#intermediate manufacturer india

Explore tagged Tumblr posts

Text

Our synthesis solutions for Pharma, Agro, CRO, CDMO, and Specialty Chemicals reflect our commitment to quality, research, and innovation. Leveraging global alliances and CRAMS expertise, we deliver streamlined production and outstanding results.

#bioscience#OctaneX Labs#API clinical trial management system#intermediates manufacturers#chemicals API#fine chemical#synthesis#CDMO Companies#CDMO India#life science chemicals#pharmaceutical fine chemicals#capsules#chemicals#cro#cdmo#cdmo companies in india#cdmo services#science#chemical synthesis#chemistry#healthcare#cro services#cdmo lab#cdmo telangana company

0 notes

Text

4-Butylaniline (CAS 104-13-2) – Key Uses and Applications by Vinati Organics

4-Butylaniline (CAS 104-13-2) is an important aromatic amine used in the production of dyes, agrochemicals, and polymers. Vinati Organics manufactures high-quality 4-Butylaniline that meets rigorous industry standards, making it ideal for various industrial applications. This compound is crucial in the synthesis of specialty chemicals and intermediates used in diverse sectors, including textile and agriculture. Explore more about 4-Butylaniline and its uses on our product page. Visit Vinati Organics

#“4-Butylaniline”#“CAS 104-13-2”#“Aromatic Amines”#“Vinati Organics”#“Dye Intermediates”#“Agrochemicals”#“Polymer Production”#“Industrial Chemicals”#“Specialty Chemicals”#“Chemical Manufacturers India”#“4-Butylaniline Applications”

0 notes

Text

Discover the significance of reactive intermediates in chemistry. Explore their role and importance in chemical reactions. Dive into the world of chemistry today

0 notes

Text

Leading Pharmaceutical Drugs intermediates manufacturer in India - Dolphinpharma

Leading Pharmaceutical Drugs intermediates manufacturer in India People Find Us by our quality. specialty chemicals manufacturer someone finding in India than we are performing top at by quality. people also known as a electroplating chemicals manufacturers in India. cleaning chemicals manufacturers in our company serving since last 14 year!! Dolphin serving best cleaning chemicals in India. Providing quality is our only Moto!!!

2 notes

·

View notes

Text

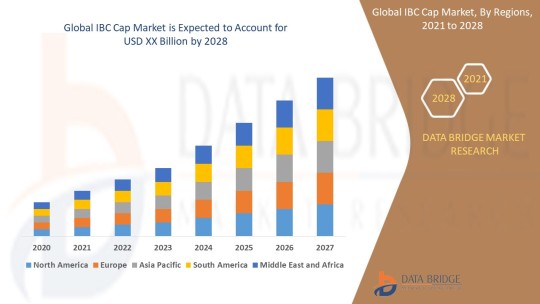

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Varni lifescience is one of the leading pharma intermediate manufacturer in India. Our intermediates are produced using premium quality ingredients. Moreover, they are highly applicable in various industrial and commercial sectors. We offer wide range of best quality intermediates at affordable prices.

#pharmaindustry#pharma intermediate#pharmaceutical#medicine#healthcare#health and wellness#pharma manufacturing#pharma marketing

2 notes

·

View notes

Text

api intermediates manufacturers

Book drug, the capital of India, produces a wide range of intermediate products exporters. We produce high quality intermediate products at affordable prices. A leading international supplier of active pharmaceutical ingredients with the industry's most extensive portfolio of specialized international manufacturing locations. Synthetic and natural are further categorized into innovative and generic. The services produced and sold there can also be considered intermediate goods if they are used as inputs in the production process of other goods. Salt is an intermediate product, and companies incorporate it into many food and non-food final products. Wheat is an intermediate product because companies process it as part of another product, usually a food or grocery product.

