#igoldencnc

Explore tagged Tumblr posts

Text

Plasma Metal Cutting Machines

Plasma Metal Cutting Machines

The plasma metal cutting machines provided by our company include metal flat plasma cutting machine, metal plate and tube integrated plasma cutting machine,metal square tube plasma cutting machine, portable metal plasma cutting machine, round tube plasma cutting machine, gantry plasma cutting machine.

Do you have a thought to DIY or buy an affordable CNC Plasma Cutter? We’ll provide you with the competitive CNC Plasma Table with expert customer service to satisfied your requirements.

CNC Metal plasma table

CNC plasma tables by iGOLDEN provide a broad range of cutting solutions. Designed for top-notch cut quality, a iGOLDENCNC plasma table is durable enough to run full production for years, yet nimble enough to cut intricate shapes with ease. iGOLDEN is here to help you select the best CNC plasma cutting table to meet your specific needs.

The table cuts a 4×4 4×8 5×10 area and works well with 4×8 and 4×10 sheets. In fact, the software allows you to automatically layout and cut 4×8 or larger (up to 20 ft long) shapes.

Industrial CNC cutting table system offers all the features to get started on cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics. The included Digital Torch Height Controller maintains distance between the plasma torch and your work – producing smooth edges, sharp details and high precision.

Gantry type metal plasma cutting machine

Heavy Frame Metal Plasma Cutting Machine Sheet Tube Metal Cutting CNC Plasma Cutter Gantry Plasma Flame Cutting Machine

1. Heavy-duty gantry cutting machine adopts heavy-duty frame, heavy-duty guide rail, good stability, large span, the gauge has a width of 4 meters, 5 meters, and 6 meters, and the length can be from 8 meters to tens of meters.

2. It can realize double flame or double plasma cutting at the same time, forming 2 workpieces at a time, increasing double efficiency, saving half of the time, half of labor and one piece of equipment.

3. Equipped with high-power plasma power supply, such as 200A 300A 400A, to achieve plasma thick plate cutting. The plasma cutting speed is 3-5 times that of flame cutting, which improves production efficiency.

4. Multi-head plasma or flame straight cutting can be added, multiple workpieces at the same time, saving time.

5. The heavy-duty gantry cutting machine has beautiful appearance and high-end atmosphere, demonstrating the strength of the enterprise and improving its competitiveness among competitors.

Portable metal Plasma cutting Machine

A new portable design man carried construction is applied to the mini CNC plasma cutter machine here. Although it is small in volume, it can still cut 5ft x 10ft metal sheets as the stroke for X & Y axis is 1500x3000mm. The portable design enables us to put the plasma cnc in any location as the production needs. Let us give an example to interpret this point here. Suppose we want to cut a 12-meter-long steel plate, and such a large steel plate is not easy to move. So how do we put it on the machine to cut it? Taking the portable cnc plasma cutter here, we put it on the metal plate, and then we start the equipment to cut. Therefore, it is the right solution for the giant metal materials cut. Except for the plasma torch, it has a flame cutting torch also. 5ft x 10ft Portable cnc flame plasma cutting machine for sale with unmatched service now!

Portable metal Flame/Plasma Cutting Machine

Mini portable design, Man-carried construction; Two options available on stroke: 1500x3000mm (5ft x 10ft) and 1500x2500mm (5ft x 8ft). Mini cnc plasma cutter with portable design

The default configuration coming with two torches, one plasma cut torch, and one Oxy-fuel flame cutting torch. plasma torch of mini cnc plasma cutter

The portable cnc plasma cutter is equipped with an automatic torque height controller (THC controller). auto torch height control of mini cnc plasma cutter

Professional plasma cutting controller dedicated for portable plasma cnc – STARFIRE control system with LED display in English. mini cnc plasma cutter control system

A cut drawing library with rich resources is built into the cnc system. Production cuts can be executed by simply setting the size parameters. drawing library in the mini plasma cutter system

Plug and Play design. mini cnc plasma cutter with plug and play design ● X & Y axis is adopting rack and pinion transmission. rack on mini cnc plasma cutter.

What is Plasma Cutting?

Plasma cutting is a process that involves cutting through electrically conductive materials using an accelerated jet of hot plasma. The technology harnesses the power of ionized gas to melt and expel material from the cut, resulting in clean and precise cuts.

How Does a Plasma Cutter Work?

A plasma cutter works by sending an electric arc through a gas that is passing through a constricted opening. The gas can be oxygen, nitrogen, argon, or even shop air. This elevates the temperature of the gas to the point that it enters a plasma state. The plasma is then directed at the workpiece, melting the metal and blowing it away.

Components of a Plasma Metal Cutting Machine

Power Supply

The power supply is the heart of the plasma cutter. It provides the energy required to maintain the plasma arc. Modern power supplies are designed to deliver consistent power, ensuring smooth and efficient cutting.

