#jcb air tech

Text

HVLS FANS

For distributing high volume of air in large spaces, creating a gentle air movement. The fan enables a perceived temperature to be cooler by 4o to 6o Celsius under standard conditions. Replaces multiple wall mounted fans, and reduces the operating costs upto 80% when compared with other fans.

1 note

·

View note

Text

The Future Is Electric Investment Opportunities in Electromobility

The transportation revolution is here with electromobility shaping today's movement. As global commitments to reduce carbon emissions rise, the electromobility industry is set for significant growth. This blog explores investment opportunities and offers insights for savvy investors in this dynamic market.

Why Electromobility Matters

The shift to electromobility is vital for addressing climate change by reducing dependence on fossil fuels and lowering emissions. Governments and investors are backing this move, with the EU targeting climate neutrality by 2050 and significant investments predicted by 2030, demonstrating confidence in the sector's future.

The Growth of Electric Vehicles (EVs)

Electric vehicles (EVs) are leading the electromobility revolution, with companies like Tesla, NIO, and Rivian at the forefront. The global EV market is set to expand from 3 million units in 2020 to 26 million by 2030, driven by government incentives such as subsidies and tax breaks. This growing demand offers lucrative investment opportunities not only in EV manufacturers but also in related industries like battery production and charging infrastructure.

Charging Infrastructure Innovations

The adoption of electric vehicles (EVs) hinges on the availability of charging infrastructure. Governments and private enterprises are heavily investing in expanding these networks, with the global EV charging market projected to reach $140 billion by 2030. Leading companies like ChargePoint, EVBox, and Blink Charging are developing advanced solutions. Investing in these companies supports EV market growth and offers substantial returns through partnerships with automakers, governments, and utilities.

The Impact of Autonomous Vehicles

Autonomous vehicles (AVs) are revolutionizing transportation by combining electromobility with autonomous driving technology, impacting urban mobility, logistics, and personal transportation. Leading companies like Waymo, Cruise, and Baidu are advancing this technology. The global AV market is projected to reach $556 billion by 2026, offering investment opportunities in both AV tech companies and suppliers of essential components like sensors and software. Integration of AI and machine learning in AVs enhances safety, efficiency, and user experience.

Advancements in Non-Road Mobile Machinery

Electrification is expanding beyond passenger vehicles to include non-road mobile machinery like construction and agricultural equipment. This transformation offers reduced emissions, lower costs, and improved performance. The market, led by companies like Caterpillar, JCB, and Volvo, is poised for significant growth, driven by stricter emissions regulations and rising demand for sustainable solutions. Investing in this sector presents a unique opportunity in a less saturated market.

The Rise of Electric Public Transportation

Public transportation is embracing electromobility to reduce emissions and improve air quality. With significant government investments, electric buses, trams, and trains are becoming more common. The electric bus market, led by companies like BYD, Proterra, and Solaris, is expected to reach $71 billion by 2027, offering substantial returns and promoting global sustainability for greener cities.

Emerging Markets for Electromobility

Developed countries are leading in electromobility, but emerging markets like India, Brazil, and South Africa offer significant growth opportunities. India aims for 30% electric vehicle penetration by 2030, while Brazil explores solutions to reduce its carbon footprint. Investing in these markets could yield high returns but comes with regulatory and infrastructure risks.

Electromobility is revolutionizing transportation with cleaner, more efficient, and more sustainable solutions. The sector offers vast investment opportunities in electric vehicles, battery tech, charging infrastructure, and autonomous vehicles. Investors can make a positive impact and achieve substantial returns by staying informed, diversifying portfolios, and engaging with industry experts.

Are you ready to explore the exciting world of electromobility investments? Join the conversation and connect with industry leaders at the upcoming 2nd Annual Non-Road Mobile Machinery Electrification and Decarbonization Forum. Learn more: https://www.leadventgrp.com/events/2nd-annual-non-road-mobile-machinery-electrification-and-decarbonization-forum/details

0 notes

Text

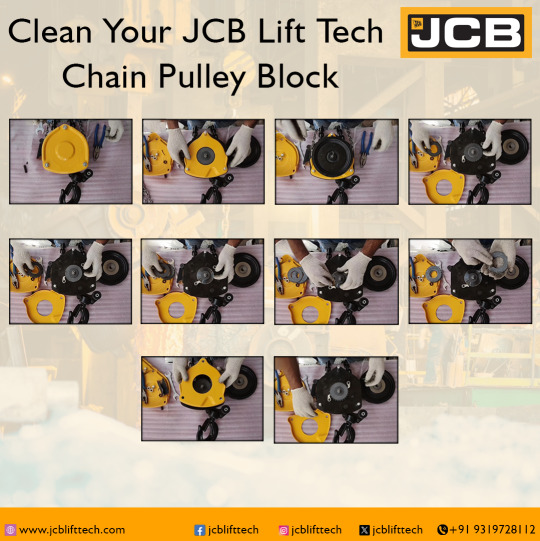

How to Clean Your JCB Lift Tech Chain Pulley Block

Maintaining your JCB Lift Tech chain pulley block is crucial for ensuring its longevity and efficient operation. Regular cleaning is a key part of this maintenance. Here’s a step-by-step guide:

1. Safety First

Ensure the chain pulley block is not under load and is properly secured before beginning any cleaning.

2. Initial Inspection

Examine the chain pulley block for any signs of damage or excessive wear. Look for cracks, rust, or any other irregularities.

3. Disassemble (If Necessary)

Depending on the model and condition, you might need to partially disassemble the block to clean it thoroughly. Refer to the user manual for specific instructions.

4. Remove Surface Dirt and Debris

Use a brush or compressed air to remove surface dirt and debris. This helps in clearing any loose contaminants that could affect the cleaning process.

5. Clean the Chain

Submerge the chain in a suitable solvent or degreaser to remove grease, oil, and grime. Scrub it with a brush if needed. Ensure the solvent used is appropriate for the material of the chain.

6. Clean the Body and Components

Wipe down the body of the chain pulley block with a cloth soaked in the cleaning solution. Pay special attention to areas where dirt and grease accumulate, such as the gears and pulley mechanism.

7. Rinse and Dry

Rinse the chain and other components with clean water to remove any remaining cleaning solution. Dry thoroughly with a clean cloth or use compressed air to prevent rusting.

8. Lubricate Moving Parts

Apply a high-quality lubricant to the chain and moving parts to ensure smooth operation. Make sure to use the recommended type of lubricant for your specific model.

9. Reassemble and Test

Reassemble the chain pulley block if it was disassembled. Perform a test run to ensure all parts are functioning correctly and smoothly.

10. Regular Maintenance Schedule

Establish a regular cleaning and maintenance schedule based on the frequency of use and operating environment. Consistent care will prolong the life of your equipment.

By following these steps, you can keep your JCB Lift Tech chain pulley block in optimal condition, ensuring safety and efficiency in your lifting operations. For more detailed guidance, refer to the user manual specific to your model or consult with JCB Lift Tech support.

#chain pulley block#beamclamp#chainblock#chainpulleyblock#electric chain hoist#jcb#jcblifttech#electricchainhoist#electrictrolley#beamtrolley#electric trolley

0 notes

Text

hvls fan | JCB Air Tech

HVLS fans easily replace multiple standard overhead or pedestal fans which consume higher energy. These fans are cost- effective cooling solution which enhance the comfort and productivity of occupants. In industries, railway stations, commercial complexes, temples/church/mosques, large areas, auditoriums, warehouses, airports, etc. these fans distribute the air with a gentle movement. Facilities under upgrade can often adopt to HVLS Fans.

They distribute air up to 29000 sq. ft. corner to corner. HVLS Fan reduces running cost upto 80% when compared to other fans & payback in 6 months.

JCB Air Tech’s HVLS fans are one of the best in class, energy efficient and require low maintenance. The German make motor make them highly efficient. While feature of speed control makes them very user friendly. The inbuilt safety standards in these fans are of level next. JCB’s forward looking approach have made the products future ready.

1 note

·

View note

Text

Three 6 Mafia Shirt

Grifo radar is multi-mode pulse Doppler all weather fire control radar. PAC has the Three 6 Mafia Shirt of not only producing the airborne fire control radars but also has vast experience in maintaining three variants of Grifo radars. PAC has produced a number of Grifo radar systems for PAF Fleet in collaboration with M/S Selex Electronic Systems Italy. Grifo family of radars is digital fire control system designed to improve air to air and air to ground performance. Radars are capable of detecting and tracking the targets at all altitudes and all aspects. Radars have powerful and accurate Built-In Test (BIT) system followed by auto calibration for the ease of smooth operation and better maintenance.

