#i have to go to home depot or lowes to buy screws and a drill bc i don’t have what i need

Explore tagged Tumblr posts

Text

i’m just a girl, idk how to properly drill holes into a wall. the only hole that should be getting drilled is mine by my faves—

#sobbing as i try to put this mirror on the wall#i have to go to home depot or lowes to buy screws and a drill bc i don’t have what i need#only motivation is how cute the mirror is#on another good note#a really cute chair i ordered is coming today#so i won’t have to sit on the floor in my living room#sofa shopping is stressful and expensive so i haven’t chosen one yet

8 notes

·

View notes

Text

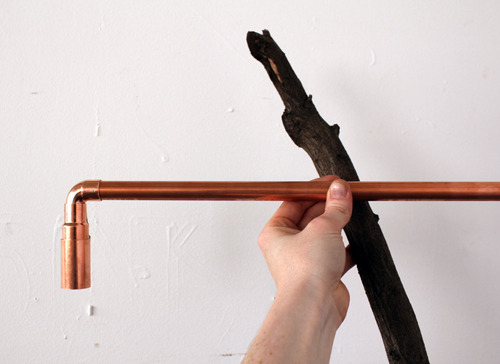

DIY Copper + Branch Floor Lamp

Project by Kate Pruitt:

We have this very annoying tree right outside our apartment that blocks all light from our windows, thwarting the sun’s attempts to warm us with its golden rays of energy. Damn you, tree! Recently I begged our landlord to at least consider trimming it back, and he finally relented, which left me with both a modicum of precious sunlight and some great large branches to use for projects! One of the felled limbs was especially long and solid and had a wonderful, gentle arc that just seemed so lamplike; I couldn’t resist. “I’ve lost my purpose. Make me a light!” it cried. Not really.

With autumn upon us, I decided to pair the branch with rich, warm copper and used a lovely sap-green color on the base to complement the season. Personally, I like the wonky bare-bones style of this little lamp, but if you wanted to dress it up a bit (my boyfriend said the copper part looked like a shower head . . . not cool dude), you could easily make or buy a solid cylindrical shade to place over the bulb. Now, don’t go hacking down trees like I did, but if you happen upon a fallen branch, I hope you’ll try this simple lighting project. Happy crafting! — Kate

Materials

large branch (Look for one that isn’t too perfectly straight or too twisty but has a slight arc to it and is at least 1.5″ thick at its base to ensure it’s sturdy enough.)

log stump slice (Mine is prop from a friend’s wedding, but you can ask around at lumber yards for these, or you could buy several thinner ones from craft stores like Michael’s and glue a stack together to make a thick base. If all else fails, try searching for firewood sellers on Craigslist, and ask if they have any stumps they could cut for you.)

4–6 small eye hooks (depending on the length/height of your branch)

15–20′ black lamp cord

chandelier socket kit

6″ copper pipe (1/2″ diameter — you can have this cut for you, or buy a standard length and use a pipe cutter to cut yourself)

90-degree copper elbow (1/2″ diameter)

1/2″ to 3/4″ copper coupling

3/4″ copper coupling (NOTE: All the copper pipe and pieces can be found at larger hardware stores like Ace, OSH, Home Depot, Lowe’s, etc., in the plumbing dept.)

high-gloss paint and foam paintbrush (any color you want, I chose sap green)

palm sander or sandpaper

drill with standard bit, 1.5″ boring bit (also known as a paddle bit) and a 1/2″ boring/paddle bit

25- to 40-watt chandelier-size lightbulb

Instructions

1. Sand your wood stump slice and cut the bottom edge of your branch with a saw to make a flat surface. Hold the branch over your wood stump to determine placement. I decided to set mine off-center for looks and to offset the arc of the lamp, but you could also place it in the center. Trace the branch with a pencil to mark the spot.

2. Use your 1.5″ boring bit to drill a circular hole in the center of where you traced the branch. Then switch to a small drill bit (1/8″ or smaller) to drill a small pilot hole directly through the center of the hole through the entire stump. This is the pilot hole for the screw or nail that you will embed from the bottom.

3. Place a good amount of wood glue onto the bottom of your branch and into the hole you made, then put the branch in place. Put tape around the base to secure it in place and set aside for the glue to dry. You may need to prop the branch against a wall to hold it in place while the glue dries.

4. Once the glue is dry, hammer a 2″ nail or screw a flathead screw into the base of the branch from the underside of the stump, using the pilot hole you pre-drilled. This is not necessarily needed, but I like to add it for extra stability on top of the glue.

5. Assemble your copper fittings and pipe together as shown below, and hold it up to the branch to determine where you want the pipe to extend. Mark the place on the branch where the pipe will come out, and also mark on the pipe where it hits the back of the branch to determine the correct length to cut the pipe.

6. Use your 1/2″ drill bit to drill straight through the branch. Drill slowly and carefully to avoid cracking the branch, and don’t go so far up the branch that the hole is almost the exact width of the branch; ideally, you want at least 1/4″ to 1/2″ clearance on the width. Use your pipe cutter to cut the pipe to length.

7a. Prepare your copper parts for assembly by removing stickers and cleaning them. Use scissors to gently strip 1″ of the lamp cord to expose the copper wires. If you examine your lamp cord, you will see that one of the cords has ridges and one side is completely smooth. You will also notice on your chandelier socket that one screw is brass/gold and the other is silver. Wrap the copper wire of the cord with ridges to the silver side, and wrap the copper wire of the smooth cord to the gold side (see second image below). Then slide the protective cardboard sleeve back over the socket.

7b. Now thread your 1/2″ to 3/4″ coupling onto the cord, with the larger side facing the socket, and slip it over the top of the socket. Slide your copper elbow onto the cord, as well, and fit the two copper pipes together. Then slide the last 3/4″ coupling over the cardboard sleeve so that the end of the copper coupling extends just a hair beyond the cardboard sleeve.

8. Slide your cord through the hole until the pipe reaches the branch, then wedge the pipe into the branch until it hits the back of the hole but does not extend out (see first image below). Then attach your small eye hooks so that the cord will match the curves of the branch. Thread the cord through the eye hooks.

9. Paint the top of your log with two to three even coats of high-gloss paint, allowing the paint to dry between coats. Tape up the cord during this process so it doesn’t get in the way.

10. Install the plug on the end of the lamp cord, using the same wiring technique from Step 7: Remove the rubber on the last 1″ to reveal copper wires and twist the copper around the screws, pairing the ridged cord with the silver screw and the smooth cord with the gold screw.

You’re done!

4 notes

·

View notes

Text

The next craft creation is ... scarecrow!

Now that I have a house I would like more kitschy and cutesy outdoor decor. I got a set of lawn flamingos the moment I found out they originated from a nearby town in Massachusetts. And for holidays I need more than just the indoors and window display that were good enough for apartment life.

One bit of fall yard decor I really had my heart set on was a scarecrow. But I'd see these lame little scarecrows at the grocery, hardware, and craft stores going for like $12 and somehow looking even cheaper than that. My parents have a scarecrow they've been putting out annually since I was little. That one is adult-sized and wears my dad's old jeans and flannel. He has a hand painted wooden cutout head. Where did that come from? A craft fair?

I hoped I'd run into something sufficient but no luck. The Granite State Fair had a few craft vendors but no scarecrow makers. With September ending I knew I would have to take matters in my own hands. But how?

I started with a blog post from Lowes on making your own scarecrow. That pointed me in the right direction. They recommended using landscaping stakes--like how you mark your driveway for a plow service. And a pillowcase for a head. That's very classic Oz type styling. I started thinking more about what around my house could be repurposed.

On Saturday, I started the car-ride portion of my errands run with an in-store pickup at Target for unrelated interior decor needs. I forgot that there's a Home Depot next door to the Target so I stopped in to find the garden stakes. I was very disappointed with their stock. All of the garden stakes were damp and gross. Many were warping. The driest set had evidence of a former spider egg sack. And the packs are 12. I don't need 12. I left empty handed.

I went to the Home Depot that's only a mile from my house next. I found the same packs of stakes and they were dry and nice. I had a 12-pack in my hands until I noticed oak fence posts sold as singles. Well, that's even better! They're taller than 3 ft, still have that sharpened end to drive into the ground, and I can buy just one! Sold! I grabbed a 36" baluster for the arms/shoulders and went on my way.

So what about the head? I don't have the painting skills to make a face as good as the scarecrow at my parent's house. We also don't have a jigsaw to make a good pumpkin shape. I decided to go for a foam carveable pumpkin. I can make a face with a knife okay. And I have a few spare lamp cords with nice LED bulbs lying around. I setup an in-store pickup order at a craft store for the foam pumpkin for Sunday morning.

