#home appliances components

Explore tagged Tumblr posts

Text

Aluminium Other Components in Pune | India

https://justpaste.it/gmjvh

#advanvcetechnologiespune#advancetechnologiesinpune#india#electrical components#shot blasting of components in pune#electronics components#home appliances components#automobile components#home appliances

0 notes

Text

Common Causes of Water Heater Rust and How to Prevent It.

Your water heater is one of the hardest-working appliances in your home. With proper care, it can serve you for up to 20 years. However, rust is one of the leading causes of premature water heater failure, turning durable tanks into brittle, leaky messes.

Why Does Rust Occur in Water Heaters?

Rust is a natural reaction when metals like iron come into contact with water and oxygen. Let’s explore the top causes of water heater rust.

Failed Anode Rods.

Hard Water and Sediment Build-Up.

Damaged Glass Liners.

The Importance of Regular Water Heater Maintenance.

Scheduling routine maintenance for your water heater can help you avoid costly repairs and extend its life. Here’s what maintenance should include:

Flushing the Tank: Removes sediment and improves heating efficiency.

Inspecting and Replacing Anode Rods: Protects the tank from corrosion.

Testing the System: Ensures all components are working properly.

Protect Your Water Heater with Emergency Plumbing

At Emergency Plumbing, we specialize in water heater maintenance and rust prevention. Our team serves homes across North Shore and Northwest suburbs of Chicago IL, and beyond, offering reliable services for:

Plumbing

Drains & Sewers

Whether you need a system flush, anode rod replacement, or help choosing a water softener, we’re here to help.

Contact us today to schedule maintenance or get a free quote.

Phone 224-754-1984

#Common Causes of Water Heater Rust and How to Prevent It.#Your water heater is one of the hardest-working appliances in your home. With proper care#it can serve you for up to 20 years. However#rust is one of the leading causes of premature water heater failure#turning durable tanks into brittle#leaky messes.#Why Does Rust Occur in Water Heaters?#Rust is a natural reaction when metals like iron come into contact with water and oxygen. Let’s explore the top causes of water heater rust#1. Failed Anode Rods.#2. Hard Water and Sediment Build-Up.#3. Damaged Glass Liners.#The Importance of Regular Water Heater Maintenance.#Scheduling routine maintenance for your water heater can help you avoid costly repairs and extend its life. Here’s what maintenance should#• Flushing the Tank: Removes sediment and improves heating efficiency.#• Inspecting and Replacing Anode Rods: Protects the tank from corrosion.#• Testing the System: Ensures all components are working properly.#Protect Your Water Heater with Emergency Plumbing#At Emergency Plumbing#we specialize in water heater maintenance and rust prevention. Our team serves homes across North Shore and Northwest suburbs of Chicago IL#and beyond#offering reliable services for:#• Plumbing#• Drains & Sewers#Whether you need a system flush#anode rod replacement#or help choosing a water softener#we’re here to help.#Contact us today to schedule maintenance or get a free quote.#Phone#224-754-1984

1 note

·

View note

Text

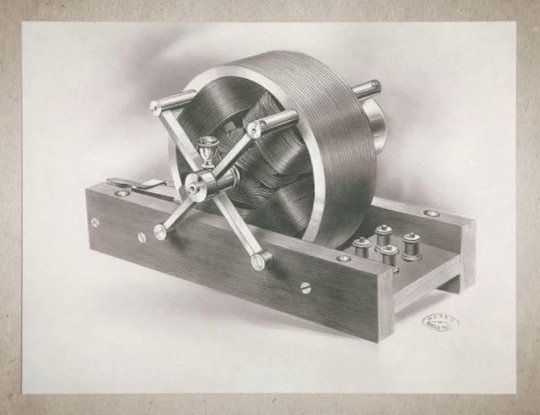

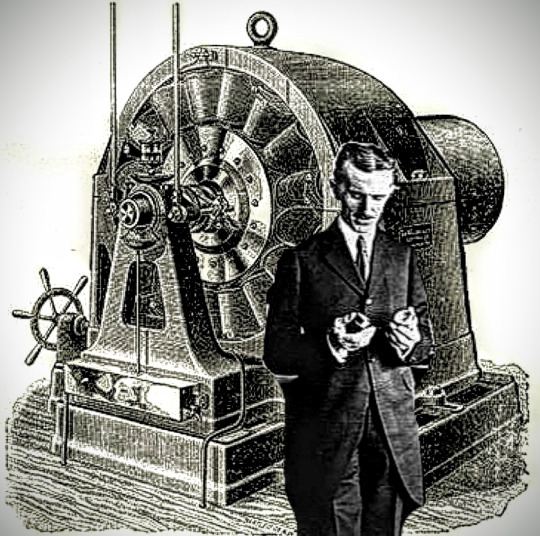

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Note

Okay so the dichotomy between your Sakuya Cherry Bomb idea and Yarra's Kuro vtuber is hilarious to me because like.

Sakuya: Fans only know him as Cherry Bomb and don't know anything about him outside of his music.

Vs

Kuro: Vtuber Lore is literally just his life but it should be fine because people dont know vampires are real.

I FUCKING FOUND IT. LINK TO THE CHERRY BOMB POST 🍒💣

Anyway one of the reasons for the difference is I headcanon Sakuya as being a 90s kid! as in, he died in the 90s--

This, naturally, makes him a lot more wary about the info he puts out there on the internet, but it also means his internet experience was molded by Ye Olden Days when creators were a lot less available to their fanbases and interacted with them very little, if at all.

He doesn't even have a fanart hub, and his icon is just a random street in tokyo he thought looked nice.

