#ketchup pouch packing machine manufacturer

Explore tagged Tumblr posts

Text

TOMATO KETCHUP POUCH PACKING MACHINE MANUFACTURER DELHI

Durag Packing Machine stands out as a premier manufacturer and supplier of Tomato Ketchup Pouch Packing Machines in Delhi, offering unparalleled quality and reliability in the industry. With a commitment to innovation and excellence, Durag Packing Machine has earned a stellar reputation for its cutting-edge technology and precision engineering.

Their Tomato Ketchup Pouch Packing Machines are designed to meet the diverse needs of the food packaging industry, delivering efficient, hygienic, and high-speed packaging solutions. These machines are equipped with advanced features like automatic pouch filling, sealing, and labeling, ensuring consistent product quality and minimizing downtime.

read more:https://www.durgapackagingmachine.com/delhi/tomato-ketchup-pouch-packaging-machine

0 notes

Text

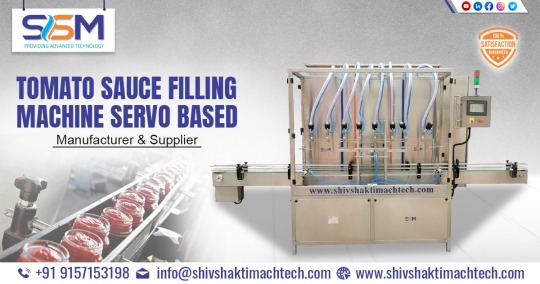

Tomato Sauce Filling Machine Servo Based

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Tomato Sauce Filling Machine Servo Based across India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech is a leading manufacturer and supplier of high-performance Servo-Based Tomato Sauce Filling Machines, designed to meet the precise filling requirements of the food processing industry. Our machines deliver accuracy, speed, and hygiene, making them ideal for small to large-scale production lines. Similar Sauce Bottle Filling Technology Machinery: Tomato Sauce Filling Machine, Ketchup Filling Machine, Automatic Tomato Sauce Servo Filling Machine, Automatic Sauce Tin Can Filling and Sealing Machine, Tomato Sauce Packing Machine, Automatic Liquid Filling Machine – Servo Based, Automatic Hot Tomato Sauce Filling Machine, Servo Automatic Sauce Filling Machin, Tomato Sauce Packaging Equipment, Tomato Sauce Bottling Machine Types of Tomato Sauce Filling Machines: Single-Head Servo Filling Machine Multi-Head Servo Filling Machine Automatic Servo-Based Filling Machine Semi-Automatic Filling Machine Custom Configurations Features: Servo Motor Technology: Ensures precision in filling volumes. Stainless Steel Construction: Durable and easy to clean, ensuring compliance with food-grade standards. Touchscreen Control Panel: Offers user-friendly operation and programmable settings. Adjustable Filling Nozzles: Accommodates various bottle sizes and shapes. Anti-Drip Mechanism: Prevents spillage and waste. High-Speed Operation: Enhances productivity for large-scale operations. What types of containers can this machine handle? Our machines can fill glass bottles, plastic jars, pouches, and even sachets. How accurate is the filling process? The servo-based design ensures high accuracy, typically within ±1% of the desired volume. Can this machine handle different viscosities? Yes, it is designed to handle various viscosities, from thin liquids to thick sauces. Is the machine suitable for small-scale production? We offer semi-automatic and single-head models that are perfect for small-scale operations. Shiv Shakti Machtech is a Supplier of Tomato Sauce Filling Machine Servo Based in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chitradurga

1 note

·

View note

Text

Nichrome: Packaging Taste and Safety into Every Bite with Integrated Food Packaging Solutions

The demand for packaged food has skyrocketed over the last decade, driven by consumers seeking convenience, hygiene, and ready-to-eat options. With changing lifestyles, rising incomes, and increasing mobility, more people are opting for packaged goods like edible oils, food grains, milk, snacks, and mithai over traditional loose products. The modern consumer is not just looking for taste but also for safety, quality, and portability, while manufacturers focus on maximizing production, minimizing downtime, and reaching new markets with international standards.

Smart Packaging for a Fast-Paced World

For food manufacturers, packaging is no longer just about wrapping a product — it’s about ensuring efficiency, safety, and convenience. A packaging partner that can deliver an integrated line, from primary to secondary and even tertiary packaging, can revolutionize a manufacturer’s operations. This is where Nichrome steps in, offering comprehensive solutions that not only streamline operations but also ensure that every element of packaging works seamlessly together.

A turnkey supplier like Nichrome takes the headache out of packaging by managing everything from design to installation, so manufacturers can focus on what they do best: producing great food.

Finding the Right Fit: How to Choose Your Packaging Machine

Choosing the right packaging machine can be overwhelming, but there are a few key factors to consider:

Size and Weight: Make sure the machine fits your floor space.

Ease of Operation: A user-friendly machine keeps your line moving.

Cost Efficiency: Consider not just the upfront cost, but the long-term savings on maintenance and operations.

Flexibility: Look for machines that can adapt to different product lines.

