#hydrocarbon utilizers

Explore tagged Tumblr posts

Link

1 note

·

View note

Text

Oxidation of saturated C−H bonds is a key chemical reaction in synthetic chemistry and the chemical industry. Nevertheless, the high bond dissociation energies (BDEs) and weak polarity of C(sp3)−H bonds, especially in saturated hydrocarbons, lead to weak interactions with many catalysts and difficult substrate activation. Aryl ethers are ubiquitous structural motifs in natural products and pharmaceuticals, including dozens of small molecule drugs in the top 200 retail sales. Although the C(sp3)−H bond of aryl ethers can be used as a synthon for organic synthesis to construct C−C/C−N bonds, its oxidative functionalization and application are still limited and challenging. Therefore, it is necessary to develop efficient and convenient methods for the functionalization of ether C(sp3)−H bonds and their utilization in organic synthesis and pharmaceutical chemistry.

Conitnue Reading.

41 notes

·

View notes

Text

Ukraine will not extend its gas transit agreement with Russia after it expires at the end of 2024, Ukrainian Prime Minister Denys Shmyhal told Slovak Prime Minister Robert Fico on Monday.

The two held talks in Uzhhorod in western Ukraine and, according to a Ukrainian official, were focused on infrastructure cooperation, energy security and support for Kyiv's peace plan. "Ukraine once again says it will not continue the transit agreement with Russia after it expires," Shmyhal told a news conference sitting alongside Fico. "Ukraine's strategic goal is to deprive the Kremlin of profits from the sale of hydrocarbons which the aggressor uses to finance the war." Slovakia, a member of NATO and the EU which shares a border with Ukraine, opposes Kyiv's accession to NATO, but has a strong interest in maintaining the transit of oil and gas from Russia to the west via Ukraine. Slovak state-owned gas buyer SPP said this month it was continuing negotiations to secure an extension of gas transit through Ukraine after Kyiv’s contract with Russian supplier Gazprom expires at the end of the year. Shmyhal said that Kyiv understands the "acute dependence" of some states, including Slovakia on the Russian gas supply, but is counting on gradual diversification of delivery. Ukraine's prime minister also said the two countries had agreed on the creation of an Eastern European energy hub, which aims to utilize large Ukrainian gas storage facilities.

Big critic

Fico has been a big critic of Western military aid to Ukraine, along with Hungarian Prime Minister Viktor Orban, and has made a big show of halting government-sponsored military aid to Ukraine while allowing commercial supplies to continue.

He reiterated his view that there was no military solution to the Ukrainian-Russian war.

"Peace must be sustainable, you have to have security guarantees. Above all, sovereignty and territorial integrity of Ukraine must be respected. We understand all that," Fico said.

He said the talks with Ukraine's government confirmed that Kyiv remained interested in using its gas and oil transit systems after the deal with Russia expires.

"I welcome our discussion which confirmed that you, like us, have an interest in the transit system you have on Ukrainian territory continuing to be used, when it comes to both oil and gas," Fico added.

6 notes

·

View notes

Text

So I was thinking the one thing I can use my degree to contribute to this fandom with is to include whatever the fuck the fake chemical Ema mentions in turnabout corner is and it's actually funny as fuck. Anyway grain of salt, I'm still in the process of getting my degree and won't be certified scientist for a few years so like, I may and probably will fuck up but hey this is a fake chemical and it's mostly just cute wordplay so.

The chemical is hydroxyacelunodosetrase.

So I'm going to break down the boring bits first. So hydroxy is an OH group. Very common. Insanely. Basically just here to denote that this is a chemical to lay people because of how common this is. Acel is a little weird. But Ace normally means a hydrocarbon chain with a length of 2 and sometimes you do need to add on stuff for pronouncablity but I think it's a deliberate misspelling (because ace like ace attorney) of an acyl group which is a C=O group but honestly outside of very specific circumstances specific it's not thaaaat common in chemical names because it doesn't provide as much utility as denoting a more specific subset of acyl groups like a ketone, aldehyde, ester or carboxylic acid group but it is still used especially when denoting ions or free radicals or especially when bonded to a halogen. So the fact it's needing to be notated puts my lab alarm off screaming "shit look into this before using it, it could be dangerous" because that normally means its reactive as fuuuuuck. Acyl groups as a whole are pretty reactive, that double bond to oxygen likes very much to no longer be a double bond but there are a lot of configurations that will make it a little more stable. If it need to be notated as such it's probably not in one of those. Very funny given its used in context as a threat.

The only other part of it that is chemically coherent is the trase suffix. (Edit edit fuck I think what I'm thinking of is ase as a suffix which means enzyme. I do not know where the tr is coming from) It's I believe common in enzymes but I am not a biochemist nor very good at biochemistry and I cannot find a source on Google backing that up and it is just coming from my brain so I may well be wrong. What matters though is how it's pronounced. Which is the same as Tres. Which makes the last 2 bits make more sense. Chemistry uses Greek numbering. The rabbit hole of chemical naming is deep and I'm not getting into it because there are multiple naming systems and one of them is standardised and the other one is actually the thing everyone uses. But Uno is not a thing in chemical names. Neither is dose but it's probably ment to be like a dose as in a drug dose. Again not found in the name it's self but I think that's why it's spelt like that. But the upshot is that the last 3 parts are pronounced Uno dos Tres which is obviously 123 in Spanish. It's cute.

So basically in conclusion it's not a real thing at all. It's all word play and it's would probably be pretty nasty even if it wasn't. I think it's cute. I'm glad some thought was put into this fake chemical instead of just a keyboard spam.

