#industrial welding cables

Explore tagged Tumblr posts

Text

The Importance of Quality Welding Cables in Achieving Stronger Welds

Welding is a crucial process in various industries, from construction to automotive manufacturing. The strength and durability of welds are paramount, as they ensure the safety and longevity of the structures and products created. The welding cable is an often overlooked but essential component in achieving high-quality welds. In this blog, we will explore the importance of quality welding cables and how they contribute to stronger welds. We will also highlight the significance of using Weldarc Welding Cables and Industrial Welding Cables, along with the role of Welding Equipment And Suppliers.

0 notes

Text

Fiber optic cable

Kabeltec is a Singapore leading supplier specialising in Flexible cable, Fiber, Crane, Coaxial & Neoprene cable, High-temperature cable, Electrical cable and wire, etc. for use in industrial, LAN, Solar, Welding, Data, Power Cable, Fiber optic cable and Communication cable.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#Power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#LAN cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

1 note

·

View note

Text

The Magic Of Coaxial, LAN, High-Temperature, And Communication Cables Revealed

The complexity of the many cables used in today’s linked world provides the foundation for faultless data transfer and communication.

Grasping the Fundamentals: The Coaxial Cable

A Revolution in Coaxial Technology

Coaxial cable stands out due to its unique structure; it is frequently called the “unsung hero” of communication. This cable has a core conductor, an insulating substance, a metallic shield, and an outside insulating layer for the best signal transmission. Strong and versatile, coaxial cable meets various technical demands, from transferring cable TV signals to high-speed internet traffic.

Putting Coaxial Cable to Work

Whether playing online games or watching your favorite show, the Coaxial cable quietly provides little signal loss and great bandwidth. Its versatility has made it an essential component of contemporary networking, finding use in fields as diverse as telecommunications and computer networks.

Finding Your Way Around the Web: The Importance of LAN Cable for Faultless Networking

Local Area Network (LAN) Cable

Modern networking would not be complete without local area network (LAN) cable, which promotes dependable local connectivity. Local area network (LAN) cables, such as Cat5e and Cat6, are essential for transferring data over small distances and are found in homes, workplaces, and data centers.

LAN Cable Versatility is shown

LAN cable provide high-speed data transfer and low-latency connectivity. LAN cables are essential in many different types of installations to get strong and reliable communication, from gaming rigs to professional office networks.

Coping with Extreme Heat: The Longevity of High-Temperature Cable Explored

High-Temperature Cable

High-temperature cables are the answer to problems caused by extreme heat. Specialized materials allow these cables to endure high temperatures without compromising signal quality. High-temperature aerospace, automobile, and industrial applications require these cables.

The Make-Up of High-Temperature Cable Unveiled

High-temperature cables are built with heat-resistant materials such as silicone rubber and fluoropolymers. They are essential in harsh industrial environments due to their composition, which protects against chemical corrosion and guarantees endurance to high temperatures.

Investigating Communication Cables: The Foundation of Communication

The Role of Communication Cables

The unseen threads that link people, companies, and countries worldwide are communication cables. These cables allow for transferring voice, data, and multimedia at previously unimaginable speeds and efficiency, whether subterranean communication cables or fiber optics laid underground.

The Importance of Communication Cables in the 5G Era

The cusp of a 5G revolution and communication cables will be essential in bringing about this new age of unparalleled connection. When laying the groundwork for future communication technologies, fiber optic communication cables are king, guaranteeing lightning-fast data transfers with almost no delay.

Conclusion

Communication, high-temperature, LAN, and coaxial cable are the threads that hold contemporary networking together. In today’s digital world, every kind of cable is essential to smoothly transferring data. As we move forward, it’s crucial to recognize the unseen but powerful function of these cables inefficiently and precisely linking our environment.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#Power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#LAN cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

1 note

·

View note

Text

High-temperature cable

Kabeltec is a Singapore leading supplier specialising in Flexible cable, Fiber, Crane, Coaxial & Neoprene cable, High-temperature cable, Electrical cable and wire, etc. for use in industrial, LAN, Solar, Welding, Data, Power Cable and Communication cable.

#Cable & Wire#Cable supplier#Electrical cable#Composite cable#power cable#Control cable#Data cable#Neoprene cable#Welding cable#Fiber optic cable#Solar cable#Coaxial cable#Flexible Cable#Industrial cable#Crane cable#Instrumentation cable#Communication cable#Marine cables#High-temperature cable

0 notes

Text

One of my neighbours recently had to get his garage lifted up a bit. I guess when you park heavy-ass classic cars in there and never drive them anywhere, all the accumulated market value makes the foundation settle. To fix this problem, he turned to "mud jacking," which is a fancy industry term for spraying a lot of mud under the foundation until the house lifts up or breaks in half, whichever one comes first.

