#it to transfer properly through the screen printing process

Explore tagged Tumblr posts

Text

LIKE I FEEL LIKE THIS WOULD BE REALLY FUN TO SCREEN PRINT YKNOW??

#my art#I'd need to get the print teachers advice on the gradient situation bc I remember theres some kind of dot-grid thing? you have to use for i#it to transfer properly through the screen printing process#but liek ???#if I prep it for print??#yknow??#IGNORE THE AWFUL MESS OF FONT BTW IM BAD AT TYPOGRAPHY#AND POSTER DESIGN SO THIS HAS JUST BEEN IN MY WIPS FOREVER#WHILE I FIGHT OF RMY LIFE WITH THE TYPE LOL

35 notes

·

View notes

Text

Prints and Patterns

A light on Prints & Patterns.

The patterns on a fabric just put colors on are definitely not woven into fabric. called Prints. These are found in several types like, customized shapes, colors, lines, etc. and in the form of objectives as well. The work of art made in multiple iterations, created through a transfer process. The word “Print” is derived from the Old French word for “Impression,” it makes a product look different from its own origin. It has the power to grasp the attention of someone towards it. When prints and patterns work together it gives a hard on its final project. Nowadays, people are using most commonly made from an acrylic polymer.

Why are Prints important?

Printing is used not merely for books and newspapers but as the time flies it is also used for textiles, plates, wallpaper, packaging, and billboards. Several studies have concluded that people simply absorb content better when it's presented on a page, rather than a screen. This is why some college students are reluctant to use PDF versions of their textbooks; reading printed material somehow allows for higher brain function and better information retention. These designs can be simple or super detailed, but they all have the same goal: to make the fabric look even more amazing! Due to some eye-catching prints and patterns, clothes become more appealing to customers, grabbing their attention and making them want to take a closer look. Printing on fabric plays a crucial role in the fashion industry, being a method for applying designs, patterns, or images to fabrics. Textile printing offers a wide range of design options, allowing clothing manufacturers to create a variety of unique Styles, Prints and Patterns, and Colors of Fashion.

Why are Patterns important?

In the garment industry, patterns are used in order to cut the fabric pieces and to make the garment. Patterns are essentially made so that the same style can be easily duplicated when it is needed and multiple pieces can be efficiently made. Improved quality: Patterns can help to ensure that garments are made to the desired specifications, which can lead to improved quality and customer satisfaction. Prints and Patterns making is the process of creating a blueprint of your garment. A pattern is used as a template to cut out fabric that matches the required specifications to sew a garment. Its factors in the type of fabric, the intended fit on the wearer, and any trims that will be used. Prints and Patterns on a fabric makes a plain to be creative.

Final product as printed fabric?

Generally, the finishing process includes three basic stages: washing and drying, stabilizing, and pressing. In addition, some fabrics are then treated to make them anti-static, water repellent, or flame retardant. Many methods applied to fabrics in these stages are very specialized and we can't discuss them all. Definitely, after applying Prints and Patterns on chic indicates customization of fabric then that fabric is processed further for next processes like cutting and stitching.

Addition of Tie & Dye in fabric:-

Tie & Dye is a term used to describe a number of resist dyeing techniques and the resulting dyed products of these processes. The process of tie-dye typically consists of folding, twisting, pleating, or crumpling fabric or a garment, before binding with string or rubber bands, followed by the application of dye or dyes. Textile printing is the process of applying color to fabric in definite prints and patterns or designs. In properly printed fabrics the color is bonded with the fiber, so as to resist washing and friction. In golden era, people were using natural objects to paint the garments i.e. Leaves, Vegetables, Stones, etc. Nevertheless, Tie and Dye fabrics are included in Rajasthani cultural traditions. Moreover, due to Social media, people are connecting globally and sharing their ideas of painting, prints and patterns to give an elegant look to their final outfits.

Prints and its historical background:-

Printing blocks have been discovered that date back to around 3000 B.C." Fabric painting remained popular on the continent, and by the time Alexander the Great invaded India (327 B.C.), fabrics full of colorful printed and painted images were a normal possession among the people. There are several thighs to disclose about the past of prints but our main topic is just for the usage of prints and patterns.

Motifs and Prints:-

A motif is a repeated idea, pattern, image, or theme. In the textile arts, a motif is also called a block or square which is a smaller element in a much larger work. Motifs can be any size, but usually all the motifs in any given work are the same size. There are types of motifs which are defined as:

Symbolic Motifs: These motifs take the form of symbols that represent a larger idea or theme.

Conceptual Motifs: These motifs are built around a particular concept or idea that recurs in the story.

Structural Motifs: These motifs are repeated patterns or structures in the story.

Types of Prints in fabric:-

There are several types of the prints and patterns in the fabric but the majorly are in used are mentioned ahead:-

Boho Prints:- Boho style is a free-spirited aesthetic that mixes different cultures and artistic expressions into an eclectic style with an emphasis on organic elements and nature. When putting together your boho style space, mixing patterns, metals, woods, materials, animal hides and trinkets from your travels is highly encouraged.

Screen Prints:- Screen Printing is a process where ink is forced through a mesh screen onto a surface. Making certain areas of the screen impervious to printing ink creates a stencil, which blocks the printing ink from passing through the screen. The ink that passes through forms the printed image.

Block Printing:- A printing block is sometimes called a printmaking block, a wood block or a block. You can also refer to one simply as a printing block.

Animal Printing:- Animal print is a clothing and fashion style in which the garment is made to resemble the pattern of the skin and fur, feathers or scales of animals such as a leopard, zebra, giraffe, tiger or cow.

Batik Prints:- Batik is an Indonesian technique of wax-resist dyeing applied to the whole cloth. This technique originated from the island of Java, Indonesia. Batik is made either by drawing dots and lines of wax with a spouted tool called a canting, or by printing the wax with a copper stamp called a cap.

Rest there are several prints and patterns which can be used by us, on a daily basis but we are not aware about it. But we should know which prints are suitable for your eyes and your comfort. Rest we are always here to help you out and provide you best opinion as always.

#fashion#fashion designer#fabric#denim#accessories#fashion trends#haute couture#fashion blog#fashion inspiration#prints#art print#printmaking#artwork#art#artists on tumblr#my art#illustration#drawings#tie dye#dyeing#cotton#upcycling#bohochic#bohemian#batik#floral#flowers#roses#plants#garden

6 notes

·

View notes

Text

Screen Print Painting Pt 2

(including stencil)

My second approach to screenprinting differed slightly from the first. It involved using a spatula instead of paintbrushes. I wanted to incorporate the same materials from the painting elective, to a achieve similar results to the impasto technique, larger shapes/ blocks of colour rather than distinct paintbrush stokes. I also tried to print on acetate, my idea for this would have been to layer with stencil and then hang as a piece or photograph with different light shining through it. However, due to the transparency of the ink, it did not transfer properly and therefore ended as a failed experiment.

I wanted to incorporate the original method of screenprinting by layering the stencils on top of the 'screen painted' paper as I felt they were too simple. I cut out the basic shapes and forms I saw from the watergram on the 100% recycled stencil paper. The registration process, using a large piece of acetate to print the stencil on top of and then lining the paper underneath it.

