#heavy weight tarpaulin

Explore tagged Tumblr posts

Text

#heavy weight tarp#heavy weight tarps#super heavy weight tarpaulin#super heavy weight tarpaulins#super heavy weight tarp#heavy weight tarpaulins#heavy weight tarpaulin#tarpaulins#tarpaulin#tarps#tarp#tarpaulin sheets#tarpaulins sheet#tarpaulin sheet#tarpaulins sheets#waterproof tarpaulins#buy tarpaulins#buy tarpaulins uk#tarps sheet#tarpaulin covers#uk

0 notes

Text

Canvas Tarpaulins for Agriculture Protecting Crops and Equipment

Introduction

Agriculture is a many-sided hit the dance floor with nature, where achievement depends on the sensitive harmony between ecological circumstances and human mediation. Canvas Tarpaulins assume a significant part in this dance, giving a defensive safeguard against eccentric components that can imperil the two harvests and cultivating hardware.

Protecting Crops

One of the essential elements of canvas tarpaulins in agriculture is protecting yields from antagonistic weather patterns. These strong covers go about as a boundary against over the top daylight, weighty downpours, hailstorms, and ice, all of which can inconveniently affect crop wellbeing.

2.1 Sun Protection:

Canvas tarpaulins act as successful awnings for crops, forestalling overexposure to extreme daylight. Delayed openness to brutal daylight can prompt burn from the sun and dry out of plants, hindering their development and lessening yields. Canvas tarpaulins, when decisively sent, moderate these dangers, establishing a favorable climate for plant development.

2.2 Rain and Hail Protection:

Exorbitant precipitation, particularly during basic development stages, can prompt waterlogging, root decay, and yield infections. Canvas tarpaulins go about as defensive layers, keeping water from immersing fields and hurting crops. Moreover, their durable development gives a safeguard against hail, a characteristic danger infamous for harming crops.

Preserving Soil Health

Canvas tarpaulins likewise add to saving soil well-being, assuming a part in soil disintegration counteraction and dampness maintenance. By covering the dirt with these coverings, ranchers can safeguard it from erosive forces, guaranteeing that important dirt remaining parts in one piece and is fruitful. Also, the coverings lessen vanishing, assisting the dirt with holding dampness, which is critical for supported crop development.

Protection During Seasonal Transitions

Farming cycles include advances between seasons, each introducing its difficulties. Canvas tarpaulins work with smooth advances by offering insurance during these weak periods. Whether it's protecting yields from late-winter ices or setting them up for the colder time of year chill, canvas tarpaulins give a solid safeguard against occasional limits.

Protecting Agricultural Equipment

Past protecting yields, canvas tarpaulins assume a urgent part in safeguarding the honesty of cultivating gear. Present day agriculture depends intensely on a different scope of hardware, from farm haulers and furrows to water system frameworks. Openness to the components, like daylight, downpour, and fluctuating temperatures, can speed up mileage, prompting expensive fixes and substitutions.

5.1 UV Protection:

Tarpaulin Sheets go about as a successful hindrance against unsafe bright (UV) beams. Drawn-out openness to daylight can cause blurring, breaking, and debasement of hardware surfaces. By covering apparatus with canvas canvases when not being used, ranchers guarantee that their gear stays shielded from the harmful impacts of UV radiation.

5.2 Rain and Moisture Resistance:

Water, particularly when joined by wind, can saturate the multifaceted hardware parts, causing consumption and lessening functional productivity. Canvas coverings, with their water-safe properties, give an impermeable hindrance against downpours, shielding gear and forestalling expected harm.

5.3 Temperature Regulation:

Outrageous temperatures, whether burning intensity or cold, can unfavorably influence the usefulness of farming gear. Canvas tarpaulins go about as encasings, directing inside temperatures and safeguarding apparatus from the limits of climate. This aids in keeping up with ideal working circumstances and broadens the life expectancy of the hardware.

Customization and Adaptability

Canvas tarpaulins offer a serious level of customization, permitting ranchers to tailor their use in view of explicit necessities. Whether covering a little vegetable nursery or safeguarding broad farmlands, these coverings can be adjusted to various sizes and shapes. This flexibility upgrades their reasonableness in different rural settings.

Durability and Longevity

The sturdiness of canvas tarpaulins goes with them a practical decision for long haul horticultural security. Produced using durable materials, these canvases endure the afflictions of open air openness, guaranteeing dependable and delayed assistance. This strength means cost-viability for ranchers, as they can depend on a solitary speculation for numerous developing seasons.

Environmental Considerations

Canvas, as a material, is biodegradable and harmless to the ecosystem. Not at all like a few manufactured other options, canvas tarpaulins don't add to natural contamination. This eco-accommodating perspective lines up with the developing accentuation on feasible horticultural works on, settling on canvas coverings a mindful decision for naturally cognizant ranchers.

Conclusion

In the domain of agriculture, where the harmony between nature and development is fragile, canvas tarpaulins arise as crucial apparatuses. Their multi-layered job in shielding crops from the components, saving soil wellbeing, and guaranteeing the life span of cultivating gear contributes altogether to the general achievement and manageability of horticultural practices. As ranchers keep on confronting developing difficulties, canvas tarpaulins stand as dependable partners, giving a canvas of security to the development and success of agriculture.

