#industrial furnaces and ovens market research

Explore tagged Tumblr posts

Text

I was born and raised in Gary, Indiana, so this story resonates deeply with me. Way too many of my high school friends died young from heart and lung diseases easily traceable to the crud in the air we all breathed for years.

Excerpt from this story from the Chicago Tribune:

The “Dirty Steel, Dangerous Air” report details the national and local health and economic costs of steel industry pollution. Industrious Labs released the report on Monday.

Industrious Labs is an environmental organization focused on cleaning up industries through network and capacity building, research and analysis, and data-driven campaigns, according to its website.

The 44-page report found that coal-based steelmaking contributes to an estimated $13.2 billion in health costs, 892 premature deaths and almost 100,000 lost school and work days annually, according to a news release from the organization.

“Steel communities have been sounding the alarm on harmful air pollution for years, and this report quantifies just how devastating and far-reaching the consequences are,” Hilary Lewis, steel director at Industrious Labs, said in the news release. “The EPA has consistently failed to safeguard the health of these communities from the dangers of coal-based steelmaking. It’s time for stronger regulations that recognize the opportunity of cleaner steelmaking technologies and tougher enforcement of penalties on polluters to truly protect public health.”

The report focuses on 17 facilities nationwide, including four plants in Northwest Indiana, each of which are owned by U.S. Steel or Cleveland-Cliffs.

In addition to steelmaking, the report looks at the harmful effects of coke, a processed form of coal used in steelmaking.

The steel industry accounts for more than 90% of the market demand for coke, according to the report, which called coke a “very dirty fossil fuel.”

The product is made by mixing coal with oil or water and heating it at 2,000 degrees for many hours. Coke requires dozens of large ovens to be made as well, according to the report.

Industrious Labs’ report also found that most residents in Gary are in the top 10% of U.S. residents most at risk for developing asthma and at risk of low life expectancy.

The city is home to U.S. Steel’s Gary Works facility, which could potentially receive $300 million for its blast furnace if a deal between the company and Nippon Steel is approved.

The $300 million investment will allow for higher steel production and reduced emissions, Gary Mayor Eddie Melton said in a statement. The furnace should have its life extended by up to 20 years.

Some residents, including those who are members of Gary Advocates for Responsible Development, have concerns about the investment.

Carolyn McCrady, member of GARD, said the only way for the steel industry to grow in “a healthy way” is to get rid of blast furnaces. McCrady believes in the use of direct reduction furnaces, which she calls more environmentally and economically friendly.

Direct reduction furnaces could reduce carbon dioxide emissions by half and produce about 20% of steel nationwide, McCrady said.

5 notes

·

View notes

Text

The Role of Vacuum Ovens in Advanced Materials Processing: Enhancing Quality & Durability

In the field of advanced materials processing, ensuring precision, quality, and durability is essential. One of the key tools in achieving these goals is the Vacuum Oven, a highly specialized piece of equipment used in a variety of industrial and research applications. These ovens play a crucial role in processes where controlling the environment is critical, such as drying, curing, and degassing materials. By removing air and moisture, Vacuum Ovens help to maintain the integrity of sensitive materials and enhance their performance.

Vacuum Ovens are commonly employed in industries that work with electronics, pharmaceuticals, aerospace, and automotive components, where the highest standards of quality are demanded. The controlled environment inside a Vacuum Oven allows for precise manipulation of temperature and pressure, which is particularly important when working with delicate materials like polymers, metals, and ceramics. The vacuum environment prevents oxidation, contamination, and moisture absorption, ensuring that the processed materials retain their optimal properties.

One of the key benefits of Vacuum Ovens is their ability to accelerate processes like drying and curing. In traditional Industrial Ovens and Furnaces, drying processes can take a considerable amount of time due to the constant exposure to air. However, in a vacuum, the boiling point of water is lowered, which enables faster removal of moisture from the materials being processed. This speed and efficiency are critical in industries where time-to-market is essential.

Moreover, Vacuum Ovens enhance the durability of materials. By preventing the absorption of moisture and contaminants, these ovens ensure that the final products are not only of high quality but also resistant to degradation over time. This is particularly important in sectors such as aerospace, where components must endure extreme conditions and maintain their performance for long periods.

As part of its commitment to advancing the materials processing industry, HHV Thermal Technologies manufactures state-of-the-art Vacuum Ovens designed to meet the rigorous demands of various applications. The company’s Vacuum Ovens are engineered with precision, offering reliable temperature control and uniform heating, essential for producing high-quality materials. HHV Thermal Technologies also manufactures Industrial Ovens and Furnaces that integrate seamlessly with the broader industrial ecosystem, providing comprehensive solutions for a range of thermal processing needs.

In addition to Vacuum Ovens, HHV Thermal Technologies offers innovative products like their Total Gas Analyzer systems. These systems are critical for the precise evaluation of gas compositions in fuel samples, ensuring that processes involving gases are controlled with the utmost accuracy. Such technological advancements contribute to the overall success of materials processing and demonstrate HHV Thermal Technologies’ dedication to quality and precision.

In conclusion, Vacuum Ovens are indispensable tools in the field of advanced materials processing, ensuring the highest quality and durability of products. By providing a controlled environment that enhances the performance of materials, these ovens are crucial in industries that demand precision and reliability. Companies like HHV Thermal Technologies continue to push the boundaries of innovation with their state-of-the-art products, setting new standards for excellence in industrial processing.

For more information, visit website: https://hhvthermaltech.com/

Contact Us

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-41931000

Fax: +91-80-41931100

Email: [email protected]

0 notes

Text

Privacy Management Software Market Size, Share, Growth, Trends [2032]

Privacy Management Software Market provides in-depth analysis of the market state of Privacy Management Software manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Privacy Management Software in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Privacy Management Software Market Report:

The report offers a comprehensive and broad perspective on the global Privacy Management Software Market.

The market statistics represented in different Privacy Management Software segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Privacy Management Software are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Privacy Management Software.

Major stakeholders, key companies Privacy Management Software, investment feasibility and new market entrants study is offered.

Development scope of Privacy Management Software in each market segment is covered in this report. The macro and micro-economic factors affecting the Privacy Management Software Market

Advancement is elaborated in this report. The upstream and downstream components of Privacy Management Software and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/privacy-management-software-market-100578

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Party Supplies MarketMarket Size