Reliability: Trust in the manufacturer’s expertise and after-sales support.

Nichrome: Pioneers of Food Packaging in India

Nichrome has been at the forefront of food packaging innovation for over 40 years. From creating India’s first indigenous milk pouch packaging machine to providing advanced automated systems today, Nichrome continues to lead the charge in delivering versatile, efficient packaging solutions. Whether you need machines for potato chips, edible oil, ketchup, sugar, or any other food product, Nichrome’s machines are designed for high efficiency with minimal downtime.

Nichrome’s Versatile Food Packaging Solutions

Nichrome’s strength lies in its ability to provide single-source convenience, offering end-to-end solutions that cover everything from product handling to warehousing. Nichrome’s solutions are highly adaptable, with many machines capable of serving multiple applications through simple changes in the filling system.

Primary Packaging Solutions: Including bottle filling, jar filling, tin filling, bulk bag filling, and Blow Fill Seal (BFS) lines.

Secondary Packaging Solutions: These can be integrated for seamless operations, such as vertical and horizontal cartoners, auto case packers, and flexiwrap systems.

End-of-Line Systems: From automatic pallet dispensing to robotic palletizers, Nichrome provides complete integration to ensure your entire packaging process is optimized.

Why Nichrome?

As a trusted name in food packaging, Nichrome’s expertise spans the packaging of everything from grains, pulses, and powders to liquids, viscous foods, and ready-to-eat products. With over four decades of experience and more than 10,000 installations in 45 countries, Nichrome offers unmatched solutions that maximize space, efficiency, and resource utilization.

Conclusion: The Complete Packaging Solution with Nichrome

Whatever your packaging needs — whether it’s tin packing, bottle filling, case packing, or flow wrap — Nichrome is your go-to partner for integrated solutions that not only meet your needs but exceed your expectations. With Nichrome’s tailored approach and extensive experience, you can be confident that your packaging operations will run smoothly, efficiently, and cost-effectively.

So, why settle for less when you can pack perfection with Nichrome? Step into the world of advanced packaging and discover how Nichrome’s solutions can propel your business to new heights!

#TinFillingMachine#AutomaticBottleFillingMachine#PackagingSolutions#NichromePackaging#IntegratedPackaging#SafeFoodPackaging

0 notes

Text

Sauce Pouch Packing Machine Manufacturer

Durga Packaging Machine specializes in crafting high-quality sauce pouch packing machines machine . designed to meet the diverse needs of the food and beverage industry. Our machines are engineered for precision, reliability, and efficiency, ensuring that each sauce pouch is filled and sealed to the highest standards. With a focus on user-friendly operation, our machines feature intuitive controls and easy maintenance, allowing for seamless integration into production lines.

Built with robust materials and advanced technology, Durga Packaging's sauce pouch packing machines offer exceptional durability and long-term performance. They are equipped with innovative filling systems that accommodate a range of sauce viscosities, from thin liquids to thick, chunky sauces. This versatility makes them ideal for various applications, including ketchup, mayonnaise, and specialty sauces.

0 notes

Text

Stick and Sachet Packing Machine Market Size, Share, Trends Analysis with Forecast 2024-2033

The global stick and sachet packing machine market was valued at US$ 7.2 billion in 2021 and it is anticipated to grow up to US$ 12.4 billion by 2031, at a CAGR of 5.5% during the forecast period.

Packaging machines are used for packaging products or components. The need for packaging machines to integrate with upstream manufacturing processes has resulted in the development of automation techniques for several sectors. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

To Know More@ https://www.globalinsightservices.com/reports/stick-and-sachet-packing-machine-market/?utm_id=Pranalip

A stick pack machine is a single lane vertical form fill seal packaging machine where a roll of film is cut, multiple small stick pack bags are formed, and products are filled and sealed inside it. The main applications include small packagings such as sugar sachet, small ketchup sachet, and coffee stick packing machine.

Sachet packaging is extensively used in the cosmetics & personal care, food & beverages, and pharmaceutical industries. Sachets are small, sealed, flexible pouches manufactured from paper, plastic, aluminum foil, and cellulosic and contain liquid, powder, or capsule products. As they are cheaper than large-size packets, sachets are generally used either for promotional trial packs or to cater to low-income or price-sensitive customers who prefer economical packs.

Market Drivers and Trends

Sugar sachet packing machines, milk sachet filling machines, sachet stick packs, and tea sachet packing machines are some examples of sachet packaging machines that are increasing in demand, and the demand for small sachet packing machines is expected to drive the market’s revenue growth due to the presence of many food and beverage manufacturers.

Sachet packing machine is most extensively used in medicine packaging. Sachet packing machines can easily produce blister foils, slip packs, and easy-open pouches at high speed which has increased manifold due to the growing demand for pharmaceutical products are expected to drive the growth of the sachet packaging machine market.