His classmates REALLY do not get why Sakuya is so paranoid, so Sakuya shows them how easy it would be for a super dedicated person to figure out exactly where Mahiru’s apartment is using his cooking tutorial videos (uploaded under the channel name "Sunny Mama" courtesy of Kuro) and basic realtor research

Things like Mahiru apologizing for any construction noise and using the time stamp to figure out which apartment complexes had construction in their vicinity during that time, floor plans, how even his living situation and the model of his appliances can all be used to narrow down the area he lives in.

“He lives with his uncle and the camera man, which means at least two rooms. We can see the stove top and the front of the oven, so I take a screenshot of that and… Ah, this is the brand. Now I research the model. Okay, I have two components. He mentions that he walks to school, so that’s a two bedroom apartment in Tokyo within walking distance of a high school with good quality appliances, which means I can rule out a lot of run down complexes. This grocery bag was in frame during this video, and a high school kid Mahiru’s age wouldn’t have a license, so now I add that name of the store to my list of things I know are around the complex because when you go grocery shopping, you don’t want to carry the bags a long distance home…”

The faces of his friends are full of horror.

"And that’s not even getting into the drinking with uncle segment that happens in their living room, with full view of the balcony because Mahiru hates the place getting musty so he leaves the curtains open a lot. Knowing what buildings are viewable from there can also tell someone where a place is, especially if you’re thorough enough to consider the angle you’re seeing everything at.” Sakuya glances up and closes his laptop. “So, yeah.”

Mahiru makes a Noise, fretting, "Wait, so what do I do now??"

Sakuya feels a little bad for scaring his friend, but it's for his own good! “Keep your curtains closed, make sure the screws in your door frame are the really long kind to prevent someone from just kicking the door off its hinges, don’t get electronic locks because it’s stupid easy to trick those into unlocking, and just… Be more careful? Wear a mask from now on and go back and edit footage to remove your face from the visible shot. Try and keep things focused on your hands instead, maybe…”

"Should I get rid of the drinking with uncle part? Since that always focuses on Uncle Tooru's reactions..."

"He’s a grown up and an old man. Nobody’s going to be interested in pulling him into a windowless white van unless it’s those creep show friends of his…”

"Wh--Why would anyone be interested in pulling me into a windowless white van?!"

"Sex trafficking."

"Eh?"

"Or stealing your organs."

"Eh?"

“Or even just some obsessive pervert who’s built up some kind of fantasy in their head that you’re fated for one another but you just don’t realize it yet.”

"What."

As you can tell. Yeah. Sakuya really internalized those 90s internet safety psas. He's also well acquainted with the idea of a very dedicated stalker for. Reasons.

Tsubaki voice: that boy just isn't right...

#Anonymous#asks#servamp#thanks for the ask nonny!!#kat's katerwauling#pawprints#sakuya watanuki#mahiru shirota

32 notes

·

View notes

Text

one of the very best tropes is when a place that is home to the characters has a thing - a person (an inhabitant, a caretaker, a pet...) or a thing (a decoration, a wonky appliance...), anything - that is metaphorically the heart of the home. The purest manifestation of its nature. It might be a literal genius loci, but it absolutely doesn't need to be. Often kind of quirky, askew with propriety, but a key component of, and symbolic of, what makes this place home, makes it safe...

And then it's removed - maybe violently, maybe insidiously - and that's when the characters realize abruptly that something is very, very Wrong.

It's Wolf 359 when the Urania crew eject the plant monster. It's Camp Half-Blood at the start of Sea of Monsters when our heroes arrive only to find that Chiron has just been fired. It's what once was good, if messy, suddenly hollowed out and likely now being corrupted by whatever parasite has moved into the space.

Overlaps with the terrible moment you realize your loved one/trusted ally has been possessed/replaced with an evil clone/etc, but a) for a place and b) ...well, I guess it kind of is like possession. Except nothing actually needs to be sentient, nor have any practical effects. It's purely symbolic.

49 notes

·

View notes

Text

Spider-Man 2099 + Pokémon hcs (part 1)

First of all I have an uncanny talent of being able to make Pokemon AU out of anything. Second of all, thank you @xinakwans for inspiring me with your post about what Pokémon Xina would have.

Miguel

Ariados

He’s Spider-Man right? He’s gotta have a spider Pokémon. There are a few different spider Pokémon I just think Ariados suits him the best.

Miguel raised Ariados for his research and experiments to re-create Spider-Man’s powers. After the lab accident which gave Miguel his powers, he takes Ariados home with him.

Ariados does not like Miguel at first but they do eventually grow closer and make a great vigilante team.

“Its feet are tipped with tiny hooked claws that enable it to scuttle on ceilings and vertical walls. It constricts its foe with thin and strong silk webbing.” – Pokémon Emerald

Umbreon

Miguel has had Umbreon since he was a kid, when they met it was still an Eevee. He was surprised when it evolved late one night.

Eevee is “The Evolution Pokémon”, I think Eevee might have sparked Miguel’s interest in genetics. Unfortunately, there isn’t much money in being a Pokémon researcher…

Salamence

The year is 2099 and dragons are still really really cool.

Zubat

No real reason for Miguel owning a Zubat, my Miguel plushie just sits next to my Zubat plushie on my window and I think they look cute together.

Xina <3 <3

So I think that Xina is one of the better actual Pokémon trainers, never went pro or anything but took training and battling seriously.

Gengar

Xina traded Miguel for his Haunter, and it evolved into Gengar.

Snorlax

I haven't decided if Xina patiently raised Snorlax from a hungry little Munchlax or is she played a mean flute solo in order to capture it.

Kadabra

Xina planned to trade Kadabra to Miguel so it would evolve into Alakazam.

Starmie

When Xina was young, she would train every day in the pool with Starmie.

Espeon

A while ago someone made a poll asking what kind of pets Xina and Miguel would have. I couldn't quite pin down if they were a dog/cat/lizard/squirrel couple but I knew for sure they were an Espeon/Umbreon couple.

Charizard

Xina and Charizard are really close, with Charizard being Xina’s starter Pokémon raised from a Charmander.

Charizard does not like Miguel. Xina may be willing to forgive Miguel but for Charizard it’s an on-sight flamethrower to the face.

Xina can mega evolve Charizard to Mega Charizard X.

Lyla

Rotom

The “lore” around Rotom in the Pokémon franchise itself is interesting. Rotom is a ghost-type Pokémon that can inhabit and “possess” appliances. Rotom originally seemed to be a sort of mischievous poltergeist, but in the latest entries in the franchise it seems to come with and be an essential working component of some electronics like phones and pcs. The Rotom inside the Pokedex even talks.

So essentially in this AU Lyla is a Rotom. She still takes the form of the Lyla we all know and love but the reason Lyla sometimes feels like a sentient being with thoughts and feelings is because…she is. Inside the box that contains “Lyla” there is a Pokémon.

Miguel had no idea that Lyla was a Pokémon until he brought her to Xina.

Lyla-Rotom is an Electric/Fairy type.

Thanks for reading! If you like these I'll drop part 2!

23 notes

·

View notes

Text

The DIY Guide to Identifying and Addressing Hidden Plumbing Issues at Home

Introduction

Homeownership brings a variety of responsibilities, and one of the most critical yet often overlooked aspects is plumbing. Understanding how to identify and resolve hidden plumbing issues can save you time, money, and stress in the long run. This comprehensive guide explores common hidden plumbing problems that may occur in your home, providing you with the knowledge necessary to tackle them head-on. By following this DIY guide, you'll gain insights into everything from slab leak detection to basement waterproofing and even main line leaks.

The DIY Guide to Identifying and Addressing Hidden Plumbing Issues at Home

Plumbing issues can be sneaky little devils, often hiding behind walls or under floors until they become major headaches. Whether it's a slow drip or a sudden flood, understanding your plumbing system is essential for any homeowner. From knowing when to call a plumber to diagnosing minor issues yourself, this guide offers step-by-step methods for identifying and addressing those pesky plumbing problems.

Understanding Your Home's Plumbing System 1. The Basics of Home Plumbing

Every home has a unique plumbing system designed for its specific needs. It's crucial to understand the basic components: pipes, fixtures, drains, and appliances connected by a network that allows for water delivery and waste removal.

youtube

2. Common Plumbing Materials

Familiarize yourself with different types of pipes used in plumbing systems: PVC, copper, PEX, and galvanized steel. Each material has its advantages and disadvantages regarding durability, cost, and ease of installation.

3. Water Supply vs. Drainage Systems

While both systems are crucial for your home's functionality, their purposes plumber near me differ significantly. Understand how each system works—water supply delivers clean water while drainage removes wastewater—and learn how they interact.

Signs of Hidden Plumbing Issues 4. Unexplained Water Bills

A spike in your water bill without increased usage can indicate hidden leaks somewhere in your system—potentially leading you toward costly repairs if not addressed promptly.

youtube

5. Damp Spots on Walls or Ceilings

Water stains are often telltale signs of leakage behind walls or ceilings. Inspect these areas closely; if left untreated, they could lead to severe structural damage over time.

6. Mold Growth

Mold thrives in damp environments; thus, its presence could signify underlying plumbing issues like leaks or condensation that must be addressed immediately.

youtube

Common Types of Hidden Plumbing Problems 7. Slab Leak Detection: What You Need to Know

Slab leaks occur when water pipes beneath your home's foundation crack or corrode, leading to significant water damage if undetected.

How Can You Identify a Slab Leak? Warm spots on floors Increased water bills Sounds of running water when all taps are off 8. Main Line Leaks: Causes and Solutions

Main line leaks involve breaks in the primary pipe supplying water into your home—often resulting from soil movement or corrosion over time.

What Are The S

2 notes

·

View notes

Text

Global Aluminum Knob Market Trends and Future Growth Analysis 2024 - 2031

The global aluminum knob market is experiencing substantial growth, driven by the increasing demand for lightweight and durable components across various industries. Aluminum knobs are widely used in consumer goods, electronics, automotive, and furniture, making them essential in contemporary manufacturing and design.

Overview of Aluminum Knobs

The global aluminum knob market is poised for continued growth, fueled by the increasing demand for lightweight, durable, and aesthetically pleasing components across various industries.

Aluminum knobs are small, typically cylindrical or rounded fixtures made from aluminum, designed to facilitate user interaction with devices or furniture. Their lightweight nature, resistance to corrosion, and aesthetic appeal make them a popular choice in many applications.

Types of Aluminum Knobs

Industrial Aluminum Knobs

Designed for machinery and equipment, these knobs are engineered for durability and functionality.

Often feature textured surfaces for better grip.

Furniture Aluminum Knobs

Commonly used in cabinets, drawers, and doors, these knobs come in various designs and finishes to enhance aesthetics.

Available in decorative styles for modern and traditional furniture.

Electronic Aluminum Knobs

Used in various electronic devices such as audio equipment and appliances.

Often designed with precision for smooth operation and tactile feedback.

Market Drivers

Growing Demand for Lightweight Materials

The increasing emphasis on reducing weight in various applications, especially in automotive and aerospace industries, is driving the demand for aluminum knobs. Their lightweight properties contribute to overall efficiency and performance.

Aesthetic Appeal

The aesthetic versatility of aluminum knobs is propelling their use in furniture and consumer goods. Manufacturers are increasingly incorporating stylish and customizable designs, making aluminum knobs an attractive option for end-users.

Environmental Considerations

Aluminum is a recyclable material, which aligns with the growing trend towards sustainability. The ability to recycle aluminum without degradation in quality is encouraging manufacturers to choose aluminum knobs over other materials.

Regional Analysis

North America

North America is a significant market for aluminum knobs, driven by a robust manufacturing base and high demand from the automotive and furniture sectors. The region's focus on innovation and quality further supports market growth.

Europe

Europe also plays a critical role in the aluminum knob market, with many prominent manufacturers and designers located in the region. The demand for aesthetically pleasing and functional designs is high, particularly in the furniture and home appliance industries.

Asia-Pacific

The Asia-Pacific region is expected to witness rapid growth in the aluminum knob market. Countries like China and India are experiencing a surge in manufacturing activities, particularly in electronics and automotive sectors, driving the demand for aluminum knobs.

Key Players in the Market

AluFlex

A leading manufacturer specializing in high-quality aluminum knobs for various applications, known for its innovative designs.

Hafele

Offers a wide range of aluminum knobs for furniture and hardware solutions, focusing on aesthetics and functionality.

Dura Knobs

Known for its industrial-grade aluminum knobs, Dura Knobs provides durable solutions for machinery and equipment.

Future Trends

Customization and Personalization

As consumer preferences shift towards personalized products, manufacturers are increasingly offering customizable aluminum knobs. This trend is expected to enhance customer engagement and satisfaction.

Smart Technology Integration

The integration of smart technology in various applications is likely to influence the design of aluminum knobs. Future knobs may incorporate features such as touch sensitivity and integrated controls for electronic devices.

Sustainable Manufacturing Practices

With the growing emphasis on sustainability, manufacturers are likely to adopt eco-friendly practices in the production of aluminum knobs. This may include using recycled materials and implementing energy-efficient manufacturing processes.

Conclusion

The global aluminum knob market is poised for continued growth, fueled by the increasing demand for lightweight, durable, and aesthetically pleasing components across various industries. As technological advancements and sustainability trends shape the market landscape, stakeholders must innovate to meet the evolving needs of consumers. With a focus on customization and smart integration, the future of aluminum knobs looks promising, ensuring their relevance in the manufacturing and design sectors for years to come.

#Global Aluminum Knob Market Size#Global Aluminum Knob Market Trend#Global Aluminum Knob Market Growth

3 notes

·

View notes

Text

Everything You Need to Know About Hotel Supplies

The hospitality industry thrives on its guests' comfort, satisfaction, and experiences. One often overlooked yet essential component is hotel supplies. These are the unsung heroes who transform ordinary stays into unforgettable experiences.

Why Hotel Supplies Are Crucial for Hospitality Success

Importance of Guest Experience

Think about it: when you stay at a hotel, what makes the experience memorable? Are they soft, luxurious sheets or eco-friendly toiletries? Hotel supplies are pivotal in ensuring guests feel pampered and valued.

Building a Competitive Edge in the Hospitality Industry

In an era of fierce competition, providing top-quality amenities can set you apart. Guests now compare even the smallest details, making your supplies a key differentiator.

Essential Categories of Hotel Supplies

Bedding and Linens

Nothing beats the feeling of sinking into a soft, clean bed after a long day. Premium-quality sheets, comforters, and pillows are must-haves.

Furniture and Fixtures

Sturdy, elegant furniture like desks, wardrobes, and lighting fixtures enhance comfort and functionality.

Bathroom Supplies

Toiletries and Towels

Could you stock up on shampoo, conditioner, body wash, and fluffy towels? High-end products leave a lasting impression.

Shower and Bath Accessories

From non-slip mats to rainfall showerheads, these small touches elevate luxury.

Lobby and Reception Supplies

Signage and Stationery

Ensure clear, professional signage and quality stationery for seamless guest communication.

Waiting Area Comfort Items

Think plush seating, magazines, and water dispensers to make guests feel at home.

Advanced Hotel Supplies for Modern Guests

Smart Room Technology

Guests expect convenience, and smart technology—like keyless entry and voice-controlled devices—delivers just that.

High-End Coffee and Snack Stations

Gourmet coffee machines and locally sourced snacks can create a memorable, personalized experience.

Sustainable Hotel Supplies

Eco-Friendly Toiletries

Swap single-use plastics for biodegradable options to impress eco-conscious travelers.

Recyclable Packaging and Biodegradable Products

From soap wrappers to laundry bags, sustainability can shine through thoughtful choices.

Energy-Efficient Appliances and Lighting

Save on costs and reduce your carbon footprint with energy-efficient solutions.

Choosing the Right Hotel Supply Vendors

Factors to Consider When Choosing Vendors

Look for reliability, quality, and competitive pricing. Ensure your vendor aligns with your sustainability goals.

How to Build Long-Term Relationships with Suppliers

A strong partnership can lead to better deals and consistent supply. Communicate your needs and expectations clearly.

Trends in the Hotel Supplies Industry

Personalization in Amenities

From monogrammed towels to custom-scented toiletries, personalization is in high demand.

Increased Focus on Sustainability

Hotels invest more in green practices, and your supplies should reflect this trend.

Technology-Driven Innovations

Automation in housekeeping and inventory management is revolutionizing the way hotels operate.

Budgeting for Hotel Supplies

Cost-Effective Buying Tips

Buy in bulk, negotiate discounts, and compare suppliers to get the best deals.

Balancing Quality and Affordability

Invest in items that provide long-term value, even if they cost more upfront.

FAQs About Hotel Supplies

What are the must-have hotel supplies? Essentials include quality bedding, toiletries, and energy-efficient appliances.

How can hotels ensure sustainability with their supplies? Opt for eco-friendly products and reusable materials to minimize waste.

How do I choose the right vendor for hotel supplies? Research their reputation, compare prices, and ensure they offer consistent quality.

Are personalized amenities worth the investment? Yes! Personalized touches can create a memorable experience and foster guest loyalty.

What role do hotel supplies play in guest satisfaction? High-quality supplies significantly enhance the guest experience, leading to better reviews and repeat business.

2 notes

·

View notes

Text

Best Home Appliances Components

Equipment plays a significant role in keeping a house completely functioning. The house is neither complete nor usable without appliances. Therefore, the market has various types of equipment to make living in a house possible, convenient and easier.

If you need your household appliances with new parts and accessories, we can help. Our Home Appliances Components in India are intended for years to come to help you take care of your family but sometimes you need a little support to look for your future. This is where our genuine components for home appliances come into India. Our factory-certified components pledge that we will only supply our brand: we will take care of your equipment like you every day by means of reliable and genuine replacement parts. visit https://justpaste.it/fkotg

#advanvcetechnologiespune#advancetechnologiesinpune#shot blasting of components in pune#electrical components#electronics components#home appliances components#automobile components#home appliances

0 notes

Text

A Rising Tide of E-Waste, Worsened by AI, Threatens Our Health, Environment, and Economy

The digital age has ushered in a wave of innovation and convenience, powered in large part by artificial intelligence (AI). From AI-driven virtual assistants to smart home devices, technology has made life easier for millions. But beneath this rapid progress lies a less glamorous truth: a mounting crisis of electronic waste (e-waste).

The global e-waste problem is already enormous, with millions of tons discarded every year. Now, with the rapid growth of AI, this tide of e-waste is swelling even faster. Let’s break this down to understand the full scope of the issue and what can be done to mitigate it.

What Is E-Waste, and Why Should We Care?

E-waste encompasses discarded electronic devices — everything from old mobile phones and laptops to smart home gadgets, electric toothbrushes, and even large appliances like refrigerators. It’s not just junk; it’s an environmental and health hazard in disguise.

Each device contains a cocktail of valuable materials like gold and silver, but also toxic substances like lead, mercury, cadmium, and flame retardants. When improperly disposed of, these toxins leach into the environment, harming ecosystems and human health.

A Problem of Global Proportions

Annual Generation: The world generates over 50 million metric tons of e-waste annually, and this figure is projected to grow by 2 million tons each year.

Recycling Rates: Only 17% of e-waste is formally recycled. The rest? It ends up in landfills, incinerated, or handled by informal recycling sectors in developing nations.

While we’re busy marveling at AI-driven innovations, the discarded byproducts of our tech obsession are quietly poisoning our planet.

The Role of AI in Escalating E-Waste

AI, often lauded as the backbone of modern technology, is inadvertently exacerbating the e-waste crisis. Let’s examine the key ways AI contributes to this issue:

1. Accelerating Product Obsolescence

AI-powered devices are evolving at an astonishing pace. Smartphones with AI-enhanced cameras and processors, smart TVs with AI voice assistants, and wearables with health-tracking AI have become must-haves.

But these devices are often rendered obsolete within a few years due to:

Frequent Software Updates: AI systems improve rapidly, making older hardware incompatible with newer software.

Limited Repairability: Many modern gadgets are designed in a way that discourages repairs — sealed batteries, proprietary parts, and inaccessible interiors push consumers toward replacing rather than fixing.

Consumer Demand for New Features: AI advancements create a “fear of missing out” (FOMO), prompting consumers to upgrade frequently.

2. Proliferation of AI-Specific Hardware

AI-driven technologies require specialized, powerful hardware. Graphics Processing Units (GPUs), Tensor Processing Units (TPUs), and custom AI chips are integral to devices and data centers. Unlike general-purpose electronics, these components are challenging to recycle due to their complexity.

3. Growing Data Center Infrastructure

AI thrives on data, which means a relentless demand for computational power. Data centers, the backbone of AI, are:

Upgrading Constantly: To keep up with AI’s demands, servers are frequently replaced, generating massive amounts of e-waste.

Consuming Energy: Outdated hardware contributes to inefficiency and waste.

The Consequences of the E-Waste Crisis

The consequences of unmanaged e-waste are vast, impacting not only the environment but also human health and economic stability.

Health Hazards

E-waste releases harmful substances, including:

Lead and Cadmium: Found in circuit boards, these cause neurological damage and kidney issues when absorbed by humans.

Mercury: Found in screens and lighting, it can lead to brain damage and developmental issues, especially in children.

Burning Plastics: Informal recycling often involves burning e-waste, releasing carcinogenic dioxins into the air.

These pollutants disproportionately affect workers in informal recycling industries, often in developing countries with lax regulations.

Environmental Devastation

Soil Contamination: Toxic metals seep into the ground, affecting agriculture and entering the food chain.

Water Pollution: E-waste dumped in waterways contaminates drinking water and harms aquatic life.

Air Pollution: Incinerating e-waste produces greenhouse gases, contributing to climate change.

Economic Loss

Ironically, e-waste is a treasure trove of valuable materials like gold, silver, and rare earth elements. In 2019 alone, the value of discarded e-waste was estimated at $62.5 billion — higher than the GDP of many countries. Yet, due to poor recycling infrastructure, most of this wealth is wasted.

Turning the Tide: Solutions to the E-Waste Crisis

For Tech Companies

Design for Longevity: Adopt modular designs that make repairs and upgrades easy. For example, Fairphone and Framework Laptop are already doing this.

Reduce Planned Obsolescence: Commit to longer software support and avoid locking critical components like batteries.

Improve Recycling Systems: Implement take-back programs and closed-loop recycling processes to recover valuable materials.

For Governments

Enforce Right-to-Repair Laws: Legislation that mandates access to repair manuals and spare parts empowers consumers to fix devices instead of discarding them.

Promote Circular Economy Models: Incentivize businesses to design products for reuse, repair, and recycling.

Ban Hazardous E-Waste Exports: Prevent the dumping of e-waste in developing countries, where improper recycling leads to environmental and human rights violations.

For Consumers

Think Before You Upgrade: Do you really need the latest gadget, or can your current one suffice?

Repair Instead of Replace: Support local repair shops or DIY fixes with the help of online resources.

Recycle Responsibly: Look for certified e-waste recycling programs in your area.

Can AI Help Solve the Problem It Created?

Interestingly, AI itself could be part of the solution. Here’s how:

Optimizing Recycling Processes: AI-powered robots can sort e-waste more efficiently, separating valuable materials from toxins.

Predicting E-Waste Trends: AI can analyze data to anticipate where e-waste generation is highest, helping governments and companies prepare better recycling strategies.

Sustainable Product Design: AI can assist engineers in designing eco-friendly devices with recyclable components.

A Call to Action

The e-waste crisis is a ticking time bomb, exacerbated by the rapid rise of AI and our insatiable appetite for new technology. But the solution lies in our hands. By embracing sustainable practices, holding companies accountable, and making conscious choices as consumers, we can ensure that the benefits of AI don’t come at the cost of our planet.

It’s time to act, because a rising tide of e-waste doesn’t just threaten the environment — it threatens our future.

#technology#artificial intelligence#tech news#ai#e waste#economy#environment#nature#beautiful planet

2 notes

·

View notes

Text

An Overview of UK Home Small Domestic Appliances Market: Trends and Insights

The UK home small domestic appliances (SDA) market has seen significant growth driven by evolving consumer lifestyles, technological innovations, and a growing focus on energy efficiency and sustainability. From kettles and toasters to handheld vacuums and smart kitchen gadgets, SDAs are becoming indispensable in UK households.

Buy the Full Report for More Category Insights into the UK Home Small Domestic Appliances Market

Download a Free Sample Report

Here’s an analysis of the key trends and insights shaping the market in 2024.

1. Market Size and Growth

The SDA market in the UK is expected to grow at a CAGR of 4-6% from 2023 to 2028, driven by post-pandemic shifts in home-based lifestyles.

Rising disposable income and increasing interest in premium and smart appliances are fueling demand.

2. Key Consumer Trends

a. Smart and Connected Appliances

Voice control integration (via Alexa, Google Assistant) and IoT-enabled SDAs are gaining traction.

Popular products: Smart kettles, Wi-Fi-enabled coffee makers, and robotic vacuum cleaners.

b. Health and Wellness Focus

Growing interest in air fryers, blenders, and juicers as consumers focus on healthier lifestyles.

Increased demand for air purifiers and humidifiers due to rising concerns over indoor air quality.

c. Sustainability and Energy Efficiency

UK consumers are prioritizing eco-friendly appliances with lower energy consumption, such as energy-efficient kettles and low-wattage irons.

Brands offering repairable and recyclable products are seeing stronger loyalty.

d. Compact and Space-Saving Designs

Urban living and smaller households drive demand for multi-functional and compact SDAs, such as 2-in-1 steamers or combination microwaves.

3. Product-Specific Insights

Kitchen Appliances

Coffee Machines:

Premium brands like Nespresso and De’Longhi dominate, with demand for bean-to-cup and pod-based machines increasing.

Air Fryers:

Brands like Tefal and Ninja lead as air fryers become a household staple.

Consumers prioritize larger capacities and multi-functionality.

Cleaning Appliances

Robotic Vacuum Cleaners:

Growing adoption of smart robotic vacuums from brands like iRobot and Eufy.

Consumers value mapping technologies and self-emptying features.

Handheld Vacuums:

Brands like Dyson continue to dominate the cordless vacuum segment, driven by innovations in battery life and suction power.

Personal Care Appliances

Growth in electric toothbrushes, hair dryers, and grooming kits, driven by brand diversification and targeted marketing.

4. Retail and Distribution Trends

E-commerce Boom:

Online channels like Amazon, Argos, and Currys are witnessing robust growth, fueled by convenience and competitive pricing.

Omni-Channel Experiences:

Retailers are integrating digital and in-store experiences, such as AR demos for products.

Subscription Models:

Brands offering subscription plans for products like coffee machines and vacuum filters are seeing higher customer retention.

5. Competitive Landscape

Key Players

Dyson:

Leader in cordless vacuum and air purifier segments, with a focus on cutting-edge design and functionality.

Ninja:

Dominates the air fryer market and continues to expand into other SDAs like blenders and multi-cookers.

Philips:

Strong presence in personal care and kitchen appliances, with a growing focus on energy efficiency.

Breville:

Known for kettles, toasters, and sandwich makers, with a strong mid-market appeal.

Market Share Dynamics

Premium brands like Dyson and Nespresso dominate the high-end segment.

Mid-range brands (e.g., Tefal, Morphy Richards) maintain steady growth by balancing affordability and quality.

New entrants offering smart or niche eco-friendly solutions are gradually gaining market share.

6. Challenges and Opportunities

Challenges

Economic Pressures:

Inflation and rising energy costs may deter discretionary spending on premium SDAs.

Supply Chain Disruptions:

Component shortages and logistical issues continue to affect manufacturing and delivery timelines.

Opportunities

Sustainability:

Brands investing in energy-efficient and recyclable products are likely to capture eco-conscious consumers.

Customization:

Offering customizable products (e.g., personalized coffee settings or modular vacuum components) can differentiate brands.

7. Future Outlook

Smart Home Integration:

Growth in smart home adoption will drive demand for IoT-enabled SDAs.

Health and Wellness Products:

Continued interest in products supporting healthy lifestyles, such as air purifiers and low-fat cooking appliances.

Sustainability Leadership:

Companies embracing circular economy principles will gain a competitive edge.

The UK small domestic appliances market is poised for steady growth, underpinned by consumer preferences for convenience, sustainability, and technology-driven innovation. Players who align their strategies with these evolving trends will be best positioned to thrive.

2 notes

·

View notes

Text

Say Goodbye to Batteries: Discover the Power and Savings of EnerTech UPS's Batteryless Solar Hybrid Inverter!

The expanding use of sustainable power systems has changed a lot over time in the area of solar. Now thanks to the recent development of the Batteryless Solar Hybrid Inverter by EnerTech UPS you can have your reliable solar power without the associated costs and complexity of batteries. This state-of-art inverter allows consumers to utilize solar energy and decrease the energy bills while at the same time decreasing the effects of climate change. Now in this post we will see, why it is unique and why it can be a great addition to your home or business.

What is a Batteryless Solar Hybrid Inverter?

If most solar inverters feature batteries to stored power, then the Batteryless Solar Hybrid Inverter does not. It uses light directly, producing power during the day which is used to power appliances during the day. It does this in the same manner that regular inverters do, drawing from the grid during instances where the sun is not available and ensuring you have an un-interrupted power supply.

Description of the Batteryless Solar Hybrid Inverter by EnerTech UPS

Cost Savings: The batteries are usually one of the most expensive components of a solar installation setup needed to store the energy. The removal of those services is made possible through EnerTech UPS hence lowering the cost of acquiring solar power at a first instance.

Low Maintenance: Batteries generally require servicing and may also be costly to get replaced. As previously said, if there are no batteries required, the inverter requires very minimal maintenance thus the easier and less expensive device to own.

Better Efficiency: In a batteryless system, energy goes directly to appliances the result being minimal energy loss. This means that you maximize returns, on the solar panel investment that you made.

Eco-Friendly: Batteries are made of materials that requires substantial amount of resource when produced and disposed. This inverter being battery-free make things easier going green therefore can be stated to meet the eco goals.

Seamless Switching with the Grid: In times when solar power is not obtainable, the inverter quickly directs the energy prevails to the grid power. This is not going to happen; and the best is that the consumer will not notice anything, apart from a power supply that is never going to fail again.

Reasons why a batteryless inverter will be good for you

1. Lower Costs All Around

Batteries where lumped in and setup was easier and cheaper without them. First, solar power is more affordable than most people think since you reduce on cost of purchasing the equipment and its installation.

2. Saves Space

Batteries are usually large in size. If not for them, you can harness the power of the sun and you don’t necessarily need an area where you can install a storage facility.

3. Long-Lasting and Reliable

Other expenses, like battery replacement, have to be incurred, although batteries do have a finite life-cycle, and need to be replaced every few years. Instead of those replacements batteryless is the system which give more enduring and less complicated and refined.

4. Flexible for Future Growth

However, if there is a change in your needs for energy, you can always incorporate more solar panels to this issues. That way, there’s no need to constantly adapt to battery capacity, making it perfect for increasing energy requirements.

Is This Inverter Right for You?

This makes Batteryless Solar Hybrid Inverter from EnerTech UPS perfect for you, especially if you need an easy, universal and cost-effective way to go solar. This is good for people living in sunny-some areas for instance California and who would like to avoid large utility bills during the day. Still, if you plan to be completely ‘off grid’ or simply require electric power for night use, the battery backed system may still be the best way.

Why Choose EnerTech UPS?

It’s known for its excellent quality products with a very robust structure and customer-oriented services. Their Batteryless Solar Hybrid Inverter is durable and aims to bring solar electricity to the ordinary people out there.

Conclusion

The concept of using solar energy doesn’t have to perfect been portrayed as a difficult one, or even an expensive one. Energy freedom is at your fingertips with EnerTech UPS Batteryless Solar Hybrid Inverter – all made easy, clean, and cost-effective. It might be a perfect option for every person who wants to save money on electricity bills, turn over a new leaf, and have no desire to adjust the levels regularly.

#BatterylessInverter#SolarHybridInverter#SolarEnergy#CleanEnergy#GreenTechnology#EnertechUPS#SustainableLiving#EcoFriendly#SolarPower#RenewableEnergy#SolarInnovation#EnergyEfficiency#SolarForHome#SolarSolutions#BatteryFreeInverter#HybridInverter#EnergySavings#FutureOfEnergy#CostEffectiveSolar#SolarTechnology

2 notes

·

View notes

Text

The Essential Steps in Our Water Restoration Process

Water damage in your home or business is not just an inconvenience; it can lead to extensive issues, such as structural problems, damage to personal belongings, and the potential growth of mold. Addressing water damage swiftly and efficiently can prevent secondary damage and reduce long-term repair costs. With a proper water restoration plan in place, you can rest assured that your property will be returned to its original condition in no time.

At our company, we pride ourselves on offering professional, award-winning water damage restoration services that protect your property from further harm. Our comprehensive water restoration process involves a series of well-structured steps to ensure every aspect of water damage is addressed. Here’s a breakdown of our water restoration process:

1. Source Identification

Before any restoration can begin, we first identify the source of the water. Whether it’s a burst pipe, a leaking roof, a malfunctioning appliance, or flooding from natural causes, we’ll locate the source and take immediate steps to stop it. By addressing the source quickly, we can prevent additional water from entering the affected areas and causing further damage.

2. Water Extraction

Once the source has been identified and stopped, the next step is to remove the standing water from your property. We utilize a variety of methods to achieve this, such as absorbing, draining, pumping, and vacuuming. High-powered extraction equipment is used to remove as much water as possible from carpets, flooring, and other materials. Removing the water promptly helps to reduce the risk of further damage to building materials and belongings.

3. Monitoring Moisture Levels

With the bulk of the water removed, our technicians will take moisture readings to determine the drying rate and make adjustments as needed. This involves taking atmospheric and moisture readings in various parts of the building to monitor the progress of the drying process. By closely tracking humidity levels and moisture content, we can adjust equipment placement to expedite the drying process and prevent the growth of mold.

4. Assessing the Extent of Damage

Before structural drying begins, we’ll conduct a thorough inspection to assess the extent of the damage. This includes documenting the affected areas, identifying damaged building materials, and determining the category of water involved. Water damage is typically classified into three categories:

Category 1: Clean water from a clean source, such as a broken water supply line.

Category 2: Gray water, which contains some contaminants and can cause discomfort or illness if ingested.

Category 3: Black water, which is highly contaminated and may pose serious health risks. Examples include sewage backups and floodwaters.

Understanding the category of water helps us develop an appropriate treatment plan and ensure proper safety protocols are followed.

5. Structural Drying

Once the extent of the damage has been assessed, the structural drying phase begins. We use specialized air movers and dehumidifiers to evaporate and extract excess moisture from walls, floors, ceilings, and other structural components. Proper air circulation and humidity control are essential during this step to prevent secondary damage, such as mold growth and wood warping. Our goal is to bring moisture levels back to a safe, dry condition as quickly and efficiently as possible.

6. Final Documentation and Claims Assistance

After the drying process is complete, we create a final report that includes photographs, invoices, and drying logs. This documentation provides a comprehensive record of the restoration process, which can be used for insurance claims and peace of mind. We also assist you throughout the entire claims process, working with your insurance company to help you get the compensation you deserve.

At our company, we understand the stress and worry that water damage can bring, which is why we are committed to providing top-quality service with the utmost care and efficiency. Our detailed water restoration process ensures that every step is taken to restore your home or business to its original state, allowing you to move forward without further concerns.

#water damage restoration near me#water damage restoration company#water damage restoration services#water damage restoration atlanta#water damage restoration san diego

2 notes

·

View notes

Text

Residential Electrical Services in Red Deer: Trusted Solutions by Bryant’s Electrical Ltd.

When it comes to ensuring the safety and efficiency of your home’s electrical systems, it’s essential to work with professionals who are both skilled and reliable. At Bryant’s Electrical Ltd., we offer top-notch red deer residential electrical service that covers everything from routine maintenance to complex installations. Our licensed electricians are committed to providing homeowners with the highest level of service, ensuring that all electrical work is done safely and up to code.

Comprehensive Residential Electrical Solutions

We understand that every home has unique electrical needs, which is why we offer a full range of residential electrical services to meet those demands. Whether you’re dealing with a flickering light, need a panel upgrade, or are planning a home renovation, Bryant’s Electrical Ltd. is equipped to handle it all. Our services include:

Electrical Repairs and Troubleshooting: Electrical issues can be frustrating and, in some cases, dangerous. Our team of experts is trained to quickly diagnose and repair any electrical problems, ensuring your home’s systems are operating safely and efficiently.

Lighting Installation and Upgrades: Whether you’re looking to brighten up your living spaces with new fixtures or upgrade to energy-efficient LED lighting, our electricians can help you create a well-lit, comfortable environment.

Electrical Panel Upgrades: Older homes may require electrical panel upgrades to meet modern safety standards and handle increased electrical loads. We can replace outdated panels to improve the safety and functionality of your electrical system.

Wiring and Rewiring Services: If you’re planning a renovation or your home’s wiring is outdated, Bryant’s Electrical Ltd. offers professional wiring and rewiring services to ensure your electrical system is safe and up to code.

Home Automation and Smart Systems: Stay on the cutting edge of technology by integrating smart home systems that allow you to control lighting, security, and other electrical components from your smartphone or tablet. Our team can install and configure these systems for seamless operation.

Surge Protection: Protect your appliances and sensitive electronics from power surges with our surge protection services. We install whole-home surge protectors that shield your home from unexpected electrical spikes.

Safety Inspections: Electrical safety should never be overlooked. Our comprehensive safety inspections identify potential hazards in your home, helping you prevent electrical fires and other dangerous issues.

Why Choose Bryant’s Electrical Ltd.?

At Bryant’s Electrical Ltd., we pride ourselves on delivering exceptional service to the Red Deer community. Our team is fully licensed, insured, and trained to handle all aspects of residential electrical work. We understand the importance of reliable and safe electrical systems in your home, and we approach each project with professionalism and care. Here are a few reasons why homeowners in Red Deer trust us:

Experience and Expertise: With years of experience serving the Red Deer area, our electricians have the knowledge and skills to handle any residential electrical job, big or small.

Quality Workmanship: We believe in doing the job right the first time. Our attention to detail ensures that every project is completed to the highest standards of quality and safety.

Transparent Pricing: We offer fair and competitive pricing for all of our services, with no hidden fees. Before starting any work, we provide upfront quotes so you know exactly what to expect.

Customer Satisfaction: Our top priority is ensuring our clients are satisfied with the work we do. We listen to your needs and provide customized solutions that fit your home’s electrical requirements.

Expert Electrical Services for Every Need

At Bryant’s Electrical Ltd., we’re committed to making your home’s electrical systems safe, efficient, and modern. Whether you’re building a new home, upgrading your current system, or dealing with unexpected electrical issues, our team is ready to provide you with reliable and affordable solutions. We offer 24/7 emergency services, so you can count on us to be there when you need us most.

As experts in both residential and commercial electrical work, we also provide solutions for businesses in the area. From wiring and lighting installation to electrical safety inspections, Bryant’s Electrical Ltd. is a trusted partner for red deer commercial electrical service, helping businesses maintain safe and reliable electrical systems.

3 notes

·

View notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes