#laboratory setup cost

Explore tagged Tumblr posts

Text

The Man & Woman from C.O.U.S.I.N.S.

Late in 1968, Caesar Stag and June Danseuse, agents of C.O.U.S.I.N.S. (Covert Organization Uniquely Specializing in Neutralizing Spies.), were able to break into one of the secret hideouts of their arch-rivals, WOOD ROBIN, a hard to define conglomeration of disgruntled scientists, rogue engineers, and spies (mostly industrial espionage truth be told being as The Illuminati, Hydra, Spectre, the Thirteenth Directorate, World Association of Girl Guides & Girl Scouts, The Guild of Calamitous Intent and F.O.W.L had, had all of the really serious stuff locked up for years.)

“What do you think this setup is all about, Caesar?” asked Danseuse, taking in the super science lab they had stumbled onto on a small Caribbean island.

“Doesn’t matter,,” said Stag. " Our job is to shoot lots of stuff and then blow the place to bits and get back to COUSINS HQ for the closing banter and vague `will they, won’t they’ innuendo.

“But what if it’s useful? Why don’t we try to take the plans back to HQ.”

“Not our job,” said Caesar.

“What if it does something interesting?” said June, persisting

“Like what?” asked Caesar, the sarcasm in his voice unmistakable.

“SIZZLE CRACKLE ZIIIG!” Went the super-science device in the WOOD ROBIN laboratory in reply.

That was when Stag and Danseuse found out that they had been observed the whole time when they had first landed on the hideout island. And had been deliberately guided in secret to find the room they were in, which housed a WOOD ROBIN innovation called the Ultimate Disguise Chamber, which was used to give their agents the perfect mission undercover disguises. And had been used by those watching the COUSINS again to turn them into a pair of spry healthy women in their 60s.

So the daring man and woman from COUSINS were left with two possibilities, destroy the device, shoot the place up and return to COUSINS HQ and stay as they were forever, or agree to join WOOD ROBIN and, after a time, be returned to their former selves.

Of course, there was only one thing such dedicated and well-trained agents could do.

A month after joining WOOD ROBIN, after all, the groups weren’t in the grand scheme of things all that different. (WR, however, did have a much better dental plan.) saw the debut on the world stage of two new super-spies, Carmille (Caesar) and Juliette (June), known now as the Glissante Sisters, with a contract to work for WOOD ROBIN for five years before they could return and step into the Ultimate Disguise Chamber to be returned to their former selves.

And a wild five years it was, too (oddly, it seemed that June Danseuse was the one most anxious to get it all over with while Caesar went with the flow.)

In 1973 at the end of those five years, The Glissante Sisters returned to the island.

Unfortunately, in the clandestine world at large, WOOD ROBIN had never really been all that much and so didn’t have that large a budget, so the Ultimate Disguise Chamber wasn’t the thing of wonder it once had been, and they just couldn’t return them exactly as they had been. They did the best they could, however.

The results were that they were remade into copies of June Danseuse as she had been when she was 23 years old (in 1968, when it all started, she had been 34, so… you’re welcome!)

Cashiered out of WOOD ROBIN, the pair found themselves at their wits end, they could hardly return to C.O.U.S.I.N.S., but what to do next?

They tried freelancing for a while, but the cost of replacing ripped, skin-tight bodysuits was just too costly.

Then Julie Danseuse, as Caesar Stag now called herself, had an idea.

It was not long then until the world was introduced to…

Julie and Juliette Danseuse, The Disco Detectives.

Their first job was The Serial Disco Inferno Case.

Then came "Blame it On the Boogeyman" and "Can’t Stop The Murders."

"The Bad Girl, Dancing Queen Kidnapping,” "Macho Manslaughter in the First Degree." and "Will I Survive." followed.

All the way to their biggest case, “We Are Family” (as in the mob)

In 1985 they just got into accounting and opened an H&R Block.

15 notes

·

View notes

Text

FFVII Rebirth and Gameplay at the Cost of Atmosphere

This is probably going to be part 1 of a series of posts/mini-essays so I'll write more on it later, but while doing one of the Chapter 12 Sidequests in Rebirth, I finally figured out how to phrase one of my biggest issues with this game:

There are several places in Rebirth where they include special gameplay at the cost of good atmosphere. This often, but not always, accompanies either a change or new addition to the plot.

I've put some elaboration on what I mean below. For now, it's only looking at that one sidequest in Chapter 12, though it happens all over the game. But the tl;dr is that sometimes game shoots itself in the foot/misses completely when trying to create a certain atmosphere because it prioritizes a certain type of gameplay that is antithetical to that atmosphere.

The Monsters Aren't Real, and How That Hurts the Atmosphere

The sidequest in question is Lament of the Damned, the sidequest in Shinra Manor where you go with Vincent to explore reports of a crying woman. The thing that got me about this one was the combat trials.

What's in the Game

When you go explore under the manor, both Vincent and Hojo mention deadly combat trials, which is a great setup for some horror and an overall creepy atmosphere. Because wow! If Hojo has no qualms about putting his own experiments to death if they don't prove worthy, that means he's really messed up! (And that Vincent in particular has had an even more disturbing past than we thought). The manor was definitely creepy in the original with all of the monsters roaming the halls and the pop up Ying Yang in particular. There are no more battles in the Shinra Manor (besides Cait Sith's section), so maybe this is their way of making up for that.

Except... in the Remake, the combat trials are just simulations. You don't have to face any real monsters. It's all fake. There are no monsters roaming the halls unchecked anymore, nor are there caged monsters, created for the sole purpose of testing your strength. And this lack of real monsters totally kills the deranged/creepy haunted house atmosphere the original Shinra Manor had.

(Which, to be fair, is already changed by the under-manor laboratory being a huge complex rather than a couple of rooms, which is part of the larger shift in atmosphere done for the entirety of Nibelheim. I won't go into to detail in this post, but while I thought the Cait Sith gameplay segment was actually a lot of fun, I was disappointed by how it killed the vibe too).

Room for Improvement

I personally believe the combat trial aspect would be much creepier and much more effective if you were trapped in a room and real monsters were suddenly let loose on you. Then it would feel like a real fight for your life, and make Vincent's comments about how subjects were disposed of via combat trial all the more impactful. Because simulations can't kill you (or at least, don't seem like they should be able to), so in the simulation verse, there should be no direct consequences to losing. It seems a lot dumber to be killed by a simulation than ripped apart by real monsters. Less scary, though I suppose there's a certain appeal to being killed by the unreal. Still, I don't think they leaned into that hard enough. Maybe they meant to imply that creatures which lost to the simulation would be disposed of either by real monsters or just euthanasia afterwards, but meh. I still think that's less disturbing than throwing test subjects into a room where they either defeat the monsters that have been loosed on them, or die a grisly death. And even if they do somehow die to the simulations, something about it just doesn't hit the same.

Having the monsters only be simulations also loses the disturbing aspect of the basement being inhabited by monsters of Hojo's creation that exist for the sole purpose of testing other experiments of his. Because isn't that messed up? For Hojo to create beings whose sole purpose is to, ideally, be killed by his more successful test subjects? To have to face creatures which may have once been normal animals or innocent civilians who have been twisted to fight but can never be saved, so you must either kill them or die yourself? When the monsters you fight are just simulations, you lose that thought/fear of "oh no, look what he's done to these real living creatures, not only mutating them but sending them to their deaths for his amusement."

When the monsters are fake/just simulations, it means Hojo isn't hurting as many real people, and you don't have to face the disturbing idea of having to put down real beings who probably once had real thoughts and feelings. (Which would've been SO GOOD with the line Vincent has after the combat trials, where he DOES talk about Monsters having feelings. But the monsters you fight aren't real. Not until the very last one. So it doesn't hit the same).

So tl;dr of this section: the fact that the simulations are just that- only simulations, i.e. not real- both reduces the threat level in terms of danger to the character, and eliminates the disturbing realization that Hojo has created creatures who are (if his experiments are successful) are meant to die. Both the atmosphere of the manor and Hojo's character lose out there, imo.

Why the Monsters Aren't Real, or the Gameplay Reason

After beating the combat trials, I came to realize (the likely reason) why they made the combat trials simulations rather than real battles: so they could include combat objectives and so you can take the trials at your own pace (i.e. leave and come back).

Repeating the Trials/Combat Objectives

First, the combat objectives.

There are two types: timers and stagger. If you were fighting against real enemies, having a stagger requirement wouldn't make as much sense, since a real battle should really just be about surviving. Why would you need to stagger them? What would happen if you didn't? Would a monster be more likely to kill you if you didn't stagger it? That's not how it works in gameplay. As for the timer, I could see there still being a timer requirement in the form of these enemies doing some sort of enrage move after a set amount of time, but the stagger one doesn't make as much sense. (For people who don't know what enrage is, it's the idea that an enemy will use an unlivable attack against you. An unavoidable OHKO.)

By making the fights simulations rather than real battles, it then makes sense for Hojo (cough cough the devs) to implement certain specific requirements to progress. It also gives them a better excuse for why you might need to repeat the trials- you didn't meet the combat objectives, so now you have to do it again. Because the trials don't auto-fail if you don't meet the combat objectives, you just don't get to go forward.

But I think it loses sight of the creepy scientist and horror basement thing if what you're fighting isn't real. There is no penalty for not doing the trial "right." If there was an actual enrage at the end of the timer (i.e. if you just straight up lost/died), then that would be terrifying! Because wow, Hojo is willing to kill his subject if they're not fast enough! But no, he just doesn't pass them and has them try again. Which makes him less creepy/insane seeming, because now he's kinder because he's willing to give things a second chance. It's less impactful.

In my opinion, being able to implement combat objectives isn't worth that loss of impact. Because combat objectives don't have to be in this part of the game. Chadley has combat objectives in his simulator. If they want us to do combat simulator stuff, have us do it with Chadley. Don't hurt the atmosphere in the manor to include this dumb requirement, which not only means there's less threat in the form of the monsters not being real, but also kills any sense of urgency because you can repeat the trials as many times as you want, or even come back later if you don't have the time. It's a loss of atmosphere for the sake of gameplay in a bad way. They didn't have to write it like this, but they did. And it happens several times through this game.

Backing Out/Limited Creature Game Logic

Speaking of which...I think it's okay to have the occasional unskippable battle, or occasional battle arena where you have to beat them all to progress/do them all over if you run, but the devs sure don't. If the battles weren't simulations, it would make a lot of sense for them to be one after the other. Battles where you've got to do them all to make it through.

Since they're not real battles and are simulations you have to execute, it makes sense that you can come and go. But I don't think that's the order that concept was conceived in; instead I think the devs went "in order to allow the player to come and go at any time, we should make it so you only have to do the battles one by one, and a simulation would be great for that!" And the game really hand holds you with that. Most of Chadley's simulations have multiple battles in a row where you have to beat them all to proceed, but the ones in this sidequests are all individual battles with individual goals.

Now, I am all for accessibility and quality of life in gaming, and I really like that, for example, you can save basically everywhere now instead of needing a save point. But it's fine to remove a little bit of Quality of Life/Accessibility for a single sidequest where you face a battle gauntlet! I mean, the game already has points where it limits your access to Fast Travel so you have to progress the plot. And like I mentioned before, most of the Chadley battle simulations have multiple rounds too! Why not do that here, where you have to do the battles (at least the 4 simulation ones, I would be fine with stopping before the boss) before moving on? You can save right then and there! You're healed between battles too! It's okay to make things slightly less convenient sometimes for the sake of atmosphere! How cool/exciting would it be if Hojo set 4 rounds of monsters on you in a row, where you had to beat them all or game over? I'd love it. That would raise the stakes. And, it would make for a more unique atmosphere. But this isn't something that seems to be a high priority for Rebirth, which I find unfortunate.

(Sidenote, this happens with both gameplay and visuals. At least in the Cave of the Gi they had runestones instead of Jukeboxes... but they didn't bother to change the Jukebox in Vincent's room for some reason. Or to put it somewhere else if they didn't want to change the model. The jukebox and potion bench are so weird man. They kill the vibe made by the rest of the creepy basement full of coffins and candles. It's supposed to feel old and out of time, but the jukebox and bench ruin it.)

I could also see the argument that the devs made this a simulation rather than a real battle based on the logic that having an infinite number of monsters (for infinite tries to complete the objectives) makes less sense when they're real monsters rather than simulations, but I don't think that matters. This is a video game. There are already infinite monsters in the overworld. There can be infinite monsters here.

Finally, going back to the idea of stagger and time objectives from above...you could technically do those with real enemies too. Have it so Hojo will just send more monsters at you if you fail. Make it real Hojo instead of hologram AI Hojo. Or have the AI be able to detect that the enemies weren't staggered/killed in time! Now that I think about it, there are combat objectives against real enemies in the overworld, so they technically didn't need to make these battles part of a simulation for combat objectives. But I still feel strongly that these battles were made to be simulations instead of real battles for the sake of combat objectives.

Last Thoughts (for now!)

FFVII Rebirth has leaned very strongly into AI, simulation, and advanced technology that had not been conceived/wasn't in the public consciousness when the original was released. At times, the game wants to lean very hard into this new technology at the cost of the atmosphere that made the original so great. It's a different type of horror. A different type of creepy.

Being trapped in a virtual world can be terrifying, but it's a different type of terror to being trapped in the real world. Being killed by simulations sounds disturbing, but it's a different type of disturbing than being killed by real creatures. The writers may have done this because they felt it was an equivalent exchange (hehe), but for me at least, I find what the original did so much more striking.

Full disclaimer, I am not, and have never been, big into sci-fi. Remake and Rebirth lean into high tech sci-fi more than the OG did (which 100% had its own sci-fi aspects! I mean, the villain is an alien for starters, and the evil scientists' actions are central to the plot!), at the cost of some of the more down-to earth horror/other aspects of the original. I find this disappointing. It's a different choice that is sometimes really cool (ex. with so much technology it becomes much more obvious that Shinra has constant global surveillance, which is very distopian), but sometimes worse (ex. President Shinra only being a hologram rather than the real guy in Reactor No. 5 makes him seem a lot less cocky since he doesn't show up in person).

I think Shinra Manor as a whole has absolutely lost the atmosphere that made me love it so much in the original. It went from a grimy mansion to a sterile lab. Both are good settings for horror, but they just don't hit the same. This sidequest suffered from wanting to be part of that sterile high tech lab, instead of the low-tech horror of the original where people/Hojo seem(ed) to be playing god in much more material ways. Which is...a different point better left for another essay.

We'll see if I ever get to writing it, lol. For now I uh. Haven't actually finished the game. I have 91 hours and am only about an hour slash two sidequests into Chapter 12, but I haven't had much free time to continue. Hopefully this weekend I'll be able to push through some more!

#i have a 27 thousand word document with my live/real time thoughts on rebirth#only going up to the very beginning of chapter 12. and it doesn't even include my full essay on my dissatisfaction with corel prison#ffvii#ffvii rebirth#final fantasy vii rebirth#ff7 rebirth#ffvii rebirth spoilers#rebirth spoilers#i don't want to spoil other slow people.#anyway i do want to say that overall i have enjoyed rebirth a lot! but i've also been absolutely baffled by some choices#kalm was great. gongaga was fascinating. corel prison sucked while cosmo canyon and nibelheim were questionable#the sidequests have been majority really good too#costa del sol and junon were fantastic too. though lower junon was so-so#who knows if i'll ever get all my thoughts out because yeah. i have a 27k word long document. that is SO many essays worth of material man#erurandomness#eruwrites#erubabbles

5 notes

·

View notes

Text

Understanding The World of Quantum Computers

Imagine a computer so powerful that it could solve problems in seconds that would take our current machines millions of years. No, it's not science fiction—it's the exciting world of quantum computing, where bits become qubits and the impossible becomes possible. Let's dive into this technological marvel that might one day be as common as your smartphone!

A quantum computer is a supercomputer that exploits quantum mechanical phenomena or in other words, a quantum computer uses tiny particles to perform complex calculations. Unlike regular computers, quantum computers use qubits instead of bits!

A qubit means that it is either neither 0 or 1, think of it as a wave; it can go up and down at any given moment! This ability to be in multiple states simultaneously is known as superposition. At the same time, a bit in a classical computer is like a simple switch that can be either off (0) or on (1), a qubit can be both off and on simultaneously, providing an incredible amount of computational power. But how do they really work?

How Quantum Computers Actually Work

Superposition: As mentioned, qubits can exist in multiple states at once. This allows quantum computers to process a vast amount of information simultaneously.

Entanglement: This is a phenomenon where qubits become intertwined, so the state of one qubit can depend on another, no matter how far apart they are. This can massively increase computational power.

Quantum Gates: Similarto logic gates (a device that acts as a building block for digital circuits) in classical computers, quantum gates manipulate qubits. but because of superposition and entanglement, quantum gates can perform complex operations much faster than classical gates (smartphones, tablets, etc).

What Do Quantum Computers Look Like?

Unlike the sleek laptops and smartphones we use today, quantum computers look very different. They are usually large (5ft wide & 20ft long), complex machines housed in specialized laboratories. A typical quantum computer setup includes:

Cryogenic Systems: Quantum computers need extremely low temperatures to function, often close to absolute zero (kelvin or -273.15 degrees Celsius or -460 degrees Fahrenheit). This requires sophisticated cooling systems.

Quantum Processor: The heart of a quantum computer, where qubits are manipulated.

Control Systems: These are used to manage and operate the quantum processor, often involving complex electronics and software.

In other words, quantum computers are not something you can slip into your pocket or place on your desk. They currently require a highly controlled environment and are far from being household items.

Why Does This Matter?

The potential of quantum computers is amazing. Here are a few areas where they could make a significant impact:

Cryptography: Quantum computers could break current encryption methods, making our data vulnerable. However, they could also create unbreakable encryption.

Drug (Health) Discovery: They can simulate molecular structures much more efficiently than classical computers, speeding up the process of drug discovery and development.

Optimization: Quantum computers can solve complex optimization problems that are currently unsolvable, impacting industries from logistics to finance.

Pros and Cons of Quantum Computers:

Pros:

Speed: Quantum computers can solve problems in seconds that would take classical computers millions of years.

Power: Their ability to handle complex calculations could revolutionize fields like cryptography, material science, and artificial intelligence (AI).

Innovation: They could lead to new discoveries and advancements in technology that we can’t even imagine yet.

Cons:

Complexity: Quantum computers are incredibly complex and difficult to build and maintain.

Cost: The technology is expensive and currently out of reach for most organizations.

Security Risks: The potential to break current encryption methods poses a significant security threat.

Will We Ever Have Quantum Computers in Our Homes?

Given their current state, quantum computers are unlikely to become household items anytime soon. The technology is still in its infancy, and the machines are expensive and complex. However, as research progresses and technology advances, it’s possible that we could see more accessible forms of quantum computing in the future.

For now, the most practical application for everyday users will likely come through cloud-based quantum computing services provided by tech companies. This means you could potentially access the power of a quantum computer over the internet, without having to own one.

Quantum computers represent a leap forward in computing technology, with the potential to transform numerous fields and solve problems that are currently intractable. However, they also come with significant challenges and risks. As this technology develops, it will be crucial to balance its immense potential with the necessary safeguards to ensure it benefits humanity as a whole.

3 notes

·

View notes

Text

What is the Difference Between Pilot Plant and Scale Up?

What is a Pilot Plant?

A Pilot Scale Bioreactor is a small-scale version of an industrial process used to test and refine production methods before scaling up to full-scale production. It is essentially a prototype that allows engineers and scientists to simulate real-world conditions on a smaller scale. Pilot plants are critical in bridging the gap between laboratory research and full-scale manufacturing.

Key Characteristics of a Pilot Plant:

Scale: Pilot plants operate on a scale that is larger than laboratory experiments but smaller than full production. The size can vary widely depending on the industry and the specific process being tested.

Purpose: The primary aim of a pilot plant is to validate the feasibility of a process or product. It allows for the testing of various aspects such as process efficiency, equipment performance, and product quality under near-production conditions.

Flexibility: Pilot plants are designed to be adaptable. They can be adjusted to test different process parameters, materials, or operating conditions.

Data Collection: Data from pilot plants helps in understanding the potential challenges and limitations of a process. This includes assessing yield, energy consumption, and potential environmental impacts.

What is Scale-Up?

Scale-up refers to the process of increasing the production scale from a pilot plant or laboratory setup to full industrial scale. It involves translating the successful results obtained in a pilot plant into a larger, commercial-scale production process.

Key Characteristics of Scale-Up:

Scale: Scale-up involves moving from a pilot plant scale to full-scale manufacturing. This can mean a significant increase in size and capacity, often requiring new or modified equipment and infrastructure.

Purpose: The goal of scale-up is to reproduce the successful outcomes of the pilot phase at a larger scale. It involves optimizing and validating the process to ensure it is economically viable and capable of meeting market demands.

Challenges: Scale-up can present new challenges that were not evident at the pilot scale. These might include issues related to equipment design, process control, and raw material sourcing.

Economic Considerations: Scale-up requires a detailed analysis of cost implications, including capital investment, operational costs, and potential market pricing. Economic feasibility is a key factor in deciding whether to proceed with full-scale production.

How Pilot Plants and Scale-Up Work Together

The transition from a pilot plant to full-scale production is not always straightforward. The insights gained from the pilot phase are crucial for a successful scale-up. Here’s how the two stages interact:

Feasibility Testing: Pilot plants provide the data necessary to evaluate the feasibility of scaling up. They help identify potential issues that might arise when moving to a larger scale.

Process Optimization: Information from the pilot phase is used to refine and optimize the process for scale-up. This includes adjusting process parameters, improving efficiency, and ensuring consistency.

Design Considerations: Lessons learned from the pilot plant can influence the design of the full-scale production system. This includes selecting appropriate equipment, designing efficient layouts, and implementing control systems.

Risk Mitigation: By thoroughly testing processes on a smaller scale, pilot plants help mitigate risks associated with scaling up. They provide a platform to address problems before committing to large-scale production.

Conclusion

In summary, pilot plants and scale-up are two crucial steps in the journey from research and development to full-scale production. Pilot plants serve as a testing ground for validating and refining processes, while scale-up involves translating those validated processes into commercial-scale production. Understanding the differences between these stages helps in managing the transition effectively and ensures that products are developed efficiently and economically.

For more details, please contact us!

Website :- https://www.fermentertechnologies.com/

Contact No. :- +91–8896456000

Email :- [email protected]

2 notes

·

View notes

Text

The Modern Marvel: Exploring the Versatility of Porta Cabins

In the realm of modern architecture and construction, versatility, efficiency, and sustainability are becoming paramount. Among the many innovations rising to meet these demands, one solution stands out: the porta cabin. These compact, portable structures are transforming the landscape of construction, offering a myriad of benefits across various industries and applications.

A Glimpse into Porta Cabins

Porta cabins, also known as modular buildings or portable cabins, are prefabricated structures that can be easily transported and assembled at different locations. Originally conceived as temporary housing or office spaces, these cabins have evolved significantly, now finding application in diverse sectors including construction, education, healthcare, events, and even residential spaces.

The Advantages of Porta Cabins

1. Mobility and Flexibility:

Porta cabins are designed for mobility, making them ideal for temporary or remote projects. Whether it's a construction site office, a classroom in a rural area, or a temporary medical facility during emergencies, these cabins can be swiftly deployed and relocated as needed.

2. Cost-Effectiveness:

Compared to traditional construction methods, porta cabins offer significant cost savings. Their modular design reduces material wastage and labor costs, while their shorter construction time translates to lower overall expenses.

3. Customization Options:

Porta cabins are highly customizable, allowing for tailored solutions to meet specific requirements. From basic office setups to fully-equipped laboratories or classrooms, these structures can be customized with various amenities, furnishings, and layouts.

4. Sustainability:

In an era increasingly concerned with environmental impact, porta cabins offer a sustainable alternative to traditional construction. Their modular design promotes resource efficiency, and many manufacturers use eco-friendly materials and construction practices, reducing both carbon footprint and construction waste.

5. Rapid Deployment:

In emergency situations such as natural disasters or public health crises, the ability to quickly establish infrastructure is critical. Porta cabins provide a rapid solution, offering shelter, medical facilities, or administrative offices in a fraction of the time required for conventional construction.

Applications Across Industries

The versatility of porta cabins enables their use across a wide range of industries and settings:

Prefab Construction Sites: Portable offices, storage units, and restrooms for construction workers.

Prefabricated Education: Temporary classrooms, libraries, or administrative offices for schools and universities.

Prefabricated Healthcare: Emergency medical facilities, clinics, or vaccination centers.

Events: Ticket booths, vendor stalls, or temporary exhibition hall spaces.

Residential: Temporary housing solutions during renovations or for disaster relief efforts.

What is the life expectancy of a porta cabin?

The life expectancy of a porta cabin, also known as a portable cabin or portable office, can vary depending on several factors such as quality of construction, materials used, maintenance, and environmental conditions. Generally, a well-maintained porta cabin can last anywhere from 30 to 50 years or more. Regular maintenance, including inspections for structural integrity, roof leaks, and ensuring the integrity of the flooring, can help extend its lifespan. Additionally, factors such as exposure to extreme weather conditions, frequency of use, and quality of installation can also affect how long a porta cabin remains functional.

What is a porta cabin made of?

A porta cabin, also known as a portable cabin or modular building, is typically constructed using a variety of materials depending on its intended use, durability requirements, and budget constraints. However, the primary materials commonly used in porta cabin construction include:

Steel: Steel frames provide structural integrity and support for the cabin. They offer strength and durability, making the structure robust enough to withstand transportation and installation.

Wood: Wood is often used for the floors, walls, and sometimes even the roofs of porta cabins. It's relatively lightweight, readily available, and offers good insulation properties.

Insulation: To regulate temperature and improve energy efficiency, insulation materials such as fiberglass, foam board, or spray foam are used between the walls and ceilings.

Exterior Cladding: The exterior of porta cabins may be clad in materials such as corrugated steel panels, aluminum, vinyl siding, or fiberglass reinforced panels (FRP). These materials protect the cabin from the elements and enhance its aesthetic appeal.

Interior Finishes: Inside the porta cabin, materials like gypsum board (drywall) are commonly used for walls and ceilings. Flooring materials can vary and may include vinyl, laminate, carpet, or tiles.

Windows and Doors: Windows are typically made of glass, while doors can be made of steel, wood, or fiberglass, depending on security and insulation requirements.

2 notes

·

View notes

Text

Laboratory Information Management Systems Market: 8-10% CAGR and the Digital Future by 2029

The global laboratory information management systems (LIMS) market is projected to grow at a CAGR of 8-10% from 2024 to 2029. This growth is driven by the increased demand for automation and regulatory compliance in laboratories across pharmaceuticals, biotechnology, environmental testing, and other industries. As laboratories adopt digital solutions to enhance operational efficiency and data accuracy, LIMS adoption continues to rise.

The laboratory information management systems (LIMS) market focuses on software solutions that enhance data management, workflow efficiency, and compliance across various laboratory environments. Unlike Laboratory Information Systems (LIS), which are tailored to healthcare and clinical applications, LIMS primarily supports non-clinical settings, including pharmaceuticals, environmental testing, and food and beverage industries.

Discover the more details-Download the PDF brochure: https://meditechinsights.com/laboratory-information-management-system-market/request-sample/

Rising Demand for Laboratory Automation and Regulatory Compliance

The rising demand for laboratory automation and regulatory compliance significantly drives the LIMS market. By automating data capture and sample tracking, LIMS enhances data accuracy, minimizes human errors, and speeds up sample processing, which is essential in high-throughput laboratories. Automation allows labs to meet stringent regulatory requirements imposed by agencies such as the FDA, EMA, and other global bodies, which increasingly mandate digital record-keeping and audit trails. Additionally, the shift toward cloud-based LIMS solutions offers laboratories scalable and flexible options, providing secure, compliant data management without the overhead of on-premises infrastructure. This enables laboratories to meet regulatory standards while achieving cost-effective, efficient digital transformation.

Key Challenges in Laboratory Information Management Systems: Data Integration and Security Concerns

The LIMS market faces several key challenges, such as data integration with other systems like electronic lab notebooks (ELNs) and enterprise resource planning (ERP) systems, especially in environments using legacy software. Additionally, data privacy and security concerns are significant, as labs manage sensitive data that require robust encryption and access control measures. The high initial setup costs for LIMS can also pose a barrier, especially for smaller laboratories. Overcoming these challenges is essential to optimize LIMS' value in laboratory environments.

Competitive Landscape Analysis

Key players in the LIMS market, including Thermo Fisher Scientific, LabWare, LabVantage Solutions, STARLIMS, Agilent Technologies, Dassault, CloudLIMS, Lablynx, Labworks, and Autoscribe Informatics, are investing in technology upgrades, expanding product portfolios, and forming strategic partnerships to maintain their market position. Increasing focus on cloud-based solutions and AI-enhanced data analysis capabilities aim to make LIMS more adaptable, efficient, and scalable for various laboratory needs.

Unlock key findings! Fill out a quick inquiry to access a sample report https://meditechinsights.com/laboratory-information-management-system-market/request-sample/

Market Segmentation

This report by Medi-Tech Insights provides the size of the global laboratory information management systems market at the regional- and country-level from 2022 to 2029. The report further segments the market based on component, deployment model, and end user.

Market Size & Forecast (2022-2029), By Component, USD Billion

Software

Services

Market Size & Forecast (2022-2029), By Deployment Mode, USD Billion

On-premise

Cloud-based/Web-hosted

Hybrid

Market Size & Forecast (2022-2029), By End User, USD Billion

Pharmaceutical and Biotechnology Companies

Contract Research Laboratories (CROs)

Food and Beverage Companies

Environmental Testing Laboratories

Others

Market Size & Forecast (2022-2029), By Region, USD Billion

North America

US

Canada

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

India

Japan

Rest of Asia Pacific

Latin America

Middle East & Africa

About Medi-Tech Insights

Medi-Tech Insights is a healthcare-focused business research & insights firm. Our clients include Fortune 500 companies, blue-chip investors & hyper-growth start-ups. We have completed 100+ projects in Digital Health, Healthcare IT, Medical Technology, Medical Devices & Pharma Services in the areas of market assessments, due diligence, competitive intelligence, market sizing and forecasting, pricing analysis & go-to-market strategy. Our methodology includes rigorous secondary research combined with deep-dive interviews with industry-leading CXO, VPs, and key demand/supply side decision-makers.

Contact:

Ruta Halde Associate, Medi-Tech Insights +32 498 86 80 79 [email protected]

0 notes

Text

Industrial Air Quality Monitor: The Key to a Safer, Healthier Workplace – Powered by PRANA AIR

As industries grow and urbanization continues at a rapid pace, one issue that is becoming increasingly difficult to ignore is the quality of the air we breathe in industrial spaces. While industries are essential for economic development, they are also major contributors to air pollution, often exposing workers and the surrounding communities to harmful gases and particulate matter. In this context, the industrial air quality monitor is not just a regulatory requirement but a necessity for occupational health and environmental responsibility.

PRANA AIR, a trusted name in smart and affordable air monitoring solutions in India, offers state-of-the-art monitoring systems that help industries take control of their emissions, ensure employee safety, and meet compliance standards. If you're looking for reliable, intelligent, and cost-effective air quality monitoring solutions, PRANA AIR is the brand you can count on.

Understanding the Importance of Industrial Air Quality Monitoring

The air within industrial premises can contain a mix of pollutants, including particulate matter (PM2.5 and PM10), carbon monoxide (CO), nitrogen dioxide (NO₂), sulfur dioxide (SO₂), ozone (O₃), volatile organic compounds (VOCs), and other hazardous gases. Exposure to these pollutants can cause short- and long-term health problems such as respiratory issues, cardiovascular diseases, eye irritation, and even chronic illnesses in severe cases. Moreover, these pollutants can corrode machinery, damage electronic equipment, and negatively affect product quality.

This is where an industrial air quality monitor plays a crucial role. It helps industries identify pollution sources, measure pollutant levels in real time, and take corrective action immediately. Monitoring air quality is not just about compliance anymore—it’s about creating a safer and more productive working environment, reducing liability risks, and improving overall operational efficiency.

PRANA AIR’s Advanced Industrial Air Quality Monitoring Systems

PRANA AIR, under the vision of Purelogic Labs India, has taken the lead in offering cutting-edge air monitoring devices specially designed for both indoor and outdoor industrial applications. These devices come equipped with high-precision sensors and smart connectivity features that provide real-time, accurate data on a wide range of air pollutants.

What makes PRANA AIR’s industrial air quality monitor truly exceptional is its ability to detect and analyze multiple pollutants simultaneously, while integrating seamlessly with your existing infrastructure. These devices are ideal for factories, manufacturing plants, warehouses, laboratories, chemical units, and even large office buildings that want to monitor and maintain clean air standards.

Whether you want to track fine dust particles or monitor harmful gas emissions, PRANA AIR offers solutions that cater to all industrial needs. Their monitors can even be customized based on specific pollutants relevant to your facility, ensuring you're always in control of your air quality data.

Real-Time Monitoring with Smart Data Access

The ability to monitor air pollution in real time can make a significant difference in how industries respond to environmental hazards. PRANA AIR’s devices not only measure air quality but also store historical data, generate detailed reports, and send alerts when pollution levels cross safety thresholds.

All the data collected by PRANA AIR’s industrial air quality monitor can be accessed remotely through mobile apps and web dashboards. This means plant managers, safety officers, and environmental teams can analyze trends, make data-driven decisions, and implement preventive measures without any delay. This kind of smart connectivity is particularly important in large industrial setups where manual tracking is neither feasible nor efficient.

Moreover, PRANA AIR’s monitoring systems can be integrated with third-party platforms, government portals, or building management systems (BMS) for broader compliance and transparency.

Compliance with Pollution Control Norms

With increasing pressure from environmental regulatory bodies like the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs), it is now mandatory for many industries to install continuous air quality monitoring systems. Failing to comply can result in hefty fines, operational disruptions, or even legal action.

A high-quality industrial air quality monitor from PRANA AIR helps industries stay ahead of regulations by providing reliable data that is compliant with national and international standards. The brand’s dedication to quality and precision ensures that your air quality data is trustworthy and audit-ready at all times.

By choosing PRANA AIR, you’re not just ticking a compliance checkbox — you’re building a cleaner, greener, and more sustainable industrial operation.

Cost-Effective Yet Technologically Superior

When industries think of deploying air monitoring systems, cost often becomes a concern, especially for small- and medium-sized enterprises (SMEs). PRANA AIR breaks that barrier by offering high-quality, feature-rich air monitors at an affordable price point. Their goal has always been to democratize access to clean air solutions without compromising on technology or performance.

The long-term benefits of investing in a PRANA AIR industrial air quality monitor far outweigh the initial costs. From reducing worker absenteeism and minimizing health risks to preventing equipment failure and meeting green certification standards — the returns are both tangible and impactful.

Designed and Manufactured in India

Proudly made in India, PRANA AIR’s devices reflect the brand’s commitment to local innovation and global standards. Designed by a passionate team of experts based in New Delhi, the products undergo stringent testing and quality checks before they reach the end-user.

The brand’s multicultural team and international collaborations enable PRANA AIR to stay at the forefront of environmental technology. Their understanding of Indian industrial challenges, combined with global expertise, makes their monitoring systems highly effective across diverse industrial setups.

Final Thoughts

Air pollution is one of the most critical environmental challenges of our time, and industrial zones contribute a large share of it. Monitoring the quality of air within and around industrial facilities is no longer optional — it’s essential for legal, ethical, and operational reasons. A reliable industrial air quality monitor ensures that you're not just reacting to pollution, but proactively preventing it.

With PRANA AIR by your side, you get access to best-in-class monitoring technology, accurate results, user-friendly dashboards, and ongoing support — all at a price that makes sense. As a brand born out of the genuine need for cleaner air and backed by the vision of Purelogic Labs India, PRANA AIR is your trusted partner in building a safer and more sustainable industrial environment.

Don’t wait for pollution to become a crisis — take charge with PRANA AIR’s advanced monitoring systems and lead the change toward cleaner industry standards.

0 notes

Text

Benefits of Sourcing from Local Lab Equipment Suppliers in Hyderabad

When setting up or upgrading a laboratory, choosing the right lab equipment supplier is just as important as the equipment itself. While many labs consider importing or sourcing from distant cities, there are strong reasons to prefer local lab equipment suppliers in Hyderabad.

From personalized support to faster delivery, Hyderabad-based suppliers bring distinct advantages, especially if you're working in research, diagnostics, education, or industry. Let’s explore the top benefits of sourcing laboratory scientific equipment locally.

✅ 1. Faster Delivery & Installation Local suppliers can deliver and install equipment for labs much quicker than national or international sources. This reduces downtime and helps labs stay productive and on schedule.

✅ 2. Cost Efficiency Sourcing from within Hyderabad reduces shipping, logistics, and handling charges. You also avoid import duties and middlemen fees, making the total lab equipment supply more budget-friendly.

✅ 3. On-Site Support and Maintenance Local suppliers provide faster on-site support, servicing, and Annual Maintenance Contracts (AMCs). This ensures that your scientific equipments remain in top condition throughout their lifecycle.

✅ 4. Access to Genuine Spare Parts Dealing with a laboratory equipment manufacturer in Hyderabad ensures you get original, compatible spare parts faster — avoiding delays that can halt lab operations.

✅ 5. Customization Options Need a custom-built incubator or a modified pH meter setup? Local manufacturers can work with you to provide tailor-made solutions that fit your specific lab needs.

✅ 6. Better Communication Dealing with a local team means better language compatibility, cultural understanding, and faster issue resolution — whether it’s about ordering, servicing, or training.

✅ 7. Stronger Vendor Relationships Proximity enables regular face-to-face interactions. Over time, this builds trust, flexibility in credit terms, and long-term collaboration on upgrades or new purchases.

✅ 8. Supporting Local Industry By choosing lab equipment suppliers in Hyderabad, you support the local economy and contribute to the growth of high-quality scientific equipment manufacturing in India.

🏢 Where to Buy Lab Equipment in Hyderabad? One trusted name is Lavaasa Scientific, a Hyderabad-based lab equipment supplier and manufacturer offering:

ISO-certified lab equipment

AMC and on-site servicing

Calibration and installation support

Scientific & agricultural equipment

👉 Visit Lavaasa Scientific Website 📞 +91-8826423285 | 📧 [email protected]

🧾 Conclusion Sourcing lab equipment locally in Hyderabad is not just convenient — it’s smart. You save time, reduce costs, and gain access to dependable after-sales support and customization. If you’re planning a new lab or upgrading an existing one, connect with experienced laboratory equipment manufacturers in Hyderabad for a smooth and successful setup.

#Lab Equipment Suppliers Hyderabad#Laboratory Scientific Equipment#Equipment for Labs#Scientific Equipments#Local Lab Equipment Support#Lab Equipment Supply Hyderabad#Laboratory Equipment Manufacturer#Hyderabad Scientific Instrument Dealers#Lab Setup Services Hyderabad#AMC for Lab Equipment

0 notes

Text

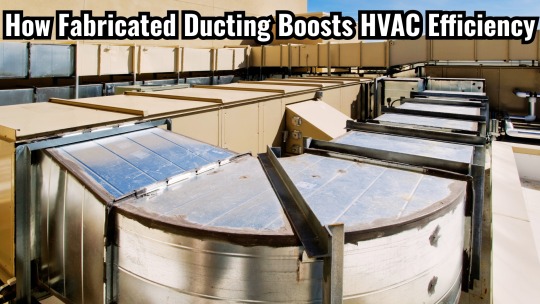

How Fabricated Ducting Boosts HVAC Performance in Real-World Projects

When we talk about HVAC systems, most people focus on chillers, AHUs, or thermostats. But what quietly does the heavy lifting? Ducting. And not just any ducting — custom fabricated ducting.

In high-demand environments like hospitals, cleanrooms, pharma labs, and commercial buildings in India, the way air moves matters. A lot. That’s where fabricated ducting makes a real difference.

Let’s break it down simply 👇

🛠️ What is Fabricated Ducting?

Fabricated ducting means air ducts that are custom-built to match your space — unlike off-the-shelf ducts, which often force you to compromise on layout or performance.

Materials commonly used:

Galvanized Iron (GI) – strong and durable

Stainless Steel (SS) – ideal for sterile spaces like pharma

Aluminium – lightweight and corrosion-resistant

Pre-insulated (PUF/Phenolic) – great for thermal control

🌬️ Why is Fabricated Ducting Crucial for HVAC?

If you’re wondering whether fabricated ducts really make a difference, here’s your answer:

✅ Improved airflow with fewer bends or leaks

✅ Energy efficiency due to lower resistance

✅ Noise control from proper insulation

✅ Custom fit, even in awkward spaces

✅ Better indoor air quality by preventing dust and microbial buildup

⚙️ How It Enhances HVAC System Performance

Your HVAC system is only as good as the ducts that carry its air. Here's how custom fabrication gives you an edge:

🚫 Reduces air loss (standard ducts can lose 20–30%!)

📈 Boosts efficiency by distributing air evenly

🔄 Extends system lifespan by reducing strain

🗺️ Supports zoning — cool different areas as needed

🧱 Where is Fabricated Ducting Used in India?

The demand is growing fast in:

🏥 Hospitals & Clinics

🧪 Pharma Plants & Cleanrooms

🏢 IT Parks & Offices

🛍️ Shopping Malls

🏨 Hotels

🔬 Laboratories & Diagnostic Centres

Any building where air quality and precision matter, fabricated ducting fits right in.

🧰 Which Duct Type Should You Choose?

Top-performing options:

GI Ducting – rugged and affordable

SS Ducting – pharma-grade quality

Aluminium – good for corrosion-prone areas

Pre-insulated – reduces cooling loss

Flexible ducts – for compact or hidden installs

🇮🇳 Best Ducting Materials for Indian Conditions

India’s heat, humidity, and dust demand tough, reliable materials. GI and SS are the most popular for long-term use. For newer, energy-efficient projects, pre-insulated ducts are gaining traction.

⚠️ Common Mistakes to Avoid

❌ Skipping insulation

❌ Using incorrect duct sizes

❌ Poor sealing

❌ No planning for future maintenance

❌ Ignoring pressure and velocity needs

💡 Why Not Just Use Ready-Made Ducts?

Because every building is different. Custom fabrication ensures:

Precise fit

Less leakage

Better insulation

Easier maintenance

Cleaner aesthetics

📌 Choosing the Right Ducting Partner

Before selecting a fabrication company, ask:

Do they have experience in your sector (e.g., pharma, healthcare)?

Do they follow ISHRAE/ASHRAE standards?

Do they offer end-to-end support — from design to installation?

Do they use certified materials?

✅ Final Thoughts

Custom fabricated ducting is no longer optional — it’s a smart, long-term investment in HVAC efficiency, comfort, and cost savings. In high-performance environments, quality airflow can make or break your system’s performance.

So, if you're building a hospital, pharma lab, or upgrading your commercial HVAC setup — it’s time to think beyond just machines and focus on the ducts that connect them.

💼 Need reliable HVAC ducting solutions? 👉 AUM Industries offers end-to-end fabricated ducting tailored for hospitals, cleanrooms, pharma, and commercial projects. Custom-built. Standard-compliant. Performance-optimized.

#FabricatedDucting#HVACPerformance#CleanroomSolutions#HVACIndia#PharmaInfrastructure#ModularOT#ICUSetup#HospitalDesign#AirflowEfficiency#TurnkeySolutions#GIducting#PreInsulatedDucts#AUMIndustries#DuctingExperts#HealthcareHVAC

0 notes

Text

ALD Equipment Market Regional Growth, Trends Report 2037

The Atomic Layer Deposition (ALD) Equipment Market is set for substantial growth in the upcoming years. Valued at USD 4.3 billion, the market is anticipated to surge to approximately USD 9.2 billion by 2037, reflecting a compound annual growth rate (CAGR) of 12.7% from 2025 to 2037. This growth is primarily fueled by the rising demand for nanoscale thin-film technologies, particularly in sectors such as semiconductor manufacturing, energy storage, and cutting-edge electronics.

ALD Equipment Industry Demand

Atomic Layer Deposition (ALD) Equipment is essential for nanofabrication processes, enabling the precise layering of atoms on substrates. This technology is crucial for producing advanced semiconductor devices, micro-electromechanical systems (MEMS), photovoltaics, and various other high-performance electronics. ALD works through a series of self-limiting chemical reactions, allowing for precise, atomic-scale deposition of thin films in multiple layers.

Key Drivers of Demand for ALD Equipment

Cost-Effectiveness: Although ALD systems have high initial investment costs, they provide high yields and minimize material waste, leading to a reduced total cost of ownership in precision manufacturing environments.

Scalability and Process Uniformity: ALD ensures that films are deposited uniformly, even across large surfaces or complex 3D structures, making it indispensable for producing smaller, high-performance devices.

Durability and Stability: ALD-produced films are chemically stable, highly adherent, and corrosion-resistant, making them ideal for applications requiring long-term durability.

Ease of Integration: ALD systems are modular and designed for easy integration with existing semiconductor fabrication lines, reducing setup time and operational complexity.

ALD Equipment Market: Growth Drivers & Key Restraint

Growth Drivers –

Semiconductor Miniaturization: As the demand for smaller and more powerful electronics increases, ALD plays a crucial role in depositing conformal films at the nanoscale. It is essential for manufacturing advanced semiconductor components, such as FinFETs and high-k dielectrics.

Technological Advancements in Energy Storage and Photovoltaics: ALD is widely used to improve battery electrode interfaces and enhance light absorption in thin-film solar cells, driving demand in energy storage and photovoltaic applications.

Investment in R&D and Manufacturing Expansion: Increased funding for semiconductor fabrication capacity, especially in regions like Asia and North America, is directly boosting the demand for ALD equipment as companies strive to keep up with innovation in the electronics industry.

Restraint –

High Capital Investment and Operational Complexity: The substantial initial costs of ALD systems and the technical expertise required for installation and maintenance remain significant challenges. This limits the adoption of ALD systems to large-scale manufacturers and research laboratories, making it difficult for small- and medium-sized enterprises (SMEs) to adopt this technology.

ALD Equipment Market: Segment Analysis

Segment Analysis by Product Type (Batch ALD Equipment, Single Wafer ALD Equipment):

Batch ALD Equipment: Designed to process multiple wafers simultaneously, batch systems are ideal for high-throughput applications, commonly used in solar cell manufacturing and memory chip production where speed and volume are critical.

Single Wafer ALD Equipment: These systems offer greater precision and control, particularly for advanced semiconductor fabrication. They are frequently used in high-performance applications such as logic chips and photonics, where uniformity and reliability are paramount.

Request Report Sample@ https://www.kennethresearch.com/sample-request-10352548

Segment Analysis by Application (Semiconductor Devices, Solar Cells and Photovoltaics, MEMS and NEMS Devices, Optoelectronics and Photonics, Energy Storage and Conversion):

Semiconductor Devices: ALD is critical in the semiconductor industry, especially for the deposition of dielectric and barrier layers in next-generation chips. The continuous scaling down of transistors fuels the demand for ALD in this sector.

Solar Cells and Photovoltaics: ALD is used to improve the efficiency of solar cells by applying high-quality passivation and anti-reflective coatings. The shift towards new types of solar cells, such as perovskite and tandem cells, also bolsters the demand for ALD technology.

MEMS and NEMS Devices: Micro- and nano-electromechanical systems benefit greatly from ALD's ability to deposit conformal coatings, enhancing device performance, reliability, and longevity.

Optoelectronics and Photonics: ALD technology is crucial in manufacturing optical coatings and components for devices like LEDs, lasers, and photodetectors, supporting advancements in optoelectronic applications.

Energy Storage and Conversion: ALD is increasingly being used in energy storage applications, such as lithium-ion batteries and supercapacitors, to enhance performance by improving interfacial stability and compatibility with electrolytes.

Segment Analysis by End‑User(Semiconductor Manufacturing, Research and Development (R&D), Electronics and Consumer Goods, Automotive and Aerospace, Medical and Healthcare):

Semiconductor Manufacturing: Semiconductor foundries and integrated device manufacturers (IDMs) are the largest consumers of ALD systems, relying on them for high-volume chip and sensor production.

Research and Development (R&D): ALD equipment is widely used in research labs and universities for developing new materials and fabricating experimental devices in nanotechnology.

Electronics and Consumer Goods: ALD technology is employed in the production of high-resolution displays, touchscreens, and other consumer electronics, where precision and long-term durability are essential.

Automotive and Aerospace: The rise of electric vehicles (EVs) and the growing need for high-reliability components in aerospace applications are driving the adoption of ALD systems for applications such as battery coatings, sensors, and other critical automotive electronics.

Medical and Healthcare: In healthcare, ALD is used to deposit biocompatible coatings on medical implants, drug delivery systems, and diagnostic equipment, where precise surface control and durability are crucial.

ALD Equipment Market: Regional Insights

North America

North America, particularly the United States, holds a significant share of the ALD equipment market. The region benefits from a robust semiconductor industry, high research and development investments, and government funding aimed at advancing manufacturing technologies. The presence of major chipmakers and equipment suppliers contributes to a stable demand base for ALD systems.

Europe

Europe remains a strong contender in the ALD equipment market, particularly in specialized applications and research-driven innovations. Countries like Germany, the Netherlands, and France are heavily investing in semiconductor self-sufficiency and green energy initiatives, further driving demand for ALD systems. European academic institutions and research organizations are key contributors to market development.

Asia-Pacific (APAC)

The expansion of semiconductor fabrication facilities in countries such as China, Taiwan, South Korea, and Japan plays a crucial role in driving market growth. Government support, along with a dominant consumer electronics manufacturing base, ensures sustained demand for ALD technologies in the region. Additionally, the growth of solar cell and battery manufacturing in APAC further strengthens ALD adoption.

Access our detailed report link: https://www.kennethresearch.com/report-details/ald-equipment-market/10352548

Top Players in the ALD Equipment Market

ASM International,Lam Research,Applied Materials,Tokyo Electron Limited (TEL),Beneq,Veeco Instruments,Picosun (Acquired by ASM),Kurt J. Lesker Company,Oxford Instruments,SENTECH Instruments,Forge Nano,ALD NanoSolutions,CN1 (China National Microtech),Wonik IPS,Jusung Engineering,Ultratech (Veeco),Sundew Technologies,SVG Optronics,NCD Co., Ltd.,Shibaura Mechatronics

0 notes

Text

At Tipco Engineering, we specialize in manufacturing high-quality ball mill machines tailored to the needs of various industries. From small-scale lab setups to large-scale production units, our industrial Ball Mills are engineered for reliability, precision, and cost-effectiveness.

0 notes

Text

Lab Spaces for Lease in Mountain View- A Prime Opportunity for Innovators

Mountain View, California, stands as a global epicenter for technology and scientific innovation, housing giants like Google, NASA Ames Research Center, and a thriving ecosystem of biotech startups. If you're seeking lab space for lease in this dynamic region, you're positioning your venture at the heart of Silicon Valley's innovation landscape.

Why Choose Mountain View for Your Lab Space?

Opting for lab space in Mountain View offers unparalleled advantages:

Proximity to Industry Leaders: Being near tech and biotech hubs fosters collaboration and access to cutting-edge research.

Access to Talent: The area attracts top-tier scientists, engineers, and researchers, providing a rich talent pool.

Robust Infrastructure: Mountain View boasts state-of-the-art facilities, including cleanrooms, specialized equipment, and high-speed internet connectivity.

Networking Opportunities: Regular industry events, conferences, and meetups facilitate connections with potential partners and investors.

Types of Lab Spaces in Mountain View for Lease Available

Mountain View offers a diverse range of lab spaces to cater to various research needs:

Biotech Laboratories: Equipped with specialized areas for cell culture, molecular biology, and protein analysis.

Cleanroom Facilities: Designed for research requiring stringent contamination control, such as semiconductor or pharmaceutical development.

Shared Lab Spaces: Cost-effective options for startups and small teams, providing access to high-end equipment and collaborative environments.

Private Lab Suites: Tailored spaces offering privacy and customization for specific research requirements.

Turnkey Lab Spaces: Fully equipped labs ready for immediate use, minimizing setup time and costs.

Key Considerations When Leasing Lab Space

Before committing to a lease, consider the following factors:

Compliance with Regulations: Ensure the facility meets local, state, and federal regulations, including safety standards and environmental guidelines.

Lease Terms and Flexibility: Understand the duration, renewal options, and any clauses related to expansion or downsizing.

Infrastructure and Amenities: Verify the availability of essential utilities, waste disposal systems, and backup power solutions.

Location and Accessibility: Assess the site's proximity to transportation hubs, suppliers, and collaborators.

Cost and Budget: Evaluate the lease rate in relation to your budget, considering both short-term and long-term financial implications.

Conclusion

Lab Spaces in Mountain View for Lease places your research or startup within a vibrant ecosystem of innovation and opportunity. With its strategic location, access to top talent, and state-of-the-art facilities, it's an ideal setting for scientific advancement. Careful consideration of your specific needs and thorough due diligence will ensure you select the perfect lab space to propel your endeavors forward.

If you require assistance in identifying available lab spaces or have specific requirements, feel free to reach out for tailored recommendations.

0 notes

Text

Diesel from Waste Plastic: Strengthening Backup Power Systems for Critical Infrastructure

In critical sectors like hospitals, data centers, and government offices, power backup is non-negotiable. Veera Group’s diesel from waste plastic technology ensures these institutions have a steady, cost-effective diesel supply — made directly from plastic waste.

When combined with plastic pyrolysis oil to fuel and tyre recycling machine setups, and accessible via the Veera Group website, organizations can secure uninterrupted energy while managing waste responsibly.

What Is Diesel from Waste Plastic?

It’s a fuel obtained by heating shredded plastic in an oxygen-free environment (pyrolysis), producing vapors that condense into diesel-like hydrocarbons — perfect for generators, emergency systems, and energy-critical operations.

Veera’s plastic pyrolysis oil to fuel model ensures consistent fuel generation for essential services.

Reliable Backup Setup

Collect Plastic Waste from Facilities and Vendors

Shred and Feed into Pyrolysis Plant (~450°C)

Condense Vapor to Create Diesel Fuel

Use Diesel Directly in Standby Gensets

Install Tyre Recycling Machine for Dual Fuel Output

Why It’s Ideal for Critical Facilities

✅ Guarantees Daily Diesel Supply from On-Site Waste ✅ Reduces Fuel Procurement Delays ✅ Secures Essential Operations During Outages ✅ Minimizes Carbon Footprint Through Local Fuel Generation ✅ Complies with Green Building and ESG Standards

Ideal Applications

Hospitals and multi-specialty health centers

Data centers and telecom towers

Government secretariats and municipal buildings

Research institutes and laboratories

Disaster management offices and shelters

By implementing diesel from waste plastic with plastic pyrolysis oil to fuel and tyre recycling machine, critical infrastructure remains energy-resilient and eco-friendly.

Institutional Incentives

Disaster resilience project grants

Renewable energy integration benefits

Carbon savings through backup energy optimization

Sustainable infrastructure certification

Conclusion

With Veera Group’s diesel from waste plastic system, critical sectors can guarantee uninterrupted power while managing waste smartly. Supported by plastic pyrolysis oil to fuel and tyre recycling machine technologies, energy security becomes clean, green, and self-sufficient.

0 notes

Text

Diesel from Waste Plastic: Strengthening Backup Power Systems for Critical Infrastructure

In critical sectors like hospitals, data centers, and government offices, power backup is non-negotiable. Veera Group’s diesel from waste plastic technology ensures these institutions have a steady, cost-effective diesel supply — made directly from plastic waste.

When combined with plastic pyrolysis oil to fuel and tyre recycling machine setups, and accessible via the Veera Group website, organizations can secure uninterrupted energy while managing waste responsibly.

What Is Diesel from Waste Plastic?

It’s a fuel obtained by heating shredded plastic in an oxygen-free environment (pyrolysis), producing vapors that condense into diesel-like hydrocarbons — perfect for generators, emergency systems, and energy-critical operations.

Veera’s plastic pyrolysis oil to fuel model ensures consistent fuel generation for essential services.

Reliable Backup Setup

Collect Plastic Waste from Facilities and Vendors

Shred and Feed into Pyrolysis Plant (~450°C)

Condense Vapor to Create Diesel Fuel

Use Diesel Directly in Standby Gensets

Install Tyre Recycling Machine for Dual Fuel Output

Why It’s Ideal for Critical Facilities

✅ Guarantees Daily Diesel Supply from On-Site Waste ✅ Reduces Fuel Procurement Delays ✅ Secures Essential Operations During Outages ✅ Minimizes Carbon Footprint Through Local Fuel Generation ✅ Complies with Green Building and ESG Standards

Ideal Applications

Hospitals and multi-specialty health centers

Data centers and telecom towers

Government secretariats and municipal buildings

Research institutes and laboratories

Disaster management offices and shelters

By implementing diesel from waste plastic with plastic pyrolysis oil to fuel and tyre recycling machine, critical infrastructure remains energy-resilient and eco-friendly.

Institutional Incentives

Disaster resilience project grants

Renewable energy integration benefits

Carbon savings through backup energy optimization

Sustainable infrastructure certification

Conclusion

With Veera Group’s diesel from waste plastic system, critical sectors can guarantee uninterrupted power while managing waste smartly. Supported by plastic pyrolysis oil to fuel and tyre recycling machine technologies, energy security becomes clean, green, and self-sufficient.

Would you like me to continue with Subblog #7? 🚀

You said:

0 notes

Text

Top Features to Look for in an Anti Vibration Table

In a modern laboratory setting, precision is everything. From microscopic analysis to high-sensitivity measurements, even the slightest external vibration can result in inaccurate results. That’s where an Anti Vibration Table becomes not just an accessory—but an essential piece of lab equipment. Whether you’re setting up a new laboratory or upgrading an existing one, knowing what features to look for in a high-quality anti vibration table can significantly impact the effectiveness and reliability of your work.

This article explores the key features that define a reliable Anti Vibration Table and why working with a trusted Modular Lab Manufacturer & Supplier makes all the difference.

What is an Anti Vibration Table?

An Anti Vibration Table is a specially engineered work surface designed to absorb and isolate vibrations. These vibrations can be generated from nearby equipment, foot traffic, or building infrastructure. In laboratories where precision instruments such as balances, microscopes, or interferometers are used, uncontrolled vibrations can severely affect outcomes.

To mitigate this, anti vibration tables use a combination of damping materials, heavy structural bases, and air or elastomeric suspension systems to eliminate or minimize the transfer of motion.

Why You Need an Anti Vibration Table in the Lab

Accuracy and reproducibility are the cornerstones of scientific research. If vibrations are interfering with your instruments, you risk compromising data integrity. Whether in pharmaceutical research, materials science, or biotechnology, the consequences of even a small error can be significant.

Key benefits of using an anti vibration table include:

Improved measurement accuracy

Enhanced durability of sensitive instruments

Reduction in measurement errors and rework

Support for high-precision and long-term studies

Top Features to Look for in an Anti Vibration Table

When choosing the ideal Anti Vibration Table for your lab, look for a combination of structural, mechanical, and ergonomic features that ensure peak performance and adaptability.

1. Vibration Isolation System

The heart of any anti vibration table is its isolation system. These are typically:

Pneumatic (air-based) isolators that use compressed air to “float” the tabletop and absorb vibrations.

Elastomeric or rubber isolators, which use high-density polymer materials to dampen vibrations.

The best choice depends on your equipment sensitivity and lab environment. Pneumatic isolators offer excellent performance for ultra-sensitive devices, while elastomeric systems are cost-effective and require minimal maintenance.

2. Heavy-Duty Construction

A high-quality anti vibration table should be made from:

Powder-coated steel or stainless steel frames for durability and corrosion resistance

Granite or marble tops, which are dense and naturally dampen vibrations

The table must be solid enough to prevent resonance and flexible enough to accommodate different instruments without compromising stability.

3. Load Capacity

Different lab instruments have varying weight requirements. Choose a table with a load capacity that matches or exceeds your equipment’s specifications. Overloading an anti vibration table can compromise its effectiveness and safety.

Check for:

Static load capacity (how much weight the table can bear)

Dynamic load capacity (how much movement or activity it can absorb)

4. Adjustable Leveling

Many lab floors are not perfectly flat. A good anti vibration table should include:

Adjustable leveling feet or screws to ensure a perfectly horizontal surface

Built-in bubble levels or digital levels to simplify alignment

Leveling is especially important for instruments like balances and optical setups where even slight angles can affect results.

5. Modular Design and Customization

In modular lab setups, flexibility is key. A reputable Modular Lab Manufacturer & Supplier should offer anti vibration tables that can be integrated seamlessly into your existing or future lab layouts.

Look for:

Modular frames that can be expanded or reconfigured

Custom dimensions and cutouts for cable management or accessory placement

Options for castor wheels with brakes for mobility

6. Ergonomic Features

Comfort matters in long lab sessions. Consider features like:

Optimal working height for sitting or standing use

Edge design for wrist comfort

Easy-to-clean surfaces for maintaining hygiene in sterile environments

These features reduce fatigue and improve productivity over time.

7. Environmental Compatibility

Labs come with varying conditions—some may have high humidity, while others may require anti-static equipment. Your anti vibration table should be:

Corrosion-resistant

Antimicrobial or easy to sterilize

EMI-shielded, if sensitive electronics are used nearby

Make sure to communicate your lab’s environment to your Modular Lab Manufacturer & Supplier so they can recommend compatible features.

Partnering with the Right Supplier

Choosing a reliable Modular Lab Manufacturer & Supplier ensures not only product quality but also proper installation, after-sales support, and customization. A specialized supplier understands the challenges of modern laboratories and can recommend anti vibration tables tailored to your workflow and budget.

They can also help with:

Lab layout optimization

Integration with other modular furniture or cleanroom systems

Compliance with industry safety standards

Final Thoughts

The importance of a well-engineered Anti Vibration Table in laboratory environments cannot be overstated. Whether it’s for precision weighing, microscopy, or spectrometry, these tables form the foundation of high-accuracy work.

By prioritizing features like isolation performance, material quality, modularity, and ergonomic design, laboratories can significantly enhance both the reliability of their results and the comfort of their researchers.

If you're in the process of upgrading your lab or setting up a new facility, consult a trusted Modular Lab Manufacturer & Supplier to ensure that your anti vibration solutions are aligned with your technical needs and future goals.

0 notes

Text

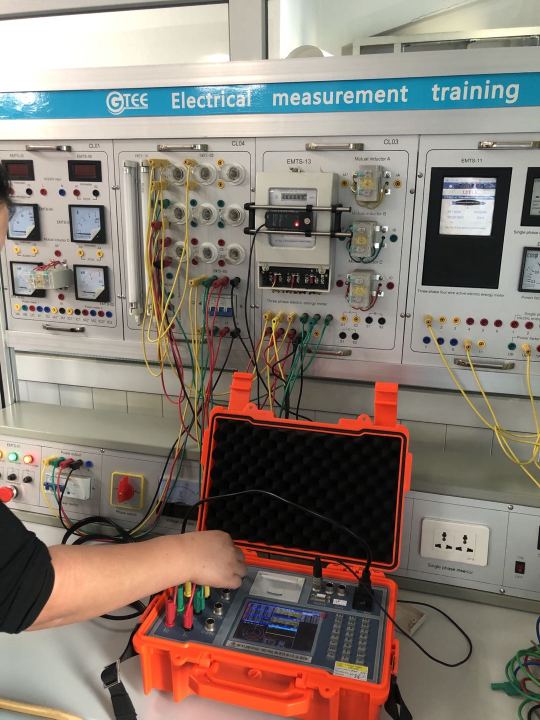

GF312B Three Phase Portable Electricity Meter Calibration Equipment

The GF312B Three Phase Portable Electricity Meter Calibration Equipment is a high-precision device designed to provide reliable and efficient calibration for three-phase electricity meters. This portable unit ensures the accuracy of energy meters in a variety of applications, making it essential for energy management, testing, and system calibration. Ideal for use in both field and laboratory settings, the GF312B offers a cost-effective solution for verifying the accuracy of three-phase electrical metering systems.

Key Features:

Three Phase Calibration: The GF312B is specifically designed for calibrating three-phase electricity meters, enabling accurate testing of all three phases simultaneously. This makes it ideal for monitoring and verifying energy usage in commercial, industrial, and utility-scale applications.