#incompressible liquid

Explore tagged Tumblr posts

Text

Well, as someone with a degree in what is essentially applied fluid mechanics, you should have known that by trying to constrict the flow, you only increase the pressure behind it and thus, the speed of its particles, right?

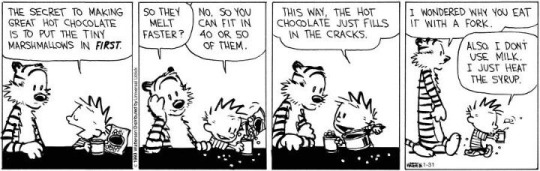

I made the Calvin and Hobbes hot chocolate.

Spoiler alert, because the marshmallows are lighter they just column out the top of the mug. I had to wait for all of them to melt to be able to drink it

as someone who has a degree in what is essentially applied fluid mechanics I should've known better. but for a moment the childish wonder just overtook me

9K notes

·

View notes

Note

Would you consider writing a poly141 version of the babytrap universe? Completely understand if it’s not to your interest to write, but I would love to see that story play out in your delicious writing style :)

ohh, absolutely. i think the best way to do it would be to have poor reader, desperate for a family of her own, and making the stupid decision to hand her resignation into Price.

and then admitting, shyly, that there's no man in your life, just a donor waiting for you to sign the papers and make the deposit for the procedure. thanking him for everything he's done, of course; but you're excited for this new chapter in your life.

He accepts it. Sure. Smiles tightly, and says, "good luck." Calls a meeting after to discuss it with the rest of the team. Closed door. A little unusual, but nothing that immediately raises your hackles. You're too busy cleaning up your desk to really pay much attention to hushed whispers in Price's office. Happy to celebrate, too, when Johnny invited you out for drinks after. Tae say goodbye properly, he said, and looking back, you should have seen through the faux sadness draped over his brow. Picked up on the giddy excitement buzzing around him as he led you to the bar, as he offered to get you drinks. Handed you an open bottle. Tipping it back for you to drink more.

Keep goin’, doe. Drink ‘er up.

Another one. Another. Your head swims. Kyle is there, hands warm on your waist, breath rippling across the sweat gathering on the nape of your neck.

“C’mon, birdie. Have a shot with me.” He coos, bringing the glass to your lips, chest glued to your spine. “Can't believe you want a baby. Fuck, birdie, that's—”

Johnny murmurs something under his breath. You blamed the three glasses of whiskey sour (Price wouldn't let you have anything else) and a shot of tequila for why it sounded like,

hope it's mine—

To the left of you, Ghost snorts under his breath. Shifts in the stool that creaks, whining under his weight. You blink through fog seeping into your head, this strange, syrupy torpor that bleeds into the corners of your vision, makes everything feel muted, far away, and turned to him with a pout.

He'd been acting strange ever since Price told him your plans. Quieter, somehow. But—

There.

Everywhere.

Your fixed shadow. Looming in the corners.

You make to ask him what the hell he's doing, why he's following you around, but the words slosh out in a tangle. Incompressible.

Ghost huffs. His gloved hand lifts, falls to your throat, holding you steady with his thumb digging shallowly into your pulse.

“Careful,” he mocks, dragging the word out like he was speaking to a misbehaving child. It bristles through you, but your tongue is thick. Liquid in your mouth. “Got a big night ahead o’you yet, pet. Try not t’hurt yourself before I get to knock you up.”

Distantly, you think you hear Gaz say something—oi, mate, maybe—but there's a shrill ringing in your ear that drowns it all out. A cotton spooling in your head. You blink—foolishly—and lean into his palm, mouth dropping in surprise. Shock.

Horror.

“Wha—?”

But it's too late, of course. What you thought were the comforting threads of a warm blanket spooling over your shoulders was the silken strands of a spider's web the whole time. Caught in their trap.

And then you come to with a warm weight pressed against your back, a thick, hairy arm slung around your shoulders. Trapping you tight against a warm, broad chest.

“Want a baby, mm?” your captain coos in your ear, humid breath tickling your skin. Dampening it slightly as he leans in close, lips pressed to the shell—a warm, wet heat that makes you tremble—and adds: “fine, love. Since you want one so bad—”

An arm lashes out of the shadows dancing around the room; through the heavy haze, the fog in your head (the last thing you remember is being offered a drink by Johnny, another by Kyle—), you struggle to make sense of what's happening around you as rough, dry fingers curl over your knee, prying your thighs apart:

“—then we'll give it to you.”

You watch, dazed, dizzy, as cherryred knuckles slip down the valley of your spread legs, the ink on their thick fingers flexing, dancing, in the slip of pale moonlight until they curl into the hem of your panties, tugging the fabric roughly to the side.

The sudden swell of cold air on your exposed cunt makes you gasp. Your knees jerking, trying to fold together to hide yourself, preserve some modicum of modesty, but the hand on your flesh tightens. Prevents you from moving. It keeps you open for their gaze. Lets them all gawk at the wide knuckles pressed against the seam of your pussy. Flushed in the low light. Dripping—

In the murk, someone groans—

“Shoulda told us sooner you wanted a fuckin’ baby, sweet’art. Woulda given you one sooner before y’had to go an’ do somethin’ so foolish—”

Foolish. Like paying for another man to put a baby inside of you when that privilege belongs to them. And them alone.

