#hmi scada

Explore tagged Tumblr posts

Text

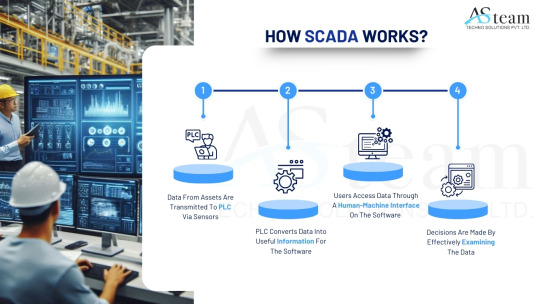

How SCADA Works?

Supervisory Control and Data Acquisition (SCADA) systems are critical in managing and monitoring industrial processes across various industries, including manufacturing, utilities, transportation, and energy.

Field Devices

At the process level, field devices like sensors, meters, and actuators are used to monitor variables like voltage, flow, temperature, and pressure. These gadgets collect information and carry out system-directed operations.

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs)

The SCADA software and the field devices are connected by RTUs and PLCs. After gathering information from the sensors, they transmit it to the control center. Additionally, the SCADA system may send them orders to modify settings or control actuators.

Communication Infrastructure

Strong communication networks are necessary for SCADA to transmit data between the control center and field equipment. This infrastructure can be wireless (such as satellite, radio, and cellular networks) or wired (such as Ethernet and fiber optics).

Centralized Control Station

SCADA software, which analyzes data, creates visualizations, and gives operators tools to monitor and manage operations, is housed in the control station.

Human-Machine Interface (HMI)

The SCADA system's user interface is called the HMI. Operators can engage with the system and make well-informed decisions because to its graphical depictions of processes, warnings, and trends.

#automation#SCADA#PLC#HMI#Automation#Technology#business and industry sectors#business#industrial automation#soft starter#software#software engineering

3 notes

·

View notes

Text

Basic PLC and HMI Training Kit Manufacturer in Pune Maharashtra India

Discover high-quality Basic PLC and HMI Training Kits in Pune. We are Manufacturer and Supplier of Siemens, Mitsubishi, and SCADA training kits for educational and industrial purposes.

#Basic PLC and HMI Training Kit Pune#PLC Training Kit Pune#Siemens S7-1200 Training Kit Pune#Siemens PLC HMI Training Pune#Mitsubishi PLC HMI Training Kit Pune#SCADA Training Kit Pune#Siemens PLC Training Kit Pune#Basic PLC HMI Kit Pune

0 notes

Text

PlC and Scada Services in Pune | India

PLCs are the workhorses. PlC and Scada Services in Pune | India carry out control tasks at the machine and equipment level. We do this while supervisory control and data acquisition (SCADA) systems offer a comprehensive perspective. This is about the entire operation. It happens through visualization monitoring and data gathering. The primary component of Supervisory Control and Data Acquisition is called SCADA in short.

Website: https://www.varadautomation.com/

Email: [email protected]

Contact Numbers: +91 86699 62225 / +91 78878 88357

Follow Us on Social Media:

LinkedIn: https://www.linkedin.com/company/varad-automation-robotics-pvt-ltd/

Facebook: https://www.facebook.com/profile.php?id=100086958252105

Instagram: https://www.instagram.com/visimaster_official/

Twitter: https://x.com/VAR_Visimaster/

YouTube: https://www.youtube.com/channel/UCK1Us7_UQ7s_SCFFbhTErqQ

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make All Type Of Industrial Automation Products As Worm Reduction Gear Box, Stepper Motor, Stepper Drive, Gear Motor, Gear Drive, Servo Motor, Servo Drive, AC motor, AC Gear Motor, AC Drive, AC Gear Drive, VFD Drive, Proximity Sensors, PLC, HMI, Scada, Panels, Drives and All Type Of Machinery Related Automatic Automation Products Exporter From Rajkot Gujarat Bharat (INDIA).

#HMPIndustrialAutomation#RamatoIndustrialAutomation#RoentIndustrialAutomation#WormReductionGearBox#StepperMotor#StepperDrive#GearMotor#GearDrive#ServoMotor#ServoDrive#ACMotor#ACGearMotor#ACDrive#ACGearDrive#VFDDrive#ProximitySensors#PLC#HMI#SCADA#Panels#Drives#AutomationProducts#MachineryAutomation#RajkotAutomation#GujaratAutomation#IndiaAutomation#IndustrialAutomationExporters#GearBoxExporters#StepperMotorExporters#ServoMotorExporters

0 notes

Text

Siemens Automation Products: The future of Industrial Automation

Siemens has emerged as a frontrunner in the constantly changing landscape of industrial automation, offering cutting-edge solutions that boost productivity, efficiency, and dependability. They provide a wide selection of automation goods for various industries, ranging from simple control functions to complicated production procedures. In this article, we will look at some of Siemens automation products and how they have shaped present-day industry.