Therefore, increasing demand in food and pharmaceutical sectors are boosting the global stick and sachet packing machine market growth.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS10460/?utm_id=Pranalip

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS10460/?utm_id=Pranalip

Global Stick and Sachet Packing Machine Market Segmentation

By Type

Stick Pack Packing Machine

Sachet Packing Machine

By Product Type

Powder and Granule

Liquid Products

Others

By End User

Food and Beverages

Pharmaceuticals

Chemicals

Cosmetics

Others

Major Players in the Global Stick and Sachet Packing Machine Market

The key players studied in the global stick and sachet packing machine market are ARANOW Packaging Machinery, S.L. (Spain), Duravant LLC (Spain), Ilapak International SA (Switzerland), Körber AG (Germany), Matrix Packaging Machinery, LLC (US), Nichrome Packaging Solutions (India), OMAG Srl (Italy), SmartPac Verpackungsmaschinen GmbH (Germany), Syntegon Technology GmbH (Germany), and Universal Pack S.r.l. (Italy).

COVID-19 Impact

In 2020, the COVID-19 pandemic resulted in economic challenges owing to subsequent lockdowns. In 2020, the manufacturing industry was severely affected due to a drastic decrease in product demand, falling prices, and storage shortages. A swift decline in manufacturing revenues due to virtually nonexistent manufacturing demand and slow production capabilities had limited the expenditure on the production of stick and sachet packing machines worldwide. Thus, the COVID-19 pandemic negatively affected the global stick and sachet packing machine market in 2020.

However, in 2021, the manufacturing industry started recovering from the significant labor and supply chain challenges that triggered the production of stick and sachet packing machines.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS10460/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Stick and Sachet Packing Machine Market to grow with CAGR of 7.9% by 2031 | ARANOW Packaging Machinery, S.L. (Spain), Duravant LLC (Spain)

The global stick and sachet packing machine market was valued at US$ 7.2 billion in 2021 and it is anticipated to grow up to US$ 12.4 billion by 2031, at a CAGR of 5.5% during the forecast period.

Packaging machines are used for packaging products or components. The need for packaging machines to integrate with upstream manufacturing processes has resulted in the development of automation techniques for several sectors. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

To Remain ‘Ahead’ Of Your Competitors, Request for A Sample – https://www.globalinsightservices.com/request-sample/GIS10460

A stick pack machine is a single lane vertical form fill seal packaging machine where a roll of film is cut, multiple small stick pack bags are formed, and products are filled and sealed inside it. The main applications include small packagings such as sugar sachet, small ketchup sachet, and coffee stick packing machine.

Sachet packaging is extensively used in the cosmetics & personal care, food & beverages, and pharmaceutical industries. Sachets are small, sealed, flexible pouches manufactured from paper, plastic, aluminum foil, and cellulosic and contain liquid, powder, or capsule products. As they are cheaper than large-size packets, sachets are generally used either for promotional trial packs or to cater to low-income or price-sensitive customers who prefer economical packs.

Market Drivers and Trends

Sugar sachet packing machines, milk sachet filling machines, sachet stick packs, and tea sachet packing machines are some examples of sachet packaging machines that are increasing in demand, and the demand for small sachet packing machines is expected to drive the market’s revenue growth due to the presence of many food and beverage manufacturers.

Sachet packing machine is most extensively used in medicine packaging. Sachet packing machines can easily produce blister foils, slip packs, and easy-open pouches at high speed which has increased manifold due to the growing demand for pharmaceutical products are expected to drive the growth of the sachet packaging machine market.

Therefore, increasing demand in food and pharmaceutical sectors are boosting the global stick and sachet packing machine market growth.

Market Restraints and Challenges

The higher costs for the production and import activities for the integrated packaging machinery, such as wrapping, automated labeling, palletizing machines, and significant others, require higher capital costs. Such factors are hindering the overall growth of the packaging machinery industry. Further, the taxes imposed on the customs duty in developing regions such as India, Argentina, and other countries were also negatively influencing the overall growth of the packaging machinery industry. Thus, the higher costs for the production and import activities and taxes imposed on the customs duty in developing regions are anticipated to hinder the growth of the global stick and sachet packing machine market.

Get A Customized Scope to Match Your Need Ask an Expert – https://www.globalinsightservices.com/request-customization/GIS10460

Major Players in the Global Stick and Sachet Packing Machine Market

The key players studied in the global stick and sachet packing machine market are ARANOW Packaging Machinery, S.L. (Spain), Duravant LLC (Spain), Ilapak International SA (Switzerland), Körber AG (Germany), Matrix Packaging Machinery, LLC (US), Nichrome Packaging Solutions (India), OMAG Srl (Italy), SmartPac Verpackungsmaschinen GmbH (Germany), Syntegon Technology GmbH (Germany), and Universal Pack S.r.l. (Italy).

COVID-19 Impact

In 2020, the COVID-19 pandemic resulted in economic challenges owing to subsequent lockdowns. In 2020, the manufacturing industry was severely affected due to a drastic decrease in product demand, falling prices, and storage shortages. A swift decline in manufacturing revenues due to virtually nonexistent manufacturing demand and slow production capabilities had limited the expenditure on the production of stick and sachet packing machines worldwide. Thus, the COVID-19 pandemic negatively affected the global stick and sachet packing machine market in 2020.

