#laser water chiller

Explore tagged Tumblr posts

Text

Professional chiller solutions for various industries. Customizable and easy to use. Reach out to me at [email protected] for any questions.

3 notes

·

View notes

Text

Differences Between Split and Integrated Laser Chillers | Cooling Circulation Pump Selection Suggestions

In the application of laser equipment, laser chillers are key components to ensure the stable operation of laser devices. By providing precise and stable temperature control, they ensure the efficient, safe, and long-lasting operation of laser equipment. With the continuous development of technology, both split and integrated laser chillers have occupied a place in the market due to their respective characteristics and advantages. This article will discuss the differences between these two types of chillers and the differences in cooling circulation pump selection for them.

Differences Between Split and Integrated Laser Chillers

Split and integrated laser chillers differ in terms of structure, installation, and application scenarios. When choosing a laser chiller, it is essential to select the appropriate type based on actual needs and application scenarios to ensure the normal operation and stability of the chiller.

1. Structure and Design

Split Laser Chiller: Its design feature is that the indoor unit and outdoor unit are installed separately and connected through pipelines and wiring. The indoor unit mainly includes the evaporator, water tank, water pump, and other components, while the outdoor unit contains core refrigeration components such as the compressor and condenser.

Integrated Laser Chiller: All components, including the compressor, condenser, evaporator, water tank, and water pump, are integrated into one cabinet, making the structure compact and easy to install and move.

2. Installation and Maintenance

Split Laser Chiller: Since the indoor and outdoor units are installed separately, it requires a larger installation space, and the installation process is relatively complex, requiring professional personnel. In terms of maintenance, both the indoor and outdoor units need to be maintained separately.

Integrated Laser Chiller: The installation process is simple; just place the whole unit in the designated position and connect the power and water sources. Maintenance is also relatively convenient because all components are concentrated in one cabinet, making inspection and repair easier.

3. Application Scenarios

Split Laser Chiller: Suitable for large industrial facilities, high heat-generating environments, places with strict noise control, and areas with high ambient temperatures. Its design advantages in heat management and noise control enable it to meet more complex and high-demand cooling needs.

Integrated Laser Chiller: Suitable for small working environments, places requiring high mobility and quick deployment, and small to medium-sized laser equipment. Its compact and easy-to-install and maintain characteristics make it an ideal choice for small and flexible application scenarios.

Differences in Water Pump Selection for Split and Integrated Laser Chillers

Regardless of whether it is a split or integrated laser chiller, cooling circulation pump plays a crucial role. It is responsible for driving the operation of the water circulation system, ensuring that the cooling water can efficiently and stably provide a cooling effect for the laser equipment. The different designs of split and integrated laser chillers result in different demands and considerations for pump selection.

1. Split Laser Chiller

Flow and Head Requirements: The flow needs to consider the distance between the indoor and outdoor units, pipe length, pipe diameter, and hydraulic loss of the system. Since split chillers usually need to deliver coolant to more distant equipment, the pump head needs to be higher to overcome pipe resistance and height differences.

Power and Efficiency Requirements: Power is determined based on the required drive power of the pump, and it is necessary to choose pumps with as high efficiency as possible to improve energy utilization and reduce energy costs.

Installation Requirements: Since the indoor and outdoor units of the split chiller are relatively independent, the pump can be installed near the chiller or separately. The installation location of the pump should be chosen based on the actual situation.

Selection Considerations: Consider the connection method and material of the pipes between the indoor and outdoor units to ensure compatibility between the pump and the pipes. Additionally, consider the ease of maintenance and repair of the pump.

2. Integrated Laser Chiller

Flow and Head Requirements: The flow is determined based on the internal heat exchange efficiency and cooling requirements of the chiller. The length and complexity of the pipes are lower. The head is relatively low because the cooling water circulates inside the chiller and does not need to be lifted to a high position.

Power and Efficiency Requirements: Due to the compact structure, more attention is paid to the energy-saving and high efficiency of the pump to ensure the overall performance of the chiller.

Installation Requirements: Since all components are integrated into one cabinet, the pump needs to be small in size and highly integrated to achieve efficient cooling in limited space.

Selection Considerations: Consider the compatibility and matching of the pump with other internal components of the chiller to ensure the overall stability and reliability of the chiller.

Advantages of TOPSFLO Laser Chiller Water Pumps

TOPSFLO has provided cooling pump solutions for many high-end integrated laser chiller customers internationally. The industrial laser chiller cooling system from a well-known American chiller brand, adopts TOPSFLO high-flow DC circulation pumps with intelligent speed control functions, helping their chillers achieve precise flow control according to actual needs and meet different cooling capacity requirements.

TOPSFLO laser chiller cooling pumps have high-precision structural design, precise flow control, low noise and energy-saving, long life and durability, and safety without leaks. They have successfully replaced pumps from many well-known imported brands.

1. High-Precision Structural Design

TOPSFLO micro brushless DC water pumps are small in size, making them an ideal choice for integration into integrated laser chiller units. Their compact size ensures that the entire cooler remains lightweight and easy to move, promoting mobility and versatility.

2. Precise Flow Control

Using imported electronic components, they can be seamlessly integrated with control systems. This function can more accurately control the flow, reduce energy consumption, and meet the long-term working cooling effects of the equipment.

3. Low Noise and Energy-Saving

The core component, the rotor, is molded in a Sino-Japanese joint venture, with high initial mold costs ensuring industry-leading low noise levels and superior batch consistency.

4. Long Life and Durability

Using the most advanced ECM brushless DC motor, they are maintenance-free with a lifespan of up to 30,000 hours, ensuring continuous and stable water flow, contributing to the optimal performance of the chiller system.

5. Safety Without Leaks

Integrated advanced magnetic drive technology ensures sealing and leak-proof systems, eliminating the risk of water leakage and improving the safety and efficiency of the chiller unit. The magnetic drive mechanism also allows the pump to withstand high temperatures, ensuring reliable performance even in harsh environments.

Conclusion

TOPSFLO is one of the earliest manufacturers in China specializing in R&D and manufacturing micro pumps, and it is the only company focusing on high-end products, with 90% of its products exported to the European and American markets. The company has long-term stable cooperation with many world-renowned brands in Europe and America. The core components are mainly sourced from joint ventures and wholly foreign-owned enterprises in the industry, and the manufacturing equipment is mainly imported equipment to ensure the stability of the manufacturing process and craftsmanship. The precision and reliability of product components remain at the leading level among domestic peers. If you want to learn more about cooling circulation pumps for integrated laser chillers, please feel free to contact our sales engineers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

youtube

#dcwaterpump#waterpump#micropump#coolingwaterpump#liquid cooling#coolingpump#water chiller#lasercoolingpump#laser chiller pump#chiller cooling pump#chillerpump#watercoolingpump

0 notes

Text

The Versatility and Precision of the Signvec CO2 Laser Marking Machine

The world of industrial manufacturing and personalized engraving has seen a remarkable evolution with the introduction of CO2 laser technology. Signvec Technology, a leader in laser engraving, cutting, and marking solutions, has brought its extensive expertise into the development of high-precision CO2 laser marking machines. This technology has become an indispensable tool for various industries, providing unparalleled accuracy, efficiency, and flexibility for marking and cutting non-metallic materials. The Signvec CO2 laser marking machine stands out as an innovative solution for industries requiring high-quality output and long-lasting performance.

CO2 Laser Marker: A Revolution in Marking Solutions

CO2 laser markers are widely used for marking non-metallic materials such as rubber, leather, wood, PVC, bamboo, acrylic sheets, and more. This flexibility makes CO2 laser markers the go-to solution for industries that need to label, engrave, or cut soft materials with precision. Whether it is a simple engraving on leather or a complex design on bamboo, the CO2 laser marker provides crisp, clear, and high-quality marks.

