#industrialwastewater

Explore tagged Tumblr posts

Text

Why are MBRs Effective in Industrial Wastewater Treatment

Membrane Bioreactors (MBRs) efficiently treat industrial wastewater by combining biological degradation with membrane filtration, ensuring high contaminant removal. Their compact design saves space, while automation reduces chemical use and operational costs. MBRs generate less sludge, adapt to variable flows, and produce high-quality effluent for reuse, making them a sustainable and cost-effective choice.

0 notes

Text

Zero Liquid Discharge (ZLD) System – Complete Wastewater Recycling

Find out how Zero Liquid Discharge (ZLD) systems in India enable industries to recycle and reuse wastewater efficiently, eliminating liquid waste discharge and conserving water.

For more information, kindly visit: https://enbiogreen.com/waste-water-treatment-plant-in-india-stp-etp-wtp-zld/

1 note

·

View note

Text

Taknik Inc publishes a new blog providing a step-by-step overview of the industrial wastewater treatment process, ensuring regulatory compliance and clean water discharge. Read now!

For more information Contact us :

email Id - [email protected]

Contact No.: 9510430147

#industrialwastewater#watertreatment#pollutantremoval#RegulatoryCompliance#effluenttreatment#CleanWater#sustainability#wastewatermanagement#waterreuse#taknikinc

0 notes

Text

Sustainable Solutions for Pharmaceutical Industry Wastewater Treatment

The pharmaceutical industry is a cornerstone of healthcare, but its operations produce significant volumes of wastewater that can be challenging to manage. Addressing these concerns with sustainable solutions is crucial to minimize environmental impact and ensure compliance with stringent regulations.

One of the primary concerns in pharmaceutical industry wastewater treatment is the presence of complex organic compounds and pharmaceuticals that are difficult to break down. To tackle this, integrating microbiology in the pharmaceutical industry has proven effective. Microbiological methods, such as utilizing specialized bacteria, can efficiently degrade harmful substances in wastewater. These microorganisms play a vital role in biological wastewater treatment solutions, ensuring the effective breakdown of pollutants.

Aerobic wastewater treatment is another key method used in this sector. This process involves the use of oxygen to support the growth of aerobic bacteria that consume organic pollutants. It is highly effective in treating pharmaceutical wastewater, as it helps reduce the biochemical oxygen demand (BOD) and total suspended solids (TSS), leading to cleaner effluent.

Additionally, advanced industrial wastewater treatment technologies focus on optimizing the use of biological processes. By incorporating aerobic and anaerobic treatment stages, these solutions can achieve a high level of purification. Aerobic processes are particularly beneficial for breaking down organic matter, while anaerobic stages help in reducing sludge production and recovering energy.

Implementing these sustainable approaches not only enhances the efficiency of wastewater treatment in the pharmaceutical industry but also contributes to environmental protection. By investing in advanced biological and aerobic treatment solutions, pharmaceutical companies can significantly mitigate their environmental footprint and promote sustainability in their operations.

For more information on effective wastewater treatment solutions tailored to the pharmaceutical industry, visit PureBact.

#PharmaceuticalIndustry#WastewaterTreatment#IndustrialWastewater#BiologicalWastewaterTreatment#AerobicWastewaterTreatment#Microbiology#PharmaceuticalWastewater#SustainableSolutions#WastewaterManagement#EnvironmentalProtection#AdvancedTreatmentTechnologies#WaterRecycling#PollutionControl#CleanWaterInitiatives#PharmaWastewaterManagement

1 note

·

View note

Text

Maintaining Modular Package Sewage Treatment Plants: Top Tips

Keep your sewage treatment system running smoothly with these essential maintenance tips. Learn how to troubleshoot common issues and ensure optimal operation.