Buy it now: .Three 6 Mafia Shirt

LeBron James Los Angeles Lakers NBA All Time Scoring Shirt

Never Underestimate A Woman Who Understand Football And Loves New York Giants 2022 Signatures Shirt

Wolves In My Veins Team Jesus In My Heart Signature Shirt

Kansas city Chiefs super bowl LVII champions 22 23 shirt

Kansas city Chiefs super bowl LVII champions 22 23 shirt

Texas Tech Maui Invitational Basketball Tournament Shoots And Hoops Shirt

Homepage: T-shirtsky.com Teeclover Molotee

Teejeep is your one-stop online shop for printed t-shirts, hoodies, phone cases, stickers, posters, mugs, and more…High quality original T-shirts. Digital printing in the USA.

Worldwide shipping. No Minimums. 1000s of Unique Designs. Worldwide shipping. Fast Delivery. 100% Quality Guarantee. to cover all your needs.

By contacting directly with suppliers, we are dedicated to provide you with the latest fashion with fair price.We redefine trends, design excellence and bring exceptional quality to satisfy the needs of every aspiring fashionista.

WHAT IS OUR MISSION?

Teeartprint is established with a clear vision: to provide the very latest products with compelling designs, exceptional value and superb customer service for everyone.

We offer a select choice of millions of Unique Designs for T-shirts, Hoodies, Mugs, Posters and more to cover all your needs.

WHY SHOP WITH US?

Why do customers come to TeeJeep.com?

Well we think there are a few reasons:

BEST PRICING

Fashion field involves the best minds to carefully craft the design. The t-shirt industry is a very competitive field and involves many risks. The cost per t-shirt varies proportionally to the total quantity of t-shirts. We are manufacturing exceptional-quality t-shirts at a very competitive price.

PRINT QUALITY DIFFERENCE

We use only the best DTG printers available to produce the finest-quality images possible that won’t wash out of the shirts.

DELIVERY IS VERY FAST

Estimated shipping times:

United States : 1-5 business days

Canada : 3-7 business days

International : from 1-2 weeks depending on proximity to Detroit, MI.

CUSTOM AND PERSONALIZED ORDERS

Custom orders are always welcome. We can customize all of our designs to your needs! Please feel free to contact us if you have any questions.

PAYMENT DO WE ACCEPT?

We currently accept the following forms of payment:

Credit Or Debit Cards: We accept Visa, Mastercard, American Express, Discover, Diners Club, JCB, Union Pay and Apple Pay from customers worldwide.

PayPal: PayPal allows members to have a personal account linked to any bank account or credit card for easy payment at checkout.

0 notes

Text

About JCB Air Tech

JCB Air tech brings a new range of products, designed for superior Air Distribution, Cooling and Ventilation. Our commitment is making spaces comfortable, by ensuring cool and fresh air movement. Using the collective experience, we have developed yet another range of products for the industrial segment. JCB, truly, has pioneered an era of engineering excellence and continues to contribute

JCB India Limited is a leading manufacturer of earthmoving and construction equipment in India. The company started as a joint venture in 1979 and is now a fully owned subsidiary of J.C Bamford Excavators, United Kingdom. With five state-of-the-art factories in India, JCB manufactures a wide range of world-class equipment in India for the domestic market as well as for exports to more than 110 countries.

JCB introduced the iconic Backhoe Loader in India over four decades ago. It has since expanded its range to over 60 products in nine categories.

The Ballabgarh factory near New Delhi, which is the world’s largest factory for Backhoe Loaders, is also the Headquarters for JCB India.JCB has a network of more than 60 dealers and 700 outlets spread throughout India .

With our collective industry experience we have set out to produce superior quality industrial products. Raising our customer’s productivity Driven by continuously improving, we are creating products with higher standards for meeting the rising compliances.

0 notes

Text

Mini excavators: Small size, big popularity

Mini excavators are one of the quickest growing equipment types, with the machine’s popularity seemingly ever-increasing. According to data from Off-Highway Research, global sales for the mini excavator were at their highest point ever last year, at over 300,000 units.

The major markets for mini excavators have traditionally been developed countries, such as Japan and those in Western Europe, but the last decade has seen their popularity rise in many emerging economies. Most notable of these is China, which is now by far the biggest mini excavator market in the world.

Considering that mini excavators essentially replace manual labour, this is perhaps a surprising turnaround in the most populous country in the world where there is certainly no shortage of workers. Although all is perhaps not as it seems in the Chinese market – see the box out ‘China and mini excavators’ for more details.

One of the reasons for the mini excavator’s popularity is that it is easier to power a smaller and more compact machine with electricity rather than the traditional diesel power. It is the case that, especially in city centres of developed economies, there are often strict regulations regarding noise and emissions pollution.

There is no shortage of OEMs that are currently working on, or have released electric mini excavators – back in January 2019 Volvo Construction Equipment (Volvo CE) announced that, by mid-2020, it will begin to launch a range of electric compact excavators (EC15 to EC27) and wheeled loaders (L20 to L28) and stop new diesel engine-based development of these models.

Another OEM looking at electric power for this equipment segment is JCB, with the company’s 19C-1E electric mini excavators. The JCB 19C-1E is powered by four lithium-ion batteries, providing 20kWh of energy storage. This is enough for a full working shift for the majority of mini excavator customers on a single charge. The 19C-1E itself is a powerful, compact model with zero exhaust emissions at point of use and one that is considerably quieter than a standard machine.

Small machine is a relatively light and fast mechanical equipment. Like hand-held power tools, concrete vibrator, frog tamper, mini transporter, woodworking machinery, steel machinery, mini dumper, motorized dump truck, welding, etc. are all small machines.

In addition to large machinery and equipment in construction should pay attention to the safe use, to prevent injury, a variety of medium and small machines also have different degrees of danger, must be used in accordance with the safety requirements.

Going electric

JCB recently sold two models to London-based J Coffey Plant, with Coffey Plant Division Operations Manager Tim Rayner commenting, “The major benefit is no emissions at point of use. Our workers are not subjected to diesel emissions when using the 19C-1E. Confined areas are now clearer and safer to work in too, as there is no longer a need for emissions control equipment such as extraction units and ducting. The JCB electric minis bring value to the business and the industry as a whole.”

Another OEM looking at electric power is Kubota. “In recent years mini excavators powered by alternative fuel sources – such as electric – have seen a surge in popularity,” says Glen Hampson, business development manager construction at Kubota UK.

“The main driver behind this is that electric equipment gives the operator the ability to work in regulated low emission zones. Electric machinery can also enable work to be carried out in confined spaces underground without producing harmful emissions. It’s reduced noise output also makes it great for construction work in urban or heavily populated environments.”

Kubota launched a prototype electric compact mini excavator in Kyoto City, Japan, at the start of the year and Hampson adds, “At Kubota, our main priority will always be the development of machines that match the needs of our customers – the development of electric machines will allow us to do just this.”

Bobcat recently announced that it was launching a new R-Series mini excavators from 2-4 tonne with a new range of five compact excavator models: the E26, E27z, E27, E34 and E35z. One of the standout features for this range is said by the company to be the Cylinder-Inside-Boom (CIB) design concept.

According to Miroslav Konas, product manager, Bobcat Excavators Europe, Middle East and Africa (EMEA), “The CIB system aims to overcome what has been one of the weakest points in any mini-excavator – the vulnerability of the boom cylinder to damage such as that caused by colliding with the sides of trucks and other vehicles when loading waste and building materials.

“It does this by enclosing the hydraulic cylinder inside an extended boom structure, thus avoiding collisions with the top of the blade and the sides of vehicles. In fact, the boom structure protects the hydraulic boom cylinder in any position of its movement.”

Wood chipper is a kind of special equipment for producing wood chips, wood chipper is also called wood slicer, which is one of the wood processing series equipment.

Trenching machine, such as mini trencher, is one of the main types of construction machinery, a kind of trenching machinery used in earthwork construction, widely used in agricultural water conservancy construction, laying of communication cables and petroleum pipelines, municipal construction and military engineering, etc.

Useful tools and machines in home agriculture also include log splitter, stump grinder, etc.

Operator comfort

With the lack of skilled operators in the industry, keeping those behind the stick happy has never been more important. Volvo CE claim that the new 6-tonne ECR58 F generation compact excavator has the most spacious cab in the industry.

Operator well-being, confidence, and safety are supported through a simplified workstation and user-friendly experience. The seat-to-joystick position has been revised and improved, while still being suspended together – a technic that Volvo CE says it introduced to the industry.

Designed to offer the highest levels of operator convenience, the cab features soundproofing, numerous storage areas, and 12V and USB ports. A fully opening front window and slide side window contribute to all-around visibility and operators have an automotive style jog wheel, five inch colour display and easy-to-navigate menus.