One of the key advantages of CO2 laser markers is their ability to create intricate and detailed designs on soft materials. Industries such as wedding and greeting card manufacturers have adopted CO2 laser technology to create hollow-out designs on cards. This capability adds a unique aesthetic touch, offering more creative freedom for designs that capture the attention of consumers. Moreover, CO2 laser markers are essential in industries such as packaging, where they are used to mark production dates and other vital information on product packaging. These markers deliver consistent and readable marks, ensuring that products meet industry standards for traceability and compliance.

CO2 Laser Cutting Machine: Customization at its Best

The CO2 laser cutting machines by Signvec are designed to offer customers a high degree of customization, allowing businesses to create a machine that fits their specific needs and branding. With over 20 years of experience in the laser industry and more than a decade in R&D and manufacturing of laser cutting machines, Signvec has earned a reputation for delivering reliable, high-quality laser systems.

The CO2 laser cutting machines are equipped with an intensive fuselage design and come with built-in features such as water chillers, air blowers, and air compressors, providing customers with a comprehensive system that meets all of their cutting needs. This integration ensures that the machine operates smoothly, even during extended periods of use. For businesses operating internationally, Signvec offers professional technical services, giving foreign dealers peace of mind by ensuring that any potential issues are quickly resolved.

The laser cutting machines are based on ultra-stable laser components and feature a modular design for the high-speed motion system. This modularity allows customers to select the right components for their specific applications, further enhancing the versatility of the machine. Whether cutting leather, garments, or paper, these machines provide the precision and consistency that businesses require to meet production demands.

Key Models of CO2 Laser Cutting Machines

Signvec Technology has a range of CO2 laser cutting machines designed for different applications, including:

Laser Cutting Machine LC6090

The LC6090 model is ideal for cutting a wide variety of non-metal materials, including wood, organic glass, crystal, plastic, garments, paper, leather, rubber, ceramic, and glass. This machine is a versatile option for industries that need to cut different types of materials, and its high precision ensures smooth edges without any sawtooth effects. The continuous curve cutting method enables faster cutting speeds without sacrificing quality.

CCD Laser Cutting Machine LC6090C

The LC6090C is equipped with a 500-megapixel high-precision visual recognition function, making it perfect for auto-recognition cutting of large-format embroidery labels, craft slippers, and plush toy components. This machine features various recognition models such as cutting with featured point positions, figure picking of designs, and cutting with mark point positioning. The advanced recognition capabilities ensure fast and accurate cutting for complex and intricate designs, making it one of the most advanced laser cutting machines available today.

Laser Cutting Machine LC1390

The LC1390 model features a unique deceleration design that ensures the mechanical system moves smoothly and stably. This machine is engineered for precision, and the edge of the cutting is smooth with no sawtooth. The software utilized in this model adopts a continuous curve cutting method, which significantly increases the cutting speed, making it an efficient solution for businesses with high output demands.

Laser Cutting Machine LC1390N

The LC1390N is configured with imported double guide rails, providing a smooth running operation with seamless incisions. This machine incorporates a three-axis drive and precision synchronous belt drive, delivering high-speed and high-precision cutting. Its cutting accuracy and speed make it ideal for industries requiring detailed and efficient cutting for production runs.

Conclusion: The Signvec Advantage

With its broad range of CO2 laser marking and cutting machines, Signvec Technology offers unparalleled solutions for industries that demand precision, reliability, and efficiency. Whether you are a manufacturer needing to mark production dates on packaging or a designer looking to create intricate designs on soft materials, the Signvec CO2 laser machines provide the versatility and accuracy required to achieve superior results. Backed by decades of experience and a commitment to innovation, Signvec remains at the forefront of the laser marking and cutting industry, delivering solutions that meet the diverse needs of its customers worldwide.

#Cnc Laser Cutting Machine in Singapore#Cnc Laser Cutter Singapore#Laser Cutter#Laser Cutting Machine

0 notes

Text

Some common types of laser parts

Laser systems are composed of various laser parts that work together to produce, manipulate, and direct laser beams. Here are some common types of laser parts:

Laser Resonator: This is the optical cavity that forms the core of a laser system. It includes mirrors or other reflective surfaces that help to amplify the laser beam through multiple passes.

Gain Medium: This is the material that actually produces the laser light through a process of stimulated emission. It can be a solid (like in a ruby or Nd:YAG laser), a gas (like in a CO2 laser), a liquid (like in a dye laser), or a semiconductor (like in a diode laser).

Pump Source: This is the energy source that excites the gain medium to produce laser light. It can be an electric current, a flash lamp, or another laser.

Optical Components:

Lenses: Used to focus or diverge the laser beam.

Beam Expanders: Used to increase the diameter of the laser beam.

Mirrors: Used to direct or reflect the laser beam, often coated to maximize reflectivity at the laser's wavelength.

Windows: Transparent materials that allow the laser beam to pass through while protecting the laser cavity from the environment.

Polarizers: Used to select the polarization state of the laser beam.

Waveplates: Used to manipulate the phase and amplitude of different polarization components of the laser beam.

Laser Diodes: These are semiconductor devices that emit coherent light when an electric current passes through them. They are used in many types of lasers, including direct-diode lasers and as pump sources for solid-state lasers.

Q-Switch: A device used to control the timing of the laser pulse, allowing for the production of high peak power pulses.

Mode-Locking Devices: These are used to produce very short pulses by causing the laser to lase in many longitudinal modes simultaneously.

Amplifiers: Used to increase the power of a laser beam without changing its characteristics.

Attenuators: Devices that reduce the power of a laser beam, often used for safety purposes.

Scanners and Deflectors: These are used to direct the laser beam in a specific pattern or to a specific location, often in laser marking or cutting applications.

Cooling Systems: Lasers, especially high-power ones, require cooling to prevent overheating. This can be done with water-cooled chillers, air cooling, or thermoelectric coolers.

Control Systems: These include the hardware and software used to operate the laser, such as power supplies, computer interfaces, and motion control systems.

Safety Equipment: Including safety goggles, beam dumps (to absorb excess laser light), and interlock systems to ensure the laser is not accidentally operated when the protective covers are open.

Laser Safety Shutters: Automatically controlled shutters that can block the laser beam in case of an emergency or when maintenance is being performed.

Power Meters and Energy Meters: Devices used to measure the power or energy of the laser beam, which is important for process control and safety.

These are just a few examples of the many laser parts that can be found in a laser system, and the specific components will vary depending on the type of laser and its intended application.

0 notes

Text

Commonly used to cool products and machinery, water chillers are used in a variety of applications including injection molding, tool and die cutting, food and beverage, chemical, laser, machine tools, semi-conductors and more. Reynold India is one of the leading chiller manufacturers that are helping to build the prosperity of this country, and we are recognized as Industrial Water Chiller Manufacturers in India. Similarly, water chiller manufacturers and packaged drinking water chiller makers are referred to as water chiller manufacturers, air chillers, and so on.

0 notes

Text

Why Industrial Chillers are Essential for UAE Industries

Industrial chillers are used to chill industrial equipment or processing. They are applications used to pump cooled water or other liquid through an industrial process such as laser welding, concrete batching, machine tooling, chemical processing, plastic injection and blow molding. Industrial chillers maintain temperature control of the equipment to save production time, increase production quality and avoid sudden breakdowns. This type of technology is necessary for particular industry applications to prevent heat damage to the manufacturing system during production.

Industrial chiller, is a specialized category of equipment, sometimes referred to as a chiller air cooled or chiller water cooled. This cooling system is extremely important in the food and beverage processing industry, vacuum systems, x-ray diffraction, power generation stations, analytical equipment, semiconductors, gas cooling as well as MRI machines and lasers. Industrial chillers are specifically engineered to prevent downtime during the production process.