#buy tarpaulins#tarps#canvas tarpaulins#tarpaulin sheets#tarpaulins uk#plastic tarpaulins#tarp#pvc tarpaulins#tarpaulins cover#clear tarpaulins#Waterproof Tarpaulins#White Tarpaulins#Green Tarpaulin#tarpaulin for sale#Super Heavy Weight Tarpaulins#Medium Weight Tarpaulins#large tarpaulin sheets

0 notes

Text

#tarpaulins sheet#white tarpaulin sheet#White Tarpaulins#Heavy Weight Tarpaulins#HeavyWeight Tarpaulins#White Tarpaulin#Super Heavyweight Tarpaulins#Super Heavy Weight Tarpaulins#Super Heavy Weight Tarpaulin#Green Tarpaulins#Green Tarpaulin#PVC Tarpaulins#Waterproof Tarpaulins

0 notes

Text

#medium weight tarpaulins#medium weight tarpaulin#medium weight tarps#medium weight tarp#waterproof tarps#waterproof tarpaulin#waterproof tarpaulins#buy tarpaulin#buy tarpaulins#tarpaulin covers#tarpaulins cover#tarpaulins#tarpaulin#tarps#tarp#canvas tarps#heavy duty tarps#clear tarps

0 notes

Text

PVC Tarp, PVC Tarpaulin Manufacturer, Professional Production Of PVC Tarpaulin | Jum Tarps

Jum Tarps is a professional pvc tarpaulin Manufacturer and have been supplying PVC tarpaulin for over ten years, As the PVC coated tarpaulin manufacturer in China we offer kinds of pvc tarp,pvc tarpaulin,lumber tarps,heavy duty tarp for you want.We can provide high-value solutions of PVC tarpaulin

If you are looking for the best PVC tarpaulins in various colors, sizes and weights sold at factory direct prices, then Jumtarps™ can meet your requirements. We are a leading provider of heavy duty PVC tarpaulins and lightweight PVC tarps. Shop and compare! Our online store offers you high quality, competitive prices, and we believe it is the best overall value found in the tarpaulin and covering industry. We provide a complete line of large heavy duty tarps that can meet almost all needs.

4 notes

·

View notes

Text

Constructing a DIY Outdoor Changing Tent with Tarps

Introduction

When spending time outdoors at campsites, beaches, or festivals, having a private space to change clothes is essential. Commercial options exist, but they can be costly and may not meet specific needs. Building a privacy tent using tarpaulins is an affordable and adaptable alternative. This guide provides step-by-step instructions on constructing a reliable and easy-to-assemble enclosure suited for various outdoor situations.

Materials Needed

To ensure a sturdy and practical tent, gather the following materials:

Tarpaulins: Choose durable, waterproof plastic tarp that provide ample coverage and withstand outdoor conditions.

PVC Pipes or Metal Poles: These create the frame. PVC pipes offer an easy, lightweight option, while metal poles add strength.

Rope or Bungee Cords: Used to secure the tarp and maintain tension.

Clamps or Clips: Fasten the tarp securely to the frame to prevent shifting.

Tent Stakes or Weights: Anchor the tent to the ground for stability.

Zip Ties or Velcro Straps: Additional fastening tools for reinforcement.

Optional Accessories: Mosquito netting for ventilation, a groundsheet for comfort, and additional decor for personalization.

Step-by-Step Construction Guide

Step 1: Selecting a Location

Choose a suitable location to set up the tent:

Flat and Even Ground: Ensures the tent remains balanced.

Sheltered Area: Reduces exposure to wind and harsh weather.

Close to Main Activity Spot: Provides convenience while maintaining privacy.

Step 2: Constructing the Frame

A strong frame ensures the tent stands securely:

PVC Pipe Method:

Cut pipes to the required lengths (four vertical poles and horizontal connectors for a rectangular frame).

Assemble using elbow and T-joints for support.

Reinforce the base with additional pipes or crossbars.

Metal Pole Alternative:

Use extendable poles or tent poles for a more rigid frame.

Secure poles into the ground for added stability.

Step 3: Attaching the Tarpaulin

Once the frame is in place, attach the tarpaulin:

Position the Tarp:

Drape the tarp over the frame, ensuring complete coverage.

Leave an opening for a door, or create a flap for easy access.

Secure the Tarp:

Use heavy-duty clips or clamps to attach it to the frame.

Reinforce with rope or bungee cords for extra support.

Overlap multiple tarps if additional coverage is necessary.

Step 4: Ensuring Stability

Proper anchoring prevents movement due to wind or other external factors:

Using Tent Stakes:

Drive stakes into the ground at each corner.

Tie the tarp or frame securely to the stakes.

Adding Weights:

Place sandbags or heavy objects at the base.

Use interior weights if needed for extra stability.

Customization and Enhancements

Improve the basic structure with these modifications:

Ventilation Features:

Cut small openings near the top and cover with mesh to improve airflow.

Leave a slight gap between the tarp and ground to prevent heat buildup.

Comfort Additions:

Lay down a groundsheet or mat for cleanliness.

Install a hook or pouch for storing small essentials.

Decorative Elements:

Select colored or patterned tarps for a unique appearance.

String LED lights inside for nighttime use.

Alternative Uses Beyond Changing Areas

This DIY tent can serve multiple outdoor purposes:

Outdoor Shower Enclosure: Attach a portable shower bag for private washing.

Temporary Restroom Cover: Set up over a portable toilet for privacy.

Emergency Shelter: Functions as a backup tent in unexpected weather.

Storage Shelter: Protects gear from rain, sun, or dust when camping.

Conclusion

Building a privacy tent from tarpaulins is a practical solution for various outdoor needs. With simple materials and clear steps, anyone can create a sturdy and functional shelter. Customizing with ventilation, comfort additions, and personalized touches enhances usability. Whether used for changing, showering, or emergency situations, this DIY project is a cost-effective and reliable option for outdoor enthusiasts. Try making one for your next trip and experience the convenience of a portable, private space.