3 notes

·

View notes

Text

Everything You Need to Know About DTF Transfer Stickers and Film Sheets

Direct to Film (DTF) printing is revolutionizing the world of custom apparel and craft projects. This innovative technique offers a versatile way to create stunning designs that can be transferred onto various surfaces. In this article, we will explore everything you need to know about DTF transfer stickers and DTF transfer film sheets, including their benefits, applications, and how to use them effectively.

What are DTF Transfer Stickers?

DTF transfer stickers are designs printed on special film sheets that can be easily transferred to fabrics or other surfaces using heat and pressure. Unlike traditional methods such as screen printing or vinyl cutting, DTF stickers allow for vibrant colors and intricate designs, making them perfect for custom apparel, home decor, and promotional items.

Key Features of DTF Transfer Stickers:

Vibrant Colors: DTF transfer stickers utilize high-quality inks that produce vibrant and eye-catching colors, perfect for various projects.

Durability: Once applied, DTF transfer stickers are durable and resistant to fading, cracking, and peeling, ensuring long-lasting quality.

Versatility: These stickers can be used on various materials, including cotton, polyester, and blends, making them suitable for a wide range of applications.

Understanding DTF Transfer Film Sheets

DTF transfer film sheets are the medium used to print the designs before transferring them onto the desired surface. These sheets are specially coated to ensure that the ink adheres properly and allows for easy transfer during the heat-pressing process.

Types of DTF Transfer Film Sheets:

Clear Film Sheets: Ideal for designs requiring transparency, allowing the fabric color to show through.

White Film Sheets: Perfect for vibrant colors, providing a solid background for the design.

Benefits of Using DTF Transfer Stickers and Film Sheets

Ease of Use: DTF transfer stickers and film sheets are user-friendly and do not require extensive training or experience. With the right equipment, anyone can create professional-quality designs.

Cost-Effective: DTF printing can be more economical than traditional printing methods, especially for small runs or custom designs.

Quick Production Time: DTF transfers can be produced quickly, allowing for fast turnaround times for orders and projects.

How to Use DTF Transfer Stickers and Film Sheets

Step 1: Design Your Artwork Create your design using graphic design software. Ensure your artwork is high-resolution to achieve the best print quality.

Step 2: Print on DTF Film Sheets Using a DTF printer, print your design onto the DTF transfer film sheets. Allow the ink to dry before proceeding.

Step 3: Apply Adhesive Powder Sprinkle DTF adhesive powder on the printed design and shake off the excess. This step is crucial for ensuring the DTF transfer stickers adhere well during the heat press.

Step 4: Cure the Design Use a heat source to cure the adhesive powder, typically done in an oven or with a heat press. This step activates the adhesive for better bonding.

Step 5: Heat Press the Transfer Position the DTF transfer sticker on your chosen fabric or surface. Use a heat press to apply the necessary temperature and pressure according to the manufacturer’s instructions.

Step 6: Peel and Reveal Once cooled, carefully peel away the film to reveal your vibrant design. Your custom sticker or transfer is now ready to be showcased!

Applications of DTF Transfer Stickers

DTF transfer stickers are incredibly versatile and can be used for various applications, including:

Custom T-shirts and apparel

Promotional merchandise

Stickers for personal projects

Home decor items like pillows and tote bags

Conclusion

DTF transfer stickers and DTF transfer film sheets offer an exciting way to personalize your projects with stunning designs. Their ease of use, durability, and vibrant colors make them a fantastic choice for crafters and businesses alike. If you’re looking to explore the world of DTF printing further, check out DTF Vancouver for high-quality materials and expert guidance.

Whether you’re a hobbyist or a business owner, DTF transfer stickers and film sheets can help you create unique and eye-catching products that stand out. Happy crafting!

1 note

·

View note

Text

How to Print DTF Transfers: Tips for Long-Lasting Designs

DTF (direct-to-film) printing is revolutionizing the printing industry, offering vibrant and durable designs on various materials, including cotton, nylon, and leather. Unlike sublimation, which is limited to polyester, DTF can handle a broader range of fabrics. If you're ready to dive into DTF transfers, this guide will walk you through the process step-by-step, ensuring your designs last.

What You’ll Need for DTF Printing

Before you start, gather these essential tools:

Best DTF Printer: Choose a printer specifically designed for DTF, or consider converting an existing inkjet printer.

DTF Transfer Film: This is the medium where your design will be printed.

DTF Ink: Specialized ink that adheres to the film and bonds with the fabric.

Curing Powder: This adhesive ensures your design stays on the fabric during the transfer process.

Heating Press or DTF Oven: These apply the necessary heat and pressure to bond your design to the fabric.

RIP Software: This software prepares your designs for printing, ensuring accurate color layering.

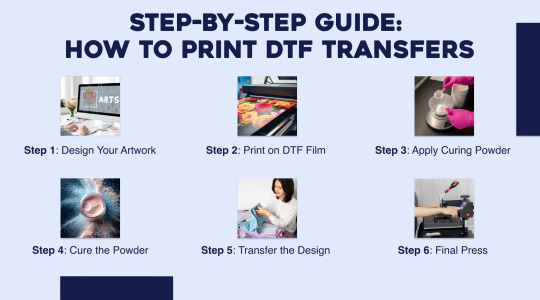

Step-by-Step Guide to Print DTF Transfers

Step 1: Design Your Artwork

Use graphic design software like Adobe Illustrator or Photoshop to create your design. For dark fabrics, ensure to include a white layer when printing. Once you're satisfied with the design, it's time to print.

Step 2: Print on DTF Film

Load the DTF transfer film into your printer. Print your artwork using DTF ink, following the order: colors first, then an uncolored layer. If using a converted inkjet printer, make sure it’s properly set up for DTF printing.

Step 3: Apply Curing Powder

Also Read: What Does DTF Transfer Mean?

While the ink is still damp, sprinkle curing powder evenly over the design. This step is crucial for ensuring the image adheres to the fabric.

Step 4: Cure the Powder

Using a DTF oven or heat press, heat the printed film at about 325°F (163°C) for 2 to 3 minutes. This step transforms the curing powder into an effective adhesive.

Step 5: Transfer the Design

Once the powder is cured, place the design on your garment. Set your heat press to around 320°F and apply pressure for 15-20 seconds. Allow the fabric to cool slightly before peeling off the film.

Step 6: Final Press

For added durability, give your fabric another press. Place a piece of parchment over the design and press for an additional 10-15 seconds. This helps embed the design into the fabric, enhancing its longevity.

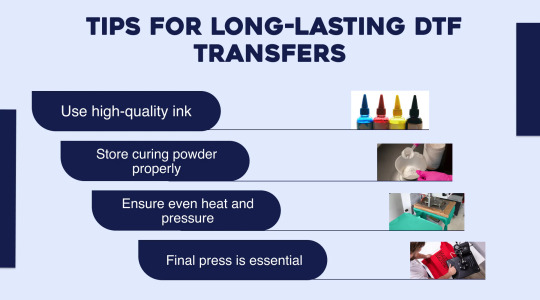

Tips for Long-Lasting DTF Transfers

Use High-Quality Ink: Invest in DTF-specific ink to prevent faded colors and ensure vibrant prints.