#WastewaterTreatment#IndustrialWastewater#ContainerizedSystems#SustainableOperations#WaterTreatment#EnvironmentalSolutions#WastewaterManagement#CleanerOperations#EcoFriendly#Efficiency#WaterSustainability#InnovativeTechnology#IndustrialProcesses#SustainablePractices#EnvironmentalImpact

0 notes

Text

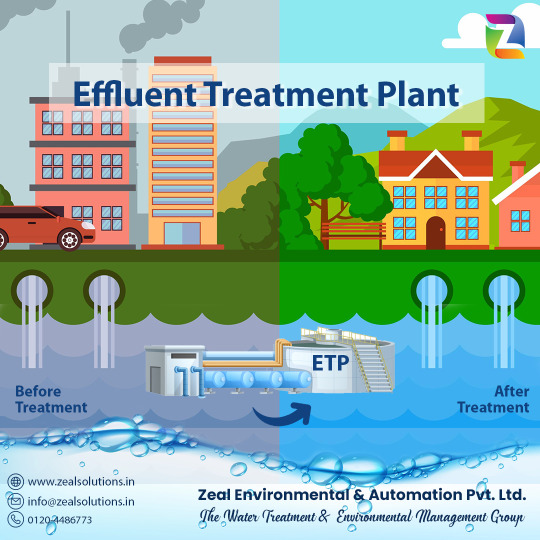

Zeal Solutions provides many types of water treatment services in India. The occurrence of trace organic contaminants in wastewater, their behavior during wastewater treatment, and the production of drinking water are key issues in the reuse of water resources.

For More Information Visit : http://zealsolutions.in

#zeal#zealsolutions#EffluentWaterTreatment#IndustrialWastewater#RemoteMoniteringControlSystem#wastewatertreatmentcompanyinindia#sewagetreatmentplant#effluentwatertreatmentplant#watertreatmentcompanyinnoida#waterfilteration#noida#delhi#pune#delhincr

0 notes

Text

A zero Liquid Discharge System is a technology that allows for complete wastewater treatment and recovery, achieving zero liquid discharge while minimizing costs and environmental impact. With the ZLD system, you can save on resources and energy costs, while ensuring regulatory compliance.

For more details, visit - https://watermanaustralia.com/product/zero-liquid-discharge-system-zld-system/

#watermanengineersaustralia#effluenttreatment#watertreatmentplant#wastemanagement#wastewatertreatment#industrialwastewater

0 notes

Text

Smart Wastewater Monitoring Market: Projected Growth from $3.2B to $8.9B by 2034

Smart Wastewater Monitoring Market is set for significant expansion, growing from $3.2 billion in 2024 to $8.9 billion by 2034, at a CAGR of 10.3%. This growth is fueled by increasing demand for efficient water management, regulatory compliance, and sustainability initiatives. Advanced solutions such as IoT-enabled sensors, real-time analytics, and cloud-based platforms are revolutionizing wastewater treatment by optimizing efficiency, reducing costs, and ensuring environmental compliance. These innovations empower utilities, municipalities, and industries to proactively monitor wastewater quality, detect leaks, and implement predictive maintenance strategies.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11122 &utm_source=SnehaPatil&utm_medium=Article

The hardware segment dominates the market, accounting for 45% of the share, with sensors, smart meters, and flow meters leading due to their essential role in real-time data collection and analysis. Software solutions hold 30% of the market, driven by AI-powered analytics and machine learning applications that enhance operational efficiency. The services sector comprises the remaining 25%, highlighting the demand for consulting, installation, and maintenance services. North America leads the market, supported by strict environmental regulations and heavy investments in smart water infrastructure. Europe follows closely, with Germany spearheading sustainability-driven wastewater initiatives. Meanwhile, Asia-Pacific presents lucrative growth opportunities, driven by rapid urbanization and increased focus on water conservation in China, India, and Japan.

Key players such as Xylem Inc., Siemens AG, and Schneider Electric are driving innovation through strategic partnerships and R&D investments in IoT, AI, and cloud-based solutions. The regulatory landscape, including wastewater discharge norms and sustainability mandates, plays a crucial role in market growth. While challenges such as high initial costs and skilled workforce shortages exist, the integration of AI-driven automation, predictive analytics, and remote monitoring presents enormous potential for market expansion. The future of smart wastewater management lies in scalable, data-driven solutions that enable sustainable and efficient water treatment globally.