Plasma Torch

The plasma torch is the tool that directs the plasma arc onto the workpiece. It consists of several components, including the electrode, nozzle, and swirl ring, each playing a crucial role in the cutting process.

Control Console

The control console allows the operator to adjust the cutting parameters, such as speed, amperage, and gas flow. Advanced consoles come with digital displays and programmable settings for enhanced precision.

FAQ

What materials can a plasma cutter cut?

Plasma cutters can cut a variety of electrically conductive materials, including steel, aluminum, brass, and copper.

How thick can a plasma cutter cut?

The cutting thickness depends on the power of the plasma cutter. Some machines can cut materials up to several inches thick.

Is plasma cutting safe?

Yes, plasma cutting is safe when proper safety measures are followed, including wearing PPE and ensuring adequate ventilation.

Can plasma cutters be used for precision cutting?

Yes, plasma cutters are known for their precision and can produce clean, accurate cuts suitable for various applications.

What is the lifespan of a plasma cutter?

The lifespan of a plasma cutter depends on its usage and maintenance. Regular maintenance can extend the life of the machine significantly.

0 notes

Text

Cabinet Making CNC Machine/ CNC Kitchen Cabinet Wooden Door

The cabinet making cnc machine is our newly-developed CNC Router with combined function of material loading and unloading for cabinet-making, widely used in home decoration, shop and office furniture. It is equipped with Italy HSD Spindle, Italy Boring unit and advanced Syntec control system, Japanese Yaskawa servo and Taiwan reducers.

Custom and general Cabinet Making Machineis one of the most popular applications for CNC routers. IGOLDENCNC CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers at a cost competitive with the less industrial designs.

📷

Features of Cabinet Making Machine:

* Square tube lathe bed with more solid structure and strong stability because of low center of gravity.

• Vacuum table in 4zones can fix materials of different sizes effectively.

• Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

• Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

• Mach3 control system, with computer controlled, very stable.

• Unique ability to save several point of origin on several workpieces.

• No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

• Auto seeking original point system, a good way to improve the working effeciency.

• Large compatibility of drawing software, such as Type3, artcam and some other CAD or CAM.

Cabinet Making Machine application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Company Information

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in router cnc, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc.We adopt international advanced producing technologies to improve our products.Our products are widely used in advertising,woodworking, artworks, model, electric, CAD/CAM Industry Model, Clothing, Package Printing, Marking, Laser Sealing and so on.And welcome to visit us for more choices.

2 notes

·

View notes

Photo

igoldencnc cheap price wood ATC cnc router machine for acrylic MDF plastic cutting #igoldencnc #cheap #price https://bit.ly/3gTk2Jd

0 notes

Text

Digital Fabric Cutting Machine with Oscillating Knife for Sale

Digital Fabric Cutting Machine are widely used in industries such as textile manufacturing, upholstery, packaging, automotive, and signage. They offer the advantages of high precision, versatility, and automation, allowing for complex cutting patterns and designs. The CNC control system ensures repeatability and consistency in the cutting process, making these machines valuable tools in modern production environments.

The CNC Fabric vibrating knife cutting machine is a cutting device mainly used for processing flexible materials. The vibrating knife cutting machine utilizes the high-frequency vibration of the vibrating knife to achieve the purpose of cutting. It has processing advantages such as flat incision, high cutting precision, fast cutting speed, and flexible processing.

CNC oscillating knife cutting machine is carried on the multi-tool cutting head–Vibration knife, Oblique knife, Circular knife, Punching knife, Milling knife,Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

IGOLDENCNC high-performance tools can crimp and cut all commonly used packaging materials with a high-quality level. A vibrating knife option is an important tool for companies that need to process flexible materials. These flexible materials include packaging foam, foam core, blender foam, corrugated plastic, or cardboard. These materials all pose challenges to traditional router planning or cutting tools, but the “saw action” of the oscillating knife makes it easy to cut these materials, providing a clean cutting edge without fraying.

Application Materials:

Used for cutting leather, gasket, PP, PE, EVA, PTFE, ETFE, carpet, carton, wood, MDF, PVC, acrylic, cardboard, rubber, corrugated carton, foam, leather, composite materials, cardboard, corrugated board, honeycomb paper, plastic film, fiber paper, plastic box, resilient glue, rubber cloth, etc.

Features of CNC Vibrating Knife Cutting Machine

1300X2500mm working size

Oscillating Knife Cutter

Creasing Wheel

MCGS CUT Panel Controller

Servo Motor and Driver

Helical Rack and Pinion and Taiwan TBI ball screw

Taiwan PMI Linear Square Guide Rail

Digital Fabric Die Cutting

Digital Fabric Die Cutting cuts shapes not easily cut with a rotary cutter. Digital Fabric Die Cutting is helpful to people who have a hard time cutting manually. Digital Fabric Die Cutting is an accurate method of cutting. Digital Fabric Die Cutting allows you to draw your own shapes.

