#helium leak detection

Explore tagged Tumblr posts

Text

What to Expect from a Professional Helium Leak Testing Service

When it comes to ensuring the reliability and safety of industrial systems, a common yet crucial issue is detecting leaks in pressure systems, especially in components like condensers. Helium leak testing is one of the most precise and efficient methods available to identify and resolve leaks. Whether you're in need of condenser leak detection, condenser tube leakage identification, or just general leak detection services, understanding what to expect from a professional helium leak testing service can help you make an informed decision. Here's an overview of what you can expect when opting for Helium Leak Detection Services and how it can benefit your operation.

What is Helium Leak Testing?

Helium leak testing is a non-destructive method used to detect small leaks in systems and components. The process involves introducing helium into the system being tested, as helium is a small, light molecule that can easily escape through even the smallest of leaks. Once helium is introduced, a sensitive mass spectrometer detects any traces of helium outside the system, signaling the location and size of the leak. This method is widely used in industries like HVAC, aerospace, automotive, and manufacturing due to its precision and reliability.

The Importance of Helium Leak Detection for Condensers

A key application of helium leak testing is in the detection of condenser leak detection and condenser tube leakage. Condensers are crucial components in cooling systems, and any leakage, especially in the condenser tubes, can lead to significant operational inefficiencies, equipment damage, or even complete system failure. Tube leaks in condensers can cause a reduction in cooling capacity, overheating, or even corrosion in the system, which may require costly repairs. By using helium leak detection services, you can avoid these issues by pinpointing the source of the problem early.

What to Expect During a Helium Leak Test

Preparation and System Evaluation A professional helium leak testing service begins with a thorough evaluation of the system being tested. This includes understanding the components involved, especially the areas prone to leaks, such as condenser tubes or seals. The technician will inspect the system to identify potential leak sources and prepare the equipment for testing. In some cases, systems might need to be pressurized with helium or a helium mixture, depending on the pressure and operating conditions of the system.

Helium Injection Once the system is prepared, helium gas is introduced into the system. Helium is chosen because it is an inert, non-toxic, and easily detectable gas that can escape through the smallest of openings. The process is designed to be as non-invasive as possible, ensuring that the system is not damaged during the leak detection process.

Leak Detection with Advanced Equipment After helium is injected into the system, the technician uses a highly sensitive mass spectrometer or a similar detection device to identify any trace of helium outside the system. The spectrometer can detect even the smallest amounts of helium, allowing technicians to pinpoint the exact location of the leak, no matter how minute. Whether it's a condenser leakage, tube leak, or any other small opening, the advanced detection tools used in helium leak testing services will find it.

Leak Analysis and Reporting Once the leak is detected, the technician will analyze the severity and location of the leak. For leaks in critical components like condensers, identifying the exact location is essential for quick repairs and minimizing downtime. The technician will then provide a detailed report outlining the findings, which can be used for planning repairs or replacing faulty components.

Leak Repair and Follow-up After leak detection, many professional helium leak testing services also offer repair solutions, whether it's patching the leak, replacing a part of the system, or conducting additional tests. If the leak is found to be in a component that is too damaged to repair effectively, the technician will recommend suitable replacement options. Additionally, follow-up testing is often conducted to ensure that repairs were successful and that the system is leak-free.

Benefits of Using Helium Leak Detection Services

High Accuracy The primary advantage of helium leak detection over traditional methods is its high accuracy. Helium leak detection services are capable of identifying even the smallest leaks in systems, which can save you from potential system failure down the line. In industries like aerospace and HVAC, where small leaks can lead to large problems, this high level of accuracy is indispensable.

Cost Savings While helium leak testing might seem like an investment upfront, it can save significant costs in the long run. Detecting leaks early means you can address problems before they escalate into major failures, which can be expensive to repair. This preventive maintenance can help your business avoid costly downtime and expensive equipment replacements.

Non-Destructive Testing Helium leak testing is a non-destructive method. Unlike other leak testing techniques that may require cutting open parts of the system or causing other disruptions, helium testing does not damage components, ensuring that your equipment remains in good condition. This method is especially useful when dealing with sensitive or high-value equipment like heat exchangers and condensers.

Versatility Across Industries Helium leak detection is highly versatile and can be used across a wide range of industries, from HVAC systems to automotive and aerospace applications. Whether it's for condenser tube leakage in an air conditioning system or a tube leak in a manufacturing plant, this method can be adapted to suit different types of equipment and components.

Improved Operational Efficiency Helium leak testing ensures that systems are functioning as efficiently as possible. For example, identifying condenser leakage in HVAC systems means that the system can operate at peak performance, reducing energy waste and lowering operational costs. By fixing leaks promptly, businesses can maintain optimal system efficiency and prolong the lifespan of critical equipment.

Why Choose American Efficiency Services?

When it comes to helium leak detection services, selecting a trusted provider is crucial to ensuring the integrity of your systems. At American Efficiency Services, we specialize in high-quality, precise leak detection methods, including helium leak detection for a variety of industrial applications. Our expert technicians have the skills and tools necessary to identify even the smallest leaks, from condenser leakage to tube leaks, and provide prompt, effective solutions.

By choosing us, you're opting for a service that prioritizes accuracy, cost-efficiency, and minimal disruption to your operations. Whether you need regular leak detection services or one-time testing for specific issues like condenser tube leakage, we are here to provide you with reliable, professional solutions.

Conclusion

Helium leak testing is a powerful and reliable method for identifying leaks in systems, especially for critical components like condensers. When you choose a professional service for helium leak detection, you can expect high-precision results, minimal system disruption, and actionable insights that help you maintain the efficiency and longevity of your equipment. If you're facing issues with condenser leak detection, tube leak, or any other type of leakage, consider reaching out to American Efficiency Services for expert helium leak detection services that you can trust.

0 notes

Text

The PTI SIMS 1915+ represents a significant advancement in packaging integrity testing, offering unparalleled sensitivity and precision for critical industries. Its adaptability and customizability ensure it can meet the diverse needs of modern packaging, ultimately enhancing product safety and reliability. Consequently, the SIMS 1915+ is instrumental in establishing new standards for packaging innovation and assurance, driving progress in maintaining the highest levels of product integrity.

0 notes

Text

Tekman: A Leading Name in Industrial Vacuum Pump Manufacturing

Tekman has established itself as a pioneer in the industrial vacuum pump manufacturing industry, consistently delivering high-quality and reliable solutions tailored to meet the diverse needs of its customers. With a strong commitment to innovation and excellence, Tekman stands out as a brand that customers trust for their critical vacuum pump requirements.