Store Curing Powder Properly: Keep it in a dry place to avoid clumping, which can affect adhesion.

Ensure Even Heat and Pressure: Consistent temperature and pressure are key to achieving smooth, durable designs.

Never Skip the Final Press: This step significantly boosts the durability of your design, helping it withstand multiple washes.

Choosing the Right DTF Printer

For beginners, selecting the right printer can be daunting. While dedicated DTF printers are available, many opt to convert existing inkjet printers like the Epson L1800 or P600. Ensure your chosen printer is compatible with DTF films and inks, and look for models with good customer support and availability of replacement parts.

DTF Printing vs. Other Methods

Also Read: What Kind of Printer Do I Need for DTF Transfers?

Screen Printing: Ideal for large orders but labor-intensive and costly for intricate designs. DTF allows for quick, smaller batches.

Sublimation Printing: Limited to polyester and lighter colors; DTF works on various fabrics and is effective on dark materials due to its white ink layer.

DTG Printing: While DTG offers a soft finish, it requires pre-treatment of fabric. DTF simplifies the process, making it more user-friendly for beginners. Also Read: How to Remove DTF from a Shirt Without Ruining the Fabric

DTF printing is a versatile, easy method for creating vibrant designs on various fabrics. Whether you’re a novice or a seasoned pro, with the right tools and a bit of practice, you can produce stunning, long-lasting transfers.

Ready to start creating your DTFIL transfers? Explore your options and bring your designs to life with ease!

0 notes

Text

Behind the Scenes of Raleigh’s Screen Printing: How It Works

Screen printing has become a popular choice for custom apparel, especially in places like Raleigh, where local businesses and communities thrive on personalization. But have you ever wondered what goes on behind the scenes of the screen printing process? Let’s take a closer look at how Raleigh screen printing works and why it’s the go-to method for creating custom T-shirts and other apparel.

Step 1: The Design Phase

Everything starts with a great design. Whether you’re printing a company logo, a custom illustration, or a unique text-based design, the artwork must first be created in a digital format. Most screen printing companies in Raleigh work with files like Adobe Illustrator (AI) or Photoshop (PSD) to ensure high resolution and precise detail.

Tip: If you’re working on your own design, make sure the file is in a vector format, as this allows for clean, sharp edges no matter the size of the print.

Step 2: Prepping the Screen

Once the design is ready, it’s time to prepare the screen. Screen printing gets its name from the mesh screen that is used to transfer ink onto the garment. Each color in the design requires a separate screen, which is coated with a light-sensitive emulsion.

The design is printed onto a transparent film and placed over the screen. The screen is then exposed to UV light, which hardens the emulsion around the design while keeping the design itself soft and pliable. After the exposure, the screen is rinsed, leaving behind the stencil of your design.

Step 3: Setting Up the Press

The next step involves placing the prepared screen onto a printing press. In Raleigh, most screen printing shops use either manual or automatic presses depending on the size of the order and the complexity of the design.

Each press has a series of platens (flat surfaces) where the garments are placed, and the screen is aligned with these platens to ensure accurate placement of the design.

Step 4: Applying the Ink

Now comes the fun part—applying the ink! With the screen in place, ink is poured across the top of the screen, and a squeegee is used to push the ink through the mesh screen and onto the garment below. This process is repeated for each color, ensuring vibrant and accurate prints.

Step 5: Curing the Print

Once the ink has been applied, the garment goes through a drying process called "curing." The printed T-shirt or garment is passed through a conveyor dryer, which heats the ink to a specific temperature to ensure it bonds properly to the fabric. This step is crucial to making sure the print is durable and long-lasting.

Step 6: Quality Check and Finishing

Before the final product is delivered to the customer, it undergoes a quality check. Any inconsistencies in the design, ink coverage, or placement are noted and corrected. In some cases, additional steps like trimming excess threads or folding the garments may be included in the finishing process.

Why Raleigh Screen Printing?

Raleigh has become a hub for high-quality, custom screen printing due to its thriving local businesses, schools, and community groups that rely on personalized apparel. Whether it’s for promotional gear, team uniforms, or local events, Raleigh screen printers offer expert craftsmanship and quick turnaround times.

Additionally, many Raleigh screen printing shops prioritize eco-friendly practices, using water-based inks and recycled materials. This commitment to sustainability, coupled with local expertise, makes Raleigh a great choice for anyone looking to bring their designs to life.

Conclusion

Screen printing may seem simple, but the process is a careful blend of art and science. From creating the perfect design to curing the final product, Raleigh’s screen printing shops are dedicated to providing top-notch service and quality apparel. So, the next time you wear a custom-printed T-shirt, you’ll know just how much work goes into making it look great!

Whether you’re a local business, a school, or just someone looking for unique, custom apparel, Raleigh’s screen printing services have the tools and expertise to make your vision a reality.

#Raleigh screen printing#Raleigh Custom T-shirts#T-shirt printing Raleigh NC#custom t-shirts Raleigh NC#Raleigh t shirt printing#T-shirt screen printing Raleigh NC

0 notes

Text

How to Pay Your Self Assessment Tax Online: A Step-by-Step Guide

Thus, the payment of Self Assessment tax online is easy and convenient and enables the person to meet the tax obligations as required by the law. Here then is a checklist that can help you avoid hitches when making payment so that you are always timely;

Step 1: collection of one’s particulars

Before you begin, make sure you have the following information ready:Before you begin, make sure you have the following information ready:

Unique Taxpayer Reference (UTR): A reference number that is issued to an individual by HMRC when he or she registers for Self Assessment and it is a 10 digit number.

National Insurance Number

Amount of Tax Due: You will be able to find this on your ‘Self Assessment tax return’ or in your ‘HMRC account.

Bank Details: For customers who are using online banking or debit/credit card in making the payment for the products.

Step 2: Log in to Your HMRC Account

Visit the HMRC Website: Enter the website, gov. uk then you will have to choose that you want to log in.

Enter Your Government Gateway ID: Login into your account with your Government Gateway ID and the password. If you aren’t on the list yet, being so can take anything from a few days if you register on the site.

Step 3: Self Assessment Section

Once logged in:

Access Your Tax Return Information: Log into your account and find the option that says “Self Assessment” simply click on it.

Select the “Make a Payment” Option: As will show amount of tax due and enable you to go further in the payment process.

Step 4: Choosing the Method of Payment

There are several ways to pay your tax online, and the method you choose will depend on how quickly you need the payment to be processed:There are several ways to pay your tax online, and the method you choose will depend on how quickly you need the payment to be processed:

Direct Debit: One can use it to authorise an initial or a standing order payment. This takes about 5 working days to process.

Debit or Credit Card: Regarding the payment you have the option to pay through credit card directly on HMRC’s website. Remember that he have to pay some additional amount as processing fee, if you are opting for credit card transactions.