0 notes

Text

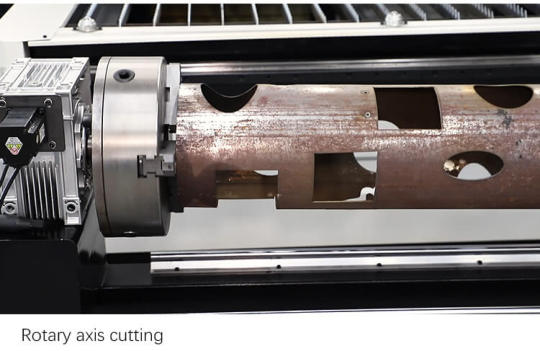

Table Type CNC Plasma Cutting Machine

iGP plasma cutting machine is used for cutting thick metals. The Hypertherm cutting head is a reliable and robust plasma source. Together with the CNC control unit and power source provides precise and high-quality cutting. P-Series plasma cutting machine is designed for precision cutting, High Performance, and High Speed. It can be equipped with Pipe cutting, a 5-Axis beveling head, multi-plasma heads, and Oxy cutting heads.

CNC plasma table machine, including flat plasma cutting machine, plate and tube integrated plasma cutting machine, square tube plasma cutting machine. The reinforced bed makes the equipment more stable during operation, compared with portable plasma cutting machine and gantry plasma cutting machine, desktop plasma cutting machine has the advantages of fast speed and high precision, and is more suitable for batch processing of medium and thin plates.

The CNC plasma cutter machine can not only meet 80% of the needs of large-scale flat cutting, but also 20% of the needs of tube cutting. It is equipped with an advanced tube-sheet dual-use CNC cutting system and a tube-sheet dual-use CNC cutting system.The software realizes the efficient and convenient interchange of cutting methods while cutting the tube and sheet material, which can not only meet the needs of users for cutting round and square tubes but also meet the special-shaped processing of steel plates.

CNC plasma and pipe cutting machine is a precision mechanical transmission device with thermal cutting technology combined with a high efficiency, high precision, high reliability. With inimitable man-machine interface, operation is simple and easy , can cut out various shapes of complex sheet metal quickly and accurately, especially suitable for automatically, thin steel non-ferrous metals, stainless steel and carbon steel plate cutting. It adopts an integrated modular design, quick installation, convenient movement.

Table Type CNC Plasma Cutting Machine Features:

The beam uses light structural design,with good rigidity structure, light deadweight .

The gantry structure, Y axis used dual-motor dual-driven system,X,Y,Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators.If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

Equipped with other advertise equipment (blister/engraving machine) . Improve the efficiency of several times.

Cutting mouth is small, tidy,and avoid a second dressing processing.

It can apply to iron sheet, the aluminium sheet, the galvanized sheet, hundred steel plates , metal plates.

The numerical control system disposes high, the automatic striking arc, the performance is stable.

Support Wentai, Astronautics Haire, ARTCAM softwares, Type3 produce standard G code way document,also can change software to read AUTO CAD softwares produce DXF form documents.

igoldencnc is professional on CNC cutting machine powered by plasma and oxy-fuel. From basic plate cutting machine, Gantry cnc plasma cutting machine, table cnc plasma cutting machine and portable cnc plasma cutting machine, igoldencnc is also Leading manufacturer in pipe and profile cutting machine, from pipe cutting and beveling, tube cutting and beveling, beam/angle steel/ channel steel/flat buld processing. By developing our own system and software in 3D profiling, igoldencnc become the top brand in metal cutting with competitive price and professional products.We have a comprehensive, made in the USA product line and the engineering expertise to customize our software and controls for your unique application needs. Our CNC plasma tables offer state-of-the-art technology and high-quality components you’d expect to find in machines that cost two to three times as much or sometimes more.

1 note

·

View note

Text

CNC Plasma Cutting Machine Factory from China

Cnc Plasma Cutting Machine

igoldencnc is professional on CNC cutting machine powered by plasma and oxy-fuel. From basic plate cutting machine, Gantry cnc plasma cutting machine, table cnc plasma cutting machine and portable cnc plasma cutting machine, igoldencnc is also Leading manufacturer in pipe and profile cutting machine, from pipe cutting and beveling, tube cutting and beveling, beam/angle steel/ channel steel/flat buld processing. By developing our own system and software in 3D profiling, igoldencnc become the top brand in metal cutting with competitive price and professional products.

A good plasma cutter can make slicing through tough material much faster and simpler, giving you a high-strength cutting tool that can work well for cutting into all kinds of different surfaces. They’re just as useful for hobbyists as they are for professional businesses, providing greater cutting strength against materials like stainless steel while also providing a range of different cut finishes for different practical purposes. But how do you choose a plasma cutter from the hundreds of brands and designs on the market today, and what sort of features are worth getting if you’ve never bought one of them before?

