#hdpe blow moulding machine manufacturer

Explore tagged Tumblr posts

Text

The Ultimate Guide to HDPE Blow Moulding Machine

HDPE Blow Moulding Machine, also known as High-Density Polyethylene Blow Moulding Machine, is a type of manufacturing equipment used to produce hollow plastic products, such as bottles, containers, and tanks, from HDPE resin. It utilizes the blow molding process, which involves inflating a molten plastic parison (hollow tube) inside a mold cavity to form the desired shape. Today, in this…

View On WordPress

#HDPE Blow Moulding Machine#HDPE Blow Moulding Machine Exporter#HDPE Blow Moulding Machine Manufacturer#HDPE Blow Moulding Machine Supplier

0 notes

Text

Are you searching for a new design for an HDPE Blow Moulding Machine?

Allied Way India is one of the best HDPE Blow Moulding Machine Manufacturers in India. HDPE blow molding Machine Made from Polypropylene (PP) Polyethylene (HDPE, MDPE, LDPE) Nylon (PA). For further details, contact us.

#hdpe blow moulding machine exporter#HDPE blow molding Machine#hdpe blow moulding machine manufacturer

0 notes

Text

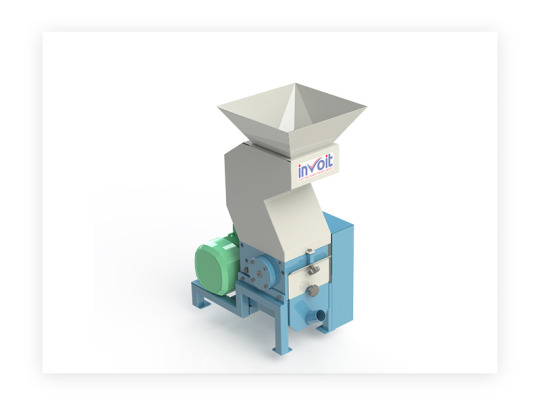

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine https://www.invoitplast.com/plastic-scrap-grinder-machine/ Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades. Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar. Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Top 5 Challenges CPGs Face in Achieving Sustainable Packaging Goals by 2025

The commitment to achieving sustainable packaging goals by 2025 has been made by many consumer packaged goods (CPG) companies, reflecting their dedication to reducing environmental impact. However, various challenges have impeded these efforts, and addressing them has proven crucial for success. This blog explores the top five challenges faced by CPGs, providing insights into strategies and solutions.

1. Limited Availability of Sustainable Raw Materials

The availability of sustainable materials has often been a bottleneck in packaging innovation. The demand for recyclable or biodegradable materials continues to surpass the supply, creating intense competition in the market.

Sustainable alternatives, such as bio-based plastics, are in limited production.

Cost and scalability have restricted smaller players from accessing these resources.

To bridge the gap, CPG, recyclers are partnering with bottle and container suppliers like Regent Plast, specializing in sustainable plastic bottle manufacturing.

Such constraints make the switch to greener materials challenging, especially when high-quality and durable options are required.

2. Recycling Infrastructure Deficiencies

Global recycling rates remain inconsistent due to inadequate infrastructure, especially in developing countries.

Recycling facilities often lack the capacity to process clean materials like HDPE for which multi-layer technology to accept recycled polymers (PCR) is required.

Non-standardized collection systems hinder efficient processing.

A lack of awareness among consumers about segregating waste adds complexity.

For companies relying on advanced materials, collaborations with HDPE bottle manufacturers and local recyclers are being explored to improve collection and processing networks.

3. High Costs of Transition

Shifting from traditional to sustainable packaging is associated with significant costs. These expenses include:

Research and development (R&D) for innovative packaging solutions.

Re-tooling existing machinery for compatibility with newer materials.

Absorbing increased material costs.

Despite these hurdles, CPG companies have sought affordable solutions by partnering with plastic bottle manufacturers that prioritize innovation, can provide a proven solution and ease the financial strain of paying a premium for recycled polymers. Regent Plast is deploying state of an art multi-cavity blow moulding machine to manufacture bottles in high quantities and reduce the manufacturing cost, and to some extent, off-set the cost of recycled polymers.

4. Regulatory Hurdles and Compliance

Governments worldwide have enacted regulations to curb single-use plastics and promote sustainable practices. However, these policies vary widely by region, creating challenges for global CPG companies.

Diverging standards for material recyclability in different markets.

Conflicting requirements for labeling, material composition, and waste management protocols.

Rising compliance costs in emerging markets.

Collaborating with specialized plastic packaging suppliers such as Regent Plast, which ensures compliance with local and international standards, has been identified as an effective strategy.

5. Consumer Behavior and Perception

Consumer preferences significantly influence packaging decisions, yet educating consumers about sustainability remains a challenge.

Misunderstandings around recyclable versus compostable materials create confusion.

Perceived inferior quality of eco-friendly packaging deters adoption.

Price sensitivity often leads consumers to prefer conventional packaging.

CPGs have responded by offering recyclable options like bottles made out of recycled plastics/ ocean plastics that align with both sustainability goals and consumer expectations. Related Article: Why Recyclable Bottles & Containers are in demand?

Brands Leading and Lagging in Sustainable Packaging Goals

Brands Making Strides:

Unilever: The company has committed to halving its use of virgin plastics and achieved significant milestones in recycled content packaging.