#SmartWaterManagement #WastewaterTech #IoTWater #AIinWater #CloudWaterMonitoring #WaterSustainability #PredictiveMaintenance #LeakDetection #BigDataWater #AIAnalytics #EnvironmentalTech #RealTimeMonitoring #GreenInfrastructure #ClimateResilience #UrbanWaterSolutions #SmartCities #WaterUtilities #IndustrialWastewater #CloudBasedSolutions #SmartSensors #DataDrivenDecisions #WaterInnovation #EcoFriendlyTech #SmartInfrastructure #WaterEfficiency #WastewaterRecycling

0 notes

Link

#PumpsEquipment#WaterExtraction#WaterTransport#MunicipalWasteWaterTransport#IndustrialWasteWater#PumpingSolutions#SubmersiblePump#RPH#Hydrobloc#Agricultural#Irrigation#Pumps

1 note

·

View note

Link

#Industrial Wastewater Treatment Plant#sewage treatment services#sewage treatment plant#acedynamics#Laundry wastewater treatment plant#i#indu#industrialwastewater

0 notes

Text

Top 5 Advantages of Recycling Industrial Wastewater

The term ‘recycling’ has been in popular usage for a long time. You have probably heard of recycled materials like aluminium cans, cardboard, paper and glass. When you choose to recycle, you’re choosing sustainability and making an effort to save the environment. Economic benefits are a huge bonus, of course.

0 notes

Text

Taknik Inc Zero Liquid Discharge (ZLD) is an advanced wastewater treatment approach designed to eliminate liquid waste from industrial operations by recycling water and......Read more !!!

Contact us :

Email Id: [email protected]

#taknikinc#ZeroLiquidDischarge#ZLD#zldmanufacturer#effluenttreatmentplant#waterconservation#wastewatertreatment#waterrecycling#SustainableWaterManagement#watermanagement#waterrecovery#circulareconomy#IndustrialWater#environmentalprotection#greentech#WaterEfficiency#WastewaterRecycling#CleanWater#ecofriendly#watersustainability#waterreuse#wastewatersolutions#WaterFootprint#wastereduction#industrialwastewater#waterresources#nowaste#SustainableIndustry#greentechnology#waterpollution

0 notes

Text

How Bacteria Culture Enhances the Efficiency of Effluent Treatment Plants

Effluent treatment plants (ETPs) play a critical role in managing industrial wastewater, ensuring that harmful pollutants do not enter our natural water bodies. Among the various methods used to treat wastewater, biological wastewater treatment stands out due to its efficiency and sustainability. One key component that significantly enhances this process is the use of bacteria culture for ETP.

Bacteria cultures are microorganisms specifically cultivated to break down organic pollutants in wastewater. These beneficial bacteria are integral to aerobic wastewater treatment, a process that requires oxygen to thrive. When these bacteria are introduced into the wastewater, they metabolize organic matter, converting it into carbon dioxide, water, and energy. This natural decomposition process is highly effective in reducing the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewater, making it safer for discharge.

The efficiency of aerobic wastewater treatment is directly related to the health and activity of the bacteria culture. By maintaining optimal conditions for bacterial growth, such as adequate oxygen supply and proper temperature, the treatment process becomes more robust and consistent. This leads to a higher quality of treated water, which can either be safely released into the environment or reused in various industrial processes.

Implementing a well-managed bacteria culture for ETP not only enhances the biological wastewater treatment process but also offers economic benefits. It reduces the need for chemical treatments, lowers operational costs, and minimizes sludge production. Moreover, it aligns with sustainable practices by utilizing natural processes to treat industrial waste.

In conclusion, the integration of bacteria culture for ETP is a cornerstone of effective and efficient biological wastewater treatment. By harnessing the power of these microorganisms, industries can achieve higher treatment efficiency, comply with environmental regulations, and promote sustainability.

For more information about how bacteria culture can enhance your effluent treatment processes, visit PureBact.

#BacteriaCulture#EffluentTreatment#ETP#WastewaterTreatment#BiologicalTreatment#AerobicTreatment#IndustrialWastewater#SustainableTreatment#WaterPurification#EnvironmentalProtection#WastewaterManagement#PureBact#effluent treatment plant

1 note

·

View note

Text

Industrial Wastewater Revolution: Containerized Solutions

Discover how containerized systems are transforming industrial wastewater treatment. Learn about innovative solutions for cleaner and more sustainable operations.