Table Cnc Plasma Cutting Machine

Cnc Gantry Oxyfuel Plasma Cutting Machine

Applied Material :Carbon steel, Stainless steel Aluminum and other alloys.

Industry :Especially for steel structure construction, shipbuilding, and other metal processing industries

CAD graphics by convert software to create cutting path, automatically identify inner and outside cutting, Automatically generated lead in and out line. Reasonable renewal, inner hole is preferred. Single accessory is preferred, can use.A non-closed graphics to special cutting. Length sheet cutting, reduce heat deformation efficiency.Can supply type3、Mastercam、ProE、CAXA、artcut.etc. software to connector.Kerf automatically compensation,subsidiary nesting,automatic sorting, continuous bulk cutting.Automatic rise and lower speed,automatic identify cutting start point, corner speed is stable ,improve cutting accuracy.Inner and outside setting U flash method, transfer file through outside U flash to inner U flash. Even electric power is off, data will not lose. Para stored by ways of compression code, improve store quality. With machine to set encrypt. Ensure datas are safe.

Gantry Cnc Plasma Cutting Machine

Economic Automatic Sheet Metal Gantry Type Cutting Plasma Machine For Metal

The structure of the gas profile cutting machine is strong and durable, multi-functional and easy to operate. The gas profile cutting machine working performance is very steady with high accuracy. high automation degree, high accuracy and reliability, economic price, simple to operate and maintain, etc.

CNC Flame Strips Cutting Machine

Multi torch straight strip cnc plasma cutter price is characterized of stable running and high efficiency, can be widely applied for strips cutting of carbon steel, manganese steel and other materials.

Pipe Cnc Plasma Cutting Machine

Large Diameter Pipe CNC Plasma Cutting Machine cnc Plasma Tube Cutter

The roller type is composed of a lifting head box, a roller bracket and a cutting trolley. The roller bracket adopts a fixed roller spacing method to support pipe. It is convenient to load the material and does not need to manually adjust the distance of the roller. Manually hanging the pipe on the roller bracket can automatically center it. After adjusting the center of the pipe, it will be cut with the trolley after cutting.

1.We are the first one develop the square tube cutting and beveling machine supplier in china.

2.Our control system together with Taiwan Advantech Industrial Computer.

3.Easy to operate, modeling making is easy , only need from software through the centerline, easily create pipe, arc tube, square tube, rectangular tube, angle, channel, H-beam and other components . Training time is short , only need input wall thickness , bevel angle , threading length on the software , it can cut directly with the graphics in the gallery.

4.Software with better compatibility , support TEKLA,3D ,3S, STCAD and AutoCAD .

5.twist angle support.

6.Support API ,small angle cutting.

Application

Material :Workpiece materials apply range: Mild steel( stainless steel,copper andnickel pipes,cut by plasma) Type :round pipe Industry :Widely used in water/chemical oil&gas pipeline industries, marine engineering, offshore buildings,boiler&vessels,heat exchangers,etc.

1. Multi torch straight strip cnc plasma flame cutting machine is suitable for the steel industry or make steel straight cutting relatively large amount of users.cnc plasma cutter price is very reasonable.

2. Straight torch choice is based on the number of torches used steel straight cutting width and the minimum size to choose.

3. Multi torch straight strip cnc plasma flame cutting machine can be made in front of CNC contour cutting back straight cutting multi-purpose functionality. cnc plasma cutter price is very competitive.

Multi torch straight strip cnc plasma flame cutting machine’s frame use gantry structure, bilateral drive to improve cutting quality. Host N Group front torch for longitudinal straight cut back a set of lateral torch for straight cuts, improve cutting efficiency. Multi torch straight strip cnc plasma flame cutting machine can configure torch number, longitudinal and transverse cutting configured according to user needs, can be cut more once to walk one time.

Plasma Power Source

Advanced Plasma Power Supply

It adopts China’s well-known industrial brand Huayuan industrial plasma power supply. Precise cutting, no burrs, and small bevel. Energy-saving, low consumption, more stable performance.

These operation instruction is prepared for experienced operator. you should be familiar with arc welding and cutting equipment’s operation.

Please not let non-training workers installation. Operate. Maintenance this equipment.

If you can not understand this instructions, please contact your supplier for more information.

Before installation and operation this machine, please make sure read above safety and notes.

Portable Cnc Plasma Cutting Machine

This portable cnc plasma cutter can cut any complex profiles on metals, which reduces machining again and improves productivity. This portable cnc plasma cutter supports both plasma cutter and oxy-fuel cutting.

With its USB port, the data transmission from a PC is as easy as downloading photos from a digital camera.