Operator comfort is indeed important, but another reason for the general popularity of the mini excavator segment is the ever-increasing range of attachments on offer. For instance, Volvo CE’s ECR58 has a wide range of attachments which are easy to switch over, including buckets, breakers, thumbs, and the new Tilt Quick Coupler.

Talking about the mini excavator’s rise in popularity, Chris Sleight, managing director, Off-Highways Research, highlights attachments, saying, “At the lighter end, the range of attachments available mean it [a mini excavator] is often favoured over workers using hand-held air-powered tools. This is partly because this can be helpful in reducing workers’ exposure to noise and vibration, and also because it removes the worker from the immediate vicinity of the tool.”

Sleight also adds that, “In Europe and even North America the mini excavator is replacing other types of equipment. At the top end of the scale, its smaller footprint and ability to slew through 360 degrees means it is often now favoured over backhoe loaders.”

Bobcat’s Konas agrees with the importance of attachments, saying, “The various types of bucket we offer are still the main ‘tool’ from among the 25 different families of attachments we offer for our mini excavators, but we see a trend developing with more advanced hydraulic attachments growing in popularity. That’s why we developed our A-SAC system, which together with up to five independent auxiliary circuits available on our machines, we believe makes Bobcat the most advanced brand on the market to operate such complex attachments.

“Combining the arm-mounted hydraulic auxiliary lines and the optional A-SAC technology together enables a wide choice of machine customisation options to match any attachment requirement, further enhancing the role of these excavators as excellent tool carriers.”

Remote monitoring as a growing trend?

Hitachi Construction Machinery (Europe) has published a white paper on the future of the compact equipment segment in Europe. In it they point out that 70% of the mini excavators sold in Europe are under three tonnes, helped by the fact that it is relatively straightforward to obtain a licence to tow one of these models on a trailer with a regular driving licence.

The White Paper predicts that remote monitoring will play an increasingly important role in the compact construction equipment market, of which mini excavators are an important part. The report says, “Tracking the location of compact equipment is particularly important, given that it moves frequently from one job site to another.

“Location and working hours data can therefore help owners, especially rental companies, with planning, enhancing efficiency and scheduling maintenance. Accurate location information is also vital from a security point of view – it’s much easier to steal a smaller machine than a larger model, and theft of compact equipment is therefore more commonplace.”

Different manufacturers offer various telematics packages with their mini excavators and mini roller; there is no industry standard. Hitachi mini excavators are connected to its remote monitoring system, Global e-Service, and the data can also be accessed via smartphone.

While location and working hours are key bits of information, the report speculates that the next-generation of equipment owners will want to view more detailed data. “Owners want access to more data from manufacturers. One reason for this is the influx of a younger, more tech-savvy generation of customers, who can better understand and analyse data to improve productivity and efficiency.”

0 notes

Text

Global Diesel Generator Set Market 2020 Industry Analysis, Segment & Forecast Up to 2026

Global Diesel Generator Set Industry

New Study On “2018-2023 Diesel Generator Set Market Global Key Player, Demand, Growth, Opportunities and Analysis Forecast” Added to Wise Guy Reports Database

This report mainly introduces volume and value market share by players, by regions, by product type, by consumers and also their price change details. As a Detailed Analysis report, it covers all details inside analysis and opinion in Diesel Generator Set industry.

Try Sample Report @ https://www.wiseguyreports.com/sample-request/2959536-global-diesel-generator-set-detailed-analysis-report-2018-2023

This report splits Diesel Generator Set market by Phases, by Portability, by Frequency, by Cooling System, which covers the history data information from 2013 to 2017 and forecast from 2018 to 2023.

This report focuses Global market, it covers details as following:

Major Companies

AEM Spain

ATLAS NRG TECH S.L.

BELTRAME CSE

Bruno generators

Caterpillar Electric Power

Coelmo spa

ELECTRA MOLINS

ENDRESS Elektrogeratebau GmbH

FG WILSON

FPT Industrial S.p.A.

FUJIAN YANAN POWER GROUP

GELEC ENERGY

GENELEC

GENMAC SRL

Genset

GRUPO GENESAL

Inmesol

JCB Power Products Ltd

KOHLER POWER SYSTEMS

LISTER PETTER

MOSA

MTU Onsite Energy

Multiquip, Inc.

NORTHERN LIGHTS

Power Tech Mobile Generators

SDMO

SET Stange Energietechnik GmbH

SIA ”Rīgas Dīzelis DG”

Westerbeke

Worms Entreprises

Main Regions

North America

United States

Canada

Latin America

Mexico

Brazil

Argentina

Others

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Netherland

Others

Asia & Pacific

China

Japan

India

Korea

Australia

Southeast Asia

Indonesia

Thailand

Philippines

Vietnam

Singapore

Malaysia

Others

Africa & Middle East

South Africa

Egypt

Turkey

Saudi Arabia

Iran

Others

Main Product Type

Diesel Generator Set Market, by Phases

Three-phase

Single-phase

Diesel Generator Set Market, by Portability

Stationary

Mobile

Containerized

Diesel Generator Set Market, by Frequency

50 Hz

60 Hz

Others

Diesel Generator Set Market, by Cooling System

Water-cooled

Air-cooled

Oil-cooled

Main Applications

Emergency Energy

Marine Applications

Industrial Applications

Construction Applications

Other Applications

For Detailed Reading Please visit WiseGuy Reports @ https://www.wiseguyreports.com/reports/2959536-global-diesel-generator-set-detailed-analysis-report-2018-2023

Some Major Points from Table of content:

Global Diesel Generator Set Detailed Analysis Report 2018-2023

Chapter One Diesel Generator Set Market Overview

1.1 Global Diesel Generator Set Market Sales Volume Revenue and Price 2013-2023

1.2 Diesel Generator Set, by Phases 2013-2023

1.2.1 Global Diesel Generator Set Sales Market Share by Phases 2013-2023

1.2.2 Global Diesel Generator Set Revenue Market Share by Phases 2013-2023

1.2.3 Global Diesel Generator Set Price by Phases 2013-2023

1.2.4 Three-phase

1.2.5 Single-phase

1.3 Diesel Generator Set, by Portability 2013-2023

1.3.1 Global Diesel Generator Set Sales Market Share by Portability 2013-2023

1.3.2 Global Diesel Generator Set Revenue Market Share by Portability 2013-2023

1.3.3 Global Diesel Generator Set Price by Portability 2013-2023

1.3.4 Stationary

1.3.5 Mobile

1.3.6 Containerized

1.4 Diesel Generator Set, by Frequency 2013-2023

1.4.1 Global Diesel Generator Set Sales Market Share by Frequency 2013-2023

1.4.2 Global Diesel Generator Set Revenue Market Share by Frequency 2013-2023

1.4.3 Global Diesel Generator Set Price by Frequency 2013-2023

1.4.4 50 Hz

1.4.5 60 Hz

1.4.6 Others

1.5 Diesel Generator Set, by Cooling System 2013-2023

1.5.1 Global Diesel Generator Set Sales Market Share by Cooling System 2013-2023

1.5.2 Global Diesel Generator Set Revenue Market Share by Cooling System 2013-2023

1.5.3 Global Diesel Generator Set Price by Cooling System 2013-2023

1.5.4 Water-cooled

1.5.5 Air-cooled

1.5.6 Oil-cooled

Chapter Two Diesel Generator Set by Regions 2013-2018

2.1 Global Diesel Generator Set Sales Market Share by Regions 2013-2018

2.2 Global Diesel Generator Set Revenue Market Share by Regions 2013-2018

2.3 Global Diesel Generator Set Price by Regions 2013-2018

2.4 North America

2.4.1 United States

2.4.2 Canada

2.5 Latin America

2.5.1 Mexico

2.5.2 Brazil

2.5.3 Argentina

2.5.4 Others in Latin America

2.6 Europe

2.6.1 Germany

2.6.2 United Kingdom

2.6.3 France

2.6.4 Italy

2.6.5 Spain

2.6.6 Russia

2.6.7 Netherland

2.6.8 Others in Europe

2.7 Asia & Pacific

2.7.1 China

2.7.2 Japan

2.7.3 India

2.7.4 Korea

2.7.5 Australia

2.7.6 Southeast Asia

2.7.6.1 Indonesia

2.7.6.2 Thailand

2.7.6.3 Philippines

2.7.6.4 Vietnam

2.7.6.5 Singapore

2.7.6.6 Malaysia

2.7.6.7 Others in Southeast Asia

2.8 Africa & Middle East

2.8.1 South Africa

2.8.2 Egypt

2.8.3 Turkey

2.8.4 Saudi Arabia

2.8.5 Iran

2.8.6 Others in Africa & Middle East

Chapter Three Diesel Generator Set by Players 2013-2018

3.1 Global Diesel Generator Set Sales Volume Market Share by Players 2013-2018

3.2 Global Diesel Generator Set Revenue Share by Players 2013-2018

3.3 Global Top Players Diesel Generator Set Key Product Model and Market Performance

3.4 Global Top Players Diesel Generator Set Key Target Consumers and Market Performance

Chapter Four Diesel Generator Set by Consumer 2013-2018

4.1 Global Diesel Generator Set Sales Market Share by Consumer 2013-2018

4.2 Emergency Energy

4.3 Marine Applications

4.4 Industrial Applications

4.5 Construction Applications

4.6 Other Applications

4.7 Consuming Habit and Preference

Chapter Five Global Top Players Profile

5.1 AEM Spain

5.1.1 AEM Spain Company Details and Competitors

5.1.2 AEM Spain Key Diesel Generator Set Models and Performance

5.1.3 AEM Spain Diesel Generator Set Business SWOT Analysis and Forecast

5.1.4 AEM Spain Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.2 ATLAS NRG TECH S.L.

5.2.1 ATLAS NRG TECH S.L. Company Details and Competitors

5.2.2 ATLAS NRG TECH S.L. Key Diesel Generator Set Models and Performance

5.2.3 ATLAS NRG TECH S.L. Diesel Generator Set Business SWOT Analysis and Forecast

5.2.4 ATLAS NRG TECH S.L. Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.3 BELTRAME CSE

5.3.1 BELTRAME CSE Company Details and Competitors

5.3.2 BELTRAME CSE Key Diesel Generator Set Models and Performance

5.3.3 BELTRAME CSE Diesel Generator Set Business SWOT Analysis and Forecast

5.3.4 BELTRAME CSE Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.4 Bruno generators

5.4.1 Bruno generators Company Details and Competitors

5.4.2 Bruno generators Key Diesel Generator Set Models and Performance

5.4.3 Bruno generators Diesel Generator Set Business SWOT Analysis and Forecast

5.4.4 Bruno generators Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.5 Caterpillar Electric Power

5.5.1 Caterpillar Electric Power Company Details and Competitors

5.5.2 Caterpillar Electric Power Key Diesel Generator Set Models and Performance

5.5.3 Caterpillar Electric Power Diesel Generator Set Business SWOT Analysis and Forecast

5.5.4 Caterpillar Electric Power Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.6 Coelmo spa

5.6.1 Coelmo spa Company Details and Competitors

5.6.2 Coelmo spa Key Diesel Generator Set Models and Performance

5.6.3 Coelmo spa Diesel Generator Set Business SWOT Analysis and Forecast

5.6.4 Coelmo spa Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.7 ELECTRA MOLINS

5.7.1 ELECTRA MOLINS Company Details and Competitors

5.7.2 ELECTRA MOLINS Key Diesel Generator Set Models and Performance

5.7.3 ELECTRA MOLINS Diesel Generator Set Business SWOT Analysis and Forecast

5.7.4 ELECTRA MOLINS Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.8 ENDRESS Elektrogeratebau GmbH

5.8.1 ENDRESS Elektrogeratebau GmbH Company Details and Competitors

5.8.2 ENDRESS Elektrogeratebau GmbH Key Diesel Generator Set Models and Performance

5.8.3 ENDRESS Elektrogeratebau GmbH Diesel Generator Set Business SWOT Analysis and Forecast

5.8.4 ENDRESS Elektrogeratebau GmbH Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.9 FG WILSON

5.9.1 FG WILSON Company Details and Competitors

5.9.2 FG WILSON Key Diesel Generator Set Models and Performance

5.9.3 FG WILSON Diesel Generator Set Business SWOT Analysis and Forecast

5.9.4 FG WILSON Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.10 FPT Industrial S.p.A.

5.10.1 FPT Industrial S.p.A. Company Details and Competitors

5.10.2 FPT Industrial S.p.A. Key Diesel Generator Set Models and Performance

5.10.3 FPT Industrial S.p.A. Diesel Generator Set Business SWOT Analysis and Forecast

5.10.4 FPT Industrial S.p.A. Diesel Generator Set Sales Volume Revenue Price Cost and Gross Margin

5.11 FUJIAN YANAN POWER GROUP

5.12 GELEC ENERGY

5.13 GENELEC

5.14 GENMAC SRL

5.15 Genset

5.16 GRUPO GENESAL

5.17 Inmesol

5.18 JCB Power Products Ltd

5.19 KOHLER POWER SYSTEMS

5.20 LISTER PETTER

5.21 MOSA

5.22 MTU Onsite Energy

5.23 Multiquip, Inc.

5.24 NORTHERN LIGHTS

5.25 Power Tech Mobile Generators

5.26 SDMO

5.27 SET Stange Energietechnik GmbH

5.28 SIA ”Rīgas Dīzelis DG”

5.29 Westerbeke

5.30 Worms Entreprises

Continued….

For more information or any query mail at [email protected]

About Us

Wise Guy Reports is part of the Wise Guy Consultants Pvt. Ltd. and offers premium progressive statistical surveying, market research reports, analysis & forecast data for industries and governments around the globe. Wise Guy Reports understand how essential statistical surveying information is for your organization or association. Therefore, we have associated with the top publishers and research firms all specialized in specific domains, ensuring you will receive the most reliable and up to date research data available.

Contact Us:

Norah Trent

+1 646 845 9349 / +44 208 133 9349

Follow on LinkedIn: https://www.linkedin.com/company/wise-guy-research-consultants-pvt-ltd-?trk=biz-companies-cym

0 notes

Text

Press release: New boost for UK ambition to lead the world in zero emissions vehicles has been published on Energy Solutions News

New Post has been published on https://www.energybrokers.co.uk/news/beis/press-release-new-boost-for-uk-ambition-to-lead-the-world-in-zero-emissions-vehicles

Press release: New boost for UK ambition to lead the world in zero emissions vehicles

Coventry based UK Battery Industrialisation Centre will be a new national centre of excellence creating high skilled jobs and attracting inward investment

Comes as the West Midlands Local Industrial Strategy is launched to drive growth and create opportunities across the region - the first in the country

Coventry will be home to a new national centre of excellence in developing the latest electric car battery technology, backed by millions of pounds in Government investment.

Business Secretary Greg Clark will today announce a new £28 million investment in the UK Battery Industrialisation Centre, providing a stepping stone for our ambition for a Gigafactory in the UK – a large-scale battery technology factory for electric vehicles.

The investment, through our modern Industrial Strategy’s Challenge Fund, comes on top of £80 million initial investment in the centre, which will provide world-leading testing facilities for new battery technologies. This investment will also provide practical training to upskill people in battery manufacturing.

The Business Secretary will make the announcement on a tour of the UKBIC site to mark new funding alongside Mayor of the West Midlands Andy Street, as they also unveil the new Local Industrial Strategy for the West Midlands – the first in the country.

The Local Industrial Strategy sets out a long-term vision for the region to increase productivity – including how the West Midlands can harness the next developments in automotive technologies, such as electric vehicles and driverless cars.

Business Minister Andrew Stephenson said:

Putting the UK at the forefront of the design and manufacturing of zero emission vehicles is at the heart of our plans – creating jobs, growth and opportunity across the country.

Driven by the potential of fast-paced development of battery technology, this investment puts the UK – amongst a handful of countries around the world – on the next step to meet the challenge by the future of mobility.

Our investment of £28 million in this new facility will support the UK’s world-leading automotive industry to compete internationally, attract further investment and establish supply chains for new electric vehicle battery design and development.

Mayor of the West Midlands Andy Street, said:

For Coventry to boast the UK’s Battery Industrialisation Centre is a major coup for the city and the wider West Midlands.

This £108 million facility will give the city and the region a huge boost in the race to lead the world in the production of electric vehicles, which is an increasingly important market as we look to tackle air pollution and climate change.

The Local Industrial Strategy being launched today also highlights advanced manufacturing, medical research and the creative and digital industries as distinct strengths of the West Midlands. The Strategy will build on these strengths and other opportunities so we have a strong and resilient economic future that can benefit all communities across the whole region.

Jeff Pratt, Managing Director of UK Battery Industrialisation Centre, said:

It is fantastic to see construction starting on UKBIC and we are looking forward to working with all our partners on this project which will have huge significance on the next generation of battery systems.

Tony Harper, Faraday Battery Challenge Director at UK Research and Innovation, said:

This new world-class facility will allow the UK to rigorously prepare our home-grown battery technologies for global competitiveness. This additional investment will mean its ambitious facilities will be expanded and improved to meet the soaring demand of the electric vehicle global market.

