#knurlings

Explore tagged Tumblr posts

Text

They are my favorites

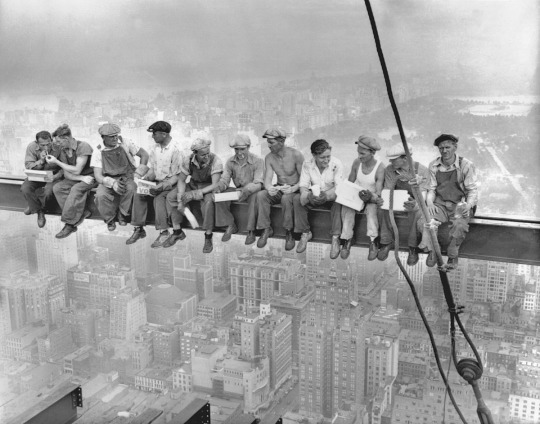

#how draw. how do I draw#team fortress 2#tf2 scout#tf2 sniper#tf2 medic#sniperscout#tbh scout’s arm is a bit long and I’ve fixed that but that’s a pretty good picture I shot so i don’t feel like retaking#I’m glad to say that after maybe like. 6 months I’ve dramatically improved my ability to draw faces#not that they were awful before but like yknow. anime same face syndrome#went from that and twinks to old knurled men. yippeee!! my true calling

287 notes

·

View notes

Text

Please appreciate this insanely adorable coaster set I 3D printed. Ft weightplates, barbell, and even a squat rack.

#AND I designed them#the goddamned knurling on the barbell nearly drove me insane#and just printing the plates in general like fuck#still not 100% happy with the finish#but it’s good enough#personal#3D printing

26 notes

·

View notes

Text

#Stainless Steel Pin Manufacturer in Delhi#Stainless Steel Pins Manufacturer#Hinge Pins Manufacturer#Dowel Pins Manufacturer#KNURLED PINS Manufacturer#Precision CNC Turned Component Manufacturer#Precision Turned Component Manufacturer

2 notes

·

View notes

Text

pencil edc :3

#ive been using the .5mm orenznero the most#got the .3mm orenznero yesterday and im p hyped about it#the .7mm sharp has colored lead in it#the other ones are just in case i wanna switch it up or smthing lol#i kinda dont like the rotring 600 ngl#its verry popular but i find that the balance really sucks#big fan of the knurling tho

2 notes

·

View notes

Text

#stainless steel dowel pins#stainless steel dowels#precision turned components#small turned parts#Stainless Steel Shafts#Stainless Steel Axis#Stainless Steel Pin#Precision Pins#Grooved Pin#Knurled pins#ss shaft#ss pins

2 notes

·

View notes

Photo

"Dragonborn, huh? Was it your ma or your pa that was the dragon?"

#the elder scrolls#skyrim#tes#gamingedit#tesedit#skyrimedit#tesvedit#the elder scrolls v: skyrim#mine*edit#mine*ocs#oc*knurl helgrind#my last post of him is 8 goddamn years old he really deserved to have a better screenshot up

13 notes

·

View notes

Text

Rapidly approaching the "can't be stuck if it's a liquid" stage of trying to get this valve cap off.

#musical instrument repair#brass instrument#brasswind#musical instrument#baritone#third valve caps are always the most annoying#the clearance around it isn't much#so I can't get a very solid grip on it#this one doesn't have chunky knurling either#which would help for grabbing it#probs gonna let it sit over the weekend with some oil on it and hope that loosens things#it'll still work fine even if the cap never comes off#but it's the principle of the thing#I do not enjoy being bested

3 notes

·

View notes

Text

CTF-6H-SC-Knurled

2 notes

·

View notes

Text

im still so annoyed about the (very cool!) planetary gear reduced 3d printer extruder design that had nonmeshing gears on purpose to try and balance out the tolerance issues with trying to 3d print perfectly meshing gears & i commented asking about it and then the description was updated to be like "SOME people have asked for a 72t (or whatever) version, even though i designed it like that for a reason, so if youre really anal about gear ratios you can try it out. youll probably have to run it in for a really long time to get it to go smoothly if you dont have good tolerances, and my first design was literally fine, but here you go. UNRELATED: in the next version were moving to sls printed part kits because theyre more reliable and have better tolerances so thats very exciting :D" like so then i was RIGHT!!!!! is what youre saying!!!!!! bastard!!!!!!!!!! and he already warned that a run in period was mandatory on fdm printed sets anyway even with his design!!!!!!!!!

