#how to use digital multimeter

Explore tagged Tumblr posts

Text

literally obsessed with drawing donnie in shitty garages. this time he's a streamer. i was literally drawing this EXACTLY like i was the ai that extended jerma's room. i just kept extending the canvas.

i think either he's a 2 view streamer, or he's actually decently popular, but his streams are actively hostile to his viewers. like they're so shitty and about such esoteric topics so nobody can really follow along. he has a Unregistered HyperCam 2 watermark. he has a stream where he shows his viewers how to make pipe bombs

try to spot all the details on your own :) but also a list of detailz under the readmore

i think 1/2 of this will be a where's waldo esque thing because "Image too fucking small" but this will generally be kind of in order. O.K.?

-miku poster -jupiter jim, gundam, and miku figures (jupier jiim figure from "purple game" ep :) ) -drinky bird -three discarded energy drink cans, one of which is DRIPPING of the TABLE !! -gamer mouse -mug that says "else {continue;}" because . whatever. good joke -dead shit in jars -kitty digital alarm clock. miau -sonic for genesis on da shelf. w/ dvds and other gamez. there is no sega genesis in the image btw but there IS a gamecube -the world's smallest cnc machine is on the shelf -michael wave -minifridge -3d printer & filament on the top shelf -drill press & electic hand drill -bandsaw. it says black & decker on it. i trust it to explode his horrible garage for a workspace -an excess number of power strips and excess number of shit plugged in them -gamecube. 2 controller <-should have made this a gameclam in hindsight. imagine if he had like a fucking ATM in his room. -crttv -function generator & multimeter. oscilloscope, aptly named othello-scope (he painted the text on it himself). he loves to make goofy slide whistle sounds with the function generator -chicken wire LOL idk what he'd use it for. caging in his siblings. -several 2x4s, one of which has a bunch of nails stuck in it haphazardly -one of those cylinder telescopes -bike -fume hood + beakers on top of it. because donnie makes his lab a hazardous environment -he's also got a meowchi on his desk (miau) & an empty smoothie cup, plus a spiral bounded page of notes ("ahh molcar" and "vanilla extract" written down)

and then the comic is from one of snapscube's realtime sonic fandubs

281 notes

·

View notes

Text

Finally...

I was looking for a really good shortwave receiver for at least a decade -an old tube equipped one of course. The problem getting one nowadays is that they were only produced in small numbers half a century (or more) ago, since then most are scrapped, botched, altered or corroded cause of bad storage -or all together. So if you have the chance getting one today you most likely will buy a 'construction site', needing hundreds of working hours for restoring it in a good working condition.

But after a looong search finally i had real luck. A big wooden crate was delivered on a pallet.

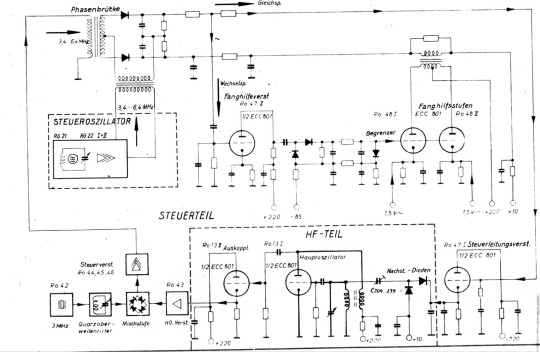

In this crate was one of the -for my opinion- ugliest shortwave receivers ever built, but at the same time also one of the best ones: a Rohde + Schwarz EK07.

Built in 1958 this one was a storage unit from the German Army. Well stored, regularly maintained and serviced, not altered, not botched, never used. So it is in nearly mint condition. It wasn't cheap but getting my hands on this was just sheer luck. Without doing anything: it's in perfect working order. No potentiometer, no switch crackles, every tube checks new -of course you can check all the tubes in the radio itself without removing them.

The manufacturer is more known for it's precision Lab-Equipment and less for it's shortwave receivers. This is also because their receivers weren't consumer or amateur gear, this was pro gear by any means. They were used in applications like coast guards or military surveillance and such. Always things where equipment costs doesn't matter -only the outcome. So back in 1958 when this unit was manufactured you could buy at least two brand new cars for the same amount of money. In exchange for this you got a masterpiece of german engineering and craftsmanship -and also an electro-mechanical nightmare if anything fails and you're not absolutely familiar with it's guts.

Fancy? No, there's absolutely nothing fancy on these. These are absolute workhorses, designed for doing an important job 24/7/365 for decades. Just take a look to that bandswich gear in the photo above. How often you have to switch over the bands until this would be worn out? Millions and Millions of times... And nope: this dark residues at that drum on the left and box below isn't mold or such. These are completely silver plated so it's just the darkened silver.

As you may see, most of the structural parts are made of die-cast and aluminum, so from the materials used it's relatively light weight. But all that built-in sturdiness and shielding adds up to staggering 147lbs/67kg. It's only a receiver, not a transmitter or a power amplifier.

Tubes... and more tubes

If you're not familiar with tube radios: your average AM (and shortwave) Radio from the 50's or 60's used 4 tubes (without the rectifier if this was a tube). Your trusty Hammarlund or Yaesu shortwave receiver from that time would have somewhat from 8 to 12 tubes -and these were quite good and sensitive receivers! This Rohde + Schwarz counts 28 tubes.

Some tubes here, some there, all fully shielded. But why the hell that much? The answer is quite simple: stability. On every count. Constant and stable gain over all bands and for a looong service time, stunningly stable VFO frequencies and all that stuff. No, they used no consumer tubes like in your TV or such. All of them are out of the 'commercial'-tube-series with a guaranteed service life of at least 10000 hours like in every aircraft of that time or such. Failing was not an option, this HAD to work.

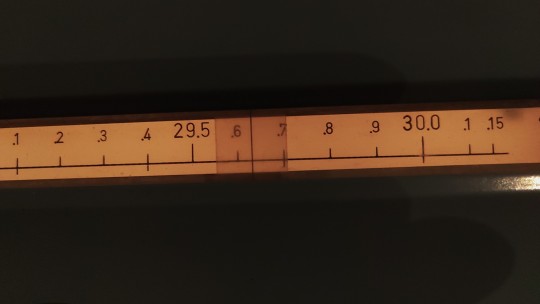

Speaking about stability and accuracy:

this of course isn't digital stuff -it's purely analog. In the pictures below you can see the dials. Just add both frequencies and you know where you are -here on 29.630MHz or 29630kHz.

As you see: your readout is easily accurate down to less than 500Hz. So you can read at least 500Hz out of 29630000Hz. With other words the accuracy of your readout is 0.001687% in this case. Your average modern digital multimeter would be proud if it came only near to this 65 year old contraption.

Of course that large dial in the picture on the left isn't the only one. There are 12 of 'em, mounted on a drum and rotating according to the selected band. Giving you a simple S-Meter like in other shortwave receiver was of course also not possible.

Instead they provided you with a Voltmeter which displays directly the input voltage at the antenna input -and the threshold voltage for the 'Squelch' (if you have set that) which isn't a normal squelch. If activated it doesn't cut your Audio, it reduces the Gain instead with a settable time constant, so it acts more like a active noise cancelling between any signal -also between any dash and dot if you're receiving CW (Morse Code). Besides that you can choose your IF-Passband between 150Hz and 12kHz, have a absolutely stable BFO, a good Envelope Detector for AM-Reception and a perfect Audio Stage - that's all.

Speaking of the Audio Stage: 2W undistorted output power from a single end class-A is more than you need with a good speaker. McIntosh ® would call that circuit 'Unity Coupled', further a E88CC for the Audio-Preamp. We're talking about an Shortwave Radio, not an 'High-End' Audio Amplifier. Wanna take recordings of what you hear? No problem: here's your Line-Output, symmetric, 600 ohms, transformer coupled and with +10dBm (if you want) and in accordance to all Studio-Standarts. Sound quality for AM Broadcasts? With a passband switchable up to max. 12kHz for the IF better than the majority of stations can provide.

Precise?

So far so good, but what's about the heart of every shortwave receiver: the Oscillator or VFO? How stable and precisely does it beat after 65 years?