SIMATIC Controllers

SIMATIC S7-1200 and S7-1500:

SIEMENS is known for their automation portfolio that has SIMATIC S7-1200 and S7-1500 series at its core. Due to their versatility, efficiency and user-friendliness, these controllers have gained a great name. The S7-1200 is compact and has an inbuilt input/output ports making it suitable for small applications. On the other hand, S7-1500 is suitable for high-end performance when it comes to complicated tasks because it has sophisticated diagnostic systems, built-in security features as well as wide-ranging communication facilities.

SIMATIC S7-200 SMART:

S7-200 SMART has been purposed for minor automation undertakings that represent a value for money while also being very strong. It can be used in numerous cases; it has either a functional format or embedded communication facilities hence making it flexible enough to serve various functions like controlling machines and organizing buildings.

HMI (Human-Machine Interface) Systems

SIMATIC HMI Panels:

Siemens' HMI panels provide operators with a user-friendly and intuitive interface for surveillance and control of industry processes. The panels go from simple text-to-speech displays to sophisticated touch screen displays with high resolution graphics. It can be easily integrated with the SIMATIC controllers, meaning that data is exchanged effectively, and timely monitoring done continuously.

SCADA Systems

SIMATIC WinCC:

SCADA (Supervisory Control and Data Acquisition) system is a highly efficient system made by Siemens and its name is WinCC (Windows Control Center). It has been fitted to work by providing solutions in the field of monitoring and control for industries. Databasing, allowing for real time viewing of data as well as offering of advanced analytical tools are some of these features found in WinCC that help businesses to improve their performance thus keeping them abreast about what is going on within their operations.

Industrial Communication

PROFINET and PROFIBUS:

Siemens has strong industrial communication offerings with PROFINET and PROFIBUS standards. PROFINET is an Ethernet-based protocol designed for high-speed, deterministic communication; this makes it ideal for real-time systems. On the other hand, PROFIBUS is a fieldbus protocol that guarantees reliable communication in difficult industrial settings.

Industrial Ethernet Switches:

Siemens’ Industrial Ethernet switch allows for quick and safe communication among devices in an industrial network. This kind of switch is made to survive difficult situations, which guarantees consistent transfer of information even in tough conditions.

Drives and Motion Control

SINAMICS Drives:

Siemens’ sacramental SINAMICS lifts cover everything from basic frequency converters to high-end servo drives. These drives ensure precise motor control, and high energy efficiency while at the same time helping to optimize processes. They are utilized in a variety of applications including conveyor belts, pumps, fans and machine tools.

SIMOTION:

Siemens’ SIMOTION is its motion control system that offers highly efficient solutions for complicated motion tasks. It brings together motion control, logic control and technology functions at one site, thus ensuring machines and processes are controlled with precision and effectiveness.

Process Automation

SIMATIC PCS 7:

Siemens’ PCS 7 is an advanced process control system for large-scale industrial processes. It has features like integrated engineering, scalable architecture and advanced control functions. As a result, it is commonly used in the chemical, pharmaceutical and oil & gas sectors where precision and reliability in process control are vital.

Conclusion

Siemens automation products have drastically modified the industry scene in terms of increased efficiency, reliability and productivity. Industrial automation is still dominated by Siemens through strong controllers and intuitive human machine interfaces (HMIs) besides sophisticated SCADA systems and durable communication protocols. For businesses out there that want higher automation, reduced operational costs and remain competitive in a changing environment code these technologies in one code.

#siemens automation products#siemens dealers in ahmedabad#siemens industrial automation#siemens programmable logic controller#siemens controller#siemens#siemens plc controller#siemens hmi#siemens ac drive#siemens servo motor#Siemens SCADA

0 notes

Text

Our curriculum is meticulously crafted to cover all aspects of Industrial Automation Training in Noida. From the basics of automation to advanced concepts, you will gain a deep understanding of programmable logic controllers (PLCs), SCADA systems, HMI, sensors, actuators, and more. We also provide training on the latest technologies and industry trends to keep you ahead of the curve.

#IndustrialAutomation#AutomationTraining#APTRONSolutions#NoidaTraining#CareerInAutomation#PLCTraining#SCADA#HMI#AutomationEngineer#SkillDevelopment

0 notes

Text

PLC SCADA, your gateway to seamless industrial automation! 🤖💡 Perfect for engineers, tech enthusiasts, and anyone passionate about optimizing processes. Dive into the world of Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. Elevate your skills and transform industries with cutting-edge automation technology. Read more: https://livewirecoimbatore.com/plc-scada/

Reach Us: 8807148869

PLC Scada

#PLC#SCADA#Automation#IndustrialTech#ControlSystems#SmartFactory#PLCProgramming#SCADASystems#AutomationEngineer#Industry40#IoT#SmartManufacturing#ProcessAutomation#DigitalTransformation#ControlEngineering#HMI#Robotics#IIoT#PLCControl#SCADATech

0 notes

Text

#humanmachineinterface#hmi#automation#industrialautomation#hmitouchscreen#hmitouchpanel#plc#iot#engineering#scada#touchscreen#inverter#siemens#visionsensor#areasensor#doorsensor#manufacturing#towerlight#mechanicalelectrical#abb#pressuresensor#allenbradley#iiot#ipc#autonics#porsche#photoelectricsensor#rotaryencoder#proximity#proximitysensor

0 notes

Text

#BD Engineering#BD Engineering Solution#industrial automation#industrial engineering#industrial equipment#plc scada training#plc#hmi#vfd

0 notes

Text

APTRON Solution Noida's Industrial Automation Training Course in Noida is your ticket to a promising career in industrial automation. With a tailored curriculum, hands-on experience, expert trainers, comprehensive content, job placement assistance, and flexible training options, we provide the ideal learning environment for aspiring automation professionals in Noida.

#IndustrialAutomation#AutomationTraining#APTRONSolution#NoidaTraining#IndustrialSkills#PLCProgramming#SCADA#HMI#RoboticsTraining#JobPlacement

0 notes

Text

Micro850 Integration with SCADA and HMI Systems

Integrating a Micro850 PLC with SCADA and HMI systems involves multiple steps, including programming the PLC, setting up communication protocols, and configuring the SCADA/HMI software.

#trending#automation#tumblr trends#viral#viralpost#bestdeals#trendingnow#allen bradley#rockwell automation#plc#HMI#SCADA#micro850plc

2 notes

·

View notes

Text

Basic PLC and HMI Training Kit Manufacturer in Pune Maharashtra India

Discover high-quality Basic PLC and HMI Training Kits in Pune. We are Manufacturer and Supplier of Siemens, Mitsubishi, and SCADA training kits for educational and industrial purposes.

#Basic PLC and HMI Training Kit Pune#PLC Training Kit Pune#Siemens S7-1200 Training Kit Pune#Siemens PLC HMI Training Pune#Mitsubishi PLC HMI Training Kit Pune#SCADA Training Kit Pune#Siemens PLC Training Kit Pune#Basic PLC HMI Kit Pune

0 notes

Text

Ultra-Reliable Industrial Computer

The Ultra-Reliable Industrial Computers based on Android/Linux OS are engineered to deliver uncompromising performance and reliability in mission-critical industrial applications. Built with high-quality components and adhering to strict quality control standards, this industrial PC offers exceptional durability and longevity, even in harsh operating conditions.

It supports various of ARM architectures including RK3588, RK3399, and RK3288 CPUs, providing powerful computing capabilities for data-intensive tasks and real-time processing.

The industrial PC offers enhanced I/O connectivity options to ensure high adaptation. With its rugged design, extensive testing, and long-term availability, the Ultra-Reliable Industrial Motherboard is an excellent choice for industrial automation, digital signage, surveillance systems, and server applications.

0 notes

Text

Wonder Automation Training Division offers comprehensive industrial automation training courses in Chandigarh. The courses encompass various automation technologies, including PLC programming, SCADA systems, HMI development, and industrial robotics. With a practical-oriented approach, students gain hands-on experience in designing and implementing automation solutions.

#industrial automation training courses in Chandigarh#Wonder Automation Training Division#SCADA systems#PLC#HMI

1 note

·

View note

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

7 notes

·

View notes

Text

HMI systems in industrial automation play a crucial role in enhancing efficiency, safety, and productivity. Their features—such as real-time monitoring, data logging, remote access, and seamless integration with SCADA and PLC systems—make them indispensable for modern industrial operations. As industries continue to embrace automation, the importance of intuitive, reliable, and secure HMI systems will only increase, providing a powerful components for operators and managers to optimize processes and improve performance.

#industrial equipment#auto2mation#industrial and marine automation#industrial spare parts#marine spare parts#marine automation#automation#industrial automation#industrial and marine automation equipment#industrial automation equipment#hmi#industrial hmi

0 notes