#milk pouch packaging machine

Explore tagged Tumblr posts

Text

Dairy packaging machines

Nichrome is a manufacturer of automatic milk & liquid packaging machines, milk & liquid filling machines for products like Milk, Flavor Milk, Lassi, Juice, Wine & Drinks, Mineral Water, Liquor, Curd, Butter Milk, Basundi

#Dairy packaging machines#Dairy products packaging machine#Dairy & milk packaging machine#Milk packing machines#Milk packaging machine manufacturers#Milk filling machine#Milk packing machine#Milk pouch packing machine manufacturer#Milk packaging machine#Milk products packaging machine#Milk packing#Milk packaging

0 notes

Text

High-Speed Milk Pouch Packing Machines for Precision

Automate your dairy packaging with high-speed milk pouch packing machines that deliver precise, hygienic, and reliable filling for milk and liquid dairy products. Learn More:

0 notes

Text

High-Quality Food Packaging Machines At Behtar Zindagi

Food Packaging Machines

Find Wide range of high-quality food packaging machines designed to meet all your packaging needs. Whether you are looking for a pouch packing machine, milk weighing machine, or container sealing machine, we have you covered.

Milk Pouch Packing Machines

Our efficient milk pouch packing machines ensure your products securely packed, maintaining freshness and quality. Ideal for packaging snacks, spices, and other food items, these machines are a must-have for any food business.

Accurate Milk Weighing Machines

Ensure precise measurements with our milk weighing machines. These machines provide accurate and consistent weight readings, making them perfect for dairy farms and milk processing units.

Reliable Container Sealing Machines

Our container sealing machines offer reliable and airtight sealing for various containers. They are suitable for sealing jars, bottles, and other containers, keeping your products safe and extending their shelf life.

Versatile Masala Packing Machines

Our masala packing machines specifically designed to pack spices and powdered products efficiently. They ensure the preservation of aroma and quality, making them ideal for spice manufacturers.

Automatic Packing Machines for Speed and Efficiency

Increase your packaging speed and efficiency with our automatic packing machines. These machines are perfect for businesses looking to streamline their packaging process and increase productivity.

Thali Packing Machines for Convenience

Our thali packing machines are designed for easy and convenient packaging of food trays. They are perfect for restaurants, catering services, and food delivery businesses.

Trusted Packaging Machine Manufacturers

As trusted packaging machine manufacturers, we are committed to providing top-quality machines that meet your needs. Our products are durable, efficient, and backed by excellent customer service at Behtar Zindagi.

#seeds#agricultural machinery#agricultural products online#agriculture in india#agritech#behtar zindagi#farming equipment#fertilizers#indian agriculture#modern farming solutions#Food Packaging Machines#pouch packing machine#Milk Weighing Machine#container sealing machine#Food Packing Machines#masala packing machine#automatic packing machine#thali packing machine#packaging machine manufacturers

1 note

·

View note

Text

Packaging Machine Manufacturer in Guwahati

As a leading Packaging Machine Manufacturer in Guwahati, we specialize in designing and producing high-quality packaging machinery tailored to the specific requirements of our customers. With years of experience and expertise in the industry, we understand the importance of reliable and efficient packaging solutions in today's competitive market.

One of our flagship products is the Pouch Packing Machine in Guwahati. Engineered with precision and built to the highest standards, our Pouch Packing Machines are designed to efficiently package a wide range of products into pouches of various sizes and materials.

One of our flagship products is the Milk Packaging Machine in Guwahati. Engineered with precision and built to the highest standards, our Milk Packaging Machines are designed specifically for the dairy industry.

One of our specialized products is the Ice Candy Packaging Machine in Guwahati. Engineered with precision and built to the highest standards, our Ice Candy Packaging Machines are designed specifically for businesses in the frozen treat industry.

One of our specialized products is the Cap Sealing Machine in Guwahati. Engineered with precision and built to the highest standards, our Cap Sealing Machines are designed to securely seal caps onto containers of various sizes and materials.

In addition to manufacturing state-of-the-art packaging machines, we also serve as a trusted Packaging Material Supplier in Guwahati. We recognize the critical importance of top-quality packaging materials in ensuring the safety, preservation, and presentation of products.

One of our flagship products is the Shrink Wrapping Machine in Guwahati. Engineered with precision and built to the highest standards, our Shrink Wrapping Machines are designed to efficiently wrap products in shrink film, providing a tight and protective seal that enhances the presentation and protection of your packaged goods.