Industrial water chillers are designed to assist in the creation of a safe, smooth and efficient application when it comes to temperature control. Whether using an air or water industrial chiller, the overall costs in energy can be significantly reduced benefiting not only the organization but the impact on the environment is greatly reduced as well. Industrial water chillers come in either central chillers for large plant environments or portable industrial chillers for precision applications. Portable industrial chillers on wheels are a convenient and cost effective way to ensure temperature regulation on sensitive applications that need closer attention to prevent unexpected problems like critical government communication heat loads.

In specific industries where cooling is required in the manufacturing or storage of products, a chiller is the solution for stability of production. Grocery distribution warehouses, fruit vegetable storage and loading docks all depend on industrial chillers for the preservation of their products.

Our skilled engineers are always here to help in various cooling system requirements to ensure stable cooling and high performance.

Our industrial chiller lines can support various industrial processes but not limited to those applications, so if you have any question about cooling, get in contact with us and we will get back to you with reliable cooling solutions.

Industrial Chiller Types

Air-Cooled Chillers: Dissipate heat by using the surrounding air. ideal for settings with limited or expensive water resources.

Water-Cooled Chillers: Displace heat with water by using a cooling tower. more efficiency than air-cooled chillers, particularly in warm regions.

Evaporative Condensed Chillers: Combining water and air cooling, evaporative condensed chillers can provide great efficiency in certain applications.

Applications

Plastic Industry: The plastics industry uses cooling molds and machinery to improve production speed and product quality.

Food and Beverage Industry: Keeping production, storage, and transit areas at safe temperatures is the responsibility of the food and beverage industry.

Pharmaceuticals: Accurate temperature regulation throughout the production and storage of medications.

HVAC systems: Supplying big business and industrial facilities with reliable cooling.

Laser cutting: Maintaining the ideal temperature for laser equipment to guarantee accuracy and effectiveness.

Advantages

Energy Efficiency: Newer chillers are made to use less energy, which lowers their running expenses.

Reliability: Designed to run continuously with little maintenance and downtime.

Flexibility: Offered in a range of configurations to accommodate diverse industry requirements and scales.

Selecting the Appropriate Chiller

Think about things like chilling capacity, energy efficiency, installation space, and particular process needs when choosing an industrial chiller. Finding the ideal chiller type and configuration for your requirements might be facilitated by consulting with an expert.

Visit MTECH CHILLER for more thorough details and expert advice on choosing and setting up industrial chillers.

1 note

·

View note

Text

What Is Bottled Water Production Process Flow Chart

Written by: John

Checked by: Mark

June 28, 2024

Home - Water filling machine technology - What is bottled water production process flow chart

Share This Post

Table of Contents

What is The Bottled Water Production Flow Chart

Raw Water Sourcing and Pumping

Mechanical Filtration

Carbon Filtration

Reverse Osmosis (RO) System

Bottle Blowing

Bottle Washing and Sterilization

Filling and Capping

Inspection and Packaging

1) Raw water pump

2) Mechanical filter

3) Activated carbon filters

4) Water softener system

5) Precision filters

6) Reverse osmosis system

Types of Equipment

Maintenance and Considerations:

1) Air conveyor system

2) Water bottling machine

3) Cap feeder machine

4) Fully automatic bottle blow dryer

5) Laser coding machine

6) Self-adhesive labeler machine

Importance in Bottled Water Production

Types of Self-Adhesive Labeler Equipment

Maintenance and Considerations:

7) Shrink sleeve label machine

8) Shrink wrap machine

9) Pallet wrapping machine

1) Fully automatic bottle blow molding machine

2)Semi-automatic blow molder

3) Air compressor

4) Bottle blowing machine water chiller

5) Blowing machine air dryer

6) Air filter of bottle blowing machine

7) Mold temperature controller

8) Air storage tank of bottle blow molding machine

Conclusion

How many types of water bottling equipment are there?

The 9 Secrets To Effective BLOW MOULDER

Complete Production Process Flow Chart Of Bottled Water Production As Below

Section 1

Water Treatment

Raw Water Pump

Mechanical Filter

Activated Carbon Filters

Water softener system

Precision filters

Reverse osmosis system

Ozone system

UV light sterilizer

Section 2

Filling & Packaging

Air conveyor

Water bottling machine

Cap feeder machine

Bottle blow dryer

Laser coding machine

Self-adhesive labeler machine

Shrink sleeve label machine

Shrink wrap machine

Pallet wrapping machine

Section 3

Bottle Blowing

Automatic bottle blow molding machine

Semi-automatic blow molding machine

Air compressor

Water chiller

Air dryer

Air filter

Mold temperature controller

Air storage tankororCap FeederLight Inspection PanelBottle DryerSleeve Shrink LabelerShrink Wrapping Machine

Film Stretch Pallet Wrapper

Code Inkjet Printer

Mineral Water Filler

Auto bottle blower

Semi-auto bottle blowerSelf-adhesive LabelerOPP Hot Melt Labeleror

Water Storage Tank

RO water treatment system

High pressure compressor

Air storage tank

Air filter

air dryer

Air filter

water cooler

High pressure compressor

Air filter

air dryer

Air filter

Auto Unscrambler

Semi-auto Unscrambler

BOTTLE BLOWING SYSTEM

WATER TREATMENT SYSTEM

FILLING AND PACKAGING LINE

What is The Bottled Water Production Flow Chart

The production process of bottled water is comprehensive, involving multiple stages to ensure the highest quality and safety standards. This detailed guide covers each critical step, from water treatment to bottling and packaging, and finally to the blowing line and auxiliary equipment. Here’s an overview of the main steps:

Raw Water Sourcing and Pumping

The process begins with sourcing raw water, which is then pumped into the filtration system.

The raw water pump provides the necessary pressurization for the filtration equipment.

Mechanical Filtration

A mechanical filter removes impurities such as manganese, iron, and suspended particles larger than 20 microns.

This step helps to prepare the water for further purification.

Carbon Filtration

The carbon filter further purifies the water by removing organic compounds, chlorine, and other contaminants.

This stage helps to improve the taste and odor of the water.

Reverse Osmosis (RO) System

The RO system removes dissolved salts, minerals, and microorganisms, producing high-purity water.

This step ensures the water meets the required quality standards.

Bottle Blowing

The PET preforms are heated and then blown into the desired bottle shape using a blow molding machine.

The blow molding machine combines preform heating and bottle blowing in an automated process.

Precise control of parameters like stretching speed, pressure, and timing ensures proper material distribution and bottle quality.

Bottle Washing and Sterilization

The bottles are cleaned and disinfected before filling to ensure they are free from any contaminants.

Filling and Capping

The bottles are automatically filled and capped to maintain the integrity of the product.

Inspection and Packaging

The filled bottles are inspected for any defects.

The approved bottles are then packaged for distribution.

The entire production process is designed to ensure the safety and quality of the bottled water in compliance with relevant regulations.

01.

Water Treatment

1) Raw water pump

Description: The raw water pump is a critical component that provides the necessary pressure and flow for the pretreatment equipment and the reverse osmosis (RO) system.

Working Principle: The pump pressurizes incoming water to ensure a stable and sufficient inlet pressure for sand filters, carbon filters, and fine filters. This pressure must exceed the permeation resistance of the mechanical filters, enabling efficient water passage and providing a sufficient source for the RO system.

Key Functions:

Pressurizes raw water.

Ensures stable inlet pressure.

Overcomes permeation resistance.

Provides a reliable water supply for the RO system.

Applications: Bottled water production, municipal water treatment, industrial water purification, desalination and seawater treatment.

Importance in Bottled Water Production: Essential for the efficiency and effectiveness of the entire water treatment process, ensuring the quality and uniformity of the packaged water produced.