26 notes

·

View notes

Text

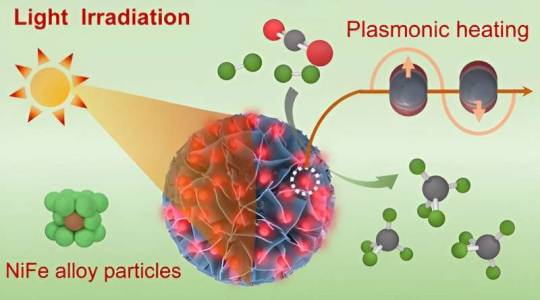

Efficient photothermal CO₂ methanation over NiFe alloy nanoparticles

The massive emissions of CO2 from the utilization of fossil fuels have caused a series of environmental issues and climate change. Driven by the fast development of green hydrogen and CO2 capture technologies, the hydrogenation of CO2 to hydrocarbon fuels and chemicals is becoming a promising process for the reduction of carbon footprint and the storage of renewable energy. Photothermal catalysis enables efficient CO2 conversion under mild conditions. A study led by Prof. Kang Cheng (College of Chemistry and Chemical Engineering, Xiamen University) and Prof. Ye Wang (College of Chemistry and Chemical Engineering, Xiamen University) evaluated catalysts using a high-pressure fixed-bed reactor quartz reactor with a square cavity in the middle to introduce light. The study is published in the journal Science China Chemistry. A series of NiFe alloy photothermal catalysts were synthesized using the urea-assisted precipitation method for CO2 methanation, in which the bimetallic NiFe nanoparticles with Al2O3 as the structural promoter and Ni/Fe atomic ratio of 7 had the best catalytic performance.

Read more.

#Materials Science#Science#Carbon dioxide#Nanoparticles#Nanotechnology#Catalysts#Nickel#Iron#Xiamen University

10 notes

·

View notes

Text

i'm not gonna reblog this post because it is overall quite good and i just have a nitpick with this part but actually the way the body processes food is pretty much combustion. like it produces CO2 and water from hydrocarbons. that's all combustion is.

food (kilo)calories are also just a measure of energy present in the food. you'll notice if you go to europe that the big label at the top of nutrition facts says Energy and not Calories. but actually, all levels on nutrition facts are theoretical; you are not going to necessarily absorb all the iron, protein, or ascorbic acid in the food either, but the amount present there is still labeled.

a calorie is defined as the measure of energy it takes to heat 1 g of water up 1 degree celsius. why we use that (x1000) to measure food calories is because a number of foods are mostly water, and so are you, but your body is of course measured in kg so it's useful to use kcal. also calorimetry measures energy of complete combustion by the change in temperature of water surrounding the combustion; many bond dissociation energies are reported in kcal/mol still rather than kJ/mol. we use bomb calorimeters because if we don't allow the internal volume to change, we can get a more accurate estimate of bond dissociation energy. calorimetry is not a hack nutritionist's plot against you, but simply the best measure we have of measuring the energy present in materials. we cannot know exactly what's in food structurally or even chemically, so we can't run molecular dynamics simulations to estimate the energies present in catabolism.

now, are energies measured by bomb calorimetry misleading as to how your body processes food? yes. your body does perform combustion on anything it can break down into glucose and co., but it doesn't necessarily perform complete combustion. some small amounts of carbon monoxide are produced in the digestive tract due to this, even! it depends on the type of food you eat how completely it combusts. for example, if you eat a tablespoon of sugar, it'll probably be processed into almost all the calories, whereas if you eat a tablespoon of rye with the same amount of theoretical glucose, it probably won't. this is a significant gripe i have with the quote unquote health food industry, actually- a lot of things are estimated as having higher amounts of accessible calories than they really have, so people end up calorie-cutting by labels in order to diet but then it's compounded by the fact that a number of the calories are entirely inaccessible. so if you calorie-cut to 1600 kcal/day but you're only eating fruits, vegetables, ancient grains, and lean meat, you're probably processing those "1600 kcal" into 1300 or less kcal!

but kilocalories aren't the only misleading thing on food labels, and while eyeballing nutrition facts can help you get enough of essential nutrients like vitamin A and K and the like, in many cases it won't be in the most easily accessible form, so you might malnourish yourself. iron is a big problem here, and why i recommend impossible foods so much to people who are vegetarian and especially vegan; heme is one of the few types of iron that the human body can process, so that impossible foods contain it without being meat makes them extremely important to a non-iron-supplemented vegetarian diet. anyway, digression aside, are the beauty and food industries intentionally being misleading about how accurate kcal are? almost certainly. is the utilization of the kilocalorie (and bomb calorimetry generally) for measurement of energy in foods due to this? almost certainly not.

(P.S.: if you'd like to know why your body isn't constantly on fire due to the fact that you're combusting all the time, that would be because thermodynamics of combustion (a reaction where the products are ludicrously heavily favored) are distinct from the kinetics of combustion commonly (in the atmosphere with so much available oxygen, the rate laws dictate that combustion goes really fast. in your body with enzymatic processes, it goes fairly slowly). everything that can combust is combusting, just very slowly, from paper to gas to sugar- if you leave glucose out in the air, it'll slowly slowly slowly burn even without heat applied; the enzymes in your body get over that initial heat/energy barrier, though, and burn it quicker. however, since there's no continual heat applied, it won't set off a chain chemical reaction and burn very quickly unless something's extremely wrong with your body. eat your antioxidants)

25 notes

·

View notes

Text

What to Consider When Choosing Your Gasket Material and Type

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of…

A gasket may be a combination of materials, which is employed to stop any fluid entry between two static components. The success of the industrial gasket and materials depends on the sort of fabric utilized in the manufacturing process. counting on the sort of application, a spread of materials are wont to produce gaskets of the many shapes and sizes. Gaskets also are chosen supported factors like application temperature, pressure, electrical conduciveness, and resistance to extreme environments.

Types of Gasket Materials

While the materials wont to produce gaskets are numerous, on a general basis, they will be segregated into 3 types:

Fibrous materials

Elastometric materials

Metallic materials

Fibrous materials: These materials are made using organic fibers. The gasket sheet is skilled as a binding solution to assist develop the gasket material. they need excellent absorption properties and are flexible enough to be made into various shapes. Some common samples of fibrous gasket materials are:

Asbestos– In fibrous materials, asbestos is perhaps the foremost recognizable and popular material. It is often used for sealing applications during a sort of environment. Asbestos maintains its shape and strength up to 450oF. It doesn’t emit any toxic odor and is safe to handle.