One of our specialized products is the Vacuum Packing Machine in Guwahati. Engineered with precision and built to the highest standards, our Vacuum Packing Machines are designed to remove air from packaging, creating a tight seal that extends the shelf life and preserves the freshness of your products.

Among our specialized products are biscuit and soap wrapping machines in Guwahati. Engineered with precision and built to the highest standards, our biscuit and soap wrapping machines are designed to efficiently wrap these products, ensuring their protection and presentation.

Among our specialized products is the Liquid Filling Machine in Guwahati. Engineered with precision and built to the highest standards, our Liquid Filling Machines are designed to accurately fill liquid products into containers of various shapes and sizes.

#packaging machine manufacturer#packaging material supplier#shrink wrapping machine in guwahati#vacuum packing machine#pouch packing machine#milk packaging machine#ice candy packaging machine#liquid feeling machine#biscuit and soap wrapping machines#cap sealing machine

0 notes

Text

#Milk Pouch Packing Machine Manufacturers in Pune#Milk Pouch Packing Machine Suppliers in Pune#Milk Pouch Packing Machine Dealers in Pune#Milk Pouch Packing Machine Exporters in Pune#Milk Pouch Packing Machine in Pune#Milk Pouch Packaging Machine Manufacturers in Pune#Milk Pouch Packaging Machine Suppliers in Pune#Milk Pouch Packaging Machine Dealers in Pune#Milk Pouch Packaging Machine Exporters in Pune#Milk Pouch Packaging Machine in Pune

1 note

·

View note

Text

Multilayer Blown Film Extrusion Machine in Namibia

Adroit Extrusion is a leading and trusted Manufacturer, Supplier, and Exporter of Multilayer Blown Film Extrusion Machine in Namibia. We manufacture Multilayer Blown Film Extrusion Machines in Ahmedabad, Gujarat, India. We designed our Multilayer Blown Film Extrusion Machine to produce films with multiple layers of material. The process involves extruding plastic resins through multiple extruders, blowing them into a tube, inflating, and cooling it to form films used for packaging. These films are typically stronger, more durable, and offer superior performance compared to single-layer films. Adroit Extrusion multilayer design is perfect for providing films with unique properties such as barrier resistance, flexibility, and strength. This makes it ideal for industries such as food packaging, agricultural packaging, and industrial applications, where the strength and quality of the film are crucial. Features: Auto Profile Film Thickness Control: Ensures precise and consistent film thickness throughout the process. Gravimetric Dosing System: Accurate and efficient control over the materials used in production. Bubble Scanner: Monitors and optimizes bubble stability during the extrusion process. Extru Touch Control System (UL-CSA Approved): Advanced control system ensuring seamless operation and safety. Applications: Liquid Packaging: Water, Milk, Oil, Ghee, Liquor Food Packaging: Wheat Flour, Rice, Sugar, Salt, Cereals Lamination Films: Biscuits, Chips, Chocolates, Confectionery, Snacks, Spices, etc. Shrink Films & Stretch Wraps: For packaging a wide range of products. Hygiene and Medical Packaging: Catering to the medical and sanitary product packaging needs. Industrial Packaging: Lubrication Oil Pouch, Grease, Chemical Packaging, and more. Adroit Extrusion is an Exporter of Multilayer Blown Film Extrusion Machine in Namibia and including locations Windhoek, Walvis Bay, Swakopmund, Henties Bay, Omaruru, Otjiwarongo, Okahandja, Grootfontein, Mariental, Outjo, Gobabis, Tsumeb, and Keetmanshoop. For more information on our Multilayer Blown Film Extrusion Machines, feel free to reach out to Adroit Extrusion today! View Product: Click here Read the full article

0 notes

Text

Edwin horizontal filling and packaging machine for coconut milk in pouches export to Philippines .

Please contact [email protected]

for more information

0 notes

Text

On a serious note I'm now so fucking curious about the whole cheap-accessible-harmless thing, and the pre-packaged products you can buy.

Obvipusly idgaf about cost in this scenario, corps can fuck off with their profit margins. So like. What are the most accessible options for these kinds of foods and drinks? What are the least harmful for the environment and stuff?

I think asking the accessibility question matters more and should be answered first, THEN eco-friendly, THEN cost. God, if more companies prioritized eco friendliness and shit, it would lower the cost and then everything can be cheaper for the good instead of having to be rich to afford to care about the environment. Ugh. Whatever.

But yeah. With drinks, what do disabled people struggle most with em? Can be canned, bottled, boxed, pouches, bagged even.