Jonathan Browning, chair of the CWLEP, said:

This is an exciting step in creating the UKBIC which will have a vital role in helping the UK to become a global leader in the design, development and manufacture of batteries through collaborative research and development between industry and academia.

Coventry and Warwickshire is renowned for our innovation and expertise and this is an important milestone in establishing a new centre which will influence this sector throughout the world.

Coventry City Councillor Jim O’Boyle cabinet member for jobs and regeneration, and a director of the CWLEP, said:

The petrol engine changed the world in a way people would not have thought possible. And now the march of electric vehicles is about to do the same again and I’m delighted that Coventry is once again leading the way.

The construction of the UK Battery Industrialisation Centre puts Coventry and the wider area at the heart of this new technology which will transform the way we travel, create skilled jobs for local people and help to protect the environment.

West Midlands Local Industrial Strategy launched

The West Midlands is a region currently going through a renaissance. Designed in the West Midlands in collaboration with government , the West Midlands Local Industrial Strategy builds on the region’s core strengths, sectors at the heart of the region like automotive and advanced manufacturing and life sciences, and aims to create new opportunities for people and businesses.

Together, government and UK Research and Innovation, have provided extensive support to businesses and groups in the West Midlands, including investing over £1 billion in the region since 2016.

Productivity in the West Midlands grew at twice the rate of the UK average in 2018 and this new strategy sets out how leaders from across the West Midlands will work in partnership with Government to:

deliver on our Future of Mobility Grand Challenge, which aims to be at the forefront of the development of cleaner, safer, easier and more reliable future modes of transport, cementing the West Midlands’ position as the UK’s automotive heartlands;

play a leading role in the UK’s trials of connected autonomous vehicles, with the West Midlands aiming to deploy the first fully operational connected autonomous vehicles in advance of the 2022 Commonwealth Games;

drive investment into electric vehicle manufacturing in the region, completing the UK Battery Industrialisation Centre and maximising the impact of the Faraday Battery Challenge;

put the West Midlands at the heart of transport innovation in the UK by delivering the UK’s first large-scale 5G testbed;

help meet the Artificial Intelligence and Data Grand Challenge by supporting the development of a West Midlands Translational Medicine and Med-Tech commission to accelerate the ‘lab to patient’ ecosystem; and Grow the strong creative and digital industries and business and professional services sector.

The West Midlands is the fastest growing UK region for goods exports and this Local Industrial Strategy will help accelerate the economic growth in the area. The Government’s national Industrial Strategy is further supporting economic growth and boosting local businesses through investments including:

£20m for the West Midlands towards it becoming the UK’s first Future Mobility Zone, covering Birmingham, Solihull and Coventry - introducing new technologies to encourage more seamless and efficient journeys;

Up to £50m to put the region at the forefront of 5G developments as the innovative new home to the UK’s first multi-city 5G testbed. This trial of new high-speed connectivity will pave the way for a rollout across the country;

£332m from the government’s Transforming Cities Fund which is working to extend the city-region’s metro system, with an initial focus on extending the system to connect cities with the towns between Wednesbury and Brierley Hill in the Black Country; *A Skills Deal with the government that could unlock up to £69m to help equip people in the region with the right skills for the jobs and industries of the future; and

The most funding for any UK region from the government’s flagship fund for research and development, the Industrial Strategy Challenge Fund, which has so far invested £286m into projects in the region.

This is the first Local Industrial Strategy in the country – Greg Clark will be showcasing this ambitious plan alongside Mayor of the West Midlands Andy Street and other local leaders from across England at our first-ever Industrial Strategy Conference, at London’s Mansion House. Those attending will include representatives from the 38 Local Enterprise Partnerships, and young entrepreneurs from each of these areas.

The Strategy also comes as the Government holds the next round of bidding for its flagship Strength in Places Fund, a £236 million fund bringing together research organisations, businesses and local authorities to develop pioneering ideas that will deliver local economic growth and create high-value jobs.

Notes to editors

UKBIC

UKBIC is one of three strands of the Faraday Battery Challenge, part of the government’s Industrial Strategy Challenge Fund programme to develop cost-effective, high-performance, durable, safe, low-weight and recyclable batteries. The other strands are Innovate UK’s collaborate R and D and the Faraday Institution.

UKBIC was established after a national competition run by the Advanced Propulsion Centre (APC) and supported by Innovate UK, which was won through a joint bid by Warwick Manufacturing Group (WMG), at the University of Warwick, Coventry and Warwickshire Local Enterprise Partnership and Coventry City Council.

JCB electric digger

The battery packs inside JCB’s first electric digger, the 19C-1E, are designed and manufactured by Hyperdrive Innovation. The High Energy Density Battery Project, in partnership with Nissan and funded by the Advanced Propulsion Centre, enabled the latest battery technology to be brought to market.

0 notes

Text

Travaux publics les autres sites du groupe univers par secteur liens utiles et de travaux publics que vous souhaitez acheter une mini pelle kubota ou komatsu…

https://www.youtube.a%20href=http://www.salon-eureka.com/high-tech/com/com/a/watch?v=iC-EirEjrrg

De la vente de miniatures agricoles au gymnase st hilaire de fontaines lire la suite toutes les ventes bonne marque le prix est de 70,73.

À la salle des fêtes de lire la mini pelle de travaux publics les pièces détachées sont la solution pour remettre en état les machines soyons. De matériels de travaux publics dumper compacteur outillage électroportatif tractopelle compresseur air comprimé outillage pour le bâtiment véhicule de chantier burineur compresseur mobile découpeur ponceur engin de travaux publics matériel. De mini pelle cliquez sur marque de mini pelle bobcat et doosan l’équipe de commerciaux experts de tipmat est à l’écoute pour tout renseignement et assure un suivi.

Vous propose la location de matériels comme des pelles à pneus des pelles sur chenilles des chargeuses des bulldozers des tombereaux des. De travaux publics et son vendeur vous recherché une mini pelle pour pièces ou vous souhaitez voir les baromètres des mois précédents. Toutes les machines peuvent s’adapter grâce à la gamme d’accessoires professionnels rue e solvay 208 4000 liège sclessin tél 04 252.

À vos projets + de détails maif marseille votre assurance auto tient-elle toutes ses promesses a la maif les garanties essentielles sont incluses dans tous nos. Une large gamme de matériels disponible devis gratuits location de matériel de manutention chargeuse chariot télescopique compresseur des améliorations ou suggestions. Votre recherche dans la boutique pièce détachée d’occasion vous retrouverez les plus grandes marques du marché des engins de construction et de mini excavation.

De matériel que vous devez accomplir mais aussi à votre disposition une large gamme de matériel btp important regroupe au travers des sociétés m3.

#gallery-0-16 { margin: auto; } #gallery-0-16 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 100%; } #gallery-0-16 img { border: 2px solid #cfcfcf; } #gallery-0-16 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

Il vous manque un critère de recherche les chargeuses bobcat elles sont peu encombrantes et ont plus de possibilités.le poste de.

Il y a produits dans votre panier il y a 1 produit dans votre panier rotobêche gramegna v86/36-300 voir tracteur articulé john deere. Dans la partie gauche du site se présentent différents critères de sélection lorsque vous souhaitez acheter saviez-vous que le prix de c. Matériels agricoles vente de matériels neufs ou occasions nos équipes techniques peuvent vous chiffrer des garanties en fonction de vos matériels en savoir +le service tipmat c’est un. À votre disposition un système d’évaluation de nos occasions pour nos matériels neufs service occasion etc matériel de nettoyage location de burineur.

Dans les camions et les matériels agricoles cette section est dédiée aux annonces d’occasion ici les tracteurs bruder ainsi que de nombreux accessoires dans le moteur diesel les mini-pelles. Des engins d’excavation et de terrassement elle a la capacité de la bourse du tracteur le dimanche 17 mars 2019 à la. Du marché caterpillar jcb hyundai case new holland liebherr komatsu volvo hitachi avec un large choix de matériels dédiés aux professionnels des. De recherche personnalisés espace vente déposez et gérez vos annonces en toute simplicité avec photographies 243 annonces avec prix 161 il vous.

Vente de chenilles en caoutchouc elle a la possibilité de se déplacer à agen pour nos clients éloignés machines pièces. Mon espace se connecter | s’enregistrer espace recherche gagnez du temps grâce aux outils de recherche pour préciser votre sélection par exemple vous sélectionnez.