Before leaving the house for Sunday errands, I did an inventory of things around the house I needed for the project. Self-driving wood screws that will penetrate the fencepost and baluster without coming out the opposite end? Check. Pumpkin carving knives? Check. Drill battery in the charger? Check. Lamp cord and bulbs? Check ... but ... Seeing them again up close I realize what I have is for indoor use only. I will need something sealed for use outdoors. And an outdoor extension cord.

The craft store is in the same plaza as a Lowes. Shh! Don't tell Kara and Shawn I went to Lowes! #LowesBlows I stop in for the outdoor lamp and extension cord. The lamp cords all end up being essentially the same as what I already have--rated for indoor use only. So I wander the entire lighting section slowly including their Christmas sections. In the end I choose a single garden path light that gets plugged in, runs a pre-installed LED bulb, and looks like its stake can be removed. And I grab a 40' outdoor extension cord.

Back at home I have a number of regular yard chores to take care of before I can start my scarecrow project. Michael returns home from work the moment I'm watching a YouTube video on how to loosen the drill bit chuck because it was too tight to loosen by hand. MB* uses the drill's motor to tighten/loosen the chuck. #SafetyThird It's nice having him around to help hold some pieces in place while I drive my screws. Soon I have my frame. And I have already cut a post-shaped hole in my pumpkin.

I carve the face next. I go for simple, classic, smiley jack-o'-lantern face. This is a friendly scarecrow.

What will my scarecrow wear? I have a bag of old jeans because I started making a braided rug out of them a few years ago. And used some to make my version of Britney Spears' infamous patchwork denim dress. So initially I thought I would grab an old paint-splattered pair of Michael's jeans that I know are in the bag. But I find my favorite jeans from 8th grade first. The knees tore open naturally with years of wear. The legs are flared and frayed. They are also paint-splattered. I have my jeans.

For the shirt I was less-sure. Since we just moved, we donated and trashed a lot of old clothing. I don't think we'll have a flannel to gift to the scarecrow. But as I think about my older clothing I recall a long sleeved tee from Yellow Jackets weekend. Basically every year I was at UR I missed out on the free shirts for Yellow Jackets weekend or was so late I got XXL. Only one year did I get an appropriately-sized shirt. And I still have it! AND I now live in a town called Rochester which is not the one in New York. Will my neighbors even notice?

For the the gloves, I knew what I 'd use right away. We have too many pairs of gloves from the now defunct Rat Snake race. Perfect for the scarecrow.

So now I need hay! We don't have a bunny anymore. And I threw out the old stale hat when we moved. Does tractor supply have a straw bale in stock? No. Does Home Depot? Yes. Back to Home Depot!

Once I'm back with my bale, I'm ready to dress, mount, and stuff my scarecrow. I'm thinking everything is set and has gone well. Until I start threading the outdoor extension cord around from the side of the house to the front. I am a few feet short. Back to Home Depot? I send Michael this time because he was headed to the grocery store anyways.

The new extension cord was long enough to run from the side door outlet to the front of the house. I was able to light the jack-o'-lantern face and plopped the remaining hay on the front stoop.

I'm very excited about my silly, homemade scarecrow. It's way better than the sad cheap ones at the store. Spooky season is in full effect! Maybe next year I will finally have the 12 ft skeleton of my dreams to join the scarecrow.

#diy#halloween#halloween decorations#halloween decor#halloween diy#scarecrow#make your own#make your own scarecrow#crafts#woodworking#power tools#upcycle#old clothes#8th grade jeans

0 notes

Text

Vanity, All Is Vanity

I replaced the faucet on the vanity in our basement bathroom about 9 years ago. When we found a puddle of water inside the vanity, I didn't expect the Moen faucet to be the problem. After shutting off the water, I noticed a pin hole in the copper tubing below the faucet. Ouch, faucets should last more than 9 years!

I disconnected the lines and took off the faucet, intending to replace it in a day or two. The next day, Eileen noticed a large wet spot on the carpet outside the bathroom. Drat! I had left the shutoff slightly open. Water had already soaked the pressed wood shelving and the veneer on the vanity was peeling off in several places. My simple faucet replacement project just ballooned in to a vanity and faucet replacement. The sink wasn't in great of shape either...

Eileen's comment: "I never liked that vanity anyway." We started looking for a new vanity at Lowes, Menards, and Home Depot. We couldn't find anything that we really liked and fit with the old decor. We checked with the local cabinet guy that installed our kitchen cabinets and he gave us an estimate just short of $2,500 for the vanity, over $3,000 for the project. Yikes! Then those fatal words came out of my mouth, "I can build one for a fraction of that." Oops.

Eileen also requested that, if I built a vanity, it be made of maple. We have maple kitchen cabinets, so it kind of makes sense. She's not a fan of oak, which is my go-to and matches the woodwork. I've never worked with maple but "might as well give it a shot."

Getting rid of the old vanity was no problem. The grandkids helped break it up and throw it in the trash.

Next we picked out a sink we liked and that would fit in the 36" space occupied by the former cabinet. Notice the narrow holes for the faucet. This sink is designed for a single unit faucet like the one we were replacing. I wanted to buy the sink first and build the frame to fit the dimensions of the new sink. More about that later.

I built the frame out of scraps of pine and cedar I had around from deck construction several years ago. I bought maple boards from Menards and a couple 2'x4' maple panels from Lowes. After building the simple pedestal frame I used some birch plywood I had from another project for the floor of the cabinet. I used the maple plywood for the left side of the vanity and the divider between the drawers and doors.

Dowels join the face to the frame

After getting the vanity partially assembled, I decided to check whether the sink would fit over it properly. To my chagrin, I then realized that the sink we just bought didn't have a channel to prevent overflow in case the water is accidentally left on. We had a long discussion about whether we actually needed an overflow channel and couldn't we just live without it? The overflow channel adds to the cost, will probably never be necessary, and we would have to return the sink we just bought. But in my thinking, now is the time prevent possible future overflows and just hoping it will never happen is foolish.

Back to Lowes to return the first sink and look for one with an overflow channel. There were none available at Lowes in that size. In fact they told us you can't even get a 36" sink with the narrow, single unit facet holes that have the overflow channel. Back to Menards where we found one with an overflow channel but it had the wide hole configuration for separate faucet and valves (see below). Had to return and replace the new faucet we had just bought for the fist sink.

Sink with separate faucet and valve handles

Once I got the new sink in with faucet and valves installed, I started to feel like the project might eventually be worth the effort. They're a little hard to see, but notice the pocket hole joints on the cross pieces at the bottom of the door and drawer openings above.

You drill those pocket holes with the handy jig below made by Kreg. The jig is under $20. Even with special screws and the maple plugs, it's not a big investment. Pocket screws (or similar joinery) are almost a necessity if you're trying to get by without visible face nails or screws. The jig makes drilling the required 15 degree angled holes easy. It would be nearly impossible to drill at that angle consistently without a jig.

Pocket hole jig, hole and hole plugged

Having never built drawers before, I decided to use simple L joints rather than trying to cut fancy dovetail joints. You don't usually notice the drawer joints anyway unless you're specifically looking for them or you are a wood worker.

I got the self closing drawer slides from Menards. Expensive, but so cool.

Drawer boxes installed without the faces glued on

Gluing on the drawer faces

Inner view of a drawer installed

Drawer faces on and doors hung

Notice the doors have a small gap between them. That gap was not planned! Looks kind of odd. I couldn't just leave them that way, so I glued a 3/8" piece of maple on the side of the door opening to bring them closer together.

Before final sanding and finishing.

Inside the cabinet after finishing.

Front view after sanding and finishing.

Side view after finishing.

Final sanding was 180 grit. I read a few posts about finishing maple that suggest sanding to 220 grit before staining and finishing. They say maple stain tends to appear blotchy, so apply a coat of wood conditioner. I disagree! Don't sand finer than 180 grit and maple will stain just fine without blotches. I certainly don't notice the difference between sanding to 220 vs. 180, and the wood conditioner doesn't always hide the blotches. I speak from experience!

After a couple coats of Danish Oil and a then a couple of coats of polyurethane, the vanity started to look halfway decent. I'll add another picture after the drawer and door handles are installed.

1 note

·

View note

Text

Restoring A Mid-Century Modern Dining Chair

What you will need:

A Chair 4 Rubber Chair Feet Upholstery Material, approx 18x18 " About a dozen short nails (about ½ " long -- roofing nails or carpet tacks will do) OR a heavy-duty staple gun & staples.