2 notes

·

View notes

Text

India, Brazil, and South Korea are the new opportunity grounds for Home Fitness Equipment market players

According to a recent research, Industry revenue for Home Fitness Equipment is expected to rise to $33.6 billion by 2035 from $12.9 billion of 2023. U.S., Germany and China are the top 5 markets and combinely holds substantial demand share. The revenue growth of market players in these countries is expected to range between 6.1% and 8.7% annually for period 2024 to 2035.

Industry transition including shift to connected equipment and advancements in compact designs, are transforming the supply chain of Home Fitness Equipment market. Smart workout gear that offers coaching is increasingly common, in modern home fitness setups.

Check detailed report here - https://datastringconsulting.com/industry-analysis/home-fitness-equipment-market-research-report

Research Study addresses the market dynamics including opportunities, competition analysis, industry insights for Type (Cardio Equipment, Strength Training Equipment, Fitness Monitoring Devices, Accessories), Target User (Beginner, Intermediate, Advanced) and Distribution Channel (Online, Offline).

Industry Leadership and Strategies

Companies such as Peloton, Bowflex, NordicTrack, Rogue Fitness, Fitbit, Garmin, Lululemon, Decathlon, ProForm, Echelon, Technogym and Schwinn are well placed in the market. Below table summarize the strategies employed by these players within the eco-system.

Evolving & Shifting Regional Markets

North America and Europe are the two most active and leading regions in the market. With different regional dynamics and industry challenges like high initial costs, space limitations and inconsistent usage rates; market supply chain from manufacturers to end users is expected to evolve & expand further, especially within emerging markets

The market in emerging countries is expected to expand substantially between 2024 and 2030, supported by market drivers such as health and wellness trends, remote working norms, and technological advancements.

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

0 notes

Text

Importance of Lactic Acid Manufacturers in Delhi

Lactic acid is an essential organic compound that serves as a cornerstone for various industries, including food, pharmaceuticals, cosmetics, and chemicals. Its diverse applications make it a highly sought-after ingredient in both industrial and commercial domains. In Delhi, a city known for its industrial prowess and dynamic economy, lactic acid manufacturers play a pivotal role in meeting the growing demand across sectors. Let’s delve deeper into why lactic acid manufacturers in Delhi are indispensable to businesses and industries.

1. Applications of Lactic Acid in Key Industries

Food and Beverage Industry Lactic acid is widely used as a preservative, flavor enhancer, and pH regulator in the food and beverage industry. It extends the shelf life of processed foods and is a critical ingredient in fermented products such as yogurt, pickles, and sauerkraut. Additionally, it is used to regulate acidity in beverages, ensuring the desired taste and stability. For Delhi’s thriving food processing sector, a reliable supply of lactic acid is crucial.

Pharmaceutical Industry In the pharmaceutical industry, lactic acid has numerous applications. It is used in drug formulation, wound care products, and biodegradable polymers. Its role in medical-grade products, including dissolvable sutures and drug delivery systems, highlights its importance in healthcare. Delhi, being a hub for pharmaceutical manufacturing, relies heavily on lactic acid manufacturers to maintain production levels and meet market demand.

Cosmetic Industry Lactic acid is a key ingredient in skincare and cosmetic products due to its exfoliating, moisturizing, and pH-regulating properties. It is commonly found in anti-aging creams, chemical peels, and moisturizers, helping to improve skin texture and hydration. For Delhi’s growing beauty and personal care market, the local availability of lactic acid supports the rapid production of high-quality cosmetic products.

Industrial Applications Beyond food and pharmaceuticals, lactic acid is essential in producing biodegradable plastics, cleaning agents, and chemical intermediates. Its eco-friendly properties make it a preferred choice for sustainable industrial processes, aligning with the global push for greener technologies.

2. Role of Lactic Acid Manufacturers in Delhi

Reliable Supply Chain Local lactic acid manufacturers ensure a consistent and timely supply of this crucial compound to industries in and around Delhi. Their proximity reduces transportation time and costs, allowing businesses to operate efficiently without interruptions.

Customization and Quality Assurance Manufacturers in Delhi often cater to specific industrial needs by providing customized solutions. Whether it’s food-grade, pharmaceutical-grade, or industrial-grade lactic acid, these manufacturers prioritize quality to meet regulatory standards and customer expectations.

Cost-Effectiveness By sourcing lactic acid locally, businesses save on import costs and enjoy competitive pricing. This affordability is particularly important for small and medium enterprises in Delhi that need cost-effective raw materials to remain competitive.

Contribution to Sustainability Many lactic acid manufacturers in Delhi adopt sustainable production methods, using renewable resources like sugarcane or corn for fermentation processes. This aligns with the global trend of reducing carbon footprints and promoting green manufacturing practices.

3. Economic and Industrial Impact

Lactic acid manufacturers contribute significantly to Delhi’s economy by generating employment and supporting allied industries. Their operations not only provide raw materials but also drive innovation in various applications, fostering a culture of research and development. Additionally, they support export opportunities, strengthening India’s position in the global chemical market.

Conclusion

The importance of lactic acid manufacturer in Delhi cannot be overstated. From ensuring a steady supply for critical industries to driving economic growth, their role is vital in sustaining Delhi’s industrial landscape. Businesses across sectors, from food to pharmaceuticals, depend on these manufacturers to provide high-quality, cost-effective solutions. As demand for lactic acid continues to grow, local manufacturers must prioritize innovation, sustainability, and quality to remain competitive and contribute to the region’s economic progress. For industries looking to thrive in Delhi, partnering with reliable lactic acid manufacturers is an essential step toward success.

0 notes

Text

Lactic Acid Manufacturer and Supplier in Delhi

In the bustling industrial landscape of Delhi, one company stands out as a leading lactic acid manufacturer and supplier in Delhi of high-quality lactic acid, playing a crucial role in multiple industries and sustainable chemical solutions. This Delhi-based manufacturer has established itself as a key player in the production of this versatile organic compound, serving diverse sectors with cutting-edge technology and commitment to quality.

Company Overview

Located in the industrial corridors of Delhi, the company has built a state-of-the-art manufacturing facility dedicated to producing pharmaceutical and food-grade lactic acid. With over two decades of experience in chemical manufacturing, the company has developed a reputation for excellence, innovation, and reliability in the production of this essential organic acid.

Manufacturing Capabilities

The manufacturer employs advanced fermentation techniques to produce lactic acid, utilizing carefully selected bacterial strains that ensure high purity and consistent quality. Their production process encompasses:

Precise fermentation of carbohydrate substrates

Advanced purification technologies

Stringent quality control measures

Sustainable manufacturing practices

Their facility can produce multiple grades of lactic acid, including:

Pharmaceutical grade

Food industry grade

Industrial grade

Cosmetic grade

Key Applications

Lactic acid produced by this Delhi-based manufacturer finds applications across various critical industries:

Food and Beverage Industry

Natural preservative

pH regulator

Flavor enhancer

Ingredient in dairy products

Pharmaceutical Sector

Active ingredient in medications

pH adjustment in drug formulations

Excipient in various pharmaceutical preparations

Cosmetic and Personal Care

Skin conditioning agent

pH balancer in skincare products

Chemical exfoliant

Natural preservative

Industrial Applications

Biodegradable polymer production

Cleaning and descaling agents

Chemical intermediate

Textile and leather processing

Commitment to Sustainability

The manufacturer has positioned itself as an environmentally conscious company, focusing on:

Reducing carbon footprint

Implementing green manufacturing processes

Using renewable raw materials

Minimizing waste generation

Developing bio-based chemical solutions

Quality Assurance

Maintaining exceptional quality is paramount for this lactic acid manufacturer. Their quality assurance process includes:

Regular laboratory testing

Compliance with international standards

ISO certifications

Advanced quality control equipment

Skilled technical team

Market Reach and Distribution

With a robust distribution network, the company supplies lactic acid across:

Delhi-NCR region

Other major Indian metropolitan areas

International markets

Various industrial clusters

Technological Innovation

Continuous investment in research and development allows the manufacturer to:

Improve production efficiency

Develop new product applications

Enhance existing manufacturing techniques

Explore sustainable production methods

Conclusion

This Delhi-based lactic acid manufacturer represents the intersection of industrial expertise, technological innovation, and sustainable chemical production. By providing high-quality lactic acid to multiple sectors, the company continues to play a pivotal role in supporting various industries and contributing to India's chemical manufacturing landscape.

With its commitment to quality, innovation, and sustainability, the manufacturer is not just a supplier but a strategic partner for businesses seeking reliable and advanced chemical solutions.

0 notes

Text

As a trusted partner, we bring advanced synthesis solutions to Pharma, Agro, Fine & Specialty Chemicals, CRO, and CDMO industries. Our commitment to quality, innovation, streamlined operations, and strong global alliances sets us apart.

#bioscience#OctaneX Labs#API clinical trial management system#intermediates manufacturers#chemicals API#fine chemical#synthesis#CDMO Companies#CDMO India#life science chemicals#pharmaceutical fine chemicals#capsules#chemicals#cro#cdmo#cdmo companies in india#cdmo services#science#chemical synthesis#chemistry#healthcare#cro services#cdmo lab#cdmo telangana company#custom synthesis#pharma company#pharma#pharmaceutical#big pharma#pharmacy

0 notes

Text

A Leading Manufacturer of Ritonavir Intermediates & API in India

Vineet Labs is a prominent player in the pharmaceutical industry, renowned for its expertise in manufacturing high-quality Active Pharmaceutical Ingredients (APIs) and intermediates. With a strong focus on innovation and quality, Vineet Labs has established itself as a leading supplier of Ritonavir intermediates and API in India.

Ritonavir: A Critical Antiretroviral Drug

Ritonavir is a crucial antiretroviral medication used in the treatment of HIV/AIDS. It belongs to a class of drugs known as protease inhibitors, which work by blocking the enzyme protease, essential for the replication of the HIV virus.

Vineet Labs' Role in Ritonavir Production

Vineet Labs plays a vital role in the production of Ritonavir by manufacturing key intermediates required for the synthesis of the final API. These intermediates are crucial building blocks in the complex chemical synthesis process of Ritonavir.

Key Strengths of Vineet Labs:

State-of-the-art Manufacturing Facilities: Vineet Labs boasts modern and well-equipped manufacturing facilities adhering to stringent quality standards like GMP (Good Manufacturing Practices). Focus on Quality and Compliance: The company prioritizes quality and compliance in all its operations, ensuring that all products meet the highest regulatory standards. Experienced Team: Vineet Labs has a team of highly skilled and experienced professionals with expertise in pharmaceutical chemistry and manufacturing. Strong R&D Capabilities: Continuous research and development efforts enable Vineet Labs to optimize manufacturing processes, improve product quality, and develop innovative solutions. Customer Focus: The company maintains strong customer relationships, providing excellent service and support to its clients globally. Contribution to Global Healthcare

By efficiently manufacturing Ritonavir intermediates and API, Vineet Labs contributes significantly to the global fight against HIV/AIDS. Access to affordable and high-quality antiretroviral medications is crucial for effective treatment and improved patient outcomes.

Conclusion

Vineet Labs is a key player in the Indian pharmaceutical industry, making significant contributions to the production of essential medicines like Ritonavir. With its commitment to quality, innovation, and customer satisfaction, Vineet Labs continues to play a vital role in improving global healthcare access.