And really—

You should have known better.

#theyre so competitive about it too :/#all eagerly trying their hardest to knock you up and then refusing to get a paternity test because thats *their* baby#a vicious cycle#poly 141 x reader#141 x reader#captain john price x reader#simon ghost riley x reader#kyle garrick x reader#johnny mactavish x reader#141drabbles

2K notes

·

View notes

Text

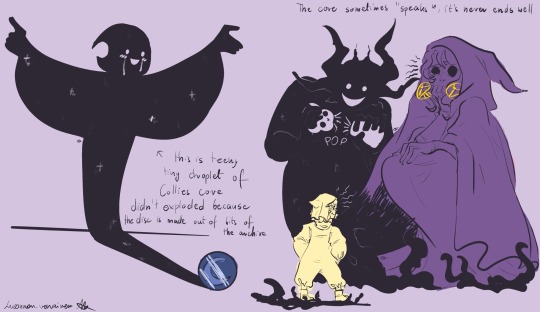

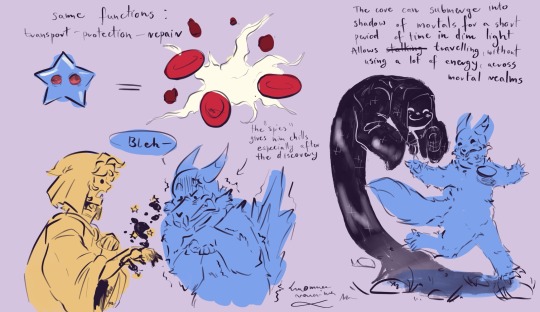

I had it in mind for a while already so I here are my thoughts and headcanon about Collie or rather the „bodily functions” of the eldritch god, here the "species" is archivist

There are some extra notes on doodles but oh boi the amount of typos there is unbearable x"d

Starting from the beginning and basic - the core:

The core is a semi-conscious substance of unknown molecular structure, if with any molecular structure, functioning as magic carrier/vector(similar to the ATP). It's a mystery whether it is really an elemental structure, a condensed energy or a form of electromagnetic waves beyond our current knowledge. In general it is said that core is pure celestial magic. It has many physical qualities of a fluid. The closest liquid to the core would be a Non-Newtonian fluid. It is a blackish, very sticky, dense liquid similar to pitch, which is highly sensitive and "reactive" to a electromagnetic field like ferrofluid. The core, most likely due to its structure and origin, is very unstable. Visible light exposure is enough to cause a spontaneous rapid reaction which ends with an explosion. Making existence on its own very unlikely. In case when the core happens to be sealed inside the archive - the semi-conscious body made of mostly gold, iridium, wolfram and glass, which contains all collected life forms - it creates what is known as an god, in this case an Archivist. This amalgamation allows to not only creat a stable form of both elements, but also develop an fully conscious eldritch, who is able to exist actively. Archivists possess almost full control over their core: shaping it, moving around, grabbing different objects with it, shielding themselves

The core is a more "human" side of an archivist. The element capable of adapting, blending, learning mortal structures both anatomical and social and rebuilding it to their own standards, experiencing emotions and many more. It plays the main role in defining what kind of person the archivist will be. Yet, the core is not equal to Archivists. It possess it's own "personality" and "opinions", similarly to the archive. Sometimes the core and the archivist are quite different and are working not very well with eachother. Situations like these are called "speaking" - a small part of core presents, usually visually, it opposing opinions against whole god's will. It's not harmful, just annoying and uncomfortable

The core is like a liquid - almost incompressible. It's quite an issue when you are a planet size entity who needs to shrink whole your body to be able to fill the archive and keep on existing, but also need to protect "guts" from exploding during day. The long, baggy robes come to aid in this case. Dresses, veils, hats, too puffed trousers and sleeves allows to hide quite a lot of the liquid from external conditions, by creating the precious shade, controlling the temperature amplitude and keeping it away from other liquids. Extra protection are given by their characteristic cloaks, which inner lining is a portal to the Grand Archive. The Grand Archive is a pocket dimensions away from intense light, where the core can be a bit safer and longer outside the capillary archive than usually. Also in order to work in an unwelcoming environment such as a planet, archivists developed a pulsating movement of the core. As the whole core cannot be at the same time in the archive, to prevent the destabilisation and consequently explosion, it is constantly flows through the body and around their closest surrounding. It's quite similar to the cytoplasmic movement around vacuoles in a plant cell or blood flow in Mollusca' s vascular system. The free flow of the core is the key reason why archivists avoid intense light and making them rather a "nocturnal" creatures

The core is inside the archive, where it's well secured and stabilised. However, there are many passages for the core to leave its shelter. These channels have no protection besides a thin membrane. They have a crucial role in an archivist's life as they are the doors to the inside of a god. All collected mortals eventually will end up inside the archive, but that requires a special spell that will reduce the mortal to smallest functional elements. Even smaller than the scrolls provide. That is possible thanks to these exact entrances. The mortal, whether in a scroll or not, will be pushed through one of those channels, encapsidated by the core, " dissolved" and placed inside one of bazillion capsules of the archive. It's unknown if the final archivisation is an painless process, but the truth is that it doesn't matter at this point - whoever was placed inside will stay there forever. The main passage are eye sockets-