In your trusty -and quite good- Hammarlund or Yaesu amateur Radio from these days the VFO usually is equipped with two tubes: the Oscillator itself and the buffer amplifier -both sometimes also united in one bulb. If i hadn't lost track here they used 12 -and tons of other stuff. So that frickin VFO has a component count which is easily about the order of a complete shortwave receiver.

What the hell is all that stuff about -and wtf they had for breakfast back then? The answer is again simple: precision and stability.

As i said: this thing is 65 years old and i touched nothing. Of course I checked how much it's 'off' in terms of the frequency. After warming up for 20 Minutes i checked it every 1000kHz from the bottom to the top of its range. It was a bit different between all points, at some less than 50Hz and about 1kHz worst case.

My Lab-Equipment is quite good and precise, but for these low errors the tolerances of the measuring equipment has absolutely taken into account. So i made a separate measurement only for 10MHz -with the aid of a frequency standard sourced from an atomic clock. So this was 'the real thing'. After warming up for an hour i measured for 15 Minutes. The deviaton was between -717 to -722Hz. Including the error of the dial. This means frickin' 71.7...72.2ppm. PPM -parts per million! 65 years after manufacturing.... Just absolutely stunning -and with what freaking kind of equipment they had calibrated this back then??? Just have in mind: this is pure analog goodness, not a modern PLL. How the f***k they got there? Here's the clear link between a manufacturer of high-grade Lab Equipment and a shortwave receiver. I'm just stunned over the knowledge of the engineers who designed that circuit back then and the precision this was built.

All without doing anything and all it's original capacitors. Yap, i could realign that but tbh it's just wayyy to less been worth the effort. So it will stay as it is.

Nope,

you're not provided with that fancy stuff your new digital or SDR may have on board. There's no notch filter, no panoramic display -not even SSB! Why the hell they just 'forgot' all these things? The answer is easy: it's modular. The EK07 is just the 'mainframe', everything else you wanted to have can be added as external components you had to buy separately -also for tons of money of course.

Wanting SSB? Just add this:

35kg/77lbs and 18 Tubes more -to mention it's also a synchronous detector for AM is not worth the effort. Panoramic display, digital frequency counter, Teletype Adaptor, a remote control for controlling that beast over a telephone line? FM? Diversity reception?? No problem, you had just buy it. Everything of course with the same standards for precision and build quality.

The outcome...

Yea, i spent a good amount of money getting this -but in my opinion it was worth every dime. I wanted a good tube receiver and i got a really good one. Compared to upper class modern Radios it's still a very good radio. So the only thing I have to add is an external SSB/AM-Synchronous Detector. The originals are nearly impossible to get today, so i decided to build one. It's on the way and i will give you the results later. So stay tuned...

4 notes

·

View notes

Text

1.) A megger is used to ___.

A. Measures resistances using high applied voltages

B. Measures current using high applied amperage's

C.Sends up to 1,500 volts DC to the motor to determine is the coils or insulation of the wiring is in good shape

D. Measures AC voltage using high applied voltages.

The accuracy of digital multimeters is within ___ and the accuracy of analog multimeters

Is within ____.

A. 0.7%, 4%

B. 0.09%, 1%

C. 0.9%, 3%

D. 0.5%, 3%

After the equipment to be worked on is verified de-energized,_______________.

A. Hot, Cold, Hot testing needs to be conducted

B. Work can be performed safely but you must be wearing your Electrically Rate Gloves

C.Temporary safety grounds should be installed.

D. Work can be performed, after you partner verifies Hot Cold Hot.

4.)How many different FR, Flame Retardent Products does Blaklader have?

A. 26

B. 13

C. 16

D. 20

5.) What year and what Country was Blaklader founded?

A. 1959, Sweden

B. 1954, Ireland

C. 1950, Great Britain

D. 1956, Canada

E. 1958, USA

6.) Bonus Question:

The Bench power supply is used to provide ____.

A. An AC Voltage necessary to Operate Various Instruments

B. DC voltage necessary to Operate Various Instruments

C. Needs to produce up to 8 amps to operate various instrument

D. Supplies 240 volts dc to Operate Various Instruments

7 notes

·

View notes

Text

Interesting history of medical technology in this machine…

This is my grandfathers vertical knee milling machine and it’s one of my favorite tools. This machine was built in 1985, it weighs 3000 pounds, it consumes 10amps of 480 volt 3 phase power, and it costs around $10,000. It can also break arms, remove fingers, and send large pieces of metal flying at your face and chest when not used correctly. But none of that is what makes this machine cool. This very machine helped build the prototype chips used in Hewlett-Packard medical equipment since it’s manufacture date. As it turns out my grandfather did the etching of silicon wafers to make custom chips for Hewlett-Packard from the late 60s to the late 90s. His largest contribution to medical technology was when he did the etching of custom chips that would go into Hewlett-Packard’s first ultrasound machine. After he etched the wafers using a milling machine gold would then be poured onto the wafers for the next step in creating these custom integrated circuits. Ultrasound machines were already being produced by other manufacturers at the time but that ultrasound machine paved the way for HPs other medical equipment including the HP Viridia line of patient monitors which we see in some older digital02 videos. There were many Viridia models made but the main difference showing when they were made was between when they were using CRT displays in them and when they put LCD displays in them. The Virida line continued under the Agilent Technologies name when HP split its Labs division off to Agilent Technologies in the early 2000s. Then the different modules that hook up to the Viridia became backwards compatible with the Phillips intelivue line of patient monitors, the intelivue line also uses the same alarm sounds as the Viridia line. And today the intelivue line has become the gold standard for patient monitors at least here in the US. My favorite set of calipers which are these metic Brown & Sharpe model 599-579-10 were also used in the production of HP medical equipment starting in the year 1975 up until 1999. These still retain an HP calibration tag from 1989 which was the year my grandfather was laid off from HP and went into business himself but ended up having HP be his biggest customer.

Edit:

I guess I should have given a bit more history on Hewlett-Packard. Hewlett-Packard was founded in 1939 by Bob Hewlett and David Packard. Like most companies it started in a garage. HP was the original Silicon Valley start up and the first tech company in Silicon Valley. In the 60s 70s and 80s HP was the largest employer in Silicon Valley and the largest tech company in the world. They had a huge presence in Palo Alto right next to Stanford university. And they had campuses all over Silicon Valley. In fact where Apple’s infinite loop headquarters sits today was once a huge HP campus. They also had a significant presence in Corvallis Oregon, and Colorado Springs/ Loveland Colorado. How things mainly worked in the 80s was products were designed in the Colorado division, and then were sent to Palo Alto for prototyping and final input and checks. Most of HPs medical equipment was designed in the Palo Alto division. In the Colorado division in the 80s HP designed the worlds most accurate digital multimeter the HP3458A, which is still unrivaled to this day. What makes it so accurate and special is it’s custom analog to digital converter. At the end of the 80s HP started to shrink its labs division and the rest of the company laying off thousands of employees. They closed their Corvallis campus in the 90s. And shrunk the size of their Palo Alto headquarters by a significant amount. In the year 1999 HP split its lab’s division into Agilent technologies. HP made computers. Agilent made electronics test equipment and medical equipment. In 2014 Agilent split into Keysight Technologies who now makes exclusively electronics test equipment, Agilent makes medical equipment and scientific equipment. Sadly these days HP is not anywhere near the size they once were and they are often forgot about. In fact the HP today isn’t even technically the same company Hewlett-Packard died in 2015 when they split into Hewlett Packard Enterprises, and Hewlett Packard Inc. The unwritten laws of Silicon Valley are very simple, keep up with modern technology or go bankrupt. HP was keeping up but they failed due to poor leadership, bad financial decisions, and board scandals. Even with some of their questionable practices today, they still don’t deserve to be forgotten about. They made many products that changed the world from pocket calculators, to some of the first computers. In most of the rest of world HP is forgotten as the company they once were but they still have a long and rich legacy in Silicon Valley. Ask anyone over the age of 40 in Silicon Valley and there’s a very good chance they worked for HP at some point in their life. Both my grandparents worked for HP, my mom worked to HP, my great uncle worked for HP, Steve Jobs and Steve Wozniak worked for HP, along with plenty of other people. Stanford University would not be the world renowned university it is today without HP. The Lucile Packard Charity Foundation is a very well known charity organization in Silicon Valley. Lucile Packard was the wife of HP co founder David Packard. I spent a lot of time at Lucile Packard Children’s Hospital when I was a kid for metal health reasons. They are associated with Stanford medicine and Kaiser didn’t offer the services I needed so I went there. I really hope some people read this and understand the significance HP had on the world and was significant enough that we would not be were we are today technology wise without them.