Types of Equipment:Equipment TypeDescriptionCentrifugal PumpCommonly used for raw water pressurization, providing high flow rates and moderate pressure.Positive Displacement PumpSuitable for high-pressure applications, such as RO systems.Submersible PumpInstalled directly in the water source, used for drawing water from wells or surface water.Booster PumpInstalled downstream of the pretreatment system to further increase pressure for the RO system.

Maintenance and Considerations:

Regular inspection and maintenance, including cleaning, lubrication, and impeller replacement.

Monitoring of pump performance, including flow rate, pressure, and energy consumption.

Proper sizing of the pump based on the system’s water demand and pressure requirements.

Ensuring the pump is compatible with the water quality and any potential corrosive or abrasive substances.

2) Mechanical filter

Description: Also known as the quartz sand filter, this multi-layered filtration device removes manganese, iron, heavy metals, silt, rust, colloidal matter, and suspended particles larger than 20 microns from raw water.

Working Principle: Performs backwashing and forward washing to ensure consistent water output and prolong equipment lifespan.

Key Functions:

Removes mechanical impurities, colloids, microorganisms, organic matter, and active chlorine from raw water.

Provides pre-treatment for downstream processes like reverse osmosis and ion exchange.

Improves water quality and extends the lifespan of water treatment systems.

Applications: Bottled water production, municipal water treatment, industrial water purification, surface and groundwater treatment.

Importance in Bottled Water Production: Vital in the pretreatment phase by removing turbidity, suspended solids, and other contaminants, ensuring the quality and consistency of the final product and protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter CartridgePE, steel-lined rubber, steel-sprayed plastic, stainless steel, fiberglass-reinforced plastic.Filter MediaQuartz sand, activated carbon, manganese sand, anthracite.Filter ConfigurationSingle-flow, double-flow.

Maintenance and Considerations:

Regular backwashing and forward washing to maintain filter performance.

Monitoring pressure drop and turbidity levels to determine filter element replacement.

Proper selection of filter media based on water quality and treatment requirements.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

3) Activated carbon filters

Description: Activated carbon filters effectively remove residual chlorine, organic molecules, colloids, pigments, and heavy metal ions, ensuring water quality and extending downstream equipment lifespan.

Working Principle: Operate on the principle of adsorption, capturing contaminants on activated carbon particles.

Key Functions:

Removal of residual chlorine to protect downstream equipment.

Adsorption of organic molecules, colloids, pigments, and heavy metals.

Reduction of COD and SDI values to improve water quality.

Extending the lifespan of RO membranes and ion exchange resins.

Applications: Pretreatment for reverse osmosis and desalination systems, drinking water purification, industrial water treatment, wastewater treatment.

Importance in Bottled Water Production: Essential in the pretreatment process, ensuring the quality and safety of the final product while protecting the RO system and other downstream equipment.

Types of Equipment:Equipment TypeDescriptionCarbon TypePowdered activated carbon, granular activated carbon.Filter ConfigurationSingle-layer, multi-layer.Housing MaterialStainless steel, fiberglass-reinforced plastic.

Maintenance and Considerations:

Regular replacement of activated carbon and sponge layers.

Monitoring pressure drop and water quality to determine replacement frequency.

Proper cleaning of new activated carbon before installation.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

4) Water softener system

Description: The automatic water softener system removes hardness minerals, such as calcium and magnesium, through ion exchange.

Working Principle: It replaces calcium and magnesium ions with sodium ions, softening the water and preventing scale buildup in plumbing and equipment.

Key Functions:

Removes hardness minerals.

Prevents scale buildup.

Improves the efficiency and lifespan of reverse osmosis systems.

Applications: Residential and commercial water treatment, boiler and cooling tower water treatment, laundry and dishwashing applications, food and beverage processing.

Importance in Bottled Water Production: Maintains the quality and uniformity of the end product by preventing scale buildup in the RO system, extending membrane lifespan and improving water purification efficiency.

Types of Equipment:Equipment TypeDescriptionSoftening TankContains the ion exchange resin.ControllerManages system operation.Salt Tank and ValveProvides brine solution for resin regeneration.

Maintenance and Considerations:

Regular regeneration of the resin bed to maintain softening capacity.

Monitoring salt levels in the salt tank.

Periodic cleaning and maintenance of system components.

Proper sizing based on water usage and hardness levels.

5) Precision filters

Description: High-performance filtration devices that remove fine particles, impurities, and contaminants from various liquids using different filter elements.

Working Principle: Use various filter media and design processes to meet specific effluent water quality requirements, with filtration precisions ranging from 0.5 to 10 microns.

Key Functions:

Filtration, clarification, and purification of liquids.

Removal of fine particles, impurities, and contaminants.

Ensuring the safety and quality of downstream water and membrane elements.

Applications: Pharmaceutical, chemical, food and beverage industries, water treatment, brewing, petroleum, printing, and dyeing.

Importance in Bottled Water Production: Maintains the purity and safety of the final product by removing fine particles and contaminants, protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter HousingPrimarily made of stainless steel (304 or 316), flange or clamp type.Filter ElementsPP meltblown, wire-wound, activated carbon, etc.Filter ConfigurationSingle or multiple elements, depending on processing capacity.

Maintenance and Considerations:

Regular replacement of filter elements based on usage and pressure drop.

Proper selection of filter media and precision based on application requirements.

Cleaning and maintenance of filter housing and components.

Monitoring flow rate, pressure drop, and effluent water quality.

6) Reverse osmosis system

Description: Highly effective water purification technology that uses selective permeation through a semi-permeable membrane to remove dissolved salts, colloids, microorganisms, and organic matter, producing high-purity water.

Working Principle: Uses a high-pressure pump to force raw water through the RO membrane, allowing only water molecules to pass through while retaining other contaminants.

Key Functions:

Removes dissolved salts and impurities.

Produces high-purity water.

Energy-efficient and low-pollution technology.

Applications: Bottled water production, pharmaceutical and electronics manufacturing, seawater and brackish water desalination, industrial water purification.

Importance in Bottled Water Production: Ensures the quality and safety of the final product by eliminating various impurities, adhering to strict industry standards.

Types of Equipment

RO Membrane TypeDescriptionBrackish Water RO (BWRO)– Used for feedwaters with relatively low total dissolved solids (TDS) compared to seawater – Require lower operating pressure (125-250 psi) – Maintain high salt rejection (>95-99%) – Typical recovery rates of ≥75%Seawater RO (SWRO)– Used for seawater or feedwaters with high TDS (35,000 mg/L or greater) – Require much higher operating pressure (800-1200 psi) – Maintain very high salt rejection (>99.5%) – Typical recovery rates of 50-70%Nanofiltration (NF)– Similar to RO but has lower rejection of monovalent ions like sodium chloride – Highly effective at rejecting divalent ions like magnesium sulfate (>97%) – Also rejects organic macromolecules to varying degrees – Operates at lower pressures than traditional RO membranesThin-Film Composite (TFC)– Most common type of industrial RO membrane – Consists of a polyamide top barrier layer, polysulfone support layer, and polyester layer – Prevents molecules greater than 100 molecular weight from passing throughCellulose Triacetate (CTA)– Alternative to TFC membranes – More resistant to chlorine but less effective at salt rejection

This table covers the key characteristics and applications of the main types of industrial RO membranes, including brackish water, seawater, nanofiltration, and the common membrane materials used (TFC and CTA).

Maintenance and Considerations:

Regular cleaning and maintenance of the RO membrane to prevent fouling and scaling.

Monitoring water quality parameters such as TDS, conductivity, and SDI.

Proper selection of membrane elements based on raw water characteristics and production needs.

Ensuring the RO system is sized correctly to handle the required water flow and quality.

02.

Filling & Packaging

1) Air conveyor system

Description: Uses fan-generated wind energy to transport empty PET containers from the bottle blowing machine to the filling or labeling machine.