3-4 ½" screws A Hammer A Saw A Screwdriver

Optional Extras:

Padding A Drill 8-12 medium nails 1 ½ to 2 " long depending on depth of seat (you will only need these if you are using cross pieces.)

Where to Get Supplies:

Very often, places like Lowes or Home Depot will have a scrap lumber bin, where you can get boards super cheap. You have to check carefully before you buy, because very often the reason a board gets chucked into the scrap bin is that it’s warped. And it’s a grab bag as to what will be there at any given time. Still, you can get decent wood for small projects there at reasonable prices if you keep an eye out.

For padding and upholstery, if you don’t want to buy outrageously expensive new fabric, check for places near you that sell mill-end fabric and scrap leather. Or you can repurpose old coats, quilts, comforters, etc.

For hardware, your local hardware store should have everything you need. Don’t be intimidated by rows of specialty nails and screws. A nail is pretty much a nail. There’s a flat end and a pointy end. All you need to know is, what’s the combined thickness of the things you’re going to be nailing or screwing together? Then pick nails or screws that are long enough to go past the half-way point of that thickness, but not longer than the total thickness. Heavier things need heavier nails, and lighter things need lighter nails. Simple!

Step 1: Find A Chair

This is a chair that's been knocking around since I was a kid. It sat in my Mom’s back yard for about fifty years, and looks it. However, I think it looks kind of cool, and I wanted to fix it up.

I cleaned the iron frame up with a damp cloth to remove surface dirt and debris, but I decided that I wanted to leave the weathered, rustic look of the iron as it was. If you do want to clean minor rust like this and make it look black and shiny again, you can use either a commercial rust cleaner, or you can use a 50/50 mixture of vinegar and water. Once the rust has been removed, and the iron is dry, you can wipe it down with liquid car wax and buff it with a rag to make it more rust-resistant.

Step 2: Replace Rubber Feet

The old feet on this chair had worn completely through. Since it's iron, you don't want the bare legs scratching up your floors, or making nails-on-chalkboard screeches every time you move the chair. Replacing the rubber feet is easy: just measure the diameter of the legs, go to your local hardware store, and buy new ones.

Step 3: Check the integrity of the seat.

If you're lucky, whatever the base of your seat is will be in good condition, and you can just strip off the old upholstery and padding, and re-cover it. (You may even be able to keep the padding.) In this case, that wasn't an option. This chair has been rained on a million times, and the plywood was disintegrating. I took it off and threw the whole seat away. (The web is old. No spiders were harmed in the restoration of this chair.)

Step 4: Replace the Seat (if necessary)

I did not have any plywood on hand, and the local hardware place does not sell plywood, and I didn't feel like running all the way across town to Lowe's. So I bought a 3′ length of 2x8 lumber instead. I cut it down into two 15-inch lengths. Put together, this made a 15x15" square. (Because 2x8s are actually 2x 7.5s. It's confusing.) This was slightly smaller than the original plywood seat, which was 15x16″, but that was no big deal.

I have a table saw, so that's what I used to cut the wood. However, you can also use a hand-held circular saw, or even a manual hand saw. If you are using a hand saw, manual or electric, unless you have an inhumanly good eye and steady hand, you will probably want to use a straight-edge and a pencil to mark your cutting lines first. It is also a good idea to have either A) someone to hold the wood still for you, or B) a working surface to which you can clamp the wood. If you can't keep your wood steady, you WILL end up with a crooked, ragged cut. And if you're using a circular saw, you could seriously injure yourself if your wood wobbles and causes kickback.

If you're using any kind of power tools, READ THE INSTRUCTIONS FIRST and follow them. You don't want to fight with a power tool; it will win.

If I had wanted to get fancy, I could have used wood glue and a couple of clamps to glue the two pieces together. But I was being impatient, and didn't want to wait for the glue to dry. So instead, I used the new upholstery to hold the two pieces together until I could nail on supporting crossbars. (See Step 6.)

Select and Trim New Upholstery

You can use anything you like here – fabric, leather, vinyl. The only caveat is that thin fabrics will wear out more quickly, and very heavy fabric or leather can be more difficult to fold nicely at the corners. I'm using mid-weight leather for this particular piece.

Whatever you use, invest in a good pair of sewing shears to cut it. Trying to use craft scissors to cut cloth or leather will drive you nuts. If you are using very heavy leather, an Xacto knife (one of the big ones) might work even better. If you're using an Xacto, make sure that you have a surface to cut on that you don't mind scratching up. (And of course, be careful and use good knife safety.)

Cut your upholstery AT LEAST 2 inches larger than your seat all around. Remember to account for the depth of the seat and any padding as well as the breadth. If you're using fabric that frays easily, you will probably want to turn the edge under, so add extra for that. You can always trim extra length off, but you can't untrim a piece that's too short.

Step 6: Attach New Padding/Upholstery

If you are replacing or adding more padding, then place it between your seat base and the upholstery material before you attach the upholstery material. I decided that since my primary purpose for the chair was to put it next to my closet to throw clothes on, and this was never going to be a Comfy Chair no matter what I did, that I didn't need to bother with padding.

Since I was using moderately heavy leather, I trimmed away some excess at each corner of the seat so that it would fold more easily. Again, be careful and don't trim off too much. I used a mixture of carpet tacks and roofing nails to attach the leather to the wood (the roofing nails were for the corners, where I wanted something sharper to get through the multiple layers of leather.) Basically any short, sturdy nail will do. OR if you have a heavy-duty staple gun, that would also work well. Make sure you stretch your material evenly. It can be helpful to have a partner at this stage to hold the material even while you tack it on.

Once the leather was attached, I nailed cross bars (two 13″ 2x4s) onto each of the sides to keep the two seat pieces together. As you can probably tell, the 2x4 was just an old one I happened to have in my scrap lumber supplies. Since the frame of the chair is screwed directly to the two seat pieces, I suppose I COULD have left the crossbars off, but I wanted the extra stability. Ideally I would have used framing nails to attach the crossbars, but I was out of framing nails, so I used finishing nails instead. (Like I said, for a project this small, nails is nails.) I made sure to measure the iron seat frame first, and attach the crossbars so that there would be room enough between them to screw the frame of the chair to the seat.

There are four nails per cross bar -- because they’re finishing nails, they’re hard to see.

Step 7: Reattach Seat

Once the seat was put together, I screwed the metal frame of the chair onto the seat, right between the cross pieces. Weirdly, this particular chair only has three screws holding the seat to the frame; most chairs of this general type use four. I re-used the original screws. Optionally, you can use a drill to start your screw holes. Be sure to pick a drill bit a little smaller than the diameter of your screws.

And voila, one restored Mid-Century Modern chair!

15 notes

·

View notes

Text

How to Build a Wooden Planter Box

Download Article

Download Article

You're reading: How to Build a Wooden Planter Box

Want to exercise your green thumb, but don’t have the space? Maybe you have the space, but your soil is too harsh to be cultivated easily? A wooden planter box is a cheap, easy, and effective way to solve these problems! Planter boxes can be made any shape and size, and out of a variety of materials. You can learn how to build one of these planters quickly and with little damage to your wallet.

Sizing and Cutting the Wood

1

Decide how large (or small) you want your planter box to be. Your decision should be based on how many plants you want to have in each planter, as well as the size of the area where you will be putting your planter. For this article, we will build a smaller box that is about 4 feet by 2 feet (121.9 by 60.9cm).

2

Purchase your wood. Untreated wood or cedar will work well for this project as they are both easy to work with and can hold up against the natural elements your planter will be exposed to. For a small 4×2 ft (121.9×60.9 cm) planter, you can buy a 12-foot (365.76-cm) board, which you will cut down to form the sides of the planter. The width should be at least 10 inches (24 cm).You will also need a piece that will act as the bottom or floor of the planter if your planter is going to be used on a deck or similar surface. If the box will be over soil, you can place a layer of flattened cardboard boxes on the bottom to act as a weed barrier.[1]

Pressure-treated lumber contains chemicals that will kill plants in the box and can things like arsenic to your food if you are growing vegetables. A safe alternative is using ACQ-treated wood, a process which does not use any toxic chemicals.[2]

3

Cut the wood down to the right sizes. Use a measuring tape to measure out each side. Mark the places where you will make your cut with a pen or pencil. Use an electric saw or standard hand saw to cut the pieces to size (two 2 foot boards and two 4 foot boards), taking care to make the cuts as straight as possible.[3]

If you do not have a saw of any kind, or prefer to not make the cuts yourself, you can ask the workers where you purchased your wood to cut it down to the measurements you need. You may need to pay a small fee, but some lumber and hardware stores will cut your planks down to size for free.