I stood out there in my nightgown, sipping my morning crankcase coffee, and I thought: I could do that shit, too. Unfortunately, my garage was not sinking into the earth at the moment. This is mostly because the surrounding area was already being depressed by approximately fourteen broken cars and their associated internal components. Levels it out a bit, I guess?

Either way, I had a real hankering to apply this new technology I had just discovered, and no safe or legal outlet for that hankering. This is the kind of thing that, in the past, the courts have historically had an issue with. I had to find something else to jack, and fast.

After driving around the neighbourhood for a few minutes, I could find no collapsed driveways, garages, basements, or even statues of losing generals in racist wars. I could already feel the rich tingle of hyperfixation wearing off. That's when I saw it: a city road that had a whole bunch of potholes! I had been driving over it for weeks and simply didn't notice that it was a thing that I could fix, without having to waste the time of brave government workers.

A few minutes and some creative reuse of toilet plumbing and a stolen air compressor later, the road was now fixed. Then the power cord caught fire and welded itself into the outlet of the stolen inverter I was using it power it. Then the cables for that inverter welded themselves to my car battery, along with part of my electrical system. This sudden influx of current made the compressor roar, its ambition to compress all air in creation no longer limited by the pitiful restrictions of mere copper. Rest assured, fair reader: mud was jacked, and jacked good.

So if you're coming through my neighbourhood, watch out for the new speed bump. It's a lot of fun to ramp, but I must admit that it doesn't add much to pedestrian safety, especially since you can't see anyone shorter than about 6'8" who is trying to cross the road anymore.

136 notes

·

View notes

Text

Our Generals that kicked Hitler's Generals asses.

* * * *

LETTERS FROM AN AMERICAN

October 23, 2024

Heather Cox Richardson

Oct 24, 2024

The struggle over whether the U.S. government should work for everyone or for the very wealthy and corporations was on display today. Cable and internet providers and home security companies sued to stop the newly finalized Federal Trade Commission “click-to-cancel” rule that says it must be as easy to cancel a service as it is to sign up for it.

Also today, the Department of Transportation reached a record settlement of $50 million with American Airlines, whose damage to wheelchairs and dangerous physical assistance to disabled passengers has broken laws. Senator Tammy Duckworth (D-IL), who lost both legs in combat in the Iraq War, praised the fine and commented: “When an airline damages or breaks someone’s wheelchair, it’s like breaking their legs.”

"The era of tolerating poor treatment of airline passengers with disabilities is over," U.S. Transportation Secretary Pete Buttigieg said in a statement. "With this penalty, we are setting a new standard of accountability for airlines that violate the civil rights of passengers with disabilities. By setting penalties at levels beyond the mere cost of doing business for airlines, we're aiming to change how the industry behaves and prevent these kinds of abuses from happening in the first place.”

A reader called to my attention that the recent Federal Election Commission filings showed one significant difference in the expenditures of the two presidential campaigns. The Harris campaign spent $34,550.02 on sign language interpreting services. The Trump campaign spent $0.00.

These details of governance are fragments of a larger picture of how we see our country. Are we all created equal and entitled to be treated equally before the law? Or are some people better than others?

CNN was supposed to host another presidential debate tonight, but while Vice President Kamala Harris accepted, Trump declined to attend. In place of a debate, CNN invited each candidate to hold a town hall. Harris accepted; Trump declined.

In her discussion with host Anderson Cooper, Harris focused on the reiteration yesterday by Trump’s longest-serving White House chief of staff, retired U.S. Marine Corps general John Kelly, that Trump had spoken admiringly of Adolf Hitler and expressed a desire to have generals like Hitler’s. In an interview with the New York Times, Kelly said Trump “met the definition of a fascist, would govern like a dictator if allowed, and had no understanding of the Constitution or the concept of rule of law.”

The ideology of fascism is associated with Italian journalist and politician Benito Mussolini, who articulated a new political ideology in the 1920s. Mussolini had been a socialist as a young man and had grown frustrated at how hard it was to organize people. No matter what socialists tried, they seemed unable to convince their neighbors that they must rise up and take over the country’s means of production. The efficiency of World War I inspired Mussolini to give up on socialism and develop a new political theory.

Mussolini rejected the equality that defined democracy and came to believe that some men were better than others. Those few must lead, taking a nation forward by directing the actions of the rest. They must organize the people as they had during wartime, ruthlessly suppressing all opposition and directing the economy so that business and politicians worked together. Logically, that select group of leaders would elevate a single man, who would become an all-powerful dictator. To weld their followers into an efficient machine, they demonized opponents into an “other” that their followers could hate.