Working Principle: Wind energy propels the containers through ducts with air storage capabilities, ensuring a stable and continuous flow.

Key Functions:

Efficient transportation of empty PET containers.

Compatibility with high-speed filling and labeling machines.

Gentle handling of containers to prevent damage.

Flexible layout options for horizontal, vertical, and curved conveyance.

Applications: Bottled water and beverage production, industries requiring the transportation of empty PET containers.

Types of Equipment:Equipment TypeDescriptionFan Power UnitProvides the wind energy for bottle conveyance.Air DuctStraight, turning, and up-and-down sections made of 304 stainless steel.Bottle Handling DevicesDividing, merging, and dropping mechanisms.Bottle Clamping DevicesEnsures stable bottle transport.

Maintenance and Considerations:

Regular cleaning and inspection of the air duct and bottle handling components.

Monitoring the fan performance and airflow to maintain optimal conveyor operation.

Adjustments to accommodate changes in bottle size or production requirements.

Ensuring the system is properly integrated with the overall bottling line.

2) Water bottling machine

Description: The PET water filling machine automates washing, filling, capping, and other functions with high precision, using advanced electrical components and high-quality stainless steel parts.

Working Principle: A suspended filling equipment design allows operation with various bottle types, sizes, and thicknesses, controlled automatically.

Key Functions:

Bottle rinsing.

Bottle filling.

Screw capping.

Cap sorting.

Applications: Filling production of 200-2000ml PET water bottles, suitable for a wide range of bottle types and sizes.

Types of Equipment:Machine TypeDescriptionLiquid Bottling MachinesDesigned to bottle liquids, including water, using volume or weight measurement to fill bottles.Rotary Bottling MachinesHave a rotary design where bottles move in a circular motion through the filling, capping, and sealing process.Linear Bottling MachinesHave a linear design where bottles move in a straight line through the different filling, capping, and sealing stations.Fully Automatic Bottling MachinesAutomate the entire bottling process from bottle rinsing to capping, requiring only a few operators.Semi-Automatic Bottling MachinesRequire more manual operation, with steps like bottle loading and unloading done by workers.Gravity, Pressure, and Vacuum Overflow Bottle FillersSpecific types of liquid filling mechanisms used in water bottling machines.Pump FillersAnother type of liquid filling mechanism used in water bottling machines.

Maintenance and Considerations:

Regular cleaning and maintenance of the filling valves and other components in contact with water.

Proper adjustment and calibration of the bottle handling and capping mechanisms.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

3) Cap feeder machine

Description: The cap feeder machine sorts and feeds caps automatically, using standardized and interchangeable parts.

Working Principle: It arranges caps using their center of gravity, ensuring smooth output.

Key Functions:

Automatic cap feeding and arrangement.

Automatic cap removal.

Applications: Can be used with three-in-one filling machines or separate capping machines, suitable for various types of caps.

Types of Equipment:Equipment TypeDescriptionThree-Screw Cap Sorting and Capping MachineDesigned based on the characteristics of three-screw caps, with different weights on both sides.Other Capping MachinesCan be provided for plastic screw caps, aluminum caps, crown caps, and other capping applications.

Maintenance and Considerations:

Regular cleaning and maintenance of the cap sorting and feeding mechanisms.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

Adjusting the production capacity based on the specifications and characteristics of the product.

4) Fully automatic bottle blow dryer

Description: The blow dryer uses high-pressure air to dry water droplets on bottle surfaces, preparing them for subsequent processing steps like coding and labeling.

Working Principle: It uses wind instead of high temperature, suitable for plastic bottles that are not heat-resistant.

Key Functions:

Dries water droplets using high-pressure air.

Facilitates coding, labeling, and packaging.

Applications: Suitable for drying various types of plastic bottles, can be used in water bottling production lines.

Components of Equipment:ComponentDescriptionAir KnifeGenerates high-pressure air flow to dry the bottles.Vortex FansHigh-powered vortex fans produce the necessary air volume.FrameMade of stainless steel and glass, providing a sturdy structure.Heating SystemHigh-pressure vortex pump generates heat during operation.Electrical ControlsIncludes control box for easy operation and monitoring.ConveyorAutomatically feeds the containers through the drying chamber.SensorsDetect the presence of containers and control the drying cycle.

Maintenance and Considerations:

Regular cleaning and maintenance of the air knives and air intake/exhaust components.

Monitoring and addressing any issues with the electrical and control systems.

Ensuring the availability of spare parts and trained technicians for timely repairs.

Adjusting the air knife positioning and airflow based on the bottle dimensions and drying requirements.

5) Laser coding machine

Description: The laser coding machine applies high-quality, permanent text, logos, and barcodes onto bottles and packaging materials.

Working Principle: A focused beam of light precisely etches or marks the desired information onto the target surface.

Key Functions:

Applies text, logos, and barcodes.

Provides high-resolution, permanent markings.

Applications: Bottled water production, canned and packaged food and beverages, pharmaceutical and medical device packaging, consumer electronics and industrial product labeling.

Types of Equipment:Equipment TypeDescriptionCO2 Laser CodersUse a carbon dioxide laser to mark on a variety of materials, including plastic, glass, and metal.Fiber Laser CodersEmploy a fiber-optic laser for high-speed, high-contrast coding on a wide range of substrates.UV Laser CodersUtilize ultraviolet laser technology to mark on sensitive materials like plastics and films.Hybrid Laser CodersCombine multiple laser technologies to offer versatile coding capabilities.

Maintenance and Considerations:

Regular cleaning and maintenance of the laser optics and components.

Proper alignment and calibration of the laser system.

Ensuring adequate ventilation and cooling for the laser unit.

Adherence to safety protocols and guidelines for laser operation.

Consideration of substrate compatibility and pre-treatment requirements.

6) Self-adhesive labeler machine

Description: The self-adhesive labeler machine automates label application onto bottles with high precision.

Working Principle: It uses mechanical, electrical, and software components to align and apply labels accurately.

Key Functions:

Accurate label positioning and alignment.

High-speed label application.

Adjustable label size and placement.

Applications: Bottled water production, beverage bottling, personal care and cosmetic products, pharmaceutical packaging.

Importance in Bottled Water Production

In the containerd water industry, the self-adhesive labeler machine plays a crucial role in ensuring consistent, high-quality labeling of containers. Accurate and efficient label application enhances the visual appeal of the product, reinforces brand identity, and provides important information to consumers.

Types of Self-Adhesive Labeler Equipment

EquipmentDescriptionRotary LabelerApplies labels to containers as they rotate on a turntableIn-Line LabelerApplies labels to bottles moving along a conveyor beltWrap-Around LabelerApplies labels that wrap around the entire bottle circumferencePrint-and-Apply LabelerIntegrates label printing and application in a single machine

Maintenance and Considerations:

Regular cleaning and maintenance of label feeding and application components.

Ensuring proper label stock compatibility and quality.

Monitoring label alignment and adjusting as needed.

Implementing preventive maintenance schedules.

Training operators on proper machine operation and troubleshooting.

7) Shrink sleeve label machine

Description: The shrink sleeve label machine applies and shrinks sleeve labels onto bottles, providing 360-degree coverage and enhanced branding opportunities.

Working Principle: Bottles are fed into the machine, where pre-cut sleeve labels are positioned and heat-shrunk onto the bottle surfaces.

Key Functions:

Accurate sleeve label positioning and alignment.

Precise heat application for shrinking labels.

Adjustable label size and bottle diameter compatibility.

Integrated label feeding and application.

Seamless integration with bottling line.

Applications: Bottled water production, beverage bottling, personal care and cosmetic products, pharmaceutical packaging.