I think that as long as the puncture film is thin enough and the structure of the packaging isn't. Difficult. (looks at pouches). Then stabbing a straw into your drink might be pretty decent. For some I'm sure there's trouble with holding a straw, or precision required to hit right, or even strength to puncture. If it's thin enough compared to the rest of the container, I think the latter two are less of an issue, generally?

Canned drinks are *ok*, but only if the tab you pull doesn't hurt you. Makes me wonder if there's an alternate design that can be used to make it easier to pull, which would open the door for not just drinks, but canned foods, too.

And speaking of canned foods, FUCK NEEDING A CAN OPENER. Genuinely. That shit fuckin hurts if it's manual and it's stupid or possibly dangerous if it's a machine (I was really uncomfortable with the magnetized one we had with our family). MAKE YOUR CANS ACCESSIBLE. You should not need external/extra TOOLS to EAT.

So yeah pull tabs are mid but could be better simply bc they're REALLY inconvenient and even painful (I shouldnt have to use my nails to pull it up). Thinking about those biscuit tubes, you pull the cardboard from one end and it pops open eventually (bc ig the structural integrity is degraded bc the cardboard technically isn't as thick). Negatives being not just pulling the corner (though it's easier than a pull tab), but also? It creates anxiety over opening it because it's unpredictable when it'll pop. Plus, potentially loud noise, not good.

I think depending on what is in the container, being able to just. Tear apart the container? Not too horrible as long as it's not too HARD. I count pull tab cans because you pull open the lid.

OH YEAH There's these containers of like. I forgor the brand but it doesn't matter, spaghetti, ravioli, beefaroni (that should hint). There's these bowl-like containers, kinda? With a plastic lid. Those slap.

GOD THERES ALSO SEALS THAT ARE LIKE A FILM THAT YOU TEAR OFF. FUCK. Those are AWFUL!! It's because the seal end that sticks out can be too small to nonexistent, and the film itself is just SUPERGLUED to the fuckin thing. If I'm pulling a film seal off, I SHOULDNT SEE IT TEAR OFF ITSELF? Ugh so like there's a very specific kind of. Structure. That is good. It can't be paper :/ I actually hate those. It also can't be firm, rigid plastic, like I see with milk so often. Like they have a piece that you pull up? Literally, the least convenient fucking way to pull a film seal off. Who the fuck designed that.

I argue that it should always be a thin plastic film seal that isn't superglued. Think what you'd find on like. Fuck I mean I can totall imagine these for sandwiches, too.

Oh also yeah that makes me think of takeout containers. But like. The containers that have the like. Indents or smth that, arguably also callable as tabs, like those buttons that can click together? Those also range from dogshit to awesome but I feel like physically they're easier. They can be loud tho and snapping open might be unpleasant.

Ughhh I'm getting fucking eepy... I can't rlly devote enough brainpower to this shit but I'm like. Genuinely fascinated by this shit.

I'm speaking off my own experiences by the way!! I know that different ppl, different disabilities, leads to different preferences. Sensory issues, muscle or nerve issues and/or things that impact mobility, (c)ptsd and the effects of trauma and any triggers, I'm sure there's more.

I think that accessibility is really important. Not think. BELIEVE, and know. I also know that realistically, it's not feasible or even possible to have packaging (and other products or services) that accommodates EVERY issue that could happen.

As long as things are commonly accessible for a majority (no not just able-bodies or neurotypicals), then individualized accommodations would follow.

God I hate us being lowkey idealistic with ideas, but to have a major company that cares about accessibility and being eco-friendly, that isn't corrupt, that doesn't care about personal profits. Then there's branches of that company that accommodate differently. Whole departments dedicated to brainstorming and designing and testing different methods of accommodation for different disabilities and stuff.

And that it doesn't matter if you NEED it or not/just want it. You're still supporting the people making the accommodations by buying or using it.

I swear that consumerism{idr why I thought this, but like. It's the whole abled ppl using stuff designed with disabled in mind}, can be ok. I promise that just because capitalism is overall bad doesn't mean that there's small little aspects that we benefit from.

There are ideas and values and structures and stuff that will, by design, promote bad things. The reason it continues is because 1) status quo 2) Curly from mouthwashing type perspectives, where the perceived good outweighs the bad, the bad can be ignored in favor of [the idea of] the good.

Ugh. Brain. Focus.

Whatever. I can see ppl hating or finding bad takes in here. That's fair. I just want good in the world, man. I'm open to changed perspectives if it makes sense enough to me (lowkey a fucking flaw of ours).