Excellence in Helium Leak Detection

The solutions designed by Tekman for Helium Leak Detection offer unmatched accuracy and precision. For companies where even the smallest leak can cause serious operational problems, these detectors are indispensable. The prompt and accurate identification of leaks by Tekman's helium leak detectors minimizes downtime and boosts overall productivity. You may be sure that Tekman will provide the highest level of dependability in meeting your helium leak detection requirements.

Cutting-Edge Helium Leak Testing Machines

Apart from leak detectors, Tekman provides cutting-edge Helium Leak Testing Machines. Because these devices are made to withstand stringent testing procedures, any possible leaks will be found before they have a chance to do any harm. The essential leak testing that Tekman's helium leak testing equipment provides surpasses the highest standards and is utilized in a variety of industries, including aerospace and automotive. Selecting Tekman means going with a company that values accuracy and superiority in every machine they make.

Innovative Helium Recovery Systems

Yet another example of Tekman's dedication to efficiency and sustainability is the Helium Recovery System. By recovering and recycling helium, these systems greatly lower waste and operating expenses. Tekman's recovery systems enable enterprises to optimize their helium utilization, guaranteeing that no helium is wasted. Helium is an invaluable resource. You can rely on Tekman to deliver environmentally friendly solutions that are also highly effective.

Leading Dry Vacuum Pump Manufacturer

Tekman, a well-known manufacturer of dry vacuum pumps, provides a selection of dry vacuum pumps to meet the unique requirements of different sectors. These pumps are perfect for cleanroom settings and applications where contamination must be prevented because they are made to function without the need for any lubricants. Industries all over the world use Tekman's dry vacuum pumps because of their reputation for dependability, efficiency, and little maintenance needs.

Superior Single Stage Oil Sealed Vane Pumps

The Single Stage Oil Sealed Vane Pump from Tekman is a product that epitomizes the company's commitment to excellence and dependability. These pumps are employed in many industries, including food processing and pharmaceuticals, where strong vacuum performance is necessary. The oil-sealed vane pumps from Tekman are designed to provide dependable and consistent performance, guaranteeing the seamless and effective running of your business. You receive more than just a pump when you work with Tekman—you get a reliable solution.

Global Reach and Industry Expertise

With a global presence and a reputation for being a top manufacturer of industrial vacuum pumps, Tekman serves a diverse range of sectors across national boundaries. Their in-depth knowledge of the sector enables them to recognize and respond to the unique problems encountered by companies globally. Tekman's products are widely regarded for their dependability and efficiency, meeting the exacting demands of many industries such as aerospace and semiconductors. Because of its dedication to quality and excellence, Tekman is now the go-to partner for global industries looking for cutting-edge vacuum solutions.

Customization for Specialized Applications

Recognizing that no two applications are alike, Tekman provides specialized vacuum solutions to satisfy particular industry requirements. Their capacity to customize goods, such as dry vacuum pumps and helium leak testing machines, to meet particular needs guarantees that customers get the most effective and efficient solutions. Tekman's engineering team collaborates closely with clients to create equipment that satisfies precise requirements, whether it is for a crucial environmental application or a high-precision manufacturing process. This degree of personalization distinguishes Tekman as a company that goes above and beyond to cater to the unique requirements of its customers.

Advanced Manufacturing Processes

Modern production techniques are used by Tekman to provide the best quality possible in each product. Every stage, from the first stages of design to the last assembly, is painstakingly regulated to adhere to strict industry requirements. With the newest technology, Tekman's state-of-the-art production facilities can precisely and consistently build complicated components. The success of Tekman's Single Stage Oil Sealed Vane Pumps and other vacuum solutions, which are recognized for their dependability and effectiveness in harsh industrial settings, demonstrates this dedication to excellence.

Robust Quality Assurance

Ensuring quality is a fundamental aspect of Tekman's activities. To guarantee it satisfies the highest requirements for performance and dependability, every product is put through a rigorous testing and inspection process. Thorough testing procedures are applied to Tekman's helium leak detectors and helium recovery systems to ensure faultless operation even in the most demanding circumstances. Customers may feel secure knowing that they are investing in the greatest products when they know that every Tekman product meets performance, longevity, and safety expectations thanks to the company's commitment to quality assurance.

Strong After-Sales Support and Maintenance Services

Tekman's dedication to client happiness doesn't stop at the transaction. They provide strong post-purchase support, such as technical help and maintenance services, to make sure your vacuum systems keep performing at their best. To ensure minimal downtime and peak performance, Tekman's team of skilled experts is ready for on-site assistance, troubleshooting, and routine maintenance. Because of their commitment to providing after-sales support, Tekman is a reliable partner for companies that depend on their vacuum technology for essential operations.

#industrial vacuum pump manufacturing#Helium Leak Detection#Helium Leak Testing Machines#Helium Recovery System#manufacturer of dry vacuum pumps

0 notes

Text

#Helium Leak Testing#Helium Recovery System#Helium Leak Detector#Helium Leak Detection Service#Helium Leak Testing Machine#Helium Leak Testing System#Helium Leak Testing Service#Rotary vane vacuum pump manufacturers#Dry Screw Vacuum Pump

0 notes

Text

« The Hindenburg air disaster of 1937 »

The LZ 129 Hindenburg is the largest dirigible of the time and its Daimler-Benz engines are very powerful. The machine covers the transatlantic link in an unprecedented way. By exposing it to the eyes of the world, particularly through the media, the company Luftschiffbau Zeppelin tends to promote the technological advances of Adolf Hitler's Nazi Germany. The dirigible was also widely used during the Berlin Olympic Games in 1936.

The aircraft bore the name of Hindenburg in tribute to the German Chancellor who had preceded Hitler (The giant of the air was to be called by the name of Adolf Hitler proposed by his Minister of Propaganda Joseph Goebbels in the spring of 1936, but as a precaution the Führer decided to give it the name of Marshal Paul Von Hindenburg, former hero of the First World War.) Nazi propaganda required that crosses be painted on the dirigible.

In addition to being one of the largest airships ever known during this time, (It was 250m long). He was often compared to the Titanic whose nickname "The Titanic of the Air".

Hindenburg will experience both a period of great success and a tragic end. But unlike the first whose shipwreck did not seal the fate of sea crossings, the forfeiture of the LZ 129 Hindenburg will end the period of dirigibles

The inauguration flight of the LZ 129 Hindenburg took place on March 4, 1936 in Friedrichshafen, Germany. It operates for 14 months without incidents, and operates several promotional flights.

The airship balloon was originally designed to be inflated with helium. But this gas was mainly produced in the United States, which restricts sales to Germany. The Zeppelin company had therefore chosen hydrogen for the lifting of the aircraft, which was more economical, but also more dangerous.

It was during his landing in Lakehurst, New Jersey (80 km from New York), on May 6, 1937, that the irreparable occurred. After a flight without history, the airship is delayed by a storm on the American coast. The dirigible gently approaches its mooring mast; but at the back of the envelope, a hydrogen leak not detected by the crew (the gas being colorless and odorless) forms a highly flammable pocket.

Suddenly, a wreath of flames, probably caused by the contact of a mooring cable with the ground, gushed out at the back of the airship and causes the explosion of the hydrogen from the envelope. In just 34 seconds the Hindenburg ignites and crashes to the ground, forming a gigantic blaze rising from the aircraft's deformed carcass.

The dirigible will cause a total of 36 deaths. (29 deaths on the spot, 6 wounded will die a few hours later.)

Nazi Germany, weakened by this failure, will use the event and the lack of scientific explanation to serve its worst conspiracy theories, and fuel anti-Semitism in the country, under Hitler's impetus.

The destruction of the LZ 129 Hindenburg is a publicized event around the world. The shot (above) photographed by journalist Sam Shere will forever remain one of his most popular images.

3 notes

·

View notes

Text

The Unsung Heroes: Analyzing the Rare Gases Market

Often invisible and odorless, rare gases – helium, neon, argon, krypton, and xenon – play a crucial role in a surprisingly diverse range of high-tech and industrial applications. From medical imaging and semiconductor manufacturing to lighting and aerospace, their unique inert properties and specific spectral emissions make them indispensable. The global rare gases market is experiencing steady growth, driven by advancements in these end-use sectors and increasing demand for high-purity gases. The Rare Gases Market is expected to register a CAGR of 8% from 2025 to 2031, with a market size expanding from US$ XX Million in 2024 to US$ XX Million by 2031.

One of the primary drivers for the market is the burgeoning semiconductor industry. Rare gases, particularly neon, krypton, and xenon, are critical in various stages of semiconductor manufacturing, including etching and lithography. The relentless demand for smaller, faster, and more powerful electronic devices fuels the consumption of these high-purity gases.

The healthcare sector is another significant consumer, with helium being essential for cooling superconducting magnets in MRI (Magnetic Resonance Imaging) scanners. The increasing adoption of MRI for medical diagnostics globally sustains the demand for helium. Xenon also finds niche applications in anesthesia and neuroprotection research.

Furthermore, the lighting industry utilizes neon, argon, and krypton in various types of specialized lighting, including energy-efficient fluorescent lamps and signage. While LEDs are gaining prominence, rare gases continue to hold a significant share in specific lighting applications due to their unique spectral characteristics.

The aerospace industry relies on helium for purging rocket fuel tanks and for leak detection in critical systems due to its low density and inertness. The ongoing space exploration initiatives and the growth of the commercial space sector contribute to this demand.

In terms of gas type, helium currently holds the largest market share due to its extensive use in MRI and other industrial applications. However, neon, krypton, and xenon are expected to witness higher growth rates driven by the expanding semiconductor manufacturing sector. Argon, being relatively abundant and cost-effective, finds widespread use in welding and as an inert atmosphere.

By application, electronics and healthcare are the dominant end-use segments. However, lighting and aerospace also contribute significantly to the overall market volume.

Geographically, Asia Pacific is the largest and fastest-growing market for rare gases, driven by the region's dominance in semiconductor manufacturing and increasing healthcare investments. North America and Europe also represent significant markets with established industrial and healthcare sectors.

The competitive landscape of the rare gases market is moderately concentrated, with a few major global industrial gas companies dominating the supply. Key competitive factors include gas purity, supply chain reliability, and pricing. The geopolitical landscape and the limited natural sources of helium can also influence market dynamics.

In conclusion, the rare gases market is characterized by steady and consistent growth, driven by the fundamental demand from critical high-tech industries like semiconductors and healthcare. As these sectors continue to advance and expand, the unique properties of rare gases will ensure their continued importance and a stable upward trajectory in the global industrial gas market.

Author's Bio:

Nilesh Shinde

Senior Market Research expert at

The Insight Partners

0 notes

Text

U.S. Helium Prices 2025, Size, Trend, Graph, Chart and Forecast

Helium is a critical element in various industries, and its market prices have been subject to volatility due to supply constraints, geopolitical factors, and growing demand across multiple sectors. The helium market has witnessed significant fluctuations over the past few years, influenced by factors such as production disruptions, increasing consumption in high-tech industries, and regulatory changes in major producing regions. This price variability has led to increased concerns among industries reliant on helium, such as healthcare, semiconductor manufacturing, aerospace, and scientific research.

One of the primary drivers of helium price fluctuations is its limited supply. Unlike many other industrial gases, helium is a non-renewable resource that is primarily extracted as a byproduct of natural gas processing. The global helium supply is concentrated in a few key regions, including the United States, Qatar, Russia, and Algeria. Any disruption in production from these regions can cause significant price hikes. For instance, the United States, historically a major helium supplier, has faced declining production from the Federal Helium Reserve, leading to a reduction in available supply. Similarly, geopolitical tensions and trade restrictions involving Russia have impacted the global helium market, further constraining supply and pushing prices upward.

Get Real time Prices for Helium: https://www.chemanalyst.com/Pricing-data/bulk-helium-1100

On the demand side, helium consumption has been rising steadily due to its essential role in various advanced technologies. The medical sector is one of the largest consumers of helium, particularly for MRI machines, which require liquid helium to cool superconducting magnets. The increasing demand for MRI technology worldwide, driven by the expansion of healthcare infrastructure and the rising prevalence of chronic diseases, has contributed to sustained helium consumption. In addition to healthcare, the semiconductor industry heavily relies on helium for chip manufacturing processes. As the demand for semiconductors continues to surge, fueled by the growth of artificial intelligence, 5G technology, and electric vehicles, helium demand in this sector has remained strong, influencing market prices.

The aerospace and defense industries also contribute significantly to helium demand. Helium is used in rocket propulsion systems, satellite technology, and space exploration activities. The increasing investments in space missions by government agencies and private companies have led to greater helium consumption. SpaceX, NASA, and other organizations require helium for fuel pressurization and cooling applications, further straining supply chains. Additionally, helium plays a crucial role in cryogenics, scientific research, and leak detection in industrial applications, adding to its overall demand.

Another factor influencing helium prices is the transition to new helium production projects. While traditional sources of helium are declining, efforts are being made to develop alternative sources, such as helium extraction from new natural gas fields and standalone helium reserves. Countries like Canada and South Africa have been exploring new helium resources to reduce dependency on traditional suppliers. However, these projects require significant investment and time to reach full-scale production, meaning that supply shortages and price volatility are likely to persist in the short to medium term.

Sustainability concerns and the push for efficient helium utilization have also impacted market dynamics. Due to the non-renewable nature of helium, industries are exploring ways to recycle and conserve the gas to minimize waste. Some medical and industrial applications have adopted helium recycling technologies to reduce dependency on fresh supplies. Additionally, research into alternative cooling technologies for MRI machines and semiconductor manufacturing is underway, aiming to lessen the reliance on helium. While these innovations could help stabilize long-term supply, their widespread adoption is still in the early stages.

Government policies and strategic helium reserves play a crucial role in market stability. The United States, through its Federal Helium Reserve, has historically influenced helium prices and supply availability. However, the gradual sell-off and depletion of this reserve have raised concerns about future supply security. Other nations are considering establishing strategic helium reserves to mitigate supply shocks and prevent extreme price fluctuations. Additionally, regulatory measures related to helium extraction and export policies in major producing countries have a direct impact on global prices.

Investment trends in the helium sector are also shaping market prices. With the rising importance of helium in advanced technologies, investors are increasingly interested in helium exploration and production projects. Companies specializing in helium extraction are securing funding to develop new sources, aiming to address supply gaps and capitalize on high prices. The emergence of new players in the helium market could help diversify supply sources and reduce market concentration, ultimately influencing long-term price trends.

Looking ahead, helium prices are expected to remain dynamic, influenced by a combination of supply constraints, increasing demand, geopolitical factors, and technological advancements. The ongoing development of new helium sources and the adoption of conservation technologies may help stabilize the market in the long run. However, short-term price volatility is likely to persist due to existing supply limitations and uncertainties in global trade policies. Stakeholders across various industries must navigate these challenges by securing reliable helium sources, exploring alternative solutions, and investing in sustainable helium management practices.

The future of the helium market will be shaped by ongoing efforts to balance supply and demand, technological advancements, and strategic investments in new helium reserves. While helium prices are expected to remain elevated due to strong demand and supply constraints, proactive measures such as recycling initiatives, diversification of supply sources, and policy interventions could help mitigate extreme price fluctuations. As industries continue to rely on helium for critical applications, market participants must stay informed about price trends, supply developments, and emerging alternatives to ensure long-term stability and efficiency in helium utilization.

Get Real time Prices for Helium: https://www.chemanalyst.com/Pricing-data/bulk-helium-1100

Our Blog:

Non-Polar Solvents Prices: https://www.chemanalyst.com/Industry-data/non-polar-solvents-13

Pharmaceuticals Raw Materials Prices: https://www.chemanalyst.com/Industry-data/pharmaceuticals-raw-materials-14

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Helium#Helium Price#Helium Prices#Helium News#Helium Market#Helium Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Boeing Starliner Mission: The Setbacks That Plagued the Aerospace Giant

The technical setbacks with Boeing’s Starline mission highlight ongoing challenges for the aerospace company, particularly in regaining trust and stability. Boeing’s Starliner was launched with astronauts Butch Wilmore and Sunita Williams. It was the spacecraft’s first human-crewed mission to the International Space Station (ISS). The engine malfunctions and a helium leak were detected soon after…

0 notes

Text

Improving Leak Detection By Vacuum leak testers

Source of info: https://www.perfectgroupindia.co.in/improving-leak-detection-by-vacuum-leak-testers.php

In the manufacturing industry, ensuring product quality and safety is of utmost importance. One crucial aspect of this process is leak detection. Leaks can lead to product failures, safety hazards, and significant financial losses. Therefore, mastering leak detection has become a manufacturing revolution, driven by advanced technologies such as vaccum leak tester.

Now, we will explore the significance of leak detection, the role of vacuum leak testers, and how this technology is revolutionizing the manufacturing industry.

The Importance of Leak Detection

1.1 Understanding the Impact of Leaks Leaks can have severe consequences in various industries. For example, in the production of automobiles, a fuel system leak can result in fires or poor vehicle performance. In the medical industry, leaks in medical equipment or packaging can cause contamination and possibly endanger patients. Finding leaks and fixing them before they cause serious damage is essential.

1.2 Ensuring Product Quality and Safety By implementing effective leak detection processes, manufacturers can maintain high product quality and safety standards. Identifying leaks early on prevents defective products from reaching the market and helps manufacturers comply with industry regulations. Additionally, leak-free products enhance customer satisfaction and protect a brand's reputation.

Introducing Vacuum Leak Testers The analyzer is the second component of the polariscope. It functions as a filter by positioning itself perpendicular to the polarizer and assessing the polarized light once it has passed through the material. Birefringence patterns and material stress can be found and examined by rotating the analyzer at different angles.

2.1 How Vacuum Leak Testers Work Vacuum leak testers are advanced instruments used to detect leaks in a wide range of products and materials. These testers create a vacuum environment around the test object and monitor pressure changes to identify any leaks. It uses various testing methods, such as pressure decay, mass flow, or helium leak detection, depending on the application requirements.

2.2 Benefits of Vacuum Leak Testing Vacuum leak testing offers several advantages over traditional leak detection methods. It provides high accuracy and sensitivity, allowing manufacturers to detect even the smallest leaks. Vacuum leak testers are non-destructive, ensuring the integrity of tested products. These testers also provide prompt and accurate results, which helps to streamline production procedures.

Applications of Vacuum Leak Testers

3.1 Automotive Industry In the automotive industry, vacuum leak testers play a crucial role in ensuring the quality and safety of fuel systems, brake systems, and other critical components. Manufacturers can avoid fuel leaks, brake failures, and other risks that could endanger vehicle performance and passenger safety by precisely identifying leaks in these systems.

3.2 Medical Device Manufacturing Medical devices, such as syringes, catheters, and surgical instruments, must be leak-free to ensure patient safety. Vacuum leak testers enable manufacturers to verify the integrity of these devices and packaging, minimizing the risk of contamination or malfunction during medical procedures.

3.3 Electronics Industry Electronics manufacturers rely on vacuum leak testing to identify leaks in electronic components, circuit boards, and hermetically sealed devices. Manufacturers can enhance product reliability, shorten the life of electronic devices, and prevent potential failures by finding leaks early on.

3.4 Food and Beverage Production In the food and beverage industry, vacuum leak testers are essential for ensuring the quality and freshness of packaged products. By detecting leaks in packaging materials, such as cans, bottles, or pouches, manufacturers can prevent spoilage, maintain product integrity, and uphold food safety standards.

The Manufacturing Revolution

4.1 Enhancing Quality Control Processes The integration of vacuum leak testers into manufacturing processes has revolutionized quality control. Manufacturers can now implement automated leak testing systems, reducing human error and increasing testing efficiency. Proactive maintenance and ongoing enhancement of product quality are made possible by real-time data analysis and monitoring capabilities.

4.2 Increasing Efficiency and Cost Savings Vacuum leak testers contribute to operational efficiency by streamlining testing procedures and reducing production downtime. Detecting leaks early in the manufacturing process prevents costly rework or product recalls. Additionally, efficient leak testing minimizes material waste and optimizes resource utilization, resulting in significant cost savings for manufacturers.

4.3 Improving Customer Satisfaction By mastering leak detection, manufacturers can deliver high-quality, reliable products to their customers. Leak-free products enhance customer satisfaction and loyalty, leading to positive brand experiences. A brand's competitive advantage and market standing are enhanced when it meets or surpasses customer expectations concerning product performance and safety.

Overcoming Challenges in Leak Detection

5.1 Perplexities in Identifying Leaks Identifying leaks can be challenging due to various factors such as the complexity of product designs, different materials, or the presence of multiple potential leak paths. Manufacturers must invest in advanced vacuum leak testers capable of detecting leaks in diverse product configurations and materials to overcome these challenges effectively.

5.2 Addressing Burstiness in Leak Testing In some industries, such as pharmaceuticals or food production, leak testing must be performed within tight production schedules. High-speed testing and short setup times for vacuum leak testers enable manufacturers to meet burstiness requirements without sacrificing precision or quality.capacities.

The Future of Leak Detection

6.1 Advancements in Vacuum Leak Testing Technology Further improvements to testing speed, sensitivity, and accuracy are anticipated with ongoing developments in vacuum leak testing technology. Manufacturers can look forward to more compact and portable leak testers with enhanced automation and integration capabilities. These advancements will enable seamless integration with other manufacturing processes and the ability to monitor and control leak testing remotely.

6.2 Integration with Industry 4.0 and IoT The future of leak detection lies in its integration with Industry 4.0 and the Internet of Things (IoT). Vacuum leak testers will be connected to smart factory networks, enabling real-time data analysis, predictive maintenance, and enhanced process control. This integration will contribute to further optimization of manufacturing operations and ensure a higher level of product quality and safety.

Conclusion Mastering leak detection is a crucial aspect of modern manufacturing processes. Vacuum leak testers have revolutionized the industry by providing accurate, reliable, and efficient leak detection capabilities. Manufacturers can raise customer satisfaction, boost productivity, and improve product quality by putting these cutting-edge testing systems into place. Leak detection has even more potential in the future to enhance production procedures and guarantee product integrity as technology develops.

0 notes

Text

What Causes Gas Leaks in Generators and How to Detect Them

Gas leaks in generators pose a serious risk to safety and efficiency. These leaks can occur in various forms, affecting both the performance and the longevity of the equipment. Identifying and addressing generator gas leaks promptly is crucial to ensuring the continued operation of the generator and maintaining safety standards. A gas leak can lead to equipment failure, system inefficiency, and potentially hazardous situations, including fire or explosion risks. In this guide, we will explore the causes of gas leaks in generators, the potential dangers, and the most effective methods for detecting them, including the use of Helium Leak Testing.

What Causes Gas Leaks in Generators?

Generators are designed to convert mechanical energy into electrical power. This process often involves fuel, including natural gas, propane, or diesel, depending on the type of generator. Gas leaks can occur at various points in the generator system, with several underlying causes. Let’s explore some of the common reasons for gas leaks in generators:

1. Corrosion of Pipes and Components

One of the most common causes of gas leaks in generators is the corrosion of fuel pipes and related components. Over time, exposure to moisture, dirt, or chemical elements can lead to the degradation of the material, making it brittle and prone to cracking. Corrosion weakens the integrity of the pipes, resulting in leaks.

In generators, the pipes carrying natural gas or propane can corrode, leading to slow leaks that can go unnoticed until they cause significant damage. Corrosion is especially prevalent in older generators or those exposed to harsh environmental conditions, such as high humidity or salty air.

2. Improper Sealing

The gaskets and seals around the fuel lines, valves, and connections play a vital role in ensuring that gas doesn’t leak. If these seals are improperly installed or deteriorate due to aging, they can cause small gaps through which gas escapes. Over time, these leaks may worsen, leading to more severe problems.

A poorly sealed connection or valve can often lead to slow but persistent leaks. For instance, improperly tightened connections, such as those on the fuel tank or generator regulator, can result in generator gas leaks that become dangerous over time.

3. Wear and Tear of Rubber Hoses

Generators rely on rubber hoses to carry gas or other fluids through the system. Like seals, these rubber hoses can deteriorate over time due to environmental exposure, heat, and frequent movement. The rubber may crack, harden, or become brittle, leading to small fissures through which gas can escape.

Regular inspection of hoses is necessary to ensure they remain in good condition. Over time, even the best-quality hoses will wear down and need replacement.

4. Faulty Valves or Regulators

Valves and regulators control the flow of gas into the generator. If these components are faulty, gas may not flow as intended, potentially causing leaks. A malfunctioning valve can lead to excess gas pressure or incorrect gas flow, which can damage seals or hoses, resulting in leaks.

Regular maintenance and testing of the generator’s valves and regulators are necessary to ensure the proper function of the entire system. Worn-out components should be replaced immediately to prevent safety hazards.

5. Incorrect Fuel Supply Pressure

If the fuel supply pressure is too high or too low, it can cause gas to leak from the generator. For example, excessive pressure can cause fuel lines and fittings to become overstressed, leading to cracks or ruptures. On the other hand, low pressure may result in an inconsistent fuel supply, causing improper combustion or leading to leaks in certain parts of the system.

Generators are designed to operate within specific fuel pressure ranges. Proper regulation and calibration of the fuel pressure are essential to preventing leaks.

6. Physical Damage from External Factors

Physical damage is another significant cause of gas leaks in generators. External factors, such as vibration from the generator, impact from nearby equipment, or extreme weather conditions, can damage fuel lines or valves. This damage can lead to generator gas leaks, either immediately after the impact or over time as the weakened component deteriorates.

Generators used in industrial or outdoor settings are particularly vulnerable to physical damage. Regular inspection and maintenance are necessary to detect and fix these issues before they lead to significant leaks.

The Dangers of Gas Leaks in Generators

Gas leaks in generators are not only a threat to the equipment but also pose several risks to the surrounding environment and personnel. Some of the key dangers include:

1. Fire Hazard

The most significant risk associated with generator gas leaks is fire. When gas leaks from a generator, it can accumulate in the surrounding area, creating an explosive mixture with air. Even a small spark, such as that produced by electrical equipment or a static discharge, can ignite the gas, leading to a fire or explosion.

This is especially dangerous in confined spaces or areas with high temperatures. Leaking gas can quickly accumulate and cause an uncontrollable fire if not detected and addressed immediately.

2. Health Risks from Toxic Fumes

Some gases used in generators, such as propane and natural gas, can produce toxic fumes if leaked. Inhaling these fumes can cause respiratory problems, dizziness, headaches, and, in extreme cases, unconsciousness or death. Proper ventilation and gas leak detection are necessary to prevent these health hazards.

In addition to fuel gases, a generator gas leak may also lead to the leakage of other hazardous substances, such as carbon monoxide. Carbon monoxide poisoning is particularly dangerous because it is odorless and colorless, making it hard to detect without proper sensors.

3. Environmental Impact

Gas leaks can also have adverse environmental effects, especially if they go undetected for an extended period. Leaked gas may contaminate soil, water, or air, depending on the generator’s location. This contamination can have long-lasting effects on the surrounding ecosystem and require costly remediation efforts.

In some cases, gas leaks may also contribute to climate change by releasing greenhouse gases into the atmosphere. Therefore, detecting and fixing gas leaks promptly is essential for both safety and environmental protection.

4. Reduced Equipment Efficiency

A generator gas leak can affect the overall efficiency of the generator. If gas is escaping from the system, the generator may not operate at full capacity, resulting in reduced performance. This inefficiency can lead to higher fuel consumption, increased operating costs, and more frequent maintenance requirements.

How to Detect Gas Leaks in Generators

Detecting generator gas leaks is critical to preventing the dangers outlined above. Several methods can be used to identify and locate gas leaks in your system. Here are some of the most effective ways to detect gas leaks:

1. Visual Inspection

One of the first steps in detecting generator gas leaks is conducting a visual inspection. Look for any signs of damage to pipes, hoses, gaskets, or seals. Pay particular attention to areas where fuel is carried into the system, including connections to the fuel tank and regulator.

Look for any signs of corrosion, cracking, or loose fittings that could indicate a potential leak. If you notice any gas smells or unusual fumes during the inspection, it may be a sign of a leak.

2. Soapy Water Method

The soapy water method is a simple and effective way to detect small gas leaks. Spray a mixture of water and dish soap on all fuel lines, joints, and valves. If there is a gas leak, you will notice bubbles forming in the affected area.

This method is useful for identifying slow leaks in areas that are difficult to access. However, it may not detect leaks in areas where the gas is not coming into contact with the surface.

3. Gas Leak Detectors

For more accurate and reliable detection, you can use specialized gas leak detectors. These devices are designed to detect the presence of specific gases, such as natural gas or propane, in the air. They can be handheld or permanently installed near the generator to monitor for leaks continuously.

There are various types of gas detectors available, including those that use infrared technology, catalytic sensors, and electrochemical sensors. Gas leak detectors provide quick and accurate results, allowing you to identify and address leaks before they become a hazard.

4. Helium Leak Testing

One of the most advanced methods for detecting gas leaks is helium leak testing. Helium is a small, light gas that can penetrate even the smallest cracks or holes. By introducing helium into the system and using a mass spectrometer or helium detector, you can accurately detect leaks in the generator.

Helium leak testing is particularly useful for high-pressure systems or areas that are difficult to access. This method can identify gas leaks that are otherwise undetectable using traditional methods, making it one of the most reliable ways to ensure the safety and efficiency of your generator.

Conclusion

Generator gas leaks are a significant concern for industrial and commercial facilities. They pose serious safety, health, and environmental risks, which can be mitigated through early detection and regular maintenance. By understanding the common causes of gas leaks and utilizing methods such as helium leak testing, you can ensure that your generator remains safe and efficient.

If you're looking for expert services in leak detection and generator maintenance, American Efficiency Services is here to help. With years of experience and the latest technology, we offer reliable and effective solutions to detect and fix Generator Gas Leak, ensuring your equipment runs smoothly and safely. Contact us today to learn more about how we can help keep your systems running at peak performance.

0 notes

Text

PTI’s LT add-on units for SIMS helium leak detectors provide an innovative solution for testing package integrity in cold storage conditions, ranging from 0°C to -160°C. These systems use precise temperature conditioning alongside advanced helium leak detection to identify potential defects, especially in critical areas like elastomeric seals. By simulating ultra-low temperatures, the technology helps manufacturers detect leaks in materials that may become brittle or degrade at cold temperatures. The LT systems not only optimize packaging designs but also ensure compliance with regulatory standards like USP 1207 and USP 382. Ultimately, these systems enhance the safety, reliability, and performance of sensitive drug and biologic formulations stored at extreme temperatures.

#container closure integrity#helium leak detection#helium leak testing#pharmaceutical package testing

0 notes

Text

Expert Helium Leak Detection Service by Tekman for Reliable Industrial Solutions

Tekman offers expert Helium Leak Detection Service, ensuring precise and reliable detection of leaks in various industrial applications. Using advanced technology and methods, Tekman guarantees accurate results, helping to maintain safety and efficiency in your systems. Whether for manufacturing, processing, or maintenance, their Helium Leak Detection Service is trusted by industry professionals to identify even the smallest leaks, preventing costly downtime and ensuring optimal performance.

0 notes

Text

Sampling Cylinders, Sampling Systems Design, Manufacturer, Dubai, UAE

Sampling Cylinders, Sampling Systems, Gas Distribution Systems, Gas Handling Systems, Manufacturer, Supplier and Service Provider, Dubai, UAE.

Gas Distribution Systems, Gas Handling Systems, Helium Leak Detection System, Helium Leak Detection Service, MEP Services, Mechanical Services, Electrical Services, Plumbing Services, Laboratory Furniture Installation, Fumehood Installation, Fume Cupboards Validation, Laminar Cabinets Validation, Biosafety Cabinets Validation, Turnkey Laboratory Project Design, Turnkey Laboratory Project Consultancy, Gas Handling Systems AMC, Lab Furniture AMC, Special Metal Fabrication, Cylinder Racks, Gas Cylinder Racks, Gas Cylinder Storage Racks, Laboratory Furniture, Fume Hoods, Gas Regulators, Cylinder Gas Regulators, Single Stage Regulators, Double Stage Regulators, High Flow Regulators, High Pressure Regulators, Auto Changeover Regulators, Point of Use Regulators, Back Pressure Regulators, Fixed Flow Regulators, Gas Manifold, Gas Manifold Systems, Safety Cabinets, Sampling Cylinders, Sampling Systems, Gas Mixing System, Gas Blending System, Gas Detectors, Gas Analysers, Gas Monitor System, Ball Valves, VCR Diaphragm Valves, Check Valves, Diaphragm Shutoff Valves, Excess Flow Valves, Globe Valves, High Pressure Master Shutoff Valves, Needle Valves, Plug Valves, Safety Relief Valves, Solenoid Valves, Toggle Valves, Gas Accessories, Cylinder Trolleys, Cylinder Brackets, Cylinder Cages, Dubai, UAE.

0 notes

Text

Guide to the Fundamentals of Helium Leak Testing

Leak detection is a crucial process in industries where even the smallest leaks can compromise product integrity, safety, and efficiency. Helium leak testing is one of the most effective and reliable methods for detecting and quantifying leaks in various industrial components. This method is widely used in sectors like aerospace, automotive, medical, and HVAC due to its high sensitivity and accuracy. We specialize in providing advanced helium leak testing solutions tailored to industry needs. This guide covers the fundamentals of helium leak testing, its importance, methods, and applications.

Helium leak testing is a non-destructive method used to detect small leaks in sealed systems or components. It involves using helium gas, which has a small molecular size and low viscosity, making it an ideal tracer gas for leak detection. The test helps identify leaks that may not be visible through traditional inspection methods.

Website: https://icon-engineers.in/guide-to-the-fundamentals-of-helium-leak-testing/

0 notes

Text

Helium Gas Market Opportunity Analysis & Industry Forecast, 2024–2030

Helium Gas Market Overview

Request Sample:

The growing need for helium in lifting applications, food packaging and the burgeoning electronics markets adds to its demand. Additionally, innovations in helium recovery and recycling, alongside strategic stockpiling by nations, emphasize its significance in ensuring supply chain security amidst resource constraints. The growing investments in helium exploration also drives the market by addressing supply challenges, supporting diverse applications, and ensuring long-term stability.

A notable trend in the helium gas market is the growing interest in space exploration. This reflects humanity’s pursuit of technological innovation, cosmic discovery and potential new resources. In March 2024, Japan launched a multibillion-dollar Space Strategic Fund aimed at supporting the Japan Aerospace Exploration Agency (JAXA). The $6.7 billion fund, approved for a decade-long period, will facilitate the development, technology demonstration and commercialization of cutting-edge space technologies, driving significant growth in the country’s space sector. Helium hard drives are HDDs sealed with helium instead of air, leveraging helium’s low density to reduce turbulence and friction, allowing for thinner platters, increased capacity (up to 10 platters), improved performance, energy efficiency, cooler operation, reduced noise and enhanced reliability. Helium HDDs are vital in large-scale data centers for efficient storage.

Market Snapshot :

Helium Gas Market — Report Coverage:

The “Helium Gas Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Helium Gas Market.

AttributeSegment

By Form

Liquified

Compressed

By Supply

Cylinders

Bulk and Micro Tanks

Drum

On-site

By Purity

High Purity Helium

Medium-Purity Helium

Industrial-Grade Helium

By Application

MRI Scanning

Welding and Metal Fabrication

Cryogenics

Lifting and Balloons

Leak Detection

Breathing Mixes

Pressurizing and Purging

Controlled Atmosphere Source

Others

By End-Use Industry

Healthcare

Electronics

Aerospace and Defence

Energy

Industrial Manufacturing

Others

By Geography

North America (U.S, Canada and Mexico)

Europe (Germany, France, UK, Italy, Spain, Netherlands, Belgium, Denmark and Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Australia, New Zealand, Indonesia, Thailand, Malaysia and Rest of Asia-Pacific)

South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

Rest of the World (Middle East and Africa).

Inquiry Before Buying:

COVID-19 / Ukraine Crisis — Impact Analysis:

Initially, the COVID-19 pandemic caused a decrease in helium demand due to reduced industrial and medical activities during lockdowns. This temporarily alleviated the helium shortage by reducing consumption. However, as industries resumed operations, the demand surged, leading to a tighter supply and rising prices. Challenges in global logistics also disrupted the helium supply chain exacerbating shortages.

Russia, a major global supplier of helium, faced production and export restrictions due to the war. Facilities like the Amur Gas Processing Plant, critical to Russia’s helium production, experienced operational disruptions. European countries’ shift away from Russian natural gas further complicated helium extraction processes in regions like Algeria, which redirected its natural gas to pipelines instead of liquefying it to extract helium. These disruptions contributed to a major helium shortage in two decades increasing global supply constraints and driving up costs.

Key Takeaways

MRI Scanning is the Largest Segment by Application

Helium, specifically in its liquid state, is a cryogenic substance used to cool the superconducting magnets in MRI systems to extremely low temperatures (around -269°C or 4 Kelvin). These low temperatures are necessary for the magnets to achieve and sustain superconductivity, which is critical for generating the strong and stable magnetic fields required for high-resolution imaging. According to Collective Minds, the global volume of MRI scans continues to grow annually, with current estimates ranging from 100–150 million scans worldwide. The demand for helium in this sector is substantial, as MRI technology is widely used in medical diagnostics to visualize detailed internal structures of the human body, aiding in the detection and monitoring of diseases. As per the 2024 India Private Equity Report, healthcare investments in India hit a record high of $5.5 billion in 2023, driven by a threefold increase compared to 2022. Additionally, the growth of the healthcare sector, advancements in imaging technology and increasing prevalence of conditions requiring MRI diagnostics further bolster the helium demand.

Schedule A Call:

Medium Purity Helium is the Largest Segment

Medium Purity Helium (99.0% to 99.99%) is the largest segment in the helium market due to its widespread applications across various industries, driven by both its properties and cost-effectiveness. In the manufacturing sector, it is extensively used in welding for non-ferrous metals like aluminium and copper, where high-quality, stable inert gases are essential for precise, clean welding. The welding industry is growing primarily driven by the construction and automotive industry. According to the American Welding Society, the US will require more than 360,000 welders by 2027. In the cryogenic industry, medium purity helium is a key component in cooling systems for MRI machines, superconducting magnets and particle accelerators. The combination of its versatile properties, availability, and lower cost compared to higher-purity helium makes it a highly attractive option for industries that require a reliable and efficient gas.

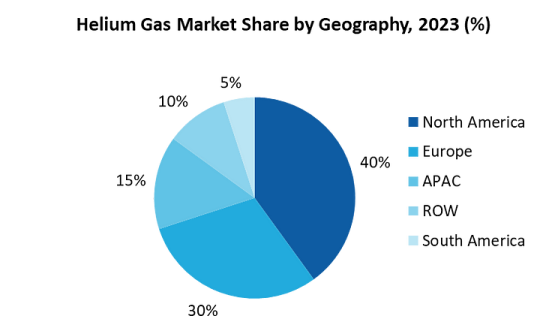

North America Leads the Market

North America continues to dominate the global helium gas market, bolstered by its abundant natural helium reserves and advanced extraction and distribution infrastructure. The United States, in particular, holds significant helium resources in regions such as the LaBarge field in Wyoming and the Texas Panhandle, which are key sources for the global market. Additionally, several companies are now interested in the helium exploration business which contribute to cutting-edge production, liquefaction and distribution technologies. Additionally, the region’s strong industrial base and healthcare advancements ensure a steady and robust demand for helium across sectors such as cryogenics, healthcare, aerospace, and manufacturing. In September 2024, North American Helium’s 9th helium purification facility at Antelope Lake, Saskatchewan, became operational. The facility has a production capacity of approximately 50 MMcf/year, increasing the company’s total capacity to 210 MMcf/year. NAH has reached a US $ 0.35 billion investment milestone in Saskatchewan, supported by government incentives such as the Critical Minerals Processing Investment Incentive (CMPII). Since launching its first facility in 2020, NAH, as of September 2024, produces ~7% of North America’s helium and aims for 20%.

Buy Now :

Limited Helium Reserves and Extraction Dependence to Hamper the Market

For more details on this report — Request for Sample

Key Market Players

Global Helium Gas top 10 companies include:

Air Liquide SA

Air Products and Chemicals, Inc.

Linde Plc

QatarEnergy LNG

Iwatani corporation

Messer Group

Nippon Sanso Holdings Corp

Matheson Tri-Gas Inc.

North American Helium (NAH)

Gazprom

By Form, By Supply, By Purity, By Application, By End-Use Industry and By Geography

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands, Belgium, Denmark and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia, New Zealand, Indonesia, Thailand, Malaysia and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa)

Key Market Players

Air Liquide SA

Air Products and Chemicals, Inc.

Linde Plc

QatarEnergy LNG

Iwatani corporation

Messer Group

Nippon Sanso Holdings Corp

Matheson Tri-Gas Inc.

North American Helium (NAH)

Gazprom

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Ultra High Purity Gas Delivery System: Precision and Reliability for Critical Applications

An ultra high purity gas delivery system is essential in industries where contamination-free gas flow is critical. From semiconductor manufacturing to pharmaceutical production, these systems ensure precision, reliability, and safety in various applications. The integrity of gas delivery directly impacts product quality, process efficiency, and regulatory compliance.

Designed to handle gases with minimal impurities, an ultra high purity gas delivery system incorporates advanced materials and engineering to prevent contamination. Stainless steel components, orbital welding, and specialized valves contribute to a seamless and leak-free operation. These features help maintain the purity of gases such as nitrogen, helium, oxygen, and hydrogen, which are vital in research laboratories, cleanrooms, and high-tech manufacturing environments.

Industries that rely on ultra high purity gas delivery systems demand consistent gas composition and pressure control. The semiconductor industry, for instance, requires ultra-clean gases for etching and deposition processes. Any deviation in gas purity can lead to defects in microchips, affecting overall device performance. Similarly, the pharmaceutical sector depends on pure gases for drug formulation, analytical testing, and biotechnology applications.

Safety is a primary concern when dealing with high-purity gases. Proper installation and maintenance of the gas delivery system ensure secure handling and distribution. Advanced monitoring systems detect leaks and pressure variations in real time, reducing risks associated with gas exposure. Automated control mechanisms further enhance efficiency by providing precise gas flow adjustments without manual intervention.

Customization plays a significant role in designing an effective ultra high purity gas delivery system. Each application has unique requirements, necessitating tailored solutions for flow rates, pressure ranges, and system configurations. Working with experienced engineers and manufacturers helps in achieving optimal performance and compliance with industry standards.

Regulatory adherence is a crucial factor in deploying an ultra high purity gas delivery system. Compliance with standards such as ISO 14644 for cleanrooms, FDA guidelines for pharmaceutical applications, and SEMI standards for semiconductor fabrication ensures that systems meet stringent industry requirements. High-quality materials, meticulous design, and rigorous testing contribute to a reliable system that upholds these standards.

The benefits of investing in a high-quality ultra high purity gas delivery system extend beyond purity and precision. Enhanced operational efficiency, reduced downtime, and minimized waste contribute to cost savings in the long run. Industries that prioritize these systems experience improved product consistency, lower maintenance costs, and a competitive edge in the market.

Innovation continues to drive advancements in ultra high purity gas delivery technology. The integration of smart sensors, automated diagnostics, and remote monitoring capabilities enhances system performance and predictive maintenance. These features enable users to proactively address potential issues, ensuring uninterrupted gas supply and optimized operations.

Selecting the right ultra high purity gas delivery system requires careful consideration of application needs, compliance standards, and future scalability. Partnering with a trusted supplier ensures access to high-performance solutions that support critical processes. As industries continue to evolve, the demand for advanced gas delivery systems will only increase, making precision and reliability essential for success in high-tech and scientific applications.

1 note

·

View note