This portable cnc plasma cutter is an automatic portable CNC machine with THC. The cutting control system can control the motion of 2 axis, which is suitable for flame or plasma cutting. The THC controller is designed to change the height between torch & workpiece. This portable cnc plasma cutter is accurate, stable, low noise, while easy to operate. With graphic to guide your use, come with 2 booklet of user manual to explicitly guide your operation.

0 notes

Text

Woodworking Cnc Router And Cnc Wood Cutting Machine Manufacturers

One machine, hundreds of CNC applications. Since 2008, Igoldencnc has been building and supplying hundreds of applications in a range of different industries, like architecture, furniture, sign making, etc. We have manufactured hundreds of different CNC machine configurations to maximize our clients’ benefit and keep the minimum cost.

Igoldencnc is one of the premium— and quality-focused—CNC router & cutting machine manufacturers and suppliers in China. We design, develop and manufacture a multitude of high-performance yet low-maintenance computer-controlled router, laser CNC cutting machine, plasma cutting machine, digital cutting machine and water jet cutting machine.

Our high quality innovative products including CNC Wood Router, ATC CNC Router, Multi spindle CNC router, Rotary CNC Router, CNC styrofoam router machine,CNC Stone Router, Foam Router, Fiber Laser Cutting Machine, CO2 Laser Engraving Machine, Plasma Cutting Machine, Glass Cutting Machine. All our products had been certificated by ISO9001, CE and SGS, etc. Product innovation, quality assurance and customer satisfaction are our long term commitment to our worldwide customers.

Igoldencnc CNC Machine

Our series of CNC routers for wood and other materials can help create elaborate carvings, including modeling decoration and 3D carving, fabricate furniture—ranging from the cabinet to closet and door panels— make signs, such as dimensional letters and directional signage, and cutouts. With a range of CNC cutting machine, we are a manufacturer that caters to industry of all scales.

Igoldencnc supply machines to a wide variety of manufacturing sectors including aerospace, automotive, marine, recreational vehicles, 3D sculpture, concept models, pattern making, formed plastics and woodworking, sign, printing etc.

0 notes

Text

Laser Cutting Machine Supplier

Fiber laser cutting machine is an affordable, easy-to-use, and versatile tool that is used for high-speed cutting of metal plates and pipes. It can help you begin a new startup venture or increase the profits of your well-established company.CNC Fiber Laser Cutting Machine for Metal Sheet1200W fiber laser cutting sheet metal maximum thickness of 14mm carbon steel, 6mm stainless steel, 4mm aluminum, 4mm galvanized steel, 4mm brass, 3mm copper.📷Closed Type Fiber Laser Cutting Machine Pallet changer fiber laser cutting system. Germany IPG fiber laser resonator. Cutting maximum 12mm mild steel, 6mm stainless steel, 4mm aluminum, 3mm brass, 3mm copper. Adopting double gear rack closed-loop system and PMAC Controller (America Delta Tau Systems Inc), enable high processing accuracy and high working efficiency during high speed cutting.📷1KW Fiber Laser Pipe Cutting Machine Pipe laser cutting machine with 1KW fiber laser source. Maximum cutting wall thickness 12mm carbon steel, 6mm stainless steel, 4mm aluminum, 3mm brass, 3mm copper. Cutting round, square, rectangular, oval, waist round metal pipe & tube, etc. Standard Φ=20mm~200mm, L=6m. Pipes length longer than 6m and diameter more than 200mm, machine can be customized.📷Tube Laser Cutting Machine IGOLDEN LASER - tube laser cutting machine is specially for metal tube of round, square, rectangular, triangle, oval, waist tube and other shaped. The tube outer diameter can be 10mm~300mm, length 6m, 8m, 12m. tube length can be customized.📷Take the oil industry for example, the main route of oil transport is the pipeline, and because of the characteristics of the oil itself, leading to the high quality requirements of the pipeline. While fiber laser cutting machine can achieve the pipes multi-angle precision processing to fulfil the oil transportation requirement.Professional tube fiber laser cutting machine—LF60M is used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube.Fiber Laser Cutting Machine for Metal Plate A variety of functions and better performance on the fiber laser cutting machine! The Highest Stability Laser Power 1KW 2KW 3KW 4KW,Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading and further improving working efficiency.📷1500W Fiber Laser Cutting Machine for Metal Large format cutting area 2m × 4m, 2m × 6m Fiber laser 1500W cutting maximum thickness 14mm mild steel, 6mm stainless steel, 5mm aluminum, 5mm brass, 4mm copper, 5mm galvanized steel。📷6000W 8000W Fiber Laser Cutting Machine It is a hi-tech system integrating laser cutting, precision machinery and CNC technology. Mainly used for cutting and forming carbon steel sheets, stainless steel sheets, aluminum alloys, composite materials, etc. With the features of high speed, high precision, high efficiency and high cost performance, it is specially for cutting larger format metal sheets, with the cutting area 1500mm×3000mm and 2500mm×8000mm. The 6000W fiber laser cutting machine can cut a maximum thickness of 25mm carbon steel and 12mm stainless steel.Laser Cutting Machine Supplier iGOLDENCNC, as a professional laser machine application solution supplier, covers flatbed fiber laser cutting machine, metal sheet and tube fiber laser cutter, metal tube fiber laser cutter, protective fiber laser cutting machine, CO2 laser engraving cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, handheld laser welding machine, handheld laser cleaning machine and so on. As the top laser cutting machine manufacturer, the equipment from iGOLDENCNC is exported to more than 180 countries and regions around the world. Every day we accept and organize the opinions and feedback from customers from different countries and regions. We believe that this will help us further improve and optimize our products.Our fiber laser cutting