This hierarchical system of government was called “fascism” after the bundle of rods tied around an axe that was the ancient Roman symbol of authority and power. Italy adopted it, and Mussolini’s ideas inspired others, notably Germany’s Adolf Hitler. These leaders believed that their new system would reclaim a glorious past with the ideology of the future, welding pure men into a military and social machine that moved all as one, while pure women supported society as mothers. They set out to eliminate those who didn’t fit their model and to destroy the messy, inefficient democracy that stood in their way.

But while today we associate fascism with this European movement, its foundational principle—that some men are better than others and have the right and even the duty to rule over the majority—runs parallel to that same strand in United States history. Indeed, Nazi lawyers and judges turned to America’s Jim Crow laws for inspiration, and Hitler looked to America’s Indigenous reservations as a way to rid a country of “unwanted” people.

For retired Marine general John Kelly to have spoken out against Trump before the 2024 election was a huge deal. As Secretary Buttigieg put it: “It’s one thing for some leftist group to call you a fascist. Quite another when it’s a fellow Republican. And absolutely astonishing when it’s your own chief of staff.” But Kelly was not alone. Former chair of the Joint Chiefs of Staff Mark Milley told veteran journalist Bob Woodward that Trump is “fascist to the core.”

In tonight’s CNN town hall, Vice President Harris told Cooper that she agreed that Trump is a fascist. She noted that when a four-star Marine general comes out two weeks before an election to warn Americans that one of the candidates is a fascist, we should see this as “a 911 call to the American people.”

Trump is “increasingly unstable,” Harris said, “and unfit to serve…. [T]he people who know Donald Trump best, the people who worked with him in the White House, in the Situation Room, in the Oval Office, all Republicans by the way, who served in his administration, his former chief of staff, his national security advisor, former secretaries of defense, and his vice president have all called him unfit and dangerous. They have said explicitly he has contempt for the Constitution of the United States. They have said he should never again serve as President of the United States,” she said.

When Trump talks about “the enemy within,” Harris said, “ [h]e's talking about the American people. He's talking about journalists, judges, nonpartisan election officials…. And he's going to sit there unstable, unhinged, plotting his revenge, plotting his retribution. Creating an enemies list.” In contrast, she said, she would have a “to-do list” to work on the things that matter to the American people.

When Trump responded to Kelly’s claims, he appeared to confuse Kelly, who was retired when Trump chose him to serve as White House chief of staff, and Mark Milley, the active-duty chairman of the Joint Chiefs of Staff. Trump referred to four-star general Kelly, whose son died in Afghanistan, as “tough and dumb,” a “LOWLIFE, and a bad General,” but then went on to talk of him as active duty and to say he stopped seeking his advice in the White House.

Forced to comment on Kelly’s comment about Trump’s embracing fascism, Republican leaders are either ducking the question or acting as if it is not a big deal. On CNN this morning, New Hampshire governor Chris Sununu said the news that Trump has praised Hitler will not affect Sununu’s support. “If we can get a Republican mindset out of Washington,” he said, “we need that culture change.”

At a rally tonight in Macon, Georgia, Trump agreed with the audience as it chanted: “Lock him up.” “You should lock them up,” Trump said. “Lock up the Bidens. Lock up Hillary. Lock ‘em up.”

Tonight, Shawn Reilly, the mayor of Waukesha, Wisconsin—a key Republican stronghold—announced he’s voting for Kamala Harris and Tim Walz.

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Letters From An American#Heather Cox Richardson#fascism#fascist#Shawn Reilly#Chris Sununu#election 2024#Mark Milley#hierarchical system#John Kelly

12 notes

·

View notes

Text

In 1964, Rajiv Machine Tools provided products and services in Welding and Cutting Equipment, Consumables, and Accessories. It has served clients for 60 years in the manufacturing and fabrication industry. Today, Rajiv Machine Tools deals in 1,100+ products, has 500+ clients, and has a 100+ dealer network across Gujarat in diverse markets and sectors. Our product range includes Welding & Cutting Equipment, Consumables, Accessories, Winding Wires, Flexible Wires, and Cables.

2 notes

·

View notes

Text

Ladder type cable tray

Ladder-type cable trays are essential for supporting and organizing cables in industrial and commercial settings.

Aparna Rollform specializes in manufacturing high-quality ladder-type cable trays, offering both bolted and welded models.

These trays are constructed from durable materials like galvanized steel, stainless steel, and aluminum, ensuring strength and corrosion resistance.

Their open design allows for easy cable installation, maintenance, and ventilation, preventing overheating. With a modular system, they can be customized to meet specific installation requirements.