Online Banking: You can transfer the funds from you bank account. Faster Payments generally take a day to be processed while Bacs takes at most 3 working days and CHAPS processes within the same day.

Bank Transfer: They also accept payment from your bank directly by using HMRC’s details which are usually given when the payment is being made.

Note: Always use your 10 digit Unique Tax Reference (UTR) as the payment reference to enable HMRC post your payment properly.

Step 5: Formalise the Payment Process

Confirm the Payment Amount: Ensure that you confirm the amount you are paying to match the amount that you require to pay.

Enter Payment Details: (if making a payment using a card or online banking), enter your particulars as provided in the instructions.

Submit Your Payment: After entering your information pay specific attention to this to confirm your payment as follows.

Step 6: Save your payment confirmation

Once you’ve completed the payment:Once you’ve completed the payment:

Save a Record: Save a copy of this payment receipt either by print or through the screen shot in your file. This will be of great help in situation where you will be required to prove that you made a payment.

Check Your HMRC Account: Usually, it may take 2-3 days for the payment to reflect in your account however you can log into the portal to check whether the payment has been processed or not.

Important Deadlines

31st January: The last date to file your Income Tax return online and to pay the tax which you have computed for the previous financial year.

31st July: For those of you who have payments on account, the second payment is due by this date.

Conclusion

It is quite easier and time effective to pay Self Assessment tax online. Actually, following this step by step guide will help you to meet the due date so that you do not have to incur the cost of paying a penalty. It is important that you confirm every detail in the payment before you execute it and it is advisable to keep a copy.

0 notes

Text

The Art and Benefits of Screen Printing in England

Screen printing is a versatile and highly popular printing technique used across various industries, from fashion and textiles to promotional products and fine art. In England, this method has gained widespread acclaim due to its durability, vibrant colors, and cost-effectiveness. If you're looking for top-notch screen printing services in England, Printnasium is your go-to destination. Here's why screen printing remains a preferred choice for businesses and individuals alike.

The Process of Screen Printing

Screen printing, also known as silkscreen printing, involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. This method allows for precise color application, making it ideal for designs that require vibrant, long-lasting colors. Here’s a step-by-step overview of the screen printing process:

Design Preparation: The first step is to create or select a design. This design is then transferred onto a screen coated with a light-sensitive emulsion.

Screen Exposure: The screen is exposed to light, which hardens the emulsion in the exposed areas, leaving a stencil of the design.

Ink Application: Ink is then pushed through the screen onto the printing surface using a squeegee.

Curing: The printed item is dried and cured, ensuring the ink sets properly and remains durable.

Why Choose Screen Printing?

Screen printing offers numerous benefits, making it an ideal choice for various applications:

Durability: Screen printed designs are highly durable and can withstand repeated washing and heavy use without fading.

Vibrant Colors: The technique allows for the use of thick layers of ink, resulting in rich and vibrant colors that stand out.

Versatility: Screen printing can be used on a wide range of materials, including fabric, plastic, metal, and wood.

Cost-Effective for Large Orders: The setup cost for screen printing can be higher than other methods, but it becomes highly cost-effective for large orders due to the lower cost per unit.

Screen Printing Services at Printnasium

At Printnasium, we pride ourselves on offering premium screen printing services in England. Our team of skilled professionals utilizes the latest technology and high-quality materials to deliver exceptional results. Whether you need custom t-shirts for an event, branded merchandise for your business, or unique designs for your clothing line, we’ve got you covered.

Applications of Screen Printing

Screen printing is incredibly versatile and can be used for a variety of applications:

Custom Apparel: Create unique t-shirts, hoodies, and other apparel with your own designs.

Promotional Products: Print logos and messages on bags, hats, and other promotional items.

Art Prints: Produce high-quality art prints with vibrant colors and fine details.

Industrial Uses: Utilize screen printing for labels, decals, and other industrial applications.

Why Printnasium?

Choosing Printnasium for your screen printing needs in England ensures you receive:

High-Quality Prints: Our state-of-the-art equipment and expert team guarantee top-quality prints every time.

Custom Solutions: We offer tailored solutions to meet your specific needs and preferences.

Competitive Pricing: Enjoy competitive rates without compromising on quality.

Fast Turnaround: We understand the importance of deadlines and ensure timely delivery of your orders.

Conclusion

Screen printing remains a highly effective and popular method for creating durable and vibrant prints on a variety of surfaces. Whether you're a business looking to enhance your brand visibility or an individual seeking unique custom prints, Printnasium offers top-tier screen printing services in England. Contact us today to discuss your project and discover the endless possibilities of screen printing.

0 notes

Text

Mastering the Art of T-Shirt Screen Printing

Screen printing, also known as silk screening, is a versatile and popular technique for customising t-shirts. This method allows for the creation of vibrant, durable designs that can withstand multiple washes. Whether you're a hobbyist or an aspiring entrepreneur, mastering the art of t-shirt screen printing can open up a world of creative possibilities. This guide will walk you through the essentials of screen printing, from the materials you need to the step-by-step process.

The Basics of Screen Printing

At its core, screen printing involves creating a stencil (known as a screen) and using it to apply layers of ink on the printing surface, in this case, a t-shirt. The process can be broken down into several key stages:

Design Creation: The first step in Nottingham Print Shop is creating your design. This can be done using graphic design software like Adobe Illustrator or even hand-drawn if you're aiming for a more organic look. The design is then transferred to a transparent film, which will be used to create the stencil.

Screen Preparation: A screen is essentially a fine mesh stretched over a frame. The mesh is coated with a light-sensitive emulsion, which hardens when exposed to light. Once the emulsion is dry, the transparent film with your design is placed on the screen and exposed to UV light. The areas of the screen blocked by the design remain soft and are washed away, leaving a stencil of your design on the screen.

Setting Up the Screen: After the screen has been prepared and dried, it is placed on a screen printing press. The t-shirt is then laid flat on the printing surface beneath the screen.

Printing: Ink is applied to the screen and spread evenly across the stencil using a squeegee. The ink passes through the open areas of the stencil and onto the t-shirt, creating the design. For multi-coloured designs, this process is repeated with different screens for each colour.

Curing: Once the design is printed, the t-shirt needs to be cured to set the ink. This is usually done using a heat press or a conveyor dryer. Proper curing ensures that the design is durable and can withstand washing and wearing.

Materials Needed

To get started with t-shirt screen printing, you'll need the following materials:

Screens and Frames: These come in various sizes and mesh counts, which affect the level of detail and the thickness of the ink layer.

Emulsion and Sensitiser: Used to coat the screen and create the stencil.

Inks: Specially formulated for screen printing, available in a wide range of colours and finishes.

Squeegees: Used to spread the ink across the screen.

Exposure Unit: To expose the screen to UV light and harden the emulsion.

Heat Press or Conveyor Dryer: For curing the printed designs.

Tips for Successful Screen Printing

Practice Good Screen Care: Properly cleaning and maintaining your screens will extend their lifespan and improve print quality. Make sure to thoroughly wash out all ink and emulsion after each use.