2 notes

·

View notes

Text

Comprehensive Guide to Computer Repair: Tips, Tricks, and Best Practices

In today’s digital age, computers are indispensable tools for work, education, and entertainment. However, like any electronic device, they are prone to issues that can disrupt our daily routines. From software glitches to hardware malfunctions, understanding basic computer repair can save time, money, and frustration. This guide explores the essentials of diagnosing and fixing common computer problems.

Common Computer Problems and Solutions

1. Slow Performance

Cause: A sluggish computer is often the result of unnecessary background processes, insufficient RAM, or malware.

Solution:

Close unnecessary programs using Task Manager.

Upgrade RAM if needed.

Run antivirus scans to detect and remove malware.

2. Blue Screen of Death (BSOD)

Cause: BSOD occurs due to hardware or driver issues, often stemming from corrupted software or incompatible updates.

Solution:

Restart the computer and check for error codes.

Update drivers through Device Manager.

Use system restore to revert to a previous stable state.

3. Overheating

Cause: Overheating can damage internal components and is typically caused by dust buildup or failing cooling systems.

Solution:

Clean the internal components, including fans, with compressed air.

Ensure proper ventilation around the computer.

Replace thermal paste if needed.

4. Unresponsive Applications

Cause: This often results from software bugs or limited system resources.

Solution:

Force close the application.

Update the software to the latest version.

Reinstall the application if issues persist.

5. Internet Connectivity Issues

Cause: Problems can arise from network adapter issues, router problems, or ISP downtime.

Solution:

Restart your router and modem.

Check network adapter settings.

Contact your ISP if the problem isn’t resolved.

Tools Every Computer Technician Should Have

Screwdrivers: For assembling and disassembling hardware.

Thermal Paste: Essential for CPU maintenance.

Multimeter: To check power supply issues.

External Hard Drive: For data backup.

Antivirus Software: To eliminate malware and viruses.

Preventive Maintenance Tips

Regular Updates: Keep your operating system and applications up to date.

Backup Data: Use cloud services or external drives to prevent data loss.

Clean Hardware: Dust and debris can lead to overheating and hardware damage.

Use Reliable Antivirus Software: Protect your system from malware.

Avoid Overloading: Don’t overload the system with unnecessary software or files.

When to Seek Professional Help

While many computer issues can be resolved at home, some require professional expertise. If you encounter persistent hardware failures, data recovery challenges, or motherboard issues, it’s best to consult a certified technician.

Conclusion

Knowing how to diagnose and resolve basic computer issues is a valuable skill in our tech-driven world. By following the tips and techniques outlined above, you can enhance your computer’s performance and longevity. For more complex problems, don’t hesitate to seek expert assistance to ensure your system remains in top condition.

#IFIXHUB Computer Repair Dallas#Ifixhub#computer repair dallas#computer repair near me#computer repair service etc.

1 note

·

View note

Text

FAQs About Installing a Rear View Mirror Camera System

When upgrading your car's safety and convenience, a rear view mirror camera system is an excellent option. These advanced systems provide real-time video feed to your mirror, improving visibility and reducing the risks associated with driving in reverse. Here, we’ll answer some frequently asked questions about installing these systems.

What Is a Rear View Mirror Camera System?

A rear view mirror camera system is a device that integrates a camera into the rearview mirror or attaches to it, offering a clear view of the area behind your vehicle. This system uses a digital display that replaces or overlays the traditional mirror, showing you what's happening behind your car. The best models, such as the HD car mirror cam, offer high-definition video for crystal-clear imagery.

How Do Rear View Mirror Cameras Work?

Rear view mirror cameras function by using a camera mounted at the back of your car. The camera captures footage and sends it to a monitor integrated into the rearview mirror. This allows the driver to see the live feed from the back of the vehicle without having to rely solely on traditional mirrors or turning their head.

Can I Install a Rear View Mirror Camera Myself?

While it’s possible to install a rear view mirror camera system yourself, it requires some technical skill. The process typically involves wiring the camera to your vehicle’s power system and connecting it to the mirror display. If you're not comfortable with electrical work or mounting, professional installation is recommended for the best results.

Is It Difficult to Install a Rear View Mirror Camera?

Installing a rear view mirror camera can be challenging if you're not experienced with vehicle electronics. The complexity depends on the system's features and the type of vehicle. Some advanced models, like the HD car mirror cam, may require professional assistance to ensure proper installation and functionality.

How Long Does the Installation of a Rear View Mirror Camera Take?

The installation time for a rear view mirror camera system typically ranges from 1 to 3 hours. This depends on the system's complexity and whether you're doing the installation yourself or hiring a professional. If you're installing a more advanced model, such as the HD car mirror cam, the process may take a little longer.

What Tools Are Needed for Installation?

To install a rear view mirror camera system, you’ll need basic tools such as a screwdriver, electrical tape, wire strippers, and a multimeter. For professional-grade installations, some models may also require special tools like a drill or wiring harness adapters, especially for vehicles with advanced electrical systems.

Do I Need Any Special Wiring for a Rear View Mirror Camera?

Yes, installing a rear view mirror camera system typically requires special wiring. The system needs to be connected to your vehicle's power supply and may also need to be wired into the reverse lights to activate when you shift into reverse. Some systems come with wiring kits, while others may require custom wiring for specific car models.

Can a Rear View Mirror Camera Be Installed in Any Vehicle?

Most vehicles can accommodate a rear view mirror camera system. However, installation can be more complicated in older vehicles or cars with complex electrical systems. It’s important to check if your vehicle supports the necessary wiring and if the system is compatible with the size and shape of your existing rearview mirror.

How Much Does It Cost to Install a Rear View Mirror Camera?

The cost of installing a rear view mirror camera system varies depending on the brand, model, and whether you opt for professional installation. Basic systems can range from $100 to $300, while premium models with features like HD video, GPS, and parking assist may cost upwards of $500. Professional installation typically adds an additional $100 to $150.

Are There Different Types of Rear View Mirror Camera Systems?

Yes, there are several types of rear view mirror camera systems. Some are basic backup cameras that show a simple feed of what's behind you, while others, like the HD car mirror cam, include advanced features such as parking guides, night vision, and integrated GPS. Choosing the right system depends on your preferences and budget.

What Are the Benefits of a Rear View Mirror Camera?

The primary benefit of a rear view mirror camera system is enhanced safety. It helps eliminate blind spots and provides a clearer view of your surroundings, especially when reversing. Advanced models, such as the HD car mirror cam, also offer features like parking assist and collision warnings, making it easier to park and drive in tight spaces.

Can a Rear View Mirror Camera Help with Parking?

Yes, a rear view mirror camera is especially helpful for parking. It provides a wide-angle view of the area behind your vehicle, helping you navigate tight spots and avoid obstacles. Some systems also include parking guidelines, making it easier to park accurately, while others, like the HD car mirror cam, include sensors for additional assistance.

Is a Rear View Mirror Camera System Worth It?

If you frequently drive in tight spaces or find reversing challenging, investing in a rear view mirror camera system is definitely worth it. It improves visibility and safety, especially for new drivers or those with larger vehicles. Premium systems offer added features like HD video, parking sensors, and GPS, which can enhance your driving experience.

How Can I Ensure My Camera System Works Properly?

To ensure your rear view mirror camera system works effectively, regularly clean the camera lens and the mirror display. Make sure the wiring remains secure and undamaged. If your system includes features like parking sensors or GPS, check the settings to make sure they are functioning properly, particularly after any system updates.