Carbon fibers- As a cloth, carbon fiber has the power to face up harsh chemical environments. It is often used for applications that have high temperatures and pressures. it’s seen as a perfect material because of its low permeability. However, it’s not suitable for oxidization.

Aramid- An artificial fiber, aramid has been used as a substitute for asbestos. it’s a high resistance towards heat and organic solvents. Though it doesn’t have a freezing point, it does tend to degrade when temperatures reach 500oC. However, it doesn’t react well to salts and acids, also as direct contact with UV rays.

Elastometric materials: because the name suggests, these materials are produced using elastomers with various composites. This makes them extremely popular materials for a spread of industries thanks to their high performance and quality. a couple of well-known elastomers are given below:

Silicone- Perhaps the foremost recognized material for gaskets, silicone is well-known for its waterproof properties. It works effectively in extreme temperatures and is immune to UV and ozone elements. Silicone is often easily molded or cut using water jet cutting systems counting on the sort of application.

Rubber- As an organic material, natural rubber has good resistance to heat, and functions wells as a cushioning pad. When utilized in gaskets, it can recover to its original shape from medium temperatures. It is often wont to protect gaskets from alkalis, mild acids, and inorganic salts.

Neoprene- this will be used as an appropriate option for rubber. The advantage that neoprene has is that while it’s almost like rubber in terms of its resistance to acids and alkalis, it also can work against oils, petroleum, and other fuels. However, it’s not recommended to be used against hydrocarbons.

Metallic materials: Usually, the various sorts of metals wont to produce gaskets are a variety of steels, alloys, titanium, copper, and aluminum.

Carbon Steel– this is often one of the favored metallic choices for gaskets. The larger the quantity of carbon within the alloy, the harder and stronger it becomes. Unfortunately, the carbon content has got to be balanced with other metal properties otherwise it can lower the general freezing point.

Aluminum– Aluminum is understood for its lightweight, machinability, and high resistance to corrosion. Aluminum alloys are an honest choice for gaskets thanks to their weldability and strength.

Titanium– Considered to be almost like 304 chrome steel, titanium is understood for its lightweight, strength, and corrosion resistance. It is often used for very high temperatures, and it’s perfect for oxidizing media.

An understanding of the varied sorts of gasket materials used can assist you to decide the proper type to use in your industrial application.

Original Source: Industrial Gaskets

#gaskets#industrial#gasket material#gasket sheet#Asbestos Gaskets#Gasket Material#Rubber Gasket Sheet#Ready Cut Gaskets#Industrial Gaskets

2 notes

·

View notes

Text

Olefin, a beloved hydrocarbon, is feeling down these days.

The main source of Olefin’s sadness stems from its lack of widespread use as an industrial feedstock. For years, Olefin has been viewed as too expensive to use in the larger volume and quantity needed for the production of various synthetic materials. This has caused a significant decline in volume production for Olefin-based products.

Moreover, some of Olefin’s key characteristics of being non-flammable and chemically stable are actually being used against it as companies are looking to use other hydrocarbons that are safer and more cost effective. Olefin’s sole reliance on petroleum means that prices and demand will always fluctuate, causing further industry uncertainty.

In a further blow, there is a lack of support from the government for this hydrocarbon, as research into renewable alternatives has become much more prominent in recent years. Additionally, more stringent environmental regulations coupled with disputes over trade have further contributed to Olefin’s financial woes.

Unfortunately, Olefin’s outlook doesn’t look to be improving any time soon, but the hydrocarbon remains hopeful for a revival in its use among industry and continued research into alternatives that utilize the many unique properties it possesses.

2 notes

·

View notes

Text

Unraveling the Depths of Bioaugmentation and Biostimulation: A Comprehensive Comparison

Introduction:

If you've ever delved into the field of environmental biotechnology, you've likely stumbled across the terms "bioaugmentation" and "biostimulation". These sophisticated approaches to environmental remediation are both aimed at enhancing natural processes to treat contamination. But what exactly distinguishes one from the other? In this article, we will delve into the specifics of Bioaugmentation vs Biostimulation, breaking down their definitions, applications, and key differences.

Understanding Bioaugmentation:

Bioaugmentation, in its simplest form, is the introduction of a group of natural microbial strains or a genetically engineered variant into an environment to enhance the rate of pollutant degradation. These microbial strains, often referred to as 'augments', are known for their specialized ability to degrade contaminants that the existing microbial community cannot effectively handle. This technique is frequently employed to address the contamination of soil and water bodies with organic pollutants such as oil spills and certain types of industrial waste.

Diving into Biostimulation:

On the other hand, biostimulation involves the stimulation of indigenous microbial communities already present in the environment by providing nutrients, electron acceptors, or substrates that enhance their activity. Unlike bioaugmentation that adds new organisms to an ecosystem, biostimulation works with the existing microbial population, encouraging their growth and pollutant degradation capabilities. Often used in environmental cleanup efforts, biostimulation can enhance the breakdown of a broad range of pollutants, including petroleum hydrocarbons and heavy metals.

Bioaugmentation Vs Biostimulation: A Comparative Study:

Now that we understand the fundamentals of both processes, it's time to compare them head-to-head.

Techniques Involved: While bioaugmentation is about introducing specific microbial strains to boost pollutant degradation, biostimulation works by providing necessary nutrients or substrates to stimulate the indigenous microbial population.

Scope of Application: Both techniques are used in environmental remediation, especially for soil and groundwater. Bioaugmentation has a slight edge in cases where specific contaminants require particular microbial strains for degradation. Biostimulation, however, is often favored for broader applications, given that it enhances the overall microbial activity and not just that of specific strains.

Economic Aspects: Bioaugmentation requires the cultivation and addition of specific microbial strains, which can be costly and technically demanding. On the contrary, biostimulation usually involves adding relatively inexpensive nutrients or substrates, making it a more economically feasible option in many cases.

Environmental Impact: Bioaugmentation involves adding new organisms, which raises concerns about the impact on the existing ecosystem and the potential for creating imbalances. Biostimulation, working with existing microbial communities, is generally viewed as having a less disruptive impact on ecosystem balance.