Choose the Right Mesh Count: The mesh count of your screen affects the detail of your print. Higher mesh counts are better for fine details, while lower mesh counts are suitable for bold, heavy ink applications.

Test Prints: Always do test prints on scrap fabric before printing on your final t-shirts. This allows you to check the alignment, ink consistency, and overall design.

Work in a Clean Environment: Dust and debris can ruin your prints. Ensure your workspace is clean and free from contaminants.

Invest in Quality Inks: High-quality inks not only provide better print results but also enhance the durability of your designs.

Conclusion

Mastering the art of T Shirt Screen Printing requires practice, patience, and a keen eye for detail. By understanding the basics and investing in the right materials, you can create stunning, custom t-shirts that stand out. Whether you're printing for fun or setting up a business, the skills you develop in screen printing will be invaluable. Happy printing!

Read Also: Guide to UK T-Shirt Printing Services

0 notes

Text

The Ultimate Guide to Custom Fabric Printing

Are you looking for custom printing on fabric? Your go-to experts in the realm of printing on fabric.

In this comprehensive guide, we'll explore the vibrant and creative world of fabric printing, offering insights, tips, and industry secrets to help you navigate this exciting process.

Whether you're a designer, artist, or fabric enthusiast, this guide is tailored to enlighten and inspire your fabric printing journey.

Here, have a look at the details of the fabric printing and other services. The below information gives you all the details for this.

Understanding Fabric Printing Services

Before diving into the specifics, it's essential to understand what fabric printing entails. Printing on fabric is the process of applying color to fabric in specific patterns or designs. In an industry where creativity knows no bounds, this technique is crucial for fashion designers, interior decorators, and textile artists.

Types of Fabric Printing

Forest Digital specializes in various fabric printing techniques, each with its unique characteristics:

Digital Printing

A modern technique where designs are processed by a computer and then printed directly onto the fabric.

Screen Printing:

An age-old technique involving transferring ink through a mesh screen onto the fabric.

Block Printing:

A traditional method of printing designs by hand using carved wooden blocks.

Choosing the Right Fabric

The choice of fabric is as important as the design. Different fabrics react differently to printing techniques. Cotton, silk, and polyester are some of the popular choices at Forest Digital. We'll help you choose the best fabric for your project, considering factors like texture, drape, and print quality.

Designing for Fabric Printing

Designing for fabric printing is an art. It requires an understanding of color theory, pattern repeat, and fabric characteristics. At Forest Digital, we offer guidance on creating designs that are not only beautiful but also print-friendly.

The Printing Process

At Forest Digital, we follow a meticulous printing process to ensure the highest quality:

Pre-Treatment: Fabric is treated to ensure it holds the dye properly.

Printing: The chosen design is printed using state-of-the-art technology.

Post-Treatment: The fabric undergoes processes like steaming and washing to set the print.

Sustainability in Fabric Printing

Sustainability is at the heart of what we do at Forest Digital. We're committed to eco-friendly practices, using water-based inks, and ensuring waste reduction in our printing processes.

Applications of Custom Fabric Printing

Custom fabric printing has a vast array of applications:

Fashion: Creating unique garments and accessories.

Home Decor: Designing custom upholstery, curtains, and linens.

Art: Producing bespoke art pieces and installations.

Tips and Tricks

Always consider the end use of the printed fabric.

Experiment with colors and patterns.

Consult with experts at Forest Digital for best results.

Wrapping Up

We believe in turning your visions into reality through the magic of fabric printing. With this guide, we hope to have provided you with valuable insights into the world of custom fabric printing. Whether you're a seasoned designer or a newcomer, we invite you to explore the endless possibilities of printing on fabric with us. Contact us now for more information.

0 notes

Text

Common Mistakes to Avoid in DIY T-shirt Printing

DIY T-shirt printing is a popular and creative hobby that allows you to express your personality and style through custom designs. While it's an enjoyable endeavor, there are common mistakes that newcomers often make. In this article, we'll highlight these pitfalls and offer tips on how to avoid them, ensuring your DIY T-shirt printing projects turn out just as you envisioned.

Skipping the Test Print:

One of the most common mistakes in DIY T-shirt printing is failing to do a test print. Before committing your design to the final T-shirt, always print it on a scrap piece of fabric or an old T-shirt. This helps you identify any design flaws or printing issues early on.

Inadequate Preparation:

Preparation is key to successful T-shirt printing. Failing to properly clean and prepare the fabric can lead to ink not adhering correctly. Make sure to wash and dry the T-shirt without using fabric softener to ensure a clean surface for printing.

Neglecting Heat Settings:

Different types of inks and printing methods require specific heat settings for curing. Neglecting to set the correct temperature and time for heat transfer can result in faded or cracked prints. Always follow the manufacturer's recommendations for heat settings.

Rushing the Drying Process:

After printing, allow the ink to dry thoroughly before handling or wearing the T-shirt. Rushing the drying process can cause smudging and distort the design. Follow the recommended drying times to ensure a lasting print.

Poor Color Choices:

Consider the color of the fabric when choosing your design's color palette. Light-colored inks may not show well on dark fabrics, and vice versa. Ensure there is enough contrast for your design to be visible and eye-catching.

Overcomplicating Designs:

While intricate designs can be stunning, overcomplicating your design may lead to difficulties during the printing process. Keep your first projects relatively simple, focusing on building your skills before tackling complex designs.

Not Using Proper Tools:

Investing in the right tools and equipment is crucial for DIY T-shirt printing. Inadequate or low-quality tools can lead to uneven prints, bleeding, and frustration. Make sure you have quality screens, squeegees, and inks suitable for your chosen method.

Improper Screen Exposure:

For screen printing, exposing the screen to light is a critical step. Underexposing or overexposing the screen can result in poor image transfer. Follow the recommended exposure times and techniques for your screen printing setup.

Neglecting Safety Measures:

Some T-shirt printing methods involve the use of chemicals and inks. Neglecting safety measures like wearing gloves, using proper ventilation, and following manufacturer instructions can lead to health risks and poor print outcomes.

Forgetting to Test the Custom Hoodies:

When expanding your DIY printing to custom hoodies, remember that different fabrics can react differently to inks and printing methods. Always test your design on a scrap piece of the hoodie fabric first to ensure it adheres correctly and looks as intended.

In conclusion, DIY T-shirt printing is a fun and rewarding activity, but it's not without its challenges. By avoiding these common mistakes and taking the time to learn and practice, you can elevate your skills and create custom T-shirts (and custom hoodies) that reflect your unique style and vision. Happy printing!

0 notes

Text

Making screens / Testing Screens/Printing on Mylar

I made my first ever screens last semester (fall 22’). The screens were my way of teaching myself how to screen print on garments. I was exploring with halftone with a picture of my face and seeing how small and larger type would translate onto, not only on a paper but on garments. How small can I print a detailed typeface and have it keep its details? This is relevant because my lack of experience with screen printing made me make a few mistakes that will be affected by my previous screen printing experimentation.