However, in 2021, the manufacturing industry started recovering from the significant labor and supply chain challenges that triggered the production of stick and sachet packing machines.

Global Stick and Sachet Packing Machine Market Segmentation

By Type

Stick Pack Packing Machine

Sachet Packing Machine

By Product Type

Powder and Granule

Liquid Products

Others

By End User

Food and Beverages

Pharmaceuticals

Chemicals

Cosmetics

Others

Buy Now – https://www.globalinsightservices.com/checkout/single_user/GIS10460

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Excel data pack included with all report purchases

Robust and transparent research methodology

New Report Published by Global Insight Services : https://www.globalinsightservices.com/reports/hydrogen-projects-database/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

0 notes

Text

From Soybean Oil to Specialty Oils: Nichrome's Filpack Servo SMD Fills Perfection to Your Oil Packaging

When it comes to oil packaging, precision and efficiency are paramount. From everyday cooking oils like soybean oil to specialty oils that cater to unique culinary experiences, the demand for high-quality packaging solutions is ever-increasing. Nichrome, a leading provider of packaging machines, understands the critical role that oil packaging machines play in delivering perfection to the oil industry. In this blog, we will explore how Nichrome's Filpack Servo SMD series offers a versatile and efficient solution for oil packaging, meeting the diverse needs of the market.

Soybean & Oil Market in Bangladesh

Soybean and the oil industry in Bangladesh have witnessed significant growth and importance in recent years. As one of the largest agricultural producers in South Asia, Bangladesh has embraced soybean cultivation to meet the growing demand for edible oils. The soybean industry plays a crucial role in enhancing food security, providing a locally sourced alternative to traditional oil imports. With government support and technological advancements, the oil industry in Bangladesh has seen notable developments in processing and packaging.

Leading companies like Nichrome have introduced innovative oil packaging machines and filling solutions, enabling local businesses to deliver high-quality oils to consumers. This dynamic industry continues to evolve, contributing to the country's economic progress and paving the way for a sustainable future in the edible oil sector.

What makes Nichrome a reliable oil packaging machine manufacturer in Bangladesh:

Mastering the Art of Viscous Liquid Filling: Oil packaging requires a filling machine capable of handling viscous liquids without compromising on accuracy. The Filpack Servo SMD, a cutting-edge viscous liquid filling machine, is specifically designed to handle a wide range of oils, including soybean oil and other specialty oils. With its servo-driven technology, this machine ensures precise filling, eliminating wastage and guaranteeing consistent quantities in every pouch.

A One-stop Solution for Oil Packaging: The Filpack Servo SMD isn't just limited to soybean oil packaging machines, it's a versatile solution that accommodates various oil types and packaging formats. Whether you need automatic sachet packing or pouch sealing for oils, this machine has you covered. Its adaptable design allows for seamless switching between different packaging requirements, reducing downtime and enhancing overall productivity.

Precision Pouch Sealing for Product Integrity: Maintaining the quality and freshness of oils is crucial to meet consumer expectations. The Filpack Servo SMD excels in ensuring airtight pouch sealing, protecting the oils from external contaminants, and preserving their flavor and aroma. This advanced pouch sealing machine guarantees that each pouch is securely sealed, enhancing product integrity and consumer confidence.

Elevating the Packaging Experience: Oil packaging is not just about functionality; it's about making a statement on the retail shelf. With the Filpack Servo SMD's sleek design and efficient operation, your oils will stand out with eye-catching pouches. Elevate your brand's presence with well-packaged oils that leave a lasting impression on consumers.

Unmatched Efficiency and Productivity: Time is money in the packaging industry, and Filpack Servo SMD knows it well. This automatic sachet packing machine is engineered for efficiency, offering high-speed packaging without compromising on accuracy. Experience increased productivity with minimal manual intervention, allowing your team to focus on other critical aspects of your business.

Filpack Servo SMD by Nichrome

For packaging oil and other viscous products such as soybean oil, ghee, ketchup, fruit pulp, mayonnaise, kitchen oil, curry pastes, and even grease, paint, adhesives, etc., FILPACK SERVO SMD spells peace of mind.

Designed with twin heads & independent operation.

Compact design which occupies less floor space

Enclosed SS cabinet for hygienic operation

Can pack quantities 100/200/500 & 1000 ml.

Output speed up to 80 to 85 packs per minute

In conclusion, from everyday cooking oils to specialty oils, Nichrome's Filpack Servo SMD series is the ultimate solution for your oil packaging needs. This viscous liquid filling machine guarantees precision, adaptability, and efficiency, ensuring perfection in every pouch. Embrace the future of oil packaging with Nichrome's advanced technology and take your brand to new heights of success in the competitive oil market.

For more information on the Filpack Servo SMD series and other packaging solutions, reach out to Nichrome today. Elevate your oil packaging experience and leave a lasting impression on consumers with perfection in every pouch.