Ideal for heavy cable loads, these trays are suitable for various applications, including industrial facilities, data centers, and power plants. (aparnarollform.com)

#Ladder Type Cable Trays#cable tray cable ladder#ladder type cable tray#cable ladder manufacturer#ladder cable trays#ladder tray

1 note

·

View note

Text

Reliable Welding Cables and Regulators in Dubai

NSGT offers top-quality welding cables in Dubai, along with welding regulators and electrodes. Ensure seamless welding operations with our durable and high-performance products. Explore our welding items in Dubai for all your industrial needs. Order today and enhance your productivity! Let me know if you'd like to refine these further!

0 notes

Text

Bright Bar Manufacturing in Delhi

Reliable Bright Bar Manufacturing in Delhi for Your Requirement

Steel bars are essential to various industries, including construction, engineering, manufacturing, and fabrication. Steel bars stand out among the various readily available and adaptable materials.

Steel may take on a wide variety of shapes, including square, round, and flat bars, among many others. Everything you need to know about excellent mild steel flat bar will be covered in this blog piece. We'll be concentrating on it.

What Uses Are There for Mild Steel Flat Bars?

There are numerous beneficial uses for both ordinary mild steel and bright mild steel. Apart from its widespread application in the production of cables and automotive parts, it is also utilized in the fabrication of smaller products such as screw fasteners and flatware. The latter is widely used during the Bright Steel Bar Suppliers in Delhi process.

The preferred material for engineering is bright mild steel. Because it responds to internal strain, it is frequently utilized in applications with modest stress levels. This is due to the fact that it is both hard and strong. Bright mild steel is frequently used as a generic material while constructing bolts, axles, and other types of machinery.

Flat bar is frequently used in a wide variety of frames and plates because to its adaptability and simplicity in cutting and welding. Although they need to be treated to prevent corrosion, their extensive use in the construction sector is also feasible.

What Is the History of Bright Mild Steel?

Regular mild steel and brilliant mild steel are two types of mild steel that are produced using different methods. Brilliant mild steel is made using the cold rolling process, also known as cold drawing and finishing.

Because the processing temperature was lower than the recrystallization temperature, the steel did not undergo recrystallization. When steel reaches the recrystallization temperature, a change in the material's grain structure could take place. The cooling process causes the metal's tensile strength and deformation to diminish. As a result, processing time and cost are reduced.

Cold drawn steel, on the other hand, is treated at room temperature. You must exert greater pressure and run it through the machine rollers more than once to obtain the desired final output.

Advantages of Using Bright Mild Steel

Steel's high carbon content makes it extremely strong in all forms, but the higher the carbon content, the more difficult it is to work with and shape. Steel that has a lower carbon content is more flexible and hence easier to deal with. Despite being less expensive, lower carbon steels are not as durable as their higher carbon equivalents.

Cold rolling increases the tensile strength of mild steel by applying more pressure to the material. Furthermore, bright mild steel is more resilient to pressure and strain than ordinary mild steel.

Furthermore, compared to mild steel, bright mild steel is more refined and has a better finish. During the hot rolling operation, the metal's recrystallization temperature is surpassed. As a result, the metal may exhibit flaws and thickness differences as it cools and contracts. Furthermore, the proportions may be somewhat incorrect.

Last Words The wide range of applications that a bright mild steel flat bar can serve is largely responsible for its versatility. Its properties make it sturdy, long-lasting, malleable, and ductile in addition to tough. There are several potential applications for this low-cost, easily workable material, including the engineering, building, and industrial sectors. If you are searching for a dependable material for your next project, bright mild steel flat bar is a great option. Choose reliable Bright Bar Manufacturing in Delhi for the very same.

#Bright Bar Manufacturers In Delhi#Bright Bar manufacturer In Punjab#Bright Bar Manufacturers In Punjab#Bright Bar Manufacturing In Punjab#Bright Bar manufacturer In Delhi#Bright Bar Suppliers Company In Punjab

0 notes

Text

How to Install an Electrofusion Coupler: A Step-by-Step Guide

Electrofusion couplers are essential components for creating strong, leak-proof pipe connections in applications such as gas, water, and industrial piping systems. Proper installation is critical to ensure optimal performance and long-lasting results. In this guide, we’ll walk you through the step-by-step process of installing an electrofusion coupler effectively.

Step 1: Gather Necessary Tools and Equipment

Before starting the installation, ensure you have the following tools and materials:

Electrofusion coupler

Pipes to be joined

Electrofusion welding machine

Pipe cutter

Scraper or pipe preparation tool

Marker pen

Alcohol wipes or a clean cloth

Measuring tape

Step 2: Prepare the Pipes

Proper preparation of the pipes is crucial for a successful fusion. Follow these steps:

Cut the Pipes: Use a pipe cutter to trim the pipe ends to the required length. Ensure the cuts are clean and square.