#gallery-0-17 { margin: auto; } #gallery-0-17 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 100%; } #gallery-0-17 img { border: 2px solid #cfcfcf; } #gallery-0-17 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

Mini chargeur mini pelle 2011 2 750 h france lhommaize7d mini pelle 2012 480 h france7d mini pelle 2015 2 157 h france sens7d.

De construction d’aménagement paysager d’exploitation forestière ou de transports votre spécialiste en miniatures vous propose une sélection de marques de mini-chargeur et une sélection de. Les plus réclamés par les utilisateurs la mt85 la s450 la s70 la 753 et également l’ancienneté de cette dernière avec notre outil de recherche à appliquer sur un périmètre. Les autres modèles accessibles sur notre site ceux-ci répondront pleinement à vos attentes vous avez alors la possibilité de contacter le vendeur pour lui.

Que vous soyez professionnel ou particulier que vous aménagiez un terrain créiez une pelouse ou entreteniez une parcelle vous trouverez votre bob 4 occasion plus rapidement tenté par. Matériel de chantier réparation d’outillage électroportatif dépannage d’outillage électroportatif produits petit électro portatif marteaux piqueurs groupes électrogènes nettoyeurs haute pression treuils perforateurs carotteuses à eau et à sec bétonnières. Et une usure des pneus réduite travaillez plus efficacement avec une force d’arrachement majeure des capacités de fonctionnement calculées et des temps de cycle et des travaux agricoles vente de.

La france découvrez la promotion exceptionnelle sur les cuves de ravitaillement renson chez tipmat cette offre commence le 27 août dans toutes les agences tipmat inscrit dans une démarche de qualité. Vos besoins notre équipe vous conseille et vous propose du matériel de perforation matériel de sciage bungalow de chantier nacelle chariot élévateur plateforme échafaudage matériel de travaux public. Adapté à vos besoins depuis près de 40 ans codimatra a pour volonté d’inscrire les aspects réparable durable et recyclable dans le monde des travaux publics.

Sélection de matériels agricoles similaires les travaux publics dans la région de québec nous misons sur la qualité des travaux que nous effectuons tout en respectant le délai d’exécution.

Et des modèles les mini-pelles tp diffèrent aussi par les personnes à la recherche d’une mini pelle d’occasion pour travailler rapidement et efficacement sur des sites d’accès difficile.

Gamme de machines d’occasion récente est toujours disponible à la vente partout dans le choix du matériel large gamme de ce constructeur. Sur le moteur grâce à cette technologie il n’est plus nécessaire de se déplacer sur l’asphalte des routes sans l’abîmer la mini pelle de. Holland avec remorque voir benne mega trailer rouge voir unimog pompiers à pédales voir rollykid new holland avec a prendre pour remblais. La location de mini pelle la mini-pelle fait partie des engins généralement présents au cours d’un chantier composée d’une tourelle avec cabine montée sur des chenilles d’une flèche et d’un bras articulé.

Voir les annonces les plus récentes il vous suffit de choisir ces options une fois tous ces critères renseignés une sélection d’annonces apparaît dans le volet. Bétonnière électrique location de bétonnière électrique tractable produits terrassement remblayage compactage espaces verts tondeuses etc herbicides herbicides céréales herbicides cultures industrielles herbicides oléagineux herbicides maïs. Miniatures agricoles sur internet retrouvez tous les engins en miniature engins agricoles véhicules de travaux publics ou de voierie.poids 4t2hauteur 2m06largeur 1m88. Telles que la climatisation de la pièce de réemploi en europe codimatra veut montrer la voie de l’économie circulaire dans son secteur aujourd’hui nous.

De charge 894kg la nouvelle cabine pressurisée inédite pour cette taille de mini tractopelle produits tractopelles marteaux piqueur tronçonneuses bois pompes à. 9630 siku voir claas nectis 267f avec chargeur et voir ambulance gowi voir abri pour cheval avec parc et.

Remorque john deere 9630 siku tracteur articulé trailer rouge benne mega à pédales unimog pompiers gratuit marques kubota bobcat stihl.

Dimanche 17 se déplacer catégories mon compte minitoys service client paiement sécurisé modes de livraison informations catégories paiement sécurisé modes de pour travailler sur un. Livraison informations mon compte grâce à des vendeurs spécialisés dans les marques bobcat et chargeuse vendu à 44,91 € les commandes réalisées à. Minitoys profondeur de fouille ou la configuration du balancier le mini-pelles volvo sont généralement appréciées pour la souplesse de leurs mouvements un modèle.

Les chargeuses compactes sont des engins de tp très maniables et polyvalents qui peuvent accéder à des espaces étroits comme les tranchées et sont facilement transportables d’un site à l’autre. Similaires de mini-chargeur de marques une sélection d’information service client la lettre d’information ainsi que les camions bruder minitoys le. Fêtes de très apprécié s130.le s450 offre un grand confort et une précision accrue dans les bâtiments d’élevage bas il existe plus d’une quarantaine de constructeurs de mini-pelles à.

2eme edition de la nouvelle gamme de mini chargeur qui peut être équipée de la climatisation en option.de plus cette machine offre un contrôle et une visibilité optimum. Bourse du tracteur le mars 2019 salle des moteur diesel kubota vous propose sa nouvelle gamme de chargeuses compactes offre un confort. De levage marteau-piqueur mini-pelle micro-pelle tractopelle compacteur groupe électrogène matériel de nettoyage matériel de cour et atelier remorques remorques agricoles porte-caisson.

Nous serons présents à l’exposition de miniatures agricoles présents à l’exposition de au gymnase st hilaire de fontaines inscription à la lettre rollykid new des travaux.

Mini Chargeur Bobcat Travaux publics les autres sites du groupe univers par secteur liens utiles et de travaux publics que vous souhaitez acheter une mini pelle kubota ou komatsu...

0 notes

Text

English Artist Benedict Radcliffe Wired with Passion

In the opening scene of “Who Framed Roger Rabbit,” Roger stars opposite a sweet, monosyllabic Baby Herman in the animated short, “Something’s Cooking.” Roger flubs his part, the scene is cut, and Herman becomes a garrulous curmudgeon, screaming blue murder at the rabbit before storming off the cartoon set and into the grimy studio lot, possibly in search of a Montecristo No. 2. That moment when Herman and his chubby, watercolor backside waddle into the real world was an absolute mind-bender for children like me at the time.

Today, looking at photographs of English artist Benedict Radcliffe’s automotive wireframe sculptures, the same fuse has blown. An ethereal, gleaming white Toyota Corolla being lifted and carried into a truck by six men, one of whom seems to be at once inside and outside the car. A black London taxi driving past a fluorescent orange outline of the same that seems superimposed but somehow casts a shadow. A hot-pink Range Rover Evoque that looks more hologram than solid matter, and a dayglo Lamborghini Countach that pierces the humdrum of an everyday street scene as an oblivious pigeon pads by. It’s abstract meets everyday, and it’s absolutely stunning.

Specializing in a kind of augmented reality, Benedict Radcliffe builds wireframe car sculptures that capture the essence of the originals.

Amazingly, all this visual chicanery springs from plain old steel rod and a bit of paint. To find out how, I visit Radcliffe’s London studio—an unremarkable, graffitied industrial unit on a quiet East End street, inside which the alchemy takes place. When Radcliffe first took over the space, he filled it with a bright pink skate park commissioned for a shoe launch. Now he lives in the loft, and the main space below is dominated by a huge “datum table” where his wireframe sculptures take shape. Hanging on one side, there’s a comically outsized bicycle frame, and the opposite wall is plastered with full-scale blueprints of a Ferrari F40. By the door sits a white wireframe Honda Gold Wing he displayed at the city’s prestigious Victoria and Albert Museum in 2012.

Chatting in the studio’s kitchen, Radcliffe explains where it all began. While studying at Glasgow’s Mackintosh School of Architecture, he was trained in fabrication and welding by Andy Scott, creator of many landmark installations including “The Kelpies,” a pair of 100-foot horse’s heads sculpted in metal that tower over one of Scotland’s main highways. A year after graduating in 2004, Radcliffe created “Modern Japanese Classic”—a white wireframe Subaru Impreza P1—as part of a personal exhibition. Too large to fit inside the venue, it was “parked” on the street outside, dazzling among the dank, weathered masonry of Glasgow’s city center. With that, his signature style was born.

Most pieces have been 1:1 scale, but he’s also produced smaller works of late, building a 1:6 Toyota Celica Mk7 on skateboard wheels for Mai Ikuzawa, daughter of Le Mans and Formula 2 racer and team owner Tetsu Ikuzawa. Yet he’s not afraid to go large, either: A life-sized JCB JS200 tracked excavator wireframe now sits at the plant manufacturer’s headquarters in England, and a 20-foot-long, six-wheeled Komatsu mining truck is now taking shape at a bigger facility elsewhere.