0 notes

Text

https://www.meghmaniglobal.com/what-are-reactive-intermediates-and-why-do-they-matter/?utm_source=Google&utm_medium=Organic&utm_campaign=SocialBook

Discover the significance of reactive intermediates in chemistry. Explore their role and importance in chemical reactions. Dive into the world of chemistry today

0 notes

Text

Top API Pharma Database Company in India

India’s pharmaceutical industry is a global leader, recognized for its cost-effective manufacturing and innovation in Active Pharmaceutical Ingredients (APIs). To navigate this dynamic landscape, companies rely on comprehensive databases that provide detailed insights into APIs, intermediates, and chemical formulations. This blog explores the top API pharma database companies in India, highlighting their roles and capabilities, while incorporating key industry-related keywords.

#Cosmetics Database#Biotech Database#Polymer Database#Veterinary Database#CDMO Database#Dyes Database

1 note

·

View note

Text

Mixed Xylene Prices, News, Trend, Graph, Chart, Forecast and Historical

Mixed xylene is an important industrial solvent that plays a significant role in various industries, including chemical manufacturing, pharmaceuticals, paints, and coatings. As a crucial intermediate in the production of chemicals such as terephthalic acid (used in polyester production) and other petrochemicals, the price of mixed xylene is influenced by a variety of factors including supply and demand, production costs, raw material prices, and geopolitical events. Over the years, mixed xylene prices have experienced fluctuations due to the volatility in crude oil prices, as well as shifts in global production and consumption trends. This article delves into the factors impacting the mixed xylene market and provides an overview of its price trends.

The mixed xylene market is closely linked to the global oil industry since the primary feedstock for producing mixed xylene is derived from crude oil. The price of crude oil directly influences the cost of mixed xylene production. When crude oil prices rise, production costs for mixed xylene also tend to increase, which, in turn, raises the price of mixed xylene. On the other hand, when oil prices decline, the cost of production tends to decrease, often leading to a reduction in mixed xylene prices. Therefore, fluctuations in crude oil prices are one of the primary drivers of mixed xylene price trends. Moreover, economic cycles play a role in the demand for mixed xylene. During periods of economic expansion, demand for mixed xylene increases due to higher manufacturing activities in sectors such as automotive, construction, and textiles. Conversely, during economic slowdowns or recessions, demand decreases, resulting in lower prices.

Get Real time Prices for Mixed xylene: https://www.chemanalyst.com/Pricing-data/mixed-xylene-80

The mixed xylene market is also shaped by regional factors. In regions like North America, Europe, and Asia, industrial growth, as well as demand for solvents and petrochemicals, can significantly affect mixed xylene prices. For example, the Asia-Pacific region, particularly China and India, has seen substantial growth in industries such as textiles, automotive, and consumer goods, which in turn drives demand for mixed xylene. China, as one of the largest consumers of mixed xylene, influences global price trends. Any shifts in its domestic production or import policies can have a ripple effect on global pricing.

Additionally, production capacity and technological advancements in the manufacturing processes for mixed xylene contribute to the pricing dynamics. The introduction of more efficient and cost-effective production methods can lower manufacturing costs, potentially reducing the price of mixed xylene. Conversely, a lack of investment in technology or limited production capacity in key regions can lead to price hikes. For instance, disruptions in supply chains, plant shutdowns, or limitations in the refining capacity of mixed xylene can cause price spikes due to limited availability.

Another important aspect influencing mixed xylene prices is the shift towards more sustainable and eco-friendly alternatives in the market. As global awareness of environmental issues grows, industries are increasingly seeking solutions to reduce their carbon footprint and dependency on fossil fuels. This has led to a growing interest in bio-based solvents and alternative chemicals that can replace petroleum-derived solvents like mixed xylene. The development of such alternatives could dampen the demand for traditional mixed xylene, potentially exerting downward pressure on its prices in the long run.