#pouch packing machine#oil packaging machine#vertical form fill seal machine#filling and packaging machine#airtight food packaging#nichromebangladesh#blister packaging machine#powder packaging machines#packaging machine supplier in bangladesh#olive oil#pouch sealing machine

0 notes

Text

NICHROME KETCHUP PACKING SOLUTIONS ARE A NOTCH UP

Globally, and across industries, pouch filling machines are a popular choice for viscous condiments packing and viscous ready to eat foods like tomato ketchup. Tomato ketchup packing is usually done in two ways—in tear away or standee pouches, or in High Density Polyethylene (HDPE) bottles.

In either case, the tomato ketchup packaging needs to be robust and leak-proof. Hence the need for superior quality packing machinery. Pouches are flexible, lightweight bags that offer many advantages over traditional packaging such as metal cans or glass bottle packing.

Types of Ketchup Packing

There are two major types of liquid pouch filling machines: vertical form fill seal (VFFS) and horizontal form fill seal (HFFS) packing machines. The filled and sealed bag is cut away. As is evident in many tomato sauce/ketchup brands, the top seal on the first bag becomes the bottom of the next bag, and the process repeats. The cut pouch falls to a collection system, typically a belt conveyor that brings the pouch to the next packaging step.

Ketchup packing is generally referred to as ‘flexible packaging’ or ‘sachet packing’ as opposed to ‘bottle and jar packing’ which is rigid.

Flexible packaging offers several advantages: it uses less material, needs less energy during formation, and produces less greenhouse gases during manufacturing. Being lightweight & unbreakable, it is economical to pack, store, and transport.

Nichrome Ketchup Packaging

There are many pouch filling machine manufacturers offering multiple packaging machines for diverse applications. If you are looking for a ketchup pouch packing machine manufacturer--Nichrome is your best bet.

Four decades of experience worldwide, intensive inhouse R&D, state-of-art manufacturing, technology tie-ups with global majors, thousands of successful installations, strong nation-wide service network – few pouch filling machine manufacturers can match the knowhow, capabilities, and record of accomplishment of Nichrome.

HFFS for Ketchup Packing

Whether your ask is for HFFS or multitrack packing machine (for 4 side seal pouches up to 100 gm); pick fill seal machines; bottling line or standee pouch/ DOYPACK pouch packing-- explore Nichrome's offerings for packing tomato paste/ketchup. Nichrome offers special sealing technology for viscous liquids on its multitrack machines.

Cost-effectiveness

Nichrome is dedicated to offering the most advanced packaging technology for food, pharma, and other relevant industries. Nichrome can deliver top quality at competitive prices with its own R&D centre, manufacturing, and testing facilities.

High ROI

Nichrome proactively supports customers from consultation and customized packaging machine development to the production of the packaging machine, backing it up with extensive after-sales service. Some hallmarks of Nichrome’s packaging solutions are high production rates, optimum accuracy, and consistent pouch quality as per the client’s requirements.

T-110

In its T-110 ketchup packaging machine, Nichrome offers an efficient integrated system for ketchup filling and packaging that covers a turntable, UV sterilisation chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labelling machine, date & batch coding system, and packing table. SKUs range from 100 ml to 20 litres. Applications include a wide range of packing solutions for food & liquids such as ketchup.

T-140

Nichrome's HFFS packaging machines bring you next generation, linear technology from Europe. The series is versatile and can be used for packing a wide range of powders, grains, snacks, liquids, and viscous products like ketchup using different fillers. The series also offers a range of pouch formats with superior pouch aesthetics.

T-170

Nichrome’s HFFS packaging machines, especially the T-170 are PLC based with touch screen interface. The compact and versatile design offers both single and perforated chain of pouches with quick and easy changeover. Well-designed duplex modules are available for higher outputs.

Nichrome is a leading manufacturer of form-fill-seal packaging machines in India. A pioneer of flexible packaging in India, Nichrome brings four decades of experience and innovation to the table.

Nichrome’s offerings include a wide range of VFFS and HFFS packaging machines. Horizontal form fill seal machines are traditionally more flexible and versatile than vertical form fill seal ones, although the latest VFFS packaging systems are more adaptable to different products, pouch types & sizes, film types than earlier versions.

Pick and Fill Seal

Nichrome’s Pick-Fill-Seal machine provides the combined benefits of variety, productivity, and specialty packaging for ready-to-eat foods. Using versatile rotary technology, the horizontal packaging machine conveniently packs a wide variety of ready-to-eat foods in eye-catching innovative shapes while maintaining freshness of the products.

The machine is sturdy and compact, easy to clean and maintain. An advanced variant of packaging technology innovated by Nichrome enables two or three different fillers to dispense multiple types of ingredients in the same pouch.

Bottle Filling Machine

Nichrome’s Automatic Bottle Filling system is designed to handle many different types of products, from water to tomato ketchup. From products with thin watery consistency to highly viscous products like ketchup, Nichrome’s liquid food packaging system can handle them all.

Nichrome’s liquid filling machine also handles a versatile SKU range with fast changeover and no change of parts. It is equally efficient packing in glass, HDPE and PP bottles or metal tins.