Scrape the Pipe Surface: Remove the outer oxidation layer from the pipe ends using a scraper. This ensures a clean surface for fusion.

Clean the Pipe Ends: Wipe the scraped surfaces with alcohol wipes or a clean cloth to remove any dirt, grease, or debris.

Step 3: Mark the Insertion Depth

Slide the electrofusion coupler onto the pipe without forcing it.

Use a marker to indicate the insertion depth on the pipe.

Repeat the process for the second pipe.

Step 4: Connect the Pipes to the Coupler

Align the prepared pipes with the electrofusion coupler.

Push the pipes into the coupler until they reach the marked insertion depth.

Verify that the pipes are properly aligned and fully inserted.

Step 5: Set Up the Electrofusion Machine

Connect the electrofusion machine’s cables to the coupler’s terminals.

Double-check the machine’s settings to ensure they match the specifications of the coupler (typically provided by the manufacturer).

Step 6: Perform the Fusion Process

Start the electrofusion machine and follow the manufacturer’s instructions to initiate the fusion process.

The machine will heat the coupler’s internal wires, melting the plastic and bonding the pipes.

Allow the process to complete without interruption. Most machines have an automatic shutoff feature once the fusion is done.

Step 7: Allow Cooling Time

Once the fusion process is complete, let the joint cool naturally. Avoid moving or disturbing the pipes during this period.

Cooling time typically ranges from 10 to 30 minutes, depending on the coupler and pipe size.

Step 8: Inspect the Joint

After cooling, inspect the joint visually to ensure proper fusion. Look for uniform weld beads around the pipe ends.

Check for any gaps or misalignment that could compromise the connection.

Step 9: Pressure Test the System

To ensure the integrity of the joint:

Perform a pressure test on the piping system according to industry standards.

Verify that there are no leaks or weak points at the connection.

Tips for a Successful Installation

Always follow the manufacturer’s guidelines for the electrofusion coupler and welding machine.

Ensure the pipes and coupler are compatible in terms of material and size.

Work in a clean and dry environment to prevent contamination.

By following these steps, you can install an electrofusion coupler with confidence, ensuring a reliable and leak-proof connection for your piping system. Whether it’s for gas, water, or industrial applications, proper installation is the key to long-term performance.

0 notes

Text

"Welding Machines: The Heart of Metal Joining"

Welding machines are indispensable tools in metal fabrication, construction, and manufacturing. They facilitate the process of joining metals by applying heat, pressure, or both, creating strong and durable bonds. With advancements in technology, welding machines have become more efficient, versatile, and accessible, catering to professionals and hobbyists alike.

Types of Welding Machines

MIG Welding Machines (Metal Inert Gas): Easy to use and versatile, MIG welders are ideal for beginners and professionals. They work by feeding a wire electrode through a spool, creating a smooth and continuous weld.

Applications: Automotive repairs, fabrication, and DIY projects.

TIG Welding Machines (Tungsten Inert Gas): Known for precision and clean welds, TIG welders use a tungsten electrode and are ideal for thin materials. They require more skill but offer superior quality.

Applications: Aerospace, piping, and ornamental metalwork.

Stick Welding Machines (Shielded Metal Arc): Stick welders are robust and effective for outdoor use and on rusty or dirty surfaces. They are a great choice for heavy-duty projects.

Applications: Construction, maintenance, and industrial work.

Plasma Welding Machines: Plasma welding offers high precision and is suitable for intricate tasks, often used in advanced industrial applications.

Applications: Electronics, medical devices, and automotive industries.

Key Considerations When Choosing a Welding Machine

Material Type: Steel, aluminum, or alloys may require specific welding techniques.

Power Requirements: Some machines run on household voltage (110-120V), while others require industrial power (220-240V).

Portability: Compact, lightweight machines are ideal for mobile or small-scale projects.

Skill Level: Beginners may benefit from MIG welders, while experienced welders might prefer TIG or plasma options.

Maintenance Tips for Welding Machines

Regularly inspect cables and connections for wear and tear.

Clean the machine to remove dust and debris after use.

Check and replace consumables like electrodes and nozzles as needed.

Store the machine in a dry, cool environment to prevent rust and corrosion.

Conclusion

Welding machines are vital for shaping the world we live in, from skyscrapers to intricate art pieces. By selecting the right type of machine and maintaining it properly, you can ensure efficient and high-quality welding results. Whether you’re a seasoned professional or just starting, a welding machine is a worthy investment in building and repairing with precision.

