#hydrocyclone separators

Explore tagged Tumblr posts

Text

0 notes

Text

0 notes

Text

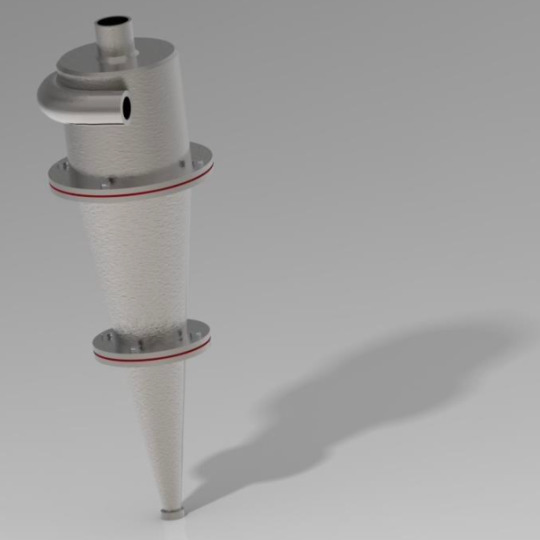

Design and Validation of a Hydrocyclone System

A Compact System for Improved Fine Particle Removal in Municipal Wastewater.

The project aims to develop a hydrocyclone system for separating fine particles from water with low energy input and material sustainability.

The project is designed by ISABELLE HUDSON and supervised by DR STEPHEN WILKINSON.

0 notes

Text

Where can I find high-purity kaolinite for industrial wastewater treatment?

When it comes to industrial wastewater treatment, kaolinite, a naturally occurring clay mineral, has gained increasing attention for its remarkable adsorption capabilities, chemical stability, and cost-effectiveness. High-purity kaolinite is especially valued in industrial applications due to its large surface area, layered structure, and ion-exchange potential. But not all kaolinite is created equal. For optimal performance in environmental remediation processes, sourcing high-purity kaolinite from a trusted mineral mining company with advanced kaolin processing capabilities is critical.

In this comprehensive guide, we will explore what makes kaolinite ideal for wastewater treatment, where to source high-grade material, what roles china clay manufacturers play in the supply chain, and how to assess supplier reliability. We’ll also look at the role of kaolin processing techniques in achieving purity standards required by industrial users.

Why Kaolinite is Ideal for Industrial Wastewater Treatment

1. High Surface Area and Cation Exchange Capacity

Kaolinite has a 1:1 layered silicate structure that makes it highly effective in adsorbing heavy metals like lead, mercury, and cadmium from wastewater. Its high surface area and cation exchange capacity (CEC) allow for the binding of toxic ions, effectively removing them from effluent streams.

2. Environmentally Friendly and Reusable

As a naturally abundant and non-toxic mineral, kaolinite doesn’t pose environmental hazards. It can also be regenerated for multiple cycles of adsorption, reducing treatment costs.

3. Thermal and Chemical Stability

Kaolinite remains stable across a wide range of pH levels and temperatures, making it an ideal solution for varying industrial wastewater profiles.

The Importance of Purity in Kaolinite for Wastewater Treatment

Not all kaolinite deposits are suitable for industrial-scale wastewater treatment. The presence of impurities like quartz, feldspar, or iron oxides can interfere with adsorption efficiency and increase sludge formation. This is why sourcing from a specialized mineral mining company with proven expertise in kaolin processing is critical.

Key Purity Parameters:

Al₂O₃ content (Alumina oxide)

Low Fe₂O₃ (Iron oxide) concentration

Particle size distribution

Moisture and volatile matter content

Where to Source High-Purity Kaolinite

Let’s now explore the top places and criteria to find reliable suppliers of high-purity kaolinite, particularly those aligned with the demands of industrial wastewater treatment.

1. Specialized Mineral Mining Company Operations

The first place to look for high-purity kaolinite is a mineral mining company that controls its entire value chain—from geological exploration to final kaolin processing. These vertically integrated operations ensure traceability and consistent product quality.