Asking that if this fake scenario ever happened, where there was a big company that wasn't corrupt and it created products that were accommodating and eco friendly and stuff, praying disabled people wouldn't gatekeepe from abled people. You don't even know in many cases if someone is or not, and they may not either. Equity instead of equality or whatever. Fix the issue. Make it accessible for everyone. You don't even know their reason why they get or use it. Please don't gatekeep accessibility 🙏 the point of it is to make it so more people can access something. Not just a select handful of people with a specific issue. That's accommodation.

Individualized accommodation should be available/accessible btw :3 (ugh I'm so fucking tired. This was 🌼 or smth who said this btw. But fucking agreed.)

UGH caring is actually exhausting but like. So worth it sometimes. Even if I'm not doing much rn, thinking about it and technically discussing it is worth it.

0 notes

Text

At RollHouse, we create packaging that keeps your products safe and fresh. From milk and beverages to liquid foods, our aseptic cartons and filling machines are designed for quality and sustainability. Explore eco-friendly solutions like Brik and Prisma cartons, Fino pouches, and paper-based composite materials for all your packaging needs.

#aseptic packaging manufacturer#aseptic packaging solutions#aseptic packaging for milk#aseptic packaging for beverage#aseptic packaging for liquid food#aseptic carton packaging#aseptic carton packages#Brik aseptic carton#Fino Aseptic carton pouch#Prisma Aseptic carton#Tetra Pak#milk cartons#paper-based packaging#liquid paper-plastic-aluminum packaging#dairy product packaging

1 note

·

View note

Text

Ceylon Tea Private Label Packaging: Brewing Success in the Tea Market

Ceylon tea is one of the world's most loved drinks and has been a person's favorite for millions of people all over the world. With a wide range of teas, Ceylon Tea has become unique because of its amazing taste and quality. However, it's not only about the tea leaves themselves; the selling of tea is also significant among the factors leading to its success. Thus, we are going to look at why Ceylon Tea is, the importance of tea private label packaging, and the conditions prevailing in this field are the main points of the article.

What is Ceylon Tea? Think about Ceylon Tea first. The name “Ceylon” comes from the island of Sri Lanka, which was once called “Ceylon”. Ceylon Tea is first and foremost mainly developed in the hilly regions of Sri Lanka. Plus, the distinct terroir, and the processing ways further make it have an individual taste that the tea lovers are looking for worldwide.

More so, Ceylon Tea comes with the choice of mouthful experiences and different regions of the production area are the ones being branched off from. Taste notes made up of brisk, citrusy, and slightly astringent types are the most common ones. You can also enjoy the versatility of this flavor straight or with milk and sugar. It can be prepared to your liking. In addition, Ceylon Tea is not only limited to black tea. The country also has green and white tea varieties and even specialty ones like oolong and flavored mixes.

What is Private Label Packaging? Tea private label packaging is a process in which a company’s products are manufactured by one company but branded and sold by another company under the latter's brand. This is how it works in the tea market and in other sectors as well. The Tea private label packaging also provides a unique chance for companies to produce individualized, branded tea with no need of growing, harvesting, or processing tea by themselves.

Key Considerations for Ceylon Tea Private Label Packaging When deciding to launch a tea private label packaging firm, there are a number of significant points that you just have to think over first:

Tea Grade Selection:

The accuracy of the tea grade you opt for plays a significant role within your market segment. Different markets are attracted to different flavors of tea. Target your market by researching them and selecting grade combinations for your tea product that are most likely to succeed.

Packaging Variety:

Close cooperation with your supplier is needed to select the most suitable packaging for your tea products. There will be a variety of choices, therefore. They range from well-crafted and classic tin packages to several others. For example; such as tea boxes, gift packs, string and tag tea bags, and tea packaging pouches.

Minimum Order Quantity:

If you come to the point of tea packaging your printing materials are nothing but special machinery. Be clear about the minimum order quantity from your packaging supplier. Special machinery and efficient processes are usually necessary for tea bag production. Congruent with your vision of setting up a tea bag that is both convenient for use and attractive for the consumers, you might demand the supplier to agree with the MOQ. Such machines and systems are indispensable for an efficient tea bag production line. To start the production you may discover that the supplier requires a minimum order quantity of, say, 50,000 units of 2g or 1.5g teabags.

Target Price:

While negotiating with your supplier be sure to include your target price. Keeping in mind, this will help you get the right option within your budget. This also relays what you want the supplier to understand in plain terms.

More info: https://acriltea.com/tea-private-label-packaging/

If you have any queries, questions, or concerns regarding your order, please contact [email protected] or call +94728251384 to speak to a member of staff directly.

Name: Acril Tea

Our Addresses Acril Holdings (Pvt) Ltd 30 1/1, Sumanarama Road, Woodland Mawatha, Kohuwala, 10250 Sri Lanka

Phone: +94 72 825 1384

0 notes

Text

Nichrome: Packaging Taste and Safety into Every Bite with Integrated Food Packaging Solutions

The demand for packaged food has skyrocketed over the last decade, driven by consumers seeking convenience, hygiene, and ready-to-eat options. With changing lifestyles, rising incomes, and increasing mobility, more people are opting for packaged goods like edible oils, food grains, milk, snacks, and mithai over traditional loose products. The modern consumer is not just looking for taste but also for safety, quality, and portability, while manufacturers focus on maximizing production, minimizing downtime, and reaching new markets with international standards.

Smart Packaging for a Fast-Paced World

For food manufacturers, packaging is no longer just about wrapping a product — it’s about ensuring efficiency, safety, and convenience. A packaging partner that can deliver an integrated line, from primary to secondary and even tertiary packaging, can revolutionize a manufacturer’s operations. This is where Nichrome steps in, offering comprehensive solutions that not only streamline operations but also ensure that every element of packaging works seamlessly together.

A turnkey supplier like Nichrome takes the headache out of packaging by managing everything from design to installation, so manufacturers can focus on what they do best: producing great food.

Finding the Right Fit: How to Choose Your Packaging Machine

Choosing the right packaging machine can be overwhelming, but there are a few key factors to consider:

Size and Weight: Make sure the machine fits your floor space.

Ease of Operation: A user-friendly machine keeps your line moving.

Cost Efficiency: Consider not just the upfront cost, but the long-term savings on maintenance and operations.

Flexibility: Look for machines that can adapt to different product lines.

Reliability: Trust in the manufacturer’s expertise and after-sales support.

Nichrome: Pioneers of Food Packaging in India

Nichrome has been at the forefront of food packaging innovation for over 40 years. From creating India’s first indigenous milk pouch packaging machine to providing advanced automated systems today, Nichrome continues to lead the charge in delivering versatile, efficient packaging solutions. Whether you need machines for potato chips, edible oil, ketchup, sugar, or any other food product, Nichrome’s machines are designed for high efficiency with minimal downtime.

Nichrome’s Versatile Food Packaging Solutions

Nichrome’s strength lies in its ability to provide single-source convenience, offering end-to-end solutions that cover everything from product handling to warehousing. Nichrome’s solutions are highly adaptable, with many machines capable of serving multiple applications through simple changes in the filling system.

Primary Packaging Solutions: Including bottle filling, jar filling, tin filling, bulk bag filling, and Blow Fill Seal (BFS) lines.

Secondary Packaging Solutions: These can be integrated for seamless operations, such as vertical and horizontal cartoners, auto case packers, and flexiwrap systems.

End-of-Line Systems: From automatic pallet dispensing to robotic palletizers, Nichrome provides complete integration to ensure your entire packaging process is optimized.

Why Nichrome?

As a trusted name in food packaging, Nichrome’s expertise spans the packaging of everything from grains, pulses, and powders to liquids, viscous foods, and ready-to-eat products. With over four decades of experience and more than 10,000 installations in 45 countries, Nichrome offers unmatched solutions that maximize space, efficiency, and resource utilization.

Conclusion: The Complete Packaging Solution with Nichrome

Whatever your packaging needs — whether it’s tin packing, bottle filling, case packing, or flow wrap — Nichrome is your go-to partner for integrated solutions that not only meet your needs but exceed your expectations. With Nichrome’s tailored approach and extensive experience, you can be confident that your packaging operations will run smoothly, efficiently, and cost-effectively.

So, why settle for less when you can pack perfection with Nichrome? Step into the world of advanced packaging and discover how Nichrome’s solutions can propel your business to new heights!

#TinFillingMachine#AutomaticBottleFillingMachine#PackagingSolutions#NichromePackaging#IntegratedPackaging#SafeFoodPackaging

0 notes

Text

Preserving Purity: Nichrome's Milk Packing Machines Nurturing Growth in African Dairy Industry

In the heart of Africa, where the sun-kissed savannas meet bustling cities, a revolution is quietly unfolding in the dairy industry. At the forefront of this transformation are the ingenious milk packaging machines by Nichrome, seamlessly blending technology and tradition to ensure the freshest milk reaches every corner of the continent.

In the rolling hills of Kenya, where the Maasai's cattle graze under the vast African sky, the significance of milk is deeply ingrained in the culture. Enter the stage, the milk packaging machine in Kenya, a silent hero empowering local dairy farmers to share the goodness of their produce with the world.