Are Rear View Mirror Camera Systems Legal?

In most regions, rear view mirror camera systems are legal and comply with safety standards. However, it’s important to ensure that the system does not obstruct the driver’s view or interfere with vehicle controls. Be sure to check local regulations to ensure your installation adheres to any specific guidelines or restrictions.

Can I Upgrade My Existing Rearview Mirror to a Camera System?

Yes, many vehicles can be upgraded by replacing the standard rearview mirror with a camera system. This is a popular choice for people looking to add a rear view mirror camera without installing a full aftermarket screen. The upgrade involves replacing the existing mirror with one that features the necessary camera and display components.

By understanding these FAQs, you can make an informed decision about installing a rear view mirror camera system, ensuring that the installation process is smooth and that your driving experience is enhanced. Whether you’re choosing a simple system or a high-tech HD car mirror cam, these devices offer improved safety and convenience for drivers.

0 notes

Note

Uhfhuguhm uh

Tell me a story

Gather round children… grandthey is going to recount the tale of how they and their pal Red met

I was walking around school at the entrance one day when i see three objects. A multimeter, a xylophone, and a ghost. Having, obviously, never seen a ghost before i went up to the group and was like ‘hey is that a ghost’ and they were like ‘yeah this Red he died because of blah blah blah vague impulsive reasons’

Now if you know me you know that i have this fixation on the supernatural and i know my way around an ancient cursed tome or two so i offered to help resurrect her! And they were like ‘ok worth a shot’ and gradually more and more people accidentally got involved and soon we were lugging Red’s corpse around trying to find a spot to do the thing

THEN when we finally DID find a place we had to wait until 3:00 am because that’s what the book said so we came up with a plan. Someone gets inside using a borrowed key and lets everyone else in 2 get ritual-y! I was the one with the key :-3

After everything was set up… as the clock struck 3:00 am… Ded LED became Not-Ded-Anymore LED!!!! We did it!!!!!!!!!!

And then we became friends!!!! I think. I’m like 80% sure we’re friends

Also future employer if you’re reading this I just remembered I have a digital footprint. Hi! Most of this is fabricated I love fiction heart emoji

0 notes

Text

8 Tips for Proper Battery Maintenance

Batteries power many of the essential devices and systems we rely on daily, from smartphones and laptops to cars and renewable energy installations. However, batteries are not "set it and forget it" components. Without proper care, their performance can degrade quickly, leading to reduced capacity, unexpected failures, and costly replacements. The good news is that with regular maintenance, you can extend the life of your batteries and keep them working at peak performance for longer.

In this guide, we’ll cover eight essential tips to help you maintain your batteries with the help of your professional mechanics Campsie, ensuring they remain efficient, reliable, and safe to use. So, whether you’re dealing with a car battery, a solar system’s power storage, or a household device, these practices will help you get the most out of your investment.

1. Keep Your Battery Clean

One of the simplest yet most effective ways to maintain your battery is by keeping it clean. Over time, dirt, grease, and corrosion can accumulate on the battery’s terminals and surrounding area. Corrosion, typically appearing as a white or blue-green residue, can interfere with the flow of electricity, reducing the battery’s efficiency and lifespan.

To clean your battery, first, disconnect it (starting with the negative terminal) to avoid any electrical accidents. You can then use a mixture of baking soda and water to gently scrub away corrosion with a soft brush or cloth. Once cleaned, dry the terminals completely before reconnecting. Regular cleaning, especially in high-humidity or dusty environments, will ensure your battery operates smoothly for a longer time.

Pro tip: Applying a light coating of petroleum jelly or terminal protector spray can help prevent future corrosion buildup on the terminals.

2. Check Voltage Regularly

Regularly checking your battery’s voltage is a critical step in understanding its overall health. The voltage of a battery tells you how much charge it’s holding, which is vital in determining whether it’s functioning optimally. Most batteries, particularly those used in cars, solar systems, or other large setups, should be monitored to ensure they remain within a safe voltage range.

For example, a car battery typically operates between 12.6V (fully charged) and 12.0V (low charge). Anything below 12.0V could indicate that the battery is struggling or has been discharged too far, which can shorten its lifespan. For solar batteries or other high-capacity units, consult the manufacturer's voltage specifications.

You can check the voltage using a multimeter or battery monitoring system, many of which are now available with digital readouts or smartphone connectivity. Make it a habit to check the voltage periodically, especially before and after heavy usage, to avoid over-discharge or damaging the battery.

3. Avoid Overcharging

Overcharging is one of the most common yet preventable causes of battery degradation. When a battery is charged beyond its maximum capacity, the excess energy can create heat, causing the internal components to deteriorate. This can lead to a host of problems, including reduced battery life, swelling, leaks, or even hazardous conditions like explosions or fires.

To avoid overcharging, it’s important to use a charger specifically designed for your battery. Many modern chargers come with built-in automatic shut-off features that stop the charging process once the battery reaches full capacity. However, if your charger doesn’t have this feature, consider setting a timer or monitoring the charge manually to prevent excessive charging.

It’s also crucial to avoid leaving batteries plugged in indefinitely, as this can lead to a continuous trickle charge, which, over time, wears out the battery’s capacity. Always follow the manufacturer’s charging guidelines for best results.

4. Store Batteries in the Right Conditions

Proper storage is key to maintaining your battery’s health when it’s not in use. Batteries are sensitive to temperature fluctuations, and storing them in environments that are too hot or too cold can cause significant damage. Ideally, you should store your battery in a cool, dry place where the temperature remains stable, ideally between 10°C and 25°C (50°F to 77°F).

Extreme heat can cause the battery’s electrolyte to evaporate, leading to reduced capacity and eventual failure. On the other hand, freezing temperatures can cause internal damage, especially in lead-acid batteries, which can freeze and crack when discharged in the cold.

Additionally, if you’re storing the battery for an extended period, ensure that it’s charged to about 50-70%. Storing a completely discharged battery can result in permanent capacity loss, while storing a fully charged one can lead to self-discharge and overstrain on the battery cells. For long-term storage, remember to check the battery’s charge every few months and recharge as necessary.

5. Inspect for Physical Damage Regularly

Physical inspections are just as important as monitoring voltage or cleaning your battery. A quick visual check can reveal potential issues before they become serious problems. Look for cracks in the battery casing, bulging sides, leaks, or unusual odours—all of which are signs of a damaged or failing battery.

If you notice any of these issues, it’s essential to stop using the battery immediately and replace it. Damaged batteries pose a significant safety risk, not just because they may stop working but also because they can leak harmful chemicals or explode if mishandled.

In particular, swelling or bulging in lithium-ion batteries can indicate internal pressure buildup caused by gas generation, often due to overheating or overcharging. Such batteries should be handled with extreme care and disposed of properly to avoid any accidents.

6. Ensure Proper Ventilation During Charging

When batteries are charged, especially large units like lead-acid or lithium-ion batteries, they can generate gases as a byproduct of the chemical reaction occurring inside the cells. Proper ventilation during charging is critical to prevent gas buildup, which can lead to explosive conditions in confined spaces.

If you’re charging a battery in a small room or enclosed area, make sure it’s well-ventilated. In some cases, specialised venting systems may be required, particularly for large battery banks used in solar or backup power systems. Refer to your battery’s user manual for ventilation recommendations to ensure safety during charging.

For smaller batteries, like those in smartphones or laptops, charging in a well-ventilated room can help prevent overheating, which can also prolong battery life.

7. Use the Correct Charger

Using the wrong charger for your battery can lead to poor performance, overheating, or permanent damage. Chargers are designed to deliver specific amounts of voltage and current, and mismatching these can cause the battery to malfunction. For instance, charging a 12V battery with a higher-voltage charger can overcharge it, while using an underpowered charger may fail to charge the battery fully.

Always ensure you’re using the charger that’s designed for your specific battery type. For some batteries, especially lithium-ion and lithium-polymer types, smart chargers are highly recommended. These chargers can optimise charging by adjusting the current and voltage automatically based on the battery’s condition, preventing overcharging or overheating.