Pizza Conveyor Oven MarketMarket Growth

Minimally Invasive Surgical (Mis) Device MarketMarket Analysis

Microwave Ovens MarketMarket Size

Global Human Capital Management MarketMarket Share

Global Reflective Insulation Material MarketMarket Growth

Custom Clothing (Made to Measure) MarketMarket

Feed Phytogenics MarketMarket Share

Next-Generation Sequencing Services MarketMarket Growth Rate

RF MEMS MarketMarket Forecast

Global Digital Twin MarketMarket Size

Cloud Electronic Design Automation (Eda) MarketMarket Growth

Off Road Electric Vehicles MarketMarket Analysis

Online Fundraising Tools MarketMarket Size

Global High Purity Synthetic Quartz Glass MarketMarket Share

Global Partial Discharge Monitoring Systems MarketMarket Growth

Battery Energy Storage Systems (BESS) MarketMarket

Solar Photovoltaic Glass MarketMarket Share

Drone Services MarketMarket Growth Rate

Healthcare Chatbots MarketMarket Forecast

Global Connected Enterprise MarketMarket Size

Annual Wellness Visits (AWV) Software MarketMarket Growth

ITSM Consulting, Implementation and Managed Services MarketMarket Analysis

Electric Vehicle (EV) Charging Infrastructure MarketMarket Size

Global Anionic Dispersants MarketMarket Share

Global Thyristor MarketMarket Growth

Electric Vehicle Range Extender MarketMarket

Organic and Natural Tampons MarketMarket Share

Sterilization Equipment and Disinfectants MarketMarket Growth Rate

Commercial Heavy-Duty Laundry Machinery MarketMarket Forecast

Global Games and Puzzles MarketMarket Size

Microchannel Plate Detector MarketMarket Growth

Honeycomb Sandwich Material MarketMarket Analysis

Soft Covering Flooring MarketMarket Size

Global Preimplantation Genetic Testing MarketMarket Share

Global Sinter Hip Furnace MarketMarket Growth

DKDP-Q-Switcher MarketMarket

Laser Picosecond Pen Market Market Share

Single-use Face shield Screens Market Market Growth Rate

Silicon on Insulator (SOI) Market Market Forecast

0 notes

Text

High Temperature Furnace Manufacturers: Leaders in Advanced Thermal Processing

High-temperature furnaces are critical in various industrial applications where materials need to be subjected to extremely high temperatures for processes like sintering, calcination, annealing, and heat treatment. These furnaces can operate at temperatures exceeding 1600°C (2912°F) and are essential in sectors like metallurgy, ceramics, aerospace, and electronics. The manufacturers of high-temperature furnaces are at the forefront of innovation, providing solutions that meet stringent requirements for performance, energy efficiency, and reliability.

Key Players in the High-Temperature Furnace Industry

1. Thermcraft Inc.

Thermcraft Inc., based in Winston-Salem, North Carolina, is a renowned name in the high-temperature furnace market. They offer a wide range of furnaces, including box furnaces, tube furnaces, and custom designs capable of reaching temperatures up to 1800°C (3272°F). Known for their innovative heating element designs and robust construction, Thermcraft's products cater to industries such as aerospace, energy, and research laboratories.

2. Carbolite Gero

Carbolite Gero, a member of the Verder Scientific group, is a global leader in the design and manufacture of high-temperature furnaces and ovens. Headquartered in the UK, Carbolite Gero provides advanced solutions for thermal processing up to 3000°C (5432°F). Their products are used in applications ranging from material testing to the production of advanced ceramics and metals. The company is recognized for its precise temperature control and cutting-edge technology.

3. Nabertherm GmbH

Nabertherm GmbH, based in Germany, is a major player in the high-temperature furnace market, offering a comprehensive range of standard and custom-built furnaces. Their furnaces can achieve temperatures up to 3000°C and are widely used in industries such as dental technology, ceramics, and heat treatment. Nabertherm is known for its user-friendly designs, innovative control systems, and commitment to sustainability.

4. Harper International

Harper International, headquartered in Buffalo, New York, specializes in thermal processing solutions for advanced materials. They are known for their expertise in designing and manufacturing high-temperature furnaces for applications requiring up to 3000°C. Harper's furnaces are used in the production of carbon fibers, ceramics, and nanomaterials, and they are recognized for their ability to deliver precise thermal environments and superior material quality.

5. Lindberg/MPH

Lindberg/MPH, part of Thermal Product Solutions, is a leading manufacturer of industrial furnaces and ovens. Based in Riverside, Michigan, the company offers high-temperature furnaces capable of operating at temperatures up to 1700°C (3092°F). Their products are extensively used in metal treatment, ceramics, and laboratory testing. Lindberg/MPH is known for its durable furnace designs and advanced control systems that ensure consistent thermal processing.

Innovative Technologies and Trends

Energy Efficiency and Sustainability

Modern high-temperature furnace manufacturers are increasingly focusing on energy efficiency and sustainability. Innovations such as regenerative burners, advanced insulation materials, and heat recovery systems help reduce energy consumption and operational costs while minimizing environmental impact. Companies like Nabertherm are at the forefront of developing eco-friendly solutions that comply with stringent environmental regulations.

Advanced Control Systems

Precision in temperature control is crucial for high-temperature processes. Manufacturers are integrating sophisticated control systems that offer real-time monitoring, data logging, and remote operation capabilities. These advanced systems not only enhance process accuracy but also improve safety and reduce downtime. Companies such as Carbolite Gero are known for their state-of-the-art control technologies that ensure precise thermal management.

Custom Solutions

High-temperature furnace manufacturers are increasingly providing customized solutions tailored to specific industry needs. Whether it’s a unique size, shape, or temperature requirement, companies like Harper International and Thermcraft excel in delivering bespoke furnaces that meet the exact specifications of their clients. This flexibility allows them to serve diverse markets, from research institutions to high-tech manufacturing.

Material Innovations

The development of new materials for furnace construction, such as advanced ceramics and high-temperature alloys, is enhancing the performance and longevity of high-temperature furnaces. These materials can withstand extreme temperatures and corrosive environments, improving furnace durability and reducing maintenance costs. Lindberg/MPH, for instance, leverages advanced materials to create robust and long-lasting furnace solutions.

Market Challenges and Opportunities

Global Supply Chain Issues

The high-temperature furnace industry, like many others, has been affected by global supply chain disruptions. Sourcing raw materials and components has become challenging, leading to delays and increased costs. However, this also presents opportunities for manufacturers to innovate with alternative materials and localize their supply chains to mitigate risks.

Technological Advancements

As industries such as aerospace and electronics continue to demand higher performance materials, the need for advanced high-temperature processing capabilities grows. This drives innovation in furnace technology, offering opportunities for manufacturers to develop new products and expand into emerging markets. The shift towards electric vehicles and renewable energy sources also creates demand for specialized high-temperature processing equipment.

Regulatory Compliance

Increasingly stringent environmental and safety regulations pose challenges for high-temperature furnace manufacturers. Companies must invest in research and development to create products that comply with these regulations while maintaining high performance. However, this also drives technological advancement and opens up markets for compliant, state-of-the-art furnace solutions.

Conclusion

High-temperature furnace manufacturers play a pivotal role in enabling advancements across various industries by providing the necessary tools for high-temperature processes. Leaders like Thermcraft, Carbolite Gero, Nabertherm, Harper International, and Lindberg/MPH continue to innovate, addressing the evolving needs of their customers while overcoming market challenges. As the demand for more efficient and precise thermal processing grows, these companies are well-positioned to drive the future of high-temperature furnace technology.

This comprehensive overview of high-temperature furnace manufacturers highlights their key roles, innovations, and challenges in the industry. Whether you are in aerospace, ceramics, or metallurgy, understanding the capabilities and advancements in high-temperature furnace technology is essential for optimizing your processes and staying competitive in the market.

0 notes

Text

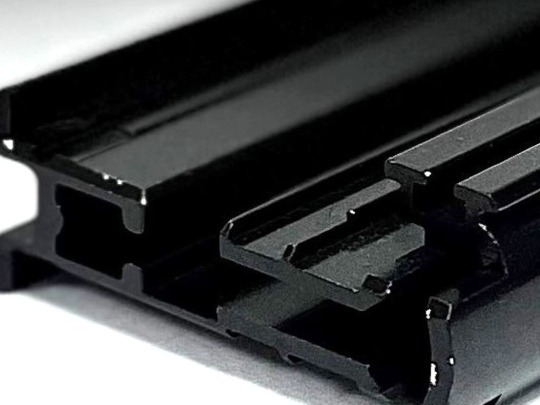

What equipment is needed to setup an aluminum extrusion factory?