Advantages of having Nichrome’s milk packing machines for Dairy Industry

Preservation of Freshness:

Nichrome's milk filling machines are designed with a primary focus on preserving the freshness of milk. Advanced technology ensures that each package seals in the natural goodness, extending the shelf life and maintaining the quality of the dairy product.

Precision and Efficiency:

The precision engineered into Nichrome's milk pouch packaging machines guarantees an efficient and accurate packaging process. From the milk filling machine to the VFFS packaging machine, every component works seamlessly to minimize wastage, enhance productivity, and optimize resources.

Versatility in Packaging Formats:

Nichrome understands the diverse needs of the dairy industry. Our milk packaging machines offer versatility in packaging formats, accommodating various sizes and types of milk containers, from pouches to bottles. This adaptability is crucial for meeting market demands and consumer preferences.

Automation for Increased Productivity:

Embracing automation, Nichrome's machines significantly increase productivity and reduce operational costs. The integration of smart technology not only streamlines the packaging process but also minimizes the risk of errors, ensuring consistency and reliability in every package.

Reduced Downtime and Maintenance:

Nichrome's dedication to reliability extends to the durability of their machines. With robust construction and advanced engineering, these milk packaging machines are built to withstand the rigors of continuous operation, minimizing downtime and maintenance costs.

Vertical Form Fill Seal Machines by Nichrome

In the realm of innovative packaging solutions, Nichrome's Vertical Form Fill Seal (VFFS) technology emerges as a meaningful change, redefining efficiency, versatility, and reliability in the packaging industry.

Filpack CMD ALPHA

FILPACK CMD Alpha is another efficient packaging solution for milk and other liquids. Built shorter than conventional machines, it also occupies less floor space as no side opening is required. The impulse seal system is controlled through solid state control technology, and there is a specially designed film roll unwinding mechanism for smooth bag pulling.

FILPACK CMD Alpha offers twin heads so you can pack two different products at the same time. You can even conduct maintenance on one track while the other is in operation.

Filpack Servo 12K

This machine is the fastest milk pouch packaging machine, with a speed of 12,000 packs/hour. It can pack CSPP pouches of 200 ml, 500 ml and 1000 ml with equal ease and accuracy. FILPACK SERVO 12K is a heavy duty machine with simple maintenance-friendly construction. It is built for hygiene with product contact parts of stainless steel and a UV film sterilisation system for the packaging material.

Independent balance tanks offer flexibility to manage single or different products simultaneously.

Conclusion:

The future is bright for Africa's dairy sector, with the milk packaging machine in Kenya and beyond playing a pivotal role. Nichrome's continuous innovation ensures that the freshness of Africa's milk becomes a global standard, fostering a legacy that transcends borders.

In conclusion, as Africa's dairy industry evolves, Nichrome's milk packaging machines emerge as catalysts for positive change. They are not just machines; they are enablers of dreams, custodians of purity, and architects of a future where every sip of milk tells a story of growth and prosperity.

#milk filling machine#powder filling machines#vertical form fill seal machines#powder packaging machine#milk packaging machine#milk pouch packing machine#automatic filling machine#automatic packaging machines

0 notes

Text

Milk Powder Packing Machine for Sale

Email: [email protected]

WhatsApp: 86 191 3975 4781

0 notes

Text

Packaging Material Supplier in Guwahati

Welcome to Maharani Machine And Textiles - A House Of Packaging Machines in Guwahati

we are also your trusted Packaging Material Supplier in Guwahati. We understand that reliable packaging materials are essential for ensuring the safety, preservation, and presentation of your products. That's why we offer a comprehensive range of high-quality packaging materials to complement our machinery and meet all your packaging needs.

So whether you're in need of a Pouch Packing Machine in Guwahati, packaging materials, or both, trust Maharani Machine And Textiles to be your one-stop solution for all your packaging needs in Guwahati.

In addition to being a leading Packaging Machine Manufacturer in Guwahati, we also excel as a trusted Packaging Material Supplier.

In addition to being your trusted supplier of packaging materials, we also specialize in Milk Packaging Machines in Guwahati. Our Milk Packaging Machines are specifically designed to cater to the unique needs of dairy businesses in the region.

we specialize in Ice Candy Packaging Machines in Guwahati. Our Ice Candy Packaging Machines are specifically designed to cater to the unique needs of businesses in the frozen treat industry.