Conclusion

It could be a small variation in a pouch format or customization of an existing machine; a pro-actively developed filling system or consultancy & system design for a complete packaging plant - -Nichrome has the expertise, capabilities and innovation to transform productivity and enrich customer relationships in endless ways. Call Nichrome to discuss your unique requirements and let us amaze you with our products and services.

#ketchup filling#pouch filling machines#tomato ketchup packaging#vertical form fill seal (VFFS)#horizontal form fill seal (HFFS) packing machines#pouch filling machine manufacturers#ketchup pouch packing machine manufacturer#pick fill seal machines#bottling line#ketchup packaging machine#Automatic Bottle Filling system#liquid filling machine

0 notes

Text

Milk Packing Machine Manufacturers in Ernakulam

Milk Packing Machine Manufacturers in Ernakulam

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Milk Packing Machine Manufacturers in Ernakulamhttps://sampackindia.com/milk-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

Seeds Packing Machine Manufacturers in Bangalore

Seeds Packing Machine Manufacturers in Bangalore

We are the popular Seeds Packing Machine Manufacturers in Bangalore. The Potato Chips Making Machine Manufacturers in Bangalore of a large number of items which incorporate pickle Filling Machine, pickle pressing machine, tea programmed pocket pressing machines, tea bundling pockets machine cost, flavors filling machine and dates pressing machine. Ketchup Packing Machine Manufacturers in Bangalore is intended for filling little amount of powders in sachets shaped from the virgin/covered material. The napping unit is a drill filler machine with uniquely planned screw/Funnel precisely releases the powder in the framing sachet. Our seal component and the item release is synchronized to give the most elevated speed and precision. 3 and 4 side seal models are likewise accessible on demand. Extraordinary element, extraordinarily intended for the items which should be filled in little sachet/pockets as well as in bottles. Pouch Packing Machine Manufacturers in Bangalore and filling machines are connected with the connector so that machine can be utilized as pocket filling machine also as it tends to be mounted on the conveyor zed framework for filling bottles. Easy to utilize microcontroller/PLC based regulator assists with setting different boundaries for the machines including the weight, half/full cutting, Pouch bunching and so on.

Pickles are a significant backup of food and it is sold in the market in pockets and bundles. The Seeds Packing Machine Manufacturers in Bangalore of pickles utilize the Pickle Packing Machine in their plant to make the most common way of filling and pressing pickles simple and easy. Machines offer an opportunity to purchase these machines in both programmed and self-loader forms. In the event that you are a producer or provider of pickles, make the most of this open door and get the machine for Seeds Packing Machine Manufacturers in Bangalore. The machine is driven by a pneumatic power. It fills pickles in pockets and afterward seals and packs it. The pressing of pickles is finished under clean circumstances to stay away from defilement in the pickles so it is a protected method.

The Seeds Packing Machine is made of tempered steel and it has major areas of strength for a vigorous development. It is a top quality machine with a long help life. This is the motivation behind why it is involved by the exporter of Seeds Packing Machine Manufacturers in Bangalore. It is feasible to tweak the machine according to the requirements of clients. The activity and utilization of the Pressing Machine are basic and simple. It has an extremely fine completion. Since the machine utilizes an extremely low influence, it gets a good deal on the energy bills.

Keywords: Dosa Making Machine Manufacturers in Bangalore, Batter Making Machine Manufacturers in Bangalore, Seeds Packing Machine Manufacturers in Bangalore, Potato Chips Making Machine Manufacturers in Bangalore, Potato chips plant Making Machine Manufacturers in Bangalore

0 notes

Text

Milk Packing Machine Manufacturers in Ernakulam-sampackindia

Milk Packing Machine Manufacturers in Ernakulam-sampackindia

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Milk Packing Machine Manufacturers in Ernakulam-https://sampackindia.com/milk-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

Milk Packing Machine Manufacturers in Ernakulam

Milk Packing Machine Manufacturers in Ernakulam

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

0 notes

Text

Milking Value with Dairy Packaging Solutions from Nichrome

India is currently the world’s largest milk producer. This happened over a period of three decades, as India transitioned from a country with severe milk shortages to the world’s foremost milk producer. A recent report states that the dairy industry in India is expected to cross INR 30,840 billion by 2027.

India’s dairy consumption is also the highest in the world. India’s dairy industry is divided into organised and mainly unorganised sectors.

CRISIL projects that the organised dairy industry will see yearly growth of 5-6%. While this consumption is primarily of liquid milk, there is an increasing demand for and consumption of other dairy products like lassi, flavoured milk, ice cream, yoghurts, cheese, ghee etc.

These factors combined suggest a growing need for systems and infrastructure that elevate milk production, its processing and product quality. The increase in population, higher disposable income, higher per-capita consumption, larger vegetarian population and the demand for hygiene have made the industry transition to a more organised market and invest in dairy and milk packaging machines.

Nichrome’s relationship with India’s dairy industry goes back more than four decades. Nichrome designed India’s first milk packaging machine in the 1970s, responding to the Government’s rallying cry for cost-effective, indigenous packaging solutions. Nichrome’s first Filpack machine was commissioned at Kurla Dairy, Mumbai where the commercial supply of milk pouches was started in 1977.