In the product designing and manufacturing industry, we get to see that there has been seen a significant increase in the use of the process of aluminum extrusion. According to some recent reports and research, it has been noted there is growth in the aluminum global extrusion market, accelerating with a compound rate of around 4%. However, a lot of us might have already heard about this process and must be wondering what it is and how it works. In order to know about the process, we need to know about the steps that are involved in it.

What is the Aluminum Extrusion Process?

Aluminum extrusion is a type of process in which the material named an aluminum alloy is forced through a die that has a specific cross-sectional profile. In order to push the aluminum through the die and to make it emerge from the opening, a powerful ram is used. When it comes out, it is in the same shape as that of a die. It is then pulled out a long runout table. At the basic level, the process of aluminum extrusion is relatively easy and simple to understand; however, the force that is applied can be similar to the force that you usually apply when you are trying to squeeze out toothpaste with the help of your fingers. For instance, when you squeeze the toothpaste, it emerges in the shape of the opening of the tube. The opening of the tube usually serves the same purpose as an extrusion die does. With the solid, circular opening of the toothpaste, we get to see that the toothpaste flowing out is in the form of long, solid extrusion.

The types of shapes that can be extruded:

When we talk about the type of shapes that can be extruded using this method, there are mainly three different categories, that are as: 1. Solid This is the shape that is a rod or beam-like structure with no enclosed spaces or openings. 2. Hollow These are the shapes that are made with one or more voids. These could be in the form of a square or rectangular tube. 3. Semi-hollow Semi-hollow tubes are the type of tubes that are partially enclosed. These could be in the form of ‘c’ channels with a narrow gap. There are various different applications in many industries. These are in the form of the architectural industry, automotive industry, electronic industry, aerospace industry, and various other industries.

What equipment Is needed to set up an aluminum extrusion factory

Setting up an aluminum extrusion factory is a really complicated task, as there are certain steps that need to be kept in mind. In order to follow those steps, one requires a lot of equipment as well. With a lot of research and experience, it was noticed that there are mainly six types of essential products that are important in order to set up your own aluminum extrusion factory. These are in the form: 1. A long billet Heating Furnace with Hot Log Shear It is a type of equipment that is used for the purpose of heating, shearing, and feeding the aluminum extrusion machine. It is designed in a way that is based on three main parts: - Billet racks - Furnace body - Hot Shearing Machine 2. Aluminum Extrusion Press When we talk about the aluminum profile extrusion press, a lot of us must be familiar with the fact that it is the main type of machine that is considered the power unit for the extrusion profile formation. 3. Mold Heating Oven The mold heating furnace is designed in a way that helps to heat the mold. a. Puller Machine These are the machines that perform the function of pulling, sawing, and adjusting lengths. Although it is not a must for the aluminum extrusion product line, it is important in a way that it reduces the needing to add on extra workers and helps fix the twist and bend problems that usually can happen during the operations. Thus, it is suggested to add the puller to the product line required. b. Aluminum Profile Cooling Bed Cooling beds are the type of beds that usually consist of - run out table, - the material conveying device, - finding a device, - straightening system, - material storage device - fixed length transmission - finished sawing table - fixed length table etc The function part is to perform functions like cooling, feeding, straightening, sawing, etc. c. Aging Furnace The aging furnace is the part that is composed of a track, a charging skip, and a furnace body. It is the part that is essential for aluminum profile hardness by applying heat. These were the 6 parts that are essentially used in order to set up an aluminum extrusion factory. However, once the equipment is arranged, there is a certain setup that needs to be followed. These are in the form of - Step 1: In the first step, the extrusion die is prepared and moved to the extrusion. - Step 2: In the second step, an aluminum billet is preheated before the process of extrusion is performed. - Step 3: In this step, the billet is transferred to the extrusion press in order to perform the process of extrusion. - Step 4: In the fourth step, the hydraulic ram pushes the billet material into the container of the extrusion process, expanding the material in a way that is pressed up against the extrusion die, taking the shape of the container. - Step 5: In the fifth step, the extruded alloy material emerges through the die as it is being pressed up against the extrusion die. - Step 6: In the next step, the extrusions are guided along the runout table and quenched y a puller which guides them through the runout table. - Step 7: In this step, as soon as the extrusion reaches the full table length, it is sheared to the length of the table. - Step 8: After shearing to the table length, the extrusions are mechanically transferred from the runout table to the cooling table. - Step 9: In this step, the extrusions that are being cooled are moved to the stretcher and are stretched into the alignment. - Step 10: In the final process, the extrusions are then moved to the finished saw and cut to the length. Read the full article

1 note

·

View note

Text

Dental Equipment Market Size, Share & Revenue Forecast 2030

Dental Equipment Market Growth & Trends

The global dental equipment market size is expected to reach USD 17.06 billion by 2030, according to a new report by Grand View Research, Inc., registering a CAGR of 6.2% over the forecast period. These tools help with an oral health diagnosis, care, and maintenance and allow practitioners to plan a precise course of action. The introduction of supportive government efforts for oral health, an increase in medical tourism for dental operations, and the incidence of dental problems all contribute to the industry's growth. In addition, manufacturers like Planmeca are always introducing fresh computer-aided technology to the market.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/dental-equipment-market

For instance, the industry demand is being driven by the company's March 2019 launch of the Planmeca Creo C5, an innovative 3D printer created to deliver chairside CAD/CAM dentistry and restorative dental treatments in a single visit.According to the estimates published by the United Nations in 2019, there were 703 million people aged over 65 years globally, and the number of older individuals is projected to double to 1.5 billion by 2050. The rising prevalence of various oral conditions in the geriatric population is likely to increase the demand for preventive, restorative, and surgical services in the future. According to the American Dental Association, 85% of individuals in the United States, value dental health and consider it an essential aspect of overall care.

The realization of the importance and maintenance of oral health combined with better access to advanced dental services will help in the growth of the industry. However, the “emergency-only” mode of dental care delivery due to the COVID-19 pandemic had a rippling effect and the industry witnessed an imminent increase in availing cost of dental care. According to the Journal of Contemporary Dental Practice, dental services were among the last to relaunch in post-pandemic relaxations since dental procedures are at high risk of transmission. This resulted in serious financial problems and revenue loss for the overall dental market.

Dental Equipment Market Report Highlights

Dental systems and parts emerged as the largest product segment in 2022 as these equipment are used for digital imaging and diagnosis of dental ailments

The dental lasers segment is expected to witness the highest CAGR during the forecast period. This is owing to its increasing application in surgical and teeth-whitening procedures.