Moreover, we specialize in Cap Sealing Machines in Guwahati. Our Cap Sealing Machines are specifically designed to ensure the secure sealing of caps onto containers, preserving the integrity of your products and protecting them from tampering and contamination.

Furthermore, we specialize in Shrink Wrapping Machines in Guwahati. Our Shrink Wrapping Machines are specifically designed to securely wrap products in shrink film, providing a tight and protective seal that enhances the presentation and protection of your packaged goods.

we specialize in Vacuum Packing Machines in Guwahati. Our Vacuum Packing Machines are specifically designed to remove air from packaging, creating a tight seal that extends the shelf life and preserves the freshness of your products.

we specialize in Biscuit and Soap Wrapping Machines in Guwahati. Our Biscuit and Soap Wrapping Machines are specifically designed to efficiently and hygienically wrap biscuits and soaps, ensuring that your products are securely packaged and presented in an attractive manner.

Moreover, we specialize in Liquid Filling Machines in Guwahati. Our Liquid Filling Machines are specifically designed to efficiently fill liquid products into containers of various shapes and sizes with precision and accuracy, ensuring consistent results and minimizing wastage.

At Maharani Machine And Textiles, customer satisfaction is our top priority

#packaging material supplier#packaging machine manufacturer#shrink wrapping machine in guwahati#biscuit and soap wrapping machines#ice candy packaging machine#cap sealing machine#liquid feeling machine#vacuum packing machine#milk packaging machine#pouch packing machine

0 notes

Text

Stick and Sachet Packing Machine Market Size, Share, Trends Analysis with Forecast 2024-2033

The global stick and sachet packing machine market was valued at US$ 7.2 billion in 2021 and it is anticipated to grow up to US$ 12.4 billion by 2031, at a CAGR of 5.5% during the forecast period.

Packaging machines are used for packaging products or components. The need for packaging machines to integrate with upstream manufacturing processes has resulted in the development of automation techniques for several sectors. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

To Know More@ https://www.globalinsightservices.com/reports/stick-and-sachet-packing-machine-market/?utm_id=Pranalip

A stick pack machine is a single lane vertical form fill seal packaging machine where a roll of film is cut, multiple small stick pack bags are formed, and products are filled and sealed inside it. The main applications include small packagings such as sugar sachet, small ketchup sachet, and coffee stick packing machine.

Sachet packaging is extensively used in the cosmetics & personal care, food & beverages, and pharmaceutical industries. Sachets are small, sealed, flexible pouches manufactured from paper, plastic, aluminum foil, and cellulosic and contain liquid, powder, or capsule products. As they are cheaper than large-size packets, sachets are generally used either for promotional trial packs or to cater to low-income or price-sensitive customers who prefer economical packs.

Market Drivers and Trends

Sugar sachet packing machines, milk sachet filling machines, sachet stick packs, and tea sachet packing machines are some examples of sachet packaging machines that are increasing in demand, and the demand for small sachet packing machines is expected to drive the market’s revenue growth due to the presence of many food and beverage manufacturers.

Sachet packing machine is most extensively used in medicine packaging. Sachet packing machines can easily produce blister foils, slip packs, and easy-open pouches at high speed which has increased manifold due to the growing demand for pharmaceutical products are expected to drive the growth of the sachet packaging machine market.

Therefore, increasing demand in food and pharmaceutical sectors are boosting the global stick and sachet packing machine market growth.

Request Sample@ https://www.globalinsightservices.com/request-sample/GIS10460/?utm_id=Pranalip

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS10460/?utm_id=Pranalip

Global Stick and Sachet Packing Machine Market Segmentation

By Type

Stick Pack Packing Machine

Sachet Packing Machine

By Product Type

Powder and Granule

Liquid Products

Others

By End User

Food and Beverages

Pharmaceuticals

Chemicals

Cosmetics

Others

Major Players in the Global Stick and Sachet Packing Machine Market

The key players studied in the global stick and sachet packing machine market are ARANOW Packaging Machinery, S.L. (Spain), Duravant LLC (Spain), Ilapak International SA (Switzerland), Körber AG (Germany), Matrix Packaging Machinery, LLC (US), Nichrome Packaging Solutions (India), OMAG Srl (Italy), SmartPac Verpackungsmaschinen GmbH (Germany), Syntegon Technology GmbH (Germany), and Universal Pack S.r.l. (Italy).

COVID-19 Impact

In 2020, the COVID-19 pandemic resulted in economic challenges owing to subsequent lockdowns. In 2020, the manufacturing industry was severely affected due to a drastic decrease in product demand, falling prices, and storage shortages. A swift decline in manufacturing revenues due to virtually nonexistent manufacturing demand and slow production capabilities had limited the expenditure on the production of stick and sachet packing machines worldwide. Thus, the COVID-19 pandemic negatively affected the global stick and sachet packing machine market in 2020.