Like I said earlier I did all this at home in my studio apartment bathroom so I do not have fancy machines or the space to clean and perfectly make screens. This made an interesting mistake while I was testing the screens because I had not properly removed the previous design on my screen with a higher mesh count and it was the screen I used to make the text “Body vs Mind” appear through negative space. I initially thought that this was just left over oil from previously used ink but it wasn’t.

The next thing that I tested was my lower mesh count screen which read “Body vs Mind” in its positive space. Although the analog way of printing mixed with the bootleg setup that I have to burn my screens give the grimy outcome that I was searching for initially, I was trying to accentuate this feeling through screen manipulation. I wanted the type to be legible but also replicate the effect that the photo was treated with. I tried pulling the mylar before lifting the screen to “ruin” the edges. This worked somewhat but it did not give the effect that I wanted. I then tried to print on top of the previous print but I moved the screen before printing again. I did this a few times to see how it looked. At first, I would use my hairdryer to dry the paper between layers of printing but I stopped and I realized that if I don’t, the ink would stain a negative part of the screen on the second layer and then would retransfer the ink onto the paper on the third layer. This process gave a lot of depth to the layers because it would add somewhat uncontrolled opacity to the words that are printed onto the surface.

This was even more present when I printed on mylar because the material absorbs less ink than the paper and would transfer more ink onto the screen and then more ink back onto the material again. This accentuated the effect while making some lines a bit less ambiguous and aided legibility.

1 note

·

View note

Text

What Is Screen Printing?

Screen printing, also known as silk screening, is a printing technique that uses a mesh screen to transfer ink onto a substrate, such as fabric, paper, or plastic. This printing method is commonly used to produce custom t-shirts, posters, signs, and other promotional materials. In this article, we will provide a complete guide to Screen Printing Services Perth, including the process, equipment, and applications.

The Screen-Printing Process

The screen-printing process involves several steps:

Design: The first step in screen printing is to create a design. This can be done using graphic design software or by hand. The design is then transferred onto a transparent film, which will be used to create the stencil.

Stencil Creation: The stencil is created by coating a mesh screen with a photosensitive emulsion. The transparent film is placed on top of the emulsion-coated screen and exposed to light. The areas of the emulsion that are not exposed to light will dissolve in water, leaving behind the stencil.

Ink Application: Ink is applied to the screen and then spread evenly using a squeegee. The ink passes through the open areas of the stencil and onto the substrate.

Drying and Curing: Once the ink has been applied to the substrate, it must be dried and cured. Drying is done by allowing the substrate to air dry or by using a dryer. Curing involves applying heat to the substrate to ensure that the ink adheres properly.

Equipment Needed for Screen Printing

To perform screen printing, you will need the following equipment:

Screen: The screen is the most crucial piece of equipment in screen printing. It is made of a fine mesh material stretched over a frame.

Emulsion: Photosensitive emulsion is used to create the stencil on the screen.

Ink: Screen printing ink is a special type of ink that is designed to adhere to the substrate and last for a long time.

Squeegee: The squeegee is used to spread the ink evenly over the screen.

Dryer: A dryer is used to dry the ink after it has been applied to the substrate.

Applications of Screen Printing

Screen printing is used in a variety of applications, including:

Apparel: Screen Printers Perth is commonly used to produce custom t-shirts, sweatshirts, and other apparel items.

Promotional Products: Screen printing is also used to create promotional items such as pens, tote bags, and water bottles.

Signs and Banners: Screen printing is an excellent method for producing signs and banners for businesses and events.

Fine Art: Screen printing is used by many artists to produce limited edition prints.

Electronic Devices: Screen printing is also used in the production of electronic devices, such as printed circuit boards.

Conclusion

Screen printing is a versatile printing method that has been used for decades to produce a wide range of products. Whether you are a business owner looking to create custom promotional items or an artist looking to produce limited edition prints, screen printing offers a cost-effective and high-quality solution. With the right equipment and a little practice, anyone can learn to screen print and produce professional-looking prints.

0 notes

Text

T-Shirt Silkscreen Printing: How to Create High-Quality Designs

T-shirt silkscreen printing is a popular technique that has been used for decades to create high-quality designs on apparel. Whether you're a business owner looking to promote your brand or an individual looking to create a unique and personalized t-shirt, silkscreen printing can be a great option. In this blog, we'll explore the process of creating high-quality designs with t-shirt silkscreen printing. What is T-Shirt Silkscreen Printing? Silkscreen printing, also known as screen printing, is a printing technique that uses a mesh screen to transfer ink onto a substrate, such as a t-shirt. The screen is coated with a photosensitive emulsion and the desired design is then exposed onto the screen. The areas of the screen that are not exposed to light are then washed away, leaving a stencil of the design on the screen. Ink is then pressed through the stencil and onto the t-shirt. Creating High-Quality Designs When creating a design for silkscreen printing, it's important to keep in mind that each color in the design will require a separate screen. This means that the more colors in your design, the more screens and setup time will be required. To ensure that your design comes out as expected, it's important to follow a few key steps. Use Vector Graphics When creating your design, it's important to use vector graphics. Vector graphics are made up of points and lines, which can be scaled up or down without losing quality. This is important because the larger the design, the more resolution it will need to be printed at. Vector graphics are also necessary for creating the film positives that are used to burn the image onto the screen. Choose the Right Ink There are many types of ink that can be used in silkscreen printing, but not all of them are created equal. It's important to choose an ink that is appropriate for the type of fabric you will be printing on. For example, if you're printing on a dark-colored t-shirt, you'll need an ink that is opaque enough to cover the color of the fabric. Additionally, some inks are better suited for printing on synthetic fabrics, while others are better suited for natural fabrics. Pay Attention to Detail When creating your design, it's important to pay attention to small details, such as lines and text. These details can be lost in the printing process if they are too small or not bold enough. It's also important to make sure that your design is aligned properly on the screen, as even a slight misalignment can cause the design to look blurry or off-center. T-shirt silkscreen printing is a versatile and cost-effective way to create high-quality designs on apparel. By following these key steps, you can ensure that your design comes out looking great. Remember to use vector graphics, choose the right ink for your fabric, and pay attention to detail. With these tips in mind, you can create a unique and personalized t-shirt that will stand out from the crowd. Read the full article

0 notes

Text

Seminars

As advised during my progress review, I went back to rewatch and catch up on the seminars on moodle.

Today I caught up on rewatching the first half of the seminars.