#WastewaterTreatment#IndustrialWastewater#ContainerizedSystems#SustainableOperations#WaterTreatment#EnvironmentalSolutions#WastewaterManagement#CleanerOperations#EcoFriendly#Efficiency#WaterSustainability#InnovativeTechnology#IndustrialProcesses#SustainablePractices#EnvironmentalImpact

0 notes

Text

Effluent Treatment Plant or ETP is one kind of waste water treatment strategy that is specially intended to cleanse mechanical waste water for its reuse and its point is to discharge safe water to condition from the harmful impact brought about by the emanating.

For More Information Visit : http://zealsolutions.in

#zeal#zealsolutions#EffluentWaterTreatment#IndustrialWastewater#RemoteMoniteringControlSystem#wastewatertreatmentcompanyinindia#sewagetreatmentplant#effluentwatertreatmentplant#watertreatmentcompanyinnoida#waterfilteration#noida#delhi#pune#delhincr

0 notes

Text

Physicochemical Characterization and the Effect of Flow-Distance on Correlation between Chemical and Biochemical Oxygen Demands of Industrial Wastewaters | Chapter 05 | Advances in Applied Science and Technology Vol. 3

This work was carried out to establish the effects of the activities of a cluster of industries in Jos-South Local Government Area of Plateau State, Nigeria, on the environmental quality of the industrial area. Some physicochemical parameters –temperature, pH, turbidity, suspended solids (SS), total solids (TS), total hardness, alkalinity, biological oxygen demand (BOD), chemical oxygen demand (COD), heavy metals (Cu²⁺, Co²⁺, Fe²⁺ & Zn²⁺), phosphates, nitrates, sulphates and chlorides –of the wastewaters from the various industries were investigated using standard protocols. Also, the influence of flow-distance on the empirical correlation between biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewaters was investigated. Wastewater samples were collected at point-sources and at 25, 50, 75 and 100m distances from the point-sources. Sampling was done twice a week for a full seasonal cycle at peak production period (morning and evening). The samples’ pH was adjusted to 7 using 0.5M acid for basic samples and 1.0M alkali for acidic samples, de-chlorinated using 0.0125M Na₂S₂O₃ and seeded when necessary and then diluted with de-ionized water. The ranges of the parameters were as follows: temperature: 22 –32°C, pH: 5.5 –10.4, SS: 0 –1,300 mg/L, TS: 200 –1.400 mg/L, sulphate: 0.37 –1.37 mg/L, nitrites: 0.10 –1.09 mg/L and phosphate: 14.80 –21.83 mg/L. The phosphate values, especially, were in excess of the maximum contamination limit specified by Federal Environmental Protection Agency (FEPA) and World Health Organization (WHO); and are capable of triggering eutrophication,which will in turn increase BOD/COD values. Concentrations of heavy metals, determined by Atomic Absorption Spectrophotometry (AAS), ranged as follows: 0.07 –2.01 mg/L for Cu²⁺, 0.58 –3.27 mg/L for Fe²⁺, 0.01 –3.18 mg/L for Zn²⁺ and 0.11 –0.18 mg/L for Co²⁺ whose specified standard is not available. BOD₅ values ranged between 5.34 –25.88 mg/L while COD values ranged from 727.30 –8,308.66 mg/L. Some BOD₅ values were in excess of the allowable limit while all COD values were observed to be very high. This implies an appreciable level of pollution exists here and recipient water bodies of these wastewaters are at risk of being polluted. COD and BOD₅ of the wastewaters from different sources highly correlated with correlation coefficients ranging 0.9396-0.9985. The empirical correlation between COD and BOD₅ was generally maintained despite the distance of flow of the wastewater from point-source and contributions of washings from farmlands and other human activities i.e. the correlation between COD and BOD₅ for wastewaters was not affected by flow distance. The correlation equations for the industries may, therefore, be used to deduce rapid effluent quality from chemical oxygen demand (COD) of sample from any point along the effluent flow path.

Author(s) Details

O. M. Myina

Department of Chemical Sciences, Bingham University, Karu, Nigeria.

A. O. Lawal

Department of Applied Science, Kaduna Polytechnic, Kaduna, Nigeria.

B. M. Ajiga

Jehovah Nissi Boutique and Accessories, Lagos, Nigeria.

A. Edah

Department of Chemistry, University of Jos, Jos, Nigeria.

Read full article: http://bp.bookpi.org/index.php/bpi/catalog/view/39/149/283-1

View Volume: https://doi.org/10.9734/bpi/aast/v3

0 notes