The global regulatory environment also plays a role in shaping the mixed xylene market. Stricter regulations around the use of hazardous chemicals, including mixed xylene, can impact pricing dynamics. Governments worldwide are imposing regulations to reduce the environmental and health risks associated with the use of solvents. These regulations may necessitate investments in safer manufacturing processes, which could increase production costs. Additionally, restrictions on emissions and volatile organic compounds (VOCs) could influence the demand for mixed xylene, particularly in markets that prioritize environmental sustainability.

Furthermore, trade policies and international relations can have a significant effect on the pricing of mixed xylene. Tariffs, import/export restrictions, and trade agreements between countries affect the flow of mixed xylene across borders. Any changes in trade policies, such as the imposition of tariffs on key raw materials or products, can lead to price fluctuations. Geopolitical tensions or trade wars between major players in the mixed xylene market, such as the United States, China, and countries in the Middle East, can create uncertainty and influence market prices.

The mixed xylene market has also been impacted by shifts in consumer preferences. As demand for cleaner and more sustainable products grows, companies in industries like automotive and consumer goods are adopting greener alternatives to reduce their environmental impact. This has led to a shift in the types of solvents and chemicals used in manufacturing processes. Mixed xylene, being a petroleum-derived product, faces increasing competition from bio-based solvents, which are considered more environmentally friendly and sustainable. The growing trend towards sustainable solutions is likely to impact the demand for mixed xylene and may influence its pricing in the future.

In conclusion, the price of mixed xylene is driven by a complex interplay of factors including crude oil prices, global economic trends, production capacities, technological advancements, environmental regulations, and trade policies. As the world moves towards more sustainable practices, the market dynamics for mixed xylene may shift, potentially leading to changes in pricing structures. For businesses and industries reliant on mixed xylene, staying informed about these factors and anticipating changes in the market can help mitigate risks and take advantage of opportunities. Understanding the factors that influence mixed xylene prices is essential for stakeholders in the chemical, automotive, pharmaceutical, and other industries that rely on this important chemical solvent.

Get Real time Prices for Mixed xylene: https://www.chemanalyst.com/Pricing-data/mixed-xylene-80

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Mixed Xylene#Mixed Xylene Price#Mixed Xylene Prices#Mixed Xylene Pricing#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Extended Depth of Focus IOL

One of the most successful and popular surgeries in the world, cataract surgery restores vision to millions of people each year. However, achieving functional and clear vision at multiple distances remains one of the greatest challenges after the surgery. Traditional intraocular lenses (IOLs) used in cataract surgery only provided clarity at one focal length and often left patients with a need for reading glasses. This has brought with it the new age of cataract surgery as Extended Vision (EDOF) Hydrophobic Acrylic Foldable Intraocular Lenses now introduce enhanced patients' vision at greater distances and improved quality of life without requiring corrective eyeglasses all the time. The Monofocal Hydrophobic Acrylic Foldable IOL will give the patient a wider range and clearer vision compared to before. Since hydrophobic acrylic lenses are very biocompatible, the EDOF IOLs made using Hydrophobic material would cause minimal complications or inflammation post a cataract surgery. Devine Meditech is regarded as the most innovative Extended Vision (EDOF) Hydrophobic Acrylic Foldable Intraocular Lenses manufacturer in India. Let us now walk you through some of the advantages associated with an Extended Vision Hydrophobic Acrylic Foldable Intraocular Lens.

Why Choose Extended Vision (EDOF) Hydrophobic Acrylic Foldable Intraocular Lens?

1. Improved Life Quality: The quality of life for patients is improved with the use of these lenses. They can now see their near, intermediate, and distant surroundings with much ease, and they can continue performing daily activities that otherwise would have required alternation between distance and reading glasses.

2. Durable for Longer Times: Extended Vision IOLs are hydrophobic acrylic. These materials are well known for their biocompatibility and durability. This ensures that the lens will have long-term optical stability with minimal possibility of problems such as opacification of the lens (PCO) or unwanted deposits. The resistance to gleaming also ensures that there will be no visual disturbances as with other types of IOLs.

To read more then Click Here.

0 notes