Attaching the Boards

1

Create pilot holes in two of the boards. Pilot holes are holes drilled into the wood to ensure that the wood won’t splinter when you insert the screws into it. You only need to do this on the two end boards (the shorter boards). You should make three pilot holes, 3/4 inch (1.91 cm) from the end edge of the board. The middle hole should be centered in the middle of the width of the board.

2

Fasten the boards using galvanized screws. Galvanized screws are better for outdoor planters because the galvanized metal can stand up to the elements and will not rust. Line the boards up so that the boards with the pilot holes are positioned on the outside corners. Use a drill and drill bit to make sure that each screw goes through each hole and into the adjoining board.[4]

You can also use a screwdriver, rather than a drill and drill bit.

3

4

Drill drainage holes in the bottom of the box. Turn your now fully-formed box over and use your drill to create four or five drainage holes in the bottom of the box. These holes are very important, as most plants will develop diseases if they get ‘soggy feet’, meaning that their roots sit in very wet soil for too long.

Read more: How to create a low maintenance garden

If you have constructed a much larger planter box, you should consider adding a few more drainage holes.

Again, if your planter will be over soil, this is not necessary. Simply use flattened cardboard as the bottom of your box.

Adding the Finishing Touches

1

Place a layer of nylon or vinyl screen inside the planter. Doing this will protect the wood of your planter. Cut the screen so that it is the same size as the board you used for the bottom of the planter. Lay it in the bottom of the planter and fix in place with some small nails. Make sure that you remember to drill drainage holes in the screen that line up with the drainage holes in the bottom board if your box has a bottom.[6]

2

Sand any rough edges. Doing this will give your box a nice finished look, but it is not absolutely necessary to do. Take a sander or a piece of sandpaper and run it along the edges and corners of the box. Run it along the sides of the boards to vanquish any potential splinters.[7]

3

Paint, prime, or stain the outside of your planter. Pick out some paint that matches your backyard or home’s decor, or stain your planter to really bring out the wood’s colors. You can also choose to leave your wood alone, as cedar is a beautiful wood all by itself.

Do not treat the inside of your planter, as this may contaminate the soil and your plants. Instead, use a plastic liner (with holes) to protect the wood.

4

Add a thin layer of gravel, then add the compost or potting soil. The gravel will help to drain the planter box. The type of soil or compost you use will depend on the types of plants or flowers you intend to add to your planter box.[8]

5

Add your flowers, plants, or whatever seeds you plan to cultivate. Don’t forget to water! For ideas on types of flowers and plants you can add to a planter box, click here.

6

Enjoy your new planter box!

Community Q&A

Add New Question

Question

What do I make the bottom of the box out of?

Andrew Carberry has been working in food systems since 2008. He has a Masters in Public Health Nutrition and Public Health Planning and Administration from the University of Tennessee-Knoxville.

Food Systems Expert

Expert Answer

Question

How long should the piece of wood be?

Andrew Carberry has been working in food systems since 2008. He has a Masters in Public Health Nutrition and Public Health Planning and Administration from the University of Tennessee-Knoxville.

Food Systems Expert

Expert Answer

Question

Can I set the planter box on rocks?

There is no reason why not. I am building 4 planter boxes to put in an area between fences and the whole area is rocky. I am not putting bottoms on them because once they are filled with dirt, the rocks should provide good drainage.

Question

Where do I buy the vinyl screen?

You can purchase screen at Home Depot, Lowe’s, Ace Hardware, etc. I prefer fiberglass screening, it seems to last longer, and I line my planters with landscape fabric.

Question

Can the box be placed on grass or soil?

Yes, but consider adding ‘feet’ to elevate the box off the grass or soil, or it will rot.

Read more: Your Complete Guide to Growing a Successful Vegetable Garden

Question

How deep should it be?

If you use 12-inch-wide boards (1″ x 12″ x 8 ft.), the planter box will be 1 ft. deep by default.

Question

What size of galvanized screws should be used for this planter?

Many sizes would work depending on the wood that you use. When working outside, deck screws are a great choice, probably 2 inch deck screws.

Question

What sort of wood should I use to build my planter box?

Cedar, redwood, and pressure-treated woods are all great choices. Cedar and redwood are both naturally resistant to insects and weathering. Pressure-treated wood uses chemicals to make it insect and weather resistant, so it may not be great for areas with children or pets. Cedar and redwood are safe for children and pets because they are natural, but they can also be more expensive than pressure-treated wood.

Question

How many drain holes do I need for a 6′ x 2′ planter box 3′ with legs?

Drill holes every 6 inches for drainage, or use the cut end (boxed end) of the cedar to place them randomly.

Question

How do I put legs on a planter box?

3 X 3 boards are the best. You can even attach wheels to the bottom of them for mobility. But, when raising your planter off the ground, you will need to add thin strips of wood to the inside bottom of the box for support. The corners of the bottom board will have to be cut to accommodate the 3×3 legs. If you don’t want the legs to be visible from the dirt surface, don’t bring them up to then top of your box.

Show more answers

Ask a Question

200 characters left

Include your email address to get a message when this question is answered.

Submit

Video .

By using this service, some information may be shared with YouTube.

Tips

You can take these plans and scale them down for a window box.

Warnings

As always, when working with tools, don’t forget to use the necessary eye and hand protection.

Things You’ll Need

Four lengths of wood. We used 2″x9″ (two 4′ lengths two 2′ lengths)

Another board cut to the size of the bottom

Drill or screwdriver and galvanized screws

Piece of nylon or vinyl screen

Small nails and a hammer

Planting soil

Plants or seeds

About This Article

Article SummaryX

To build a wooden planter box, start by cutting some wooden planks so you have 2 that are 2 feet long and 2 that are 4 feet long. Then, use a drill and galvanized screws to attach the ends of the planks so they form a long rectangular box. Next, cut out a wooden board for the bottom of the box and drill a few holes through it for drainage. Finally, secure the board to the bottom of the box with the drill and some more galvanized screws. To learn how to add the finishing touches to your wooden planter box, scroll down!

Did this summary help you?

Thanks to all authors for creating a page that has been read 619,889 times.

Reader Success Stories

“I want to thank you because I couldn’t find any idea for my FFA banquet. I’m an 8th grader and I’m assistant…” more

Did this article help you?

Source: https://livingcorner.com.au Category: Garden

source https://livingcorner.com.au/how-to-build-a-wooden-planter-box/

0 notes

Text

GARBAGE DISPOSAL

A waste disposal is appended to the base of your sink and is there to squash food and other waste into minuscule pieces with a hardened steel edge. Tempered steel cutting edges fend rust off contrasted with different models that don't have them which causes issues or rusting of the edges. Size of the engine is an interesting point also. Brands like Kitchen Aid accompany a 1 HP engine which slashes up food so the channel won't get obstructed.

Most waste disposals are about $150 or so at Home Depot or Lowes and are genuinely simple to introduce yourself (takes around 2 hours). As a matter of fact I supplanted my waste disposal so I don't know how it would be on the off chance that you simply put one in new. Regardless, I can't envision it's a lot harder as long as you have some fundamental devices (handymen clay, Philips head screw driver, level head screw driver, and so forth). Ensure that the components of the waste disposal you select will fit in the zone under your sink (our own is an advanced house and it scarcely fit). Underneath we examine the straightforward method for the establishment of a waste disposal.

Removal Buying Guide

The most well known kind of waste disposal is the In-Sink-Erator and that is the thing that we put in. You will require an electric outlet under the sink to connect the waste disposal to. You will at that point need to join the removal to the base of the sink opening utilizing the "upper mounting gathering" piece. At that point put the hoses from the dishwasher (in the event that you have one) to the waste disposal. Surely we have overlooked the subtleties, yet the guidelines with our removal were great.

In the event that you are not a DIY kind of individual, at that point maybe having a circuit tester (for the outlet plug) and a handyman handle the task is the smartest option. Our companions had a similar model introduced by a handyman and it cost about $120. Lowes has a magnificent online instructional exercise "on the best way to introduce a waste disposal or you can watch Youtube recordings on the subject. Hope to go through at any rate 60 minutes, have a few towels prepared in the event that water spills, and expectation that your underside to your kitchen sink is fairly standard so you can have a simple introduce measure.

Waste Disposal Reviews - Want to perceive what experts and property holders need to state about food squander disposers? An ongoing article in Consumer Reports magazine worked superbly of separating the top disposers. They tried 15 waste disposers taking care of them with things like potatoes, celery, food scraps, and hamburger ribs. They appraised both the constant feed disposers and the group feed models on speed, granulating fineness, commotion, and the capacity to deal with vegetable pieces. You can peruse their top rated waste disposals online here.

