the international market. In this blog, we will explore the most important innovations in textile products and discuss what exporters need to know to remain competitive, particularly for those aiming to be recognized as the best exporter in Gujarat or even among the top 10 textile products exporters in Gujarat.

Understanding the Role of Innovation in the Textile Industry

Innovation is the key to staying relevant in today’s textile market. With constant advancements in technology, sustainability practices, and production techniques, the textile industry has seen a profound transformation over the last decade. Exporters who embrace these innovations can offer products that not only meet global demand but also offer higher quality, durability, and sustainability, thus increasing their competitive advantage.

For textiles products exporters in Gujarat, leveraging these innovations is especially important given Gujarat's reputation as a textile hub. Known for its strong historical ties to the textile industry, Gujarat plays a leading role in India’s textile exports, contributing significantly to the country’s economic growth. Exporters here need to constantly evolve to maintain their position as leaders in the industry.

Key Innovations in the Textile Industry

1. Smart Textiles and Wearables

One of the most exciting developments in the textile industry is the rise of smart textiles, also known as e-textiles or electronic textiles. These are fabrics embedded with digital components such as sensors, LEDs, and batteries, offering added functionalities such as temperature regulation, moisture monitoring, and even health tracking.

For instance, there are textiles that can track the wearer’s heart rate, alert them of potential health issues, or adjust temperature depending on the environment. The demand for such smart fabrics is growing, especially in industries such as healthcare, fitness, and fashion. Textile products exporters in Gujarat who are looking to differentiate themselves in the international market should consider incorporating smart textile solutions into their product lines.

2. Sustainable Textiles

Sustainability is no longer just a trend; it is a necessity. Consumers across the globe are becoming increasingly eco-conscious, seeking products that are produced with minimal environmental impact. Sustainable textiles, including organic cotton, recycled polyester, and eco-friendly dyes, are gaining prominence.

India, and particularly Gujarat, is well-positioned to lead in this arena due to its vast agricultural resources and established textile infrastructure. Exporters who focus on sustainability can capitalize on this growing demand by offering products that are not only high in quality but also eco-friendly, making them the best exporter in Gujarat for green textiles.

3. 3D Printing in Textiles

3D printing has revolutionized various industries, and textiles are no exception. The ability to create complex designs and patterns without traditional weaving or knitting has opened up a world of possibilities. 3D printing allows for rapid prototyping, reducing waste, and enabling designers to experiment with unique shapes and forms that were previously impossible with conventional textile production techniques.

For top 10 textile products exporters in Gujarat, incorporating 3D-printed textiles can set them apart in international markets. From customized clothing to technical textiles, 3D printing offers a versatile solution that caters to both fashion and industrial sectors.

4. Nano-Textiles

Nanotechnology is another innovation that has made its way into the textile industry. Nano-textiles are fabrics that have been enhanced with nanoparticles to provide additional functionalities such as stain resistance, UV protection, and antimicrobial properties.

These textiles are particularly popular in the sports, healthcare, and outdoor sectors, where performance and durability are crucial. By embracing nano-textiles, textile products exporters in Gujarat can offer high-performance fabrics that cater to niche markets, thus expanding their customer base internationally.

5. Revolutionary Dyeing Techniques

Traditional dyeing processes often involve the use of toxic chemicals and large amounts of water, making them harmful to the environment. However, new, innovative dyeing techniques such as digital printing and waterless dyeing have revolutionized the industry. These methods use significantly less water and energy, while also allowing for more precise and vivid color reproduction.

For exporters aiming to be the best exporter in India, embracing such innovative dyeing processes can offer a distinct advantage. Offering textiles that are environmentally friendly, yet vibrant and high-quality, positions you as a leader in both innovation and sustainability.

6. Performance Fabrics

Performance fabrics, engineered to offer enhanced functionality like moisture-wicking, breathability, or thermal insulation, are in high demand across various sectors such as sports, military, and outdoor apparel. With advancements in fabric engineering, these materials can be designed to meet very specific needs.

For textiles products exporters in Gujarat, exporting performance fabrics can open up new markets and ensure higher profitability. By offering cutting-edge fabrics that cater to the growing demand for performance-based textiles, exporters can solidify their standing as leaders in innovation.

Why Innovation is Essential for Exporters

In a rapidly evolving global market, staying ahead of the competition requires constant innovation. For textiles products exporters in Gujarat, embracing these advancements can yield several key benefits:

1. Increased Competitiveness

Innovative products stand out in crowded markets. By offering unique, cutting-edge textiles, exporters can differentiate themselves from competitors and attract premium customers. This is especially important for exporters aiming to be among the top 10 textile products exporters in Gujarat.

2. Access to New Markets

Innovative textiles such as smart fabrics, sustainable textiles, and nano-textiles are in high demand in emerging markets such as healthcare, sports, and fashion. Exporters who incorporate these products into their offerings can access new customer segments, expanding their global reach.

3. Customer Loyalty

Consumers and businesses are increasingly drawn to companies that prioritize innovation and sustainability. Exporters who offer eco-friendly, high-performance textiles are more likely to build long-term relationships with customers, ensuring repeat business and brand loyalty.

4. Compliance with Global Standards

Many international markets have stringent standards regarding environmental impact and product performance. By incorporating innovative, sustainable practices into production, exporters can ensure compliance with these standards, making it easier to enter and succeed in global markets.

Entail Global: Leading the Charge in Textile Innovations

At Entail Global, we are proud to be one of the best exporters in Gujarat, offering a wide range of innovative textile products that meet the highest international standards. We understand that the textile industry is constantly evolving, and we are committed to staying ahead of the curve by embracing the latest innovations in the field.

Our portfolio includes smart textiles, sustainable fabrics, and performance-based materials, all produced using state-of-the-art technology and environmentally friendly practices. As one of the top 10 textile products exporters in Gujarat, we are dedicated to delivering exceptional quality to our global clients.

Why Choose Entail Global?

As the best exporter in India for textile products, we offer:

1. Innovation at the Core

We believe that innovation is the key to success. By continually investing in research and development, we ensure that our products reflect the latest advancements in textile technology.

2. Sustainability Focus

Our commitment to sustainability sets us apart from the competition. We use eco-friendly materials and processes, allowing our clients to offer products that align with today’s demand for greener solutions.

3. Global Expertise

With years of experience in exporting textile products across the globe, we understand the unique needs of different markets. Our expertise ensures smooth logistics and compliance with international standards, making us a reliable partner for businesses worldwide.

4. Customer-Centric Approach

At Entail Global, we prioritize our customers. Our dedicated team works closely with clients to understand their specific requirements, offering tailored solutions that meet their exact needs.

Conclusion

The textile industry is at the forefront of innovation, with advancements in smart textiles, sustainability, 3D printing, and nano-technology reshaping the market. For textiles products exporters in Gujarat, staying informed about these innovations and integrating them into product offerings is crucial for maintaining competitiveness on a global scale.

At Entail Global, we are proud to be leading the charge in textile innovation, offering cutting-edge products that meet the highest global standards. Whether you are looking for smart fabrics, sustainable textiles, or performance materials, we are your go-to partner in the world of textile exports.

Embrace innovation, choose Entail Global – the best exporter in Gujarat, and elevate your position in the global textile market!

#Best exporter in Gujarat#Best exporter in India#Textiles products exporters in Gujarat#Top 10 textile products exporter in Gujarat#India#business#import and export

4 notes

·

View notes