North America dominated the global industry in 2022 owing to the high demand for new technologies & the prevalence of dental disorders and the presence of a large pool of key players & advanced healthcare infrastructure

Asia Pacific, on the other hand, is expected to register the highest CAGR over the forecast period

Dental Equipment Market Segmentation

Grand View Research has segmented the global dental equipment market on the basis of product type and region:

Dental Equipment Product Type (Revenue, USD Million, 2018 - 2030)

Dental Radiology Equipment

Intra-Oral

Digital X-ray Units

Digital Sensors

Extra-Oral

Digital Units

Analog Units

Dental Lasers

Diode Lasers

Quantum well lasers

Distributed feedback lasers

Vertical cavity surface emitting lasers

Heterostructure lasers

Quantum cascade lasers

Separate confinement heterostructure lasers

Vertical external cavity surface emitting lasers

Carbon Dioxide Lasers

Yttrium Aluminium Garnet Lasers

Systems & Parts

Instrument Delivery systems

Vacuums & Compressors

Cone Beam CT Systems

Cast Machine

Furnace and Ovens

Electrosurgical Equipment

Other System and Parts

CAD/CAM

Laboratory Machines

Ceramic Furnaces

Hydraulic Press

Electronic Waxer

Suction Unit

Micro Motor

Hygiene Maintenance Devices

Sterilizers

Air Purification & Filters

Hypodermic Needle Incinerator

Other Equipment

Chairs

Hand Piece

Light Cure

Scaling Unit

Regional Insights

North America dominated the global industry in 2022 with a market share of more than 38.35% and is expected to showcase a significant CAGR over the forecast period. This is attributed to the rising geriatric population, strong medical infrastructure, well-established reimbursement policies, the existence of key players, and advancement in preventive and restorative dental treatments. Moreover, according to the American Dental Association, 85% of individuals in the United States truly value dental health and consider oral health an essential aspect of overall care. The combination of all these factors will make North America the most promising regional market over the forecast period.

The APAC region is expected to witness the highest CAGR over the forecast period. China, Japan, and India are emerging economies with well-developed healthcare infrastructure & facilities and are now more focused on leading on the basis of R&D activities. They have suitable infrastructure and fundings for the same. A total of 43.6% of the spending is expected to emanate from Asia with countries like China, Japan, and India being the topmost to spend on R&D activities.

Attributes like favorable government policies, the rising geriatric population, the presence of key players, and the rise in the demand for dental procedures are paving way for the market in the Asia Pacific region. Moreover, medical tourism in the region is rapidly increasing due to shorter patient waiting times, low-cost treatment, availability of a large pool of skilled dental practitioners & high-end technology, and the presence of tourist destinations & quality accommodations. These aforementioned factors will assist in the market growth in the region.

List of Key Players of Dental Equipment Market

A-Dec Inc.

Planmeca Oy

Dentsply Sirona

Patterson Companies Inc.

Straumann

GC Corp.

Carestream Health Inc.

Biolase Inc.

Danaher Corp.

3M EPSE

Authoritative Research: https://www.grandviewresearch.com/industry-analysis/dental-equipment-market

#Dental Equipment Market#Dental Equipment Market Size#Dental Equipment Market Share#Dental Equipment Market Growth

0 notes

Text

US Oil and Gas Burner Management System Market Insights in Research Report 2021 to 2028

“The US oil and gas burner management system market was valued at US$ 853.2 million in 2021 and is expected to reach US$ 1,308.5 million by 2028; it is estimated to grow at a CAGR of 6.3% from 2021 to 2028.”

A report added on the Business Market Insights, titled “US Oil and Gas Burner Management System Market” by Company, Regions, Type and Application, forecast to covers several well-known organizations, key market players who are leading in the market. The report contains a thorough summary of US Oil and Gas Burner Management System Market that includes several well-known organizations, key market players who are leading in terms of sales, variable market change, revenue, end-user demands, conformity through trustworthy services, restricted elements, products and other processes.

To a Sample Copy of the Report, Click Here:

https://www.businessmarketinsights.com/sample/TIPRE00028701

US Oil and Gas Burner Management System includes market research report Top Companies:

· ACL Manufacturing Inc

· Cimarron Energy

· Combustex Corp

· Kimark Control Solutions

· Platinum Control Technologies

· Profire Energy Inc

· Zeeco Inc

· Surefire Burner Management Systems

US Oil and Gas Burner Management System Market Split by Product Type and Applications:

This report segments the US Oil and Gas Burner Management System Market on the premise of Types is:

· Oil

· Gas

· Electricity

On the premise of Application, the US Oil and Gas Burner Management System Market is segmented into:

· Furnaces

· Ovens

· Boilers

· Kilns

· Others

NOTE: Our analysts who monitor the situation around the world explain that the market will create a conservative outlook for producers after the COVID-19 crisis. The report aims to provide a further explanation of the latest scenario, the economic downturn, and the impact of COVID-19 on the entire industry.

Competitive Landscape:

This report will drive companies present in this market. Outstanding players in the market are studied through a full analysis of the company profile, product portfolio, production and manufacturing capabilities, technology and product development, and revenue estimation. The US Oil and Gas Burner Management System Market is highly integrated as there are many companies across this industry. The report then explains the current market conditions, past performance, demand and supply graphs, sales networks, and distribution channels for these companies.

Directly Buy a Copy of this research report:

https://www.businessmarketinsights.com/buy/single/TIPRE00028701

Questions answered in US Oil and Gas Burner Management System Market research study:

• What is the market growth rate of US Oil and Gas Burner Management System Market?

• What will be the global market size of the market?

• Who are the leading global manufacturing companies in the US Oil and Gas Burner Management System Market?

• What are the major current trends and predicted trends?

• What are the challenges faced in the US Oil and Gas Burner Management System Market?

• How share promote US Oil and Gas Burner Management System their worth from different manufacturing brands?

• Which will be the niches in which players profiling with thorough plans, financials, and also recent advancements should set a presence?

• Which will be the anticipated growth rates for your own US Oil and Gas Burner Management System economy altogether and also for every segment inside?

• Which will be the US Oil and Gas Burner Management System application and types and forecast accompanied closely by producers?

• What are the conclusions of the US Oil and Gas Burner Management System Market report?

*If you need anything more than these then let us know and we will prepare the report according to your requirement.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications.

Contact Us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Sameer Joshi

Phone: +16467917070

Email: [email protected]

0 notes

Text

Fueling the Future of Industry: A Comprehensive Overview of the Industrial Burner Market and its Evolution

The Industrial Burner Market refers to the market for combustion systems that are used in various industries, including oil and gas, chemicals, food and beverage, and manufacturing, among others. Industrial burners are used for heating and processing applications, such as boilers, furnaces, ovens, and kilns. The market is driven by the growing demand for energy-efficient and eco-friendly burners that are designed to reduce emissions and increase fuel efficiency.

The Asia Pacific region is expected to be the largest market for industrial burners, driven by the growing demand for energy-efficient burners in countries such as China and India. North America and Europe are also significant markets, driven by the presence of established industries such as chemicals, oil and gas, and food and beverage. Additionally, the increasing demand for renewable energy sources such as biomass, solar, and wind power is expected to drive the demand for industrial burners in the coming years.

Request For The Sample Copy of The Report @ https://www.persistencemarketresearch.com/samples/28051

Some of the key players in the Industrial Burner Market include Honeywell International Inc., Mitsubishi Heavy Industries Ltd., Siemens AG, Alfa Laval AB, and Weishaupt AG, among others. These companies are focusing on product innovation, development, and customization to meet the specific requirements of different industries. They are also focusing on expanding their global presence through strategic partnerships and collaborations, mergers and acquisitions, and new product launches, to increase their market share and revenue growth.