Effectiveness: Both techniques have proven effective in various scenarios, but their success heavily depends on site-specific conditions. For instance, bioaugmentation's effectiveness might be hindered by the inability of the added microbes to survive in the new environment. Biostimulation's success, on the other hand, could be limited by the potential growth of undesired microbial communities.

Conclusion:

Bioaugmentation and biostimulation, though conceptually distinct, share a common goal: to utilize biological processes for environmental remediation. Choosing between them demands a clear understanding of the contamination at hand, the existing microbial community, and the economic and environmental implications of each approach. As scientists continue to explore these fascinating techniques, our ability to heal the environment using nature's own tools will only continue to improve.

#Bioaugmentation#Biostimulation#Bioremediation technologies#Environmental Remediation#Pollution control methods#Bioaugmentation vs Biostimulation#Benefits of bioaugmentation#Benefits of biostimulation#Bioaugmentation in habitat restoration#Biostimulation for pollution control#Limitations of bioaugmentation#Limitations of biostimulation#Bioaugmentation-assisted biostimulation#Microbial bioremediation#Sustainable environmental practices#Choosing between bioaugmentation and biostimulation#Understanding bioaugmentation#Understanding biostimulation#Industrial waste management#Oil spill cleanup techniques

5 notes

·

View notes

Text

What are Electric Resistance Welding (ERW) Pipes?

Welding Utilizing Electric Resistance Pipes and tubes find widespread application in a variety of industries, such as fencing, engineering, scaffolding, line pipe installation, and much more. The agricultural and irrigation industries are two of the most common places to find ERW pipes being put to use. These pipes are typically utilised in water mains, sewage systems, plant plumbing, deep tube wells, industrial water lines, and many other similar applications. In addition, they find widespread application in the gas pipeline industry, particularly in the production of pipelines that are used to transfer natural gas, LPG, and other non-hazardous gases.

Rolling the metal and then welding it longitudinally along its length is the process that is used to make ERW pipes. If you examine the process of making seamless pipes, you'll see that the metal is extruded to the required length before the pipes are made. This indicates that there are no joints in the cross-section of seamless pipes anywhere along their length. On the contrary, the joints of ERW pipes are welded together in the cross-section of the pipe. Tube Trading Co. is an excellent MSERW Pipe dealer in Gujarat that can fulfil all of your industrial piping and tubing needs.

Pipes that are seamless are made by passing a solid billet across the piercing rod, giving them a round shape and a hollow interior. They find widespread application in hydrocarbon refineries & industries, oil and gas exploration, drilling and transportation, air and hydraulic cylinders, automobiles, boilers, bearings, as well as other high-pressure applications. Because of the intricate manufacturing process and a limited number of competitors in the seamless pipe industry, the unit cost of seamless pipe is more expensive per tonne.

Strip or coil is used throughout the manufacturing process of ERW pipes. The transfer of low- or medium-pressure fluids, such as water and oil, respectively, are examples of common applications for these pipes. If you are seeking ERW pipes of good quality, then you need to choose one of the leading manufacturers of ERW stainless steel pipes. If you are looking for the most prominent as well as distinguished MSERW Pipe supplier in Gujarat, Tube Trading Co., is the best pick for you.

Particular characteristics of ERW tubes and pipes of the highest grade

● High-strength corrosion resistance

● High malleability

● Superior strength

● Durable and sturdy

In order to guarantee that ERW pipes are of the highest possible quality, they are put through a series of rigorous examinations, such as a hydro-test, an ultrasonic weld inspection, a micrometre check, a straightness evaluation, as well as a ring gouge test. ERW pipes, in a nutshell, are pipes that are more economical, have tighter dimensional tolerances, and are lighter in weight. ERW pipes have been used in a variety of different sectors. In addition to the transportation of oil, water, and gas, ERW pipes are also seeing widespread use in the fields of agriculture and vehicle manufacturing. ERW pipes are frequently used in collieries for water extraction, thermal power stations, drinking water, as well as employed as hand pumps for boring wells, and as protection for cables by the telecom sector. This is due to the fact that ERW pipes have a diverse range of applications and are reliable. Get in touch with the most distinct as well as noteworthy MSERW Pipe provider in Gujarat, Tube Trading Co., for your industrial pipes and tubes requirements. The following is a list of some of the most common applications for ERW pipes:

● Structural as well as Engineering purposes such as line pipes, Fencing, scaffolding, etc.

● Automobiles Sector

● Water and gas transportation, oil country tubular

● Agriculture Sector

● Collieries for Water extraction as well as Thermal Powers

● Hand pumps that are used for deep boring wells, Drinking water in houses

● Robust cable protection by the Telecom Department

The Bottom Line:

You should choose a quality-aware manufacturer that creates high-quality pipes in India if you are the MSERW Pipe dealer in Gujarat, MSERW Pipe supplier in Gujarat or MSERW Pipe provider in Gujarat. This is true regardless of the type of pipe you are searching for. The selected manufacturer must be able to create pipes of high quality in a variety of specifications, sizes, and grades to accommodate the requirements of various industries, such as public health, agriculture, housing, oil and gas, engineering, irrigation, etc.

5 notes

·

View notes

Text

Fumaric Acid Prices | Pricing | News | Database | Chart | Forecast

Fumaric Acid Prices a key chemical used widely in food, beverage, and industrial applications, has experienced significant fluctuations in pricing due to various market dynamics. This dicarboxylic acid, known for its sour taste and preservative properties, is utilized across sectors, including food processing, animal feed, resins, and unsaturated polyester. The prices of fumaric acid have historically been influenced by a combination of factors such as raw material costs, global demand trends, supply chain disruptions, and environmental regulations that impact production processes. In recent years, the market has witnessed some notable shifts due to these elements, creating a complex landscape for industry stakeholders.

One of the major factors driving the price of fumaric acid is the cost of raw materials. The primary feedstock for fumaric acid production includes maleic anhydride, which itself is derived from hydrocarbons like benzene or butane. Therefore, any changes in the cost of hydrocarbons can directly impact the pricing of fumaric acid. Fluctuations in crude oil prices, for example, have ripple effects throughout the supply chain, affecting both production costs and market prices. When crude oil prices rise, maleic anhydride production costs increase, which in turn raises the cost of producing fumaric acid. Additionally, geopolitical tensions and changes in trade policies can lead to volatility in raw material prices, further compounding the cost challenges faced by manufacturers.