Exploring ideas- part 1

-dont be afraid of ideas / concepts

-encouraged discuss and share ideas with peers

-on going concept devlopment

-trust the process and critically reflect + evaluate work

-draw

-concepts can be anything; colour, processes, connecting things ect

Exploring ideas- part 2

-"best way to have a good idea is to have lots of ideas"

-small gap between quantity and quality of ideas, more small ideas = more good big ideas

-exposing myself to new experiences such as new music, new movies ect could lead to new ideas

-note those new ideas immediately

Drawing seminar- part 1

-drawing is a way of talking to people through art

-practice drawing as it is a skill, everyone can draw

-people draw from what is around them/what influences them

-choice of style for artwork has an affect on the final outcome of an artwork

Drawing seminar- part 2

-dont be afraid to go back to things youve already drawn

-try to draw in the actual space / setting of your objects instead of taking a photo and drawing from a photo

-drawing in the actual space helps get the essence of your subject

Ideas development seminar

-research book

-bullet points work

-opinions about art

-historical and modern relevance of ideas

-can judge success of ideas

-concept, plan, opinions

-critically reflect

colour seminars

-copyrighted colours: worlds blackest black

-artifical and natural are examples of colour

-test cards to set up tv cameras

-pantone colour matching system

typography seminar

-the way "type" is displayed

-huge history behind it

-printing press made it accessible

-basis for how we communicate

-everywhere: producs, bus stops, signs ect

Creative recording seminar

-time based art: photos or videos

chris burden-747

Composition seminar

-applies to everything and is foundation of image making

-variation has no limits

-the arrangement of visual elements such as shapes, pattern, colour ect

-main elements: colour, form, line, shape, texture, value

-principles: balance, emphasis, depth, movement, contrast, tension ect

-shape of canvas affects image

Relief print seminar

-image manipulation

-everywhere: even armor -> etching

-4 main groups- relief block print, intaglio print, lithography and screen print

-print; mark on surface which is then transferred to other surfaces, allows for copies

-also utilized in other areas such as lino cast in plaster for large scale pieces broken into blocks

-accessible process that can be done everywhere

Form development seminar

-clay has a lot of potential

-soft-> print rolled, pressed, mold, shape, sculpt.

-melts with water

-can cast and recycle it

-ceramic is fired clay

-prototypes can be made from paper

-craft led practice: jack doherty

-design led process: ann mcbride

-surface: paul scott

3d studies seminar

-core element

-engagement with physical and tacticle elements

-artist: ruth asawa- wire that has been hand twisted

Tumblr seminars

-explain how everything is related to "temporary" theme

-research

-edit on pc as it looks different on a phone

-edit photos properly

3 notes

·

View notes

Text

♡ꜜ lipstick stain﹫jaemin na

she looks so perfect - 5 seconds of summer

pairing : jaemin x reader (f)

genre : smut with little plot, roommate!jaemin, college!au.

warnings : solo masturbation.

word count : +2,5k

synopsis : you leave lip stick stains on your roommate Jaemin’s skin before leaving for the night and he can’t help himself and his hidden feelings. or : “your lipstick stain is a work of art, i got your name tattooed in an arrow heart.”

“Y/N, what are you doing ?”, Jaemin wonders out loud, a small laugh coming out of his lips after taking your expression in. Resting the controller of his PlayStation 4 on his thigh, covered by his light grey sweatpants, your roommate lets his eyes wonder up to you as his game loads on the screen of your shared television. From his spot on the couch of your apartment, he was watching you carefully tap your index on your lower lip, before examining your fingertip with a bit too much curiosity.

“I need to see if my lipstick is going to stay through the night, Jaems.”, you explain like it’s obvious, eyes still on your reflection in the entrance’s mirror. Tapping once again your finger on your bottom lip, you slowly check the makeup you flawlessly applied to your features moments prior. You were going out tonight. Any other night, you would probably go out with your beloved roommate but, you were seeing old high school friends. A reunion organized by teachers you barely kept in contact with and, you unfortunately wouldn’t bring the pink haired man with you. You have to say, you wish you could have him with you. The dress you’re wearing hugs your body, your makeup is flawless if it is not for the said lipstick. You know your presence alone will be able to take some people’s breaths away just like it took your roommate’s. But, having Jaemin with you would’ve sealed the deal. Maybe it was a bit childish, wanting to make people jealous. Can you blame yourself ? You were the first to gush over your roommate’s looks and melt at his sweet and gentleman-like personality. Let’s say he isn’t helping you at all at this very moment, legs spread wide, he isn’t wearing a shirt, abdomen on full display.

“Is that the one you got last week ?”, asks the tallest, eyes quickly going back from his game to your figure. The theme song of The Last of Us Part Two plays in the background, the young man’s eyes get stuck on your exposed neck for a bit too long. Brushing your hair with one hand, you use the other to apply some perfume to the base of your neck. Jaemin has to say, you look good every day of the week, every hour of the day. You look ravishing when you two go out every now and then but, it’s clear you decided to make a lot more today. He couldn’t complain, having a roommate like this but God, he wishes he could come with you at this reunion, make sure everyone understands you’re bound to be his. You hum at his question, unaware of his racing thoughts, remembering the day you dragged him to some makeup store, right after getting your paycheck. Fortunately, he didn’t complain, or maybe you just didn’t listen to his desperate sighs. Regardless, he helped you pick a color, he thought would go well with you after some minutes of thinking in front of the large display.

“Why don’t you just do the thing you do with your hand.”, he asks gesturing to the top of his hand. You and Jaemin decided to live together at the beginning of university and, after some years, he caught on to some things. Like how you had the habit of placing your lips on the back of your hand to check if any product would transfer on your skin. He had a good point, you would. But, you were too lazy to wash your hand after, your nails were freshly painted and you were running late.

“Ugh, I’m too lazy to wash my hand after. We’re also out of tissues.”, you sigh, eyebrows raised. Jaemin was the one who finished the roll and didn’t even think about buying a new one. Looking at the watch adoring your wrist, you quietly smack your lips together, hoping the lipstick wouldn’t leave a mark on the cups and straws at the reunion. You had a…weird hatred for lipstick stains. Jaemin laughs a bit at your antics, leaving his controller on the side. Getting up, he doesn’t hesitate to stand right next to you. Extremely underdressed, he pushes your shoulder with his, checking his own appearance in the mirror. The pink haired man loves annoying you a little bit every now and then.

For a split second, you look over at your friend in the mirror. “We’d look good together”, you think to yourself but, you have to brush the thought away in a flash. See, for the past months, you stopped seeing Jaemin as a friend. And you hated it. You hated how whenever the two of you would cuddle in front of a movie, you’d wish he wouldn’t let go of the embrace to walk to his own, separate room. You started hating the way he’d sing while doing the dishes and while taking a shower. You wanted more and yet, couldn’t see yourself bring the subject up.

“Do it here, we’ll see if it leaves a stain.”, your roommate proposes, taking you out of your thoughts. His finger points at his slightly rounded cheek. Worst thing is, it isn’t the first time that the pink haired allowed you to test your lipsticks on him, he probably knew you were dying to test this one on him too. It happened one time where you were on a rush for work, no tissues or anything else to place your lips on and take the excess product out. Jaemin didn’t mind having a stain as he didn’t have class this morning, he could wash off properly right after and, he gained the guinea pig title. You don’t think twice, grabbing your roommate’s chin between your fingers. Under your touch, Jaemin faces you, angelic face too close to your own. He doesn’t seem to mind either, innocently blinking. There’s a small sigh coming from your lips, one Jaemin doesn’t bring up, like you can’t believe you’re doing this to your crush. You’ve faced it, the growing feeling, blooming butterflies whenever the man would look down at you, whenever he’d smile at one of your jokes. Your lips quickly find his cheek in a loud kiss, a dramatic “mwah” to dedramatize. They trail down without you understanding or processing your actions, placing your lips on his jaw and right under the sharp bone as he willingly tilts his head.