However, in 2021, the manufacturing industry started recovering from the significant labor and supply chain challenges that triggered the production of stick and sachet packing machines.

Buy your copy here@ https://www.globalinsightservices.com/checkout/single_user/GIS10460/?utm_id=Pranalip

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

SWASTIK PLASTIC

product polythene printing

The majority of polythene products are available with full color printing, adding the finishing touch to packages and making your brand instantly recognizable.

We offer a broad variety of printing techniques and designs, such as:

Branding: We are able to fully brand polythene items.

Mark and Identifying Information

For internal sorting and packing of a wide range of products, we can print clear labels on polythene products, which enables personnel to rapidly write product details on packages.

Usage Guidelines for the Product

Polythene packaging can be an excellent way to emphasize that your products need assembly, fitting, or additional instructions.

Safety Alert

Additionally, polythene packaging is ideal for highlighting any possible dangers or risks associated with the product, providing your clientsProduct Types

Applications for printed polythene materials are numerous and include:

Personalized Carrier Bags

Printed polythene carrier bags are perfect for the retail industry since they make it simple to promote your brand both in-store and at trade exhibitions and events.

Layflat tubing that is printed

Printed polythene layflat tubing is perfect for packaging long goods, creating custom-sized bags or packages, and enhancing the security of your products during shipment.

Polythene bags with printing

Polythene bags with printing work well for shipment and regular packaging at your warehouse. Perfect for applications in retail and industry, where you can brand things before they are sold or quickly and simply identify them.

Printed PP Sacks with Weave

When it comes to loose items, printed woven PP sacks are the ideal option because they guarantee that clients can easily recognize the products. Nuts, soils, and other loose or perishable commodities are especially well-suited applications for printed woven polypropylene (PP) sacks.

Product polythene printing is important

When it comes to branding and marketing, high-quality printing is crucial. Businesses can draw in clients, build brand awareness, and project a dependable and strong image by creating polished and eye-catching products. The advantages of superior printing for a company's branding and marketing initiatives will be discussed in this section.

The impact of high-quality printing on brand image: A company's brand image is positively impacted by high-quality printing, which is one of the biggest advantages. Customers' perceptions of a firm and its goods or services make up its brand image.

Technology used

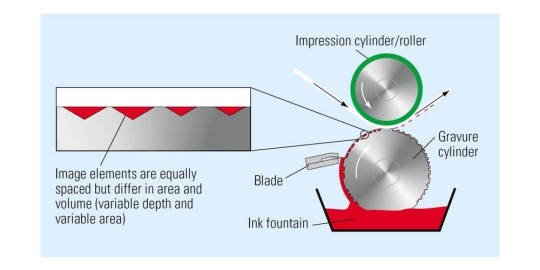

We have used rotogravure printing in an industry.

Rotogravure printing:Rotogravure printing is frequently used to print on packaging materials as bread wrappers, polythene packs,milk pouches, soap wraps, and other pliable packaging materials. Because more and more of these packaging products are being used, rotogravure printing is becoming more and more important.

Components of a rotogravure

The engraved cylinder:This is one of the key components of the gravure planting machine, sometimes referred to as the gravure cylinder. The image you wish to print is typically engraved on the cylinder. The cylinder surface will be bent into cells through etching. The various diameters of the cells need to be carefully specified. The ink will be transported to the cell in order to be transferred to the substrate. In this instance, the substrate is paper. Large, deep cells are a fantastic choice for colors that are darker and more intense, and vice versa. Steel or plated copper are the usual materials used to make these cylinders. Moreover, ceramic gravure cylinders are in demand.

Rotogravure Ink:The ink fountain is the component where the ink is stored. It is then transferred to the cylinder carefully and precisely.

Doctor blade assembly:The doctor blade's job is to take away extra ink from the areas that aren't etched. An assembly of doctor blades is also present on the engraved cylinder because it has multiple cells on it. Before the ink is applied to a printing plate, the blades can also produce a homogeneous layer of ink. Keep in mind that standard doctor blades used in flexographic and other printing processes are usually not very expensive.

An impression roller:It is the imprint roller's responsibility to exert pressure such that the entire substrate makes contact with the cylinder. The substrate is sandwiched between the impression roller and the gravure cylinder. Therefore, the impression roller aids in ensuring maximal and uniform coverage.

1 note

·

View note