machine is suitable for cutting carbon steel, stainless steel, alloy steel, spring steel, aluminum, copper, brass, galvanized iron, etc., and has been widely used in the processing of metal sheet fabrication, steel furniture, fire pipes, automotive, fitness equipment, agricultural and forestry machinery, food machinery, advertising, electrical cabinets, elevators and other industries.

0 notes

Text

Desktop fiber laser cutter

Browse the 2021 new best fiber laser cutter buyer’s guide as follows, we’ll provide you with the competitive fiber laser cutters with expert customer service to satisfied your requirements.

Metal Tube Fiber Laser Cutting Machine iGR-T The tube laser cutting machine is a laser cutting machine specially designed for tube cutting. It can cut round tubes, square tubes, oval tubes, rectangular tubes and irregular tubes. It is equipped with a special cutting operating system, which is simple to operate, high precision and professional. Strong, suitable for professional profile cutting, widely used in sports equipment, petroleum pipelines, chemical equipment and other industries. It can cut carbon steel and stainless steel.Flatbed Fiber Laser Cutting Machine iGR-FThe entry-level laser cutting machine, really cost-effective, open-type, single platform, simple structure, convenient installation, high precision, fast speed, simple operation, convenient maintenance, affordable equipment, low operating cost, it is a sheet metal processing enterprise customized product. Dual-use Fiber Laser Cutting Machine iGR-FT The dual-use fiber laser cutting machine can realize the cutting of two different materials on the same equipment. It can cut both metal plates and tubes (including square tubes, round tubes, channel steel, angle steel, etc.). One machine with multiple functions, high cost performance, professional pipe cutting control system, high precision, full function, easy to use, simple operation, suitable for comprehensive processing and manufacturing enterprises. Dual-worktable Fiber Laser Cutting Machine iGR-E The dual-worktable fiber laser cutting machine comes standard with a fast exchange platform, which is convenient for loading and unloading. The plate cutting and loading and unloading can be carried out at the same time. The processing efficiency is high, the operating cost is low, and the equipment is affordable.It is the first choice for processing and manufacturing enterprises.

Protective Fiber Laser Cutting Machine iGR-P Full-protection fiber laser cutting machine adopts a fully enclosed laser protective cover, is equipped with a special laser protective glass observation window, which is overall beautiful, safe and environmentally friendly; at the same time, it is equipped with a special exchange platform for fast exchange speed. It is a high-end special equipment for laser cutting of sheet metal, and it is the first choice for modern manufacturing enterprises.iGOLDENCNC, as a professional laser machine application solution supplier, covers flatbed fiber laser cutting machine, metal sheet and tube fiber laser cutter, metal tube fiber laser cutter, protective fiber laser cutting machine, CO2 laser engraving cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, handheld laser welding machine, handheld laser cleaning machine and so on. As the top laser cutting machine manufacturer, the equipment from iGOLDENCNC is exported to more than 180 countries and regions around the world. Every day we accept and organize the opinions and feedback from customers from different countries and regions. We believe that this will help us further improve and optimize our products.

#iGOLDENCNC#laser cutting machine manufacturer#dual-worktable fiber laser cutting machine#laser cutting machine

0 notes

Text

Chinese laser engraving machine

Chinese laser engraver machine, 15 Years Of Professional Manufacturing, Lifetime Service, Free Consultation。Provide Customized CNC Fiber Cutting Machine Design Solution For Clients. Contact Us Now. Metal Cutting Machine。CNC Fiber Laser Machine-IGOLDENCNC LASER.

What is a Laser Engraver?

The laser engraving machine uses the thermal energy of the laser to engrave materials. The CO2 laser tube in the laser engraving machine is its core. Generally speaking, the use range of laser engraving machine is more extensive, and the engraving accuracy is higher, and the engraving speed is faster. And compared to the traditional manual engraving method, laser engraving can also achieve a very delicate engraving effect, no less than the level of hand engraving. It is precisely because the laser engraving machine has so many advantages, so now the application of laser engraving machine has gradually replaced the traditional engraving equipment and methods, and has become the mainstream engraving equipment.