“Oh, that’s a lot...!”, you notice out loud, brushing your actions off, eyebrows furrowed. A mark of your lips was clearly visible of his cheek, another one on the sharp jawline, and the last one in the middle of his neck. Faded, sure, but still clearly visible. “I’m taking it with me, will probably have to do some touch ups, y’know.”, you mumble quickly, grabbing the lipstick before throwing it in your purse. Get out, quick. Jaemin’s eyes are glued on the mirror, not daring to look at you. Pupils blowing a little wider, they expend a bit more at each new stain discovered. His lips are dry, he noticed. Poking his pink tongue out to wet his bottom lip, he slowly parts them, a feeling he knows too well growing in his stomach.

Biting softly on his chest, he nods as he hears you saying something about time and some teacher you’re excited to see. The pink haired doesn’t pay attention, a finger coming to touch the stain on his neck, cheek growing the same color as his locks. Why was he so…turned on by such a simple thing ? Was it the stains, or you ? Probably both ? The marks, proofs of your lips on his skin, he wonders what they’d look like lower, lower. His pants grow tighter, the poor thing has to move to the side and hopefully hide the print on the grey fabric. The heat travels down to his chest, coloring the smooth skin there. His breath gets caught in his throat for a second and he has to clear it to hide the fact, wrapping his wondering hand around his upper arm. It’s aching to wrap around his growing length, release the tension growing, but his line of thoughts gets cut by the loud sound of the front door closing behind him. He didn’t even hear you saying good bye, he doesn’t even know when you’re coming back but all of this, are second thoughts.

His breath grows uneven as he looks around the now empty apartment. When the thought finally registers in this foggy brain, he quickly walks towards his room, the theme song of his game still playing. He doesn’t care to close his door, leaving it slightly open. He can not believe he’s already semi-hard, the young man will never understand the affect you have on him. His mind, his body, it all reacts too quickly to anything you do. From the way you make playlists for his showers and manage to always bend down for the washing machine just at the right moment for him to see by the opened door of the kitchen. Sitting on the edge of his bed, the mattress sinks down under his weight, Jaemin faces the mirror installed right in front of him. Giving him a full view of his body, Jaemin leans back on his hand, his free one wondering on the smooth skin of his chest. With the huge mirror, it was even better. He could clearly see the three marks along his cheek and neck, the last one almost looking like a fading hickey. Oh, how his imagination could wonder so far, so quickly. The young man’s mouth falls slightly agape at how good the color looks on his skin, contrasting with his epiderma. Veiny hand goes down to his bulge, feeling his semi length through the fabric of his pants. His digits wrap around the base, sighing as he teased himself like he knows you’d do too. Lips reddened by his relentless biting, glittering with a coat of saliva, Jaemin’s hand grabs his sheet as the other sneaked beneath the fabric of his sweatpants. Finally giving himself some skin to skin contact he was craving for, though he wishes it was someone else’s. A sigh of relief leaves the pink haired’s lips when he feel his rough hand wrapping around his base, tinted lock falling in front of his dark eyes. His dick feels heavy in his hand, a vein pumping at the side. Ever so slowly, his hand moves up, and down. Drawing the pleasure out, his thumb wipes the small pearl of precum threatening to fall. He uses it for smoother movements, lewd sounds echoing in his room. Mind blurred, focused on the ounce of pleasure he was giving himself, he tilts his head to the side. Jaemin was trying his hardest not to close his eyes, he wanted to see the marks and his skin. He was feeding off of them, letting the most perverted side of his brain make whatever he could up in his daze. A pleased sigh leaves his lips the moment he fully pumps his shaft up and down. They grow faster, pleasure taking over his body, sweat gathering at his hairline and soon enough, he was pushing the hem of his pants down. Entirely exposing himself, his imagination was out of control. He wasn’t picturing his hand, rather yours. Petite compared to his, wrapping around his thick shaft, Jaemin wondered what you’d look like, on your knees in front of him. He knows you’d let your tongue drag up his length just like when you catch a drop of melted ice cream. A grown leaves his lips when he vividly pictures your mouth around him and deep down he knows, he knows you’d beg him to fuck you in front of this very mirror. The sound of skin fills the room, rhythmically. Alongside, his sighs grow deeper and deeper, turning into groans and desperate moans. Jaemin doesn’t care to hide them, all alone in his bedroom. He tries his best to remember the feeling of your lips on his skin, picturing them kissing his neck, down his torso, and his hand pumps faster. Maybe your lipstick would leave a few rings around his shaft, a deep moan coming from his chest at the thought, his eyes screwing shut. “God.”, he whines, his hips bucking against his hand. A gasp leaves his lips as his lips his hips fuck his fist. He pictures you again, seeing you in that dress, how the silky fabric hugs deliciously hugs your body. Wishing he could take it off, he’d probably let the fragile fabric rip under his hands, Jaemin couldn’t help himself when it came to you. He wonders, what does you skin would feel like under his fingers, he knows you’d react in the most hypnotizing way to his teases, he knows he can make you cry his name out if you’d let him. His lip gets caught between his pearly teeth again, drawing blood. The iron taste lingers on his tongue, fighting with the newly made fantasy of your arousal coating his tongue. God, he wishes you didn’t leave, his hand moving faster and faster, chasing his high desperately. “Y/N, fuck.”, it leaves his lips without thinking, he doesn’t care to understand the meaning behind the desperate moan. The blurry image of your body underneath his clouds his mind, made up moans of his name, picturing just how you’d babble because of his cock. God, he wants to hear you moaning, whining, begging. Even better, not being able to form coherent sentence just because of him, coming around his cock because of his, for him. The pink haired loses track as he wonders, getting closer and closer to your climax. His Adam’s apple bobs against the skin of his throat, regular gasp leaving his lips as he mumbles incoherent phrases himself, because of you and, you aren’t even there. He knows he’s about to come, bucking his hips. Letting out a loud moan, his voice cracks towards the end in what sounds like your name, yet again. Jaemin comes in a few short moments, hand never stopping as he milks, giving himself too much pleasure. Zoned out, he pants, a familiar ringing blocking his hearing, some cum on the smooth, slightly red skin of his torso. Jaemin slowly opens his eyes, slightly regaining more coherent thoughts. Chest falling up and down at an irregular pace, he tries to catch his breath as best as he can, a small curse falling from his lip as his strong orgasm fades away. Damp colored hair in front of his eyes, Jaemin tries to comprehend everything, letting his body fall down on his bed. Closing his eyes, his veiny hands half of his face and he doesn’t even bother covering himself. Poor thing only now starts to calm down, hear clearly again. It’s weird, did he turn his game o-.

“Jaemin…? I forgot my wallet.”

His eyes shot open.

© NEOVISIONED l NO REPOSTING OR TRANSLATIONS ALLOWED.

864 notes

·

View notes