In the present day, Nichrome is amongst the country’s top milk packaging machine manufacturers. Nichrome’s world-class range of milk and dairy packaging machines and systems enable milk and dairy producers to develop their business while keeping the product quality intact. Whether it be small dairy farmers, large dairies or multinationals, Nichrome partners with this industry starting from consultation to customized solution development and finally onto reliable service and support.

Nichrome VFFS Filpack Series

The Filpack Series from Nichrome consists of a number of automatic packaging machines for the filling and packing of milk and related dairy products. This range includes:

Filpack Servo 12K: This is India’s fastest milk pouch packaging machine with a capacity to pack at the rate of 12,000 pouches per hour.

Filpack Servo 6K: This is a high-speed, low wastage milk packaging machine with a capacity to pack at the rate of 6,000 pouches per hour.

Both the above automatic liquid packaging machines offer a range of pouch width options - 100 mm, 125 mm and 150 mm, with volumes of 200 ml, 500 ml and 1000 ml.

These liquid pouch packing machines are composed of a complete stainless steel structure, with a digital heat control system that allows for maximum accuracy and insulated tanks that regulate product temperature. The HMI can be used to set the recipe and change the quantity, and machine automation can be remotely controlled.

Filpack CMD Alpha

This is an automatic milk packing machine that is shorter and occupies less floor space. Twin heads mean that two products can be packed at once, and maintenance can be conducted on one while the other is in operation. This automatic packaging machine is the favoured choice for packaging milk, flavoured milk, lassi, curd etc.

Filpack CMS 5L

A versatile machine that can pack both liquids and viscous products with speed and accuracy in larger 5500 ml pouches. This machine can pack liquids at a speed of 800 pouches/hour, while viscous products can be packed at 400 pouches/hour. It consists of a pneumatic filling system that ensures better filling uniformity while the enclosed stainless steel cabinet and SS 304 parts ensure hygienic and low-maintenance operations.

Filpack Universal

This is a leading-edge solution from Nichrome in dairy products packaging machines. It has multiple applications in free-flowing liquids (milk, buttermilk, water, juices etc) and viscous products (cream, ghee, mayonnaise, ketchup, etc.). The output speed can go up to 5000 packs per hour. This machine is also available in a Double Head Combo.

Nichrome’s HFFS Machines for Dairy Packaging

T-series: This range of horizontal-form-fill-seal HFFS machines incorporates the latest linear technology from Europe and has the capacity of filling and packing a diverse range of products - granular, liquid, viscous or powder. The T series is ideal for packaging milk, lassi, buttermilk, flavoured milk, cream, curd etc for dairy producers who would like to go with a horizontal packaging machine for their packaging operations.

Nichrome’s Mini Dairy Plant

Nichrome’s special, entry-level mini dairy plant was developed for small dairy farmers to help them achieve the goal of independent retail operations. This milk processing plant is small, doesn’t have a boiler, and filters, pasteurises, homogenises and packs milk in 200 ml, 500 ml or 1000 ml pouches. This definitive milk plant is designed to be compact, energy-efficient, and easy to operate for small dairy farmers.

Conclusion

Nichrome’s renowned expertise in dairy products packaging technology is well proven - in India as well as other countries. Nichrome’s offerings include multiple packaging solutions for dairy products such as milk, lassi, buttermilk, curd, cream, ghee and even dairy whitener and milk powder. If you’re looking to package dairy powders, you should consider Nichrome’s Maxima 400, Excel 400 Plus Servo Auger, Sprint 250 Plus Servo Auger, Multilane Stickpack and Nichrome’s Multitrack machine for Milk Powder in small SKU or their Machine for packing Spray dried Millk .

Nichrome has also carried out the addition of a bottle filling line, tin filling line and cup filling line that can be adapted for dairy applications.

Nichrome epitomises quality, technology and cost-efficiency across all its products and systems. Customers get the assurance of advanced technology, high-quality components and manufacturing, stringent testing, and comprehensive installation, training and service support.

Nichrome is participating in Propak East Africa 2022 being held at The Sarit Exhibition Centre in Nairobi, Kenya between 10-12 May 2022. Do visit us at stall no A13!

Visit www.africa.nichrome.com for more information.

#dairy and milk packaging machines.#milk packaging machine#country’s top milk packaging machine manufacturers#dairy packaging machines#automatic packaging machines#milk pouch packaging machine#liquid packaging machines#liquid pouch packing machines#automatic milk packing machine#automatic packaging machine#dairy products packaging machines.#HFFS machines#horizontal packaging machine#mini dairy plant#bottle filling line#tin filling lines#Milk powder packaging machine#Yogurt packaging machine

1 note

·

View note

Text

Everything You Need to Know About Bag-in-Box Packaging

Bag-in-box has impressed a major segment of the population and quite successfully replaced the other packaging solutions available in the market. It has a strong bladder-like structure made of several metallic films or other plastics embedded in an uneven fiber case.