Get Real Time Prices for Fumaric Acid: https://www.chemanalyst.com/Pricing-data/neopentyl-glycol-npg-1194

Global demand for fumaric acid also plays a crucial role in shaping market prices. The food and beverage industry represents a significant portion of the demand for fumaric acid due to its use as an acidity regulator, flavor enhancer, and preservative in a wide range of products, including bakery items, beverages, and candies. The rising consumer preference for processed and packaged foods, driven by changing lifestyles and increasing disposable incomes, has led to a steady demand for fumaric acid in this sector. This consistent demand helps stabilize prices; however, any major shifts in consumption patterns or regulatory changes that limit the use of additives could lead to price fluctuations.

The industrial applications of fumaric acid, particularly in the production of resins, unsaturated polyester, and alkyd resins, also contribute to market demand. The construction and automotive industries are significant consumers of these materials, and any changes in economic conditions or infrastructure spending can have a notable impact on fumaric acid prices. For example, periods of robust economic growth typically lead to increased demand for construction materials, which in turn boosts the consumption of fumaric acid and supports price increases. Conversely, economic downturns or slowdowns in key end-use sectors can reduce demand and lead to downward pressure on prices.

Supply chain dynamics also have a considerable influence on the price of fumaric acid. Disruptions such as transportation bottlenecks, port closures, and labor shortages can lead to delays in the delivery of raw materials and finished products. The COVID-19 pandemic highlighted the vulnerability of global supply chains, causing disruptions that affected the availability of many chemical products, including fumaric acid. While supply chain challenges have gradually improved since the height of the pandemic, lingering issues, such as shipping delays and increased logistics costs, continue to impact the market and contribute to price volatility.

Another key factor affecting fumaric acid prices is environmental regulation. Stringent environmental policies, particularly in regions such as Europe and North America, have led to tighter controls on chemical production processes to minimize emissions and reduce environmental impact. Compliance with these regulations often requires significant investments in cleaner and more sustainable production technologies, which can increase production costs and, consequently, market prices. As sustainability becomes a more pressing concern across industries, manufacturers are increasingly focused on adopting eco-friendly practices, which may further influence pricing trends.

In recent years, China has emerged as a major producer and supplier of fumaric acid, playing a pivotal role in the global market. The country’s dominance in this sector has a significant impact on prices, as any changes in Chinese production capacity, government policies, or trade tariffs can influence global supply and pricing dynamics. For example, efforts by the Chinese government to enforce stricter environmental regulations have led to the closure of some chemical manufacturing facilities, reducing the overall supply of fumaric acid and contributing to price increases. Additionally, the ongoing trade tensions between China and other major economies, such as the United States, have the potential to disrupt trade flows and affect prices.

Looking ahead, the price outlook for fumaric acid will likely continue to be shaped by a complex interplay of factors, including raw material costs, demand dynamics, supply chain stability, and regulatory developments. The growing emphasis on sustainability and environmentally friendly practices may drive innovation in production technologies, potentially altering the cost structure of fumaric acid manufacturing. Moreover, economic conditions and consumer preferences will play a pivotal role in determining demand across various end-use sectors. As market participants navigate these challenges, the ability to adapt to changing conditions and maintain a competitive edge will be critical in managing price risks and ensuring a stable supply of this essential chemical.

In summary, fumaric acid prices are influenced by a multifaceted set of factors that include raw material costs, global demand trends, supply chain dynamics, and regulatory pressures. These elements interact in complex ways, creating a dynamic market environment that requires careful monitoring and strategic planning by industry stakeholders. As the market continues to evolve, businesses must remain agile and responsive to changes in order to optimize their operations and effectively manage price fluctuations. The future of fumaric acid pricing will depend on the ongoing balance between supply and demand, as well as the industry's ability to adapt to emerging trends and challenges.

Our Related News for Fumaric Acid: https://www.chemanalyst.com/Pricing-data/fumaric-acid-1134

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Fumaric Acid#Fumaric Acid Price#Fumaric Acid Prices#Fumaric Acid Pricing#Fumaric Acid News#Fumaric Acid Price Monitor#Fumaric Acid Database

0 notes

Text

Converting Waste Plastics into Fuel Oil through Pyrolysis

The management of plastic waste has become a critical global issue, with millions of tons of plastic being discarded annually. Conventional disposal methods such as landfilling and incineration are not only unsustainable but also environmentally detrimental. An emerging solution to this problem is the pyrolysis of plastic waste, a process that transforms discarded plastics into valuable fuel oil. A plastic to oil machine is central to this process, enabling the conversion of plastic waste into usable products.

The Pyrolysis Process

Pyrolysis is a thermal desorption process that occurs in the absence of oxygen. When plastic waste is exposed to high temperatures (typically between 350°C and 500°C), it breaks down into smaller molecules. This chemical reaction results in the production of a variety of byproducts, including fuel oil, gas, and carbon black. The key advantage of pyrolysis is its ability to convert plastics into fuel oil that can be used in engines, industrial boilers, or refined further for use as a substitute for crude oil.

In a plastic to oil machine, the plastic is first shredded and fed into the pyrolysis reactor. The reactor is equipped with a heating system that raises the temperature to the necessary level for the pyrolysis reaction to occur. During this process, the plastic waste undergoes a complex chemical transformation, producing gaseous hydrocarbons that are condensed into liquid form to create fuel oil. The remaining solid residue, known as carbon black, can be further processed or used in various industrial applications.

youtube

The Role of a Plastic to Oil Machine

The plastic to oil plant is the cornerstone of the pyrolysis process. These machines are designed to handle various types of plastics, including polyethylene (PE), polypropylene (PP), and polystyrene (PS). The machine's design ensures efficient heating, precise temperature control, and the safe handling of gases and liquids produced during the process.

The key components of a plastic to oil machine include the pyrolysis reactor, condenser, and cooling system. The reactor is where the plastic waste is heated and broken down into smaller molecules. The gases produced are then cooled and condensed into liquid oil through the condenser. The remaining gases, which may contain some combustible components, are often re-circulated and used as fuel to power the machine, making the process more energy-efficient.

Fuel Oil Production and Its Uses

The fuel oil produced through pyrolysis is a valuable commodity. It can be used as a fuel for power generation, industrial applications, or as a feedstock for further chemical refining. Pyrolysis oil, also known as plastic oil, is similar in composition to diesel or heavy oil and can be utilized in diesel engines or boilers with little to no modification.

This fuel oil can also be refined into higher-value products such as gasoline, kerosene, and other petrochemical derivatives. The ability to convert waste plastics into usable fuel not only provides an alternative energy source but also reduces the reliance on fossil fuels, contributing to energy sustainability.

Additionally, the environmental impact of plastic waste is significantly mitigated. By diverting plastic waste from landfills and incinerators, pyrolysis offers a cleaner and more efficient way to process plastic waste, preventing harmful emissions and reducing the burden on waste management systems.

Environmental and Economic Benefits

The conversion of waste plastics into fuel oil through pyrolysis offers numerous environmental and economic benefits. One of the primary advantages is the reduction of plastic waste in landfills and oceans. Plastics, which take hundreds of years to decompose, often pose a threat to wildlife and ecosystems. Pyrolysis, by breaking plastics down into fuel, reduces the volume of waste, contributing to waste-to-energy initiatives.

From an economic perspective, the fuel oil produced can be sold in the market, providing an additional revenue stream. This is particularly valuable in regions where energy costs are high and alternative sources of fuel are in demand. The carbon black byproduct, which has uses in industries such as rubber and construction, also holds commercial value, further enhancing the profitability of the pyrolysis process.

Furthermore, the pyrolysis process helps reduce the demand for new plastic production. With more plastics being converted into fuel or other valuable products, the need for raw materials is reduced, which can lead to lower production costs for manufacturers.

Conclusion

Pyrolysis offers a sustainable and economically viable solution for transforming plastic waste into fuel oil. The plastic to oil machine plays a critical role in this process, enabling the efficient breakdown of plastic waste into valuable energy resources. With the growing need to address plastic waste and find alternative energy sources, the pyrolysis of plastic waste stands out as a forward-thinking solution that can have significant environmental and economic benefits. By converting plastic waste into fuel oil, this process not only mitigates pollution but also contributes to energy sustainability, providing both immediate and long-term advantages.

0 notes

Text

Embracing Green Refrigeration in HVAC

As our planet increasingly faces the effects of climate change, adopting sustainable practices in all sectors, including HVAC (Heating, Ventilation, and Air Conditioning), has become essential. One of the progressive shifts within the HVAC industry is the move toward green refrigeration. But what is green refrigeration, and why is it crucial for our environment?

Understanding Green Refrigeration

Green refrigeration refers to the use of environmentally friendly refrigerants and practices in HVAC systems. Traditional refrigerants, such as hydrofluorocarbons (HFCs), are known to contribute significantly to global warming and ozone depletion. In contrast, green refrigeration utilizes natural and low-impact refrigerants, like ammonia, carbon dioxide, and hydrocarbons, which are less harmful to the environment.

The Benefits of Green Refrigeration

Reduced Environmental Impact: Green refrigerants typically have a much lower Global Warming Potential (GWP) compared to traditional ones. This means their contribution to climate change is far less, helping to create a more sustainable future.

Energy Efficiency: Many green refrigeration systems are designed to be more energy-efficient. By optimizing energy use, they lower operating costs and reduce the overall carbon footprint of HVAC systems.

Regulatory Compliance: With increasing regulations on harmful refrigerants, adopting green refrigeration ensures compliance with environmental laws and helps businesses avoid potential fines.

Enhanced Performance: Many modern green refrigerants perform better under certain conditions, providing improved cooling and heating performance, which can lead to increased comfort in residential and commercial buildings.

Innovation and Market Demand: As consumers become more environmentally conscious, businesses that adopt green practices may find a competitive edge. Investing in green refrigeration can attract eco-minded customers and enhance a company’s reputation in the marketplace.

Making the Transition

Transitioning to green refrigeration involves several steps:

Evaluate Current Systems: Begin by assessing existing HVAC systems to determine which green alternatives can replace outdated refrigerants.

Consult with Professionals: Engage HVAC professionals who have experience with green technologies to help design and implement the transition effectively.

Educate Stakeholders: Inform employees and stakeholders about the benefits and importance of switching to green refrigerants. Creating a culture of sustainability in the workplace can foster greater support for the transition.

Invest in Training: Adequately training staff on the handling and maintenance of green refrigerants is crucial, ensuring safety and compliance with regulations.

HVAC Recycling with ACRE of Texas

Another vital component of creating a sustainable HVAC industry is responsible recycling practices, and ACRE of Texas leads the way in this regard. ACRE focuses on the safe recycling of old HVAC systems and components, ensuring that harmful materials are disposed of properly and recyclable parts are reused. By partnering with ACRE, businesses and homeowners can minimize waste and reduce their environmental impact, further contributing to a healthier planet.

Conclusion

As the urgency for environmental action grows, the HVAC industry must adapt by embracing green refrigeration and responsible recycling practices. By prioritizing sustainability, we can significantly reduce our environmental footprint while providing efficient heating and cooling solutions for future generations. Whether you’re a business owner looking to modernize your systems or a homeowner focused on sustainability, investing in green refrigeration and partnering with organizations like ACRE of Texas is a significant step toward a brighter, greener future.

0 notes

Text

Choosing Eco-Friendly Refrigerants for Appliances

A few refrigerants are preferable for the climate over others, yet pursuing the ideal decision is far from simple or easy for the typical shopper. We investigated the accessible choices to attempt to improve on things a piece.

The issue with engineered refrigerants

Engineered refrigerants were carefully targeted of earthy people currently during the 1980s, as a result of their damaging consequences for the ozone layer. Chlorofluorocarbons (CFCs) are currently prohibited therefore. They were supplanted by other fluorinated gases, what capability well as refrigerants yet have a high an Earth-wide temperature boost potential.

What is a refrigerant?

Refrigerants are substances utilized in cooling frameworks and intensity siphons. So, they move heat around. We should take a gander at how precisely that occurs by taking a cooler for instance.

A refrigerant works by coursing through loops inside your cooler, and engrossing intensity from the encompassing region simultaneously. As it retains heat, it changes from fluid to gas.

The gas then gets sucked into a blower. The blower expands the tension of the gas, which additionally builds its temperature. Then, this high-pressure, hot gas moves through one more arrangement of loops or cylinders, this time outside the cooler, and deliveries its intensity. As it loses heat, it turns around into a fluid. The refrigerant is then gotten back to within the cooler by the tension distinction, and the cycle begins once more.

The refrigerant known as R-410A, for instance, found in many intensity siphons utilized for family warming in Norway, has an Earth-wide temperature boost capability of around 2000. Researcher, a specialist in refrigerants, makes sense of what this signifies: "R-410A having an unnatural weather change capability of 2000 intends that in the event that a kilo of that gas spills into the air, it will add to warming multiple times in excess of a kilo of CO₂, over a time of 100 years."

The narrative of CO2 as a refrigerant

Refrigerants are actually not intended to be delivered into the environment, yet practically speaking, this frequently winds up occurring. Coolers and intensity siphons age and glitch, spills happen, and the gases escape into the climate.

One more issue with fluorinated gases spilling into the climate is that a large portion of them have a place with the purported PFAS (Per-and polyfluoroalkyl substances), and in the long run separate into tireless parts like TFA (trifluoroacetic corrosive). These substances persevere in the climate and have been displayed to gather in people, leading to different issues like malignant growth, thyroid sickness, and low sperm count.

Normal refrigerants

Normal refrigerants, similar to their name proposes, are not engineered, yet happen normally in the biosphere. They incorporate alkali, CO₂, hydrocarbons (like propane or isobutane), and, surprisingly, such everyday substances as water and air. Smelling salts, propane and isobutane have unimportant an Earth-wide temperature boost potential, while CO₂ has an unnatural weather change capability of 1.

They affect the ozone layer, and they don't separate into relentless synthetic compounds in the climate.

That being said, regular refrigerants have their downsides also. Smelling salts is harmful, destructive, and combustible when concentrated. Isobutane and propane are likewise combustible. These hindrances are managed through cautious designing. Frameworks utilizing alkali, for instance, are planned with materials that can endure its destructive impacts. Family frameworks utilizing isobutane and propane regularly utilize a restricted sum. "The most extreme measure of isobutane or propane permitted as a refrigerant in domestic devices is only 150 grams, says Researcher. Regardless of whether a hole happens, with such a modest quantity, the refrigerant will probably be available at such a low focus in the air that burning won't be imaginable."

What to get: cooler

The uplifting news assuming you're an earth cognizant shopper keeping watch for another fridge is that finding one that utilizes normal refrigerants is very simple. The most broadly accessible option on account of family fridges and coolers is isobutane.

The justification behind this is that starting around 2015, refrigerants with an unnatural weather change capability of at least 150 have been taboo in new homegrown coolers and coolers in Europe. The standard will probably be fixed in 2026 to prohibit all fluorinated gases - with exemptions made for situations when they are expected to meet wellbeing necessities.

Really, this implies that the overwhelming majority of family fridges and coolers sold from 2026 onwards will utilize regular refrigerants.

Really taking a look at the refrigerant prior to purchasing

Not all sales reps know about refrigerants, so it's best not to depend on them altogether to get the data. A fast mind the sites of some huge gadgets retailers in Norway shows that the refrigerant utilized is many times recorded under the item specs (spesifikasjoner, in Norwegian). It is normal to need to tap on "specs" and afterward again on "show more specs" to get to the section about the refrigerant.

Refrigerants are typically recorded with a code beginning with "R". We recorded a few normal ones in the table underneath. "R-600a", for instance, compares to isobutane, a characteristic refrigerant. As far as we can tell, the specs distributed on the web notice the refrigerant sort in about portion of the cases. In the event that the data isn't recorded under "specs", really look at the item's guidance manual: the refrigerant is some of the time determined there.

On the off chance that you can't find the data on the web, you want to truly inspect the unit to find out (makers are committed by regulation to determine the refrigerant on the actual item).

0 notes

Photo

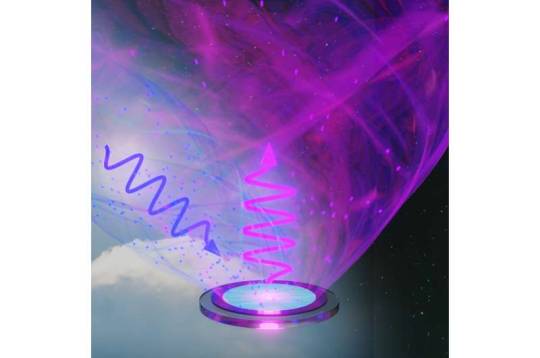

Solid material that 'upconverts' visible light photons to UV light photons could change how we utilize sunlight

The importance of solar power as a renewable energy resource is increasing. Sunlight contains high-energy UV light with a wavelength shorter than 400 nm, which can be broadly used, for example, for photopolymerization to form a resin and activation of photocatalysts to drive reactions that generate green hydrogen or useful hydrocarbons (fuels, sugars, olefins, etc.). The latter of these is often called "artificial photosynthesis." Photocatalytic reaction by UV light to efficiently kill viruses and bacteria is another important application. Unfortunately, only about 4% of terrestrial sunlight falls within the UV range in the electromagnetic spectrum. This leaves a large portion of sunlight spectrum unexploited for these purposes.

Photon upconversion (UC) could be the key to solving this problem. It is the process of converting long-wavelength, low-energy photons (such as those present in visible light) to short-wavelength, high-energy photons (such as those present in UV light) via a process called "triplet-triplet annihilation" (TTA). Previous work in this field has reported visible-to-UV UC using organic solvent solutions that required the solution to be deoxygenated first and then sealed in an airtight container to prevent exposure to oxygen that deactivated and degraded TTA-based photon UC samples. These materials not only lacked photostability in the presence of oxygen, but also failed to perform effectively with sunlight-intensity incident light. These issues presented roadblocks in the practical applications of photon UC.

Read more.

#Materials Science#Science#Photons#Light#Optics#Visible light#UV Light#Tokyo Institute of Technology

34 notes

·

View notes

Text

Applications of 2D Seismic Survey in India: A Comprehensive Overview

In today's infrastructure landscape, accurate and reliable data is key to the successful planning and implementation of various projects. One of the most effective tools in this domain is the 2D seismic survey in India, which provides vital insights for industries like construction, mining, and natural resource exploration. The 2D seismic survey in India serves as a foundational geophysical technique that helps stakeholders make informed decisions based on subsurface data, enabling precise project planning.

Understanding 2D Seismic Survey

A 2D seismic survey in India utilizes sound waves to create a two-dimensional image of subsurface formations. This survey method involves sending sound waves into the ground and recording the reflected signals. These reflections help geologists and engineers analyze the structures beneath the earth’s surface, identifying critical details such as fault lines, rock layers, and other geological features. This data is essential for assessing the feasibility of projects, especially in sectors like oil and gas exploration, civil engineering, and groundwater studies.

In India, where diverse terrains and geological complexities exist, the 2D seismic survey method provides a cost-effective and efficient way to map the subsurface. By providing a clear picture of underground formations, this method reduces risks associated with excavation, drilling, and construction activities.

Key Benefits of 2D Seismic Surveys

The 2D seismic survey in India has numerous applications and benefits across industries. Here are some of the key advantages:

Cost-Effective Subsurface Mapping: Compared to 3D seismic surveys, 2D seismic surveys offer a more affordable solution for obtaining essential subsurface data. The cost-effectiveness of 2D seismic surveys makes them suitable for preliminary exploration, especially in regions where budget constraints exist.

Efficient Data Collection: A 2D seismic survey in India is highly efficient in gathering data over large areas. This is particularly useful for initial exploration phases, helping project planners gather insights without incurring high costs.

Environmental Benefits: With minimal ground disturbance, 2D seismic surveys offer a low-impact method for studying subsurface geology. This approach aligns well with environmentally sensitive areas, where protecting the ecosystem is a priority.

Risk Mitigation: By identifying subsurface conditions, a 2D seismic survey helps mitigate risks associated with drilling, mining, and construction. This proactive approach minimizes unforeseen challenges during project implementation.

Applications of 2D Seismic Survey in Various Industries

The 2D seismic survey in India finds applications across a variety of industries. Below are some of the most notable sectors where 2D seismic surveys play an essential role:

Oil and Gas Exploration: In oil and gas exploration, accurate data on subsurface formations is critical. The 2D seismic survey in India provides a reliable method to locate potential hydrocarbon reserves. By mapping fault lines and rock structures, these surveys help companies identify drilling sites with promising resources. The insights gained from 2D seismic surveys significantly increase the success rate of drilling operations, saving time and resources.

Groundwater Exploration: Groundwater is a vital resource in India, particularly in areas facing water scarcity. A 2D seismic survey in India is a valuable tool for locating underground water sources, making it easier to develop sustainable water extraction plans. By providing data on aquifers and water-bearing formations, 2D seismic surveys assist in responsible water management, benefiting both agricultural and urban regions.

Infrastructure Development: For infrastructure projects like bridges, tunnels, and highways, a clear understanding of subsurface conditions is essential. The 2D seismic survey in India supports civil engineers by offering insights into rock density, fault lines, and other geological features that impact construction stability. This information is instrumental in designing structures that are safe and durable, ensuring the longevity of essential infrastructure.

Mining Industry: The mining sector relies on accurate geological data to identify mineral-rich areas. A 2D seismic survey in India provides mining companies with valuable information on mineral deposits, helping them plan excavation activities more effectively. With a reliable map of subsurface layers, mining operations can be conducted safely, reducing the risk of unexpected geological complications.

Disaster Management: India is prone to natural disasters, including earthquakes and landslides. The 2D seismic survey in India plays a critical role in understanding seismic activity and fault lines, contributing to disaster preparedness efforts. By identifying high-risk areas, authorities can implement preventive measures, potentially saving lives and minimizing property damage.

The Process of Conducting a 2D Seismic Survey

Conducting a 2D seismic survey in India involves several stages. Each step is designed to ensure that accurate and useful data is collected:

Planning: This phase includes site selection, equipment setup, and a review of the area’s geological features. Planning is crucial to ensure that the survey aligns with the project’s objectives.

Data Collection: In this stage, sound waves are generated and transmitted into the ground. Sensors placed on the surface detect the reflected waves, which are then recorded for analysis.

Data Analysis: Using specialized software, the collected data is processed to create a two-dimensional image of subsurface structures. This image provides information about various geological features, enabling better decision-making.

Report Generation: A detailed report is prepared, outlining the findings and providing recommendations based on the survey results. This report is essential for project planners, as it guides the next steps in the project.

Challenges in Implementing 2D Seismic Surveys in India

While the 2D seismic survey in India is highly beneficial, it does come with challenges. Terrain complexity and urban environments can make data collection difficult. Additionally, certain areas may require special permissions for survey activities, which can delay the process. However, advancements in technology continue to improve the efficiency of 2D seismic surveys, enabling more accurate and accessible data collection even in challenging locations.

The Future of 2D Seismic Surveys in India

As India continues to expand its infrastructure and energy sectors, the demand for reliable geophysical surveys will grow. The 2D seismic survey in India is expected to play an increasingly important role, particularly in rural and urban development projects. Ongoing research and development in seismic technology will likely enhance the capabilities of these surveys, making them even more essential for safe and effective project planning.

Conclusion

In summary, the 2D seismic survey in India is an invaluable tool for industries ranging from oil and gas exploration to infrastructure development and groundwater management. This survey method provides critical insights into subsurface conditions, helping stakeholders make well-informed decisions. As technology advances, the accuracy and efficiency of 2D seismic surveys will continue to improve, supporting India’s development efforts in a sustainable and responsible manner.

0 notes