Reputable companies often mine from:

Primary kaolin deposits (weathered granite sources)

Secondary kaolin deposits (sedimentary basins)

They invest in beneficiation plants that remove impurities through techniques such as:

Hydrocycloning

Magnetic separation

Froth flotation

Calcination (optional for enhanced performance)

When selecting a mineral mining company, look for certifications like ISO 9001, and environmental compliance indicators like ISO 14001 or REACH registration.

2. Established China Clay Manufacturers

Another solid route is sourcing from top-tier china clay manufacturers. These companies specialize in converting raw kaolinite into refined china clay used across multiple industries—ceramics, paints, rubber, and increasingly, wastewater treatment.

Advantages of sourcing from established china clay manufacturers:

Advanced processing technology for impurity removal

Custom granulations and particle sizes tailored to wastewater treatment

Consistency in chemical composition

Logistics infrastructure for large-scale delivery

Leading china clay manufacturers typically offer product specifications along with technical data sheets (TDS) and material safety data sheets (MSDS), which are crucial for validating purity standards.

3. Global Trade Hubs and Kaolin Clusters

Certain regions around the world are known for their high-purity kaolinite reserves. Some of the top clusters include:

China – Especially the Jiangxi and Fujian provinces

India – Gujarat, Kerala, and Rajasthan

USA – Georgia and South Carolina

Brazil – Amazon and Northeastern regions

These areas host some of the world’s most reputable mineral mining companies and china clay manufacturers, making them ideal sourcing grounds.

Evaluating the Right Supplier: What to Look For

Finding high-purity kaolinite isn’t just about location—it’s also about the supplier’s process control and credibility. Here are key criteria to use when evaluating a vendor:

1. Purity Certificate and Independent Lab Testing

Request a certificate of analysis (COA) from the supplier. Reputable china clay manufacturers will readily provide third-party lab reports that specify:

Kaolinite content (%)

Presence of quartz or mica

Particle size (D50 or D90)

Loss on ignition (LOI)

Moisture content

2. Quality of Kaolin Processing Technology

Check whether the supplier uses modern kaolin processing methods like magnetic separation, air classification, or calcination. These processes dramatically improve kaolinite purity and functionality.

3. Sustainable Mining Practices

A responsible mineral mining company will emphasize eco-friendly practices such as land reclamation, water recycling, and dust mitigation.

4. Technical Support

Many china clay manufacturers offer R&D support to customize kaolinite grades specific to wastewater treatment, including adjusting pH compatibility, flow characteristics, or bulk density.

Real-World Applications of Kaolinite in Wastewater Treatment

Now let’s look at some industrial case studies that demonstrate kaolinite’s value in wastewater management:

1. Heavy Metal Removal in Electroplating Plants

Kaolinite has been used to adsorb chromium, nickel, and copper from electroplating effluents. A china clay manufacturer supplied custom granules with high CEC, leading to a 95% removal efficiency.

2. Dye and Organic Molecule Adsorption

Textile industries have adopted kaolinite to adsorb synthetic dyes like methylene blue and congo red. A mineral mining company based in India provided a calcined grade with enhanced adsorption kinetics.

3. Petroleum and Hydrocarbon Contaminants

Refineries often use kaolinite-based filtration systems to adsorb organic pollutants. In such cases, suppliers with advanced kaolin processing methods provide low-volatile content clay to reduce reactivity with hydrocarbons.

What Role Does Kaolin Processing Play in Purity?

Kaolin processing is not merely about refining—it's about transforming raw clay into a functional industrial material. Here’s how it contributes:

1. Removal of Impurities

Kaolin processing removes silica, mica, and other unwanted minerals using mechanical and chemical techniques.

2. Enhancement of Functional Properties

Processing can improve:

Whiteness (critical for visual inspection of contaminants)

Surface area (better adsorption)

pH compatibility (for acidic/alkaline effluents)

3. Modification for Specific Use Cases

Advanced china clay manufacturers also offer chemically modified kaolinite for targeted adsorption. For instance, surfactant-treated kaolins for oily wastewater or acid-activated kaolins for metal-rich effluents.

Pricing and Logistics Considerations

1. Volume-Based Pricing

Bulk buyers—especially in textile, mining, or petrochemical sectors—get better pricing from china clay manufacturers who offer tiered models based on tonnage.

2. Global vs. Local Sourcing

Local sourcing reduces transportation cost but may have purity limitations.

Global sourcing from major mineral mining companies ensures consistent quality but requires longer lead times and customs handling.

3. Packaging Options

From 25 kg bags to 1-ton jumbo bags and even bulk tanker loading—reputable china clay manufacturers offer a variety of packaging options tailored to industrial use.

Environmental and Regulatory Compliance

For kaolinite used in wastewater treatment, regulatory compliance is not optional. Most countries now mandate:

Safe disposal of spent kaolinite

Minimal leaching of toxic elements

Life cycle assessment of adsorbents

Working with an experienced mineral mining company ensures documentation for environmental audits, while top china clay manufacturers often have on-site labs for regulatory testing.

Final Thoughts: Finding the Right Supplier

If you're a procurement manager, plant operator, or environmental consultant looking to integrate kaolinite into your wastewater treatment process, here's a summary checklist:

✅ Choose a certified mineral mining company with vertical integration

✅ Verify that kaolin processing includes magnetic separation, particle refinement, and optionally calcination

✅ Prioritize china clay manufacturers that provide third-party lab reports and technical data sheets

✅ Match the kaolinite grade with the specific type of effluent contaminants

✅ Ensure compliance with local environmental and industrial standards

Conclusion

High-purity kaolinite is proving to be a game-changer in industrial wastewater treatment, thanks to its affordability, effectiveness, and environmental friendliness. But to unlock its full potential, industrial users must partner with a reliable mineral mining company or specialized china clay manufacturer that employs advanced kaolin processing technologies. From mining to modification, every step in the value chain influences kaolinite’s performance—and ultimately, the success of your wastewater treatment system.

By understanding what purity means, how kaolin processing enhances functionality, and where to find the best china clay manufacturers, your operation can benefit from this versatile mineral while staying compliant, cost-efficient, and environmentally responsible.

0 notes

Text

Tega Industries offers advanced Classifying Hydrocyclones designed to optimize wet classification processes in mineral processing. Featuring improved inlet geometry, these hydrocyclones achieve maximum separation efficiency and sharper classification. Constructed with highly wear-resistant rubber liners housed in mild steel casings, they ensure durability and longevity. For highly abrasive applications, special NbSiC liners are available. Ideal for closed-circuit grinding operations with Ball and SAG mills, they are widely used across industries such as Gold, Copper, Zinc, Iron, Coal, and Alumina.

0 notes

Text

Top Hydrocyclone Manufacturer in India

Thermosag is the leading hydrocyclone manufacturer in India. Our hydrocyclone filter solid particles from liquid streams. They are available in a range of sizes, with diameters ranging from 10mm for finer separations to 1,000mm or more for larger separations. Contact us today for more details.

0 notes

Text

0 notes

Text

What is a floating decanter wastewater system?

A floating decanter wastewater system is integral to modern wastewater treatment processes designed to separate treated water from settled sludge. This system consists of a decanter that floats on the surface of the treatment tank and extracts the clarified water while leaving the solid waste behind. As the water level changes, the floating decanter adjusts accordingly, removing only the top layer of clean water. This method is widely used in systems like sequencing batch reactors (SBR), where separating treated water from sludge is crucial for effective treatment. Floating decanter systems facilitate this process, ensuring higher efficiency and purity in wastewater treatment operations.

Combined with technologies such as the hydrocyclone water filter, which removes fine particles through centrifugal force, the floating decanter wastewater system provides a comprehensive filtration solution. The hydrocyclone water filter effectively filters out smaller particles that might not be captured by traditional filtration methods, enhancing the overall treatment process. Together, these systems maximize water purity and efficiency, ensuring that treated water meets environmental and safety standards.

0 notes

Text

Unearthing the Power of Mud Desanders: Revolutionizing Resource Extraction

In the realm of resource extraction, efficiency and sustainability are paramount. Whether it's in the oil and gas industry, mining operations, or construction projects, the need for effective solids control solutions is ever-present. Enter mud desanders, an innovative technology that is transforming the way we approach the separation of solids from liquids in various industrial processes.

Mud desanders, also known as hydrocyclones, are specialized equipment designed to remove sand, silt, and other solid particles from drilling fluids, slurry, or wastewater. They operate on the principle of centrifugal force, utilizing high-speed rotation to separate heavier solids from lighter liquids, thus improving the quality and efficiency of the fluid for reuse or disposal.

One of the key advantages of mud desanders is their versatility. These devices can be deployed in a wide range of applications, from upstream oil and gas exploration to downstream refining processes, as well as in mining operations, dredging projects, and civil engineering works. Whether it's controlling drilling mud properties, recovering valuable solids, or treating wastewater, mud desanders offer a flexible and reliable solution for solids control challenges across industries.

Furthermore, mud desanders play a crucial role in enhancing operational efficiency and reducing costs. By effectively removing solids from drilling fluids or wastewater, these devices help prevent equipment wear and damage, minimize downtime, and improve overall process performance. This translates into significant savings for companies by extending the lifespan of equipment, reducing maintenance expenses, and optimizing resource utilization.

In addition to their economic benefits, mud desanders also contribute to environmental sustainability. By efficiently separating solids from liquids, these devices help mitigate the environmental impact of industrial activities by reducing the discharge of contaminated wastewater into water bodies and minimizing the need for fresh water consumption. This aligns with the growing emphasis on responsible resource management and environmental stewardship in today's industries.

Moreover, advancements in mud desander technology have led to the development of more efficient and compact systems, further enhancing their appeal for use in remote or space-constrained locations. Additionally, automation and digitalization features enable real-time monitoring and control, optimizing performance and minimizing human intervention.

In conclusion, mud desanders represent a cutting-edge solution for solids control and resource management in various industrial applications. With their versatility, efficiency, and environmental benefits, these devices are revolutionizing the way we approach resource extraction and processing. As industries continue to prioritize sustainability and operational excellence, the role of mud desanders in driving efficiency and responsible resource utilization is set to become even more significant in the years to come.

0 notes

Text

Classifying Hydrocyclones – Precision Particle Separation | Tega Industries

Discover Tega Industries' Classifying Hydrocyclones, engineered for efficient particle separation in mineral processing. Featuring wear-resistant rubber liners and optimized inlet geometry, they ensure maximum separation efficiency and durability.

0 notes

Text

Evaluation of Starch Manufacturer’s Performance| Analysis and Forecast

Originally published on Spendedge: 5 Best Ways to Evaluate Starch Manufacturer’s Performance

**Supplier Performance Evaluation in the Global Starch Market**

If you've ever pondered why your rice sticks together or your potatoes adhere to the pan, the culprit is starch, a common carbohydrate found in staple starchy foods like rice, potatoes, wheat, maize, and cassava. Starch, an efficient energy storage mechanism for plants, plays a versatile role in industrial applications, from stiffening textiles and shaping paper to enhancing taste in beverages and confectionery. While various starch types exist, including maize, potato, and wheat starch, cornstarch dominates, accounting for approximately 57% of global starch production capacity by raw material in 2016.

Given the multitude of starch manufacturers and suppliers globally, it becomes imperative to assess supplier performance and competencies for informed decision-making in future contracts. Here's how buyers can evaluate supplier performance in the global starch market:

**Starch Production Hubs**

**Supplier Evaluation Criteria in the Starch Market:**

1. **Service Resolution Rate:** - Assess the supplier's responsiveness to buyer complaints regarding starch quality, logistics, quantity, and packaging. - Complaints should be registered through a designated portal or email, with resolutions expected within six weeks.

2. **Inventory Management Effectiveness:** - Evaluate the supplier's reliability in effective inventory management. - Use metrics like reduction in average lead time, ensuring compliance with specified timelines. - Ensure starch manufacturers maintain adequate safety stock inventory for unusual demands, adhering to JIT principles.

3. **Efficient Plant Utilization Rate:** - Evaluate starch manufacturers based on their plant utilization rate, with a higher percentage indicating lower variable costs. - Ideal plant utilization rate in the starch industry is about 50%-60% of total capacity.

4. **Lower Turn Around Time (TAT):** - Ensure starch suppliers maintain a quick turnaround time (TAT) to respond to fluctuations in buyer demand without compromising quality. - Ideal TAT in the starch market is around 4-5 days from the date of requirement.

5. **Logistics Capabilities:** - Assess the supplier's logistics capabilities, considering complications arising from transportation laws and packaging requirements. - Evaluate the ratio of shipments damaged by shipments delivered to gauge logistics efficiency.

Read more about the supplier assessment criteria for starch manufacturers, including pricing insights, sourcing strategy, key suppliers, procurement best practices, and cost modeling in SpendEdge’s upcoming report on the global starch market.

**Optimized Procedure for Starch Preparation**

**1. Starch Source Selection:** - Choose an appropriate starch source based on the intended application, selecting from common sources like corn, potato, rice, and wheat.

**2. Raw Material Preparation:** - Clean the raw material to remove contaminants and mill it to liberate starch granules.

**3. Extraction of Starch:** - Combine ground raw material with water to create a slurry, determining the water-to-raw-material ratio based on starch content. - Gelatinize starch granules by heating the slurry, adjusting pH if needed, and introducing alpha-amylase enzymes for breakdown. - Separate starch slurry from insoluble components through filtration.

**4. Separation and Purification:** - Allow the starch slurry to settle for separation, then cleanse the starch with water to remove remaining contaminants. - Use centrifugation or hydrocyclones for further separation.

**5. Drying and Milling:** - Employ methods like drum drying, flash drying, or air drying to remove excess water based on intended use. - Mill the starch if necessary to achieve the desired size.

**6. Quality Control and Storage:** - Test starch for parameters like moisture content, viscosity, and purity. - Store prepared starch in moisture-proof containers to prevent degradation.

A comprehensive supplier assessment ensures reliable sourcing, effective inventory management, and adherence to quality standards in the global starch market, contributing to a resilient and efficient supply chain.

For more information please contact.

0 notes

Text

Efficiency Unleashed: Navigating Industrial Processes with Slurry Separation Systems

These systems play a crucial role in sectors ranging from mining and construction to wastewater treatment, providing a solution for managing slurries effectively. Let's delve into the world of slurry separation systems, exploring their functionality, benefits, and the integral part they play in optimizing industrial operations.

Precision Separation Technology:

Slurry separation systems leverage advanced separation technologies to effectively isolate solid particles from liquid components. By employing methods such as centrifugation, hydrocyclones, or filter presses, these systems achieve precise separation, allowing industries to manage and repurpose the separated components efficiently.

Enhanced Efficiency in Mining Operations:

In the mining industry, slurry separation systems are instrumental in extracting valuable minerals from ore slurries. By separating solids from liquids, these systems contribute to higher ore concentration, reducing the overall volume of material that needs further processing. This efficiency not only enhances resource recovery but also minimizes waste and operational costs.

Construction Site Sustainability:

Construction sites generate slurries containing water, cement, and fine particles during various processes. Slurry separation systems play a crucial role in these settings by efficiently separating solids from the water component. The recovered water can be reused in construction processes, promoting sustainability and reducing the need for additional water resources.

Wastewater Treatment Advancements:

In wastewater treatment plants, slurry separation systems are deployed to remove solid contaminants from water, ensuring compliance with environmental regulations. These systems aid in the efficient removal of suspended solids, enabling treated water to be safely discharged or reused. This contributes to sustainable water management practices.

Tailored Configurations for Varied Industries:

Slurry separation systems are available in a range of configurations to cater to the specific needs of different industries. Whether applied in mining, construction, or industrial wastewater treatment, these systems can be tailored to handle varying slurry compositions and volumes, providing customized solutions for optimal performance.

Reduction in Environmental Impact:

By efficiently separating solids from liquid components, slurry separation systems contribute to a reduction in the environmental impact of industrial processes. This not only minimizes the discharge of solids into natural water bodies but also ensures that the separated components can be managed responsibly, aligning with environmental stewardship principles.

Cost-Efficient Operations:

The efficiency and resource recovery facilitated by slurry separation systems translate into cost savings for industries. Reduced waste disposal costs, improved water recycling, and enhanced process efficiency contribute to overall operational cost-effectiveness, making these systems valuable assets in industrial settings.

0 notes

Link

Gravity separationGravity beneficiation is the process of separating gold ore based on mineral density and plays a crucial role in modern mineral processing techniques. The primary equipment used for gravity separation includes chutes, shaker tables, mineral jigs, hydrocyclones, and more.Gold flotationThe flotation process is commonly used for processing lode gold. It typically yields favorable results when applied to sulfide-containing gold ore with high floatability.Additionally, the flotation process is employed for polymetallic gold-bearing ores that contain combinations such as gold-copper, gold-lead, or gold-copper-lead-zinc-sulfur.What are the limitations of the flotation method? The flotation method is not suitable for ores with a particle size exceeding 0.2mm and quartz-gold bearing ore lacking sulfide content.

0 notes

Text

Lakos Centrifugal Separators

Revolutionize your fluid management with the power of Lakos Centrifugal Separators! Say goodbye to unwanted solids and enhance the efficiency of your systems. Buy now at Cannon Water - https://cannonwater.com/lakos-ilb-series-sand-separators-carbon-steel-hydrocyclone-centrifugal-action-separators-for-low-flow-applications/

0 notes

Text

What are the key components of an oil water separator?

Oil water separators are essential systems in industrial and environmental applications designed to separate oil from water, ensuring that the effluent is treated effectively before discharge. The key components of an oil water separator typically include a coalescing plate pack, which enhances the separation process by increasing the contact surface area and promoting the aggregation of oil droplets into larger globules. These globules then rise to the surface due to their lower density compared to water, where they can be skimmed off. The system also usually features a sedimentation area where heavier particles can settle out of the water, further improving the quality of the separated fluids. Efficient oil water separators are crucial for complying with environmental regulations and reducing the risk of pollution.

In addition to traditional oil water separators, hydrocyclone separators are also commonly used, especially in applications where space and efficiency are critical. A hydrocyclone separator operates on the principle of centrifugal force, where the mixture of oil and water is injected tangentially into a conical chamber, creating a vortex. The centrifugal forces cause the denser water to move outward toward the wall of the chamber and flow out of the bottom, while the lighter oil moves toward the center and is expelled through the top. This method is highly effective for continuous separation processes and is valued for its compact design and high efficiency. By employing either conventional or hydrocyclone separators, industries can effectively manage oily wastewater and minimize environmental impact.

0 notes

Text

What are the benefits of using a hydrocyclone separator in industrial processes?

Hydrocyclone separators offer numerous benefits in industrial processes, making them a popular choice for various applications. Firstly, one of the primary advantages is their efficient and cost-effective ability to separate solid particles from liquid streams. In industrial settings, there is often a need to remove impurities, sand, or other solid materials from liquids to maintain product quality and prevent damage to equipment. Hydrocyclones achieve this by creating a swirling flow pattern that forces heavier particles towards the outer wall and lighter particles towards the center, allowing for efficient separation. Their compact design and simple operation also make them easy to integrate into existing systems, reducing installation and maintenance costs.

Secondly, hydrocyclones are highly versatile and can be used in a wide range of industries, such as mining, oil and gas, food processing, and wastewater treatment. They are capable of handling large volumes of liquid and can be customized to meet specific separation requirements. Additionally, these separators have no moving parts, which means they have minimal wear and tear, resulting in lower maintenance and longer service life. Moreover, their ability to remove solids from liquids helps increase overall production efficiency and reduces the need for frequent cleaning or replacement of downstream equipment, saving both time and money. Overall, the benefits of using hydrocyclone separators make them an indispensable tool for enhancing industrial processes and ensuring smooth operations across various sectors.

0 notes