Types of Equipment:Equipment TypeDescriptionContinuous Motion Shrink Sleeve LabelerApplies labels to bottles moving on a conveyor belt.Intermittent Motion Shrink Sleeve LabelerApplies labels to stationary bottles.Sleeve ApplicatorApplies pre-cut sleeve labels onto bottles.Shrink TunnelProvides controlled heat to shrink and secure sleeve labels.

Maintenance and Considerations:

Regular cleaning and maintenance of label feeding and application components.

Ensuring proper label stock compatibility and quality.

Monitoring label alignment and adjusting as needed.

Maintaining optimal heat settings for effective shrinking.

Implementing preventive maintenance schedules.

Training operators on proper machine operation and troubleshooting.

8) Shrink wrap machine

Description: The shrink wrap machine wraps bottled beverages in shrink film, using a constant temperature PE shrinking furnace to achieve the packaging effect.

Working Principle: The machine uses steel and stainless steel components with a compact design, incorporating electrical and pneumatic components from renowned brands for efficient operation.

Key Functions:

Automatic wrapping, sealing, cutting, heat shrinking, and cooling.

Suitable for shrink films like PE and PVC.

Provides a neat, compact, and secure packaging of the bottles.

Applications: Packaging of bottled beverages such as purified water and mineral water, cans and glass bottles, various food, pharmaceutical, and chemical products.

Types of Equipment:Machine TypeDescriptionThroughputSuitable ProductsAutomatic Bottle Stack Sleeve Shrink Wrapping MachineDesigned for automatic bottle stacking, film feeding, sealing, and shrinking.8-30 bottles/minuteBottles, cans, glass bottlesContinuous Motion Shrink Wrapping MachineUses a direct feeding method with no length limit for packaged items.Up to 120 bottles/minuteLong-length objects, beverages, beer, mineral water, cans, glass bottlesSemi-Automatic Shrink Wrapper with Shrink TunnelProvides a reliable solution for high-quality shrink-wrapped packs.10,800 bottles/hourBottles, cans, and other containersIntermittent Motion Tray Shrink Wrapper with Integral Shrink TunnelSuitable for wrapping bottles, cans, and other containers on a tray or with a cardboard pad.6-20 bottles/minuteCylindrical, flat, square, and complex-shaped containers

Maintenance and Considerations:

Regular maintenance of the machine components, including cleaning and lubrication.

Proper storage and handling of the shrink film to ensure its quality and performance.

Monitoring of the temperature and air circulation in the shrinking furnace to ensure consistent and effective shrinking.

Adjusting the machine settings to accommodate different bottle sizes and packaging requirements.

Ensuring the proper alignment and functioning of the conveyor belt and bottle separating board.

9) Pallet wrapping machine

Description: The pallet wrapping machine wraps goods stacked on pallets with LLDPE stretch film, providing stability, protection, and waterproofing during storage and transportation.

Working Principle: Controlled by a PLC programmable controller, it offers adjustable film tension, automatic photoelectric tracking, and multifunctional packaging modes.

Key Functions:

Automatic wrapping of palletized goods.

Adjustable film tension for optimized packaging.

Partially enhanced wrapping for reinforced top/bottom.

Manual/automatic switching and automatic protection.

Multifunctional packaging modes (standard, quasi, single-layer, enhanced).

Automatic reset to initial position after each use.

Dynamic pre-stretching film frame system.

Applications: Food and beverage production, irrigation equipment, paper manufacturing, dyes and chemicals, glass and ceramics, electro-mechanical castings.

Types of Equipment:Equipment TypeDescriptionTray-type Pallet Wrapping MachineWraps palletized goods using LLDPE stretch film.Top-pressure Resistance-stretch Pallet Wrapping MachineApplies top pressure during wrapping.Pre-tension Automatic Pallet Wrapping MachineAutomatically pre-tensions the stretch film.

Maintenance and Considerations:

Regular inspection and maintenance of machine components.

Proper storage and handling of stretch film.

Monitoring of film tension and wrapping patterns.

Adjusting settings for different pallet sizes and products.

Ensuring proper alignment of sensors and lifting mechanisms.

Maintaining a clean work environment.

03.

Blowing Line

1) Fully automatic bottle blow molding machine

Description: The fully automatic bottle blow molding machine is used to blow all kinds of plastic containers and beverage bottles using PET raw material.

Working Principle: The machine features a user-friendly interface, smooth operation, high and stable output, low energy consumption, and a high degree of automation. It uses a double toggle and primary link hinge mechanism with solid clamping force for stable and reliable blowing action.

Key Functions:

Automatic preform loading and feeding.

Precise temperature control and even heating of preforms.

Stable and fast mold clamping and bottle blowing.

Automatic bottle ejection and transfer to filling machine.

Integrated PLC control with automatic fault detection.

Applications: Production of water bottles, juice, soda, and other beverage bottles, plastic containers for food, cosmetics, and household products.

Types of Equipment:Machine TypeDescriptionLinear Stretch Blow Molding MachineUses linear motion to stretch and blow preforms into bottles. Cost-effective with a good balance of production speed and quality.Rotary Stretch Blow Molding MachineUses rotary motion to stretch and blow preforms. Faster production speed compared to linear machines. Can achieve higher quality bottles.

Maintenance and Considerations:

Regular inspection and maintenance of mold clamping, heating, and blowing components.

Proper storage and handling of the preform raw material.

Monitoring temperature control system and energy consumption.

Adjusting machine settings for different bottle sizes and production requirements.

Ensuring proper alignment and functioning of automatic feeding, ejection, and transfer systems.

2)Semi-automatic blow molder

Description: Semi-automatic blow molding machines are versatile equipment used for producing a variety of plastic bottles and containers.

Working Principle: These machines use a combination of manual and automated processes to blow mold plastic preforms into the desired bottle shapes.

Key Functions:

Preform heating and softening.

Mold clamping and bottle blowing.

Bottle ejection and trimming.

Applications: Beverage bottles (water, juice, soda, etc.), personal care bottles (shampoo, lotion, etc.), household chemical containers, pharmaceutical packaging.

Types of Equipment:FeatureManual Preform LoadingAutomated Preform LoadingPreform LoadingManual hand-feedingAutomatic preform insertionBottle RemovalManual removalManual removalEfficiencyLowHigherLabor Required1-2 workers1 workerCostVery lowModeratePreform HandlingRequires gloves for hot preformsAutomated preform handling

Maintenance and Considerations:

Regular cleaning and maintenance of molds and machine components.

Proper temperature and pressure control for consistent bottle quality.

Operator training for safe and efficient machine operation.

Consideration of energy efficiency and environmental impact.

3) Air compressor

Description: An air compressor converts power into potential energy stored in pressurized air.

Working Principle: It works by drawing in ambient air, compressing it to a higher pressure, and discharging the compressed air for various applications.

Key Functions:

Intake and compression of air.

Storage of compressed air.

Delivery of compressed air to end-use applications.

Applications: Powering pneumatic tools and equipment, inflating tires, spray painting, cleaning and drying, controlling and operating industrial machinery.

TypeDescriptionReciprocatingPiston-driven compressors that use a back-and-forth motion to compress air.Rotary ScrewUse two meshing helical screws to draw in and compress air.CentrifugalUse rotating impellers to draw in and accelerate air, increasing pressure.ScrollUse two spiral-shaped scrolls to compress air in a continuous process.

Maintenance and Considerations:

Regular filter and oil changes.

Monitoring for air leaks.

Proper sizing and selection for the application.

Ensuring adequate cooling and ventilation.

Adhering to safety protocols when operating.

4) Bottle blowing machine water chiller

Description: A water chiller regulates the temperature of the water used in the bottle blowing process.

Working Principle: The chiller circulates water through the bottle blowing mold to maintain a consistent temperature, ensuring proper formation and cooling of the plastic bottles.

Key Functions:

Temperature regulation of the bottle blowing mold.

Consistent cooling of the molded plastic bottles.