8. Cycle Your Battery Correctly

Many modern batteries, particularly those used in cars, laptops, or solar energy systems, benefit from regular cycling, which involves charging and discharging the battery. This process helps maintain battery capacity over time. However, it’s important to avoid deep discharges, where the battery is drained to 0%, as this can significantly shorten the lifespan of most rechargeable batteries.

Instead, try to recharge your battery when it reaches about 20-30% capacity. Deep discharges are especially harmful to lithium-ion batteries, so keeping them in the mid-range (20-80% capacity) is ideal for long-term use.

For lead-acid batteries, avoid letting them sit in a discharged state for too long, as this can cause sulfation, where lead sulphate crystals form and reduce the battery’s capacity. Regular cycling and proper charging techniques can keep your battery in good condition for years.

Proper battery maintenance is essential for maximising the performance and longevity of your battery. From regular cleaning and voltage checks to using the correct charger and ensuring proper ventilation, these simple practices can prevent common issues and save you money in the long run. By taking the time to care for your battery, you’ll not only enjoy better performance but also reduce the risk of sudden failures and safety hazards.

Remember, a well-maintained battery is not just about extending its lifespan—it’s about keeping your devices, vehicles, or systems running smoothly and efficiently, day in and day out.

0 notes

Text

How to Use a Multimeter for LED Testing

Testing an LED with a multimeter is a simple and effective way to determine if it’s working. Here's a step-by-step guide to help you test your LED using a digital multimeter.

1. Gather Your Tools

You’ll need:

A multimeter (with a diode test mode)

The LED you want to test

2. Set the Multimeter to Diode Mode

Turn the multimeter’s dial to the diode symbol (a triangle pointing to a line). This mode applies a small voltage to the LED, allowing it to light up if it's functional.

3. Identify the LED Leads

LEDs have two leads:

The longer lead is the positive (anode).

The shorter lead is the negative (cathode).

4. Connect the Multimeter Probes

Red probe to the positive lead.

Black probe to the negative lead.

5. Check the Reading

If the LED is working, you should see:

The LED briefly lighting up.

A reading of 1.8V to 3.3V, depending on the LED type.

6. Interpreting the Results

If the LED lights up and shows a voltage reading, it's working.

If it doesn’t light up or shows OL (over-limit), the LED is faulty.

Final Tip: Always Test Safely

Always ensure the LED is disconnected from any circuit before testing to avoid damage to your multimeter or the LED itself.

Testing LEDs with a multimeter is an easy way to troubleshoot your projects quickly!

0 notes

Text

Understanding Electronic Measuring Instruments: Precision and Innovation

Electronic Measuring Instruments are vital tools in various industries, providing accurate and reliable measurements for a wide range of applications. These instruments have revolutionized how professionals in fields such as engineering, manufacturing, healthcare, and construction gather and analyze data, ensuring quality control and compliance with industry standards.

At the core of electronic measuring instruments is their ability to provide precise measurements through advanced technology. Unlike traditional mechanical instruments, electronic devices utilize sensors and digital displays, allowing for quicker and more accurate readings. This technological advancement minimizes human error and enhances the efficiency of measurement processes.

One of the most common types of electronic measuring instruments is the digital multimeter. Widely used in electrical engineering and maintenance, multimeters measure voltage, current, and resistance. Their versatility makes them essential for troubleshooting electrical circuits and ensuring proper functioning of devices. With features such as auto-ranging and data logging, modern multimeters provide users with a wealth of information at their fingertips.

Another essential electronic measuring instrument is the electronic caliper, used primarily in manufacturing and engineering. This tool measures internal and external dimensions with remarkable accuracy. Digital calipers often feature LCD displays that provide easy-to-read measurements in various units, enhancing user convenience. The ability to switch between metric and imperial units further increases their usability in international contexts.

In addition to calipers and multimeters, electronic measuring instruments include various specialized devices. For instance, laser distance meters offer precise distance measurements without the need for physical contact, making them ideal for construction and surveying applications. These devices use laser technology to calculate distances quickly and accurately, streamlining the measurement process.

Temperature measurement is another critical aspect of various industries, and electronic thermometers have become standard tools in many settings. From laboratories to industrial processes, electronic thermometers provide fast and precise temperature readings. Some models offer features such as data logging and connectivity to computers or smartphones, enabling users to track temperature changes over time.

The impact of electronic measuring instruments extends beyond industrial applications. In healthcare, electronic measuring devices play a crucial role in diagnostics and patient monitoring. Instruments like digital blood pressure monitors and pulse oximeters allow healthcare professionals to obtain accurate readings quickly, facilitating timely interventions and improving patient outcomes.

The integration of electronic measuring instruments with software solutions has further enhanced their functionality. Many modern instruments can connect to computers or mobile devices, allowing users to analyze data in real-time and generate detailed reports. This capability is particularly beneficial in research and development, where precise measurements are critical for validating hypotheses and ensuring compliance with regulatory standards.

Despite the many advantages of electronic measuring instruments, users must remain vigilant regarding calibration and maintenance. Regular calibration ensures that instruments provide accurate readings, while proper maintenance extends their lifespan. Manufacturers often provide guidelines for calibration frequency and maintenance procedures, emphasizing the importance of keeping instruments in optimal condition.

In conclusion, electronic measuring instruments are indispensable tools that have transformed measurement processes across various industries. Their precision, versatility, and technological advancements enhance efficiency and accuracy, making them essential for quality control and compliance. As technology continues to evolve, we can expect further innovations in electronic measuring instruments, paving the way for even greater accuracy and reliability in measurements. Embracing these tools not only improves operational efficiency but also supports a culture of safety and excellence in every field.

For More Info-

Contact: +61 3 5157 8309

Mail:[email protected]

Time: Mon- Fri(7.30AM - 6.00PM)

Visit - https://banksiacontrols.com.au/

0 notes

Text

Capacitor Tester: A Crucial Tool for Electronics Troubleshooting

Capacitors are fundamental components in nearly all electronic devices, storing and releasing electrical energy as needed. Over time, capacitors can degrade, fail, or develop faults, leading to malfunctioning circuits or complete system breakdowns. To diagnose issues related to capacitors, electronic engineers and technicians use a specialized tool known as a capacitor tester.

A capacitor tester is an essential piece of equipment for anyone working with electronics. It measures a capacitor’s capacitance, and often other parameters such as Equivalent Series Resistance (ESR) or leakage current, to ensure the component is functioning properly. In this article, we'll explore what a capacitor tester is, how it works, different types of testers, and why it’s an invaluable tool for anyone involved in electronics repair and maintenance.

What is a Capacitor?

Before diving into capacitor testers, it’s important to understand the role of capacitors in an electrical circuit. A capacitor is a passive electrical component that stores energy in an electric field. It consists of two conductive plates separated by an insulating material (called the dielectric). When a voltage is applied across the plates, electric charge accumulates on them, and the energy is stored in the electric field created by the charge difference.

Capacitors have many uses in electronics, such as:

Smoothing the output of power supplies.

Filtering signals in audio and RF circuits.

Storing energy in flash photography or power backup systems.

Timing in oscillators and clocks.

Capacitors vary widely in capacitance values, typically measured in farads (F), but most practical capacitors used in everyday electronics operate in microfarads (µF), nanofarads (nF), or picofarads (pF).

The Need for Capacitor Testing

Over time, capacitors can degrade due to age, heat, voltage spikes, or physical damage. When a capacitor fails or becomes weak, it can lead to symptoms such as:

Power supply instability or failure.

Unwanted noise or distortion in audio circuits.

Loss of timing or frequency control in oscillators.

General malfunctioning of electronic devices.

In many cases, faulty capacitors don’t exhibit visible signs of failure, making it difficult to diagnose issues just by looking at the component. A capacitor tester is used to identify whether a capacitor is functioning properly or if it has degraded, helping technicians isolate and fix the problem.

What is a Capacitor Tester?