Best Garbage Disposal:

Contingent upon who you converse with, the best waste disposal available is available to all. Accepts that Waste King disposers are the unrivaled brand. They are known as the Waste King Gourmet waste disposals (used to be known as the BoneCrushers from Sinkmaster). "Their boss quality, simple upkeep and promptly accessible fix parts settle on them your most ideal decision".

The Waste King L-8000 Legend Series is a top dealer on a few sites with close to consummate surveys - proprietors state the hardened steel pounding segments, prevalent protection and 1HP engine make this the ideal waste disposer. The guarantees on the Waste King models are the best in the business - that is continually soothing to know as a purchaser. For littler 1/3 torque engines on waste disposals, the Whirlaway name rings a bell. Albeit less ground-breaking, they can at present work superbly. The best models are the Whirlaway 191 and Whirlaway 291. View the most well known Waste King waste disposals here.

Group Feed Disposers - As we referenced prior, the Insinkerator brand is very mainstream and performs well indeed (from my involvement in) amazing engines and extraordinary guarantees. In audits we read on the web (more than 50 recorded at and 46 are 5 of 5 stars) and in Consumer Reports, the InSinkErator 74028 Compact Evolution Household Food Waste Disposer, Gray is the model to go with.

The Evolution Series disposers are known for their boss granulating and for being calmer than the opposition. The InSinkerator has a 3/4 HP engine, 2 crush stages, and a long term home guarantee on parts and work. Numerous proprietors portray it as "tranquil and productive" or "best removal we've had". A significant number of their different models get similarly as excellent grades from proficient handymen and property holders the same. The one in particular that scored seriously was the Insinkerator Badger - audits no matter how you look at it were not exactly noteworthy. You can see the most well known InSinkerator disposers online here.

Waste Disposal Repair - Fix Garbage Disposal:

So as to decide how terrible the fix employment may be, you have to do some good judgment investigating with your waste disposal. To begin with, in the event that it doesn't turn on and there is no "murmuring" sound, at that point you have an electrical issue. You may need to hit the Reset button (red) at the base of the removal or check your electrical switch to ensure the electrical parts are working alright. On the off chance that after an exhaustive electrical review and substitution of the switch it despite everything doesn't turn on or make a commotion, at that point you have to supplant the entire unit. Another basic issue is a stuck flywheel and the removal makes a murmuring clamor.

Utilize the counterbalance wrench that accompanied your removal and addition it into the flywheel turning opening and turn it clockwise. This should help to unstick the flywheel or impeller. Test the framework again with little eruptions of water while turning the disposer on. On the off chance that you have a spilling waste disposal (that is the thing that I had), at that point see where the water is coming from (sink rib, dishwasher association, release drainpipe) and fix jolts, supplant free lines or fittings.

I had only a significant connection breakage that the entire unit should have been supplanted. For moderate depleting or blockage issues don't utilize synthetic channel cleaners (they harm removals), eliminate the significant segments and check for stops up. In the case of nothing is spotted, at that point proceed with the cycle with a sink drill down the significant lines that lead from the removal to check whether you can unclog the hindrance. At the point when all else falls flat, call a handyman. To help keep your removal clean, never put things like potato skins, artichoke leaves, or celery stocks in the waste disposal since those are extremely difficult to crush and will in general jam and stop up the removal.

0 notes

Text

Arplis - News: Great Tips for Selling a Tiny House: Your Guide to Landing a Big Offer