Efficient heat transfer from the hot mold to the circulating water.

Applications: Bottle blowing in PET, HDPE, and other plastic bottle production, cooling of molds in injection molding and extrusion blow molding processes, temperature control in various industrial cooling applications.

Types of Equipment:TypeDescriptionRecirculating ChillerContinuously circulates and cools a closed-loop water system.Inline ChillerCools water as it flows through the system, without a closed loop.Portable ChillerSelf-contained, mobile units for temporary or flexible cooling needs.Integrated ChillerBuilt-in to the bottle blowing machine for a compact, all-in-one solution.

Maintenance and Considerations:

Regular cleaning and maintenance of the water system.

Monitoring and adjusting water temperature and flow rate.

Ensuring proper ventilation and heat dissipation.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

Considering the cooling capacity and efficiency requirements for the specific bottle blowing application.

5) Blowing machine air dryer

Description: An air dryer removes moisture from the compressed air used in the bottle blowing process.

Working Principle: The air dryer uses various drying techniques, such as refrigeration or desiccant adsorption, to reduce the moisture content of the compressed air before it is used in the bottle blowing mold.

Key Functions:

Removal of water vapor from compressed air.

Preventing condensation and moisture buildup in the bottle blowing system.

Ensuring a consistent, dry air supply for the blowing process.

Applications: Bottle blowing in PET, HDPE, and other plastic bottle production, drying of compressed air for various industrial processes, preventing moisture-related issues in pneumatic equipment and tools.

Types of Air Dryers:TypeDescriptionRefrigerant DryerUses refrigeration to cool the air and condense water vapor.Desiccant DryerUtilizes a desiccant material to adsorb moisture from the air.Membrane DryerEmploys a semi-permeable membrane to selectively remove water vapor.Heatless DryerRegenerates the desiccant using a portion of the dried air.

Maintenance and Considerations:

Regular cleaning and replacement of filters and desiccant materials.

Monitoring and adjusting air flow and pressure.

Ensuring proper ventilation and heat dissipation.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

Considering the air flow and drying capacity requirements for the specific bottle blowing application.

6) Air filter of bottle blowing machine

Description: An air filter removes contaminants such as dust, oil, and moisture from the compressed air stream.

Working Principle: The air filter uses a combination of mechanical filtration, coalescence, and gravity separation to capture and remove harmful particles and liquids from the compressed air.

Key Functions:

Removal of solid particulates (dust, rust, etc.).

Separation of liquid water and oil droplets.

Providing clean, dry compressed air for downstream equipment.

Applications: Compressed air systems in industrial facilities, pneumatic tools and equipment, instrument air systems, bottling and packaging machinery, painting and coating applications.

Types of Air Filters:TypeDescriptionCoalescing FilterRemoves liquid water and oil droplets through coalescence.Particulate FilterCaptures solid particulates such as dust and rust.Combination FilterIntegrates both coalescing and particulate filtration.Desiccant FilterRemoves water vapor through adsorption on a desiccant material.

Maintenance and Considerations:

Regular inspection and replacement of filter elements.

Monitoring pressure drop across the filter.

Proper drainage of collected liquids.

Ensuring adequate air flow and system compatibility.

Adhering to manufacturer’s recommendations for maintenance and service intervals.

7) Mold temperature controller

Description: A mold temperature controller regulates the temperature of the mold in the bottle blowing process, ensuring proper appearance and quality of the final plastic bottles.

Working Principle: It maintains the mold at a constant, optimal temperature to prevent defects such as lack of gloss, deformation, bubbles, and uneven wall thickness.

Key Functions:

Precise temperature control and fast heating/cooling response.

Stable and accurate temperature maintenance within ±1°C.

Automatic temperature regulation and monitoring.

Liquid level alarm to prevent damage from low heat transfer fluid.

Applications: Plastic bottle manufacturing, other blow molding processes for plastic products.

Types of Equipment:EquipmentFeaturesHorizontal High-Temperature Resistant PumpStable flow, reliable performance.Stainless Steel Pipelines and Fuel TanksRust-resistant, long service life.Visualized Heat Transfer Oil Level TubeEasy to monitor oil level.Brand-Name Components (Omron, Fuji, LG, Schneider)Excellent performance, long lifespan.Imported Heating ComponentsSuperior quality and durability.

Maintenance and Considerations:

Regularly check and maintain the heat transfer fluid level.

Ensure proper insulation of pipelines to minimize heat loss.

Perform periodic cleaning and inspection of system components.

Monitor temperature control accuracy and make adjustments as needed.

Properly store and handle the heat transfer fluid to prevent contamination.

8) Air storage tank of bottle blow molding machine

Description: The air storage tank stores compressed air generated by the air compressor and provides a consistent and controlled supply of compressed air for the bottle blow molding process.

Working Principle: The tank stores pressurized air and releases it as needed to inflate the preform during the blow molding stage, shaping the bottle.

Key Functions:

Stores compressed air.

Ensures a consistent and reliable air supply.

Regulates air pressure and flow to the blow mold.

Applications: Bottle blow molding for water, beverages, and other liquid products, plastic container manufacturing, hollow plastic part production.

Types of Equipment:Equipment TypeDescriptionVertical Air Storage TankCompact design, suitable for limited space.Horizontal Air Storage TankLarger capacity, suitable for high-volume production.Stainless Steel Air Storage TankDurable, corrosion-resistant, suitable for food-grade applications.Aluminum Air Storage TankLightweight, suitable for mobile or portable applications.

Maintenance and Considerations:

Regular inspection and cleaning of the tank to prevent contamination.

Monitoring and maintaining proper air pressure levels.

Checking for leaks and ensuring airtight seals.

Replacing worn or damaged components as needed.

Adhering to the manufacturer’s recommended maintenance schedule.

04.

Conclusion

The production process of bottled water involves several intricate steps, from initial water treatment through bottling, packaging, and bottle blowing. Each stage requires specific equipment, regular maintenance, and careful monitoring to ensure the highest quality and safety standards are met. By following this detailed process flow, you can ensure efficient and effective bottled water production, meeting industry standards and consumer expectations.

For more detailed information, expert assistance, or to get quotes for your specific bottled water filling needs, feel free to get in touch with us through the contact form provided. We are here to help you achieve the best results in your bottled water production endeavors.

0 notes

Text

The Essential Parts of a Laser Cutter

Laser cutters are sophisticated machines used to cut and engrave various materials with high precision. To understand how these machines achieve such accuracy and efficiency, it's essential to explore their key components.

Laser Source: laser cutter parts source, such as a CO2 or fiber laser, generates the high-intensity beam required for cutting. The type and power of the laser source determine the materials it can cut and the thickness it can handle.

Laser Head: The laser head contains the optics that focus the laser beam onto the material. It is equipped with mirrors and lenses that direct and concentrate the beam, ensuring precise cutting.

Cutting Bed: The cutting bed is where the material is placed for processing. It often features a honeycomb or slat design to minimize reflections and support the material during cutting.

Motion System: The motion system includes motors, belts, and rails that move the laser head across the material. High-quality motion systems ensure smooth and accurate movement, crucial for detailed cuts.

Control System: The control system manages the laser cutter’s operations, including power settings, movement, and cutting parameters. Advanced control systems allow for automation and integration with CAD software.

Cooling System: To prevent overheating, laser cutters use cooling systems such as water chillers or air cooling units. Effective cooling ensures consistent performance and prolongs the lifespan of the laser components.

Exhaust System: Cutting materials with a laser generates smoke and debris. An efficient exhaust system removes these byproducts, keeping the workspace clean and maintaining air quality.

By understanding these essential parts, users can ensure proper maintenance and optimal operation of their laser cutters. Regular inspection and timely replacement of worn-out components can prevent downtime and enhance cutting performance.