0 notes

Text

Lifting Eye Nuts: Comprehensive Guide and Overview

Introduction

Lifting Eye Nuts are vital components in industries requiring heavy lifting and secure fastening. Known for their robust construction and versatile design, these fasteners are used in various applications, ranging from industrial machinery to maritime equipment. This article provides an in-depth exploration of Lifting Eye Nuts, including their types, applications, materials, and advantages.

What are Lifting Eye Nuts?

Lifting Eye Nuts are specialized fasteners designed with a loop (or "eye") at the top, allowing for the attachment of hooks, cables, or ropes. These components are threaded internally, enabling them to be securely fastened onto bolts, studs, or other threaded surfaces. Their main function is to ensure safe and efficient lifting operations.

Types of Lifting Eye Nuts

Collared Eye Nuts:

Designed for heavy-duty lifting applications.

Provide added strength and stability due to the collar around the base.

DIN 582 Eye Nuts:

Manufactured as per DIN 582 standards.

Commonly used in Europe and conform to strict load capacity requirements.

Long Shank Eye Nuts:

Feature an extended shank for better thread engagement.

Suitable for applications requiring additional reach or depth.

Welded Eye Nuts:

Made from welded materials for added durability.

Ideal for demanding applications where high tensile strength is required.

Applications of Lifting Eye Nuts

Lifting Eye Nuts are extensively used in various industries for their reliability and versatility. Some common applications include:

Construction and Infrastructure:

Used for lifting heavy construction materials, equipment, and machinery.

Maritime and Offshore:

Essential for securing and lifting cargo, mooring lines, and anchor points.

Industrial Machinery:

Facilitates the lifting and transportation of large machines and components.

Automotive and Transport:

Helps in towing, lifting, and securing loads on vehicles and trailers.

Oil and Gas:

Utilized in rigging and lifting operations on oil rigs and pipelines.

Materials Used in Lifting Eye Nuts

The choice of material impacts the performance, durability, and safety of Lifting Eye Nuts. Common materials include:

Stainless Steel:

Corrosion-resistant, making it perfect for marine and outdoor applications

Carbon Steel:

Provides exceptional strength, making it ideal for heavy-duty lifting tasks.

Alloy Steel:

Provides excellent tensile strength and durability.

Brass and Bronze:

Used in environments requiring non-sparking properties, such as chemical plants.

Advantages of Lifting Eye Nuts

Safety:

Built to handle defined load capacities, reducing the likelihood of accidents.

Durability:

Made from high-quality materials that withstand extreme conditions.

Versatility:

Compatible with various lifting and rigging systems.

Ease of Use:

Simple installation and removal, making them convenient for repetitive tasks.

Corrosion Resistance:

Certain materials like stainless steel provide long-term performance in harsh environments.

Standards and Certifications

To ensure safety and performance, Lifting Eye Nuts are manufactured as per international standards, such as:

DIN 582: German standard defining load capacities and material specifications.

ISO 3266: A global standard for forged steel lifting components.

ASME B30.26: American standard for rigging hardware.

Choosing the Right Lifting Eye Nut

When selecting a Lifting Eye Nut, consider the following factors:

Load Capacity:

Ensure the eye nut can handle the intended load with an appropriate safety factor.

Thread Size:

Match the eye nut’s internal threading with the external threading of the bolt or stud.

Material:

Choose a material suitable for the application environment (e.g., stainless steel for corrosive settings).

Standards Compliance:

Confirm that the product meets the relevant safety and performance standards.

Conclusion

Lifting Eye Nuts are vital for safe and efficient lifting operations in various industries. Their robust design, diverse materials, and adherence to international standards make them a reliable choice for heavy-duty tasks. Whether in construction, maritime, or industrial applications, Lifting Eye Nuts ensure safety, durability, and functionality.

Frequently Asked Questions (FAQ)

1. What is the load capacity of a Lifting Eye Nut?

The load capacity is determined by the size, material, and design of the eye nut. Always refer to the manufacturer’s specifications.

2. Can Lifting Eye Nuts be used outdoors?

Yes, materials like stainless steel are ideal for outdoor applications due to their corrosion resistance.

3. Are Lifting Eye Nuts reusable?

Yes, provided they are not damaged or deformed during previous use. Regular inspections are recommended.

4. How do I ensure safety while using Lifting Eye Nuts?

Use eye nuts that meet international standards, inspect them regularly, and adhere to specified load limits.

5. Where can I purchase high-quality Lifting Eye Nuts?

Ananka Group is a leading manufacturer, supplier, and exporter of premium-grade Lifting Eye Nuts, offering products that meet global standards.