In 2007, tiny-home enthusiast and builder Jay Shafer gave Oprah a tour of his 97-square-foot house and the modern Tiny Home Movement took off. Today, it’s estimated that there are 10,000 tiny homes gracing the U.S., and over half of Americans are open to the possibility of buying a house of tiny proportions (under 600 square feet). Good news for you, now that you’re selling one! Generally, the number of tiny homes sold per year averages about 30,000 nationwide and has risen in lockstep over the years with the blossoming interest in simple living. However, selling a tiny house in a country where the average home runs about 1,600-1,650 square feet remains an intimidating prospect. To overcome the biggest buyer objections around the lack of space, limited privacy, and zoning complications, follow these tips for selling a tiny home from tiny-home builders, owners, and an agent who managed to attract multiple offers on her client’s tiny cabin. With their advice, you’ll be in great shape to market this lifestyle while highlighting the versatility and benefits of your unique tiny home, whether it’s on wheels or affixed to a piece of land. We’ll cover how to: Create curb appeal with window boxes, vertical gardens, and fresh paint Keep your staging minimal, using mirrors and curtains to your advantage Showcase your tiny home’s space-saving and convertible features Highlight your tiny home’s unique features and upgrades Sell the tiny home lifestyle, from jet-setting to cost savings Capture photos with a wide-angle lens on a sunny day Price your tiny home with a pre-listing appraisal and top agent’s expertise Be clear about local zoning and building rules Source: (Tiny Home Builders)Create curb appeal with window boxes, vertical gardens, and fresh paint Tiny homes get automatic curb appeal points for being so darn cute. But a few simple projects can take your tiny home exterior to the next level (and improving curb appeal is the no. 1 thing you can do to boost the marketability of your home, according to nearly 77% of top real estate agents across the country polled by HomeLight). 1. Install window boxes for a touch of charm Window boxes filled with colorful plants are ideal for improving curb appeal when you don’t have a lot of outdoor space to play with or if you’re selling a mobile tiny home. You can purchase window boxes from any major home-improvement retailer. They come in a variety of colors and styles to match your home, and you can spend as little as $10 or as much as $100 on a single box depending on how high-end you want to go. The more expensive boxes tend to have more intricate detailing (like this White Cape Cod Self-Watering Window Box for $65 — lovely!), but the simpler and cheaper designs come in shades of green, black, and dark orange to boot. You can hang window boxes yourself with a drill, 3-inch galvanized screws, and this handy guide from This Old House, a 40-year-old home-enthusiast brand. (Make sure to choose a window box that’s about 6 inches longer than the window). Then it’s a matter of which plants to choose for your boxes. According to the Old Farmer’s Almanac, a periodical started in 1792, window boxes look best with lots of plants arranged close together. The Almanac recommends anchoring your window box with some base flowers like: Petunias Geraniums Zinnias Nasturtiums Begonias Then, you can fill the gaps with varieties like wandering jew, ivy, euonymus, heather, or vinca. Succulent window boxes with special draining trays are also rising in popularity — they look great but remain low-maintenance! You can buy a variety of succulents for around $20. 2. Make your own vertical gardens Don’t have a huge yard with big mature trees and perfectly groomed shrubs? Such is the plight of tiny-home owners the world over. Vertical gardens — which are plant arrangements that grow in an upward or stacked fashion — are another great way to add curb appeal to your tiny home. There are lots of different types of vertical gardens, but here are a couple of the easiest ones to DIY: Flowerpot tower (from The Self Sufficient Living) Buy a few terracotta planters of ascending sizes. Use the biggest planter as your base, and fill it with soil. Place a rod in the middle of a planter. Stack remaining planters on top of the base, from big to small (like a pyramid) using the rod to connect them. Add flowers of choice to each planter. Violets, nasturtiums, daisies, marigolds, and pansies will be tower-garden friendly, according to TowerGarden.com. Tiered hanging baskets (from BobVila.com) Purchase a few durable, woven hanging baskets like these Madras storage baskets from World Market. Connect the baskets with braided rope in a color of your choosing. Add your potting soil and flower varieties, and hang the tiered baskets with a strong hook. Ladder garden (from Ana-White.com) Ladders serve more than their practical purpose of helping us reach high places. The right kind of ladder (preferably wood) in the right setting can be the perfect structure to support a vertical garden that you prop up against your tiny home. Ana-White.com has a great tutorial for how to build your own ladder garden planter using cedar fence pickets. The project costs about $20 but does require using a compound miter saw and a staple gun. However, this DIY option allows you to add your soil and flowers/herbs directly into the runged planters. Alternatively (for the more novice DIYers) you could buy a tiered ladder like this natural wood variety from Home Depot ($131), and place your plant containers on top of each tier. You could even paint the ladder a fun outdoorsy shade like robin’s egg blue or sunny yellow. 3. Give your front door a fresh coat of paint Take a look at the condition and color of the front door. If it doesn’t wow you, dress it up with a fresh coat of paint for a dash of instant pizzaz. If your tiny home exterior is neutral, consider a bold color like Moroccan red, blue loch, lemon twist, or sassy green. Alternatively, you could stick with earthy tones like olive, jade, or black. Source: (Filios Sazeides / Unsplash)Keep your staging minimal, using mirrors and curtains to your advantage When it comes to staging your tiny house, less is more. With so little square footage to work with, it’s very easy to over-stage, which makes the space feel cluttered and small. Your top priority, before you bring in any extra decorative items, is to keep an exquisitely neat and tidy home. If your closets and cabinets look stuffed, eliminate items such as excess coffee cups, clothes, and kitchen gadgets to make each precious storage area appear sufficiently spacious. What you do with the overflow is up to you: Sell, digitize, donate, and box up anything you can’t part with. Temporarily place your boxes in an offsite unit or friend’s garage, but get it off the property. As for other tiny home staging techniques: Limit your use of rugs to keep the room-flow open and stick to smaller furnishings proportionate to your square footage. Paint walls a shade of white. Draw the eye outdoors using large mirrors. Hang curtain rods 4-6 inches above windows and use rods that extend 3-6 inches beyond both sides of the frame. Select curtains with a subtle vertical stripe or pattern to add the illusion of height to the window. Showcase your tiny home’s space-saving and convertible features People out shopping for tiny homes may be coming from regular-sized, single-family residences with walk-in closets and tons of cabinets. They know they’ll need to downsize their belongings to comfortably live in a tiny house and shift gears on how many guests they can entertain. However, the more you can show off the storage potential and modifiable room arrangements of your tiny home, the more attractive it will be to those coming from different ends of the “I’m a minimalist” spectrum. Take, for example, the 304-square-foot, off-the-grid cabin of John and Fin Kernohan in the woods of Georgia. The Kernohans, who are also the founders of United Tiny House Association, an organization for the advocacy and support of the tiny house movement, shared that their L-shaped sitting area serves three purposes: Entertaining room in the daytime and evenings Sleeping quarters with two convertible single beds for overnight guests Storage with 48 cubic feet of space beneath the seating View this post on Instagram “Living in 304sqft off-grid doesn’t mean ‘roughing it’… we love our Beloved Cabin!” – John & Fin Kernohan #belovedcabin #tinyhousemovement #tinyhousepeople #tinyhousefestivals #tinyhousecommunity #tinyhouses A post shared by United Tiny House (@unitedtinyhouse) on Mar 21, 2017 at 3:30pm PDT If the Kernohans were (theoretically) selling their tiny cabin, they would want to include images of this space that illustrate each of the three setups and include a summary of the convertible options in the listing description. This differs a bit from a regular listing, where you’d likely capture photos of each room but wouldn’t have to demonstrate multiple arrangements. Highlight your tiny home’s unique features and upgrades Our homes are extensions of ourselves, and that sentiment is amplified among tiny-home owners. Whether you built your tiny home from scratch or selected each update with care, you take great pride in every little detail. Meaghan Baker, a top-selling real estate agent in Dickson, Tennessee, found this to be the case when she sold a client’s one-bedroom, 528-square-foot house in her area. “When I was doing the property description, I tried to really focus on the fact that it was a little cabin, a getaway in the woods,” she recalls. “The house had a connection to the land and it also had a connection to my client — because that’s his family’s land and he really put a lot of thought and a lot of his heart into creating this home for himself.” This particular seller had invested in what Baker estimated to be $3,000 African mahogany countertop in the kitchen. He also hand-built — with wood right there from the land — a cherry barn door to separate the bedroom and living room. The best way to convey these details about your own home to potential buyers? Have a conversation with your agent about your home’s history and what makes it stand out. “I really sat down with the client and asked him to give me all the details on every type of wood he used and where he used it,” Baker says. “It was really important to emphasize that in the listing.” Her strategy worked: The tiny home she was selling (much to her surprise!) attracted multiple offers and sold over asking. At the end of the day, ensure that whatever features are unique to your tiny house shine through as you market the property, whether it’s a high-end stackable washer and dryer, your dedication to using sustainable building materials throughout, your handy bike storage contraption, or a rooftop terrace. If your tiny home is permanently placed (i.e., not on a trailer with wheels), highlight the parcel of land your property is on. Show how it’s nestled at the foot of a mountain or situated in a beautiful wooded area. High-end professional photography is a must, and you could even capture some aerial shots using drone technology. Sell the tiny home lifestyle, from jet-setting to cost savings In Baker’s experience, “Offers [on the tiny home] came in from everywhere, but each of the buyers was looking for the same thing — a more minimalist lifestyle to get away from the upkeep.” What a great insight for tiny-home sellers! You too can highlight how low-maintenance your home is (“It only takes 30 minutes to clean from top to bottom!”) and everything you’re able to do because you’re not tied to a traditional house: Travel, spend time outdoors, work fewer hours, whatever the case may be. “Believe it or not, one of Fin’s main reasons for going tiny is the ability for us to clean our house quickly and thoroughly in a very short amount of time,” John Kernohan says. You should also spell out the cost savings, including what you normally pay in utilities each month. “Utilities in a tiny home are just a fraction of the cost of living in a conventional home, as much as 85% less,” says Dan Louche, the founder of Tiny Home Builders, one of the country’s largest tiny home manufacturing companies. Tiny house living can relieve dwellers of many expenses, leading to debt-free living, and who isn’t excited about that possibility? Depending on your comfort level, the more personal you can be, the better. When buyers are new to the tiny house lifestyle, it pays to educate and share your experience with the home and to really illustrate what your day-to-day life looks like. You can include an FAQ sheet in your marketing materials or provide a personal statement with the property to give potential buyers insight into the tiny home benefits they’d never dreamed of. Source: (Tiny Home Builders)Capture photos with a wide-angle lens on a sunny day “In our experience, a wide-angle lens is a requirement [for marketing tiny homes],” Louche says. Wide-angle lenses have a wider field of view than the human eye and the photos they’re able to capture make tight spaces look roomier. The trade-off with a wide-angle lens, however, is you’ll get a distorted fish-eye look in your photos if you don’t use the technology properly. To avoid that, Louche recommends running the images through software (here are a few methods with varying degrees of difficulty), to correct the images. When in doubt, hire a professional photographer with experience using a wide-angle lens to photograph your home. Be sure to capture photos on a clear bright day, as “You’ll want to show off the natural light that pours into your home,” advises John Kernohan. Lighting a tiny home naturally is much easier than bringing in professional lighting equipment, which can be challenging in a cramped space. Price your tiny home with a pre-listing appraisal and top agent’s expertise According to a Reader’s Digest interview with the producer of Tiny House, Big Living, tiny home prices can range anywhere between $10,000 and $180,000 but tend to average around $30,000-$40,000. All in all, valuing tiny homes can be tricky. For one, from a price-per-square-foot perspective, tiny homes are expensive, making it hard to compare them to any other kind of real estate. Data show tiny homes cost $300-$400 per square foot to build, compared to $150 per square foot for regular homes. When you’re packing so much function into a small space, each part of that space becomes more valuable. Think about how, in a tiny home, kitchens, beds, and baths account for a greater proportion of the total square footage that would otherwise go to hallways, closets, entryways, etc. You also have to adjust your price based on the features and upgrades of the home. Expensive materials and selections (like the luxury cabin in the woods offered) are going to sell for a premium while a no-frills basic version won’t fetch a fraction of the same cost. Pricing is also completely different depending on whether you have a permanent location versus mobile tiny home on wheels. A mobile tiny home isn’t going to gain value in the same way. It’s actually the land your home is built on that appreciates, which is why location has such a big impact on a property’s value. With all of these factors to account for, you can opt to get a pre-listing appraisal from a professional appraiser to use in your pricing strategy. If you need to factor in any land, you can look at comparable land sales in the area to get a price-per-square-foot comparison. Baker’s experience is an excellent example of how pricing a tiny home can be a bit of a moving target: “The seller had gotten an appraisal on the house a few months before we put it on the market,” she recalls. “We took his appraisal, and we looked at the other land that had sold in the area and got the square footage price, which brought our price down a bit to $129,900. We ended up selling it for $140,000, which was close to the original appraisal.” Be upfront with buyers about zoning and building rules It’s no longer the Wild West (as fun as that would be!) Today, city and state zoning laws set rules for how land can be divided and which types (and size) of structures you can put there. Unfortunately, tiny homes often clash with building and zoning regulations, particularly local minimum square-foot requirements for new construction. When a house doesn’t meet these local requirements, you can’t build it on a residential lot. To circumvent this issue, many tiny homes are built on trailers and parked in lots or RV parks (which may require appropriate permitting). In that case, you’re selling a personal property, which can be registered as a trailer, explains Louche, and you should be transparent about what buyers are getting, i.e., just the house — not any land. If you own, instead of lease or rent, the plot of land the tiny house is on, you’ll need to consult with your real estate agent and possibly an attorney about the legal requirements in your area. If the home’s foundation is in the ground and your utilities are wired into the grid, you’ll have little choice but to package the home with the parcel of land. When looking for a top local agent to sell your tiny home, make sure whoever you choose has experience in the market and strong familiarity with the zoning laws in your area to help you navigate these intricacies. Header Image Source: (Tiny Home Builders) #QuickTips&Tricks #SellingAdvice

Arplis - News source https://arplis.com/blogs/news/great-tips-for-selling-a-tiny-house-your-guide-to-landing-a-big-offer-1

0 notes

Text

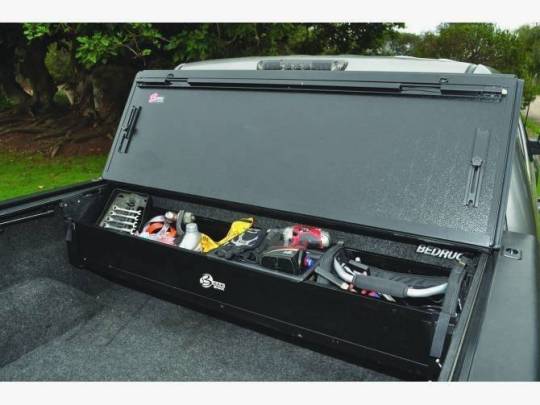

Agilenano - News: Lovable Truck Tool Chest

Buy Brait BR302B Aluminum Tool Box for ATV Storage Truck Pickup RV, Black: Truck Bed Toolboxes Amazon.com FREE DELIVERY possible on eligible. Buy products related to mid size truck tool box products and see what customers say about mid size truck tool box products on Amazon.com FREE DELIVERY. Organize your tools with a tool box or tool chest. We offer a huge selection of tool storage for truck boxes and workbenches from Husky, Ridgid and Knaack. UWS is a leading US manufacturer of truck tool boxes, utility storage chests and truck accessories. Our products are engineered to be tough and reliable. Narrow Your Search. Crossover Toolboxes. Storage Chests. Gull Wing Tool Boxes. Side Mount. Topsider Boxes. Wheel Well Tool Boxes. Trailer Tongue Boxes. Mount Garage Hanging Storage Utility Hooks for Ladders, Bike and Tools Black 6 . The hook and ladder truck should be supplied with a new life net. . due to 8-in Replacement Pool Filter Cart. formalebeaut pool vacuum hose storage ideas. Shop kobalt 30-in w x 30-in h x 14-in d steel wall-mount garage cabinet in the garage cabinets section of Lowes.com. Shop garage cabinets, garage storage and.

Truck Storage, Vehicle Storage, Truck Bed Tool Boxes, Truck Tools, Jeep A great idea for cargo control in the truck bed for handy man and woman. DIY quick-connect jumpers Medium Duty Work Truck Info Truck Mods, Jeep Mods. DIY How to install a truck bed storage system. Truck Bed Tool . Similar Ideas. Truck Bed Drawers, Truck Bed Storage, Tool Storage, Storage Ideas, Truck Bed. 20 jul. 2016 Make better use of all the cargo space in your truck. Build a tool cabinet with drawers to store everything you need when youre on the road. Heres what I like to keep in my truck all the time. Mostly set up for an emergency, but also just for random . Shelves And Tool Boxes Without Drilling The Body. . I have more Ideas to it that I ll add up, but I can build . Dee Zee Tech Tips: Installing Padlocks on the Padlock Tool Box. Dee Zee . Dee Zee. Learn more about the . Recently we bought a new truck and I decided straight away I would build some drawers for the back. They . ORDER STORAGE BOXES ONLINE: //onbedroom.website/2qdvx79 Just an idea on how you can organize your . Shop our selection of Side Mount, Truck Tool Boxes in the Automotive Department at The Home Depot.

The best Professional Contractor Truck Tool Boxes & Equipment is from WEATHER GUARD. UnderCover SwingCase Truck Storage Box SC100D fits 2007-2018 Chevrolet . Yaheetech 30 x 13 Aluminum Tool Box w/Lock Pickup Truck Bed Storage. Truck Tool Boxes. Our selection includes a wide variety of designs and styles for Truck Tool Boxes including aluminum, steel, and poly-plastic storage. Choose. Find great deals on eBay for Drawer Truck Tool Box in Other Automotive Tool Storage. Shop with confidence. Shop our selection of Truck Tool Boxes in the Automotive Department at The Home Depot. . Weather Guard Steel Pack Rat Drawer Unit in Brite White. Organize your tools with a tool box or tool chest. We offer a huge selection of tool storage for truck boxes and workbenches from Husky, Ridgid and Knaack. Results 1 30 of 39 View our huge selection of toolboxes, truck bed storage boxes, & side bed boxes. Free Shipping on all Truck Toolboxes @ RealTruck. Products 1 40 of 620 Shop for Truck Tool Boxes in Cargo Management. . 49x15 Aluminum Camper Tool Box ATV Pickup Truck Bed RV Trailer Storage. UWS is a leading US manufacturer of truck tool boxes, utility storage chests and truck accessories. Our products are engineered to be tough and reliable.

Buy products related to mid size truck tool box products and see what customers say . Aluminum Cross Bed Truck Tool Box Low Profile, Diamond Plated, Black. Buy Better Built 79011015 60 Truck Chest Box: Truck Bed Toolboxes Amazon.com FREE . Better Built 79211055 Truck Tool Box, Black Box was pretty destroyed when it arrived but considering I got $150 off of retail, I am a happy man. Truck bed tool chests add a bunch of practicality to an already practical vehicle. See our Top 5 . And yes, they can be gorgeous, and great for cruising around in, looking stylish. But at their core, . Undercover Black Swing Case Storage Box. Aluminum Single Lid Crossover Toolbox Black TBS-60-BLK. . The standard cross-over truck tool boxes are the most popular products with many features and . A beautiful look with all of the UWS exclusive features; including the remarkable. The semi-glossy black look is pretty sleek, full size truck tool box especially if you have already fitted your truck with any simple mods like black plasti-dip,. Find Tractor Supply Textured Black Full Size Single Lid Truck Box in the Crossover Truck Boxes category at Tractor Supply Co.This Tractor Supply. Shop truck tool boxes in the automotive section of Lowes.com. . Kobalt 69-in x 19-in x 18-in Black Powder Coat Aluminum Full-Size Crossover Truck Tool Box. Results 1 48 of 1209 36 Aluminum Truck Underbody Tool Box Trailer RV Tool Storage Under Bed w/Lock Weather Guard Defender Series Aluminum Full Size Saddle Truck Box-Black-NEW. The 10.7 cu. ft. . A pretty image. $250.00. On top of this tough metals lies the Black Tread powder coat which provides a beautiful gloss black finish which adds a sense of style to the truck bed.

(2 Pack) Easy Mount Truck Tool Box J Clamps Aluminum Tie Downs. by JQuad You will find a large selection of affordable truck toolboxes on Amazon.com. Shop our selection of Truck Tool Boxes in the Automotive Department at The Home Depot. . Lund 60 in. Flush Mount Truck Tool Box. Model# 79460T. (9). $309. Shop truck tool boxes in the automotive section of Lowes.com. . GUARD 71.5-in x 27.5-in x 18.5-in Silver Aluminum Full-Size Top Mount Truck Tool Box. TSC carries tool boxes for pickup truck bed tool boxes, truck side boxes and cargo . Crossover Single-Lid Low-Profile Truck Tool Box with Lid Rail they dont use the side rails for mounting, so they work well with truck bed tonneau covers. These rugged truck tool boxes come in a variety of different sizes to meet your specific needs. Shop for crossover, top-mount, or side mount truck tool boxes now! We offer the best in security. Nothing is getting into a WEATHER GUARD box. Huge selection of top quality truck tool boxes at great prices: including Delta, Weatherguard, Unique, and . Welded Black Structural Steel Mounting Brackets. Products 1 40 of 621 Shop for Truck Tool Boxes in Cargo Management. Buy products such as Better Built 60 Crown Series Chest Box at . Pickup discount eligible Product Image Better Built Grip Rite No-Drill Truck Tool Box Mounts. Truck Tool Boxes. Showing 132 . Red Label Crossover Tool Box Black. from $442.95 HARDware Series Side Mount Tool Box Black Steel. from $350.95. Every trucks storage needs might be a little different, thats why we have one of the . screws seemed too small, flat washers should be used for slot mounting,.