A capacitor tester is a specialized tool used to measure various characteristics of a capacitor to determine if it is operating within its specified parameters. The most common function of a capacitor tester is to measure the capacitance of a component, which is the amount of electrical charge it can store for a given voltage. Many capacitor testers can also measure other critical parameters such as:

Equivalent Series Resistance (ESR): A measure of the internal resistance of the capacitor, which can increase as the capacitor ages or becomes damaged.

Leakage Current: The current that flows through a capacitor when it should ideally act as an insulator. High leakage current indicates a degraded capacitor.

Voltage Rating: Some testers can apply a voltage to a capacitor to check whether it can hold the rated voltage without breaking down.

Types of Capacitor Testers

There are different types of capacitor testers available, ranging from basic handheld devices to advanced benchtop models. The type of tester required depends on the specific needs of the user and the level of detail needed for the diagnosis.

1. Handheld Digital Multimeters with Capacitance Mode

Many digital multimeters (DMMs) include a capacitance measurement mode, which allows users to measure the capacitance value of a capacitor directly. While DMMs with capacitance mode are convenient for basic testing, they typically cannot measure ESR or leakage current, which are critical in identifying aging or faulty capacitors.

Advantages:

Affordable and widely available.

Suitable for quick checks of capacitance values.

Limitations:

Limited to measuring capacitance only.

Not as accurate as dedicated capacitor testers for diagnosing faults such as high ESR or leakage current.

2. Dedicated Capacitance Meters

A dedicated capacitance meter is a tool designed specifically to measure the capacitance of a capacitor. These devices are more accurate than multimeters with capacitance functions, and they often provide better resolution for small capacitance values.

Advantages:

Higher accuracy and better resolution.

Useful for measuring a wide range of capacitance values.

Limitations:

Typically measures capacitance only, without ESR or leakage testing.

3. ESR Meters

ESR meters are specialized devices designed to measure the Equivalent Series Resistance of a capacitor. ESR is a critical parameter because even if the capacitance value remains within spec, a high ESR can severely affect the performance of the capacitor, especially in high-frequency circuits. High ESR can lead to overheating and inefficiency in power supplies or signal distortion in audio circuits.

Advantages:

Essential for testing capacitors in circuits where low ESR is critical.

Can diagnose aging capacitors without needing to remove them from the circuit in some cases.

Limitations:

Measures ESR only, so additional tools may be needed to measure capacitance.

4. LCR Meters

LCR meters are versatile devices that can measure inductance (L), capacitance (C), and resistance (R) in electronic components. These meters are typically used in more advanced electronics troubleshooting and design. High-end LCR meters can measure capacitance, ESR, and other key parameters, offering a comprehensive view of the capacitor’s performance.

Advantages:

Versatile tool for advanced users.

Provides accurate measurements of capacitance, ESR, and other parameters.

Limitations:

More expensive and often bulkier than handheld testers.

How to Use a Capacitor Tester

Using a capacitor tester is generally a straightforward process, though the exact steps can vary depending on the type of tester and the capacitor being tested. Below is a basic guide for testing a capacitor:

Discharge the Capacitor: Before testing, ensure that the capacitor is fully discharged to avoid any dangerous voltages. This can usually be done by shorting the capacitor leads with a resistor.

Set the Tester to Capacitance Mode: If using a digital multimeter or dedicated capacitance meter, set the device to the appropriate measurement range.

Connect the Capacitor: Attach the leads of the tester to the terminals of the capacitor. Ensure proper polarity if testing electrolytic capacitors.

Read the Measurement: The tester will display the capacitance value. Compare this value to the capacitor’s rated capacitance to determine if it is within an acceptable range.

Check ESR (Optional): If using an ESR meter, follow the same procedure to measure the Equivalent Series Resistance and compare it to the acceptable range for the capacitor.

The Importance of ESR Testing

While capacitance is the most obvious characteristic to test, ESR often reveals issues that capacitance testing alone may miss. A capacitor with high ESR may still show the correct capacitance value, but its performance in a circuit will be impaired due to internal resistance. Testing for ESR is particularly important in circuits like power supplies, where even a small increase in ESR can cause overheating and failure.

Conclusion

A capacitor tester is an invaluable tool for anyone involved in electronics, from hobbyists to professional technicians. Whether you are troubleshooting a malfunctioning circuit or performing preventive maintenance, capacitor testers provide critical insight into the health and performance of capacitors. With the ability to measure capacitance, ESR, and other key parameters, these devices help ensure that electronic systems continue to function reliably. By catching faulty capacitors early, you can avoid system failures and keep your devices running smoothly.

#capacitance#Inductance#ElectricalCircuits#Electronics#CircuitDesign#Capacitors#Inductors#ElectricalEngineering#CircuitTheory#EngineeringBasics#TechEducation#ElectronicsFundamentals#PowerManagement#SignalProcessing#ElectronicComponents

1 note

·

View note

Text

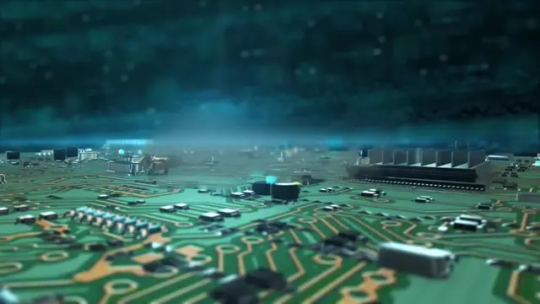

Mastering PCB Reverse Engineering: A Comprehensive Guide

Circuit boards that have been printed (PCBs) are the foundation of modern electronics. They are everywhere, from your smartphone to your home appliances. PCB reverse engineering is a vital process that allows engineers and hobbyists to understand and replicate these crucial components. In this guide, we'll dive into PCB reverse engineering, exploring its significance, methods, and practical applications.

What is PCB Reverse Engineering?

Reverse engineering a printed circuit board is dissecting it to determine its layout and purpose. The goal is to recreate the board's schematics, layout, and connections. This process of pcb reverse engineering is crucial for repairing, improving, or replicating existing electronic devices. By examining how components are connected, engineers can troubleshoot issues or design compatible replacements.

Why is PCB Reverse Engineering Important?

PCB reverse engineering serves several purposes. It helps in:

Repairs and Maintenance: By understanding the layout and connections, technicians can fix malfunctioning devices.

Legacy Systems: Many older systems have outdated or unavailable documentation. Reverse engineering aids in the upkeep and modernization of these systems.

Security Analysis: It is used to identify vulnerabilities and improve the security of electronic systems.

Innovation: Engineers can learn from existing designs and develop improved versions or entirely new devices.

Methods of PCB Reverse Engineering

There are several methods of pcb reverse engineering. Here are the most common techniques:

1. Visual Inspection

The simplest method involves visually inspecting the PCB. Using a magnifying glass or microscope, you can examine the components and their connections. This method is often the first step in understanding the board's layout.

2. Circuit Tracing

Tracing a circuit entails navigating the PCB's electrical routes. By using tools like continuity testers or multimeters, you can map out the connections between different components. This technique is useful for creating a basic schematic of the circuit.

3. Decapsulation and Microscopy

For detailed analysis, especially in the case of integrated circuits (ICs), decapsulation and microscopy are used. An IC's covering layers must be removed during decapsulation in order to access its interior circuitry. Then, you can use microscopy to look at the circuit's minute features.

4. Software Tools

Reverse engineering can be substantially improved by using contemporary software technologies. Programs like KiCad and Eagle allow you to create digital schematics and layouts from your findings. These tools can also simulate the circuit to ensure accuracy.

Practical Applications of PCB Reverse Engineering

Reverse engineering of PCBs has several applications:

Product Development: Companies use reverse engineering to improve or modify existing products.

Educational Purposes: It helps students and hobbyists understand complex electronic systems.

Competitive Analysis: Businesses analyze competitors' products to understand their design and functionality.

PCB reverse engineering is a powerful technique that opens up numerous possibilities in electronics. Whether you're repairing an old device, analyzing security vulnerabilities, or innovating new technology, understanding how PCBs work is crucial. By mastering pcb reverse engineering, you can unlock the secrets of electronic designs and drive advancements in technology. For anyone involved in electronics, PCB reverse engineering is an invaluable skill. Embrace it to enhance your understanding, solve complex problems, and push the boundaries of what's possible.