#i REALLY want that on guys insane screw thread extruder to take off i want population testing like regular knurled gear ones have gotten#it feels like the only evolutions of extruders since the wades or whatever has just been different ways to sequence gears & having a whole#new strategy is exciting!!! AND its insane that it can be like 1/8 the weight of a regular one!!!!!#i still wish i could figure out how to stick a gimbal motor onto it it would literally all work fine except trying to mix 4x screw holes on#the motor plate with 3 spaces on the extruder body. i wanna try it out with 2 rollers and 2 guards instead of 3 rollers but i dont like#have any of the components so its just been an idle thought for the last like year#its THE PERFECT excuse to use a brushless motor though. i know it deep in my heart

2 notes

·

View notes

Note

.

Is spider silk being as strong as steel another lie from childhood? Bc you're able to break it pretty easily on accident. Genuinely asking.

spider silk IS actually significantly stronger pound-for-pound than the same amount of steel, but only in one direction! and coincidentally, it's the same exact direction that got a bunch of people killed in a submersible last month.

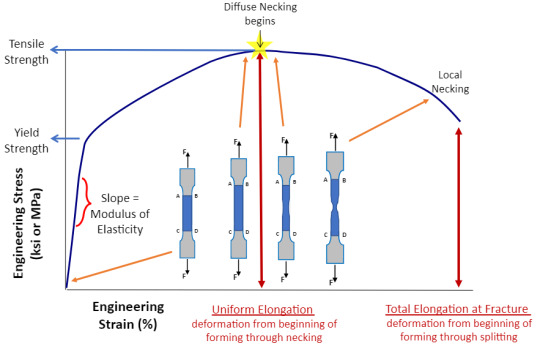

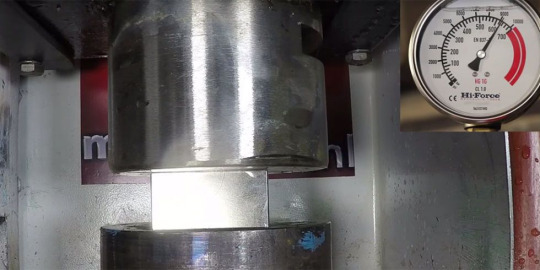

see, when people talk about the "strength" of spider silk versus steel, they're specifically talking about tensile strength:

which is specifically the measure of the strength of a material when two forces are pulling at it from the ends, like when a steel cable is holding up a bridge support, or crane cargo:

or like when a strand of silk is supporting the entire spider.

that's tensile strength, baby!

but there's another type of strength that's very important to take into consideration when you're actually building things like bridges and submersibles, and spider silk and similar materials like carbon fiber are absolutely garbage at it! and that's compressive strength.

this is basically the inverse of tensile strength, where instead of being yanked at from both ends, the forces are crushing inwards at the material from both directions instead.

you can expect to see these kinds of forces involved in road surfaces, vehicle engines, and again, submersibles.

now steel and its more competent cousin titanium are fucking GREAT at compressive strength! the harder the outside forces are compressing them, the stronger the metals get.

NOT TODAY, FUCKERS

but strand-based materials like spider silk and, again, carbon fiber, are fucking garbage at this. they can take a certain amount of pressure, but each round with compressive forces snaps some of the strands that makes up the material! and those don't grow back, so basically you're just gradually reducing your poor overstressed carbon-fiber hull into a completely useless shell of shattered thread fragments over time as the strands of fiber that actually give it strength die off one by one.

and eventually, something's gotta give! and then people die about it.

this is why, even though spider silk IS stronger than steel in one specific way, we're never going to stop using steel in industrial applications and switch over to spider silk or carbon fiber full time. these materials all have their areas of use, and steel just covers a wider base of applications.

and don't even get me started on shear strength. we'll be here all damn day.

#huh. i was going to take issue with the 'more competent cousin' statement#but titanium alloys have come a long way since my undergrad days#it seems they've resolved the fatigue limit issues and now the main barrier is cost#though i wonder if the hcp structure is as friendly to production techniques like knurling#machining is still a splosion hazard i think

5K notes

·

View notes

Text

Knurling & Embossing Roller

We can emboss your Imagination, our product is most probably used in Textile industry, Plastic industry & Glass industry, Embossing on Cloth & Paper, Raxin & Leather, non woven.

1 note

·

View note

Text

gymnasts: i just completed an insane bar routine with a bunch of pirouettes and handstands. oh my hands are bleeding profusely because i ripped all my calluses? didnt even notice lol

me: omg my lil baby callus has started ripping at the corner, to reveal a smaller, identical callus underneath? sorry but i simply cannot continue this 115 deadlift

#somebody shut me up#deadlifts hurt my hand SO MUCH because the bars at the gym are so aggressively knurled lol#but i know im being a baby about it. i got lil sensitive baby hands lol#how did i play rugby??? i fold so easy at any pain

1 note

·

View note

Text

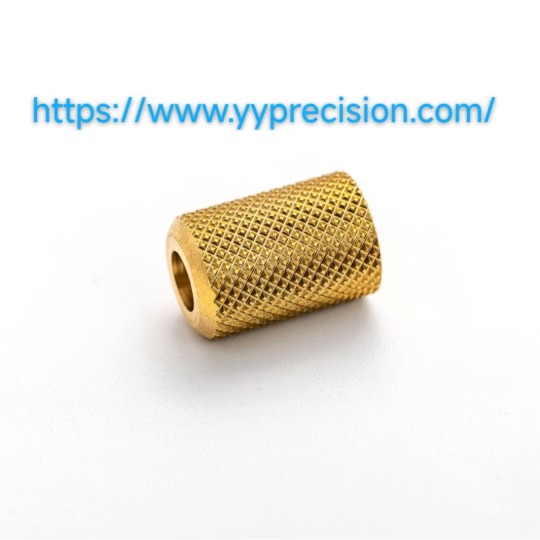

Fastening connection function:

In mechanical equipment: used to connect two or more mechanical parts to ensure the stable operation of the equipment. For example, in some small transmission devices, instruments and other equipment, circular knurled nuts can firmly connect different parts together, withstand a certain vibration and tension, and prevent parts from loosening or separation.

In the field of construction: It can be used to connect various components in the building structure, such as in steel structure buildings, round knurled nuts can be connected to steel beams, steel columns and other components to ensure the stability and safety of the building structure.

Easy to manually operate and adjust: The pattern on the surface of the knurled nut can increase the friction, and it is convenient for people to directly twist the nut by hand without the help of other tools, which is very practical in some occasions that need to be adjusted or disassembled frequently. For example, on some equipment that requires frequent adjustment of height or Angle, the use of circular knurled nuts can be easily adjusted manually.

For injection molding and embedding process: In the injection molding process of plastic products or other materials, the round knurled nut is pre-buried in the mold, and then the injection molding is carried out to make the nut and the plastic part tightly. This can form a strong threaded connection structure on the plastic products, which is convenient for subsequent assembly and use. For example, in the shell of electronic equipment, auto parts, toys and other plastic products, this kind of embedded round knurled nut is often used.

As a connector for thin plate connection: in the connection of some metal sheets, such as in the manufacture of chassis, cabinets, metal furniture, etc., round knurled nuts can be used with the pull riveting process. The nut is fixed on the thin plate by the rivet gun to realize the connection between the thin plate, which is both firm and beautiful, and can avoid welding or tapping operations on the thin plate, and reduce the damage to the thin plate.

In furniture manufacturing: used for the assembly and connection of furniture, such as the frame connecting tables and chairs, the panel fixing furniture, etc. The appearance of the knurled nut can be selected according to the design requirements of the furniture, which meets the functional requirements of the connection without affecting the aesthetics of the furniture.

0 notes

Text

Buy Online H-type knurled door pulls In USA- Doorpulls

Upgrade your doors with our top-quality H-type knurled door pulls. These stylish and practical handles provide a strong and comfortable grip, making them perfect for homes and businesses. The knurled texture gives extra grip, and the modern H-shape adds a sleek look. They come in different finishes and sizes to match any style. Improve your doors with our high-quality H-type knurled door pulls!

0 notes

Text

Brass Anchor Fastener Manufacturer in Jamnagar India

GK Metals is a leading brass anchor manufacturer in Jamnagar, India. We manufacture, supply and export a wide range of brass anchor fastener like brass drop in anchor, brass wood anchors, brass sleeve anchors, brass pool anchors and more as per custom requirements.

#brass anchors#brass anchor manufacturer in Jamnagar#brass anchor manufacturer#brass anchor fastener#brass concrete anchors#brass drop in anchor#brass wood anchors#brass wedge anchors#brass sleeve anchors#brass pool anchors#brass spring anchors#brass knurling anchors

0 notes