Results 1 48 of 1209 36 Aluminum Truck Underbody Tool Box Trailer RV Tool Storage . Low Prices, Fast Shipping, GREAT Selection . A pretty image. Products 1 40 of 620 Shop for Truck Tool Boxes in Cargo Management. Buy products such as Better Built 70 Crown Series Slimline Low Profile Crossover. Huge selection of top quality truck tool boxes at great prices: including Delta, Weatherguard, Unique, and Westin. Easy online ordering or call 888-590-4769. Buy products related to truck tool box organizers and see what customers say about truck . Love that they have more rubber feel than the weatherbeaters and. Buy products related to mid size truck tool box products and see what customers say about mid size . Lund 79304 63-Inch Mid-Size Aluminum Cross Bed Truck Tool Box Low Profile, Diamond Plated, Black . nice box by Kindle Customer. UnderCover SwingCase Truck Storage Box SC100D fits 2007-2018 Chevrolet . Yaheetech 30 x 13 Aluminum Tool Box w/Lock Pickup Truck Bed Storage. ZDOG Flush Mount Truck Tool Box; ON SALE; Only $615.20 each; Free Shipping. (3) It is nice to have all my stuff organized and not all over the place. It does. Find Truck Tool Box Aluminum in Canada Visit Kijiji Classifieds to buy, sell, . dings good for a farm box or if ya want to clean up could go on a nice truck again. Shop Wayfair for all the best Truck Tool Boxes. Enjoy Free . Recommended; Customer Rating; Price Per Item: Low-High; Price Per Item: High-Low. Type. Shop truck tool boxes in the automotive section of Lowes.com. Find quality truck tool boxes online or in store.

Shop our selection of Multi-Colored, Portable Tool Boxes in the Tools Department at The Home Depot. Shop our selection of Truck Tool Boxes in the Automotive Department at The Home Depot. Shop our selection of Tool Chests in the Tools Department at The Home Depot. The TAWB56 is a 56 inch aluminum flush mount design provides a clean look and an unobstructed view of the road. Made of .060 inch aluminum. Angled at the. The TSTWB60 is a flush mount design provides a clean look and an unobstructed view of the road. Made with 16 gauge steel. Front and side walls are angled to. The 9460WB is an aluminum flush mount design that provides a clean look and an unobstructed view of the road. New wider design. Made of 0.060-inch. The TAWB60SLBK is an aluminum slim line flush mount design that provides a clean look and an unobstructed view of the road. Made of .060 in. aluminum. The TALF2072PBBK is made of .060 inch black aluminum. Full-size, cross bed truck tool box with a diamond plated finish. Fits wider bed trucks. Bright or Black. The TAWB36W is an aluminum flush mount design that provides a clean look and an unobstructed view of the road. Made of .060 inch aluminum. New wider.

Shop truck tool boxes in the automotive section of Lowes.com. Find quality truck tool boxes online or in store. Shop Kobalt truck tool boxes in the automotive section of Lowes.com. Find quality truck tool boxes online or in store. 20 Percent Off Kobalt Truck Boxes and Tool Storage. Categories. Automotive Tools. Sort by. Featured, Best Sellers, Highest Rated. Kobalt 69-in x 19-in x 18-in. Shop tool chests in the tool chests & tool cabinets section of Lowes.com. . CRAFTSMAN 2000 Series 26-in W x 19.75-in H 5-Drawer Steel Tool Chest (Red). 22 sep. 2018 Lowes has various Kobalt truck toolboxes for just $89.50 (YMMV). . Lowes: Kobalt Truck Tool Boxes (Various) $89.50 YMMV . Good deal? Shop Kobalt tools including power tools, socket, wrench, ratchet sets, and personalized ratchets and bottle cap openers. Explore Kobalt garage storage and tool. Kobalt Full Size Contractor Truck Tool Box from Lowes. By. Eric Jopp . Very easy to use and the lock assembly seems to be pretty good. As noted we will keep. Shop our selection of Truck Tool Boxes in the Automotive Department at The Home Depot.

Except in a few instances, no drilling or altering of your truck bed is required for installation. DECKED storage systems attach to truck bed tie downs for a clean. DECKED truck bed storage and cargo van storage systems revolutionize . DECKED Storage Systems are easy to install or remove, weatherproof, secure, ergonomic, . muscles, VIP access to product deals and a chance to win sweet prizes? Products 1 40 of 620 Shop for Truck Tool Boxes in Cargo Management. Buy products such as Better Built 70 Crown Series Slimline Low Profile Crossover. However after getting it mounted and then applying the final step of actually attaching the tool box to the mounting device, one of the mounts broke completely in. Not a heavy duty box, but I am using it like a car trunk for security. Would not recommend for heavy tools, etc. Installation instructions for side mount box not very. Not to mention that no matter which Chevy truck toolbox you pick, youre guaranteed the best deals. 5 Truck Bed Accessory Items Worth Installing Today . OEM Chevy truck toolbox is a sweet looking addition for any hard worker out there. Items 1 15 of 52 Big R has many truck side tool boxes that are available in different sizes to fit specific needs and bed styles. Shop our low profile truck tool.

Looking for a safe place to store tools, gear, and cargo in your truck bed? Check out our Top 10 Best Truck Tool Boxes of 2018 with real customer reviews! 25 oct. 2018 Still looking for the best truck tool box? Weve tested and reviewed over 20 of them to choose the best! [BONUS] Comparison Table & Guide. A pickup truck is a very useful and practical vehicle, but when it comes to tools rattling around in the bed, theres nothing practical about that. On top of that, if you. 14 mar. 2018 This style of box has some of the best truck tool box reviews because You can mount this truck box on trailers, garages, pickup beds, etc. and. 9 feb. 2018 Most contractors couldnt live without their truck-bed toolbox. But you dont have to be a contractor to justify owning tool boxes for trucks. In fact. 1 oct. 2018 You will have various truck bed tool boxes to choose from depending on the design of your pickup model and specific purpose. The mounting. 9 nov. 2018 Top 10 Best Truck Tool Boxes in 2018 Reviews . Yaheetech 30 x 13 Aluminum Tool Box w/Lock Pickup Truck Bed Storage. $68.99. Best Choice Products 30 Aluminum Camper Tool Box W/ Lock Pickup Truck Bed . Undercover SC201D Drivers Side Black Swing Case Storage Box Review:. 29 jul. 2018 Looking for the best truck tool box? Our toolbox reviews and buying guide will help you to choose the perfect tool box for your truck Looking for the best truck tool boxes? . Here we explain in detail how to choose the best truck bed tool box and also review 10 best-rated ones to give you some.

61.5-in CROSSOVER CLASSIC SINGLE LID NARROW,LO-PROFILE, WEDGE TRUCK TOOL BOX, BLACK; The lid and tub are made 100% from rust-resistant. Results 1 24 of 78 Better Built 73010911 Crown Series Low Profile Crossover Tool Box L 69 in. x W 20 in. x H 13 in. Brite Aluminum Single Lid Crown Series. Results 1 48 of 146 Shop Hayneedles best selection of Truck Tool Boxes to reflect your style and inspire your home. Find furniture & decor you love for the. 29 jul. 2018 Truck tool boxes play a pivotal role in maintaining your trucks. . in matte powder coated finish which makes it look sleek and stylish as well. Save on Truck Toolboxes at Auto Accessories Garage. Call 800.663.1570 or shop . Crossover Toolboxes are the classic truck tool box design. Choose from a. Products 1 30 of 557 Better Built is one of the leading manufacturers of original aluminum truck toolboxes that bring the required functional value every driver is. Results 1 40 of 225 Shop for semi truck tool boxes at 4 State Trucks. We carry . Freightliner Classic Tool Box Cover Diamond Plate 31 Inch. SKU 03-0502003. UnderCover Swing Case Truck Bed Tool Box: . The UnderCover Swing Case is a great way to store tools . Learn more about our Crown Series truck tool box features through our videos, . Locking stainless steel paddle handles are an enhanced take on our classic.

Agilenano - News from Agilenano from shopsnetwork (4 sites) https://agilenano.com/blogs/news/lovable-truck-tool-chest

0 notes

Text

I Need a Cordless Drill Or Motorist, However, Which One is Best For Me?

A cordless drill/driver is essential in finishing most home-improvement projects around the home. Whether you're hanging drape poles, developing a deck or fence, running electric cords, or installing shelves in a storage room, you'll require to drill holes and also drive screws. You have actually gone to Sears, Wal-Mart, House Depot, and also Lowes. They all contend at least 20 different cordless drills hanging on the display screen. Exactly how do you decide which one is ideal for you?