If your company is in the manufacturing, electronics, or even medical sectors, sooner or later, you will require laser marking for your products and components. The best solution for this is fiber laser engraver machine. The non-contact fiber laser marking process is well-known among customers for the following reasons:

Durability

High-temperature resistance

Application to various materials

Use of nontoxic inks, solvents, and acids.

But simply understanding the advantages of fiber lasers is not enough. There are other factors that you need to consider.

These three basic factors can help you make an informed decision when purchasing a fiber laser marking system for your company.

Of course, nearly all customers will pay more attention on price. In China market, we can find so many different price. After confirmed what kind of machine we need, then we need to choose the best supplier between thousands of supplier.

Next time we will talk how to choose suppliers of fiber laser engraver.

Factors for Choosing a Fiber Laser Engraver Machine

The following are parameters you need to keep in mind when choosing a fiber laser engraver machine.

A laser with better beam quality can remove material much faster, with better resolution, and improved quality.

Laser markers with high beam quality can produce a focused optical spot size down to 20 microns.

High beam quality lasers are particularly suited for scribing and cutting materials such as silicon, aluminum, and stainless steel.

Beam Quality: Beam quality is an important parameter, as it affects the laser’s processing capability. The reasons for the importance of beam quality are simple:

Single or Multi-mode Lasers: There are two types of fiber lasers – single mode and multi-mode. Single mode fiber lasers deliver a narrow, high intensity beam that can be focused down to a spot size as small as 20 microns and are generated within a fiber core of less than 25 microns. This high intensity is ideal for cutting, micro machining, and fine laser marking applications. Multi-mode lasers (also called higher order mode), use fibers with core diameters greater than 25 microns. This results in a beam with a lower intensity and large spot size.Single mode lasers have the best beam quality, while multi-mode lasers allow for the processing of large components.

iGOLDENCNC, as a professional laser machine application solution supplier, covers flatbed fiber laser cutting machine, metal sheet and tube fiber laser cutter, metal tube fiber laser cutter, protective fiber laser cutting machine, CO2 laser engraving cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, handheld laser welding machine, handheld laser cleaning machine and so on.

#iGOLDENCNC#iGOLDEN#Fiber Laser Engraver Machine#CO2 laser tube in the laser engraving machine#CNC Fiber Laser Machine

0 notes

Text

This fiber laser cutting machine is designed for pipes and sheets. The sheet and tube fiber cutting machine adopts the cast iron bed, rack drive system, professional pipe cutting CNC system, which ensure good cutting accuracy and efficiency of the CNC laser cutting machine. Over 3500 sets CNC fiber laser cutting machine have been sold to over 80 countries. It is an ideal choice to cut plates and pipes for economic users.

0 notes

Text

iGOLDENCNC, as a professional laser machine application solution supplier, covers flatbed fiber laser cutting machine, metal sheet and tube fiber laser cutter, metal tube fiber laser cutter, protective fiber laser cutting machine, CO2 laser engraving cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, handheld laser welding machine, handheld laser cleaning machine and so on.

1 note

·

View note

Text

New wood CNC Nesting Machine For Sale

This cnc nesting machine is igoldencnc company's vacuum table machine. It working size is: 1300x2500x200mm, vacuum table, using the vacuum pump to absorb the mould on the table, it is convenience for our users is don't need the materials holders, put the mould on the table , open the vacuum pump , then can working , but it has one point that not absorb the irregular , out of faltness mould , 3D embossment. This vacuum table machine fit for the users who has the large volume productions, it can improve the working efficiency, it is save the time and labor than the aluminium profile wood cnc router.

1530 ATC Wood Cnc Router

7 factors affecting the machining accuracy of the cnc nesting machine for sale appearance design.

First of all, the premise of product performance is the scientific design of the professional team. And the improvement of product performance is the scientific research and innovation of the professional team. Secondly, the various parameters of the products of each nesting CNC router manufacturer are different, and the processing methods are different.

Therefore, the required nesting CNC router machines may not be exactly the same, so a scientific customized design is required. The support of a professional team is the root of after-sales problem-solving. And it is also the strength comparison of the first and second-line CNC nesting machine manufacturers. The configuration of the nesting CNC machine. This problem is similar to the relationship between computer hardware and computer games. Only the graphics card, memory, hard disk, etc., can drive various games if the performance of each accessory reaches the standard.