0 notes

Text

How To Choose the Right Multimeter Calibration Service?

Whether you're an electrician, engineer, or someone who enjoys tinkering with electronics, your multimeter is one of your most trusted tools. But like any tool, it needs regular calibration to ensure it's giving accurate readings.

However, choosing the right digital multimeter calibration service can take time and effort. You don't want just to hand over your device to anyone - accuracy matters, right? So, how do you pick a calibration service you can trust? Let's break it down!

Why Proper Calibration Matters

Before diving into how to choose a multimeter calibration service, it's worth understanding why calibration is so important. Multimeters measure electrical properties like voltage, current, and resistance.

Over time, wear and tear can affect their accuracy. A miscalibrated multimeter could lead to incorrect readings, which could, in turn, result in faulty repairs, dangerous installations, or even safety hazards. So, it's not just about keeping your tool in top shape - it's about safety and precision.

Key Factors to Look For

1. Accreditation - The Gold Standard

The first thing to check when choosing a multimeter calibration service is accreditation. Look for companies accredited by NATA (National Association of Testing Authorities).

Accreditation ensures that the service provider follows rigorous standards and guarantees that its processes are regularly audited. It is your first clue that the provider is serious about quality.

2. Experience and Expertise

Would you trust your car with someone who's only changed a tyre once? Probably not. The same logic applies to calibration services.

You want to ensure that your chosen company has years of experience and specialised knowledge in calibrating multimeters.

A service provider with a long track record likely knows the ins and outs of different models and understands the finer details of precision testing.

3. Turnaround Time - Don't Get Left Waiting

Time is money, and no one wants to be left without their multimeter for weeks. Some multimeter calibration services might offer lower prices but take a long time to complete the job.

Always ask about the turnaround time upfront. A good service provider will be transparent about how long it will take and may even offer express services if you need them quickly.

4. Detailed Calibration Reports

Calibration is more than just tuning your multimeter and sending it back. You should receive a detailed report outlining the tests performed and the results.

This documentation is crucial for keeping your records and ensuring compliance with industry standards, especially if your work requires you to follow strict guidelines. Make sure the service provider includes this without extra cost or hassle.

5. Customer Support - It Matters More Than You Think

Have you ever tried to get help from a company only to be bounced around from one department to another? Not fun, right? Excellent customer support should be a priority when selecting a multimeter calibration service.

Are they easy to reach if something goes wrong? Do they answer your questions clearly and promptly? A reliable company will offer excellent pre- and post-calibration support, ensuring you're never left in the dark.

Comparing Costs - Don't Be Fooled by Bargain Prices

It's tempting to choose the cheapest option, but cheaper isn't always better when it comes to multimeter calibration. While staying within your budget is important, extremely low prices can be a red flag.

They might cut corners, use inferior equipment, or employ unqualified personnel. Conversely, paying too much doesn’t always guarantee better service. Look for a service provider offering competitive pricing, accreditation, experience, and quality customer care.

Reputation - What Are Others Saying?

Lastly, reputation matters. Before making your decision, check reviews, testimonials, and industry forums. If a company consistently gets high marks for reliability, accuracy, and customer service, it's a good sign they know what they're doing.

Word of mouth or online reviews can give you a clear sense of what to expect and whether previous customers were happy with the multimeter calibration services they received.

Final Thoughts - Your Multimeter Deserves the Best

Choosing the right multimeter calibration service comes down to a combination of factors: accreditation, experience, speed, customer service, and cost. Don't rush the decision. After all, your multimeter is a precision tool that requires expert care.

Take the time to do your research, ask the right questions, and read reviews. Your tools - and your safety—depend on it. Now that you know what to look for, you can confidently choose a service that will keep your multimeter performing at its best, ensuring your work remains accurate and safe.

0 notes

Text

How to Set Up and Configure the A4988 Stepper Motor Driver

The A4988 Stepper Motor Driver Carrier Black is a versatile and widely-used driver for controlling bipolar stepper motors. Setting up and configuring the A4988 correctly is crucial to ensure optimal performance and prevent damage to your motor and driver. This article provides a comprehensive guide on how to set up and configure the A4988 Stepper Motor Driver.

1. Unboxing and Initial Inspection

Before you begin, ensure that you have all the necessary components:

A4988 Stepper Motor Driver Carrier Black

Stepper motor

Power supply (typically 8V to 35V)

Microcontroller (e.g., Arduino)

Breadboard and connecting wires

Inspect all components for any visible damage.

2. Wiring the A4988 Stepper Motor Driver

Proper wiring is crucial for the safe operation of the A4988. Follow these steps:

Connect the Motor:

Connect the stepper motor coils to the A4988’s output pins (2A, 2B, 1A, 1B). Ensure the connections are correct to avoid damaging the motor driver.

Connect Power Supply:

Connect the motor power supply (8V to 35V) to the VDD and GND pins of the A4988. Ensure the power supply can deliver sufficient current for your motor.

Connect Microcontroller:

Connect the step, direction, enable, and ground pins of the A4988 to the corresponding pins on your microcontroller. Typically, these connections are:

STEP pin to a digital output pin on the microcontroller

DIR pin to another digital output pin

ENABLE pin to ground (or a digital output pin if you want to control it)

Optional Connections:

You may also connect the MS1, MS2, and MS3 pins to configure microstepping settings. These can be connected to logic high (5V) or low (GND) according to your desired microstepping mode.

3. Configuring Current Limit

Setting the correct current limit is vital to prevent overheating and ensure smooth motor operation. Follow these steps to configure the current limit:

Adjust the Potentiometer:

Locate the small potentiometer on the A4988 board. This potentiometer adjusts the current limit.

Use a small screwdriver to turn the potentiometer. Turning it clockwise increases the current limit, while turning it counterclockwise decreases it.

Measure VREF:

To set the current limit accurately, measure the VREF voltage with a multimeter. Place the positive probe on the potentiometer’s test point and the negative probe on a ground pin.

Calculate Current Limit:

The formula for setting the current limit is: Current Limit = VREF / (8 * R_SENSE), where R_SENSE is the current sense resistor value (typically 0.05 ohms).

Adjust the potentiometer until the desired VREF voltage is reached.

4. Setting Microstepping Mode

The A4988 supports various microstepping modes, which can be set by configuring the MS1, MS2, and MS3 pins:

Microstepping Table:

Full step: MS1 = 0, MS2 = 0, MS3 = 0

Half step: MS1 = 1, MS2 = 0, MS3 = 0

Quarter step: MS1 = 0, MS2 = 1, MS3 = 0

Eighth step: MS1 = 1, MS2 = 1, MS3 = 0

Sixteenth step: MS1 = 1, MS2 = 1, MS3 = 1

Connecting MS Pins:

Connect the MS1, MS2, and MS3 pins to logic high (5V) or logic low (GND) according to the desired microstepping mode.

5. Programming the Microcontroller

To control the A4988, you’ll need to write a program for your microcontroller. Upload the code to your Arduino. Adjust the delay Microseconds value to control the speed of the stepper motor.

6. Testing and Fine-Tuning

Once everything is connected and configured, it’s time to test your setup:

Power On:

Turn on your power supply and microcontroller.

Initial Test:

Run the microcontroller program to ensure the motor steps as expected.

Adjustments:

Fine-tune the current limit and microstepping settings if necessary.

Monitoring:

Monitor the motor and driver for any signs of overheating or unexpected behavior.

Conclusion

Setting up and configuring the A4988 Stepper Motor Driver Carrier Black requires careful attention to wiring, current limiting, and microstepping settings. By following this guide, you can ensure your stepper motor operates efficiently and reliably, making the most of the A4988’s capabilities. Happy tinkering!

0 notes

Text

How to Install XCF32PFS48C: A Step-by-Step Guide

The XCF32PFS48C is a versatile and essential component in the field of programmable logic devices. Whether you're a seasoned engineer or a beginner, installing this chip correctly is crucial to ensure your project runs smoothly. In this guide, we'll walk you through the installation process step by step, making it easy to follow and understand.

Introduction

Installing the XCF32PFS48C can seem daunting, but with the right guidance, it becomes a straightforward process. This guide will help you install the chip correctly, ensuring optimal performance for your electronic projects.

1. Overview of XCF32PFS48C

The XCF32PFS48C is a complex programmable logic device (CPLD) known for its flexibility and high performance. It's used in various applications, including digital signal processing, communications, and embedded systems. Understanding its features and specifications is the first step in ensuring a successful installation.

2. Tools and Materials Needed

Before starting the installation, gather the necessary tools and materials:

Soldering iron and solder

Antistatic wrist strap

Magnifying glass or microscope

Flux

Desoldering braid or pump

Multimeter

XCF32PFS48C chip

Clean, well-lit workspace

Having these items ready will make the process smoother and more efficient.

3. Preparing for Installation

Work Area Preparation

Ensure your workspace is clean and well-lit. An organized workspace reduces the risk of errors and makes the process more efficient.

Antistatic Precautions

Wear an antistatic wrist strap to prevent static electricity from damaging the chip. Ground yourself and your tools to eliminate any static charge.

4. Step-by-Step Installation

Step 1: Inspect the Chip and Board

Carefully inspect the XCF32PFS48C chip and the circuit board. Ensure there are no visible defects or contaminants that could affect the installation.

Step 2: Apply Flux

Apply a small amount of flux to the pads on the circuit board where the chip will be placed. Flux helps in making better solder joints.

Step 3: Position the Chip

Using tweezers, carefully position the XCF32PFS48C chip on the pads. Make sure all the pins are correctly aligned with the corresponding pads.

Step 4: Solder the Pins

Begin by soldering one pin to secure the chip in place. Then, proceed to solder the remaining pins, ensuring each connection is clean and solid. Use a magnifying glass to inspect the joints.

Step 5: Clean the Board

Once all the pins are soldered, clean the board with isopropyl alcohol to remove any excess flux and ensure a clean installation.

5. Testing the Installation

Initial Power-Up

Before applying full power, do a continuity check with a multimeter to ensure there are no shorts. Once confirmed, power up the board and check for correct operation.

Functional Testing

Run a functional test to ensure the XCF32PFS48C is operating as expected. This might involve running specific programs or tests relevant to your project.

6. Troubleshooting Tips

Common Issues

Solder Bridges: Use desoldering braid to remove any excess solder causing bridges between pins.

Misalignment: Carefully reheat and adjust any misaligned pins.

Tools for Troubleshooting

Multimeter: For checking continuity and proper connections.

Oscilloscope: To verify signal integrity if needed.

7. Maintenance and Care

Regular Inspections

Regularly inspect the solder joints and connections to ensure they remain solid. This helps in identifying potential issues before they become significant problems.

Proper Storage

Store the board and chip in a clean, dry place. Use antistatic bags to prevent static damage.

8. Common Mistakes to Avoid

Insufficient Solder

Ensure enough solder is used to make a good connection, but not so much that it creates bridges.

Overheating

Avoid applying excessive heat to the chip and board, as this can damage both. Use a temperature-controlled soldering iron.

9. Advanced Tips for Experts

Fine-Tuning Soldering Techniques

For experienced users, practice advanced soldering techniques such as drag soldering for quicker and more efficient installations.

Custom PCB Design

Consider designing custom PCBs that optimize the layout for the XCF32PFS48C, improving performance and ease of installation.

Conclusion

Installing the XCF32PFS48C doesn't have to be a daunting task. By following this step-by-step guide, you can ensure a successful installation, leading to reliable and high-performance operation in your projects. Remember to take your time, be precise, and double-check your work.

0 notes

Text

The Ultimate Guide to Digital Multimeters: Working and Benefits of Use

In the world of electronics and electrical troubleshooting, the digital multimeter stands out as a versatile and indispensable tool. Whether you are a professional electrician, an electronics hobbyist, or a DIY enthusiast, understanding how a digital multimeter works and its benefits can significantly enhance your work. This blog explores the working principles and advantages of using a digital multimeter, with a special focus on popular brands like Fluke and Hioki.

What is a Digital Multimeter? A digital multimeter is an electronic measuring instrument that combines several measurement functions in one unit. Typically, it can measure voltage, current, and resistance. Modern digital multimeters can also measure a variety of other parameters such as capacitance, frequency, and temperature.

How Does a Digital Multimeter Work? Understanding how a digital multimeter works can demystify its operation and improve its utilization in various applications. Here's a detailed breakdown: Selection of Measurement Mode: The first step in using a digital multimeter is to select the appropriate measurement mode. This is done by turning the rotary switch to the desired function (voltage, current, resistance, etc.).

Connecting the Probes: The multimeter comes with two probes: red (positive) and black (negative). These probes are connected to the circuit or component being tested.

Measurement Process:

Voltage Measurement: To measure voltage, the probes are placed across the component or section of the circuit. The digital multimeter measures the potential difference between the probes.

Current Measurement: For current, the circuit must be opened, and the multimeter probes are placed in series with the circuit. The device measures the flow of electric charge.

Resistance Measurement: When measuring resistance, the probes are placed across the component. The multimeter sends a small current through the component and measures the voltage drop, which is then used to calculate resistance.

Displaying the Results: The measured value is displayed on the digital screen of the multimeter, making it easy to read and interpret the results. Benefits of Using a Digital Multimeter Investing in a digital multimeter comes with numerous benefits, enhancing both accuracy and efficiency in electrical measurements:

High Precision and Accuracy: Digital multimeters provide highly accurate readings, which are essential for precise measurements in electronics and electrical work. Brands like Fluke digital multimeters and Hioki digital multimeters are renowned for their reliability and precision.

Versatility: A digital multimeter combines multiple measurement functions in one device, making it a versatile tool for various applications. It can measure voltage, current, resistance, and more, eliminating the need for multiple instruments.

Ease of Use: Modern digital multimeters are designed with user-friendly interfaces. Clear digital displays and simple controls make them accessible even to beginners.

Safety Features: Quality digital multimeters come with built-in safety features like overload protection and auto-ranging capabilities, ensuring safe and effective use in various conditions.

Portability: These devices are compact and portable, making them convenient to carry around for fieldwork or use in different locations.

Durability: Brands like Fluke and Hioki are known for their durable and robust designs, ensuring that the multimeters can withstand rough handling and harsh environments.

Specifications to Consider When choosing a digital multimeter, consider the following specifications: Display Count: This indicates the maximum number the display can show. Higher display counts mean better resolution. Accuracy: Look for a device with high accuracy for precise measurements. Auto-Ranging: This feature automatically selects the measurement range, simplifying operation. Input Impedance: High input impedance is essential for measuring sensitive electronics to prevent circuit loading. Safety Ratings: Ensure the multimeter complies with relevant safety standards (e.g., CAT ratings) for your specific application. Digital Multimeter Price The price of a digital multimeter varies based on its features and specifications. Basic models suitable for simple tasks can be found at affordable prices, while advanced models with more features and higher accuracy will cost more. It is important to balance your budget with the required specifications to get the best value for your needs. Applications of Digital Multimeters Digital multimeters are used in a wide range of applications due to their versatility and accuracy:

Electronics: Essential for troubleshooting and repairing electronic devices, digital multimeters help in identifying faulty components and ensuring proper operation.

Electrical Work: Electricians use digital multimeters for various tasks, including wiring installations, maintenance, and diagnosing electrical issues.

Automotive: In the automotive industry, these meters are used for testing electrical systems and components in vehicles.

Educational: They serve as valuable teaching tools in educational institutions, helping students learn about electrical measurements and circuit analysis.

DIY Projects: Hobbyists and DIY enthusiasts use digital multimeters for various projects, from building circuits to repairing household appliances. Conclusion A digital multimeter is an essential tool for anyone working with electronics or electrical systems. Its ability to measure multiple parameters accurately and reliably makes it a must-have in any toolkit. Whether you choose a Fluke digital multimeter or a Hioki digital multimeter, understanding how it works and its benefits will enhance your efficiency and accuracy in electrical measurements.

0 notes