#ananka#fasteners#manufacturer#fastenersmanufacturer#linkedin#liftingeyenuts#eyenuts#nuts#anankafasteners#article#latestupdate#mumbai#supplier#hex#bolt#usa#uk

0 notes

Text

Revolutionizing Production - The Role of Wire Machinery in Modern Industries

With every day being a quick-paced industrial mechanized world, efficiency and accuracy highly prevail. And so, in the aspect of highly technical and sophisticated machinery, industries all over the world rely on various kinds. Such a highly significant aspect of manufacturing is the aspect of welding wire machinery.

These machines are employed for drawing, twisting, cutting, and coating wires intended for use in construction, electronics, automotive, telecommunications, and virtually all other aspects of life. Wire machinery is important in ensuring that wires and cables meet the exact specifications required by different industries, which in turn contributes to their success and technological advancement.

What is Wire Machinery?

Wire machinery refers to a category of machines and equipment used for the production and processing of wire products. These machines are used at several stages in the production of wires, starting from the wire drawing process and finally coating or finishing. Drawing wire is one where the metal is pulled through a die to make the diameter thinner while increasing its length. Then the drawn wires may be twisted into strands or cables, cut to size, or coated to prevent corrosion or add insulation.

The technology of wire machinery is constantly changing, with a focus on increasing productivity, improving precision, and reducing energy consumption. Modern wire machinery is equipped with automated control systems that ensure consistent quality and minimal human intervention, which leads to reduced costs and higher output.

Types of Wire Machinery: -

Wire machinery comprises a very large series of various machines each specialized in providing different functions to the whole process of making wires. Such kinds of wire machines are some of the most generally used by this industry:

Wire drawing machine:

A set of wires in a rod can be passed through progressively smaller dies to reduce their diameter. First and foremost is the stage known as drawing, one that is regarded as highly critical for a wire because drawing determines its diameter, strength, and quality.

Wire Twisting Machines:

Several wires are twisted together to form a strand or cable by wire twisting machines. Twisting machines are vital in the manufacture of multi-strand cables that have been applied broadly in electrical wiring and many other applications where flexibility is desired.

Wire Cutting Machines:

The wire that has been drawn and twisted might have to be cut into some required lengths after all. Wire-cutting machines are fitted with cutting mechanisms that can make accurate and clean cuts without waste and hence increase efficiency.

Wire Coating Machines:

Coating is quite crucial for the wire to protect it with insulation and safeguard it from the environment in the form of corrosion. Coating machines on the wire are provided by various types of coatings such as PVC, polyurethane, and many specialized materials for enhanced durability and functionality of the wire.

Wire Bending Machines:

It bends wire to any specific shape. The main products made using this are wireframes, mesh, or any particular parts for machinery and construction.

Wire Spooling Machines:

After drawing, twisting, and coating, wire is often wound to spools for easy transportation and handling. Wire spooling machines ensure the wire is wound uniformly and tightly so it will not tangle and be damaged.

The role of wire machinery in modern industries: -

Wire machinery is of significant importance in numerous industries since its use determines the quality of products manufactured the speed of production, and the cost. For instance:

Automobile:

Wire machines allow wire harnessing that is specific, thus car wiring harnesses come about correctly, providing adequate electrical work to automotive systems

Telecom:

Through telecommunication equipment production, such wire machines in wire machinery have proven to manufacture quality cables meant for effective and high-speed communication networking

Construction:

Wire machines are used for the manufacture of reinforced mesh and reinforcing concrete wire ensuring there is complete solidity in any kind of infrastructure structure

Conclusion

Wire machinery has been an integral part of present-day manufacturing and industrial applications. For autos to telecommunications, machinery ensuring wires meet the 'requirements necessary for their performance, safety, and durability' has comprised a large section of the machines.

Lämneå Bruk provides custom-made, high-quality welding wire solutions specifically tailored to meeting the specific requirements of the machine wire industry. Our offerings include single machines, complete wire production cells, and even entire factory setups for the manufacturing of welding, stainless steel, and high/low carbon wire.

0 notes

Text

Explore Welding Techniques, Equipment, and Safety Tips on svarka.fun

Explore welding techniques, equipment, and safety tips on https://svarka.fun/. Learn about various welding methods, materials, and practical advice to enhance your skills and ensure top-notch results.

Welding is a critical process in metal fabrication, construction, and repair work, offering unparalleled strength and durability to joints and structures. If you're eager to learn or improve your welding skills, svarka.fun is a comprehensive resource tailored to welders of all levels. The platform covers a wide range of welding techniques, equipment options, and essential safety practices to help you achieve high-quality results while staying safe.

Understanding Welding Techniques

Welding involves joining two or more pieces of metal by applying heat, pressure, or both. Different welding methods are suited to specific materials, applications, and skill levels. Here are some of the most popular techniques explored on svarka.fun:

Arc Welding

Arc welding uses an electric arc to melt and fuse metals together. This method includes subtypes like Shielded Metal Arc Welding (SMAW), Flux-Cored Arc Welding (FCAW), and Submerged Arc Welding (SAW). Each variant offers distinct advantages for different projects.

MIG Welding (Gas Metal Arc Welding)

MIG welding is ideal for beginners due to its ease of use and clean results. It involves feeding a wire electrode through a welding gun, shielding the weld area with gas to prevent contamination.

TIG Welding (Gas Tungsten Arc Welding)

TIG welding delivers precision and high-quality welds. It’s perfect for thinner materials and requires more skill and practice to master. This technique is commonly used for stainless steel and aluminum welding.

Spot Welding

A resistance welding method, spot welding is frequently used in automotive manufacturing. It’s best for joining thin sheets of metal quickly and efficiently.

Plasma Arc Welding

Plasma arc welding is similar to TIG but offers enhanced precision, making it suitable for micro-welding and high-tech industries.

Choosing the Right Welding Equipment

Selecting appropriate welding equipment is crucial for achieving desired results. svarka.fun provides guidance on various tools and accessories, including:

Welding Machines: From portable inverter welders to industrial-grade machines, choosing the right one depends on your welding method and project requirements.

Electrodes and Wires: Different metals require specific types of electrodes and filler materials for optimal bonding.

Protective Gear: Safety should always come first. Invest in quality helmets, gloves, aprons, and boots to protect yourself from heat, sparks, and UV radiation.

Gas Tanks and Regulators: For processes like MIG and TIG welding, understanding how to handle shielding gases ensures weld quality and safety.

Welding Safety Tips

Safety is paramount in welding. svarka.fun emphasizes best practices to minimize risks:

Wear Proper Protective Equipment (PPE)

Use flame-resistant clothing, a welding helmet with auto-darkening features, gloves, and sturdy boots.

Ensure Proper Ventilation

Welding fumes can be hazardous. Work in a well-ventilated area or use fume extraction systems to reduce exposure.

Inspect Equipment Regularly

Check cables, connections, and welding tools for wear and tear to avoid accidents.

Practice Fire Safety

Keep a fire extinguisher nearby and remove flammable materials from the workspace.

Stay Informed

Continually educate yourself on safety protocols and techniques to stay ahead in your craft.

Practical Advice for Beginners and Experts

Whether you're just starting or refining your skills, svarka.fun offers practical advice tailored to your experience level. From tips on setting up your workspace to troubleshooting common issues, the platform’s resources are designed to help you succeed in your welding projects.

Conclusion

Welding is an art and science that requires skill, precision, and adherence to safety standards. Explore the wealth of information on svarka.fun to discover the best welding techniques, equipment insights, and safety tips. Enhance your craft and achieve professional-grade results by leveraging the knowledge shared on this user-friendly platform.

1 note

·

View note

Text

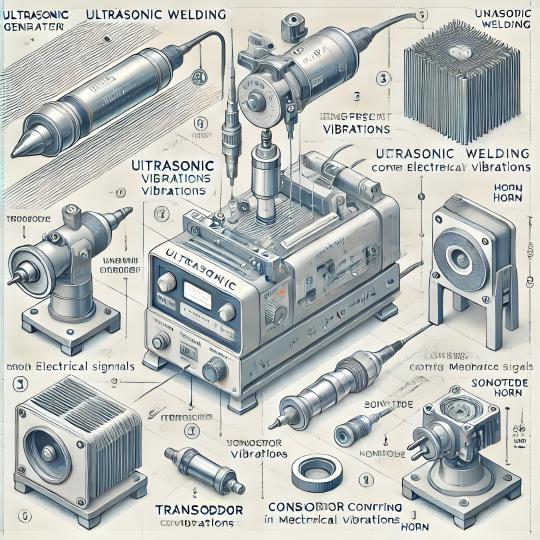

Ultrasonic Welding: An Efficient Solution for Data Cable Production

In modern life, data cables are indispensable tools. However, traditional welding methods often face challenges such as low efficiency and unstable quality. To address these pain points, ultrasonic welding technology has emerged. With its advantages of efficiency, eco-friendliness, and stability, it has become a popular choice in the data cable production industry.

Chart: Comparison Between Traditional Welding and Ultrasonic Welding

Principle of Ultrasonic Welding

Ultrasonic welding uses high-frequency vibrations to rapidly create friction and melt the contact surfaces of materials, joining them together. The process is both efficient and eco-friendly, requiring no glue or solder.

Components of Ultrasonic Welding Equipment

Advantages of Ultrasonic Welding

Chart: Typical Applications of Ultrasonic Welding in Data Cable Production

https://mechtechsupply.com/product-category/ultrasonic-series/ultrasonic-welding/

0 notes