0 notes

Text

Global Top 24 Companies Accounted for 42% of total Laboratory Chillers market (QYResearch, 2021)

Chillers generate chilled water, which is used to provide air conditioning in buildings. All building generate a lot of unwanted heat, whether is be solar heat gain from the sun beating down on it or from the occupants inside and the equipment they use.

This report focuses on Chillier for laboratory.

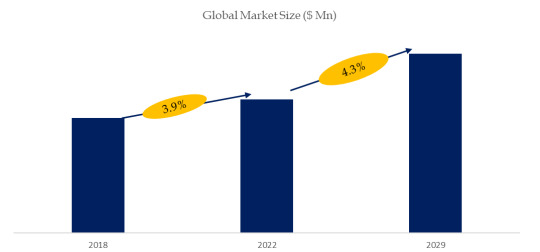

According to the new market research report “Global Laboratory Chillers Market Report 2023-2029”, published by QYResearch, the global Laboratory Chillers market size is projected to reach USD 0.45 billion by 2029, at a CAGR of 4.3% during the forecast period.

Figure. Global Laboratory Chillers Market Size (US$ Million), 2018-2029

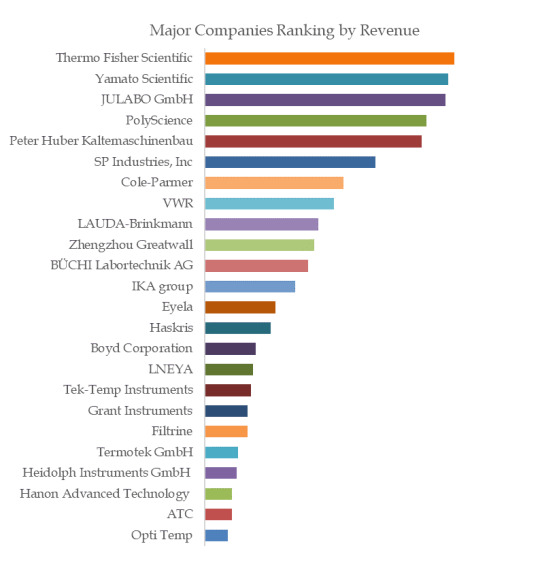

Figure. Global Laboratory Chillers Top 24 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Laboratory Chillers include Thermo Fisher Scientific, Yamato Scientific, JULABO GmbH, PolyScience, Peter Huber Kaltemaschinenbau, SP Industries, Inc, Cole-Parmer, VWR, LAUDA-Brinkmann, Zhengzhou Greatwall, etc. In 2021, the global top 10 players had a share approximately 42.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Re-Circulating Chiller

A re-circulating chiller is a type of cooling system commonly used in laboratory settings and industrial processes where precise temperature control is required. It works by circulating a coolant, typically water or a water-based solution, through a closed loop system to remove heat from a process or equipment.Re-circulating chillers are essential in various applications such as laser systems, medical devices, analytical instrumentation, and semiconductor manufacturing, where maintaining stable temperatures is critical for accurate results and equipment longevity.

0 notes

Text

Affordable Handheld Metal Laser Welding Machine for Sale

A metal laser welding machine, also known as a laser welder or laser welding system, is a specialized equipment used for precise and efficient welding of metal components. It utilizes laser technology to generate a highly concentrated and intense laser beam that melts and fuses metal materials together.

Handheld Metal Laser Welding Machine

Handheld metal laser welding machines are designed to be lightweight and portable, allowing for easy transportation and maneuverability. They typically have a compact size and ergonomic design, enabling operators to access and weld difficult-to-reach areas or perform welding tasks in different locations.

Handheld metal laser welding machines offer the advantages of mobility, accessibility, and versatility in metal welding applications. They provide a convenient solution for on-site repairs, small-scale production, or situations where traditional fixed-position laser welding machines may not be feasible.

Welding head

The laser is eventually fired from the welding head and applied to the material.It consists of nozzle,scale tube, protective glass,focusing lens, reflector,motor,collimator,wire feeding bracket, switch button, waterways,QBH protective sleeve and so on. Nozzle and protective lens are wearing parts. And when workers’ welding, auxiliary gas is often needed to avoid material producing gas that could react with air and to avoid residue and aerosol entering the welding head to damage the components.So we need to prepare extra nozzles and protective lens. How laser welding works?The laser is generated by laser source and is transported to welding head, then it is collected and reflected by reflector and is focused by focusing lens to reach the nozzle and finally fired to the material, after all this happens, the user could conduct welding conveniently and flexibly.

When considering a handheld metal laser welding machine, factors to consider include laser power, portability features, battery life (if applicable), cooling system, ease of use, and the specific welding requirements of your application.

Main body

Displayer is a window for interaction between user and machine. The screen of displayer is touch screen, its functions are machine parameter adjustment and language conversion. Control board equals to computer mainframe. And wire feeder is designed to melt the wire into the welding joint during material processing when the welding joint width over 5 mm.

Water chiller is used to cool laser source and welding head and could only be filled with distilled water and purified water in summer and with antifreeze in winter. And the volume of liquids contained is 15L, the replacement period of liquids is 2-3 months.

Metal Laser Welding Machine for Sale

Ranging from entry-level handheld laser welding guns to automatic laser welding systems with CNC controller, as well as professional 3D laser welding robot. All types of laser beam welders available in IGOLDEN with powers of 1000W, 2000W and 3000W for machinists.

Three-in-one laser welder

The advanced version of laser welder is the three-in-one laser welder, as its name suggests, it has multifunctions of of welding, cleaning and cutting. Its welding function is the same as that of a normal laser welder. And it could be easily to changed into the cutting pattern by the change of nozzle, when it is converted into the pattern of cutting, it could only cut some extra and useless pieces of the material edges with less precision and worse effect than normal fiber laser cutters. If it is applied in cleaning, cleaning head and special focusing lens for laser cleaner should be installed. It is easy and convenient in operation and alteration of patterns.

Metal Laser Welding Machine Features

Laser Source:

Metal laser welding machines use a laser source, typically a solid-state laser, to generate the laser beam. Common types of lasers used include fiber lasers, Nd:YAG lasers, and disk lasers. These lasers provide high power and excellent beam quality for precise and controlled welding.

Welding Process:

Metal laser welding involves focusing the laser beam onto the joint or area to be welded. The laser beam rapidly heats and melts the metal surfaces, creating a localized molten pool. Upon cooling, the molten metal solidifies, resulting in a strong and durable weld joint. The process can be performed in continuous wave (CW) mode or pulsed mode, depending on the application requirements.

Non-contact Welding:

Laser welding is a non-contact welding process, meaning the laser beam does not physically touch the workpiece. This eliminates the need for mechanical force or contact between the welding tool and the material, reducing the risk of contamination or damage to the welded parts.

Materials:

Metal laser welding machines can be used to weld a wide range of metals and alloys, including stainless steel, carbon steel, aluminum, titanium, copper, brass, and various other alloys. They are particularly effective for welding thin sheets or components with high precision and minimal distortion.

Speed and Efficiency:

Laser welding is a fast and efficient welding method. The concentrated energy of the laser beam results in rapid heating and cooling rates, allowing for high welding speeds. This contributes to increased productivity and reduced production time compared to traditional welding techniques.

Precision and Control:

Metal laser welding machines offer high precision and control over the welding process. The laser beam can be accurately focused and directed to the desired welding area, allowing for precise positioning and control of the heat input. This enables the welding of intricate or complex geometries with minimal damage to the surrounding material.

Versatility:

Metal laser welding machines are versatile and can be used for various welding applications. They can perform spot welding, seam welding, overlap welding, and even 3D welding of complex components. Laser welding can also be combined with other processes, such as laser cutting or laser marking, to create integrated manufacturing solutions.

Automation and Integration: