#how to make clamp for round pipe

Explore tagged Tumblr posts

Text

PVC Clamp Manufacturing Business Plan

🔧🏭 Ready to dive into the world of PVC Clamp Manufacturing? Learn the ins and outs to kickstart your own business! 💡 Discover the secrets to success in this industry. CLICK LINK to explore more. #PVCmanufacturing #SmallBusinessTips

PVC clamps are integral components used across industries for various applications. These clamps, made from durable PVC and steel material, cater to various industries, offering secure and reliable fastening solutions for pipes, cables, and other applications. Their significance in securing pipes, cables, and other fixtures positions them as indispensable commodities in the construction,…

View On WordPress

#best business ideas#business ideas#clamp manufacturing business#how to make clamp for pipe#how to make clamp for round pipe#make a round pipe clamp#manufacturing business ideas#new business ideas#pipe clamp#pipe clamp machine#pipe clamp making#pipe clamp making ideas#pipe clamp manufacturing#pvc clamp manufacturing business#pvc pipe clamp#pvc pipe clamp solidworks#small business ideas#small scale manufacturing business ideas#steel clamp

1 note

·

View note

Text

TO YOUR SHOULDERS.

— you always looked better with your hair down.

summary : despite always wearing your hair up, jason thinks it looks better down.

note : yes this is totally ripped off from a scene in dexter s4,, and also reader is described with long hair but not explicitly fem ??? so just a heads up for that

it had never been a question of if you looked nice, it was just that it worked better for you in every way.

your trusty, dusty claw clip.

having your hair out of your face helps you think, helps you concentrate. you don't need to worry about fly-aways when you're eating, nor food getting stuck in the ends. it goes with every outfit, your claw clip.

whoever invented this thing needs everything they deserve and more, wherever they are.

that morning, as you dressed for work, you'd been standing in the bathroom mirror, clip lodged between your teeth as you gathered your hair at the back of your head.

jason's reflection emerged through the door, and he stepped up to the toilet next to you, lifting the seat up with the back of his knuckle — something he preferred doing to avoid getting germs on his fingers, which he'd wash off anyway.

but he paused, looking at you, and you could feel his gaze, as well as see it in the mirror if you tilted your head just a little.

your movements never ceased, and you reached to the front of your face, fingers closing around your clip.

"hey," jason piped up, almost urgent in a way that caused you to drop your hair and spin to look at him. his eyebrows were raised, but lowered in an instant, and his eyes were calm, kind.

after touching the toilet, he didn't want to reach up and ruin your hair, but he ghosted a hand over the front of your locks. "have i ever told you how good you look with your hair down?"

no, he hadn't, but now he has.

instinctively, you pulled away with a bashful grin threatening to poke out from pulled-up cheeks, soft like fresh bread. "really?" you breathed out, a small laugh like a song to your voice.

"really," he smiled with a nod.

"okay, i'll keep it down today." as you leaned forward into him, placing a hand on his toned chest, your smile still lingered as you kissed him, and you could feel the muscles in his face doing the same.

however, you hadn't kept your promise — not that it was a promise at all, but it was a compliment and it had made you feel warm and fuzzy.

but it's a force of habit, putting your hair up.

so when the work you were doing got a little bit more stressful, a little bit more things for you to rush around and do, the claw clip you'd kept safe in your bag just in case came out and clamped itself in your hair, keeping it up and out of your face.

by the time you'd closed the front door behind you and kicked your shoes off, jason was rounding the corner into the hallway to welcome you home.

your bag slipped from your fingers, falling to the floor as he appeared, and your arms stretched out for him. there was a slight pause in his actions, but it was barely anything noticeable in the exhaust of your head.

his wide frame slotted between your open arms, strong biceps holding you within his own. whilst your hands lay half-limp on his back, jason's embrace was tight, a hand coming to position on the nape of your exposed neck.

soft kisses tickled your temple.

"missed me?" you chuckled, voice muffled by the fabric of jason's grey t-shirt.

to which he only hummed in return, pulling his head away from where he'd been kissing to burrow in the crook of your shoulder. and then he said something, but you couldn't make it out, for his words had got lost in the threads of your clothes.

"speak up?" you offered, carefully twitching your head away so he'd look up.

when his face finally emerged, you found his black hair messed with affection and his eyes soft like the fur of a labrador. his lips thinned with a similar shyness you'd felt that morning.

"you put your hair up," jason finally mustered himself up to say, pads of his fingers dancing along the curls that had fallen down at the back after a busy day.

with a sharp inhale, you brought a hand to feel the clip, as if just realising it was there. "oh! sorry, it's been a long day."

you felt jason's hand rise to the clip too, and you moved yours away, settling it around the base of his neck, where your other hand met it.

"it's okay." his voice was soft and soothing, like a cup of chamomile and honey on a horridly rainy day; the scent of lavender when you're trying to get to sleep.

suddenly the tension at the back of your head was lost.

jason's other hand came around, brushing through the hair released from its clip, coming up to the top of your head to style it to frame your face. his eyes never looked at the hair, only you.

"perfect."

and the styling hand rested upon your cheek, thumb absently skimming across the skin.

with a gentle pull on his neck, you leaned forward, eyes fluttering shut, to meet him in the middle. if you were perfect, he was heaven-sent.

#aangelinakii#dc#dc comics#dc imagines#dc reactions#dc headcanons#dc universe#jason todd#jason todd x reader#jason todd imagines#jason todd fluff#jason todd au#jason todd headcanons

247 notes

·

View notes

Text

★ amethyst ; poly!marauders.

info: fluff, poly!marauders x gn!reader, under 1k.

there's a slight burn to your scalp as you apply more bleach to the small chunks of your hair, all sectioned into four neat squares to make the process easier.

your gloved hands squeak as you continuously clamp and unclamp your fingers over your locks, rubbing in the solution to get your hair to the light blonde you desire but it becomes increasingly difficult as you reach the back of your head.

"whatcha' doing, dolly?" sirius chirps, head popping past the door frame to get a good look at your odd stature: one foot on the lid of the toilet, the other planted firmly on the tiled floor as you attempt to get the last strand towards the base of your skull.

"can you see if i got the roots towards the back?" voice huffing in frustration as you scratch your burning scalp.

sirius coos teasingly, kissing at your clean temple when you pout. "you missed a couple spots. got any extra gloves?" his voice softer than before with a sickly sweet expression that makes your brain all gooey and melty.

you nod dumbly, handing him a pair of black latex gloves and practically purr as he gently scratches at your scalp, ceasing all itching and burning with his magic touch.

"are the boys back too?" you ask, already hearing the two pairs of socked footsteps thud against the hardwood floors. you've got your answer.

"hi, sweetness!" james pipes up, head peeking round the corner alongside remus'.

you smile, lazily reaching for them but not enough to disturb sirius who's hard at work. "what color are we going for today, dovey?" remus asks with curiosity, grin matching yours as he rushes to grasp at your hand.

"not sure... i have two different colors but i need your help deciding," your lips tucked into an adorable pucker as you mull over which color to go with.

two boxes lay on the countertop, pink and purple hair dye that are basically close in color but completely different vibes. you glance over to the boys, more so at sirius due to the fact that he's the best styled out of the bunch.

"i think i'm leaning more towards purple but i asked marls and she said pink so now my brain's all in a twist..." you pout slightly.

silence falls, the only thing being heard is your phone playing music. sirius is the first to speak, "i think you should stick to purple, doll."

then a flurry of agreements can be heard from both remus and james as if they were waiting for sirius' opinion before speaking upon their own.

"agreed, purple suits your skin tone!" james speaks as if he's just happy to be here, starry-eyed with a dopey grin to match.

remus nods along with james, "and it doesn't seem like it's a royal purple, it's more of an amethyst. i think you'll look extra pretty, dove."

you flush pink, "purple's the way to go then," soft giggle bubbling past your throat.

★ diwa's notes: i'm actually not sure how i feel abt this one but ty for 300 (?) notes on "lovely"!!!

© hobietopia 2024.

#★ amortentia ; poly!marauders.#★ fluff.#poly!marauders fluff#poly!marauders x reader#poly!marauders x you#poly!marauders imagine#poly!marauders comfort#poly!marauders drabble#marauders x y/n#marauders x you#marauders x reader#marauders masterlist#james potter x reader#sirius black x reader#remus lupin x reader#james potter fluff#sirius black fluff#remus lupin fluff#james potter masterlist#sirius black masterlist#remus lupin masterlist

705 notes

·

View notes

Text

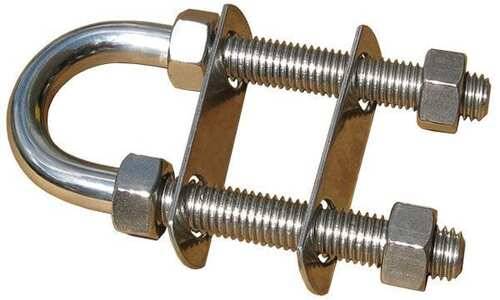

Stainless Steel U-Bolts: The Ultimate Guide to Strength and Durability

Thia article helps in understanding U-bolt as a U-shaped metal bolt with threads on both ends. It’s commonly used to secure pipes, hoses, and other round or cylindrical objects to surfaces or other components. When made from stainless steel, these bolts are highly resistant to corrosion, rust, and the elements, making them ideal for outdoor and harsh environments.

Stainless steel U-bolts are typically used in industries such as construction, automotive, and infrastructure, where strength, stability, and long-term durability are essential.

Stainless steel U-bolts come in various styles to meet different application needs. Here are the most common types:

Standard U-Bolts: These are the most basic form, used to secure objects like pipes to flat surfaces. They typically feature a simple U-shape with threads on both ends.

Square U-Bolts: Designed for specific applications requiring a square shape, square U-bolts provide extra grip and stability in some installations.

Threaded U-Bolts: These bolts have threads that run the entire length, providing a more secure hold when fastening multiple components together.

Non-threaded U-Bolts: In some cases, you might need a U-bolt without threads for particular installation applications.

Heavy-Duty U-Bolts: These U-bolts are reinforced and built for high-pressure or heavy-load applications, making them perfect for industrial or construction use.

The exact type you choose will depend on the load-bearing requirements, the installation environment, and the material you're securing.

Choosing the right stainless steel U-bolt is essential to ensure the safety, longevity, and success of your project. Here are some factors to consider:

Material: Always choose 316 stainless steel or 304 stainless steel for the best corrosion resistance. If the bolts will be used in marine environments, 316 stainless steel is ideal due to its superior resistance to saltwater corrosion.

Size and Diameter: U-bolts come in various sizes, so be sure to measure the pipe or component you need to secure. You want a snug fit for optimal performance.

Thread Length: The length of the threads should match the installation requirements. Ensure the bolt threads are long enough to fasten securely.

Application Needs: Consider the load requirements and the specific environment where the U-bolts will be used. For example, use heavy-duty U-bolts for high-pressure environments and light-duty U-bolts for lighter applications.

Clamping Surface: Ensure that the U-bolt is compatible with the clamping surface, whether it’s round, square, or flat. This ensures a secure fit and prevents damage to the components.

Stainless steel U-bolts offer unmatched strength, durability, and corrosion resistance, making them the ultimate choice for many industries and applications. Whether you're working in construction, automotive, piping, or marine environments, choosing the right U-bolt ensures your project’s success.

By understanding the different types of stainless steel U-bolts, their benefits, and how to properly install and maintain them, you can ensure that they will provide reliable service for years to come. Always opt for quality U-bolts manufacturers to guarantee superior performance in your projects.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Stainless Steel U-Bolts: The Ultimate Guide to Strength and Durability

#StainlessSteelUBolts#UBoltsGuide#StrengthAndDurability#ConstructionHardware#DurableFasteners#IndustrialFasteners#StainlessSteelFasteners#UBoltsApplications

0 notes

Text

Essential Tips and Techniques for Using Holesaw Cutters

Have you ever found yourself needing to make a precise hole in wood, metal, or plastic, but you weren’t sure how to do it efficiently? A holesaw cutter might be the tool you need! But how do you use it properly? What are the best techniques for getting clean, accurate cuts? In this article, we’ll explore essential tips and techniques for using holesaw cutters to help you achieve great results in your projects.

A holesaw cutter is a tool designed to cut large, round holes in various materials. Unlike a regular drill bit, which only makes small holes, a holesaw cutter has a circular blade that lets you cut through larger areas. Mostly used in woodworking, metalworking, and DIY projects. Understanding how to use a holesaw cutter effectively can save you time, effort, and frustration. Let’s dive into some straightforward tips and techniques to get the most out of this handy tool.

1. Choose the Right Size

Before you start cutting, it’s crucial to select the correct size of the holesaw cutter for your project. Holesaw cutters come in various diameters, so pick one that matches the size of the hole you need. For example, if you need a hole for a pipe, choose a holesaw cutter with a diameter slightly larger than the pipe’s diameter to ensure a proper fit.

2. Use the Correct Drill

Holesaw cutters are designed to be used with a power drill. Ensure that the drill you use has enough power to handle the cutter, especially if you’re working with tough materials like metal. A drill with adjustable speed settings is also useful, as it allows you to control the cutting speed based on the material you’re working with.

3. Mark Your Cutting Area

Before you begin cutting, mark the center of the hole you want to make. Use a pencil or marker to draw a small dot or circle where you want the hole to be. This guide will help you position the holesaw cutter accurately and prevent it from slipping or wandering off course.

4. Secure the Material

To get a clean and precise cut, it’s important to secure the material you’re working on. If the material is not firmly held in place, it may move during cutting, resulting in an uneven hole. Use clamps or a vise to secure the material to your work surface. For large pieces, consider asking someone to help you hold the material steady.

5. Start with a Slow Speed

When begin to cut, start with a slow drill speed. This will help you maintain control and reduce the risk of overheating the holesaw cutter. As the cutter starts to bite into the material, you can gradually increase the speed for smoother cutting. Avoid going too fast, as this can cause the cutter to overheat or dull quickly.

6. Apply Steady Pressure

Apply steady, even pressure while cutting. Pushing too hard can strain the drill and cause the holesaw cutter to become stuck or break. Let the cutter do the work and guide it gently through the material. If you encounter resistance, reduce the speed and check if the cutter is becoming clogged with debris.

7. Use Cutting Fluid

For tougher materials like metal, using a cutting fluid can help reduce friction and heat, which prolongs the life of the holesaw cutter and results in a cleaner cut. The cutting fluid has to be applied to the area being cut, and make sure to use it according to the manufacturer’s recommendations.

8. Clear Debris Regularly

As you cut, debris will accumulate inside the holesaw cutter. Stop and clear out the debris to prevent it from clogging the cutter and affecting the performance regularly. You can use a small brush or tap the cutter gently to remove the buildup.

9. Check for Wear and Tear

Inspect the holesaw cutter regularly for signs of wear and tear. If you notice that the teeth of the cutter are dull or damaged, it’s time to replace it. Using a worn-out cutter can result in rough cuts and may even damage your material.

10. Practice Safety

Safety should always be your top priority when using a holesaw cutter. Safety goggles protects your eyes from flying debris, and gloves helps to avoid any potential injuries so make sure to wear them. Ensure that your work area is clean and free of obstructions to reduce the risk of accidents.

Using a holesaw cutter can make creating large, precise holes in various materials much easier and more efficient. By following these essential tips and techniques, you’ll be able to achieve clean cuts and make the most of this versatile tool. Remember to choose the right size, secure your material, start slow, and prioritize safety. With a bit of practice and attention to detail, you’ll become skilled at using holesaw cutters and enhance the quality of your projects.

0 notes

Text

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

How To Make A Churchwarden Pipe Stem

The Churchwarden pipe stem is an important part of the Churchwarden pipe. Having a high-quality Churchwarden pipe stem will affect your smoking experience, so in this blog, we will take you to make a Churchwarden pipe stem. You must know that the Churchwarden pipe stem takes a very long time, and you need to invest a lot of energy in the production process, so I hope you read our blog carefully before making the pipe stem, which will help you to a great extent . So let’s get our tools ready and start making the Churchwarden pipe stem According to the material, there are two types: most cigarette holders are Vulcanite cigarette holders. This pipe stem is made of natural rubber and is vulcanized. But in the past 20 or 30 years, some pipe manufacturers began to equip their high-end pipe series with Acrylic cigarette holders. Although the cost is higher, it is not easy to oxidize and fade, which is an advantage that vulcanized hard rubber ( Vulcanite) does not have. On the other hand, synthetic resin has a harder taste, so some pipe smokers prefer the softer vulcanized hard rubber. However, there is a style called Cumberland pipe stem, which is becoming more and more popular in high- end pipe series. They are dark brown in color and dotted with stripes of black, red, and other colors, making them very noble and beautiful. There are two popular shapes of pipe stems on the market: One is Tapered - a simple streamlined shape with straight lines tapering to a sharp point. One is Saddle - the lines are relatively square for easier bite, and the bottom is "saddle-shaped". A pipe stem's opening primarily comes in two main types: the wide flat bore and the round bore. In some cases, there is a type of pipe stem with twin bores inside, commonly referred to as the "Twin-Bore" design. In addition, the composition of the pipe stem also includes Mounts: various hoops attached to the mouth of the bucket handle. Although the handle base is a decorative item, it also has a practical purpose: to protect the easily cracked handle opening. The handle base can be made of various base metals, but high-end pipes are usually made of silver, sometimes even gold (the most famous silver handle base is the British brand Ferndown, and Mr. Les Wood himself is a silversmith). The handle base can also be made of animal horns and various semi-precious stones. Here we use the Saddle design to make it. You only need to use a plane and file to start carving the shape of the pipe stem.Just use a plane and file to start carving the shape of the pipe stem. Once the carving is complete, you can start sanding the pipe stem using coarse sandpaper, then gradually transition to finer sandpaper to achieve a smooth surface. When our Churchwarden pipe stem shape is completed, we need to start drilling. Before starting, you need to prepare a drill press, and then Place the pipe stem blank in a vise or clamp, ensuring it is held firmly and securely. This will prevent any movement during the drilling process. Then Measure and mark the desired drilling point on the pipe stem blank. Start slowly. This can largely avoid cracks in the Churchwarden pipe stem, so we recommend using a drill speed of 750 rpm. In addition, we also need to apply a small amount of lubricant on the drill bit. This has the advantage of preventing the drill bit from overheating due to severe friction during drilling, causing the valve stem material to melt and causing production failure. After everything is completed, you only need to use tools to continue fine polishing, and a beautiful Churchwarden pipe stem is completed. Read the full article

0 notes

Text

DIY Hanging Copper Chandelier

Project by Megan:

I love decorating for the holidays and always find myself exploring Pinterest for hours to get ideas. I happened upon an image of a gorgeous copper chandelier that felt like the perfect thing to light up a low-key holiday table. Inspired, I decided to figure out how to build it myself using supplies from my local hardware store, and the end result will last well beyond the holidays. To give this a little extra holiday flair, I cut a few short pieces of greenery and wired them to the base of the pipes. Simply remove the greens after the holiday to keep this look year-round. Ready to make one of your own? Keep reading for my step-by step guide, or to see this project take shape in real time, check out the how-to video on the One Kings Lane Style Blog! —Megan

Here’s what you’ll need: • two 1/2” x 24” copper pipes • three 3/4” x 24” copper pipes • two ceiling hooks (not pictured) • a spool of rope or twine to hang (not pictured) • two 3/4” copper 90-degree elbows • four 1” to ¾” couplings • two ½” copper tees • two ¾” copper tees • two ¾” to 1/2” copper tees • a pipe cutter • J-B Weld two-part epoxy

Prep the Pipes

To get started, I used a little rubbing alcohol on a paper towel to remove the manufacturer markings on the outside of the pipes.

Measure and Cut

After I mapped out the measurements for the overall length and various arm heights of my chandelier (one of the best things about this project is it’s totally customizable), I used a permanent marker and a tape measure to mark the ¾” pipes at the desired lengths.

Tip: You can totally experiment with different lengths and configurations for the chandelier; just ensure that your candle flame is clear of the rope or twine you use to hang it.

To cut the pipe, I clamped the pipe cutter around the copper, positioning the blade on the mark, and twisted it to make the cut. Tighten the blade every few turns until the pipe is cut. It might seem unlikely that this inexpensive little tool will actually do the job, but trust me, it works!

Here’s My Cut List: -five ¾” x 6” pieces (to form the bottom edge to the chandelier) -two ¾” x 4” pieces (to form the middle 2 pillars) -two ¾” x 6” pieces (to form the outer 2 pillars) * The two ½” x 24” pipes don’t get cut.

Tip: Lay it out! I think it helps to see how all your cut pieces work together before you start to glue so you don’t get confused.

Assemble and Glue

I used a special two-part epoxy designed for use with metal. It is super strong! I recommend only mixing a little bit at a time. I used a matchstick to mix the two parts together.

I also used the matchstick to apply the glue to one end of the pipe. A little goes a long way, so don’t overdo it. If any glue does seep out after you glue two pieces together, just use a little rubbing alcohol to wipe it away.

Tip: Be sure to assemble your chandelier on a flat surface where the project can stay for a few hours while the glue dries.

Finish and Hang

Once the glue is fully dry (about 4 hours), thread a length of rope or twine through the top of the chandelier and hang. I used a couple of ceiling hooks (the kind you use to hang plants) to secure my chandelier in place. To finish it off I added a few taper candles and the greenery. I found that regular taper candles fit perfectly into the openings, but you can always use a bit of aluminum foil around the bottom of the candle to help hold it in place.

1 note

·

View note