0 notes

Text

#heavy duty tarp#heavy duty tarps#heavy duty tarpaulins#heavy duty tarpaulin#tarpaulin#tarpaulins#tarpaulin sheet#tarps#tarp#tarpaulin sheets#tarpaulins sheet#large tarpaulin#tarpaulin uk#waterproof tarp#waterproof tarps

0 notes

Text

10 Tips for Storing and Handling 600 TMT Bars on Site

TMT bars are the backbone of modern construction, ensuring strength and durability in infrastructure. Proper storage and handling of TMT bars on-site not only maintain their quality but also enhance safety, reduce wastage, and promote efficiency in operations. With Maithan Steel's commitment to excellence and innovation in the steel-making industry, we've outlined the essential best practices to ensure your 600 TMT bars are stored and handled safely and effectively.

1. Designate a Proper Storage Area

Creating a dedicated storage space is the first step to maintaining the safety and quality of your TMT bars.

Dedicated Space: Select a level, well-drained area to store the bars. Ensure it's free from flooding or excessive moisture.

Clearance: Leave ample clearance around the storage area for the easy movement of equipment and personnel. This avoids congestion and ensures safe handling.

2. Secure Storage Practices

Improper storage of TMT bars can lead to toppling, damage, or corrosion.

Stacking: Arrange the TMT bars neatly in layers to avoid toppling. Avoid creating overhangs that might destabilize the stack.

Separation: Use wooden planks or pallets to separate layers and prevent direct contact, reducing the risk of damage.

Protection: Cover the stacks with tarpaulins or plastic sheets to shield them from excessive sunlight, rain, or dust.

3. Safe Transportation and Handling

TMT bars, due to their shape and weight, require proper handling to ensure workforce safety and product integrity.

Use Appropriate Equipment: Employ heavy-duty cranes or forklifts for movement, operated by trained personnel.

Proper Lifting Techniques: Use sturdy slings or chains when lifting to maintain safety during operations. Ensure proper balancing while lifting to avoid accidents.

Minimize Manual Handling: Limit manual handling to reduce the potential for injuries or mishandling.

4. Maintain Accurate Inventory Records

An organized inventory system is crucial for maximizing efficiency and minimizing risks like theft or material wastage.

Accurate Logs: Track the receipt, usage, and storage of TMT bars with precise records.

Regular Inspections: Frequently inspect stored TMT bars to identify any potential damage, rust, or missing materials.

5. Ensure Rigorous Quality Control

Maintaining the quality of TMT bars is key to ensuring their reliability on-site.

Visual Checks: Inspect the bars regularly for cracks, bends, or other damage. Address any irregularities immediately.

Quality Testing: If required, conduct tensile strength or other lab tests to verify the integrity of the TMT bars.

6. Prioritize Fire Safety

Fire hazards can pose danger when dealing with construction materials. Implement strict protocols to prevent fires in the storage area.

No Smoking: Enforce a strict no-smoking policy near stored TMT bars.

Accessibility of Fire Extinguishers: Place fire extinguishers in easily accessible locations to ensure quick action, if needed.

7. Strengthen Security Measures

Unsupervised storage areas can be prone to theft or unauthorized access. Proactive security measures safeguard your valuable resources.

Perimeter Fencing: Install fencing around the storage site to prevent unauthorized access.

Surveillance: Utilize CCTV cameras and other security systems to monitor the storage area around the clock.

8. Align with Environmental Considerations

Your on-site practices should be environmentally responsible to comply with regulations and protect the surrounding ecosystem.

Rainwater Runoff Prevention: Prevent runoff from contaminating nearby water bodies by implementing proper barriers or drainage systems.

Waste Disposal: Handle scrap and waste generated during cutting or handling responsibly to reduce environmental harm.

9. Regular Maintenance of Storage and Equipment

A well-maintained site minimizes accidents and ensures the longevity of equipment and materials.

Clear the Area: Remove debris from the storage space regularly and fix any drainage issues promptly.

Maintain Equipment: Frequently inspect and maintain machinery used for handling and transporting materials to avoid operational disruptions.

10. Train and Educate Staff

Empowered and well-informed workers can make a significant difference in ensuring workplace safety and efficiency.

Safety Training: Train workers on best practices for storage, handling, and overall site safety.

Awareness Programs: Conduct regular sessions to reinforce the importance of following proper procedures.

Final Thoughts

These guidelines not only help maintain the structural integrity of TMT bars but also prioritize safety and sustainability. Leveraging the robust features of Maithan Steel—crafted with Thermex HYQST European Technology—you can further enhance the durability and quality of your materials.

If you’re looking for trusted and high-quality TMT bars for your next project, Maithan Steel is here to provide you with the best. With over 50+ years of experience, cutting-edge technology, and a commitment to nation-building, we're your reliable partner in construction success. Reach out to us today to learn more!

0 notes

Text

Fire Retardant Tarpaulin: The Ultimate Protection Solution for UAE’s Industrial and Commercial Needs

Introduction

Fire safety is a paramount concern in the UAE, given the region's dynamic industrial growth and extreme climate conditions. Whether for construction sites, warehouses, or outdoor events, fire retardant tarpaulins provide unmatched protection and durability. In this blog, we delve into the benefits, applications, and features of fire retardant tarpaulins, shedding light on why they are essential for safeguarding properties and people in the UAE.

What is a Fire Retardant Tarpaulin?

A fire retardant tarpaulin is a heavy-duty protective covering made from specialized materials designed to resist ignition and slow down the spread of fire. Unlike regular tarpaulins, these are treated with flame-resistant chemicals, making them ideal for high-risk environments.

Key Features of Fire Retardant Tarpaulins

Flame Resistance: Certified to meet international fire safety standards.

Durability: Built to withstand harsh weather conditions and prolonged use.

UV Protection: Offers additional protection against the UAE’s intense sunlight.

Waterproof: Prevents water damage during unexpected weather changes.

Lightweight and Portable: Easy to transport and install across various applications.

Applications of Fire Retardant Tarpaulins

Construction Sites: Protect materials, equipment, and workers in high-risk zones.

Oil and Gas Industry: Safeguard assets in flammable and hazardous environments.

Event Management: Secure temporary structures like tents and stages for outdoor events.

Storage and Warehousing: Cover goods and prevent fire-related damages.

Transportation: Protect combustible goods during transit.

Why Fire Retardant Tarpaulins are Essential

The UAE's industrial and commercial sectors are diverse, with many operations requiring robust fire safety measures. Fire retardant tarpaulins offer a cost-effective and practical solution for ensuring safety. Their ability to endure extreme heat and prevent fire escalation makes them indispensable, especially in regions prone to high temperatures and dry conditions.

Benefits of Using Fire Retardant Tarpaulins

Enhanced Safety: Minimize the risk of fire-related accidents and damages.

Regulatory Compliance: Adheres to UAE fire safety and civil defense standards.

Cost Savings: Reduces potential losses due to fire incidents.

Versatility: Suitable for a wide range of industries and applications.

Choosing the Right Fire Retardant Tarpaulin

When selecting a fire retardant tarpaulin, consider the following:

Material strength and durability.

Certification for fire resistance.

Size and weight for your specific application.

Weather resistance features like UV and waterproofing.

Conclusion

Fire retardant tarpaulins are an essential investment for businesses and individuals in the UAE aiming to prioritize safety and compliance. Their versatility, durability, and fire-resistant properties make them the ideal choice for industrial, commercial, and residential use. Ensure the safety of your assets and workforce with high-quality FR tarpaulin in UAE, and contribute to creating a safer environment. For premium fire retardant tarpaulins tailored to your needs, explore our range and enhance your fire safety measures today.

#dubai#uae#abu dhabi#united arab emirates#dutarp#fire retardant tarpaulin#tarpaulin sheet#fr tarpaulin#tarpaulin dubai#tarpaulin uae#fireproof tarpaulin#tarpaulin cover#flame retardant tarpaulin#pvc tarpaulin#container tarpaulin#best quality tarpaulins#open top container tarpaulin#tarps#fire retardant canvas

0 notes

Text

What to Do When Your Roof Is Storm Damaged

Storms can cause significant damage to homes, and one of the most vulnerable areas is the roof. High winds, heavy rain, hail, and debris can all wreak havoc, leading to leaks, structural issues, and costly repairs if not addressed promptly. If your roof is storm-damaged, acting quickly and methodically is crucial to minimise further damage and restore your home’s safety.

Here’s a comprehensive guide on what to do when your roof is damaged by a storm.

1. Ensure Safety First

Your safety and that of your family should always be the top priority. After a storm, inspect your surroundings for hazards such as fallen trees, live wires, or unstable structures before attempting to assess the damage. If the damage is severe, evacuate the property and wait for professional assistance.

Avoid climbing onto the roof yourself, as it could be unsafe due to structural instability, slippery surfaces, or hidden damage. Instead, perform an initial inspection from ground level or inside your home.

2. Assess the Damage

Begin by inspecting your property for visible signs of roof damage. Common indicators include:

Missing or Dislodged Shingles: High winds can tear off shingles, exposing the underlayment and roof deck to the elements.

Dented or Cracked Tiles: Hailstones or falling debris can cause visible damage to tiles or slates.

Leaking or Stained Ceilings: Water stains on walls or ceilings inside your home may indicate a roof leak.

Accumulated Debris: Fallen branches or other debris on the roof can lead to punctures or broken tiles.

Gutter Damage: Check for sagging, detachment, or blockages caused by debris.

Take photos and videos of any visible damage from a safe distance. Documenting the extent of the damage will be helpful when filing an insurance claim.

3. Prevent Further Damage

If possible, take steps to mitigate further damage while waiting for professional repairs. Cover exposed areas with a tarpaulin to prevent water from entering your home. Secure the tarpaulin with weights or fasteners, ensuring it’s properly anchored to withstand additional wind or rain.

Inside your home, place buckets or containers under any leaks to catch dripping water and protect your belongings by moving furniture and electronics away from affected areas.

4. Contact Your Insurance Provider

Notify your insurance company as soon as possible to report the damage. Provide them with your documentation, including photos, videos, and a detailed description of the damage. Many policies require prompt reporting to ensure coverage, so act quickly.

An insurance adjuster will likely visit your property to assess the damage and determine the cost of repairs. Keep copies of all correspondence and notes from conversations with your insurer for your records.

5. Hire a Professional Roofing Contractor

Choosing a reliable and experienced roofing contractor is critical for repairing storm damage. Avoid attempting DIY repairs, as these can be dangerous and may void warranties or insurance coverage. Look for a licensed and insured contractor with a strong track record in storm damage repair. In urgent cases, emergency roofing specialists can provide swift assessments and temporary solutions to protect your home while permanent repairs are arranged.

When hiring a contractor, consider the following:

Verify Credentials: Check that the contractor is licensed and insured.

Read Reviews: Look for testimonials and online reviews to gauge their reliability and quality of work.

Get Multiple Quotes: Obtain at least three quotes to compare pricing and scope of work.

Beware of Scams: Be cautious of contractors who show up unsolicited after a storm offering repairs at unusually low prices.

Professional roofers will inspect the damage thoroughly and provide a detailed estimate for the necessary repairs. They can also assist with temporary fixes, such as tarping, if immediate repairs cannot be carried out.

6. Understand the Repair Process

The extent of repairs will depend on the severity of the damage. Common repair scenarios include:

Replacing Shingles or Tiles: Missing or damaged shingles can be replaced individually to restore the roof’s protective layer.

Repairing Flashing: Damaged flashing around chimneys, vents, or skylights can be replaced to prevent leaks.

Fixing Structural Damage: If the storm has caused structural issues, such as sagging or broken rafters, professional repairs will be necessary to restore the roof’s integrity.

Re-Roofing: In cases of extensive damage, a complete roof replacement may be required.

A professional contractor will guide you through the process and recommend the most cost-effective and durable solution.

7. Consider Future Storm Preparedness

Once your roof has been repaired, take steps to prevent or minimise damage from future storms. Regular maintenance and proactive measures can make a significant difference in protecting your home:

Inspect Your Roof Regularly: Check for loose shingles, cracked tiles, or signs of wear and tear.

Trim Overhanging Trees: Keep trees near your home well-trimmed to prevent branches from falling onto your roof during storms.

Clear Gutters and Downspouts: Ensure your gutters are free of debris to allow rainwater to drain away from your home effectively.

Install Impact-Resistant Materials: Consider upgrading to impact-resistant shingles or tiles to enhance your roof’s durability.

8. Work with Local Authorities if Necessary

In severe storms, widespread damage can lead to local authorities or government agencies offering assistance. Keep an eye out for local announcements or resources such as grants, low-interest loans, or temporary housing support. Being informed about available options can help ease the financial burden of repairs.

9. Address Hidden Damage

Storm damage isn’t always immediately visible. Water can seep into roof decking or insulation, causing long-term issues like rot or mould growth. After repairs are completed, consider hiring a professional inspector to ensure no hidden damage remains. Addressing these issues promptly can prevent costly repairs in the future.

10. Stay Patient and Persistent

Recovering from storm damage can be a stressful and time-consuming process. Insurance claims, contractor schedules, and repair timelines may take longer than expected, especially during periods of high demand after severe storms. Stay organised, keep detailed records, and remain persistent in following up with your insurance company and contractor to ensure the process runs smoothly.

Conclusion

Dealing with storm damage to your roof can be overwhelming, but a proactive and methodical approach can help you navigate the situation effectively. Prioritise safety, document the damage, and seek professional help to prevent further issues and restore your roof promptly.

As you recover, consider taking preventive measures to fortify your roof against future storms, ensuring your home remains safe and secure no matter what the weather brings. By addressing the damage promptly and maintaining your roof regularly, you can protect both your home and your peace of mind.

#stormdamage#roof#roofing#RoofDamage#StormDamage#EmergencyRepairs#HomeMaintenance#RoofingTips#PropertyCare#WeatherPreparedness#StormSafety#RoofRepair#HomeImprovement#EmergencyRoofing#ProtectYourHome#HomeInsurance#StormSeason#RoofingContractor#RoofingHelp#HomeSafety#StormDamageRepair#RoofingSpecialists#PropertyProtection

0 notes

Text

#glass clear tarps#clear tarp#glass clear tarpaulin#glass clear tarp#heavy weight tarp#heavy weight tarps#super heavy weight tarpaulin#super heavy weight tarp#super heavy weight tarpaulins#heavy weight tarpaulins#heavy weight tarpaulin#tarpaulin sheet#tarpaulin sheets#tarpaulins sheet#buy tarpaulins#tarpaulins sheets#waterproof tarpaulins#buy tarpaulins uk#tarpaulin covers#tarps sheet#uk#waterproof tarpaulin#tarpaulin cover#clear tarpaulin#clear tarpaulins#clear tarps#tarpaulins#tarpaulin#tarps#tarp

0 notes

Text

Why Should You Invest in a Waterproof Tarpaulin?

Weather Resistance:

The essential capability of a Waterproof tarpaulin is to go about as a powerful hindrance against the components. Be it heavy downpours, weighty snowfall, or the burning beams of the sun, these coverings act as a defensive safeguard against your effects. Whether you're covering a heap of wood on the terrace or protecting your vehicle during a tempest, the waterproof idea of these canvases guarantees that your assets stay protected and dry

Versatility: A Tool for Every Occasion One of the champion elements of waterproof tarpaulins is their flexibility. These versatile covers can be modified for different purposes, making them key in a large number of circumstances. Whether you really want a stopgap rooftop for an open-air occasion, a ground cover for setting up camp, or insurance for development materials on a place of work, a waterproof canvas can be easily reused to meet your particular requirements.

Durability: A Long-Term Investment Putting resources into a great waterproof covering is similar to putting resources into long-haul insurance. Made from sturdy materials, for example, polyethylene or PVC, these canvases are impervious to wear, tear, and the destructive impacts of the sun. Not at all like regular canvases that might decay over the long run, a waterproof covering offers to get through security, making it a dependable and savvy interest in the life span of your effects.

Cost-Effectiveness: Preventing Damage and Expenses While the underlying expense of a waterproof covering might appear to be a cost, it's a practical arrangement when seen with regard to counteraction. By safeguarding your assets from unfavorable weather patterns, these coverings moderate the gamble of expensive harms. Whether it's safeguarding your porch furniture from downpours or forestalling sun harm to your vehicle's paintwork, the interest in a waterproof canvas is a proactive measure that saves you from possible fix or substitution costs.

Agricultural Protection: Safeguarding Crops and Equipment For those associated with agribusiness, the job of waterproof tarpaulins in safeguarding harvests and hardware is important. These canvases give a dependable safeguard against inordinate downpours, hail, and daylight, saving the quality and yield of harvests. Besides, waterproof tarpaulins are utilized to protect farming apparatus from the components, guaranteeing their usefulness and life span.

Construction and Renovation: Enabling Uninterrupted Work In development and redesign projects, where weather patterns can be unusual, waterproof tarpaulins offer a brief yet powerful arrangement. Whether you're dealing with a rooftop, painting, or directing fixes, these canvases give a defensive hindrance against downpours, permitting work to go on without interference. The versatility of waterproof tarpaulins makes them a fundamental instrument for project workers and Do-It-Yourself aficionados the same.

Emergency Preparedness: A Swift and Reliable Solution Amid crises, like Medium Weight Tarpaulin abrupt storms or surprising holes, having a waterproof canvas available to you is an essential move. These canvases can be quickly conveyed to cover and safeguard fundamental things, giving a speedy and dependable answer for forestalling water harm. In crisis readiness units, a waterproof covering is a flexible resource that guarantees you're prepared for the unforeseen.

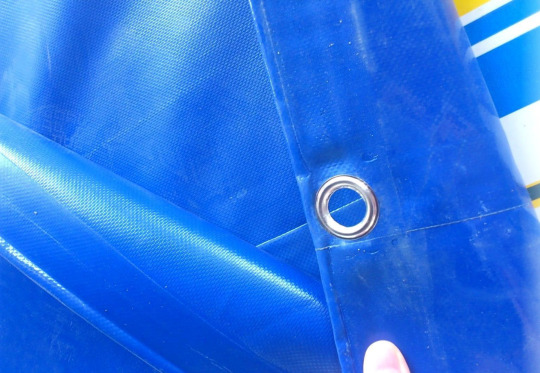

Ease of Use: Practical and Portable Waterproof tarpaulins are planned in light of client accommodation. Outfitted with built-up grommets along the edges, they can be effortlessly gotten utilizing ropes, bungee lines, or other straps. The lightweight and foldable nature of these canvases make them exceptionally convenient, permitting you to convey them any place insurance is required. This usability adds to the general allure of waterproof tarpaulins as a pragmatic and open defensive arrangement.

Ecological Contemplations: A Reasonable Decision Settling on a strong waterproof covering line up with the developing accentuation on maintainability. Dissimilar to dispensable other options, for example, plastic sheets or conventional coverings that add to squander, a top-notch waterproof canvas can be reused for a lengthy period. This decrease in squandering mirrors an honest decision toward harmless to the ecosystem.

Conclusion

All in all, putting resources into a waterproof canvas is a logical choice that delivers profits in different parts of life. Whether you're safeguarding your open-air possessions, getting crops on the ranch, or guaranteeing continuous work on a building site, the flexibility, toughness, and cost-viability of waterproof tarpaulins make them a crucial device. As we explore a universe of climatic vulnerabilities, having a waterproof covering isn't simply an interest in material security but additionally a demonstration of readiness, flexibility, and a manageable way to deal with protecting our assets.

#PVC tarpaulins#waterproof tarpaulins#heavy weight tarpaulins#buy tarpaulins#tarpaulin sheets#Canvas tarpaulins#Tarpaulins cover#Large tarpaulins#Tarps#Tarp#White Tarpaulins#Tarpaulins uk#Heavy duty tarp#Clear Tarpaulins

1 note

·

View note

Text

#heavy weight tarpaulins#large tarpaulin sheets#heavy duty tarpaulin sheet#waterproof tarps#waterproof Tarpaulin sheets#heavy duty waterproof tarpaulin#tarpaulin heavy duty#tarpaulin black#black tarpaulins#Tarpaulins Sheeting#waterproof tarp#Heavy Duty tarpaulins#Heavy Duty tarpaulin

0 notes

Text

Why PP Fibrillated Yarn Beats Other Materials for Durability?

When it comes to selecting materials for various applications, especially in the textile and industrial sectors, the durability of the material is often paramount. Among the many options available, polypropylene (PP) fibrillated yarn has gained recognition for its exceptional durability and performance. This article will explore the unique characteristics of PP fibrillated yarn, comparing it with other materials and highlighting why it stands out as a top choice in durability.

Understanding PP Fibrillated Yarn

Fibrillated yarn is made from polypropylene, a thermoplastic polymer known for its strength and lightweight properties. The process of fibrillation involves splitting the yarn into finer filaments, resulting in a fibrous structure that enhances its surface area. This structure contributes significantly to the yarn's mechanical properties, making it a preferred choice for various applications, from geotextiles to industrial fabrics.

Exceptional Strength and Resilience

Comparing Strength

One of the primary reasons PP fibrillated yarn is favored for durability is its exceptional strength. Polypropylene yarn exhibits high tensile strength, which means it can withstand significant pulling and stretching forces without breaking. This characteristic makes it ideal for demanding applications, such as agricultural nets and industrial fabrics, where the material must endure heavy loads and stresses.

Resistance to Environmental Factors

Unlike some natural fibers, PP fibrillated yarn is highly resistant to environmental factors such as moisture, chemicals, and UV radiation. This resistance means that it will not degrade or lose its strength when exposed to harsh conditions, making it particularly suitable for outdoor applications. Natural fibers, on the other hand, can weaken and deteriorate when exposed to moisture and sunlight over time.

Lightweight and Cost-Effective

Lightweight Advantages

Another advantage of PP fibrillated yarn is its lightweight nature. This characteristic not only makes it easier to handle and transport but also contributes to cost savings in shipping and installation. In applications such as protective coverings or tarpaulins, the reduced weight of the material can be a significant benefit, allowing for easier setup and handling.

Cost-Effectiveness

When considering the overall lifecycle cost, PP fibrillated yarn often proves to be more economical than alternative materials. While the initial purchase price may be comparable to other synthetic or natural fibers, the longevity and durability of polypropylene yarn result in lower replacement and maintenance costs over time. This cost-effectiveness is particularly appealing to businesses looking to optimize their budgets without compromising quality.

Versatility in Applications

Diverse Use Cases

PP fibrillated yarn is incredibly versatile, with applications ranging from agricultural netting and geotextiles to packaging and construction. In agriculture, for instance, its strength and UV resistance make it ideal for protective covers, while in the construction industry, it is used in reinforcement materials for soil stabilization. This adaptability further underscores its durability, as it can perform reliably in various demanding environments.

Customized Solutions

Manufacturers often offer PP fibrillated yarn in different colors, thicknesses, and constructions, allowing for customized solutions tailored to specific needs. This customization can enhance the performance of the material in various applications, ensuring it meets the durability requirements for each unique situation.

Comparison with Other Materials

Natural Fibers

When comparing PP fibrillated yarn to natural fibers such as cotton or jute, the differences in durability become apparent. While natural fibers have their advantages, they often lack the strength and resistance to environmental degradation that PP fibrillated yarn offers. Natural materials can absorb moisture, leading to mold and mildew, while polypropylene yarn remains unaffected by moisture and is resistant to such issues.

Other Synthetic Fibers

When contrasted with other synthetic fibers like nylon or polyester, PP fibrillated yarn still holds its ground in specific applications. While nylon is known for its strength and flexibility, it may not provide the same level of UV resistance as polypropylene. Polyester, while durable, can also be less resistant to chemical exposure than PP. The unique properties of PP fibrillated yarn make it a better fit for many situations where durability is crucial.

Environmental Considerations

Sustainability

With growing concerns about sustainability in material production, PP fibrillated yarn presents a balanced option. While it is a synthetic material, its long lifespan reduces the need for frequent replacements, thereby lessening its overall environmental impact. Additionally, many manufacturers are increasingly adopting recycling practices for polypropylene, which can further mitigate its environmental footprint.

Biodegradability

It is essential to note that while PP fibrillated yarn is durable, it is not biodegradable. However, advancements in technology are leading to the development of more environmentally friendly alternatives, including biodegradable options. Still, for applications where longevity and durability are paramount, PP remains a leading choice.

Real-World Applications of PP Fibrillated Yarn

Agricultural Industry

In the agricultural sector, PP fibrillated yarn is widely used for making crop covers, nets, and twines. Its durability allows it to withstand weather changes, protecting crops from pests and environmental elements. Farmers appreciate its ability to maintain structural integrity over time, resulting in less frequent replacements and reduced costs.

Construction Industry

In construction, PP fibrillated yarn is often utilized in geotextiles for soil reinforcement and stabilization. The yarn's strength and resistance to moisture and chemicals make it ideal for applications like drainage systems and erosion control. By enhancing the durability of construction materials, PP fibrillated yarn contributes to more robust and long-lasting infrastructure.

Packaging Solutions

The packaging industry also benefits from the versatility of PP fibrillated yarn. It is commonly used in the production of bags, sacks, and bulk containers. The strength of the yarn ensures that packaging can hold heavy loads without tearing, while its lightweight nature facilitates easier handling and transportation.

Future Trends in PP Fibrillated Yarn

Innovations in Manufacturing

As the demand for durable materials continues to rise, manufacturers are focusing on innovation in PP fibrillated yarn production. Advances in technology may lead to even stronger and more versatile formulations, expanding the range of applications and improving overall performance.

Growing Market in India

The market for Fibrillated yarn in India is growing, driven by increased demand across various sectors. As industries seek more durable and cost-effective materials, the adoption of PP fibrillated yarn is expected to rise, making it a cornerstone of industrial applications in the country.

Conclusion

PP fibrillated yarn stands out as a durable and versatile material suitable for a wide range of applications. Its exceptional strength, resistance to environmental factors, lightweight nature, and cost-effectiveness make it a superior choice compared to both natural fibers and other synthetic options. As industries continue to evolve and seek materials that offer reliability and longevity, the importance of PP fibrillated yarn is set to grow.

Whether in agriculture, construction, or packaging, the benefits of using polypropylene yarn are clear. For those looking to optimize durability in their materials, choosing PP fibrillated yarn is a decision that will pay off in performance, efficiency, and cost savings over time. As the market for this innovative material expands, particularly in regions like India, the future looks bright for PP fibrillated yarn in various applications.

FAQs about PP Fibrillated Yarn

1. What is PP fibrillated yarn?

PP fibrillated yarn is a type of yarn made from polypropylene that has been processed to create a fibrous structure, enhancing its strength and surface area for various applications.

2. What are the primary advantages of using PP fibrillated yarn?

The main advantages include exceptional strength, lightweight properties, resistance to moisture and UV radiation, cost-effectiveness, and versatility in a wide range of applications.

3. How does PP fibrillated yarn compare to natural fibers?

Unlike natural fibers, PP fibrillated yarn is resistant to environmental degradation, moisture absorption, and pests, making it more durable for outdoor and industrial applications.

0 notes

Text

How Advantageous The Tarpaulins Suppliers in US Can Be?

From the US, tarpaulins to pond liners are critical products in waste management and water feature construction, among many other uses. It makes a whole lot of difference to know the advantages of dealing with credible suppliers of these two kinds of products in making or breaking your projects. In this writing piece, you can know more about the tarpaulins suppliers in US, and Pond liner suppliers US.

For covering and protecting various surfaces, tarpaulin fabric is manufactured to bear harsh conditions of UV rays and heavy rainfalls. The pond liners, which are to be used in creating waterproof barriers in ponds and lakes, are designed to prevent leakage and contamination. High-quality products would provide enhanced performance and longer life.

You will have top suppliers offering you customized solutions tailored to meet your requirements, whether in terms of the size, weight, and color of tarpaulins or pond liners in specific thicknesses and materials. It improves the efficacy of products and guarantees that the product delivered is suitable for the unique needs of your projects.

Reliable Supply and Distribution

Established suppliers can offer a steady and dependable supply of tarpaulins and pond liners. These suppliers have developed efficient distribution channels, allowing extensive orders to go through without any problem, processed easily, and with an assurance of prompt delivery. One can imagine how reassuring it is to have such reliable suppliers in matters of large-scale projects or other pressing needs.

Tarpaulins suppliers in US

They also provide valuable advice and assistance in choosing the right products for your requirements. They will guide you in choosing materials, and product specifications, and advice on good installation practices. With that kind of advice, it aids in making the right decisions for the successful execution of projects.

Tarpaulins suppliers in US and pond liners contribute to the enhanced performance of your projects. Durable tarpaulins protect surfaces from environmental damage and prolong their lifespan, while effective pond liners prevent leaks and maintain the integrity of water features. Investing in quality products ensures that your projects perform as intended and require less maintenance.

#Tarpaulins suppliers in US#Landfill Tarp suppliers US#Pond Builder in Kentucky#Hazardous waste containment liners US#Litter Fence for landfills US

0 notes

Text

Choosing the Right Fabric: Non-Woven vs. Woven

Choosing the Right Fabric: Non-Woven vs. Woven

Selecting the right fabric for your products or projects is crucial to ensuring quality, durability, and functionality. Among the most common types of fabrics are non-woven and woven fabrics, each offering unique properties suited to different applications. This guide will help you understand the key differences between non-woven and woven fabrics and how to choose the best one for your needs.

1. What is Non-Woven Fabric?

Manufacturing Process:

Non-woven fabrics are made by bonding or felting fibers together through mechanical, thermal, or chemical processes, without the need for weaving or knitting. These fabrics are typically made from synthetic materials like polypropylene or polyester, though natural fibers can also be used.

Characteristics:

Durability: Non-woven fabrics are generally less durable than woven fabrics but are strong enough for single-use or limited-use applications.

Breathability: These fabrics offer good breathability, making them ideal for medical and hygiene products.

Water Resistance: Non-woven fabrics can be treated to be water-resistant or waterproof, making them suitable for disposable items.

Cost-Effective: Non-woven fabrics are usually cheaper to produce, especially in bulk, due to the simplicity of the manufacturing process.

Common Applications:

Medical and Hygiene Products: Face masks, surgical gowns, and sanitary pads.

Packaging: Non-woven bags, covers, and wraps.

Agriculture: Crop covers and weed control fabrics.

Home Products: Disposable tablecloths, dust covers, and cleaning wipes.

2. What is Woven Fabric?

Manufacturing Process:

Woven fabrics are made by interlacing two sets of yarns or threads—warp and weft—in a perpendicular pattern on a loom. This traditional method creates a fabric that is strong, durable, and versatile.

Characteristics:

Strength and Durability: Woven fabrics are known for their high tensile strength and long-lasting durability, making them suitable for products that require longevity.

Versatility: Available in a wide range of textures, patterns, and weights, woven fabrics can be used in both light and heavy-duty applications.

Comfort: Woven fabrics are often softer and more comfortable, making them ideal for clothing and upholstery.

Shrinkage and Stretch: Woven fabrics can shrink or stretch over time, depending on the fiber content and weave type.

Common Applications:

Clothing and Fashion: Shirts, jeans, dresses, and suits.

Home Furnishings: Curtains, upholstery, and bed linens.

Industrial Uses: Canvas, sails, and tarpaulins.

Accessories: Bags, belts, and footwear.

3. Key Differences Between Non-Woven and Woven Fabrics

**1. Strength and Durability:

Non-Woven: Suitable for applications where strength is not the primary concern, such as disposable or short-term use items.

Woven: Offers superior strength and durability, making it ideal for products that need to withstand wear and tear.

**2. Cost:

Non-Woven: Generally more cost-effective, especially for large-scale or disposable products.

Woven: Typically more expensive due to the complexity of the manufacturing process and the materials used.

**3. Production Process:

Non-Woven: Quicker and simpler to produce, often resulting in lower costs.

Woven: More time-consuming and complex, requiring skilled labor and machinery.

**4. Customization:

Non-Woven: Limited customization options, mostly available in basic colors and patterns.

Woven: Highly customizable with endless possibilities in terms of patterns, colors, textures, and finishes.

**5. Environmental Impact:

Non-Woven: Often made from synthetic materials that may not be biodegradable, though recyclable options exist.

Woven: Can be made from natural fibers like cotton, which are biodegradable, but may require more resources to produce.

4. How to Choose the Right Fabric

**1. Consider the Application:

For disposable, lightweight, and cost-sensitive applications, non-woven fabrics are often the best choice.

For products requiring strength, durability, and a premium feel, woven fabrics are more suitable.

**2. Evaluate Cost vs. Durability:

Weigh the upfront cost against the expected lifespan of the product. Woven fabrics may have a higher initial cost but can offer better long-term value for durable goods.

**3. Environmental Considerations:

Consider the environmental impact of your choice. If sustainability is a priority, look for biodegradable woven fabrics or recyclable non-woven options.

**4. Aesthetic and Comfort:

For products where appearance and comfort are key, such as clothing and home furnishings, woven fabrics typically offer a wider range of options.

5. Conclusion

Choosing between non-woven and woven fabrics depends largely on your specific needs, including the intended use, budget, and environmental considerations. Non-woven fabrics offer cost-effective solutions for disposable or short-term use, while woven fabrics provide durability, comfort, and versatility for long-lasting products. By understanding the differences and evaluating your priorities, you can select the right fabric that aligns with your goals and ensures the success of your project.

https://favouritehub.com/choosing-the-right-fabric-non-woven-vs-woven/

0 notes