Bag-in-boxes are used by the companies to transport juice, wine, or other liquids and even act as singles for the semi-automated machines. Initially, an extensive procedure was mandatory, but now the manufacturers make this packaging via FSF (form seal fill) technology.

To know about the history, uses and advantages of bag-in-box, please check out the rest of the discussion now.

History

The first bag-in-box liquid packaging was invented in the year 1955 by an American chemist for transporting and dispensing battery acids securely. This invention revolutionized the packaging industry to a great extent, and the concerned chemist and his team gained a footing in the hall of fame.

Uses

Bag-in-box is noted for having a series of commercial applications. The most common one is to supply syrups to the soft drink cascades and to distribute condiments such as mustard and ketchup in bulk to the hotel industry, especially the fast-food outlets.

Bag-in-box technology also managed to retain its original application – the transfer of sulfuric acid for filling the car batteries in dealerships and garages. As described further, this particular packaging has been implemented to sell wine.

For the commercial syrups, the customers have to open one part of the box, connect a compatible tube to the fitment on the bag, and pump the contents out carefully. The fitment has a valve which opens only when pressure is applied from the tube. This keeps contamination at bay.

In case of boxed wine, the tap is already fixed to the bag, so all one has to do is find the location of the tap on the box.

Advantages

Bag-in-box packaging has attained widespread recognition probably because it is inexpensive, thus, can be afforded by all. It also does not harm the environment because the contents in between 1.5 and 1000 liters are always labeled. The material is lighter than the plastic alternatives, so, have a proper carbon footprint.

Aseptic Package

Bag-in-boxes have lately been utilized extensively to pack dairy products and processed fruits in the aseptic processes. Aseptic packaging is considered beneficial because the products require no refrigeration and last for a prolonged period (up to 2 years at least).

The key is to fill the product in the bag without exposing it to external environmental conditions at any stage. So, there is no possibility of germ infestation. The bag is again irradiated. If planning on investing in bag-in-box, stand up pouch machinery, or any other flexible packaging solution for that matter, please make sure to rely on an authentic provider. He/she must assure quality products for a reasonable price.

0 notes

Text

Pickle Packing Machine Manufacturers in Ernakulam

Pickle Packing Machine Manufacturers in Ernakulam

We are the popular Pickle Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of a large number of items which incorporate pickle filling machine, pickle pressing machine, tea programmed pocket pressing machines, tea bundling pockets machine cost, flavors filling machine and dates pressing machine. Ketchup Packing Machine Manufacturers in Ernakulam is intended for filling little amount of powders in sachets shaped from the virgin/covered material. The napping unit is a drill filler machine with uniquely planned screw/Funnel precisely releases the powder in the framing sachet. Our seal component and the item release is synchronized to give the most elevated speed and precision. 3 and 4 side seal models are likewise accessible on demand. Extraordinary element, extraordinarily intended for the items which should be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are connected with the connector so that machine can be utilized as pocket filling machine also as it tends to be mounted on the conveyor zed framework for filling bottles. Easy to utilize microcontroller/PLC based regulator assists with setting different boundaries for the machines including the weight, half/full cutting, Pouch bunching and so on.

Pickles are a significant backup of food and it is sold in the market in pockets and bundles. The Pickle Packing Machine Manufacturers in Ernakulam of pickles utilize the Pickle Packing Machine in their plant to make the most common way of filling and pressing pickles simple and easy. Machines offer an opportunity to purchase these machines in both programmed and self-loader forms. In the event that you are a producer or provider of pickles, make the most of this open door and get the machine for Pickle Packing Machine Manufacturers in Ernakulam. The machine is driven by a pneumatic power. It fills pickles in pockets and afterward seals and packs it. The pressing of pickles is finished under clean circumstances to stay away from defilement in the pickles so it is a protected method.

The Pickle Packing Machine is made of tempered steel and it has major areas of strength for a vigorous development. It is a top quality machine with a long help life. This is the motivation behind why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is feasible to tweak the machine according to the requirements of clients. The activity and utilization of the pressing machine are basic and simple. It has an extremely fine completion. Since the machine utilizes an extremely low influence, it gets a good deal on the energy bills.

Pickle Packing Machine Manufacturers in Ernakulamhttps://sampackindia.com/pickle-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

Milk Packing Machine Manufacturers in Bangalore

Milk Packing Machine Manufacturers in Bangalore

We are the famous Milk Packing Machine Manufacturers in Bangalore. The Milk Packing Machine Manufacturers in Bangalore of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket Squeezing Machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Bangalore is expected for filling the little measure of powders in sachets molded from virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Bangalore and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Bangalore of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Bangalore. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs them. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle Squeezing Machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Bangalore. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Keywords: Vegetable cutting Machine Manufacturers in Bangalore, Pickle Packing Machine Manufacturers in Bangalore, Milk Packing Machine Manufacturers in Bangalore, Ketchup Packing Machine Manufacturers in Bangalore, Tomato sauce Packing Machine Manufacturers in Bangalore

0 notes