#hydrocarbon value chain

Explore tagged Tumblr posts

Text

Maximizing Efficiency Along the Hydrocarbon Value Chain with Hydrocarbon Consulting

Unlocking the full potential of the hydrocarbon value chain is crucial for companies in the oil and gas sector to stay competitive and profitable. Hydrocarbon Consulting specializes in optimizing every stage of this complex process, from exploration and production to refining and distribution.

At Hydrocarbon Consulting, our team of experts brings decades of industry experience to the table. We understand the intricacies of the hydrocarbon value chain and offer tailored solutions to streamline operations, minimize costs, and maximize efficiency.

From reservoir modeling and drilling optimization to refinery operations and logistics management, Hydrocarbon Consulting provides comprehensive support at every step of the value chain. Our innovative approach leverages cutting-edge technology and data analytics to drive informed decision-making and deliver tangible results.

By partnering with Hydrocarbon Consulting, companies can gain a competitive edge in today's dynamic market environment. Our proven track record of success speaks for itself, with numerous clients benefiting from increased productivity, reduced downtime, and improved profitability. In conclusion, Hydrocarbon Consulting is your trusted partner for optimizing the hydrocarbon value chain. With our expertise and dedication to excellence, we help companies navigate challenges, seize opportunities, and achieve sustainable growth in the ever-evolving energy sector. Experience the difference Hydrocarbon Consulting can make for your business today.

0 notes

Text

"At some point in the life-history of rubbish it changes from trash to treasure. It passes through some lens and becomes a valued artefact. Is it scarcity? A distance from memory? Perhaps it is the reassurance that two hundred years from now future humans will look at our detritus with something other than the disgust with which we view it now. When all the plastic landfills have been mined for their hydrocarbon chains, someone will hold one half of an IKEA saucer and admire its broken Scandinavian patterns. That is what these objects are. They are in the river because someone didn’t want them enough. But being found, they have been brought back to life. I want them.

More than anything I love having these around. I love to look at them. To admire their brush strokes, their depictions, their colours. I love the richness of their tones. I like to hold them, to feel their weight or their weightlessness in my hand, their sheens and lustres. I like how some of these are dramatically over-the-top; I particularly love the sense that these are beautiful only in fragment, that a complete object decorated like this would be garish, intrusive, fusty. But broken, they are the perfect metaphor for humanity, and that makes them beautiful too."

―Ted Sandling, London in Fragments: A Mudlark's Treasures

#quote#Ted Sandling#London in Fragments: A Mudlark's Treasures#mudlarking#History#Current Reading#Current Reading Quotes#Not Out of Void But Out of Chaos

13 notes

·

View notes

Photo

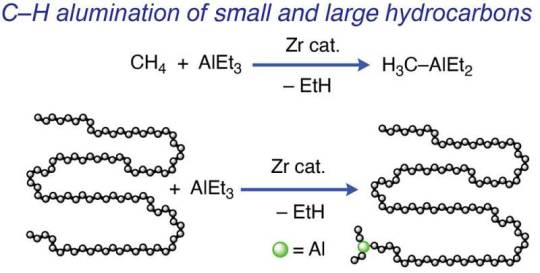

New zirconia-based catalyst can make plastics upcycling more sustainable

A new type of catalyst breaks down polyolefin plastics into new, useful products. This project is part of a new strategy to reduce the amount of plastic waste and its impact on our environment, as well as recover value that is lost when plastics are thrown away. The catalyst was developed by a team from the Institute for Cooperative Upcycling of Plastic (iCOUP), a U.S. Department of Energy, Energy Frontier Research Center. The effort was led by Aaron Sadow, the director of iCOUP, scientist at Ames National Laboratory, and professor at Iowa State University; Andreas Heyden, professor at the University of South Carolina; and Wenyu Huang, scientist at Ames Lab and professor at Iowa State. The new catalyst is made only of earth-abundant materials, which they demonstrated can break carbon-carbon (CC) bonds in aliphatic hydrocarbons.

Aliphatic hydrocarbons are organic compounds made up of only hydrogen and carbon. Polyolefin plastics are aliphatic hydrocarbon materials composed of long chains of carbon atoms linked together to form strong materials. These materials are a big part of the plastic waste crisis. Wenyu Huang said, "More than half of produced plastics so far are polyolefin based."

Read more.

#Materials Science#Science#Catalysts#Polymers#Plastics#Recycling#Polyolefins#Zirconium#Iowa State University#University of South Carolina

32 notes

·

View notes

Link

#AtmaNirbharBharatscheme#Bengaluru#BSE#buildings#civilconstructioncompany#constructionarm#effluenttreatment#electrolyzermanufacturing#EPC#Gigawatt-scalemanufacturingfacility#greenhydrogenmarket#heavyengineering#hydrocarbonbusiness#installation#intra-daytrade#Jharkhand#L&Tshares#Larsen&Toubro#McPhyEnergy#offshorepackages#S&PBSESensex#turnkeybasis#watertreatment

2 notes

·

View notes

Text

CAPB Your GoTo Guide to Cocamidopropyl Betaine in Cosmetics

Introduction

Cocamidopropyl Betaine, often abbreviated as CAPB or referred to as coco betaine, is a widely used ingredient in the personal care and cosmetics industry. Derived from coconut oil, this amphoteric surfactant is known for its gentle cleansing, moisturizing, and foaming properties. Whether you’re using shampoo, body wash, or even toothpaste, chances are you’ve encountered cocamidopropyl betaine in your daily routine.

As a leading cocamidopropyl betaine manufacturer, KSMA takes pride in providing high-quality CAPB to cocamidopropyl betaine suppliers worldwide. This versatile ingredient is not only effective but also safe for most skin types, making it a popular choice in formulations for cocamidopropyl betaine for skin and hair care products. In this blog, we’ll explore the uses, benefits, and safety of CAPB, along with its role in personal care products.

What is Cocamidopropyl Betaine?

Cocamidopropyl betaine (CAPB) is a synthetic surfactant derived from coconut oil and dimethylaminopropylamine. Its chemical structure consists of a long hydrocarbon chain (from coconut oil) and a polar group, making it an effective surfactant and detergent. This unique structure allows CAPB to lift oil and grease, making it easier to rinse away dirt and impurities.

CAPB is commonly used in products like shampoos, body washes, and toothpaste due to its ability to create a rich lather without causing excessive irritation. It’s also used as a foam booster, emulsifying agent, and thickener in cosmetics.

Cocamidopropyl Betaine in Personal Care Products

1. Cocamidopropyl Betaine for Hair

CAPB is a star ingredient in hair care products, especially shampoos. Its gentle cleansing properties make it suitable for all hair types, including sensitive scalps. Unlike harsher surfactants like sodium lauryl sulfate (SLS), CAPB helps maintain the natural moisture balance of the hair, leaving it soft and manageable.

2. Cocamidopropyl Betaine for Skin

In skincare products, CAPB is valued for its mildness and ability to reduce irritation caused by other surfactants. It’s commonly found in face wash, body wash, and hand soaps. For those with sensitive skin, CAPB-based products are often a safer alternative to harsher detergents.

3. Cocamidopropyl Betaine in Shampoo

If you’ve ever wondered why your shampoo lathers so well, you can thank CAPB. As a cocamidopropyl betaine surfactant, it enhances the foaming action of shampoos while being gentle on the scalp. It’s also used in cocamidopropyl betaine-free shampoos for those who prefer alternatives.

4. Cocamidopropyl Betaine in Toothpaste

CAPB is added to toothpaste to improve its foaming effect, making brushing more enjoyable. However, some people prefer cocamidopropyl betaine-free oral care products due to concerns about potential allergens.

Benefits of Cocamidopropyl Betaine

Gentle Cleansing: CAPB effectively removes dirt and oil without stripping the skin or hair of its natural moisture.

Moisturizing Properties: It helps retain hydration, making it ideal for dry or sensitive skin.

Foam Boosting: CAPB enhances the lathering ability of products, improving the user experience.

Antistatic Agent: In hair conditioners, CAPB reduces static and makes hair easier to manage.

Safety and Side Effects

While cocamidopropyl betaine is generally considered safe, some individuals may experience cocamidopropyl betaine allergy or sensitivity. Symptoms can include redness, itching, or tightness, known as contact dermatitis. These reactions are often caused by impurities like amidoamine (AA) and dimethylaminopropylamine (DMAPA) rather than CAPB itself.

To minimize risks, KSMA ensures that our CAPB products meet strict quality standards, with impurities like sodium monochloroacetate and glycerol kept within safe limits. Additionally, CAPB is biodegradable, making it an environmentally friendly choice.

Cocamidopropyl Betaine vs. Other Surfactants

Cocamidopropyl Betaine vs. SLS

Compared to sodium lauryl sulfate (SLS), CAPB is much milder and less likely to cause irritation. While SLS is known for its strong cleansing properties, it can be harsh on the skin and scalp. CAPB, on the other hand, offers a gentler alternative without compromising on performance.

Cocamidopropyl Betaine vs. Coco Betaine

Although the terms are often used interchangeably, coco betaine is a broader category that includes CAPB. CAPB is a specific type of coco betaine with unique properties, making it a preferred choice in many formulations.

Environmental Impact

One of the concerns about CAPB is its environmental impact. While it is biodegradable, the production process involves chemicals that can be harmful if not managed properly. KSMA is committed to sustainable practices, ensuring that our cocamidopropyl betaine manufacturing process minimizes environmental harm.

Alternatives to Cocamidopropyl Betaine

For those who prefer cocamidopropyl betaine-free products, alternatives like disodium cocoamphodipropionate are available. These ingredients offer similar benefits without the risk of irritation for sensitive individuals.

Conclusion

Cocamidopropyl betaine (CAPB) is a versatile and effective ingredient that plays a crucial role in personal care products. From shampoos and body washes to toothpaste and cosmetics, CAPB’s gentle cleansing and foaming properties make it a favorite among manufacturers and consumers alike.

At KSMA, we are proud to be a trusted cocamidopropyl betaine manufacturer, providing high-quality CAPB to cocamidopropyl betaine suppliers worldwide. Our commitment to safety, sustainability, and innovation ensures that our products meet the highest standards.

Whether you’re looking for cocamidopropyl betaine for skin, hair, or other applications, KSMA has you covered. Choose KSMA for reliable, eco-friendly, and effective personal care ingredients.By incorporating cocamidopropyl betaine into your daily routine, you can enjoy the benefits of gentle cleansing and moisturizing without compromising on safety or performance.

#cocamidopropyl betaine#capb#cocamidopropyl betaine manufacturer#cocamidopropyl betaine suppliers#coco betaine#cocamidopropyl betaine for skin#cocamidopropyl betaine uses#cocamidopropyl betaine for hair#cocamidopropyl betaine price#cocamidopropyl betaine shampoo#cocamidopropyl betaine in shampoo#cocamidopropyl betaine side effects#cocamidopropyl betaine surfactant#cocamidopropyl betaine in toothpaste#cocamidopropyl betaine formula#cocamidopropyl betaine structure#cocamido propyl betaine#cocamidopropyl betaine msds#is cocamidopropyl betaine natural#cocamidopropyl betaine chemical structure#cocamidopropyl betaine in cosmetics#cocamidopropyl betaine synthesis#cocamidopropyl betaine vs sls#cocamidopropyl betaine chemical#cocamidopropyl betaine allergy#cocamidopropyl betaine properties#cocamidopropyl betaine pregnancy#cocamidopropyl betaine alternative#cocamidopropyl betaine free shampoo#cocamidopropyl betaine safety

0 notes

Text

Europe Hydrocarbon Resins Tackifiers Market, Outlook and Forecast 2025-2030

The Europe Hydrocarbon Resins Tackifiers market was valued at US$ 245.82 million in 2024 and is projected to reach US$ 365.42 million by 2030, at a CAGR of 6.85% during the forecast period 2024-2030.

Advanced petroleum-derived resins designed for adhesive applications, featuring controlled molecular weight distribution and specific compatibility profiles. Modern production ensures consistent tackifying properties.

Adhesives sector leads with 48.6% share, tapes (32.4%), labels (11.5%). Germany maintains 35.6% share. Performance metrics improved 38.8%. R&D investment reached €72.5 million. Technical innovation grew 34.5%.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/285546/europe-hydrocarbon-resins-tackifiers-forecast-market-2025-2030-307

Report Includes

This report is an essential reference for who looks for detailed information on Europe Hydrocarbon Resins Tackifiers. The report covers data on Europe markets including historical and future trends for supply, market size, prices, trading, competition and value chain as well as Europe major vendors¡¯ information. In addition to the data part, the report also provides overview of Hydrocarbon Resins Tackifiers, including classification, application, manufacturing technology, industry chain analysis and latest market dynamics. Finally, a customization report in order to meet user's requirements is also available.

Download a free Sample Report PDF

This report aims to provide a comprehensive presentation of the Europe Hydrocarbon Resins Tackifiers, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Hydrocarbon Resins Tackifiers. This report contains market size and forecasts of Hydrocarbon Resins Tackifiers in Europe, including the following market information:

We surveyed the Hydrocarbon Resins Tackifiers manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Total Market by Segment:

by Country

• Germany

• United Kingdom

• France

• Italy

• Spain

• Netherlands

• Belgium

by Products type:

• C5 Resin

• C9 Resin

• C5/C9 Resin

• Others

by Application:

• Adhesives

• Inks and Coatings

• Chewing Gum

• Polymer Modification

• Others

key players include: (At least 8-10 companies included)

• Eastman Chemical Company

• ExxonMobil Chemical

• Kraton Corporation

• Arkema Group

• Neville Chemical Company

• Kolon Industries, Inc.

• Cray Valley

• DRT (Les Dérivés Résiniques et Terpéniques)

• Lawter Inc.

• RÜTGERS Group

Competitor Analysis

The report also provides analysis of leading market participants including:

• Key companies Hydrocarbon Resins Tackifiers revenues in Europe market, 2019-2024 (Estimated), ($ millions)

• Key companies Hydrocarbon Resins Tackifiers revenues share in Europe market, 2023 (%)

• Key companies Hydrocarbon Resins Tackifiers sales in Europe market, 2019-2024 (Estimated),

• Key companies Hydrocarbon Resins Tackifiers sales share in Europe market, 2023 (%)

Key Points of this Report:

• The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

• The report covers Europe and country-wise market of Hydrocarbon Resins Tackifiers

• It describes present situation, historical background and future forecast

• Comprehensive data showing Hydrocarbon Resins Tackifiers capacities, production, consumption, trade statistics, and prices in the recent years are provided

• The report indicates a wealth of information on Hydrocarbon Resins Tackifiers manufacturers

• Hydrocarbon Resins Tackifiers forecast for next five years, including market volumes and prices is also provided

• Raw Material Supply and Downstream Consumer Information is also included

• Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

• Analyzing the outlook of the market with the recent trends and SWOT analysis

• Market dynamics scenario, along with growth opportunities of the market in the years to come

• Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

• Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

• Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

• Distribution Channel sales Analysis by Value

• Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

• Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

• 1-year analyst support, along with the data support in excel format.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/285546/europe-hydrocarbon-resins-tackifiers-forecast-market-2025-2030-307

0 notes

Text

Value-added tax VAT in Qatar

As one of the wealthiest countries in the world, Qatar has traditionally relied on oil and gas revenues to fuel its economy. However, to diversify its revenue streams and reduce reliance on hydrocarbons, the Qatari government has introduced VAT in Qatar to generate additional income.

VAT is a consumption tax added to the price of goods and services at each stage of the supply chain. It is ultimately borne by the end consumer, making it an indirect tax. Implementing VAT in Qatar will be a part of a broader effort to modernise the country's tax system and bring it in line with international standards.

If you're considering VAT registration in Qatar, you must understand the current status of VAT implementation, including key dates and compliance requirements.

0 notes

Text

C10 Solvent Prices: Current Trends and Market Dynamics

C10 solvents, a group of hydrocarbons derived primarily from petroleum refining, are essential in a variety of industries, including paints and coatings, adhesives, and industrial cleaning. These solvents are valued for their high solvency power, low evaporation rates, and compatibility with many formulations. However, like other petrochemical products, the pricing of C10 solvents is subject to multiple factors, including raw material costs, global supply-demand balances, and market-specific dynamics.

Recent Price Trends

The prices of C10 solvents have seen significant fluctuations over the past year. This volatility is largely tied to crude oil prices, as C10 solvents are derived from petroleum feedstocks. In 2023, the global oil market experienced price surges due to geopolitical tensions, OPEC production cuts, and increased energy demand post-pandemic. These factors directly impacted the cost of petrochemical intermediates, including C10 solvents.

As of the fourth quarter of 2024, C10 solvent prices are stabilizing but remain on the higher end compared to historical averages. This stabilization is attributed to several factors:

Moderating Crude Oil Prices: After peaking earlier in the year, crude oil prices have eased slightly due to improved supply dynamics and slower economic growth in major markets like China and Europe.

Seasonal Demand Variations: Demand for C10 solvents typically fluctuates based on seasonal activity in the coatings and construction sectors. The autumn months often see a dip as these sectors wind down.

Currency Fluctuations: The strengthening of the U.S. dollar in recent months has made imports of petrochemical products more expensive for countries with weaker currencies, impacting global trade flows.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Supply Chain Dynamics

The global supply chain for C10 solvents has faced disruptions in recent years due to logistical bottlenecks, particularly during the COVID-19 pandemic. While supply chains have largely normalized, occasional disruptions continue to occur, particularly in regions prone to natural disasters or political instability.

Additionally, the global transition towards greener energy and stricter environmental regulations have placed pressure on the petrochemical industry. Producers are increasingly focusing on sustainable practices, which may lead to higher production costs for traditional solvents like C10. Some manufacturers are also exploring bio-based alternatives, which could eventually impact the market share and pricing dynamics of conventional C10 solvents.

Outlook for 2025

Market analysts forecast a steady demand for C10 solvents, particularly in emerging economies where industrial growth remains robust. However, potential challenges include:

Environmental Regulations: Stricter emissions standards and sustainability initiatives could limit the use of traditional solvents, encouraging a shift towards low-VOC or bio-based alternatives.

Raw Material Prices: Crude oil and naphtha prices will continue to play a pivotal role in determining the cost of C10 solvents.

Technological Innovations: Advances in solvent recovery and recycling technologies may reduce overall demand for virgin solvents, impacting market dynamics.

Conclusion

The C10 solvent market remains a critical component of the global petrochemical industry, with its pricing influenced by a complex interplay of macroeconomic factors, raw material availability, and regulatory changes. Stakeholders, including manufacturers, distributors, and end-users, must stay attuned to these dynamics to navigate the market effectively. As the industry evolves, adapting to environmental trends and technological advancements will be crucial for long-term sustainability and profitability.

Get Real time Prices for C10 solvent: https://www.chemanalyst.com/Pricing-data/c10-solvent-1466

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#C10 Solvent#C10 Solvent Price#C10 Solvent Prices#C10 Solvent Pricing#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Well Cementing Services Market Future Outlook: Analyzing Size, Share, Growth Patterns

The global well cementing services market is expected to reach USD 11.6 billion by 2030. The market is projected to grow at a CAGR of 4.1% from 2024 to 2030, according to a new report by Grand View Research, Inc. Rising drilling activities to recover unconventional hydrocarbons such as shale and tight gas coupled with rehabilitation activities in existing oil & gas fields is expected to remain a key driving factor for the global market.

Well Cementing Services Market Report Highlights

The primary type dominated the market with a global revenue share of 77.7% in 2023 and is projected to continue its dominance from 2024 to 2030.

The well cementing services market in North America secured 41.1% of the global revenue share in 2023. The development of untapped hydrocarbon reserves was a major driving force.

The Asia Pacific well cementing services market was significantly augmented owing to the strong growth in cement consumption, partially due to the reopening of the Chinese economy.

The global industry is dominated by various integrated players present across the value chain. Key companies operating in the well cementing service market include Schlumberger Ltd., Baker Hughes Inc., Halliburton, Weatherford & Gulf Energy Llc., and Calfrac Well Services Ltd.

For More Details or Sample Copy please visit link @: Well Cementing Services Market Report

A large number of unexplored reserves particularly in Brazil, Russia, and China, coupled with technological advancements in well cementing equipment and services provided by oil service providers is projected to have a positive impact on the market growth in the near future. Stringent environmental regulations coupled with low crude oil prices are expected to hinder market growth over the next eight years. Low crude oil prices are anticipated to support stronger economic growth, but it may hamper growth among energy-producing states.

Primary cementing was the leading service segment and accounted for over 75% of total market revenue in 2015. It is estimated to remain the largest segment over the next eight years owing to rising E&P to exploit unconventional hydrocarbon reserves. Remedial cementing is anticipated to emerge as the fastest-growing well cementing service market over the forecast period owing to increasing rehabilitation of oil & gas wells in both onshore and offshore activities.

List of major companies in the Well Cementing Services Market

Advanced Cementing Services Incorporated

Baker Hughes Company

Calfrac Well Services Ltd.

China Oilfield Services Limited

Gulf Energy SAOC

Halliburton Company

Magnum Cementing Services Ltd.

Sanjel Energy Services

Schlumberger Limited

For Customized reports or Special Pricing please visit @: Well Cementing Services Market Analysis Report

We have segmented the global well cementing services market on the basis of type, well type, deployment and region.

#WellCementing#OilfieldServices#EnergyIndustry#DrillingOperations#WellConstruction#CementingSolutions#PetroleumEngineering#OilAndGas#EnergyInnovation#SubsurfaceTech#WellIntegrity#ReservoirManagement#FieldDevelopment#IndustrialServices#EnergySector

0 notes

Text

Alpha Olefin Market: A Look at Global Growth and Regional Insights

The global alpha olefin market was valued at approximately USD 10.42 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This market growth is primarily driven by the increasing demand for polyethylene, which is one of the most widely used plastics in various industries, including packaging, consumer goods, and industrial processes. The versatility and demand for polyethylene are expected to significantly boost the alpha olefin market, as alpha olefins are crucial raw materials used in the production of polyethylene and other synthetic materials.

Polyethylene is used extensively in packaging applications, ranging from plastic films and containers to bottles and bags. In addition, it plays a key role in various industrial processes, such as in the production of automotive parts, construction materials, and medical supplies. Its widespread use across different sectors is expected to drive a continuous demand for alpha olefins, which are essential in polyethylene production.

The most common method of alpha olefin production is the oligomerization of ethylene, where ethylene molecules are linked to form larger compounds. This process is the predominant method used globally to produce alpha olefins, resulting in the creation of products with even-numbered carbon chains, typically ranging from C4 to C30+. These products are crucial in the production of various derivatives like polyethylene, synthetic lubricants, detergent alcohols, and plasticizers.

In addition to the growing demand for polyethylene, oil drilling activities in the United States have emerged as a significant contributor to the market growth. The U.S. has witnessed a substantial increase in oil drilling activities, particularly in major oil-rich regions such as the Permian Basin in Texas and New Mexico, the Bakken Formation in North Dakota, and the Eagle Ford Shale in Texas. These regions are characterized by high oil production rates, which have, in turn, enhanced the availability of ethylene, a critical raw material for the production of alpha olefins.

Gather more insights about the market drivers, restrains and growth of the Alpha Olefin Market

Regional Insights

North America Alpha Olefin Market

North America led the global alpha olefin market with a revenue share of 39.3% in 2023, largely due to the surge in shale gas production in the U.S., which has significantly boosted ethylene production. Since ethylene is the primary feedstock for producing alpha olefins, this increase in production directly impacts the alpha olefin market. Furthermore, ongoing oil exploration activities in the Gulf of Mexico are expected to contribute further to market growth, as these activities increase the availability of hydrocarbons used in the production of ethylene and other key petrochemicals. Additionally, crude oil production in Canada is anticipated to further support the growth of alpha olefins in the region, as Canada is a major player in the global petrochemical market.

U.S. Alpha Olefin Market Trends

In the U.S., the alpha olefin market is primarily driven by the demands of the packaging sector, which requires vast quantities of polyethylene and other polymer products made from alpha olefins. Additionally, advances in polymer technology have contributed to the growing use of alpha olefins in high-performance plastics. The market is dominated by large, well-established players such as Chevron Phillips Chemical Co., The Dow Chemical Company, and ExxonMobil, who are heavily involved in the production and development of alpha olefins. These companies contribute significantly to the market’s expansion through innovation, large-scale production, and strategic investments in ethylene production capabilities.

Europe Alpha Olefin Market Trends

Europe holds the second-largest share of the alpha olefin market in 2023. The region is witnessing steady growth, driven by a focus on sustainable production methods and a rising demand for bio-based alpha olefins. As the demand for specialty chemicals and performance products continues to grow, the need for high-quality alpha olefins to meet these requirements is increasing. Germany, one of the leading players in the European market, is known for its emphasis on technological innovation and sustainability. The country has a strong presence of companies like Shell plc, which plays a crucial role in driving the development and production of alpha olefins. The demand for synthetic lubricants, plasticizers, and cosmetics is also contributing to the growth of the alpha olefin market in Germany, which is a hub for chemical innovations.

In the UK, the alpha olefin market is supported by demand from various sectors, including coatings, paper, pharmaceuticals, cosmetics, and the automotive industry. The easy availability of raw materials and the presence of abundant natural resources in the region are expected to further fuel market growth.

Asia Pacific Alpha Olefin Market Trends

The Asia Pacific region is expected to witness significant growth in the alpha olefin market from 2024 to 2030. This growth is attributed to the increasing demand from the packaging industry, rapid industrialization, and the expansion of the automotive sector. The region is also seeing significant investments in research and development (R&D), focusing on the development of specialty chemicals, which are increasingly being used in a wide range of applications.

In China, the alpha olefin market is growing due to the strong presence of domestic companies like Sinopec and PetroChina, who play a pivotal role in producing alpha olefins. The industrial expansion in China, particularly in the polyethylene and detergent alcohols sectors, has led to a growing need for high-quality alpha olefins. As China's industrial and manufacturing sectors continue to expand, the demand for alpha olefins is expected to rise further, making it one of the most significant contributors to the global market.

The Indian alpha olefin market is also growing, primarily due to the increasing demand for polyethylene and rising consumption in the automobile sector. However, the market faces challenges such as the high costs of raw materials and manufacturing processes, which could be a barrier to more widespread growth. Despite these challenges, India is expected to remain a key player in the alpha olefin market.

Central & South America Alpha Olefin Market Trends

The Central and South American market for alpha olefins is expected to experience significant growth from 2024 to 2030. The market is supported by the abundant availability of raw materials, particularly ethylene, and the presence of major industry players such as Braskem and Petrobras. The focus on renewable and environmentally friendly solutions is shaping market trends in the region, as more companies seek to integrate sustainable practices into their operations.

In Brazil, the market for alpha olefins is driven by the country's focus on sustainable growth, with a growing need for specialty chemicals and plasticizers. Major producers like Braskem are concentrating on developing high-quality alpha olefins to meet the diverse needs of the Brazilian market. Additionally, the growing demand for synthetic lubricants and adhesives in various sectors, including automotive and construction, is further supporting the market's growth in Brazil.

Middle East & Africa Alpha Olefin Market Trends

The Middle East and Africa (MEA) region is poised to see significant growth in the alpha olefin market during the forecast period. The region's strong petrochemical industry, combined with efforts to diversify its economy, is contributing to market expansion. Strategic investments in advanced polymer technologies and the development of innovative production methods are also key drivers of the region's growth.

In Saudi Arabia, the market is experiencing significant growth due to the country's vast natural resources and the prominent role of key players like SABIC. The increasing demand for alpha olefins in industries such as oil and gas and petrochemicals is a significant driver for the region's market. Furthermore, Saudi Arabia's efforts to enhance its chemical and petrochemical manufacturing capabilities are expected to lead to a rising demand for alpha olefins, further strengthening the market in the region.

Browse through Grand View Research's Organic Chemicals Industry Research Reports.

• The global isobutanol market size was valued at USD 1.28 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030.

• The global pentaerythritol market size was valued at USD 2.80 billion in 2023 and is expected to grow at a CAGR of 43.2% from 2024 to 2030.

Key Alpha Olefin Company Insights

Companies in the alpha olefin industry are focusing heavily on the development of new products and building long-term partnerships with raw material suppliers. These strategic efforts are aimed at driving growth in the market, with key factors contributing to success including the range of products offered, competitive pricing strategies, and advanced manufacturing technologies. As the demand for alpha olefins continues to rise, many companies—especially large international players—are investing significantly in research and development (R&D). They are also working to innovate and adopt sustainable production methods to stay ahead of competition and meet regulatory requirements for environmental sustainability. In addition, to capitalize on emerging opportunities, these companies are expanding their presence by establishing production facilities in developing countries, where market potential is rapidly growing.

Several key players in the alpha olefin market include:

1. Chevron Phillips Chemical Company LLC

Chevron Phillips Chemical is a leading global chemical company that offers a comprehensive product range. This includes aromatics, drilling specialties, olefins, performance pipe, polyethylene, and specialty chemicals. Within its product portfolio, the company also produces alpha olefins, which are integral to many of the industries the company serves. Chevron Phillips is known for its strong technological capabilities and large-scale production of high-quality alpha olefins, particularly in the normal alpha olefin segment. The company’s research and development efforts continue to support its leadership position in the market, focusing on developing new applications and more efficient manufacturing processes.

2. Evonik Industries AG

Evonik Industries is a prominent global player in the chemical industry, offering a diverse range of products. Under its business segment VESTOPLAST, Evonik produces co- and terpolymers of propene, ethane, and 1-butene, which are essential building blocks for various applications in plastics and specialty chemicals. In addition to traditional alpha olefins, the company provides modified versions of amorphous poly-alpha olefins that incorporate silane. These modifications enable enhanced performance for products used in applications like adhesives, coatings, and sealants. Evonik's continued focus on innovation and sustainability makes it a key player in the ongoing development of the alpha olefin market.

Key Alpha Olefin Companies:

The following are the leading companies in the alpha olefin market. These companies collectively hold the largest market share and dictate industry trends.

• Chevron Phillips Chemical Company LLC

• Exxon Mobil Corporation

• Petrochemicals (Malaysia) Sdn. Bhd.

• INEOS Oligomers

• Mitsubishi Chemical Corporation

• SABIC

• Sasol

• Shell plc

• Jam Petrochemical

• Dow

Order a free sample PDF of the Alpha Olefin Market Intelligence Study, published by Grand View Research.

#Alpha Olefin Market#Alpha Olefin Market Analysis#Alpha Olefin Market Report#Alpha Olefin Market Regional Insights

0 notes

Text

The Crude Oil Refining Process: From Raw Material to Refined Product

Crude oil is often referred to as "black gold" due to its immense value and critical role in the global economy. The refining of crude oil transforms this complex mixture of hydrocarbons into valuable products such as gasoline, diesel, jet fuel, and various petrochemicals. Understanding the refining process is essential for appreciating how these products are derived and the technology behind their production.

Understanding Crude Oil

Crude oil is a natural resource extracted from the earth, consisting primarily of hydrocarbons, along with various other organic compounds. The quality and composition of crude oil can vary significantly depending on its source, influencing how it will be refined. Key characteristics include the oil’s density (measured in API gravity) and sulfur content. These factors determine the refining techniques and processes employed.

The Refining Process

The crude oil refining process is typically divided into three main stages: distillation, conversion, and treatment.

Distillation: The first step involves heating crude oil in a distillation column. As the oil is heated, it vaporizes, and the vapors rise through the column, where they cool and condense at different levels. This process separates the oil into various fractions based on boiling points, allowing for the collection of lighter products such as gasoline and heavier products like diesel and residual fuel oil.

Conversion: The second stage is conversion, where heavier fractions undergo additional processing to break down larger molecules into smaller, more useful ones. Techniques such as cracking, hydrocracking, and reforming are employed to enhance yield and improve product quality. Cracking uses heat and pressure to break large hydrocarbon chains, while hydrocracking adds hydrogen to convert heavy oils into lighter products.

Treatment: Finally, the separated and converted products undergo treatment processes to remove impurities, stabilize the products, and ensure they meet specific industry standards. Treatment methods may include desulfurization, hydrotreatment, and blending with additives to enhance performance characteristics.

The Importance of Technology

Modern refining is heavily reliant on technology to optimize efficiency and minimize environmental impact. Advanced monitoring systems enable refineries to track key parameters in real time, ensuring optimal operation. Additionally, automation enhances safety and reduces human error, leading to a more reliable refining process.

Moreover, innovations such as digital twins—virtual replicas of physical assets—allow operators to simulate processes, identify inefficiencies, and test new strategies without disrupting actual operations. These technologies are integral to enhancing productivity while maintaining safety and compliance with environmental regulations.

Conclusion

The refining of crude oil is a complex yet fascinating process that transforms raw materials into essential products used daily. By understanding the stages of refining—distillation, conversion, and treatment—one can appreciate the technological advancements that enable the production of high-quality fuels and chemicals. As the demand for cleaner energy sources grows, refining processes will continue to evolve, adopting more sustainable practices and technologies to meet future needs.

0 notes

Photo

A newly developed catalyst makes single-use plastics easier to upcycle, recycle and biodegrade

Researchers created a new catalyst that transforms hydrocarbons into chemicals and materials that are higher value, easier to recycle, and biodegrade in the environment. This catalyst transforms materials such as motor oil, plastics in single-use grocery bags, water or milk bottles, and their caps, and even natural gas. It was developed by a team of scientists led by Aaron Sadow, a scientist at Ames National Laboratory, director of the Institute for Cooperative Upcycling of Plastic (iCOUP), and professor of chemistry at Iowa State University.

The new catalyst is designed to introduce functional groups into aliphatic hydrocarbons. Aliphatic hydrocarbons are organic compounds made up of only hydrogen and carbon. They typically do not mix with water, instead creating distinct layers, partly because they do not contain functional groups. Functional groups are specific groupings of atoms within molecules that have unique characteristics. Adding functional groups to these hydrocarbon chains can drastically affect their properties and make the materials recyclable.

"Methane in natural gas is the simplest of hydrocarbons with nothing but carbon-hydrogen (CH) bonds. Oils and polymers have chains of carbon atoms, linked by carbon-carbon (CC) bonds," Sadow explained.

Read more.

19 notes

·

View notes

Text

The Commercial Refrigeration System Market is projected to grow from USD 54766 million in 2024 to USD 75239.81 million by 2032, expanding at a CAGR of 4.05% from 2024 to 2032.The global commercial refrigeration system market is witnessing rapid growth, driven by several key factors such as rising demand from the food and beverage industry, technological advancements, and an increasing emphasis on energy efficiency. Commercial refrigeration systems are essential for preserving perishable goods, maintaining food safety, and ensuring product quality across various industries. This market encompasses various types of equipment, including refrigerators, freezers, walk-in coolers, display cases, and ice-making machines, used in sectors such as supermarkets, convenience stores, restaurants, and food processing facilities.

Browse the full report at https://www.credenceresearch.com/report/commercial-refrigeration-system-market

Market Overview

The commercial refrigeration system market has seen substantial growth in recent years, driven primarily by increasing urbanization, rising disposable incomes, and changing consumer preferences towards ready-to-eat and frozen food products. In addition, the expansion of the foodservice industry, including restaurants, cafes, and hotels, has spurred demand for efficient and advanced refrigeration solutions.

According to industry reports, the global commercial refrigeration market was valued at approximately USD 30 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of around 5% between 2021 and 2027. This growth is further boosted by the ongoing developments in cooling technologies, the need for greener refrigeration solutions, and the increasing awareness of food safety regulations.

Key Drivers of Growth

1. Rising Demand in the Food and Beverage Industry The food and beverage industry is one of the largest end-users of commercial refrigeration systems. The increasing demand for frozen and chilled food products has resulted in a heightened need for efficient refrigeration solutions. Supermarkets, grocery stores, and food processing facilities rely heavily on these systems to store perishable products, maintain their quality, and extend their shelf life. The growth of e-commerce and online grocery delivery services has also driven the adoption of commercial refrigeration systems to meet the requirements of cold chain logistics.

2. Technological Advancements Technological innovations in the commercial refrigeration sector have led to the development of energy-efficient and environmentally friendly systems. New refrigeration units with advanced features such as digital temperature control, smart monitoring systems, and energy-efficient compressors have gained significant traction in the market. The adoption of natural refrigerants such as ammonia, CO2, and hydrocarbons, which have low global warming potential (GWP), is another major trend, in line with global efforts to reduce greenhouse gas emissions and meet environmental standards.

3. Stringent Food Safety Regulations Regulatory bodies across the globe have introduced stringent food safety standards to ensure the quality and safety of food products. These regulations require businesses to maintain proper refrigeration and storage practices to prevent contamination and spoilage. As a result, companies in the foodservice, retail, and hospitality industries are increasingly investing in commercial refrigeration systems that comply with these regulations, further driving market growth.

4. Growth of the Hospitality Industry The global hospitality industry, encompassing hotels, restaurants, and cafes, has experienced steady growth due to increasing tourism and consumer spending on dining out. These establishments require reliable refrigeration systems to store food and beverages safely. The trend of cloud kitchens and ghost kitchens, which are food delivery-only operations, has also contributed to the demand for commercial refrigeration systems to maintain operational efficiency.

Challenges Facing the Market

Despite the positive growth trajectory, the commercial refrigeration market faces certain challenges. The high initial investment required for purchasing and installing advanced refrigeration systems is a significant barrier for small and medium-sized enterprises (SMEs). Additionally, the rising cost of energy and the need for regular maintenance and repairs add to the overall operational expenses.

Moreover, environmental concerns regarding the use of refrigerants with high GWP have led to stricter regulations on traditional cooling technologies. Businesses are now required to phase out older systems and adopt more eco-friendly alternatives, which can be cost-prohibitive.

Future Outlook

The future of the commercial refrigeration system market looks promising, with continued growth anticipated over the next decade. The increasing focus on energy efficiency and sustainability will drive the development of innovative refrigeration solutions. Companies are expected to invest in research and development to create systems that not only reduce energy consumption but also comply with environmental regulations.

Moreover, the growing trend of smart and connected refrigeration systems, which enable real-time monitoring and predictive maintenance, will further revolutionize the industry. As businesses seek to enhance operational efficiency and reduce downtime, the adoption of these advanced technologies will become more prevalent.

Key Players:

Daikin

Johnson Controls

Carrier

Dover

Baltimore Aircoil Company

Blue Star Limited

De Rigo Refrigeration

Fogel

Hussmann

Imbera

Segmentation:

Based on Product Type

Refrigerator & Freezer

Transportation Refrigeration

Refrigerated Display Cases

Beverage Refrigeration

Ice Cream Merchandiser

Refrigerated Vending Machine

Based on Refrigerant Type

Fluorocarbons

Hydrocarbons

Inorganics

Based on Application

Hotels & Restaurants

Supermarkets & Hypermarkets

Convenience

Based on Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/commercial-refrigeration-system-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Indian Oil Corporation

Indian Oil Corporation is a Maharatna Company controlled by GOI. This entity possesses business interests that encompass the entire hydrocarbon value chain, including refining, pipeline transportation, and the marketing of petroleum products, as well as research and development, exploration and production, and the marketing of natural gas and petrochemicals. The foremost refining enterprise in…

0 notes

Text

Surging Demand for Consumer Appliances to proliferate the Refrigerant Market!

A comprehensive overview of the refrigerant market is recently added by UnivDatos Market Insights to its humongous database. The report has been aggregated by collecting informative data from various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the refrigerant market globally. This report offers a detailed analysis of the latest industry developments and trending factors that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the global market at regional and country levels. The Refrigerant Market is likely to showcase a growth of around 8% during the forecast period (2022-2028).

Market Overview

A refrigerant is a mixture of fluid substances that are utilized in the refrigeration or heat pump cycle. It changes from liquid to gas during the refrigeration cycle. Refrigerants are employed because of their non-corrosive characteristics, high heat of vaporization, moderate liquid density, and high gaseous density. Furthermore, there is a variety of compounds with refrigerant qualities, such as HCFC, HFC, HFO, and others. Air conditioning systems for the construction, chemical, pharmaceutical, and food industries are the most common uses of refrigerants.

The growth of the market is influenced by the factors such as the growing demand for refrigerants in commercial & industrial refrigeration, air conditioning system, and others. Moreover, urbanization and improvement in the standard of living led to high demand for air conditioners helping in the growth of the refrigerant market.

COVID-19 Impact

The Refrigerant market has been negatively impacted by the COVID-19 pandemic. This is due to interruptions in value chains induced by the closure of national and international borders in 2020, numerous sectors had to slow down their operations, resulting in decreased demand for refrigerants. The COVID-19 epidemic produced price fluctuations in raw materials used to make refrigerants. As a result, in 2020, the refrigerant market is predicted to increase at a negative rate. However, from 2021 onwards, demand is predicted to pick up and persist throughout the forecast period.

Refrigerant market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

By Type, the market is primarily bifurcated into:

Fluorocarbons

Hydrocarbons

Inorganic refrigerant

Others

Based on type, the market is segmented into fluorocarbons, hydrocarbons, inorganic refrigerants, and others. The inorganic refrigerant segment is expected to witness the highest CAGR during the forthcoming years. Inorganic refrigerants consist of inorganic compounds (which do not contain carbon-hydrogen bond) used primarily as refrigerants such as R718, 717, and 744. The benefits of these refrigerants such as non-toxic, environment friendly, inexpensive & non-flammable are contributing to the market growth.

By Application, the market is primarily bifurcated into:

Residential

Commercial

Industrial

Based on the application, the market is categorized into residential, commercial, and industrial. Amongst them, the commercial segment is expected to witness the highest CAGR during the forecast period. This is due to an increase in demand for infrastructural development in inter-country and the growing demand for air conditioners in commercial sectors. A rise in the number of hypermarkets/ supermarkets, malls, hospitals, and healthcare facilities is contributing to the growth of the market.

Refrigerant Market Geographical Segmentation Includes:

North America

United States

Canada

Rest of north America

Europe

Germany

France

United Kingdom

Spain

Italy

Rest of Europe

Asia-Pacific

China

India

Japan

Australia

Rest of Asia-Pacific

Rest of World

For a better understanding of the market adoption of the Refrigerant market, the market is analyzed based on its worldwide presence in the countries such as North America (United States, Canada, Rest of North America), Europe (Germany, France, Spain, Italy, United Kingdom, and Rest of Europe), Asia-Pacific (China, Japan, India, Australia and Rest of APAC), and Rest of World. The Asia Pacific is projected to hold the largest share of the Refrigerant market by 2028 because of the increase in infrastructure development in emerging economies. actors such as a huge industrial base, increasing disposable income, increasing urbanization, and changing lifestyles are expected to drive the market for refrigerants in different application segments.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25239

The major players targeting the market includes:

Arkema S.A.

Dongyue Group Co. Ltd.

Honeywell International Inc.

The Chemours Company

The Linde Group

Air Liquide

Sinochem Lantian Co. Ltd.

Daikin Industries

Mexichem

Asahi Glass Corporation.

Competitive Landscape

The degree of competition among prominent companies has been elaborated by analyzing several leading key players operating globally. The specialist team of research analysts’ sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Refrigerant market. The major players have been analyzed by using research methodologies for getting insight views on market competition.

Key questions resolved through this analytical market research report include:

What are the latest trends, new patterns, and technological advancements in the Refrigerant market?

Which factors are influencing the Refrigerant market over the forecast period?

What are the global challenges, threats, and risks in the Refrigerant market?

Which factors are propelling and restraining the Refrigerant market?

What are the demanding global regions of the Refrigerant market?

What will be the market size in the upcoming years?

What are the crucial market acquisition strategies and policies applied by the companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature. Please let us know If you have any custom needs.

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Nanotechnology enables innovative foam containers recycling

Fuelre4m has launched a new product called Styrex, which changes the way polystyrene waste is managed and reused, and puts the closed-loop system of foam container recycling into practice. In this process, nanotechnology shrinks the hydrocarbon chain of EPS and converts it into high-value resin. The material is then compressed to 1/50 of its original size to form a solid, sustainable fuel. In fact, in addition to this innovative technology, there are already physical recycling methods that make foam container recycling truly practical. Physical recycling refers to the processing of foam container waste into PS particles through EPS recycling machines such as EPS densifier and foam pelletizer, and their application in remanufacturing environmentally friendly products. EPS densifier can turn foam into a renewable resource, helping companies to obtain additional benefits in foam container recycling. This EPS recycling machine can help you quickly turn messy foam containers into neat foam ingots, increase space utilization efficiency by 90 times, maintain the factory's 5S and avoid safety hazards. INTCO Recycling provides customers with a repurchase service for foam ingots, helping customers achieve one-stop foam container recycling. We hope to work with the world to protect the beauty of nature.

0 notes