The eldritch gods and deep sea creatures are extremely similar in terms of their adaptation to the environment, conserving energy idea and their life motto "eat or be eaten". So no wonder that archivists put a lot of effort to become the most efficient and effective as they could. The core shaped the archive to resemble intelligent life forms displaying a beautiful example of aggressive mimicry. As mortals are the most troublesome in terms of catching them without excessive energy loss. Looking like a young and lost in the forest nymph can really boosts chances of putting hand on curious mortals. After all who wouldn't try to figure out who the hell is this and why it's in my forest at 11 pm(at least I would, but I'm the natural selection's target for a while so I'm not the best example xd). Why go and chase when you can make them come to you. There are way more of the adaptations but it's more the archive than the core topic and I'm not writing it down today

A skilled archivist can use the surrounding matter, even quite reactive one like water, to temporarily shield the core or divide it and archive in order to create the "puppet - puppetmaster" form. A terrible thing to encounter on a long voyage or while wandering on the desert, especially if your specie decides to resist god's will-

#the collector#toh#toh collector#the owl house#the archivists#the collecter toh#the collectors#toh archivists#toh the archivists

69 notes

·

View notes

Photo

As taken from Wikipedia:

A liquid is a nearly incompressible fluid that conforms to the shape of its container but retains a nearly constant volume independent of pressure.

The proof continues to stack up that cats are in fact, liquid.

catcube

34K notes

·

View notes

Text

Pressure Safety Valve vs Pressure Relief Valve – Key Differences for Engineers

Pressure Safety Valves (PSVs) and Pressure Relief Valves (PRVs) serve similar purposes but operate differently. PSVs instantly release pressure at set limits, primarily in gas systems. PRVs open gradually and are common in liquid systems. Both are essential for protecting equipment and pipelines in Udhhyog environments.

Introduction

Pressure control is critical in industrial systems to avoid equipment failure or explosions. Two main valve types used are:

Pressure Safety Valves (PSVs)

Pressure Relief Valves (PRVs)

Understanding their distinctions is crucial for engineers, operators, and Udyog-based industries.

Pressure Safety Valve (PSV)

Definition

A PSV is a spring-loaded valve designed to open immediately when the system pressure exceeds a predetermined setpoint.

Common Applications

Steam boilers

Gas storage tanks

High-pressure air compressors

Key Features

Instant pressure release

Used in compressible (gas/steam) media

Reset automatically after pressure normalizes

Pressure Relief Valve (PRV)

Definition

A PRV gradually opens to relieve excess pressure in a system, ensuring fluid flow remains steady without abrupt changes.Common Applications

Hydraulic systems

Water pipelines

Oil processing units

Key Features

Modulated release

Used in incompressible (liquid) media

Typically requires manual reset or remains open until pressure drops

PSV vs PRV – Comparison Table

Feature Pressure Safety Valve (PSV)Pressure Relief Valve (PRV)Response Type Immediate (pop-action)Gradual (modulated)Media Gas, Steam Liquid Reset Type Automatic Manual or pressure-dependent Usage Boilers, Air tanks, Gas units Water lines, Hydraulic machines Certification Standards ASME Section I / VIII API 520 / ISO 4126

Which Valve Should You Use?

Selection Guide

Check media type (gas = PSV, liquid = PRV)

Evaluate pressure conditions (high surge = PSV)

Review Udyog compliance (UL/FM or ASME rated?)

Look for space and maintenance factors

H1: Pressure Valve Pricing in India (2025)

Valve TypeMaterialPrice Range (INR)BrandsPSV (1 inch)SS304₹1,500 – ₹3,500Zoloto, Sant, LeaderPRV (1 inch)Brass₹1,200 – ₹2,800DRP, FlowtechPRV (Hydraulic)Cast Iron₹2,000 – ₹4,500VVT, SIR

Applications in Indian Udyog &

PSV

Chemical manufacturing

Steam heating plants

Pharma & distillation units

PRV

Water treatment plants

Food processing units

Irrigation systems

FAQs

Q1. Can a PRV be used in place of a PSV?

Answer: No. PRVs are unsuitable for gas systems with sudden pressure surges. PSVs are designed for such conditions.

Q2. What certifications apply to PSVs in India?

Answer: PSVs often follow ASME, ISI, or IBR codes for safety and industrial compliance.

Q3. Are both valves required in industrial systems?

Answer: Yes. Systems with both liquid and gas sections use PSVs for gases and PRVs for liquids.

Q4. How do I identify valve types in old systems?

Answer: Check the valve nameplate for pressure rating, media type, and standard codes (ASME/API).

0 notes

Text

What is the isostatic pressing process of zirconia ceramics?

Isostatic pressing is one of the molding methods of zirconia ceramics. It is mainly a molding method that utilizes the incompressibility and uniform pressure transmission of liquid media. It can form complex, large, thin, and long products that cannot be produced by general methods, and the molding quality is high. Do you know what the isostatic pressing process of zirconia ceramics is like?