About us: –

Persistence Market Research is a U.S.-based full-service market intelligence firm specializing in syndicated research, custom research, and consulting services. Persistence Market Research boasts market research expertise across the Healthcare, Chemicals and Materials, Technology and Media, Energy and Mining, Food and Beverages, Semiconductors and Electronics, Consumer Goods, and Shipping and Transportation industries. The company draws from its multi-disciplinary capabilities and high-pedigree team of analysts to share data that precisely corresponds to clients’ business needs.

Contact Us:

Persistence Market Research Address – 305 Broadway, 7th Floor, New York City, NY 10007 United States U.S. Ph. – +1-646-568-7751 USA-Canada Toll-free – +1 800-961-0353 Sales – [email protected]

0 notes

Text

Eight Steps to Selling a House

1) Find a local real estate agent when selling a house. Because of all the things that need to be considered and to ensure appropriate research, negotiations, and contracts are handled, it's strongly recommended that you use a local real estate agent to guide you through the process of selling a house. The benefits of using a local real estate agent are many and will only simplify things if you are not experienced in these matters. A local real estate agent can help you achieve your goals by formulating a real estate marketing plan that meets your expectations and finds buyers that meet your conditions.

2) Identify the current value of your house. Here, you (or your local real estate agent) will research the most recent sales prices of comparable properties in your neighborhood, understanding that the price of a house depends on the interior and exterior conditions of the property thereby helping you identify how to value your house. You can get this information via different websites that offer online home values. A local real estate agent will also be able to gather updated information and determine the right price of your home from other comparable prices in your area.

3) Get it ready to market. Do all the necessary inspections before you put your house on the market. When selling a house, prepare your house to be visited frequently; sometimes investing in simple repairs could increase the value of your house by thousands. "If a car is worth $200 dirty, it will be worth $220 cleaned up," Donald Trump once said.

4) Make your home price attractive. We all want to get as much as we can for our house. That is why getting a good, realistic valuation is of the utmost importance when selling a house. Once you know the real worth of your home, you can price it attractively enough to sell with the assistance of a local real estate agent. Set the price at an acceptable range, but a little lower than expected so that you can move it quickly. Overpricing a house (led by emotional pride and economic concerns) are easily the two main reasons why homes don't sell well. You want to attract buyers and make them feel like they can't pass up the deal. Remember, you have competition from other nearby home sellers. When selling a house, make your option the most attractive in price, reliability, and conditions.

5) Marketing your home. Reaching the buying public and getting the word out that you are selling your house is something that many can do for you, including a local real estate agent. The important part is making sure that the right form of marketing is being used to reach the targeted audience. Different tactics might be needed to make sure your home is seen in a positive way. Things that might seem small like good lighting, pictures, and landscaping go a long way in selling your house to the different types of buyer sets. A local real estate agent is always valuable in this instance for his or her industry expertise when a homeowner is selling a house.

Newspapers, flyers, real estate marketing online, bandit signs, open houses, and the assistance of a local real estate agent will help in the overall marketing plan to make sure the word gets out that you are selling your house and interested buyers stop in.

6) Negotiate and agree on price and terms. Be as clear as you can with the buyer when selling a house. Be specific on how much money you want for your property and try to work out a deal that makes sense for both you and the buyer. Write down all the terms when you accept the offer, including any improvements or repairs that you agree to make.

7) Get the home ready for closing (inspection, appraisal, perform fixes, etc). Once the terms and conditions have been agreed upon and the house is up for closing, make sure all improvements or repairs are complete and that your house is ready for a possible inspection. According to the American Society of Home Inspectors (ASHI), a general inspection includes a thorough evaluation on the following aspects of the house:

Structural elements: construction of walls, ceilings, floors, roof and foundation Exterior evaluation: wall covering, landscaping, grading, elevation, drainage, driveways, fences, sidewalks, fascia, trim, doors, windows, lights and exterior receptacles Roof and attic: framing, ventilation, type of roof construction, flashing and gutters Plumbing: identification of pipe materials used for potable, drain, waste and vent pipes, including condition Systems and components: water heaters, furnaces, air conditioning, duct work, chimney, fireplace and sprinklers Electrical: main panel, circuit breakers, types of wiring, grounding, exhaust fans, receptacles, ceiling fans and light fixtures Appliances: dishwasher, range and oven, built-in microwaves, garbage disposal and, yes, even smoke detectors 8) Closing, the last and most important step in this journey. This usually takes place in an attorney's office where the required documents are signed in order to transfer your property to the new owner. Cash or financing is provided at this point of sale in exchange for a legal title and ownership of the property. Legal rights and responsibility are passed to the buyer at the moment, and hopefully, you will have had the chance to leave behind many great memories from your time there.

Click the link to visit our site Steady Properties

Details

Company Name: My Florida Home Buyers Address: 31120 Deal Dr Sorrento, Florida 32776 Phone Number: (352) 519-4512 Google Map URL: https://goo.gl/maps/BQGNVgpdb3544iSK8

1 note

·

View note

Link

Summary Key Content of Chapters (Including and can be customized) Part 1: Market Overview, Development, and Segment by Type, Application & Region Part 2: Global Market by company, Type, Application & Region Part 3: Asia Market by company, Type, Application & Region Part 4-10: Key Regions of Asia Market by Type, Application Part 11: Company information, Sales, Cost, Margin etc. Part 12: Conclusion Market Segment as follows: By Region Global (Asia, Europe, America etc.) Asia (China, Southeast Asia, India, Japan, Korea, Western Asia, Others) Key Companies Andritz Tenova Despatch Primetals Technologies Aichelin Group ALD Inductotherm Corporation SECO/WARWICK Ipsen Nachi-Fujikoshi Gasbarre Furnace Cieffe(Accu) Surface Combustion Mersen JUMO Nutec Bickley CEC Wisconsin Oven Sistem Teknik AVS PVA TePla TAV Shenwu Phoenix Furnace Market by Type Combustion type Electric type Market by Application Metallurgy Petrochemical industry Material handling Others

#industrial furnaces and ovens market#industrial furnaces and ovens market trends#industrial furnaces and ovens market size#industrial furnaces and ovens market data#industrial furnaces and ovens market structure#industrial furnaces and ovens industry analysis#industrial furnaces and ovens market research#industrial furnaces and ovens market report

0 notes

Text

Industrial Oven Market Size, Growth, Segmentation - Ali S.p.A., Duke Manufacturing, The Middleby Corporation

An industrial oven is a heated chamber used to perform a wide range of applications among varied industry verticals. Generally, these ovens process raw material at extremely high temperatures to perform a heat treatment process. Typical applications of industrial oven include food production, chemical processing, as well as deployment in the electronics industry.

According to a new report published by Allied Market Research, titled, “Industrial Oven Market by Product, Process, Heating Medium, and End-user Industry: Global Opportunity Analysis and Industry Forecast, 2022–2031,” the global industrial oven market size was valued at $9,422.1 million in 2020, and is projected to reach $15,967.7 million by 2031, registering a CAGR of 4.5% from 2022 to 2031.There is a rapid shift among end-users on use of continuous industrial oven over batch industrial oven, as continuous ovens do not require repeated loading and unloading, or heating up and cooling down between each batch, and labor and energy demands often are much lower than batch ovens.

Key Leaders:

Ali S.p.A., Duke Manufacturing Co. Inc., The Middleby Corporation, Alto-Shaam, Inc., Edward Don & Company, Fujimak Corporation, Avantco Equipment and Hobart Corporation

Rapid adoption of continuous line industrial oven where multiple operations can take place continuously during the processing stage and reduced dependence on workforce skills are major developments witnessed in the global industrial oven market. However, high initial cost and low awareness among the end users regarding the difference between industrial oven and industrial furnace are expected to hamper market growth in the near future.