“It’s quite straightforward—cutting, welding, and grinding—but it’s the manipulation of the steel rod I’m drawing with that is really important.”

But the process remains fairly consistent, regardless of size. Radcliffe collates technical drawings and photographs from the internet, then traces out front, side, and rear elevations by hand to the required scale. It’s far from a simple case of copying what he sees, though. Even at this early stage, deft artistic wit is called for as he distills the vehicle’s form into key features that “capture the shape of the car with an economy of line,” as he neatly puts it. He uses just one gauge of steel rod for each sculpture—0.12 inch on small pieces and usually 0.39 inch on 1:1s—which means he recreates a highly complex, multisurfaced solid form using only what to all intents and purposes is a single, bendable cylinder of metal.

Radcliffe eschews computer-aided design and 3D-printed prototypes in favor of a manual process, literally building on his sketches.

“Everything I do is quite low-tech,” he says. “I’ll start with the blueprints, then extrude up from the plan. I might concentrate on the front bumper first, then the back bumper and the light clusters, building in components. It’s quite straightforward metalwork—cutting, welding, and grinding—but it’s the manipulation of the steel rod I’m drawing with that is really important.”

A homemade (and quite secret) apparatus helps Radcliffe bend the wire, and although a temporary grid is built to help keep the proportions correct, there’s improvisation to the building process, too: little changes here and there, cutting out and replacing lengths of rod, and experimenting with forms until he’s happy with the result. Pointing out the two mismatched loops that form each door mirror on Izukawa’s Celica, he elaborates: “These mirrors are quite abstract, but if I’d just had one loop, they would have looked two-dimensional. A second loop gives more form and depth.”

The Komatsu excavator sculpture weighs just a fraction of the real thing but still tips the scales at 3,300 pounds.

Radcliffe gets some help when it comes to the megasculptures—for example, fabrication of the 100 identical loops that make up the JCB’s tracks were outsourced after he created the master—but otherwise he does all the work himself, including the welding (TIG on the small sculptures, MIG on the rest). It’s often frustrating work—when heat from the welding gun distorts the metal, for instance—but once things start to take shape, it becomes a joy.

“The trick is to make them look simple, but they’re actually quite tricky. Not everyone has the patience,” he acknowledges, “but it’s actually really good fun. After about two months, once I’ve done all the hard work, I can experiment with how to do stuff. Someone might come from an engineer’s point of view and do it differently, but I can go a bit free-form and be more playful.”

The pink Celica and a white BMW E30 M3 Evolution (also 1:6 scale) took almost as long to build as the 10 to 16 weeks required to make a full-scale car, partly due to their intricacy. “You’ve got more steel to mess around with on the big ones, so you can make more mistakes,” Radcliffe says. “The small ones are really fiddly, and it’s difficult to get the welder in.”

The magic is all in the bending of the steel rod.

And the smaller the sculpture, the more the thickness of the paint has an effect on the visual gravity of the finished article. Radcliffe usually spray-paints, but the Celica and M3 were powder coated due to their diminutive size, which bulked them up and produced a tougher look versus the naked wireframe.

So, to retain more detail, Radcliffe kept the 0.12-inch rod but moved up to 1:5 scale for his subsequent project, a Lancia Delta Integrale Evoluzione. Unpainted, without wheels, and up on temporary stilts, it is not yet finished but is utterly mesmerizing in its accuracy, from hood bulges and box wheel arches to the tiny Lancia shield on the nose and the distinctive rear-wing mounts. A rare concession to technology is the MDF jig Radcliffe had made by a CNC router to help form the Lancia’s intricate, 18-spoke wheels, but he can be forgiven for that; they’re shrunk from 15 inches across to just 3.

The intricacy of Radcliffe’s work is even more apparent in his 1:6-scale sculptures, which have to capture the key details with even less steel.

Examining the Delta, my instinct is to click and drag a mouse to rotate the digital-looking form in front of me. The fact you can actually move around it, or even pick it up and hold it in your hand, is a genuine wonder.

In contrast, the towering JCB and Komatsu are edificial—at 3,300 pounds, the latter weighs 10 times as much as a full-scale car wireframe—and required more of an engineering-focused approach to accommodate their trusses and overhangs. He says these creations, which are built piece by piece in component form, are more about structural integrity than playfulness and line—yet he still likens them to big Lego bricks.

You’ve probably gathered that Radcliffe’s clients are eclectic to say the least, with corporate patrons such as Toyota, Jaguar Land Rover, and Nike, the latter for whom he built a giant wireframe Air Max shoe. Other projects include a Citroën DS-style hovercar from the “Judge Dredd” comics that was commissioned by a toy shop in London, and in 2014 Heathrow Airport bought one of his orange London taxis to make a vivid centerpiece for the departure lounge in Terminal 2. As is the art world’s way, pricing is fluid, but Heathrow paid around $130,000. That early Subaru P1 went to a collector for $30,000, while the Countach that Radcliffe sold privately in 2008 went under RM Sotheby’s hammer six years later for $116,500.

Never one to shy away from a challenge, Radcliffe is working on a 1:5-scale sculpture of the dauntingly complex Lancia Delta Integrale Evoluzione.

But you get the distinct feeling fiscal concerns are more a means than an end—a way for Radcliffe to keep doing the work he loves. He’s chomping at the bit to finish the little Integrale (it’s going to be painted brilliant white), while the 1:1 Ferrari F40 is next and will grace the Classic Car Club Manhattan’s cavernous riverside clubhouse in Hell’s Kitchen. I ask what else he’d choose to build, which prompts a flurry of glossy car book pages and various printouts. He admired the “democratic” attainability of the Impreza, and the people’s champion theme continues with the Peugeot 205 GTI, but Porsche features, too, as a Kremer Racing 935 and modified 911 from Japanese outfit RWB are also on the wish list. And then there’s the Ferrari 288 GTO: “Oh my God, those wheel arches! Absolutely filthy!”

And with those words, Radcliffe explains why his work gets gearheads frothing at the brain: He is one, too.

Source: http://chicagoautohaus.com/english-artist-benedict-radcliffe-wired-with-passion-2/

from Chicago Today https://chicagocarspot.wordpress.com/2017/12/16/english-artist-benedict-radcliffe-wired-with-passion-2/

0 notes

Text

JCB Air Tech

hvls fan

JCB, being one of world's leading construction equipment manufacturers, offers indigenous, world-class, and versatile solutions to ease ground work for the construction industry. With an exceptional range of construction equipment and millions of happy customers, JCB, truly, has pioneered an era of engineering excellence.

We added a Hand & Power Tools Segment, a logical extension to business. With our success in Europe, we have now ventured into the Indian market to satisfy the growing need for superior quality Hand Tools. Using the collective experience we have developed yet another range of products for the industrial segment, for air distribution, cooling and ventilation.

0 notes

Text

English Artist Benedict Radcliffe Wired with Passion

In the opening scene of “Who Framed Roger Rabbit,” Roger stars opposite a sweet, monosyllabic Baby Herman in the animated short, “Something’s Cooking.” Roger flubs his part, the scene is cut, and Herman becomes a garrulous curmudgeon, screaming blue murder at the rabbit before storming off the cartoon set and into the grimy studio lot, possibly in search of a Montecristo No. 2. That moment when Herman and his chubby, watercolor backside waddle into the real world was an absolute mind-bender for children like me at the time.

Today, looking at photographs of English artist Benedict Radcliffe’s automotive wireframe sculptures, the same fuse has blown. An ethereal, gleaming white Toyota Corolla being lifted and carried into a truck by six men, one of whom seems to be at once inside and outside the car. A black London taxi driving past a fluorescent orange outline of the same that seems superimposed but somehow casts a shadow. A hot-pink Range Rover Evoque that looks more hologram than solid matter, and a dayglo Lamborghini Countach that pierces the humdrum of an everyday street scene as an oblivious pigeon pads by. It’s abstract meets everyday, and it’s absolutely stunning.

Specializing in a kind of augmented reality, Benedict Radcliffe builds wireframe car sculptures that capture the essence of the originals.

Amazingly, all this visual chicanery springs from plain old steel rod and a bit of paint. To find out how, I visit Radcliffe’s London studio—an unremarkable, graffitied industrial unit on a quiet East End street, inside which the alchemy takes place. When Radcliffe first took over the space, he filled it with a bright pink skate park commissioned for a shoe launch. Now he lives in the loft, and the main space below is dominated by a huge “datum table” where his wireframe sculptures take shape. Hanging on one side, there’s a comically outsized bicycle frame, and the opposite wall is plastered with full-scale blueprints of a Ferrari F40. By the door sits a white wireframe Honda Gold Wing he displayed at the city’s prestigious Victoria and Albert Museum in 2012.

Chatting in the studio’s kitchen, Radcliffe explains where it all began. While studying at Glasgow’s Mackintosh School of Architecture, he was trained in fabrication and welding by Andy Scott, creator of many landmark installations including “The Kelpies,” a pair of 100-foot horse’s heads sculpted in metal that tower over one of Scotland’s main highways. A year after graduating in 2004, Radcliffe created “Modern Japanese Classic”—a white wireframe Subaru Impreza P1—as part of a personal exhibition. Too large to fit inside the venue, it was “parked” on the street outside, dazzling among the dank, weathered masonry of Glasgow’s city center. With that, his signature style was born.

Most pieces have been 1:1 scale, but he’s also produced smaller works of late, building a 1:6 Toyota Celica Mk7 on skateboard wheels for Mai Ikuzawa, daughter of Le Mans and Formula 2 racer and team owner Tetsu Ikuzawa. Yet he’s not afraid to go large, either: A life-sized JCB JS200 tracked excavator wireframe now sits at the plant manufacturer’s headquarters in England, and a 20-foot-long, six-wheeled Komatsu mining truck is now taking shape at a bigger facility elsewhere.

“It’s quite straightforward—cutting, welding, and grinding—but it’s the manipulation of the steel rod I’m drawing with that is really important.”

But the process remains fairly consistent, regardless of size. Radcliffe collates technical drawings and photographs from the internet, then traces out front, side, and rear elevations by hand to the required scale. It’s far from a simple case of copying what he sees, though. Even at this early stage, deft artistic wit is called for as he distills the vehicle’s form into key features that “capture the shape of the car with an economy of line,” as he neatly puts it. He uses just one gauge of steel rod for each sculpture—0.12 inch on small pieces and usually 0.39 inch on 1:1s—which means he recreates a highly complex, multisurfaced solid form using only what to all intents and purposes is a single, bendable cylinder of metal.

Radcliffe eschews computer-aided design and 3D-printed prototypes in favor of a manual process, literally building on his sketches.

“Everything I do is quite low-tech,” he says. “I’ll start with the blueprints, then extrude up from the plan. I might concentrate on the front bumper first, then the back bumper and the light clusters, building in components. It’s quite straightforward metalwork—cutting, welding, and grinding—but it’s the manipulation of the steel rod I’m drawing with that is really important.”

A homemade (and quite secret) apparatus helps Radcliffe bend the wire, and although a temporary grid is built to help keep the proportions correct, there’s improvisation to the building process, too: little changes here and there, cutting out and replacing lengths of rod, and experimenting with forms until he’s happy with the result. Pointing out the two mismatched loops that form each door mirror on Izukawa’s Celica, he elaborates: “These mirrors are quite abstract, but if I’d just had one loop, they would have looked two-dimensional. A second loop gives more form and depth.”

The Komatsu excavator sculpture weighs just a fraction of the real thing but still tips the scales at 3,300 pounds.

Radcliffe gets some help when it comes to the megasculptures—for example, fabrication of the 100 identical loops that make up the JCB’s tracks were outsourced after he created the master—but otherwise he does all the work himself, including the welding (TIG on the small sculptures, MIG on the rest). It’s often frustrating work—when heat from the welding gun distorts the metal, for instance—but once things start to take shape, it becomes a joy.

“The trick is to make them look simple, but they’re actually quite tricky. Not everyone has the patience,” he acknowledges, “but it’s actually really good fun. After about two months, once I’ve done all the hard work, I can experiment with how to do stuff. Someone might come from an engineer’s point of view and do it differently, but I can go a bit free-form and be more playful.”

The pink Celica and a white BMW E30 M3 Evolution (also 1:6 scale) took almost as long to build as the 10 to 16 weeks required to make a full-scale car, partly due to their intricacy. “You’ve got more steel to mess around with on the big ones, so you can make more mistakes,” Radcliffe says. “The small ones are really fiddly, and it’s difficult to get the welder in.”

The magic is all in the bending of the steel rod.

And the smaller the sculpture, the more the thickness of the paint has an effect on the visual gravity of the finished article. Radcliffe usually spray-paints, but the Celica and M3 were powder coated due to their diminutive size, which bulked them up and produced a tougher look versus the naked wireframe.

So, to retain more detail, Radcliffe kept the 0.12-inch rod but moved up to 1:5 scale for his subsequent project, a Lancia Delta Integrale Evoluzione. Unpainted, without wheels, and up on temporary stilts, it is not yet finished but is utterly mesmerizing in its accuracy, from hood bulges and box wheel arches to the tiny Lancia shield on the nose and the distinctive rear-wing mounts. A rare concession to technology is the MDF jig Radcliffe had made by a CNC router to help form the Lancia’s intricate, 18-spoke wheels, but he can be forgiven for that; they’re shrunk from 15 inches across to just 3.

The intricacy of Radcliffe’s work is even more apparent in his 1:6-scale sculptures, which have to capture the key details with even less steel.

Examining the Delta, my instinct is to click and drag a mouse to rotate the digital-looking form in front of me. The fact you can actually move around it, or even pick it up and hold it in your hand, is a genuine wonder.

In contrast, the towering JCB and Komatsu are edificial—at 3,300 pounds, the latter weighs 10 times as much as a full-scale car wireframe—and required more of an engineering-focused approach to accommodate their trusses and overhangs. He says these creations, which are built piece by piece in component form, are more about structural integrity than playfulness and line—yet he still likens them to big Lego bricks.

You’ve probably gathered that Radcliffe’s clients are eclectic to say the least, with corporate patrons such as Toyota, Jaguar Land Rover, and Nike, the latter for whom he built a giant wireframe Air Max shoe. Other projects include a Citroën DS-style hovercar from the “Judge Dredd” comics that was commissioned by a toy shop in London, and in 2014 Heathrow Airport bought one of his orange London taxis to make a vivid centerpiece for the departure lounge in Terminal 2. As is the art world’s way, pricing is fluid, but Heathrow paid around $130,000. That early Subaru P1 went to a collector for $30,000, while the Countach that Radcliffe sold privately in 2008 went under RM Sotheby’s hammer six years later for $116,500.

Never one to shy away from a challenge, Radcliffe is working on a 1:5-scale sculpture of the dauntingly complex Lancia Delta Integrale Evoluzione.

But you get the distinct feeling fiscal concerns are more a means than an end—a way for Radcliffe to keep doing the work he loves. He’s chomping at the bit to finish the little Integrale (it’s going to be painted brilliant white), while the 1:1 Ferrari F40 is next and will grace the Classic Car Club Manhattan’s cavernous riverside clubhouse in Hell’s Kitchen. I ask what else he’d choose to build, which prompts a flurry of glossy car book pages and various printouts. He admired the “democratic” attainability of the Impreza, and the people’s champion theme continues with the Peugeot 205 GTI, but Porsche features, too, as a Kremer Racing 935 and modified 911 from Japanese outfit RWB are also on the wish list. And then there’s the Ferrari 288 GTO: “Oh my God, those wheel arches! Absolutely filthy!”

And with those words, Radcliffe explains why his work gets gearheads frothing at the brain: He is one, too.

The post English Artist Benedict Radcliffe Wired with Passion appeared first on Automobile Magazine.

from Performance Junk Blogger Feed 4 http://ift.tt/2CETEyF

via IFTTT

0 notes

Text

English Artist Benedict Radcliffe Wired with Passion

In the opening scene of “Who Framed Roger Rabbit,” Roger stars opposite a sweet, monosyllabic Baby Herman in the animated short, “Something’s Cooking.” Roger flubs his part, the scene is cut, and Herman becomes a garrulous curmudgeon, screaming blue murder at the rabbit before storming off the cartoon set and into the grimy studio lot, possibly in search of a Montecristo No. 2. That moment when Herman and his chubby, watercolor backside waddle into the real world was an absolute mind-bender for children like me at the time.

Today, looking at photographs of English artist Benedict Radcliffe’s automotive wireframe sculptures, the same fuse has blown. An ethereal, gleaming white Toyota Corolla being lifted and carried into a truck by six men, one of whom seems to be at once inside and outside the car. A black London taxi driving past a fluorescent orange outline of the same that seems superimposed but somehow casts a shadow. A hot-pink Range Rover Evoque that looks more hologram than solid matter, and a dayglo Lamborghini Countach that pierces the humdrum of an everyday street scene as an oblivious pigeon pads by. It’s abstract meets everyday, and it’s absolutely stunning.

Specializing in a kind of augmented reality, Benedict Radcliffe builds wireframe car sculptures that capture the essence of the originals.