Isostatic pressing process of zirconia ceramics:

1. Powder pretreatment

The isostatic pressing process of barren powder also requires the pretreatment of zirconia ceramic powder. The fluidity of the powder is improved through the granulation process, and the friction in the powder is reduced by adding binders and lubricants. The bonding strength is improved to adapt to the needs of the zirconia ceramic molding process.

2. Molding process

Including loading, pressurization, pressure holding, pressure relief, and other processes. The loading should try to make the zirconia ceramic powder fill evenly in the mold to avoid the presence of pores; the pressure should be stable and the pressure speed should be appropriate; according to different zirconia ceramic powders and green body shapes, choose the appropriate pressure and holding time; at the same time, choose the appropriate pressure relief speed.

3. Forming mold

Isostatic pressing has special requirements for the forming mold, including sufficient elasticity and shape retention, high tensile crack strength and wear resistance, good corrosion resistance, no chemical reaction with the medium, good demolding performance, etc.

In summary, this is the isostatic pressing process of zirconia ceramics. It is highly applicable, especially suitable for experimental research and small batch production. It can simultaneously press more than two different shapes of parts in a high-pressure cylinder and produce large and complex zirconia ceramic parts, with a short production process and low cost.

Edgetech can provide various Zirconia precision machined parts such as tubes, washers, insulators, rods, flanges, and other high-strength ceramic parts to meet customers' customized requirements.

0 notes

Text

This sounds like a description of a hydraulic system or a pneumatic system.

Here's a breakdown:

Pipes: These are the conduits that carry the fluid (liquid or gas).1

Valves: These control the flow of fluid by opening, closing, or restricting passageways.2

Gas/Liquid: The working fluid that transmits force within the system.

Pumps: These devices create and maintain pressure within the system by moving the fluid.

Pounds per square inch (PSI): This is the unit of pressure, measuring the force exerted per unit area.3

Square inches: This is the unit of area used in conjunction with PSI to calculate force.4

How it works:

In a hydraulic system, an incompressible fluid (like oil) is used to transmit force.5

Pressure applied to one part of the fluid is transmitted equally throughout the entire system.6

This principle, known as Pascal's Law, allows for the amplification of force.7

A small force applied to a small area can create a much larger force over a larger area.

Examples of hydraulic systems:

Hydraulic jacks: Used to lift heavy loads.8

Hydraulic brakes: Used in automobiles and other vehicles.9

Construction equipment: Such as excavators and bulldozers.10

Pneumatic systems operate similarly, but use compressed air as the working fluid.11

Let me know if you'd like to explore any of these concepts further!

0 notes

Text

I am actually surprised that the egg would burst from fairly uniform pressure all around it, i think that the bag was too small for the sealer, and started being pulled into the side of the sealer, and eggs are notoriously weak on the sides.

Additionally, i'm not sure how fresh the egg is. as eggs age, liquids evaporate through the shell, the pocket of air in the base of the egg gets larger, and as such there would be more space for the egg to compress and would similarly increase forces on the shell.

This is also tangentally related to why they hydrotest pressure vessels, pushing an incompressible fluid into an air tank means that there isn't any energy stores in the compressed liquid, so there's no energy to explode if the air tank fails.

in any case, this calls for more egg testing.

141K notes

·

View notes

Text

#aFactADay2024

#1438: a hydrostatic skeleton is a skeleton that gets its rigidity from fluid, usually water or blood. it's generally the body shape of "worms" (see fotd#1026) - a long tube of liquid surrounded by muscles. the muscles are either circular, wrapping around the sac, or longitudinal, from head to tail. because liquids are basically incompressible, you can pretty well control your shape, size and width with relatively few muscles (eg, contracting a few ringed muscles means that section also gets longer). it makes it very efficient for locomotion and getting around strange corners, like underground. however, it does make you a little bit vulnerable compared to a proper exoskeleton, and it means it's quite tricky to get arms involved (hence why worms are all a bit limbless). if the hydrostat gets damaged, on the one hand, all you need to fix it is some water, but on the other hand it means that you have to live in a place where there's plenty of water.

1 note

·

View note

Text

Hydraulic Systems For Heavy Equipment

Modern heavy equipment wouldn’t work as efficiently without hydraulics. On account of this liquid-based system, heavy machinery can utilize small operator movements to make huge attachments and things they hold. However, knowing when to fix the hydraulic system of heavy machinery requires understanding the system. This guide gives essential data to be aware of hydraulic systems for heavy equipment.

Facts About Hydraulic Systems For Heavy Equipment

A hydraulic system is an operation that utilizes pressurized fluid to power motion. The pressure of the liquid duplicates the pressure set on it to expand the power at the output. A hydraulic system involves this fluid in cylinders or hydraulic power units to take care of business like stopping a vehicle through its brakes, lifting a crane and its load, or moving a bucket on a loader.

Inside a hydraulic system, some parts put the incompressible fluid under pressure. Since the hydraulic oil doesn’t press into a more modest space, its power gets moved to the opposite end of the oil region. The pressure applied from the oil moves an enormous piston that can work alone or with extra cylinders to move things requiring additional power.

When equipping equipment with a hydraulic system, you can expand how much work the system can manage without expanding the force you put into it. For example, hydraulic systems permit a little joystick movement to lift a tractor bucket filled with heavy rubble using heavy machinery.

Such an activity would not be imaginable with people using their muscles and digging tools to lift the same debris. For example, a steam-driven ancestor of the present hydraulic-powered heavy equipment could move the same amount of substance in a day that two men furnished with a work cart could do in about fourteen days.

Three Features of Hydraulic Systems for Heavy Equipment

The hydraulic system offers three real benefits when industries use it within heavy equipment:

Reliability: Hydraulic systems offer reliable operation if the system remains closed and the fluid stays free of contaminants.

Power density: The output of hydraulics is many times greater than the force put into the system, reaching close to 7,000 pounds per square inch in some pieces of heavy construction equipment.

Versatile control: Innovations allow hydraulic systems that move in multiple directions and have electronic controls.

The Hydraulic Systems Operation

Hydraulic systems work with one of two strategies: cylinders or hydraulic power units. Cylinders are the primary parts used to duplicate power with hydraulic liquid. However, engineering advances permit further developed operations from bigger hydraulic power units that increment the system’s working ability.

Hydraulic Systems With Cylinders

Hydraulic systems have small and large cylinders. The smaller one has a piston for work put into the system. The piston pushes down on hydraulic fluid in the little cylinder and streams into the bottom of the giant cylinder. The large cylinder has a piston that moves based on the power of the oil.

The power applied to the smaller cylinder should move farther than the movement made by the result from the large cylinder considering the movement of the giant cylinder. The amount the smaller cylinder should move is equivalent to the variety of differences in the area of cylinders. For example, assuming that the giant cylinder is multiple times greater than the smaller ones, the piston on the smaller cylinder should move multiple times the distance of the required output. To move the more oversized piston one inch, the smaller one should travel five inches.

Hydraulic Systems With Hydraulic Power Units

The other kind of system that equipment uses is a hydraulic power unit that expands the system’s abilities by using a pump and pressurized fluid to replace the small cylinder.

How Does The Hydraulic Drive Systems Work

The utilization of small and large cylinders and pistons works in some mini equipment. However, heavy equipment’s weighty loads and massive movements need robust hydraulic solutions. Therefore, hydraulic power units substitute cylinders for higher power output for this more broad equipment.

Since hydraulic power units (HPUs) acquire additional fluid from a pump at higher pressures, they can make a power that equals a greater travel distance required by a bit of piston. In addition, since these HPUs don’t have the actual size of a small cylinder to restrict them, they can make more power for the result than two-cylinder systems can.

0 notes

Text

Performance of Wholesale Pressure Switches Across Diverse Media in Industrial Settings

The performance of the Wholesale Pressure Switch is a pivotal consideration for industries that rely on precise pressure monitoring and control. These switches are engineered to operate in a variety of media, including gases, liquids, and even slurries, making them indispensable in numerous industrial applications. The versatility of Wholesale Pressure Switches is a testament to their design, which must accommodate the unique challenges posed by different media without compromising on accuracy or reliability.

In the context of gaseous media, Wholesale Pressure Switches must be capable of detecting minute changes in pressure without being affected by the compressibility of gases. This requires a high degree of sensitivity and precision, which is often achieved through the use of advanced sensing technologies. For instance, some switches employ diaphragm-based sensors that can flex in response to pressure changes, providing a reliable and consistent signal output.

When it comes to liquid media, the challenges are somewhat different. Liquids, being incompressible, exert a more consistent pressure on the Wholesale Pressure Switch. However, the viscosity of the liquid can affect the switch's performance. High-viscosity liquids may require a switch with a more robust design to withstand the additional stress. Additionally, the presence of particulates or contaminants in the liquid can impact the longevity and accuracy of the switch, necessitating the use of filters or other protective measures.

The performance of Wholesale Pressure Switches in slurries or other abrasive media presents a unique set of challenges. The abrasive nature of these media can cause wear and tear on the switch's components, causing reduced accuracy and a shorter lifespan. To counteract this, manufacturers often use materials that are resistant to abrasion, such as stainless steel or other hard-wearing alloys. Furthermore, the design of the switch may incorporate features that minimize contact with the abrasive particles, such as recessed sensing elements or protective coatings.

Temperature is another factor that can significantly impact the performance of Wholesale Pressure Switches. Extreme temperatures can cause materials to expand or contract, affecting the switch's sensitivity and response time. To ensure consistent performance across a range of temperatures, switches may be designed with temperature compensation features or made from materials that exhibit thermal expansion.

The environmental conditions in which Wholesale Pressure Switches operate can also influence their performance. Humidity, corrosive gases, and other environmental factors can degrade the switch's components over time. To mitigate these effects, switches may be sealed or coated with materials that protect against corrosion and moisture.

In addition to the physical properties of the media, the operational requirements of the system in which the Wholesale Pressure Switch is installed must also be considered. The switch must be able to withstand the pressures, temperatures, and other conditions that it will encounter in its specific application. This may involve customizing the switch to meet the unique demands of the system, such as adjusting the pressure range, response time, or output signal.

The calibration of Wholesale Pressure Switches is another critical aspect of their performance. Accurate calibration ensures that the switch provides reliable readings and responds appropriately to pressure changes. This process typically involves testing the switch under controlled conditions to verify its accuracy and adjust its settings as needed.

Maintenance and servicing are also essential for maintaining the performance of Wholesale Pressure Switches. Regular inspections and cleaning can help to identify and address any issues before they become critical, prolonging the life of the switch and ensuring its continued reliability.

In conclusion, the performance of Wholesale Pressure Switches in different media is a complex interplay of design, materials, calibration, and maintenance. By understanding the specific challenges posed by each type of media and taking the necessary steps to address them, manufacturers can ensure that their Wholesale Pressure Switches provide consistent and reliable performance in a wide range of industrial applications.

0 notes

Text

A centrifugal pump is intended to transfer fluids using concentric force generated by the rotating motion of an impeller. It converts this mechanical operating energy into hydraulic energy. The mechanical energy induced by the turbo-engine transforms it into kinetic energy or the pressure of an incompressible fluid.

Definition of a centrifugal pump

A centrifugal pump is intended to transfer fluids using the concentric force generated by the rotating motion of an impeller. It converts this mechanical operating energy into hydraulic energy. The mechanical energy induced by the turbo-engine transforms it into kinetic energy or the pressure of an incompressible fluid.

How does a Centrifugal pump work?

You require having a perfect idea of the functioning principles of centrifugal pumps. It is for better comprehending and troubleshooting your industrial pumps. The elementary principle of operation of centrifugal pumps happens to be force vortex flow. This means that when a liquid body is acted upon by an external torque, it increases the pressure head of the rotating liquid. This increase in pressure is directly proportional to the speed of the liquid. So the pressure rise is higher at the propeller outlet, which causes the discharge liquid to have high pressure at the outlet. Because of this high pressure head, the displaced liquid happens to be lifted to high heights in a centrifugal pump system.

The high performance centrifugal pump

Features

High performance centrifugal pumps are designed to provide high efficiency, large pumping capacity, improved wear resistance and reduced maintenance. Flowmore high performance centrifugal pumps are all premium pumps, offering a wide range of options. Their solid and reliable construction is suitable for both the hygienic and industrial sectors.

Applications

High performance centrifugal pumps are found in petrochemical industries, refineries and power plants.

0 notes

Text

Hydraulic Goods Lift - Legend Elevator Industries

The hydraulic goods lift is a non-scissor hydraulic lifting mechanical equipment. It is used to transfer goods between the second and third floors of industrial plants, restaurants and restaurants. The lower height is 150-350mm, especially suitable for the site where can not dig pit to install the lift. Hydraulic lifts are powerful devices used to handle heavy loads in manufacturing warehouses, construction sites, and other industrial environments. Available in a range of designs, these ergonomic lifting solutions enhance the safety and efficiency of various material handling tasks. A hydraulic lift is a device for moving objects using force created by pressure on a liquid inside a cylinder that moves a piston upward. Incompressible oil is pumped into the cylinder, which forces the piston upward. When a valve opens to release the oil, the piston lowers by gravitational force. Hydraulic systems are capable of moving heavier loads as well as providing greater force than mechanical, electrical or pneumatic systems. The fluid power system means it can easily cope with a large weight range without having to use gears, pulleys or heavy leavers.

For more details clicks here - https://www.legendelevator.com/faridabad/hydraulic-goods-lift/ITB-AFC97224

0 notes

Text

“We assume that car use is an incompressible liquid that must be routed somewhere. But it’s more more like a gas that fills whatever space it's given.”

—Ian Lockwood

0 notes

Text

Erosion Control Solutions

Erosion control solutions are a vital part of any construction project. They protect buildings and structures from damage caused by wind or water erosion, reduce environmental impacts and maintain soil quality on construction sites.

They also support sustainability, a growing trend in residential and commercial construction. Effective erosion control measures promote earth stewardship and ensure compliance with regulations, saving time and money for construction companies.

Structural

Erosion is a natural process that can have devastating effects for construction sites, including mudslides and flooding. However, erosion control solutions can be used to stabilize sites that would otherwise be at risk of such damage. These structural solutions range from retaining walls to gabions, concrete shoreline protection, and more. They can also be combined with soft-armor engineering systems, such as coir logs and vegetation, to ensure the best results at particularly challenging sites.

These innovative techniques can help prevent erosion, reduce the need for costly site repairs, and protect waterways from sediment runoff. Moreover, they can help promote sustainability and compliance with environmental regulations. Incorporating erosion control measures into the construction process at the outset can help minimize environmental impacts while providing significant cost savings for contractors.

Some examples of erosion control solutions that are both effective and affordable include silt fences, jute blankets, grassed swales, and hydroseeding. These methods work by promoting vegetation growth and slowing down runoff, thus preventing soil erosion.

Using geotextiles is another effective technique to mitigate erosion. These are fabrics with a warp-knitted design that can be made of either natural or synthetic materials. These are then placed on slopes to reduce erosion. For example, a jute or coconut fiber woven mat can be placed on a slope to stabilize the surface while plants grow.

Vegetative

Erosion that washes soil away is costly, depletes nutrients, alters the landscape and pollutes water supplies. Effective vegetation control solutions are often the most cost-effective and environmentally friendly way to restore damaged sites.

Grass, groundcovers and shrubs are natural erosion control solutions because they have wide-ranging roots that keep soil in place. They also help prevent runoff and sediment from washing into lakes, rivers and streams.