Get Free Sample Copy @ https://www.alliedmarketresearch.com/request-sample/2880

Continuous technological advancements in the global industrial oven market is expected provide ample growth opportunities for oven manufacturers and suppliers in the near future. Major players in the market have already shifted their focus toward innovation & technological advancements to maintain competitiveness and garner major market share. Furthermore, introduction of new heating technologies, interactive oven interfaces, high-speed convection ovens, and vent less ovens are anticipated to provide potential opportunities for market expansion. Moreover, some of the manufacturers in industrial oven market offer in-house-built industrial oven named as walk-in ovens, which save money on construction and shipping. Such advancements are expected to bolster market growth during the forecast period.

Major companies have adopted agreement, product launch, expansion, and merger strategies to sustain the intense market competition. Key players profiled in the report industrial oven analysis include ASC Process Systems, Harper International, Eastman manufacturing ltd., Rowan Technologies, Wisconsin Oven Corporation., JPW Ovens & Furnaces, Davron Technologies, Grieve Corporation, JLS Ovens, and Steelman Industries, Inc.

Moreover, due to the outbreak of the COVID-19 pandemic, the manufacturers have seen drop in sales. However, implementation of lockdown and curfew practices globally hasaffectedthe domestic as well as international production of industrial oven’s products, which in turn, hampers the growth of the overall market. Thus, the outbreak of COVID-19 negatively impacted the market in 2020, as sales of companies reduced and operations were halted.

Key Findings Of The Study

By type, the curing ovens segment dominated the global market in 2020, and is expected to retain its dominance throughout the industrial oven market forecast period.

On the basis of process, it is bifurcated into batch and continuous. The continuous segment held the dominant industrial oven market share in 2020, and is also expected to register the highest CAGR.

Depending on heating medium, the market is categorized into electric heat, fuel- & gas-fired, infrared heaters, and others. The infrared heaters segment held the major share in the market, and is projected to remain dominant during the forecast period.

The end-user industries analyzed in this study are food production & processing, chemical processing, electrical & electronics, automotive & aerospace, pharmaceuticals, and others.Food production & processing accounted for the highest market share in 2020, and is expected to grow at a significant CAGR during the forecast period.Increase in preference for vent less ovens in food production and processing is anticipated to drive the industrial oven market growth during the forecast period.

By region, Europe accounted for highest market share in 2020, and is expected to grow at a significant CAGR during the forecast period. The demand for industrial oven in Europe is fueled by advancements in production and processing technologies in the industrial sector and improvements in metal manufacturing techniques in countries such as Germany, Italy, the UK, and others.Germany dominated the European industrial oven market.

#Industrial Oven Market#Industrial Oven Market Size#Industrial Oven Market Share#Industrial Oven Market Growth#Industrial Oven Market Key Players#Industrial Oven Market Forecast#Industrial Oven Industry

0 notes

Text

BUY HEATER ROD ELEMENTS AT THE BEST PRICES ONLINE

For convection heating, conduction heating, and radiation heating, heater rod elements are frequently used in industry. They are widely used in furnace apparatus of the Lindberg and Old Sauder types and can be found in a wide range of sizes and shapes.

Because they may be bent into any shape and work at high temperatures, heating rods are extremely versatile. Electrical rod elements are produced by Airex Heaters. using NIKChrome® alloys, Iron-Chrome-Aluminum Alloys, and pure Molybdenum.

Heater rod elements are essential in many homes and businesses as they provide warmth during colder months. There are many different types of heater rod elements available on the market, and it is important to choose the right one for your needs. Heater rod elements come in a variety of sizes, and each type has its own benefits and drawbacks. Before purchasing a heater rod element, it is important to do your research to find the best option for you. Airex heaters provide an overview of the different types of heater rod elements available, as well as the installation process.

A common material used in panel heaters is ceramic because of its great efficiency. Ceramics is a highly effective conductor, thus it heats up quickly and uses less energy as a result. Ceramic heaters can usually be quite small since they can generate a lot of heat from a small surface area. This is excellent if you have a small space or simply like a cleaner, more modern touch.

Ceramic is so good at retaining heat that after the required temperature is reached, it shuts off and uses the heat it has already stored to keep the room warm for several hours. This makes ceramic a very economical heating material to operate. If you want your heater to adhere to the highest energy efficiency requirements, look for Economically designed compatible heaters.

Rod heating element sets are commonly fixed on sidewalls, floors, doors, and rear walls. To lift it off of any insulation, the majority of parts are kinked. To allow for waste to collect underneath floor elements, these elements are frequently suspended from foundations. For rod elements and machines to accommodate electrical terminal clamps, NEI supplies a complete complement of terminals.

Applications

Radiant heaters (air conditioning)

Ovens with convection and hot air

For room heaters

drying sheds

Shorter tunnels

smoking and roasting (food)

varnish, ink, or paint curing

Defrosting

sealing bars

tools and dies

Melting

#heater rod element#airex heaters#electrical appliances#industrial heating elements#electronic heating elements#rod elements in delhi#buy electronics online#airex heater rod elements#domestic heater rod elements#temperature sensor

0 notes

Text

U.S Vertical Lift Module (VLM) Market 2022 Data Analysis and brief review - Modula, MDCI Automation (Sapient Automation), Zecchetti, ICAM

"https://tealfeed.com/vanadyl-sulfate-market-future-scope-demands-iyssw https://tealfeed.com/mri-contrast-media-market-2022-analysis-2cmty https://tealfeed.com/pd-1-pd-l1-inhibitors-market-m81tl https://tealfeed.com/heat-treatment-furnace-market-witness-huge-wy6ff https://tealfeed.com/hypnotics-sedatives-market-next-big-thing-wb6st https://tealfeed.com/absolute-pressure-transmitters-market-2022-2027-8lumi https://tealfeed.com/new-report-cellular-m2m-value-added-k23ry https://tealfeed.com/metallic-gasket-seal-market-current-business-ihgj5 https://tealfeed.com/rail-wheel-axle-market-demand-future-bkdrl https://tealfeed.com/oven-bag-market-size-share-trend-0yhsd https://tealfeed.com/dth-drill-rig-industry-future-demand-tipaj https://tealfeed.com/sweeper-scrubber-dryer-market-2022-latest-e9x02 https://tealfeed.com/fpga-telecom-market-2022-top-industry-ghm8y https://tealfeed.com/synthetic-sizing-agents-market-2022-top-nzpfh https://tealfeed.com/leisure-luggage-bag-market-2022-omicron-cem2q https://tealfeed.com/cylindrical-lithium-ion-battery-market-size-8agwn https://tealfeed.com/hemp-products-market-covid19-omicron-updated-kmixz https://tealfeed.com/protein-cookie-market-growth-possibilities-analysis-kqczc https://tealfeed.com/cellulose-ether-market-witness-huge-astonishing-9rrgg https://tealfeed.com/conducting-polyaniline-market-pointing-capture-largest-7qxp5 https://tealfeed.com/bioplastics-biopolymers-2022-market-huge-growth-pyem5 https://tealfeed.com/sachet-packaging-market-2022-challenges-business-8uokc https://tealfeed.com/fungi-bacteria-food-market-expected-boom-wqsh8 https://tealfeed.com/lighting-service-market-size-scope-top-asjzj https://tealfeed.com/spine-surgical-retractors-market-size-outlook-dp1aj https://tealfeed.com/concrete-drill-bits-market-2022-pointing-bi20p https://tealfeed.com/ibc-liner-market-size-analysis-leading-z8lda https://tealfeed.com/ultra-fine-eye-liner-brush-market-dipxi https://tealfeed.com/medical-sensors-market-size-growth-set-ndo3d https://tealfeed.com/electrodynamic-shaker-systems-market-expecting-outstanding-oi4og https://tealfeed.com/optical-measuring-instruments-market-2022-development-wzkre https://tealfeed.com/power-grid-automation-systems-market-report-mvipk https://tealfeed.com/card-personalization-equipment-market-growth-trends-simgv https://tealfeed.com/pos-printers-market-challenges-opportunities-size-plguh https://tealfeed.com/concrete-admixtures-construction-chemicals-market-overview-ekm69 https://tealfeed.com/2022-wood-plastic-composites-wpc-market-xwzgs https://tealfeed.com/wlan-equipment-market-outlook-post-covid-fcfur https://tealfeed.com/circulating-water-baths-market-huge-growth-a7nhs https://tealfeed.com/uv-c-disinfection-robot-market-2022-epk1j https://tealfeed.com/bath-rugs-market-2022-demand-future-ac4yt https://tealfeed.com/talent-acquisition-staffing-technology-services-market-znpfl https://tealfeed.com/aromatic-process-oil-market-global-production-j3dpg https://tealfeed.com/heated-scarf-market-size-incredible-possibilities-9i7nm https://tealfeed.com/sealing-paste-market-size-growth-set-hpiyg https://tealfeed.com/unmanned-aerial-vehicle-uav-batteries-market-x7mat https://tealfeed.com/fire-protective-clothing-industry-future-demand-pfgr0 https://tealfeed.com/gigabit-ethernet-test-equipment-market-size-shhm7 https://tealfeed.com/high-performance-insulation-materials-market-industry-ikggn https://tealfeed.com/polytetrefluoroethylene-ptfe-market-future-scope-demands-7st04 https://tealfeed.com/stone-processing-market-2022-analysis-research-i9v4u https://tealfeed.com/self-powered-relays-market-2022-analysis-hc8pi https://tealfeed.com/self-powered-relays-market-2022-analysis-hc8pi https://tealfeed.com/surgical-suction-instruments-market-witness-huge-1fa84 https://tealfeed.com/milling-machine-market-next-big-thing-rjvks

0 notes

Text

Tabular Alumina Market

Market Overview

The Global "Tabular Alumina Market" is expected to grow at a high CAGR of 7.3% during the forecasting period (2021-2028).

It comprises large (50 – 200 µm), flat, tablet-shaped corundum crystals. The feedstock is calcined Alumina which is ground to a fine powder and palletized to balls with a distance across of abt. 25 mm. These balls are sintered at 1750°C in present-day shaft ovens and following pounded, processed, and sieved to standard divisions/sizes.

Download Free Samples @ https://www.datamintelligence.com/download-sample/tabular-alumina-market

Market Drivers & Restraints

Rapid growth and expansion of the steel industry in emerging markets is the prime driver of the tabular alumina market. The emerging markets of APAC and RoW regions have seen rapid growth and expansion in the tabular alumina industry in the last decade.

The growth is mainly due to the higher growth in the industrial sectors like construction, mining, and manufacturing in these regions.

This growth in industrialization in emerging countries like China, Brazil, India, and so on has increased the need for iron, steel, power, cement, and construction materials like glass. Another primary driver in the global tabular alumina markets is increased R&D spending by vendors.

Tabular alumina is widely used in high-performance refractory materials. Refractory materials play a significant role in determining the efficiency of a furnace or kiln that is used in manufacturing industries. Hence, a lot of research is being conducted in the production of refractory materials.

For instance, a significant part of the R&D is conducted for the development of chrome-free refractory materials. Currently, mag-chrome bricks are widely used in copper production furnaces. Research is also being undertaken for the development of an alternative that is as efficient as the mag-chrome bricks.

Market Segment Analysis

The global tabular alumina market report segments the market by an application such as the abrasive industry, ceramic industry, refractory industry, and others.

Among all applications, the refractory industry holds the highest market share in 2018 with approximately 85% of the total tabular alumina market owing to a surge in the utilization of refractory materials in steel and power generation sectors.

The demand for refractory materials has grown proportionately with the growth of the power generation industry. The need for refractory materials has increased in tandem with the growth of the power generation industry. Refractories are used in this industry to control heat output during power generation.

Boilers used to extract energy from coal are coated with high-strength refractories to protect against thermal shock. Conventional thermal power plants accounted for nearly 65% of the global electricity generation in 2018. Coal-fired and fossil fuel-fired power plants also have a sizeable share in the power generation industry.

In the US, petroleum derivatives represented 70% of power generation; in China, this went up to 80%. China has the most significant thermal capacity of 900 GW, trailed by the US having a limit of 823 GW (41% coal and 59% flammable gas). Japan has the third most significant capacity of 189 GW pursued by India having 168 GW. Despite all the regulations forced on coal-fired power generation, its interest will sustain in the coming years.

Market Geographical Analysis

The report segments the market by geographic region which includes North America, South America, Europe, Asia-Pacific, and RoW. Asia-Pacific held the largest market share in 2018, and it is expected to continue its dominance during the forecast period

APAC will see an increase in its market share over the forecast period while the other regions will register slight declines in their respective market shares globally. The rapid expansion of the construction, mining, and manufacturing industries in APAC countries is the primary reason for the growth of the region.

The leading countries in this region are China, Japan, India, and South Korea. China dominates the APAC tabular alumina market as it is the largest manufacturer and supplier of magnesia, bauxite, brown fused alumina, graphite, and silicon carbide in APAC.

It also has ample supplies of raw materials for refractory material production. The presence of well-established end-use industries like iron, steel, glass, aluminum, and cement in China has resulted in a developed supply chain in the country.

The growth of the construction, automobile, aerospace, and railways sectors will lead to higher demand for iron and steel, cement, and glass, which bodes well for the refractory materials market in the region.

View Full Report @ https://www.datamintelligence.com/research-report/tabular-alumina-market

Key Players

The global tabular alumina market is fragmented due to the presence of many established and local players around the world.

The report profiles the following companies – Almatis, AluChem, Bisley & Company, KT Refractories US Company, Possehl Erzkontor, and Imerys. These companies are adopting various growth strategies like mergers & acquisitions, expansions, and new product developments for enhancing their market shares.

For instance, Almatis constructed a new Tabular Alumina plant in Falta, India to meet India’s refractory requirements. Almatis is the primary provider of alumina and alumina-based items for the ceramics market globally. Its objects are utilized to fabricate electronic ceramics production, for example, ceramic insulators and film substrates, and engineered ceramics such as wire guides and thread, cutting tools, bearing and wear-resistant engine, sealing rings, and pump parts.

For Enquiry @ https://www.datamintelligence.com/enquiry/tabular-alumina-market

About Us

DataM Intelligence was incorporated in the early weeks of 2017 as a Market Research and Consulting firm with just two people on board. Within a span of less than a year, we have secured more than 100 unique customers from established organizations all over the world.

For more information:

Sai Kiran

Sales Manager at DataM Intelligence

Email: [email protected]

Tel: +1 877 441 4866

Website: www.datamintelligence.com

0 notes

Text

Thermochromic Pigments Market Outlook and Opportunities in Grooming Regions: Edition 2030

Description:

Thermochromic Pigment Market Research Report: by Product (Liquid Crystal Material, Leuco Dyes), Pigment Type (Reversible Thermochromic Pigments, Irreversible Thermochromic Pigments), End-Use Industry (Printing Ink), Region - Forecast to 2030

Keywords:

Thermochromic Pigment Market industry, Thermochromic Pigment Market, Global Naphtha Thermochromic Pigment industry, Thermochromic Pigment Market Industry value, Thermochromic Pigment Market segment

Read more reports at: https://www.marketresearchfuture.com/reports/thermochromic-pigment-market-7409

Thermochromic Pigments Market Overview

Thermochromic pigments are materials which change color with change in temperature. These pigments are temperature-sensitive which use liquid crystal technology which leads to change in the color of liquid crystals. These pigments are widely used in traffic signs, printing inks, fire-fighting equipment, emergency signs, novelty decorations, path marking, instruments and controls.

By product, the global thermochromic pigment market has been classified into liquid crystal material, leuco dyes, and inorganic materials. The liquid crystal material segment accounted for the largest market share in 2017 and is expected to grow at a high CAGR during the forecast period owing to its consumption in precision applications as their responses can be engineered at accurate temperatures. They are widely used in electronics and in mood rings.

Based on pigment type, the global thermochromic pigment market report has been segmented into reversible thermochromic pigments and irreversible thermochromic pigments. The reversible thermochromic pigments accounted for the largest market share in 2017 in terms of value, owing to its reversible color changing property and find applications in decorative and aesthetic products. The irreversible thermochromic pigments segment is expected to be the largest in 2017 in terms of volume, due to its low cost. It can be used only once due to its irreversible nature and is used in detecting the temperature of engine components, furnaces, house appliances, and high-temperature ovens.

Thermochromic Pigments Market Segmentation

The global thermochromic pigment market overview has been segmented on the basis of product, pigment type, end-use industry, and region.

On the basis of product, the global thermochromic pigment industry has been categorized into liquid crystal material, leuco dyes, and inorganic materials.

Based on pigment type, the global thermochromic pigment market has been bifurcated into reversible thermochromic pigments and irreversible thermochromic pigments.

Thermochromic Pigments Market Regional Analysis

Geographically, the global thermochromic pigment market share has been studied across the five regions —Asia-Pacific, North America, Latin America, Europe, and the Middle East & Africa.

The North American market witnessed the largest market share in 2017 owing to the rising consumption of the product in printing ink applications. Smart packaging and technical textiles are some other applications which utilise thermochromic pigments in the region. The US is the major contributor in the region due to the growing demand for thermochromic pigments in smart textiles and food and beverages segments. The Asia-Pacific market is expected to be the fastest-growing market during the forecast period owing to the high consumption of the product in textiles; and paints & coating industry.

Competitive Analysis

RPM International Inc. (US), 3M (US), Sherwin Williams (US), Hammer Packaging, Corp. (US), NanoMatriX International Limited (China), Clariant (Switzerland), OliKrom (France), QCR Solutions Corp (UK), LCR Hallcrest LLC (US), Gem'innov (France), Smarol Industry Co. Ltd. (China), and Special Effects and Coatings. (UK) are some of the key players operating in the global thermochromic pigment market.

Read more details at: https://www.marketresearchfuture.com/infographics

Read more details at: https://www.marketresearchfuture.com/videos

Get a Sample Report Now : https://www.marketresearchfuture.com/sample_request/7409

About Market Research Future

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

Contact

Market Research Future

Office No. 528, Amanora Chambers

Pune - 411028

Maharashtra, India

+1 646 845 9312

Email: [email protected]

0 notes

Text

Electric Kiln Market (2020-2026) by Product Type, End User, Distribution Channel, and Region

Maximize Market Research's latest report, " Global Electric Kiln Market Global Demand Analysis and Opportunity Outlook 2027", offers a comprehensive analysis of the market. It provides market segments by type and shape, as well as end-user industries and regions.

Global Electric Kiln Market size was valued at US$ XX Bn. in 2019 and the total revenue is expected to grow at 4.8 % through 2020 to 2026, reaching nearly US$ XX Bn.

Global Electric Kiln Market Overview

A kiln is a chamber insulated to sustain high temperatures. A Kiln is a type of oven used for manufacturing goods that require high temperatures to set in the desired form. Products like Brick, glass, and ceramic goods are manufactured by using Kiln. Electric Kiln is the latest type of Kiln that is small in size and is used for transferring the state of the material from one shape to another at high temperature. Electric Kiln has no open flames to consume oxygen and is attached with gas input assembly.

Get a Sample PDF of the Report at : Request Free Sample Report

Global Electric Kiln Market Major Market Players

• AMACO, Inc. • Holger Krause • SKUTT • Cone Art • Leslie Ceramics • BTF Furnaces • Thermomelt SRL • JIM Engineering Ltd. • Paragon Industries, L.P. • Cress Manufacturing Company Inc. • Alpine Kilns & Equipment LLC • Even Heat • Tabletop Furnace Co. • FGK Thermal Pvt. Ltd. • L & L Kiln Manufacturing Inc.

The Market Impact of COVID-19 The COVID-19 epidemic has quickly spreaded since its inception in Wuhan (China), in December 2019. All around the globe. As of March 2020, the US and China were the most affected. The COVID-19 crisis has had a significant impact on many countries, resulting in travel bans or lockdowns. Industries. This outbreak has severely affected the global food and beverage industries. This includes office closures, cancellations of technology events, and supply chain disruptions. China is the world's largest manufacturing country and has the largest number of raw material suppliers. COVID-19 has an adverse effect on overall production because it closes factories and creates supply chain challenges. Market growth.

Segmentation of Global Electric Kiln Market by Types and Applications:

The report has covered the market size by country (regions) for the global Electric Kiln market. Segment by Application. The Electric Kiln Market is divided into the North America Europe, ASIA Pacific, Middle East & Africa. The report also includes market size estimates by region. 2019-2027 Forecasts and market size for each type and segment are included. Sales and revenue are included for the period 2019-2027.

Analysis of the Electric Kiln Market Share and Competitive Landscape:

This report provides a detailed analysis of the Global Electric Kiln Market for all stakeholders. . It also contains historical and forecasted market size information. Trends are also included in the report. The report is simple and simplifies complicated data using simple language. This report includes information on all aspects of the industry, as well as key players like market leaders, followers and new entrants. The report includes a PORTER, SVOR and a PESTEL analysis. The report also analyzes the potential market impact of microeconomic variables. This report examines both internal and external factors that can have a positive or negative effect on the business. This report will provide a clear view of the industry for decision-makers.

More about us: Maximize Market Research has been a trusted partner for many prestigious clients including Yamaha, Sensata and Etnyre in Canada, ALCOR M&A Microsoft and Harman. Maximize Market Research offers market research to both B2B and C2C regarding 5000 emerging technologies & potentials in Transportation, Chemical and Healthcare, Electronics & Communications, and Pharmaceuticals. Contact Us: Maximize Market Research Pvt ltd Email: [email protected]

0 notes