Nestlé: Launched a $2 billion fund to invest in sustainable packaging innovation.

Coca-Cola: Progressed toward its “World Without Waste” goal, aiming to collect and recycle one bottle for every one sold by 2030.

READ MORE- https://regentplast.com/top-5-challenges-cpgs-face-in-achieving-sustainable-packaging-goals-by-2025/

0 notes

Text

Premier Injection Blow Moulding Machine Manufacturers in India

Injection blow moulding is a pivotal process in the manufacturing of plastic products, combining the precision of injection moulding with the flexibility of blow moulding. This process is essential for producing high-quality, consistent, and durable plastic containers, bottles, and other hollow products. In India, several manufacturers have established themselves as leaders in producing state-of-the-art injection blow moulding machines. This blog explores the premier injection blow moulding machine manufacturers in India, highlighting their innovations, technological advancements, and contributions to the industry.

Understanding Injection Blow Moulding

Before delving into the manufacturers, it’s essential to understand the injection blow moulding process. This method involves three main stages: injection, blowing, and ejection. Initially, plastic is injected into a perform mold to create a perform. Finally, the product is ejected from the mold. This process is highly efficient, allowing for the production of complex shapes with excellent surface finish and structural integrity.

Technological Excellence in Manufacturing

India's premier injection blow moulding machine manufacturers have leveraged advanced technology to enhance the efficiency, precision, and versatility of their machines. These manufacturers utilize cutting-edge CNC (Computer Numerical Control) machinery, automation, and robotics to ensure that their machines meet the highest standards of performance and reliability. The integration of Iota (Internet of Things) and Industry 4.0 principles further enables real-time monitoring and control, optimizing the production process and minimizing downtime.

Customization and Versatility

One of the hallmarks of leading manufacturers in India is their ability to offer customized solutions tailored to the specific needs of their clients. Whether it’s designing machines for producing small pharmaceutical bottles or large industrial containers, these manufacturers provide versatile options that cater to various industries, including pharmaceuticals, food and beverage, cosmetics, and automotive. Their machines are designed to handle different types of plastics, such as PET, PP, HDPE, and LDPE, ensuring broad applicability.

Innovation and Research

Innovation is at the core of the top injection blow moulding machine manufacturers in India. By continuously exploring new materials, process improvements, and design innovations, they are able to introduce machines that offer superior efficiency, reduced energy consumption, and enhanced product quality. Collaboration with academic institutions and global industry leaders also plays a crucial role in driving innovation.

Quality Assurance and Certification

Quality is paramount in the production of injection blow moulding machines, and India’s leading manufacturers adhere to stringent quality assurance protocols. These companies are often ISO certified and comply with international standards, ensuring that their machines deliver consistent performance and longevity. Rigorous testing and inspection at various stages of manufacturing guarantee that each machine meets the specified quality criteria before it reaches the customer.

After-Sales Support and Training

a significant advantage of working with premier injection blow moulding machine manufacturers in India is the comprehensive after-sales support they provide. These manufacturers offer installation assistance, maintenance services, and prompt troubleshooting to ensure smooth operation of the machines. Additionally, they provide training programs for the clients’ technical staff, equipping them with the necessary skills to operate and maintain the machines effectively.

Sustainable Manufacturing Practices

In response to the growing emphasis on sustainability, leading manufacturers in India are adopting eco-friendly practices in their production processes. They are focusing on energy-efficient machines that reduce carbon footprint, utilize recyclable materials, and minimize waste. These efforts align with global sustainability goals and help clients achieve their own environmental objectives.

Conclusion

India is home to some of the premier injection blow moulding machine manufacturers in india that have made significant strides in technology, innovation, and quality. Their commitment to excellence, customization, and sustainable practices makes them reliable partners for businesses across various industries. By choosing to work with these manufacturers, companies can ensure that they have access to advanced, efficient, and versatile injection blow moulding solutions that meet their specific production needs and contribute to their overall success.

#injection blow moulding machine manufacturers in india#injection blow moulding machine manufacturers#injection blow moulding machine

0 notes

Text

The FCS LM series revolutionizes plastic injection moulding with clamping forces from 500 to 4,000 tons, it handles projects of any size. Its intelligent controller optimizes efficiency, while the precise injection system ensures top-quality parts.

Equipped with a high-performance controller, it provides stable injection for uniform mixing and plasticization. Rapid mould opening reduces cycle times, enhancing productivity. Versatile, it manufactures storage boxes, stools, trash bins, and washing machine tubs.

Experience the future of plastic injection moulding. Connect with us for more information.

To know more click on the below given link-

0 notes

Text

Exploring the Versatility of Plastic Extrusion Products Directly from Manufacturers!

In Australia, plastic extrusion products are utilised primarily for safeguarding industrial machines in automobile development, electric and electronics, aviation and military, marine and boating, healthcare, agriculture, and a few other private sector businesses.

Because they specialise in producing plastic extrusions with remarkable endurance and flexibility, reputed manufacturers provide a guarantee of the product's effectiveness and security throughout usage.

On the other hand, the plastic extrusion process provides various benefits to firms looking to make high-quality items efficiently and cost-effectively. One of the primary benefits of plastic extrusion is its adaptability.

The procedure can be used to make everything from simple smooth tubes and profiles to sophisticated forms and designs including perforated tubes, circular wraps, heat-shrink, and solar conductors.

Reputable manufacturers frequently use substances such as polypropylene, LDPE, HDPE, ABS, polyamide, PVC (flexible & rigid), polycarbonate, thermoplastic polyurethane, PBT, and TPEs in the process of extrusion, enabling them to make a wide range of items for different industries.

The plastic protrusions, in particular, have a wide range of applications, including blow-moulded extrusion corrugators for corrugated tubing, standard plastic extruders for tube, cable, and profile-producing goods, vacuum testing for complex shapes, and co-extrusion for multi-layer or multi-coloured products.

Furthermore, plastic extrusion provides remarkable uniformity in product quality, allowing companies to produce large quantities of products with little variation.

The use of multiple materials in the extrusion process allows producers to develop top-quality UV-protected products with unique features, such as longevity and can withstand harsh weather and chemicals.

For instance, when these plastic extrusions are used in large transport vehicles, cars, or aircraft, they do not break down by changing their physical state and shape and never lose their natural elasticity.

These features make their plastic extrusion products appropriate for a wide range of applications from building door frames and window profiles to pipes and electrical enclosures.

Therefore, contact a reliable manufacturer and get suitable products for your business needs.

Source

0 notes

Text

Essential Facts About Injection Moulded Pallets

Injection Moulded Plastic Pallet manufacturing has advanced throughout time, with businesses working hard to utilize the latest technologies. The technique aims to optimize the parts, enhancing their thickness and structure, lowering their weight, boosting their longevity, and creating ever-more intricate patterns. Today, there are several methods for producing plastic pallets, making it often challenging to decide which way would improve our company’s supply chain’s efficiency the most. Injection, thermoforming, blowing, compression, and roto-molding are some of the most popular manufacturing methods we can find today.

The packaging company of pallets firmly believes that plastic pallet injection manufacturing ensures the quality of every one of our goods. Moreover, it adheres to our corporate core principles of sustainability and environmental care.

What are the main benefits of each available injection molding form?

One of the most common procedures for giving this material the desired form and size is the manufacture of plastic pallets using injection. For large-scale production, especially when maintaining stability and uniformity over time is necessary for the same pallet design, this method proves ideal.

Through a hopper, the plastic is fed into the machinery. The frictional force and heating bands melt the plastic. The heating chamber discharges the hot plastic through a nozzle into a cavity or mold, where a refrigeration system cools and solidifies it. The pallet will then assume the shape of the attached mold.

Various injection system types

Injection moulding plastic pallets use two different production procedures: low-pressure and high-pressure systems. Each of them has unique qualities and benefits.

1. Low-pressure apparatus

In this instance, the mold cavity receives the introduction of the plastic substance and inert gas. That is to say, a gas that doesn’t cause the importance to be introduced to react chemically. In this process, typically, carbon dioxide or nitrogen activates the blowing agents in the polypropylene/polyethylene combination through heating, creating a stiff plastic material enclosing a cellular core.

2. High-pressure injection molding

High-density polyethylene (HDPE) or polypropylene (PP) plastic pallets are frequently made using high-pressure injection technology. It is a very accurate method that leaves a high gloss surface and doesn’t need any additional treatment.

In this production process, the raw material is heated to 250 degrees Celsius within a barrel with a spinning screw. Once it reaches the desired temperature, the machine injects the plastic into a mold. Here, it holds it under pressure, cools it, and then expels it at the other end. Therefore, the high-pressure injection molding method is the best choice when you require a plastic pallet with outstanding features.

Tailored Plastic Pallet Production: Professional Guidance for Every Business Need

1. Raw Materials Preparation.

Start with the stock’s raw elements. The following often accept five hundred kilos or one tonne. The following is a combination known as a formula. Permit mixing of the same hue. Inject the plastic pellets into the mixture and incorporate the color from the formula bundle. Heat the mixture to prevent warping of the plastic pallets in each injection lot. Part 2 then appeared.

2. Mold Alteration

Once the mold has been made, the mold department must be contacted, or the mold must be changed. Turn on the injection molding device for plastic. CANE must be utilized to transfer the mold from the lifting or moving mold to the injection molding machine. The injection department’s role is to perform this. Mounting the mold to the injection machine for plastic pallets involves coupling the mold to the coolant pipe.Cold molded plastic creates an injection moulded plastic pallet.

3. Adjustment in Injection Moulded Plastic Pallet

The majority of them are chiefs in the injection department. This will change around the time of the injection. A robot will be adjusted to handle and remove plastic pallets from the mold, and the quantity of plastic pallets required to create a full plastic pallet will be modified to align with the injection cycle.

4. Plastic Injection for Pallets.

The injection process initially injects a substantial amount of plastic pallets. Because plastic is still in its early stages, plastic pallets are not ideal. Plastic injection molding is insufficient. Furthermore, the machinery employed in plastic injection molding must undergo tuning. Such as changing the injection time and heating the syringe. Slower to provide more time for the polymers to flow into the mold. Additionally, they will begin to minimize the injection time each time they inject 1–10 plastic pallets into a whole exercise, making the process quicker. To be able to provide additional injections each hour.

5. Pallet Cuts made of Plastic.

The quality control division determines which injection moulded plastic pallet require customization. This includes tasks such as removing any protruding fins and runners cleanly. Plastic pallets may also incorporate rubber and plastic sealing. Quality control checks are conducted on plastic pallets before they are delivered to the warehouse.

6. Quality Check of Plastic Pallets before Warehouse Delivery

Does the Quality Assurance Department have a quality checklist to ensure that the injected plastic pallets are good enough to turn clients away? We will identify the reject plastic pallets, which require mending, as soon as we assess the quality if the plastic pallets are not superior. However, clients can still deliver orders using plastic pallets that have previously received an injection for inspection—delivered to the warehouse in preparation for client delivery.

Conclusion

Injection systems with high and low pressures are crucial to producing plastic pallets. The industry opted for this method of production for its plastic pallets because, over the past several years, there has been a trend in the plastic injection industry towards equipment that is quieter, smaller, faster, and with a reduced environmental impact. Additionally, these advancements have led to more controlled hydraulic systems and energy consumption.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#injectionmoldedpallet

0 notes

Text

How to Choose The Best Blow Moulding Machine?

Plastic-blowing equipment aids in the blow moulding process used to create thermoplastic items. Manufacturers utilise various blow moulding techniques to shape and enlarge plastic goods. Extrusion, compression, injection, and injection stretch blow moulding are among the several moulding processes.

Manufacturers might need assistance determining which plastic-blowing machine works best for each approach. The ideal machine should be simple to choose. As a result, this post will look at some advice for selecting the best blow moulding machine.

Global Market Overview

In 2022, the market for blowing machines was worth US$13.08 billion. By 2030, it is expected to reach US$17.33 billion, increasing at a 3.5% CAGR. The necessity for plastic containers in the medical sector is primarily responsible for the sizeable market. Blow moulding equipment is used by plastic producers to create storage containers for medications, such as bottles and syringes.

Blow moulding equipment demand has also been spurred by the necessity to recycle plastic to fulfil the rising demand from the food and beverage industries. Food manufacturing facilities make significant investments in recycled plastic for food and beverage packaging.

Tips to choose a blow moulding machine

1. Production potential

Businesses investing in plastic-blowing equipment should pay close attention to the maximum output that the equipment is capable of. The number of thermoplastic goods produced by blow moulding equipment is limited at a given time. Therefore, it’s crucial to study and learn more about the various plastic-blowing machine models’ capacities.

Before choosing a plastic blowing machine or world’s fastest automatic bagging machines with the appropriate production capacity, they should also consider how much plastic they need to make. While small-scale companies can purchase blow moulders with a smaller output, large-scale producers may require equipment with a high production capacity.

2. Product class

When purchasing plastic blowing machines, firms must consider the type of plastic product. Different forms of plastic are produced by the machines using heat. An extrusion blow moulding tool is suitable for manufacturing HDPE or LDPE plastic bottles with a broad neck. Bottles with a broad body and narrow mouth can be produced with compression blow moulding equipment.

3. Usage of less energy

Consider the amount of energy a blow moulding machine uses before making a purchase. Buyers should always prioritise purchasing energy-efficient equipment. Both the overall cost of production and the energy expenditures associated with running the equipment will be reduced thanks to the machines.

4. Auto-deflashing

Unwanted residue may accumulate on the plastic product during moulding. In a process known as deflashing, workers used a sharp object, like a knife, to cut the extra flesh off the bottles or containers.

Businesses should think about purchasing a machine with an auto-deflashing option, given how labour-intensive, laborious, and time-consuming manual deflashing is. Bottle manufacture is precise and accurate thanks to auto-deflashing equipment. Additionally, they boost the productivity of the production processes.

5. Advanced machine design

Different plastic-blowing machine or world’s fastest automatic bagging machine designs may have an impact on the productivity of the machine and the finished product of the moulding process. For instance, older machine designs cannot function as well as newer designs with more sophisticated capabilities. Old technology plastic-blowing models have significant drawbacks. They may be expensive to maintain, sluggish, and energy-intensive.

Companies should think about investing in modernised machinery. These devices operate quickly, use little energy, and require less upkeep. It guarantees a hassle-free process while generating high-quality items quickly and precisely.

6. Parosin controller

Buyers looking for dependable plastic blowing machines should consider the parison controller function. To produce more precise products, a parison controller aids in controlling the thickness of plastic goods during the blow moulding procedures.

A parison controller additionally aids in quality assurance and adherence to industry requirements for the necessary axial and radial product thickness.

7. Maximum capacity for work

The highest working capacity of a plastic-blowing machine is crucial. The production needs to determine the machine’s functioning capacity. The three types are fully automatic, semi-automatic, and partially automatic blow moulding machines.

Fully automatic plastic blow moulders are a great choice for companies looking for a machine that can produce many goods quickly, precisely, and at a high rate.

Production intervals for moulds can be customised in speed and time using semi-auto and partial auto plastic blow moulding machines. Their advantage is that they are small and may produce at levels determined by the customer’s needs. Therefore, small-scale manufacturers can use this equipment.

8. Clamping pressure

When purchasing a plastic blowing machine, the clamping force is essential. It is the pressure needed to compress and maintain the mould’s integrity. Customers should invest in a machine to sustain maximum clamping pressure.

Low-quality moulds could be created if the plastic blowing tool’s clamping force exceeds the required pounds or kilogrammes. Additionally, if the machine generates a lot of force, more operating capacity is wasted, and excessive electricity is used.

Contact Mitchell Industries to Get The Best Blow Moulding Machines

Making the best choice for your blow moulding operation will significantly affect your plastic production operation. Your decision should be based on thoroughly evaluating several variables, such as machine type, production volume, material compatibility, energy efficiency, and the manufacturer’s or supplier’s reputation. You can make sure that the chosen machine satisfies your unique production requirements, maximises productivity, and ultimately helps your business succeed by giving priority to these factors. Making a well-informed choice now will pay off significantly in the long run for your plastic manufacturing endeavours regarding cost-effectiveness, product quality, and sustainability.

#blow moulding machine alphamac#inspection machine#injection moulding machines#blow moulding machines#moulding machine#plastic molding machine jih huang#recycling machine

0 notes

Text

Leading Blow Moulding Plastic Suppliers In UAE

We are the top Blow Moulding Plastic Suppliers UAE. We specialize in offering a variety of blow-moulded products, including PET bottles, HDPE bottles, jerry cans, containers, and other unique plastic packaging options. Our goods can be used in a range of industries, including the packaging of food and drinks, pharmaceuticals, the automotive industry, and more. We have a group of highly qualified experts who can give you the finest guidance on the appropriate plastic packaging option for your requirements. For any special requirements, we also provide customized packaging solutions. We promise to provide the highest-quality items at reasonable prices thanks to our cutting-edge technology and knowledge. Contact us right away to find out more about our products and services.

How Do Plastics Used in Blow Moulding Operate?

Heat is applied to softened plastic polymer pellets before they are shaped into tubular shapes to begin the blow moulding plastics process. Then, a hole is created in the tube's one end so that pressurized air can enter the plastic. It enters a specially made mould and is fastened into place after being softened and having the hole created.

As a result, the plastic may remain perfectly still as pressurized air is pumped within, forcing the sides outward and forming the hollow, moulded portion. The component is then cooled and solidified, removed from the mould, sent for quality check, and shipped.

Various Blow Moulding Styles

A softened plastic tube serves as the structure for the moulded product when using the extrusion blow moulding technique. This is put into a blow moulding machine, where hot plastic melts to conform to the shape of the cavity in the mould. Following this step, pressurized air is added to hollow out the interior of the plastic. About three-quarters of all blow-moulded products use this common blow-moulding technique.

Second, rather than beginning with a softened polymer tube, injection blow moulding uses a premade plastic shape. It is hollowed out by pressured air and secured inside the machine by a core metal pin. In stretch injection blow moulding, the softened plastic prefabricated shape is stretched into its final design prior to compressed air being injected, as opposed to being held in place by a pin as it is in injection blow moulding. PVC and PET goods can be processed using stretch injection blow moulding because of the unique characteristics of these two extremely adaptable plastic materials.

Why Choose the Blow Moulding Method?

The vast number of items that may be produced using any of the three adaptable and effective approaches makes adopting the blow-moulding plastics process in manufacturing operations advantageous. While shampoo bottles and soap dispensers have good chemical resistance and the capacity to take on complex shapes, plastic food containers can maintain their hygienic qualities and beautiful branding. For use in heavy industry, construction, and other demanding areas, industrial tubs and drums and automotive ducting offer strong, long-lasting construction. The manufacturing process is highly valued in the medical industry for its lightweight and simple sanitization capabilities. Simply put, objects made of plastic that have been blow-moulded are widely used in both household and business settings.

There are limitations on how much the wall thickness can be adjusted because the goods must be hollowed out while maintaining acceptable strength and integrity. Products may be harder to recycle if thermosetting polymers are used. And we are the top Injection Mould Plastic Manufacturers in UAE. This is because such materials can only be reshaped once before they can no longer be melted or softened for reforming or recycling.

0 notes

Link

Unique Techno Lab LLP is having its H.O. as well as their Works at Ahmedabad, which is known as the Central Hub for Plastic Machineries & Ancillaries for all India.

Product we Manufacture 1 Universal Tensile Testing Machine 2 Melt Flow/Auto Melt Flow Indexer 3 Digital Computerized Hydro Pressure Testing Machine 4 Carbon Black Content Test Apparatus 5 Carbon Black Dispersion Tester 6 Hot Deformation Tester 7 Motorized Notch Cutter 8 Pipe Notch Cutter 9 Impact Tester For Pipes 10 Opacity Tester 11 Density Test Apparatus 12 Muffle Furnace 13 Humidity Chamber 14 Freezer(Zero Degree Chamber) 15 Emitting Flow Rate Checking Machine 16 Dumbbell Press 17 Hot Water Bath 18 Cool Water Bath 19 Hot / Cold Water Bath 20 Reversion Oil Bath 21 Air Circulating Oven / Hot Air oven 22 Full Width Projects 23 End Fittings 24 Tear Strength Tester 25 Laboratry Hot Plate 26 Izode / Charpy Impact Test Apparatus 27 Sheet Mouldig Press 28 Travelling Microscope 29 OIT Tester

*INDUSTRIES SERVED BY US*

- PIPE INDUSTRY – HDPE, MDPE, LLDPE, U-PVC, C-PVC, R-PVC, O-PVC, CASING, SWR, LATERAL, IN-LINE, CONDUITS AS PER INDIAN AS WELL AS INTERNATIONAL STANDARDS. - ROTO MOULDING – WATER TANKS - FILMS - RUBBER - PLYWOOD - FIRE RETARDANT PLYWOOD - CEMENT - CABLE - WOVEN SACKS - BLOW MOULDING - SANITARY PADS

For more information visit our web site www.uniquetechnolab.com or call 9316274635 also mail us on [email protected]

1 note

·

View note

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine Manufacturer, Exporter https://www.invoitplast.com/plastic-scrap-grinder-machine/ Our Plastic Scrap Grinder Machine is a special addition for your delight with its high performance and cost effectiveness. They are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc.

2 notes

·

View notes

Text

Scrap Grinder for Scrap available at NAROTO

Naroto offers sturdy and efficient Scrap Grinder Machine used for recycling the rejected moulded articles made from LLDPE, LDPE, HDPE and all types of PVC.NAROTO UNIVERSAL SCRAP GRINDERS (GRANULATORS) are commonly used by almost all the polymers processing industries like Rotomoulding, Blow moulding, PVC Extrusion, manufacturing plants to recycle waste materials through size reduction for reprocessing.

#Rotomouldingmachineexporter#Rotationalmouldingmachinemanufacturer#Rotationalmouldingmachinemanufacturerinindia#Rotationalmoldingmachinesuppliers#Rotomouldingmachineindia#Rotationalmouldingmachinemanufacturersinindia#Rotationalmouldingmachine#PulverisermachineforLLDPE#Rotationalmoldingmachinery#Plastictankmakingmachine#Plasticwatertankmachinemanufacturer#Rotomoldingindia#Watertankrotomoldingmachineprice#Rotationalmoldingmachineryexporter#Rotationalmoulds#Rotationalmouldingequipment#Watertankmakingmachine#Verticaltankmanufacturingmachine#Plasticmouldingmachinemanufacturers#Plasticmouldingmachineexporter

0 notes

Text

If you are considering converting your existing

Converting Your HDPE EXTRUSION MOULD

If you are considering converting your existing HDPE EXTRUSION MOULD to another material, you'll find some useful tips here. This article covers Injection blow molding, HDPE Extrusion Mold, and Die-casting. It also discusses how to control the parison geometry. So, what are these terms? Read on! And remember to keep a few things in mind. Here are some examples: Extrusion blow molding

HDPE extrusion blow molding is a process wherein a solid polymer is molded into a shape. The polymer has excellent plastic properties, including high strength, high tensile strength, and high flexural rigidity. These properties are vital in the manufacture of various products, including food containers. The elasticity modulus can be determined by AUTOMATIC CAP FOLDING & SLITTING MACHINE three different methods, including tensile tests, three point bending tests, and dynamical mechanical analysis. In these tests, test specimens are stamped from the center zone of a blow-molded part, where the wall thickness distribution is uniform. In this test, the influence of orientation is also studied, including the direction of extrusion and the pressure of blowing/stretching.

Extrusion blow molding is one of the most common methods of hollow plastic containers. Typical extrusion products include consumer goods, bulk containers, and technical parts such as air ducts. Although most thermoplastic polymers can be blown into hollow plastic containers, polyethylene is especially relevant for consumer packaging. The process is composed of two steps: the extruder produces a hollow tube, or parison, which is then inflated in a closed mold with a negative shape. Once the mold is completely cooled, the part is demolded. Injection blow molding

Injection blow molding uses a different process than plastic injection molding to create reusable and disposable parts. Both processes involve plastics that are either molten or solid. HDPE injection blow molding is a popular choice among OEMs because it produces a range of specimen containers from custom-formulated polymers to thermoplastics. The process is also effective for producing a variety of parts such as lighting lenses and medical equipment. For more information on the advantages of injection molding over blow molding, read on.

Injection blow molding involves the injection of molten polymer into a mold. During the process, a preform is made that is either thin or thick. The thickness of the preform can range from one micron to several millimeters. The length of the preform should be adjusted to clear the inside length of the blow mold by 0.005 in. (0.125 mm) or less. Injection blow molding can create bottles with a higher rigidity than extrusion blow-molded bottles. Die-casting

Injection molding and die casting are similar processes, but they use different types of materials. Injection molding uses polymers, while die casting utilizes non-ferrous metals. Both processes use dies to mold molten materials into the desired shape. Some common materials used for die casting include polyethylene, polypropylene, and polysulfone. These materials are used in many industrial applications, from household items to automotive parts.

Regardless of the method chosen, the end result is a piece with a uniform cross-section and a consistent strength-to-density ratio. Moreover, HDPE extrusion molds produce one-step manufacturing. HDPE plastic is widely used in a variety of industries, from medical devices to toys. The advantages of HDPE over other materials make this type of molding process very useful. Controlling the geometry of a parison

The shrinkage effect on parison is often higher with a higher extrusion speed. This is because the parison undergoes different changes during the extrusion process, including swelling and shortening. Therefore, it is necessary to know the final parison length before blowing. The mould's dimensions must be adjusted to account for this variation in final length. Fortunately, this study has found a few ways to control the shrinkage effect.

One of the most common methods of improving parison quality is controlling the parison geometry. This is possible by altering the mandrel gap on the extrusion die. During extrusion, the gap can be adjusted to control wall thickness along the parison length. The mandrel gap can also be controlled before blowing to alter the final parison wall thickness. A well-controlled mandrel gap is essential for parison properties. Common problems with extrusion blow molds

The most common HDPE extrusion mold problems are related to the speed of the injection. If the injection speed is too fast, the plastic will escape from the mold through the parting line and the ejector pin location, which causes flashing. Flash can also be a symptom of an overly old mold. In either case, the mold must be closed in two steps, and excessive pressure can force plastic out through the path of least resistance.

The human mind is the most powerful troubleshooting tool available. Apply critical thinking to determine the root cause of the problem and to identify the correct solution. Remember that one person's opinion does not always mean that a different solution is right or is out of the question. While it is easy to blame another person for a problem, it is not a good idea to change your position based on numerical disadvantage. Instead, use solid evidence to support your position.

0 notes

Text

Ghee Packaging for Healthy Outcomes From Nichrome

Ghee is the second most consumed dairy product in India and is widely used in Indian cooking. There are a number of factors for the growing ghee market - population growth, rising incomes, easy availability, and a greater appreciation of the health benefits of ghee. It comes as no surprise that the ghee market is forecast to grow at a rate of 15% till 2024.

Uttar Pradesh currently accounts for the majority of the ghee market in India, followed by Rajasthan and Madhya Pradesh. Some of the prominent players in the market are GCMMF (Amul), RCDF, Mother Dairy, Patanjali, SMC Foods etc.

Ghee Packaging from Nichrome

Even though ghee has a long shelf life - it can be stored for 6 to 12 months under the right conditions - proper filling and packaging play an important role. The ghee can turn rancid when exposed to heat, light, air, water vapour and certain metals that cause deterioration.

Nichrome’s technology can be used to package ghee in commonly used ghee packaging materials:

Tin Cans: Most commonly used for bulk packs of 5L and 15L. Coated to prevent rusting.

Glass Bottles: Provide excellent protection to maintain the quality of ghee. Normally used for retail packs of 100g to 500g.

Semi-rigid Containers: Generally made from HDPE and provide advantages of being lightweight, economical and easy to transport. These containers come in a few types: blow moulded HDPE bottles, jars and cherry cans; and odour-free PET bottles that act as gas barriers.

Flexible Pouches: The most economical approach for ghee packaging. These pouches need to be made using materials with the following characteristics:

- No reaction with ghee

- Easy availability at low cost

- Non-toxic materials

- Should not let the printing ink penetrate into the produce

- Should have good barriers to prevent spoilage

- Should be able to survive the rigours of transportation

Ghee Packaging Solutions from Nichrome

Nichrome is a ghee packing machine manufacturer whose product range has many solutions for the packaging of ghee to match your space, packaging format and budget requirements.

Some of the more popular ones are:

● VFFS Ghee Pouch Packaging Machine The Filpack Servo SMD is Nichrome’s most popular ghee packaging machine and is a durable, heavy-duty option, with a touch screen HMI panel and PLCs that control operations. It comes with an enclosed SS cabinet for hygienic operation and also occupies less floor space. The Filpack Servo SMD operates at speeds of 70-85 pouches per minute depending on the package size and can package ghee and other viscous products such as oil, ketchup, fruit pulp, mayonnaise, curry pastes and even products like grease, paint, adhesives etc. The pouches are in 3 side seal format and quantities range from 50 ml to 1000 ml. This machine also comes with independent head operation so one can pack two different products and quantities simultaneously.

● Bottle Filling Line Nichrome’s efficient integrated system for bottle filling and packaging covers a turntable, UV sterilization chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labelling machine, date & batch coding system, and a packing table. The system is controlled by PLCs and packs a number of viscous products such as ghee, ketchup, chocolate sauce and more. Some of the other applications of this system include a wide variety of food & beverage products such as flavoured milk, soft drinks, energy drinks, water & buttermilk and non-food liquids such as perfumes, oil, shampoos and handwash with SKUs ranging from 100 ml to 20 litres.

● Tin Filling Line The Tin Filling Line from Nichrome offers sturdy, low maintenance operation with accurate and efficient performance. This line is controlled by PLCs and has a digital LCD touch screen to display settings and safety enclosures with interlocks for rotary parts. This is a composite friendly line that offers auto lid feeding, placing, and lid seaming. The machinery can be constructed in SS3014, SS316 and MS painted materials with various sterilization and cleaning options available

Conclusion

If you want to take advantage of the rising demand for ghee and the cost-effectiveness of flexible packaging, you should consider Nichrome’s ghee packaging solutions. In addition to offering the latest technology, Nichrome also offers the expertise to customise and manufacture solutions for businesses of all scales.

Nichrome - among the best food packaging machine manufacturers in India - started operations 4 decades ago as a pioneer in milk pouch packaging machines for India’s White Revolution. In the present day, Nichrome’s know-how and capabilities cover the packaging of a wide range of dairy products. Nichrome has a reputation for being a leading integrated packaging solutions provider and oil packing machine manufacturer and is trusted for the superior technology of its automatic packaging machines, manufacturing capabilities, nationwide service support and trenchant problem-solving skills. Nichrome - as a food packaging machine and automatic oil filling machine manufacturer - believes in partnering with customers through the complete lifecycle of the solution, delivering the most effective application-specific solutions.

Nichrome is based out of Pune, India and possesses a service network that spans the world. With a presence in 45 countries and more than 7000 successful installations worldwide, Nichrome is truly a Global Player in its domain. Visit www.nichrome.com for more information.

#milk pouch packaging machines#oil packing machine manufacturer a#automatic packaging machines#food packaging machine#automatic oil filling machine#integrated packaging solutions#best food packaging machine manufacturers in India#ghee packaging solutions#Tin Filling Line#● Bottle Filling Line

0 notes

Text

Rotational Moulding Technology

The manufacture of thin-walled goods of broad dimensions necessitates the use of complex manufacturing methods. Rotational moulding technology is becoming more popular due to its ability to produce waste-free thermoplastic products at relatively low investment costs. It replaces previous processes such as lamination and injection moulding. Thermoplastic polymer rotational moulding is a low-shear technique that, due to the long-lasting shaping process, helps us to obtain thin-walled ready-to-use products with no internal stress in a single technical procedure. The feed material, in the form of polymer powder, is inserted into the mould cavity during the process. The Rotomoulding Grade LLDPE Powder rotational acceleration precludes the occurrence of centrifugal powers. The free covering of unmeted material fractions within the revolving mould helps us to achieve uniform product wall thickness. The mould and the material piled at the internal surface of the mould are cooled after the material has fully melted. The factor of low material losses and the probability of material recovery of after-use materials, as opposed to other thin-walled metal processing processes such as extrusion blow moulding or laminating, partially compensates for a large amount of energy used to manufacture a single product. Currently, polyethylene (high-density (HDPE), low-density (LDPE), and linear low-density polyethylene (LLDPE) account for more than 95 percent of the demand for products intended for forming in rotational moulding technology; the remaining materials are polyamide (PA), poly(vinyl chloride) (PVC), polypropylene (PP), and biodegradable polymers such as poly(-caprolactone). Because of the dynamics of the technical process, much more focus is generally put on the production of new types of materials intended for forming in this technology than on computer and system technology and design solutions. Rotational moulding of polymer composites, especially those containing filler materials from renewable sources, such as natural lignocellulosic fillers, is one of the most dynamically established research topics.

Until now, the only published examples of rotomolded composites based on polyethylene (PE) and polylactide (PLA) have been based on wood flour or natural fibres. The use of natural powder fillers when forming polymer composites in rotational casting technology has many advantages, including an increase in material rigidity and an enhancement in product aesthetics. However, studies to date have shown a noticeable decrease in the effective strength of UV based LLDPE Powder Material as larger volumes of filler are added. Since Prime Grade LLDPE Powder Supplier are natural fillers are hydrophilic, there is a possibility of inadequate interfacial adhesion as well as product porosity due to the release of residual moisture from the filler particles.

As a result, linear low-density polyethylene (LLDPE) was used as a polymeric matrix in the presented experiments, as a medium with excellent impact resistance in rotational moulding applications. Furthermore, if the process parameters are not properly chosen, there is a chance of thermal deterioration of the composite's organic fraction. Although Roto Moulding Grade LLDPE Powder Supplier, such as salinization or mercerization, increases the hydrophobicity of lignocellulosic materials. They are frequently residues or by-products of different manufacturing processes that have little industrial use or, despite some, a substantial surplus on the material. This approach aims to partially substitute plastics. A similar result can be achieved by using bran as a filler in polymer composites, which has been studied extensively.

The structure of wheat bran is an intriguing aspect. Unlike commonly used lignocellulosic fillers like wood flour, it incorporates not only fibre but also a large amount of starch and proteins, which can serve as plasticizers in the resulting WPCs and improve their flowability. Such an effect would be advantageous for the use of composites containing wheat bran in rotational moulding, which involves proper molten material flowability. Roto Moulding Grade LLDPE Powder Supplier involving the incorporation of wheat bran into a polymer matrix, we discovered that protein content has a positive effect on the melt flow index of the polymer melt. Incorporating wheat bran improved flowability relative to olive stone flour, while composites containing brewers' spent grain, a by-product of the brewing industry that produces more than 21 wt. percent protein has the highest melt flow index values.

Brass Inserts for plastic are commonly found in applications that require solid and sturdy metal threads. This is also the case in places where the machine is assembled and disassembled for servicing or repair. In reality, one of the better fastening choices for a job like this is a plastic insert.

Electronics, aerospace, and aeronautics are some of the most popular applications. Electronics, transportation, aerospace, and some sporting equipment are among the most popular applications.

Brass Insert for thermoplastics or thermoset plastics, as well as softwoods such as chipboard or plywood, are available in a variety of materials, shapes, and styles. The most common material used to make a plastic insert is brass; but, with environmental concerns at the forefront, non-lead substitutes such as stainless steel or aluminium are becoming more popular. Both of the alternatives have their advantages, such as stainless steel's superior corrosion resistance and weight, while aluminium inserts are significantly lighter.

youtube

However, the material in which the implant will be inserted is equally relevant. Some thermoplastics can only be introduced into the body by two processes: ultrasonic and heat-staking. Since thermoplastics do not usually experience a chemical shift until moulded, they may be moulded and remoulded several times using ultrasonic or heat-staking methods. Polyvinyl chloride, polyethylene, acrylic, and polypropylene are examples of typical thermoplastics, while polyurethane, melamine, polyester, and fiberglass are examples of Brass Insert for Plastic.

0 notes