In addition to promoting plant growth, vegetative solutions such as groundcovers, grasses, and shrubs provide habitat enhancements and are aesthetically pleasing. They also work well alongside structural erosion control techniques such as rip rap, soil erosion blankets and coir fiber biologs.

Rolled erosion and sediment control blankets and mats are made of a netting or fabric that secures soil in place, preventing runoff. They also absorb water, creating an environment that encourages seed germination and vegetative growth. They are also resistant to floods, rain or wind and won’t be swept away like other erosion controls.

Stiff-stemmed vegetative barriers are narrow strips of perennial, stiff-leafed plants planted along or close to the contour to stabilize slopes. They reduce erosion by reducing the velocity of runoff water, causing upslope deposition of sediment and lessening scouring on steep slopes. They also prevent ephemeral gully formation and facilitate benching of sloping cropland.

Hydraulic

For centuries people harnessed the power of liquids in motion and under pressure for practical uses. French scientist-philosopher Blaise Pascal and Swiss physicist Daniel Bernoulli developed the laws on which modern hydraulic power technology is based.

The basic principle involves an incompressible fluid like oil connecting two cylinders. When a force is applied to one cylinder, it exerts an equal and opposite force on the other cylinder because of the law of conservation of linear momentum. This results in a force multiplier effect, allowing machines to lift huge loads with relatively small amounts of effort.

Hydraulics are a vital component of many pieces of machinery, from cranes and construction equipment to forklifts and car engines. They can lift and lower huge loads, move heavy equipment with ease, operate elevators and even control wing flaps on airplanes.

The lubrication and cooling functions of hydraulic systems are also important, keeping mechanical parts from wearing out and reducing friction between them. Hydraulic oils can also help prevent overheating by dissipating heat. They can also serve as sealants and eliminators of foreign particles. Some hydraulic oils are biodegradable and environmentally safe. They can also resist oxidation, maintain filtration efficiency and provide corrosion resistance. They can also separate water from the system or demulsify it, which protects equipment from damage. These qualities allow the hydraulic system to perform reliably in harsh conditions and environments.

Chemical

Erosion is a natural phenomenon that happens due to wind, rain, gravity and other elements. But when it’s accelerated by human activity, it leads to environmental and economic disasters like loss of fertile topsoil, clogged ditches, culverts and storm sewers which increase flooding, turbid waterways, filled-in ponds, lakes and channels, damaged habitats and structural damage to buildings, roads and other infrastructure.

One of the best ways to prevent erosion is by planting vegetation on slopes and other areas that are prone to soil degradation. But for a more permanent solution, chemical solutions are the way to go. Soil stabilizers and tackifiers help to counteract the erosive effects of rainfall, snow melt and wind on bare soil. They are effective on a wide range of slope, temperature and weather conditions.

Other products include woven fiber mats, riprap and synthetic turf. Oftentimes, these products are required by federal or local regulations for specific projects. For example, Midwest Industrial Supply’s Soil-Sement prevents fugitive dust and is used on coal, mineral, ore, limestone and clay storage piles; mine tailings, ash ponds and landfills; as well as radioactive and asbestos-contaminated waste sites.

In addition to preventing erosion, these materials are also eco-friendly and more cost-effective than traditional concrete, block or gabion retaining walls. Contact us today to learn more about the products and services we offer.

0 notes

Text

The Battle of Power Systems: Hydraulics or Pneumatics for Modern Industries

Any of modern construction or manufacturing applications are using one or all of three different kinds of power: electrical, hydraulic or pneumatic. Pneumatics provides power by means of pressurized air or gases, whereas, Hydraulics provides fluid power by means of pressurized liquids, such as oil or water. In choosing one of the two, some of the factors to be considered are cost-effectiveness, materials to be moved, availability of resources and space etc.

Each type of power has its advantages and disadvantages, according to circumstances.

Strength:

Hydraulics is the best option for strength, because the liquid medium used for its operation has a high mass density and is highly incompressible. This means that hydraulics can develop much higher levels of pressure, and can use that pressure to transmit the power that will drive your application. Industrial applications using hydraulic power may command anything from 1,000-5,000 pounds per square inch (psi) of pressure, while some specialized applications such as mining equipment or heavy lifting cranes can develop 10,000 psi or more.

When implementing hydraulics, one crucial aspect to consider is the utilization of hydraulic tube fittings. These fittings play a vital role in ensuring a secure and reliable connection between hydraulic components. By incorporating hydraulic tube fittings, you can effectively channel the immense power generated by the hydraulic system, ensuring seamless transmission throughout your application. These fittings are specifically designed to withstand the demanding conditions and high pressures associated with hydraulic systems, providing an essential link that enables efficient and dependable operation.

The media used in pneumatics have low mass density and are easily compressible. In some circumstances, gas or air can be compressed up to several hundred psi, but most mechanical applications are based on an operational pressure of only 80-100 psi. This means that pneumatic systems are largely incapable of the much larger force as offered by hydraulics, and are unsuited to the moving or lifting of heavy loads. Compressed air is also subjected to unexpected pressure drops or fluctuations which can cause operations to become jerky or unstable.

Hygiene:

Pneumatic systems win out over hydraulics in the field of hygiene, as the only thing that can leak out of your system is air. Within the system itself, the compressed air will be cleaned of oil, water or metal particles, and any other contaminants, by the filtration unit. Pneumatic systems are generally favored by environmentally-conscious companies.