The same is true for the nesting CNC router machine, the configuration of the product is fundamental to the product performance. In the comparison of the configuration of the CNC cutting machine, the authenticity of the configuration needs to be investigated on the spot. Machine structure. Starting from the selection of materials, special steel for nesting CNC router is required. And the welding process, professional electric welder operation is required to ensure the firmness of welding. Only one positioning process can fundamentally ensure the accuracy and stability of the equipment. And this process is not available in small manufacturers. Then it is subjected to vibration aging treatment, which is sturdy and durable, and not easily deformed. The assembly process of the CNC nesting machine. Reasonable equipment assembly can guarantee the stability and accuracy of the equipment. And this process cannot be replaced by machinery, for the time being, so only professional and proficient CNC nesting machine assemblers can do it. Product inspection. After the assembly of each nesting CNC router is completed,

one of the key steps is the adjustment and quality inspection of the equipment. Before leaving the factory, each piece of equipment must complete the adjustment of various data and parameters. Every requirement on the inspection form must meet the standard requirements. And the customer should come to the factory to inspect the machine before shipping. Then the machine can be shipped to the customer only after the machine is qualified. The after-sales service of the machine. Any machinery will inevitably have mechanical failures under the interference of many external and human factors, and timely after-sales treatment is especially important. Maintenance of the nesting CNC machine.

In different processing environments, the nesting CNC router will definitely be subject to various disturbances, such as magnetic field, vibration, ambient temperature and humidity, dust, and other factors. And these external influence factors are different, and their influences are also different.

The working workshop of the nesting CNC router must be clean and tidy. And the equipment must be cleaned and tested before and after to avoid dust falling on the electronic components, affecting the heat dissipation of the equipment and the sensitivity of the contactor. Regular maintenance is a necessary task to maintain the performance of the nesting CNC machine.

Advantage of cnc nesting machine for sale:

1. Automatic work table cleaning, lubrication and knife device, which bring a high efficiency

2. Module design. Several knife modules are available.

3. Professional appearance and structure design and high precision CNC processing

4. Domestic and imported CNC system, which has a stable performance.

5. Operate easily and only a simple training is needed

6. Automatic knife changing device is available

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Nesting CNC Router ATC Tool Changer With Drilling Wood Machine Application:

1. Furmiture: Cupboard, wardrobe, panel furniture, office furniture, solid wood fumiture, wood door, table, chair, door and window

2. Woodwork: Sound box, game machine box, computer desk, sewing machine table and musical instrument.

3. Panel machining: Insulating parts, plastic and chemical parts, PCD, inner body of bullet train, bowling ramps and stainways, carbonization mixtures such as compact board, phenolic resin, epaxy resin, ABS, PP and PE.

4. Decoration industry: Carving, milling and cutting processing of acrylic, PVC, density board, artificial stone, PMMA, Plastic and soft metal plates including copper plate and aluminum

0 notes

Text

Fiber Laser Rust Removal Gun/igolden cnc laser

As a highly selective process, Fiber laser rust removal gun is a quick way to improve the quality of your welded parts. With rust and dirt layers completely removed, the number of porosities in the welding joints are greatly reduced, and their size is two to three times smaller. As a result, the welds have a greater yield strength, tensile strength, ductility and fatigue life. bw5f28sd

Laser cleaning gun from IGOLDENCNC are widely used in pulse laser cleaning machine. The following are its features:

1.Small size and light weight, convenient for manual and flexible use.

2.The front-end support frame can realize precise cleaning, and the whole cleaning work is done on the focal plane.

3.Easy to operate, power on, can be handheld or with the robot to achieve automated cleaning.

4.Laser cleaning line width and oscillating speed of the mirror can be adjusted by the button on the handheld gun. The laser cleaning gun head is made of aluminum profile, anti-vibration and high stability

The principle of Paints Removal Laser Cleaner

The principle of laser rust removal is that when rust is subjected to high temperatures, it evaporates instantly and, after plasma separation, the underlying metal does not damage the removed parts even when exposed to the laser due to its high reflectivity to light. The corners can even be cleaned perfectly. So, whether it is difficult to laser rust removal or not, it is easy to handle.

Advantages of rust removing machine:

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Advantages of environmental protection: laser cleaning is a "green" cleaning method. It does not need to use any chemical agent and cleaning solution. The cleaned waste is basically solid powder. It is small, easy to store and recyclable. It can easily solve the problem of environmental pollution caused by chemical cleaning.

2. Effect advantages: the traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium is attached to the surface of the cleaned object,which cannot be removed and produces secondary pollution. The non grinding and non-contact of laser cleaning can solve these problems; Laser cleaning can remove various types of pollutants on the surface of various materials and achieve cleanliness that conventional cleaning cannot achieve. It can also selectively clean the pollutants on the material surface without damaging the material surface.

3. Control advantages: the laser can be transmitted through optical fiber, cooperate with manipulator and robot, conveniently realize long-distance operation, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places.

4. Cost advantage: laser cleaning has high efficiency and saves time; Although the one-time investment in the purchase of laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time and has low operation cost.

Winding area , More tidy

0 notes