You'll also be likely to choose pneumatics if you're installing systems in a clean room, a pharmaceutical laboratory, or the food and beverage industry. In these environments there must be absolutely no risk of contamination, so hydraulic systems are generally off-limits as they may be susceptible to leakage.

Whether you choose water or oil in a hydraulic system, either of these may potentially leak out via faulty hydraulic seals, hydraulic valves or worn hoses. This will contaminate your clean environment despite any safeguards you may put in place. The presence of liquids may also invite corrosion of the hardware, with a further risk of introducing contaminants. Storage tanks are also required for the fluids, and residues must be disposed of at the end of the operational process.

Speed:

Speed is one of the pneumatic system's biggest advantages. Compressed air has a high flow rate, which enables the quick release of energy and high-speed motion of moving parts such as actuators. Pneumatic actuators can achieve high cycle speeds and increased duty cycling, which deliver greater productivity. The advantage of rapid cylinder movement is further enhanced by the availability of equipment in very small sizes, ideal for use in applications where miniaturization is a priority.

Air has a much lower mass density and can flow much more quickly and easily through pipework. Another advantage of the pneumatic system is that valves and cylinders can quickly alter their state or change direction by dumping their compressed air. This can be voided straight to the atmosphere and requires no further disposal.

Water and hydraulic oil have a much greater resistance than air, with the viscosity of oil making it much slower. Although it will ultimately develop a greater degree of force and maintain constant pressure, it does not have the same rapidity as air movement and may take longer to get your system running. In the event of a leakage or emergency, hydraulic fluid may not be vented rapidly to the environment, but must be re-routed back to its tank or reservoir.

Energy:

Comparing hydraulics to pneumatics with regard to energy consumption, there are several factors to be considered. Both systems usually require an input of electrical power to drive them, and a pneumatic system needs the continuous running of a compressor to provide the compressed air. The air supply cannot be recycled and requires constant replenishment, so energy consumption in this respect may be high. Any air leakage will also a waste energy in the system.

You also have to take into account the fact that pneumatic systems lose energy through heat produced by the compression process – though there are several measures that can be taken to make your system more energy-efficient. Fortunately, air is still free of charge, so there is no need to pay for energy in obtaining, replenishing or disposing of waste products.

Hydraulic fluids can use the same oil or water over and over again after the initial start-up. Provided you have a good filtration system and keep it properly maintained, a hydraulic system can be very energy-efficient in the long run. However, electrical power is still generally required to drive the pump, and much of the energy consumed by the pump is wasted. This is because the fluid medium is in constant circulation to maintain system pressure, even though only short periods of actuation may be required to drive the application. The more viscous the fluid medium, the more energy will also be required to move it. However, significant improvements are being achieved, with technological advancements involving different types of pump and the potential of modulating drives.

Safety:

Considering hydraulics and pneumatics in the industrial environment, pneumatics is undoubtedly the safer option. A leakage of compressed air is not going to cause contamination, since air is not poisonous or corrosive, although other gases used in stand- alone or portable equipment may be hazardous. Compressed air does not generally pose a risk of fire and it won't explode, but the forcible escape of air through mechanical failure may cause physical injury.

Hydraulic fluids, on the other hand, are always at risk of potentially dangerous leaks. Even water can cause damage if it's hot enough to scald. Other fluid media such as oil, ethylene glycol, plasma and fluid synthetics may be corrosive and/or poisonous. The fluid media may be combustible and require extra safety precautions, and used oil or fluids must eventually be drained and safely disposed of. In general, hydraulic systems incorporate fewer mechanical parts, but these may be subject to corrosion and potential component failures.

Complexity:

Hydraulic systems typically have fewer moving parts and may be easily controlled with push buttons and simple levers. On the other hand, hydraulics rely on complex engineering that requires a system of valves and hoses, as well as a pump powered by an external energy source and a tank for storage of the liquid medium. It is possible to install a centralized power unit in a manufacturing plant in order to control several different hydraulic applications. Newer technology is introducing much better systems of managing speed, pressure and power.

Pneumatic system designs are also typically very simple, and operate at a much lower pressure, so their component parts may be made from cheaper and less complex materials. Since the fluid medium is not corrosive or combustible, precautions do not need to be built in against these safety hazards. Technological advances have increased the variety of uses for pneumatic systems, with miniaturization and new materials helping to reduce weight as well as bulk.

Maintenance:

Pneumatic systems are cleaner and easier to maintain than hydraulic ones, since the fluid medium is air. A regular schedule of inspection and preventive maintenance is usually all that's required to keep a pneumatic system running, e.g. checking the seals and making sure there is no leakage of air. The air does need to be cleaned of contaminants, and one of the most important maintenance procedures is the cleaning and regular replacement of the filter-regulator-lubricator unit.

With hydraulic systems, the main issue is corrosion. Unless you’re able to install pipes made of non-corrosive material, such as Electro plated, regular monitoring will be required to assess how the pipes are being affected by the fluid medium. Water may cause oxidation, and oils or other media may leave deposits that will cause corrosion. Regular checks and replacements will be required for critical components such as seals, hoses and valves.

0 notes